Optimized Strain Response in (Co0.5Nb0.5)4+-Doped 76Bi0.5Na0.5TiO3-24SrTiO3 Relaxors

Abstract

1. Introduction

2. Materials and Methods

2.1. Preparation of BNST24-x CN Ceramics

2.2. Characterization

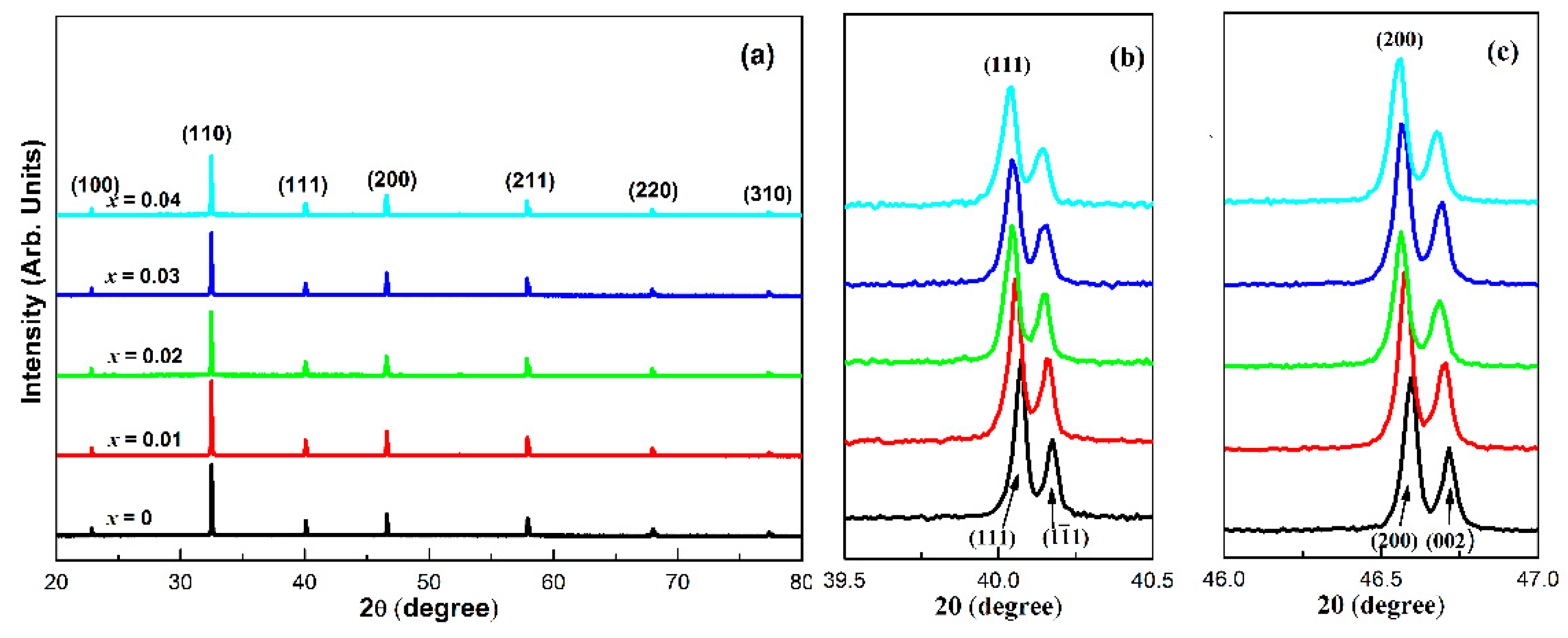

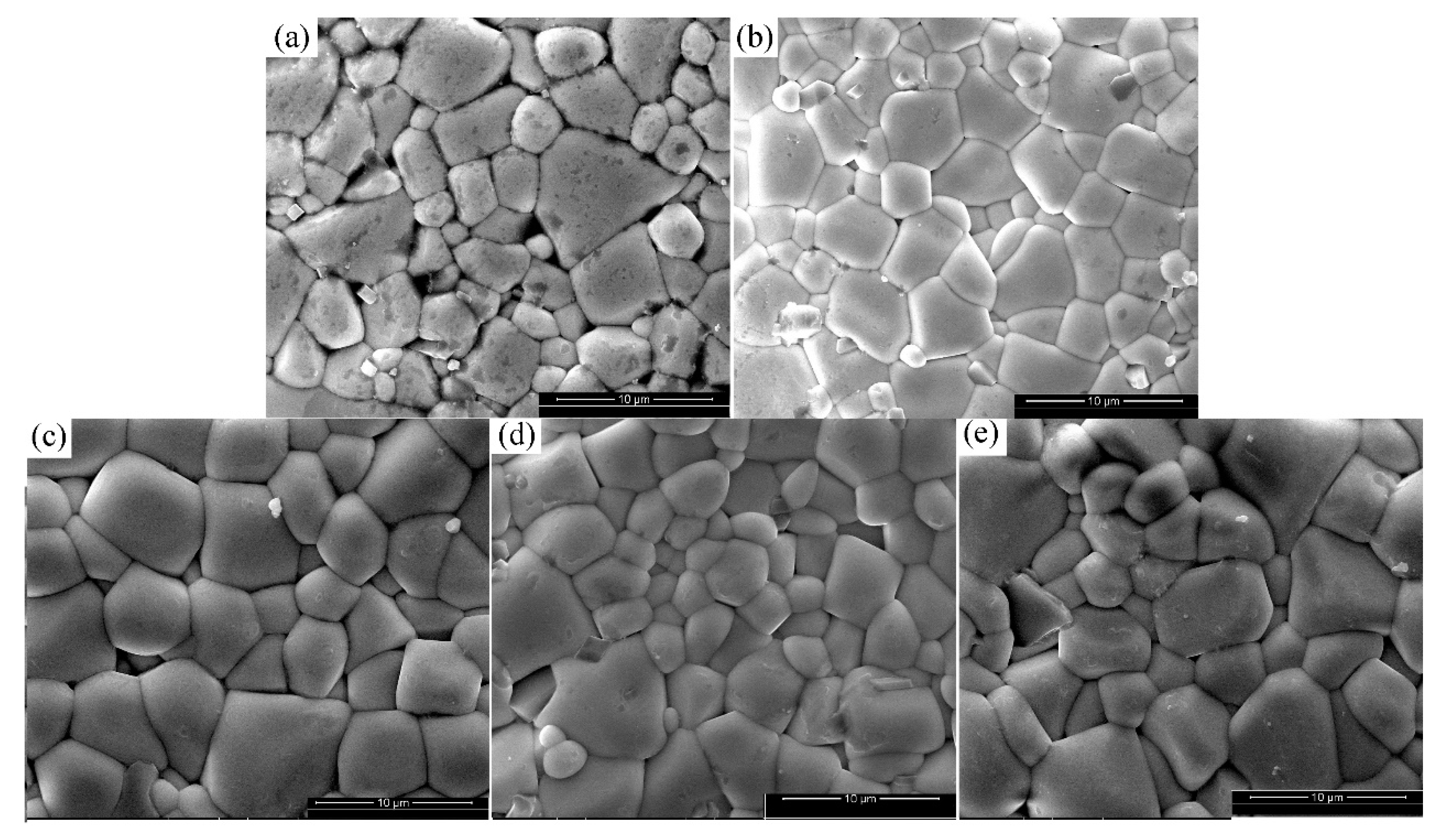

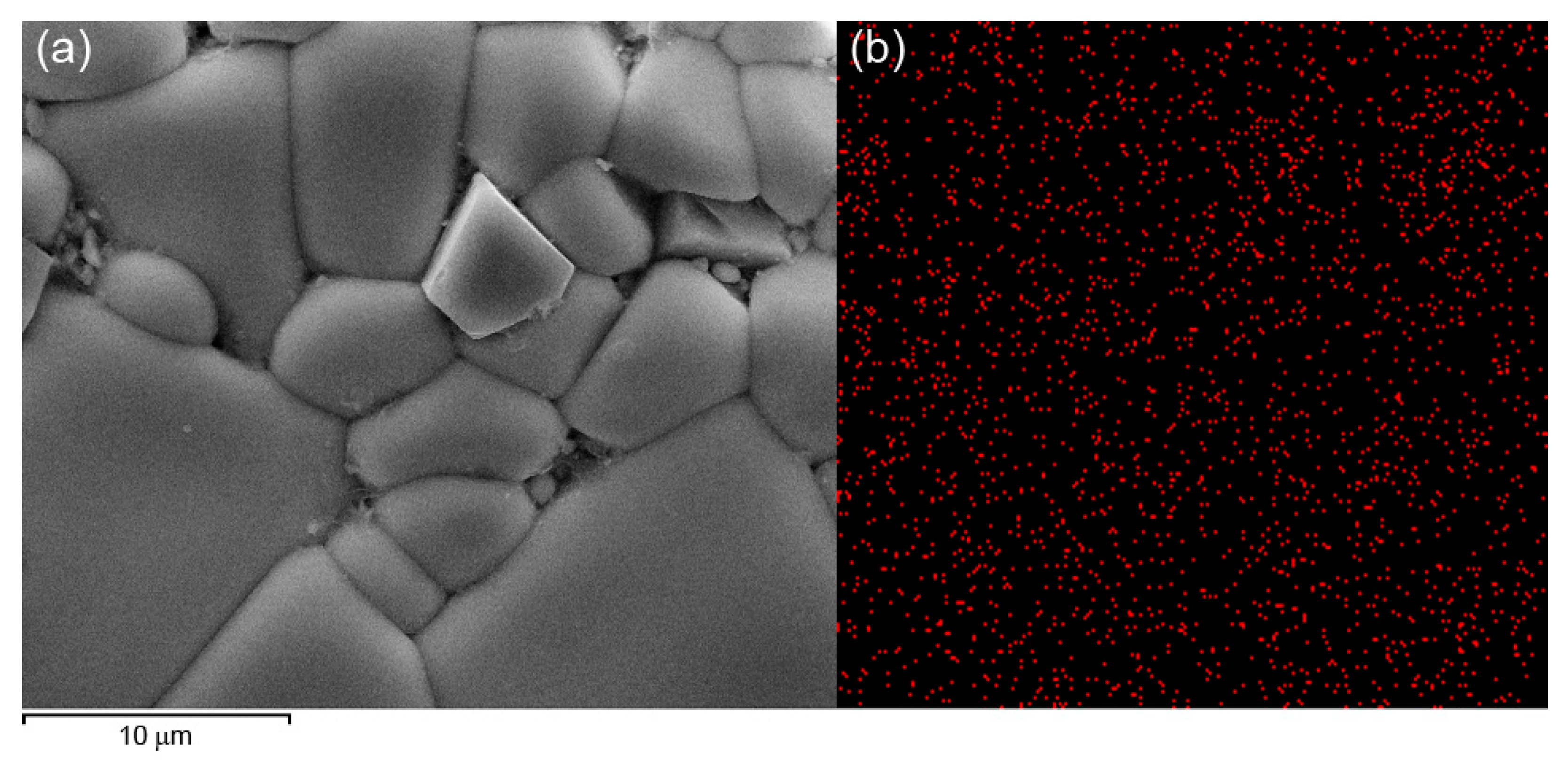

