Laser–Direct Current arc Hybrid Additive Manufacturing of Cu-Cr-Zr Alloy: Microstructure Evaluation and Mechanical Properties

Abstract

:1. Introduction

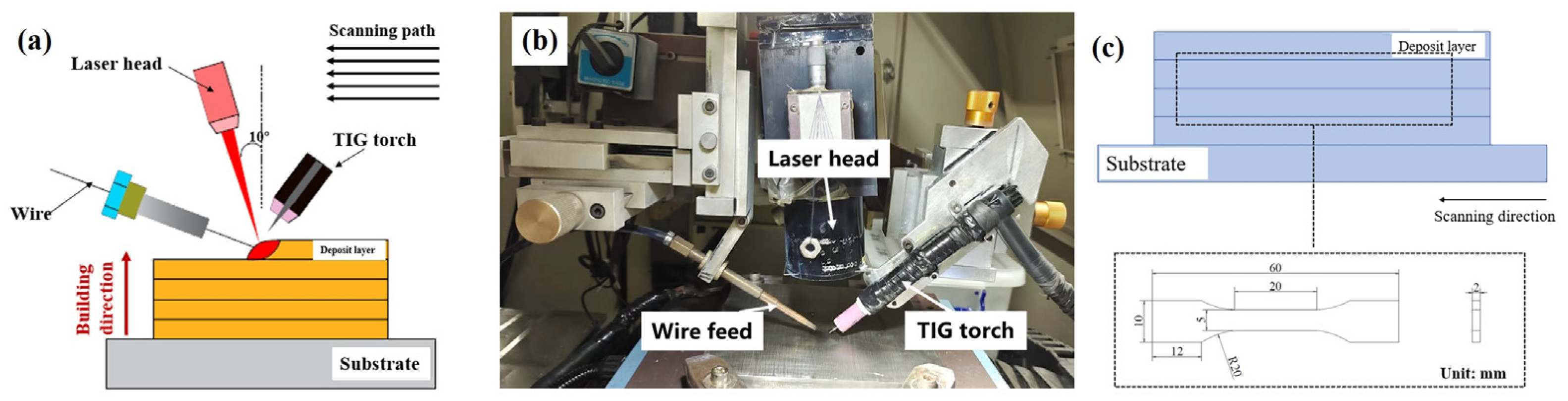

2. Material and Methods

2.1. Experimental Materials and Equipment

2.2. Experimental Procedure

3. Results

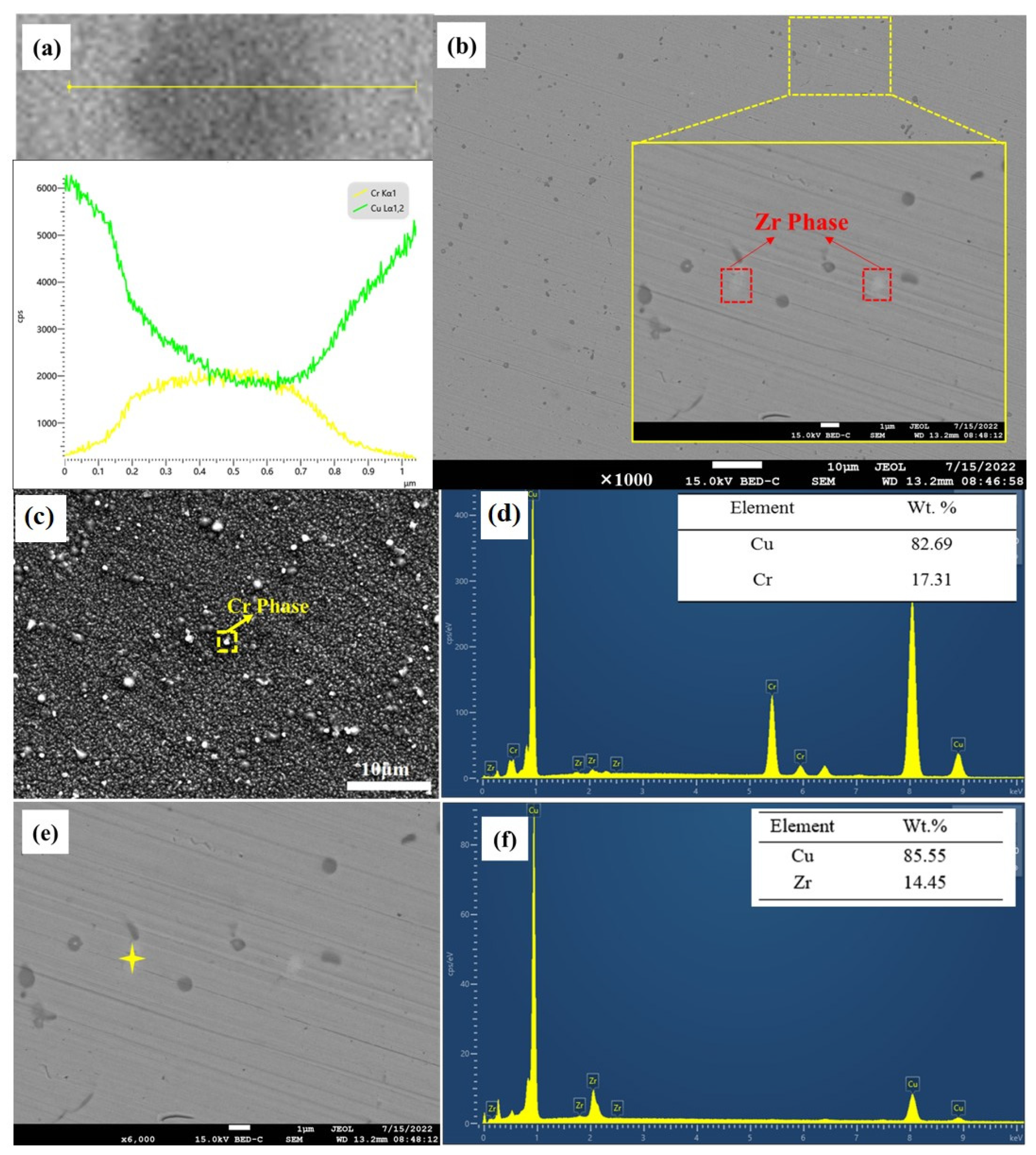

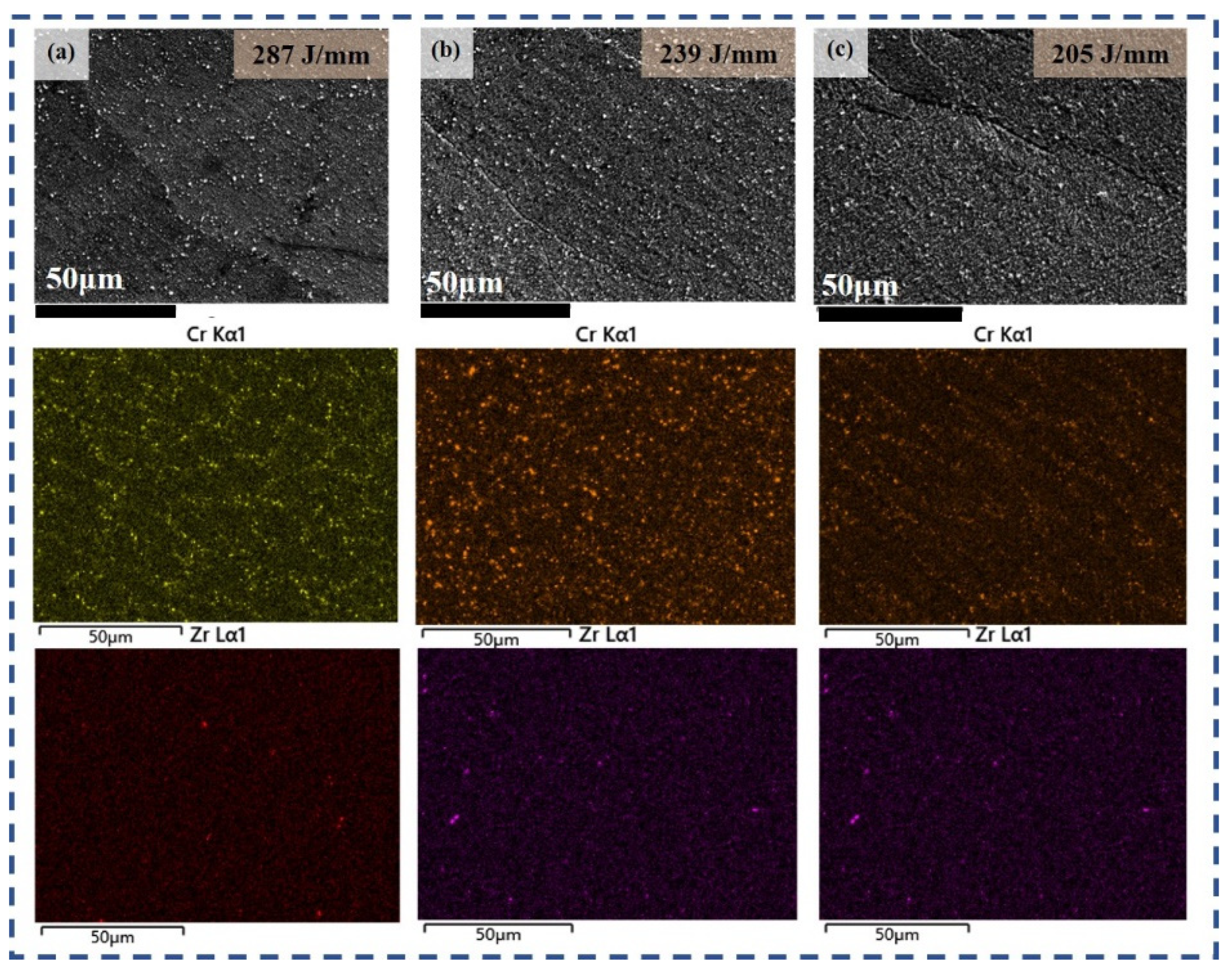

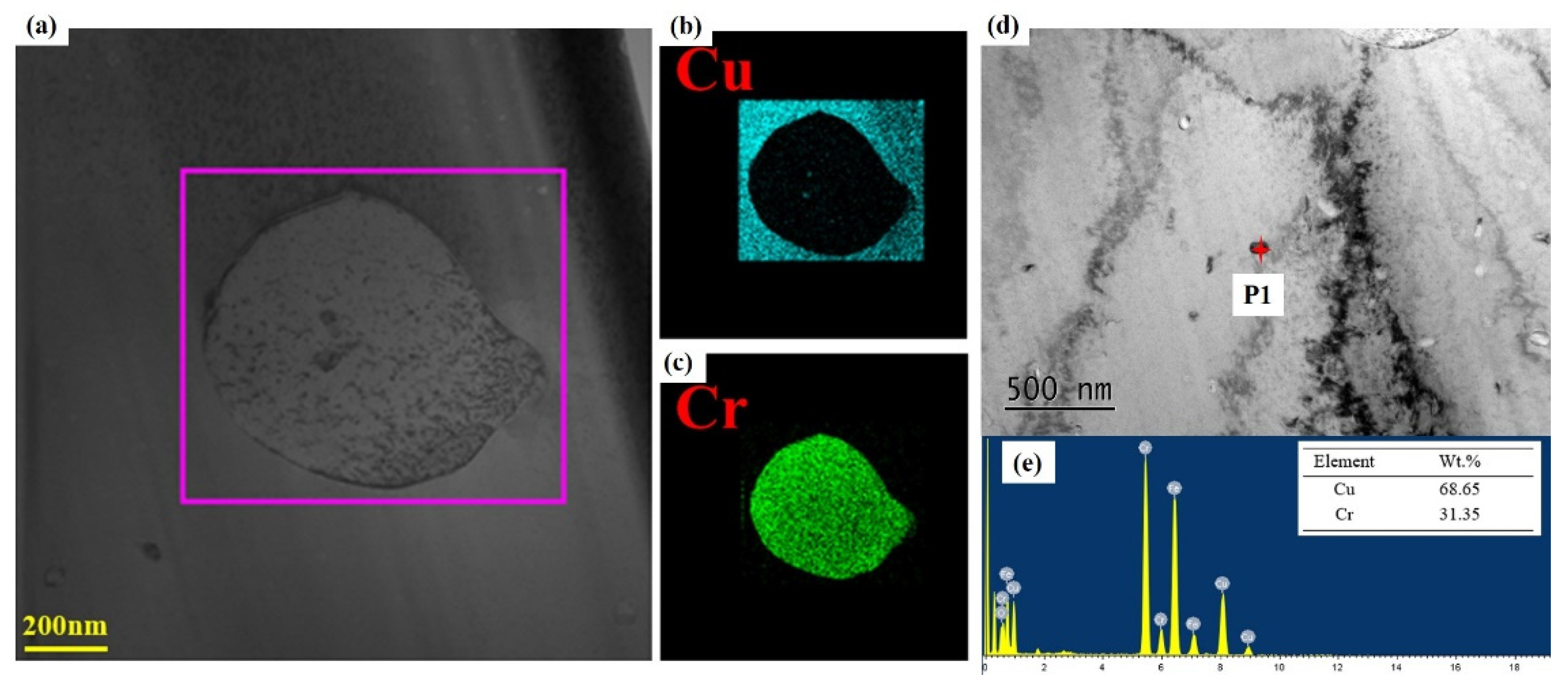

3.1. Microstructure Morphology

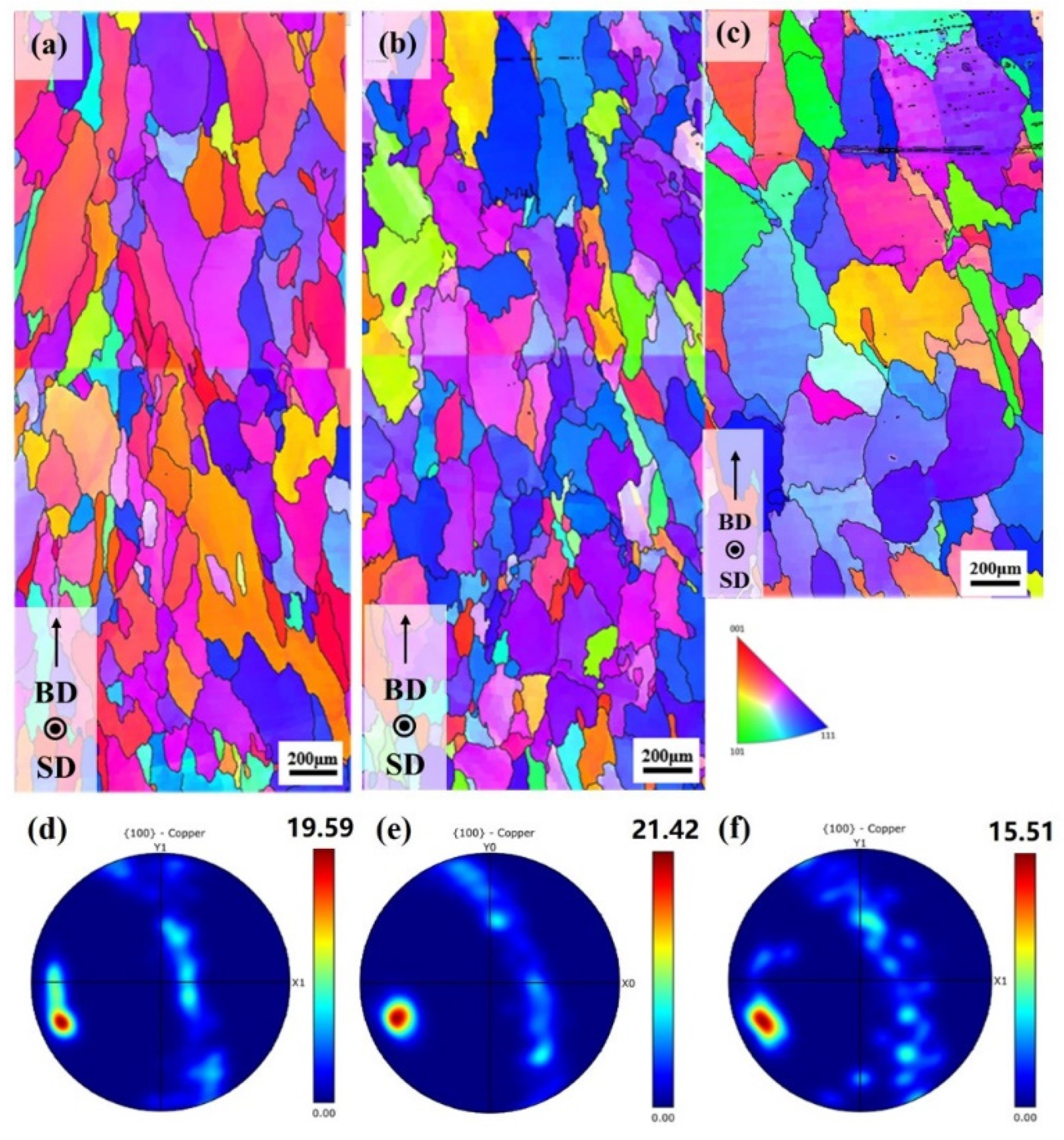