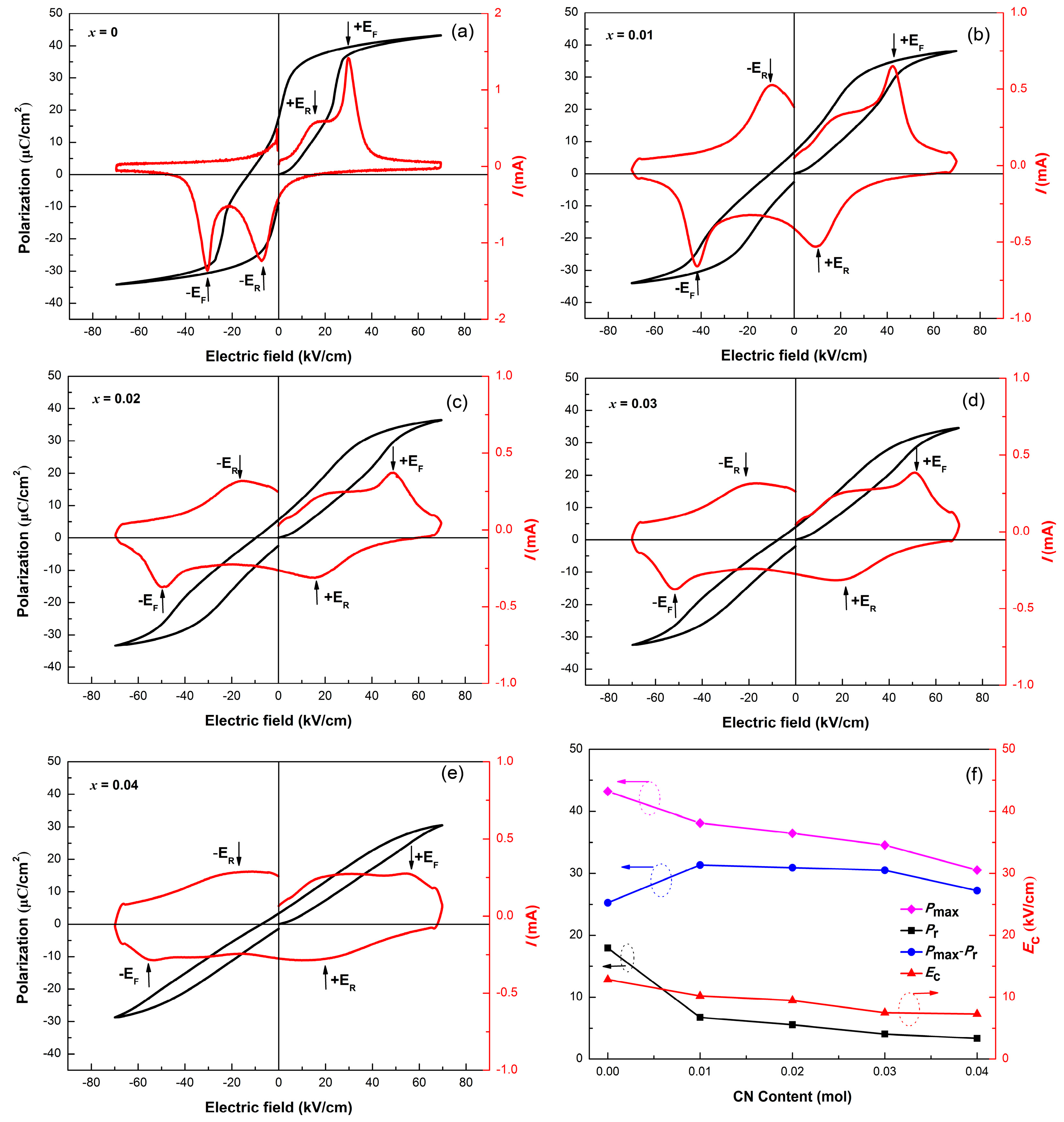

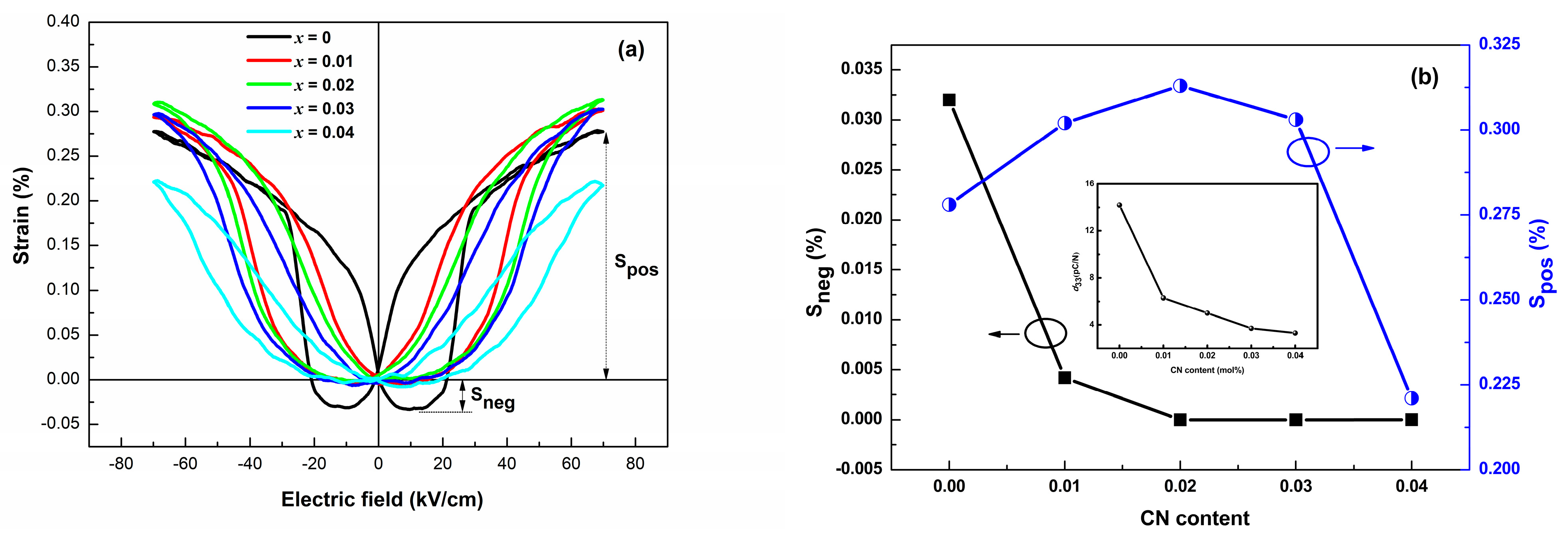

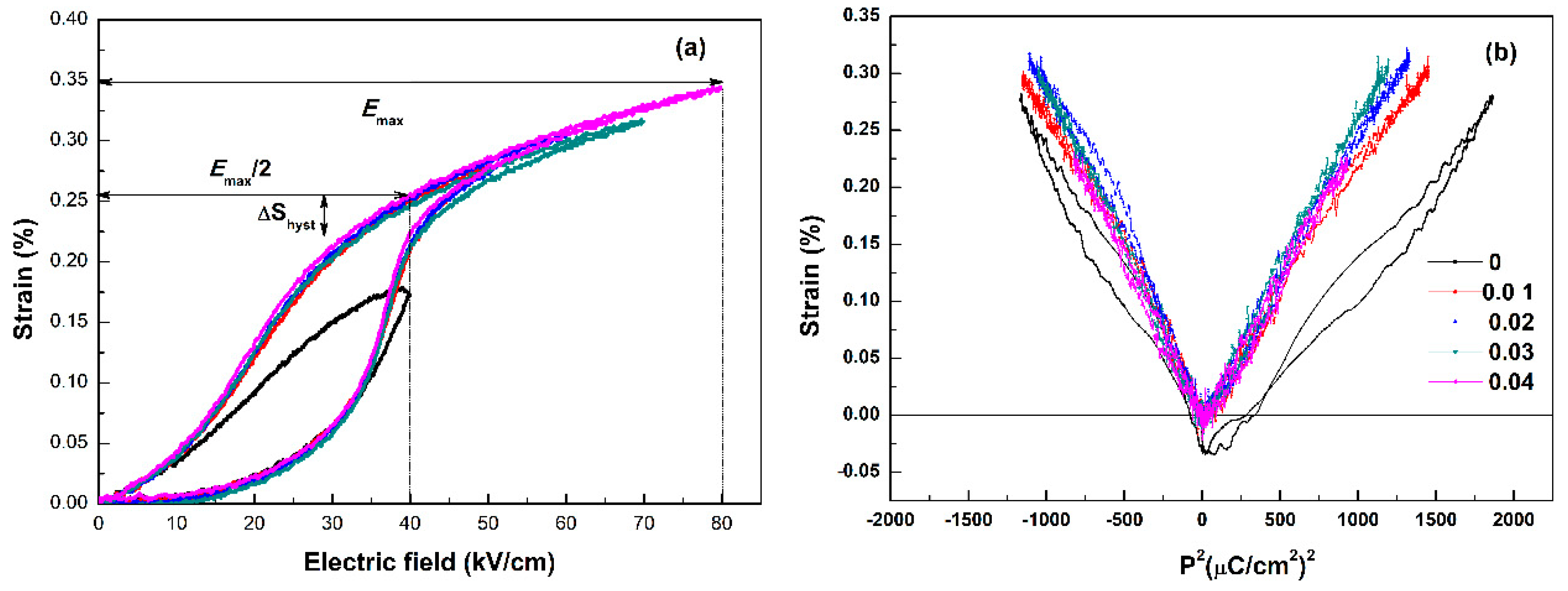

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Yan, B.B.; Fan, H.Q.; Wang, C.; Zhang, M.C.; Yadav, A.K.; Zheng, X.K.; Wang, H.; Du, Z.N. Giant electro-strain and enhanced energy storage performance of (Y0.5Ta0.5) 4+ co-doped 0.94(Bi0.5Na0.5)TiO3-0.06BaTiO3 lead-free ceramics. Ceram. Int. 2020, 46, 281–288. [Google Scholar] [CrossRef]