3.2. Grain Morphology and Texture

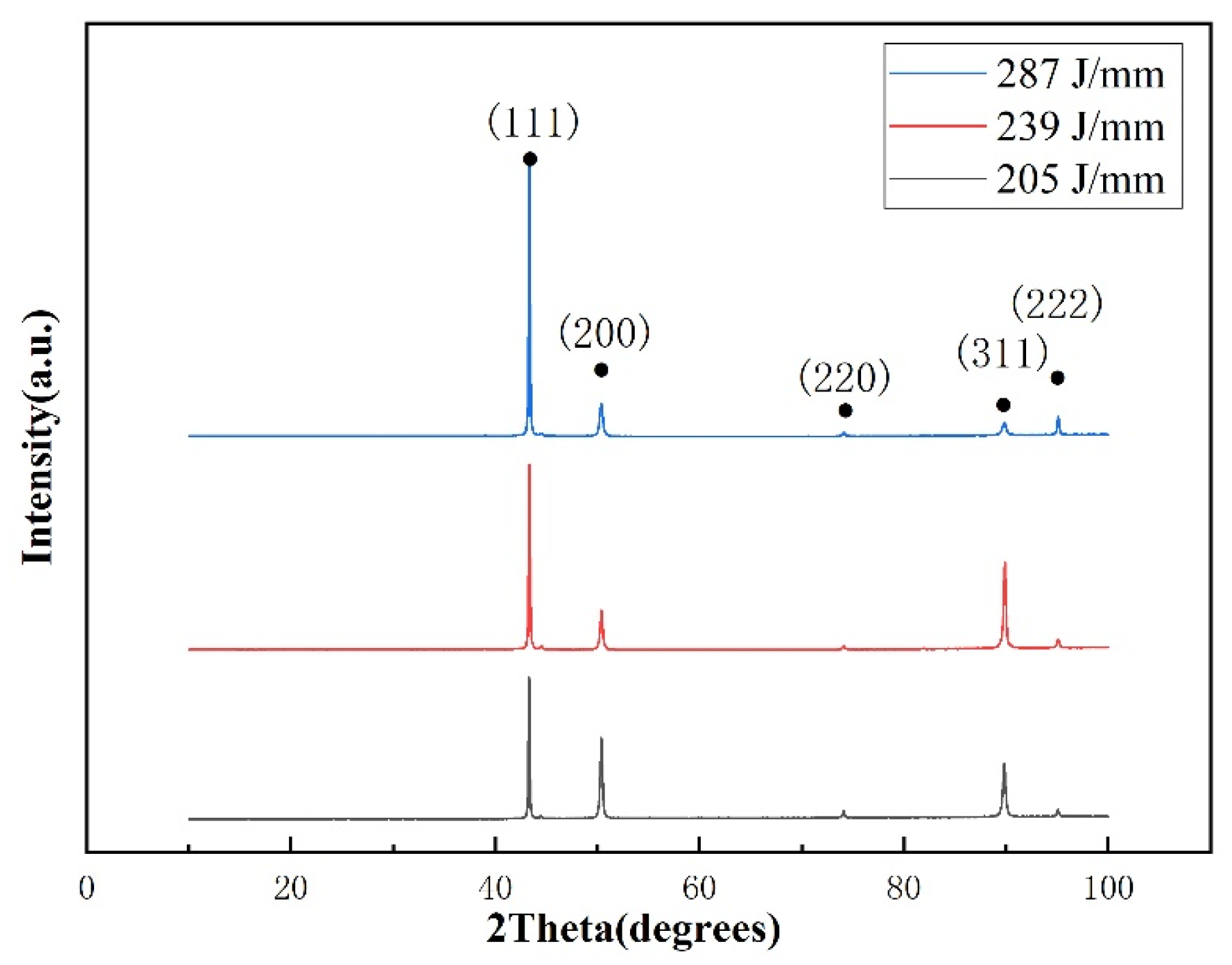

3.3. Phase Composition

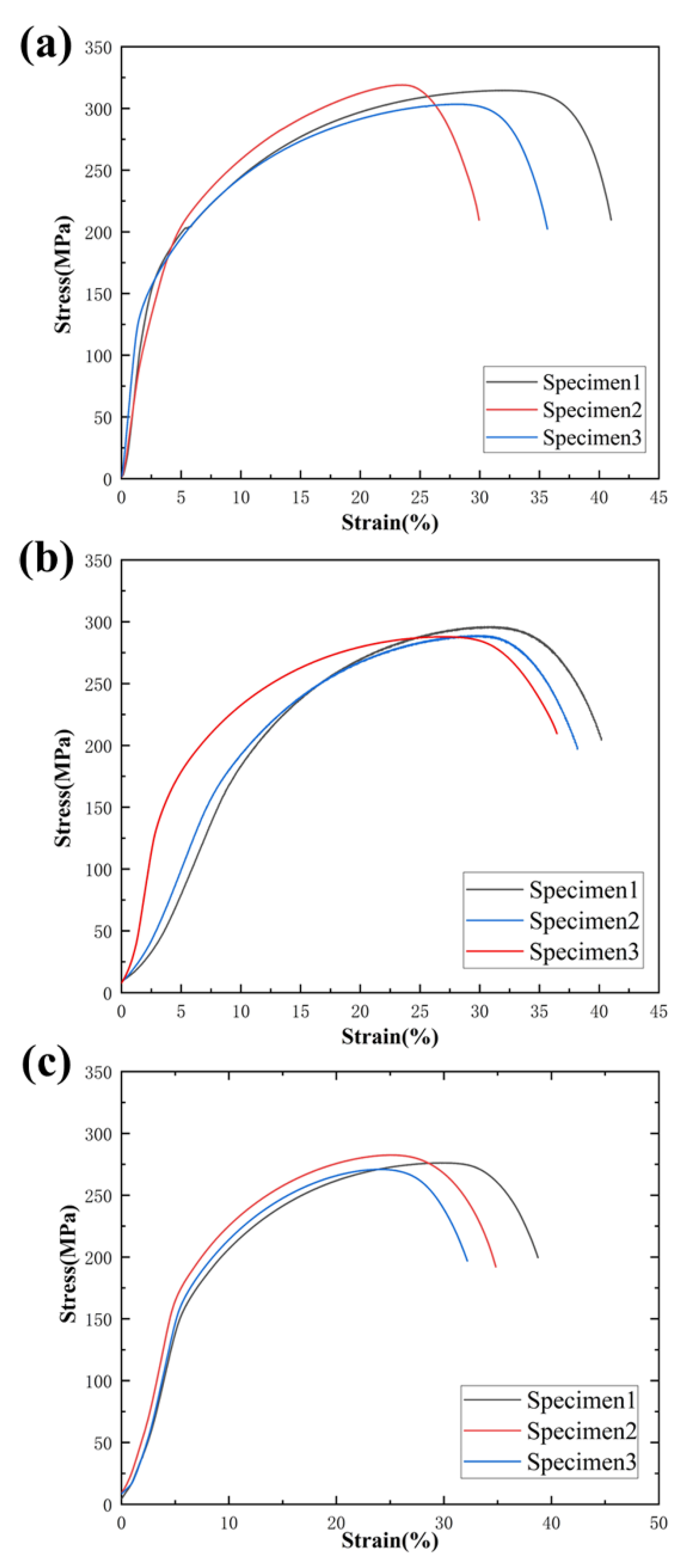

3.4. Mechanical Properties

4. Conclusions

- (1)

- The LAHAMed Cu-Cr-Zr alloy samples presented no cracks or porosity defects. Columnar grains with a growth direction tending to the center of the molten pool were observed. The columnar grain size increased by 38.16% when the scanning speed was extended from 300 mm/min to 350 mm/min.

- (2)

- The Cr precipitate was uniformly distributed in the Cu matrix, whereas the Zr phase was dispersed in only a few positions. The spherical Cr precipitate exhibited a semi-coherent interface with the Cu matrix, playing an important role in the improvement of the mechanical properties.

- (3)

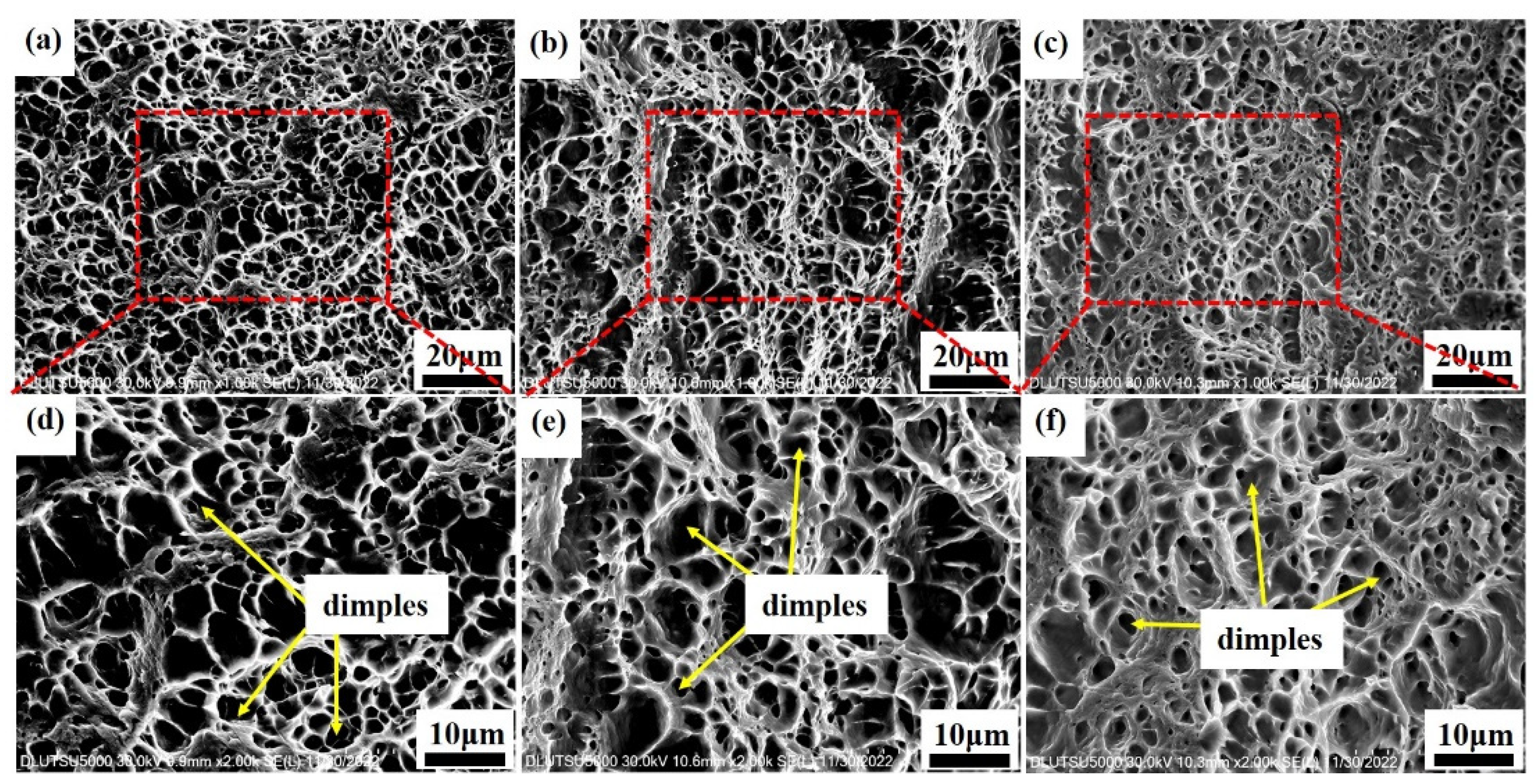

- At a scanning speed of 250 mm/min, the ultimate tensile strength had a maximum of 311.3 ± 7.8 MPa with an elongation of 38.6 ± 5.6%, which was greater than that of Cu-Cr-Zr alloy prepared by L-PBF or casting. The fracture mode was a ductile fracture with typical dimple characteristics.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Zhou, K.; Chen, W.G.; Feng, P.; Yan, F.L.; Fu, Y.Q. Arc ablation behavior and micro-structure evolution of plastically deformed and micro-alloyed Cu-Cr-Zr alloys. J. Alloy. Compd. 2020, 820, 153123. [Google Scholar] [CrossRef]

- Sousa, T.G.; Moura, I.; Da Garcia, F.C.; Monteiro, S.N.; Brandao, L.P. Combining severe plastic deformation and precipitation to enhance mechanical strength and electrical conductivity of Cu-0.65Cr-0.08Zr alloy. J. Mater. Res. Technol 2020, 9, 5953–5961. [Google Scholar] [CrossRef]

- Auwal, S.T.; Ramesh, S.; Yusof, F.; Manladan, S.M. A review on laser beam welding of copper alloys. Int. J. Adv. Manuf. Technol. 2018, 96, 475–490. [Google Scholar] [CrossRef]

- Sun, F.; Liu, P.; Chen, X.; Zhou, H.; Guan, P.; Zhu, B. Mechanical Properties of High-Strength Cu–Cr–Zr Alloy Fabricated by Selective Laser Melting. Materials 2020, 13, 5028. [Google Scholar] [CrossRef] [PubMed]

- Mishnev, R.; Shakhova, I.; Belyakov, A.; Kaibyshev, R. Deformation microstructures, strengthening mechanisms, and electrical conductivity in a Cu-Cr-Zr alloy. Mater. Sci. Eng. A 2015, 629, 29–40. [Google Scholar] [CrossRef]

- Derekar, K.S. A review of wire arc additive manufacturing and advances in wire arc additive manufacturing of aluminium. Mater. Sci. Technol. 2018, 34, 895–916. [Google Scholar] [CrossRef]

- Casuso, M.; Veiga, F.; Suárez, A.; Bhujangrao, T.; Aldalur, E.; Artaza, T.; Amondarain, J.; Lamikiz, A. Model for the Prediction of Deformations in the Manufacture of Thin-Walled Parts by Wire Arc Additive Manufacturing Technology. Metals 2021, 11, 678. [Google Scholar] [CrossRef]

- Veiga, F.; Suárez, A.; Aldalur, E.; Bhujangrao, T. Effect of the Metal Transfer Mode on the Symmetry of Bead Geometry in WAAM Aluminum. Symmetry 2021, 13, 1245. [Google Scholar] [CrossRef]

- Ding, J.; Colegrove, P.; Mehnen, J.; Ganguly, S.; Almeida, P.S.; Wang, F.; Williams, S. Thermo-mechanical analysis of Wire and Arc Additive Layer Manufacturing process on large multi-layer parts. Comput. Mater. Sci. 2011, 50, 3315–3322. [Google Scholar] [CrossRef] [Green Version]

- Popovich, A.; Sufiiarov, V.; Polozov, I.; Borisov, E.; Masaylo, D.; Orlov, A. Microstructure and mechanical properties of additive manufactured copper alloy. Mater. Lett. 2016, 179, 38–41. [Google Scholar] [CrossRef]

- Kuai, Z.; Li, Z.; Liu, B.; Chen, Y.; Lu, S.; Tang, X.; Liu, T. Selective laser melting of CuCrZr alloy: Processing optimisation, microstructure and mechanical properties. J. Mater. Res. Technol. 2022, 19, 4915–4931. [Google Scholar] [CrossRef]

- Ma, Z.B.; Zhang, K.F.; Ren, Z.H.; Zhang, D.Z.; Tao, G.B.; Xu, H.S. Selective laser melting of Cu–Cr–Zr copper alloy: Parameter optimization, microstructure and mechanical properties. J. Alloy. Compd. 2020, 828, 154350. [Google Scholar] [CrossRef]

- Hu, Z.P.; Du, Z.F.; Yang, Z.W. Preparation of Cu-Cr-Zr alloy by selective laser melting: Role of scanning parameters on densification, microstructure and mechanical properties. Mater. Sci. Eng. A-Struct. Mater. Prop. Microstruct. Process. 2022, 836, 142740. [Google Scholar] [CrossRef]

- Zhang, S.; Zhu, H.; Zhang, L.; Zhang, W.; Yang, H.; Zeng, X. Microstructure and properties of high strength and high conductivity Cu-Cr alloy components fabricated by high power selective laser melting. Mater. Lett. 2019, 237, 306–309. [Google Scholar] [CrossRef]

- Lassègue, P.; Salvan, C.; De Vito, E.; Soulas, R.; Herbin, M.; Hemberg, A.; Godfroid, T.; Baffie, T.; Roux, G. Laser powder bed fusion (L-PBF) of Cu and CuCrZr parts: Influence of an absorptive physical vapor deposition (PVD) coating on the printing process. Addit. Manuf. 2021, 39, 101888. [Google Scholar] [CrossRef]

- Lindström, V.; Liashenko, O.; Zweiacker, K.; Derevianko, S.; Morozovych, V.; Lyashenko, Y.; Leinenbach, C. Laser Powder Bed Fusion of Metal Coated Copper Powders. Materials 2020, 13, 3493. [Google Scholar] [CrossRef]

- Jadhav, S.D.; Dhekne, P.P.; Brodu, E.; Van Hooreweder, B.; Dadbakhsh, S.; Kruth, J.-P.; Van Humbeeck, J.; Vanmeensel, K. Laser powder bed fusion additive manufacturing of highly conductive parts made of optically absorptive carburized CuCr1 powder. Mater. Des. 2021, 198, 109369. [Google Scholar] [CrossRef]

- Baby, J.; Amirthalingam, M. Microstructural development during wire arc additive manufacturing of copper-based components. Weld. World 2020, 64, 395–405. [Google Scholar] [CrossRef]

- Deshmukh, P.S.; Tomar, K.; Sathiaraj, G.D.; Palani, I. Optimum strength and ductility of pure copper fabricated by Wire Arc Additive Manufacturing. Manuf. Lett. 2022, 33, 24–28. [Google Scholar] [CrossRef]

- Miao, Q.Y.; Wu, D.J.; Chai, D.S.; Zhan, Y.; Bi, G.J.; Niu, F.Y.; Ma, G.Y. Comparative study of microstructure evaluation and mechanical properties of 4043 aluminum alloy fabricated by wire-based additive manufacturing. Mater. Des. 2020, 186, 108205. [Google Scholar] [CrossRef]

- Liu, D.H.; Wu, D.J.; Niu, F.Y.; Miao, Q.Y.; Zhao, K.; Tang, B.K.; Bi, G.J.; Ma, G.Y. Al-Cu alloy fabricated by novel laser-tungsten inert gas hybrid additive manufacturing. Addit. Manuf. 2020, 32, 100954. [Google Scholar]

- Ma, G.; Wang, R.; Liu, D.; Wu, S.; Niu, F.; Wu, D. Laser-arc hybrid additive manufactured Al Cu alloy for T-shaped structure: Microstructure evaluation and molten pool behavior. J. Manuf. Process. 2022, 79, 442–459. [Google Scholar] [CrossRef]

- Liu, D.; Wu, D.; Ge, C.; Lu, H.; Chen, Z.; Liu, M.; Wang, Y.; Niu, F.; Ma, G.; Luo, K.; et al. Superior strength of laser-arc hybrid additive manufactured Al-Zn-Mg-Cu alloy enabled by a tunable microstructure. Addit. Manuf. 2023, 68, 103526. [Google Scholar] [CrossRef]

- Gong, M.C.; Zhang, S.; Lu, Y.; Wang, D.Z.M.; Gao, M. Effects of laser power on texture evolution and mechanical properties of laser-arc hybrid additive manufacturing. Addit. Manuf. 2021, 46, 102201. [Google Scholar]

- Ma, G.Y.; Wu, S.N.; Wang, R.Z.; Liu, D.H.; Niu, F.Y.; Bi, G.J.; Wu, D.J. Microstructure evaluation and resultant mechanical properties of laser- arc hybrid additive manufactured Cu-Cr-Zr alloy. J. Alloy. Compd. 2022, 912, 165044. [Google Scholar] [CrossRef]

- Liu, D.; Wu, D.; Wang, R.; Shi, J.; Niu, F.; Ma, G. Formation mechanism of Al-Zn-Mg-Cu alloy fabricated by laser-arc hybrid additive manufacturing: Microstructure evaluation and mechanical properties. Addit. Manuf. 2022, 50, 102554. [Google Scholar] [CrossRef]

- Wu, S.; Hu, Y.; Duan, H.; Yu, C.; Jiao, H. On the fatigue performance of laser hybrid welded high Zn 7000 alloys for next generation railway components. Int. J. Fatigue 2016, 91, 1–10. [Google Scholar] [CrossRef]

- Ramirez, D.A.; Murr, L.E.; Martinez, E.; Hernandez, D.H.; Martinez, J.L.; Machado, B.I.; Medina, F.; Frigola, P.; Wicker, R.B. Novel precipitate-microstructural architecture developed in the fabrication of solid copper components by additive manufacturing using electron beam melting. Acta Mater. 2011, 59, 4088–4099. [Google Scholar] [CrossRef]

- Laghi, V.; Tonelli, L.; Palermo, M.; Bruggi, M.; Sola, R.; Ceschini, L.; Trombetti, T. Experimentally-validated orthotropic elastic model for Wire-and-Arc Additively Manufactured stainless steel. Addit. Manuf. 2021, 42, 101999. [Google Scholar] [CrossRef]

- Liu, D.; Wu, D.; Ma, G.; Zhong, C.; Niu, F.; Gasser, A.; Schleifenbaum, J.H.; Bi, G. Effect of post-deposition heat treatment on laser-TIG hybrid additive manufactured Al-Cu alloy. Virtual Phys. Prototyp. 2020, 15, 445–459. [Google Scholar] [CrossRef]

- Hatakeyama, M.; Toyama, T.; Nagai, Y.; Hasegawa, M.; Eldrup, M.; Singh, B.N. Nanostructural Evolution of Cr-rich Precipitates in a Cu-Cr-Zr Alloy During Heat Treatment Studied by 3 Dimensional Atom Probe. Mater. Trans. 2008, 49, 518–521. [Google Scholar] [CrossRef] [Green Version]

- Zeng, K.; Hämäläinen, M.; Lilius, K. Phase relationships in Cu-rich corner of the Cu-Cr-Zr phase diagram. Scr. Met. Mater. 1995, 32, 2009–2014. [Google Scholar] [CrossRef]

- Li, Y.; Xiao, Z.; Li, Z.; Zhou, Z.; Yang, Z.; Lei, Q. Microstructure and properties of a novel Cu-Mg-Ca alloy with high strength and high electrical conductivity. J. Alloy. Compd. 2017, 723, 1162–1170. [Google Scholar] [CrossRef]

- Chbihi, A.; Sauvage, X.; Blavette, D. Atomic scale investigation of Cr precipitation in copper. Acta Mater. 2012, 60, 4575–4585. [Google Scholar] [CrossRef] [Green Version]

- Ma, Y.X.; Chen, H.Q.; Li, H.S. Dang. Influence mechanism of ageing parameters of Cu-Cr-Zr alloy on its structure and properties. Materials 2022, 15, 7605. [Google Scholar] [CrossRef]

- Hu, G.X.; Cai, X. Fundamentals of Materials Science; Shanghai Jiao Tong University Press: Shanghai, China, 2001. [Google Scholar]

- Li, J.L.; Cheng, L.L.; Li, S.L.; Zhu, X.D.; An, Z.X. Microstructure and properties of as- cast Cu-Cr-Zr alloys with lanthanum addition. J. Rare Earths. 2018, 36, 424–429. [Google Scholar] [CrossRef]

- Zhou, S.; Wang, K.S.; Wang, W.; Peng, P.; Zhang, S.Y.; Huang, L.Y. Microstructure and Mechanical Properties of Cu-Cr-Zr Alloy Friction Stir Welded Joints. Heat. Treat. Met. 2020, 3, 35–41. [Google Scholar]

- Li, J.; Ding, H.; Li, B. Study on the variation of properties of Cu–Cr–Zr alloy by different rolling and aging sequence. Mater. Sci. Eng. A 2021, 802, 140413. [Google Scholar] [CrossRef]

- Wang, W.; Li, R.G.; Zou, C.L.; Chen, Z.N.; Wen, W.; Wang, T.M.; Yin, G.M. Effect of direct current pulses on mechanical and electrical properties of aged Cu-Cr-Zr alloys. Mater. Des. 2016, 92, 135–142. [Google Scholar] [CrossRef]

- Hu, J.; Tian, Y.; Yu, H.; Ling, G.; Li, S.; Jiang, M.; Li, H.; Qin, G. Optimizing strength and electrical conductivity of Cu-Cr-Zr alloy by two-stage aging treatment. Mater. Lett. 2022, 315, 131937. [Google Scholar] [CrossRef]

| Number | Arc Current (A) | Scanning Speed (mm/min) | Average Laser Power (W) | Heat Input (J/mm) |

|---|---|---|---|---|

| 1 | 140 | 250 | 150 | 287 |

| 2 | 140 | 300 | 150 | 239 |

| 3 | 140 | 350 | 150 | 205 |

| Scanning Speed (mm/min) | 250 | 300 | 350 |

|---|---|---|---|

| Ultimate tensile strength (MPa) | 311.3 ± 7.8 | 291.3 ± 4.8 | 276.7 ± 5.8 |

| Elongation (%) | 38.6 ± 5.6 | 43.4 ± 1.5 | 39.2 ± 3.3 |

| Elastic module (GPa) | 123 ± 5 | 115 ± 7 | 110 ± 4 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shi, J.; Liu, L.; Liu, D.; Ma, G.; Chen, Z.; Niu, F.; Yu, S.; Wu, D. Laser–Direct Current arc Hybrid Additive Manufacturing of Cu-Cr-Zr Alloy: Microstructure Evaluation and Mechanical Properties. Coatings 2023, 13, 1228. https://doi.org/10.3390/coatings13071228

Shi J, Liu L, Liu D, Ma G, Chen Z, Niu F, Yu S, Wu D. Laser–Direct Current arc Hybrid Additive Manufacturing of Cu-Cr-Zr Alloy: Microstructure Evaluation and Mechanical Properties. Coatings. 2023; 13(7):1228. https://doi.org/10.3390/coatings13071228

Chicago/Turabian StyleShi, Jingan, Liu Liu, Dehua Liu, Guangyi Ma, Zhuo Chen, Fangyong Niu, Shiyong Yu, and Dongjiang Wu. 2023. "Laser–Direct Current arc Hybrid Additive Manufacturing of Cu-Cr-Zr Alloy: Microstructure Evaluation and Mechanical Properties" Coatings 13, no. 7: 1228. https://doi.org/10.3390/coatings13071228