- Si, Y.; Li, Y.; Li, L.; Li, H.; Zhao, Z.H.; Dai, Y.J. Giant electrostrain in textured Li+-doped 0.852BNT-0.11BKT-0.038BT ternary lead-free piezoelectric ceramics. J. Am. Ceram. Soc. 2020, 103, 1765–1772. [Google Scholar] [CrossRef]

- Liu, G.; Dong, J.; Zhang, L.; Yan, Y.; Jing, R.; Jin, L. Phase evolution in (1−x) (Na0.5Bi0.5)TiO3−xSrTiO3 solid solutions: A study focusing on dielectric and ferroelectric characteristics. J. Mater. 2020, 6, 677–691. [Google Scholar] [CrossRef]

- Zhou, C.; Zhang, Y.; Wang, Y.; Li, Q.; Xu, J.; Chen, G.; Yuan, C.; Rao, G. An intermediate metastable ferroelectric state induced giant functional responses in Bi0.5Na0.5TiO3 ceramics. J. Mater. Chem. C 2019, 27, 8255–8260. [Google Scholar] [CrossRef]

- Lin, D.; Xiao, D.; Zhu, J.; Yu, P. Piezoelectric and ferroelectric properties of [Bi0.5(Na1−x−y KxLiy)0.5]TiO3 lead-free piezoelectric ceramics. Appl. Phys. Lett. 2006, 88, 062901. [Google Scholar] [CrossRef]

- Yin, J.; Liu, G.; Lv, X.; Zhang, Y.; Zhao, C.; Wu, B.; Zhang, X.; Wu, J. Superior and anti-fatigue electro-strain in Bi0.5Na0.5TiO3-based polycrystalline relaxor ferroelectrics. J. Mater. Chem. A 2019, 7, 5391–5401. [Google Scholar] [CrossRef]

- Jo, W.; Dittmer, R.; Acosta, M.; Zang, J.; Groh, C.; Sapper, E.; Wang, K.; Rödel, J. Giant electric-field-induced strains in lead-free ceramics for actuator applications–status and perspective. J. Electroceram. 2012, 29, 71–93. [Google Scholar] [CrossRef]

- Liu, X.; Tan, X. Giant strains in non-textured (Bi1/2Na1/2)TiO3-based lead-free ceramics. Adv. Mater. 2016, 28, 574–578. [Google Scholar] [CrossRef]

- Yin, J.; Zhao, C.; Zhang, Y.; Wu, J. Ultrahigh strain in site engineering-independent Bi0.5Na0.5TiO3-based relaxor-ferroelectrics. Acta Mater. 2018, 147, 70–77. [Google Scholar] [CrossRef]

- Pham, K.N.; Hussain, A.; Ahn, C.W.; Kim, I.W.; Jeong, S.J.; Lee, J.S. Giant strain in Nb-doped Bi0.5(Na0.82K0.18)0.5TiO lead-free electromechanical ceramics. Mater. Lett. 2010, 64, 2219–2222. [Google Scholar] [CrossRef]

- Zhang, S.T.; Kounga, A.B.; Aulbach, E. Giant strain in lead-free piezoceramics Bi0.5Na0.5TiO3-BaTiO3-K0.5Na0.5NbO3 system. Appl. Phys. Lett. 2007, 91, 112906. [Google Scholar] [CrossRef]

- Bai, W.F.; Zhao, X.Y.; Ding, Y.Q.; Wang, L.J.; Zheng, P.; Hao, J.G.; Zhai, J.W. Giant field-induced strain with low hysteresis and boosted energy storage performance under low electric field in (Bi0.5Na0.5)TiO3-based grain orientation-controlled ceramics. Adv. Electron. Mater. 2020, 6, 2000332. [Google Scholar] [CrossRef]

- Yin, J.; Zhao, C.; Zhang, Y.; Wu, J. Composition-induced phase transitions and enhanced electrical properties in bismuth sodium titanate ceramics. J. Am. Ceram. Soc. 2017, 100, 5601–5609. [Google Scholar] [CrossRef]

- Krauss, W.; Schütz, D.; Mautner, F.A.; Feteira, A.; Reichmann, K. Piezoelectric properties and phase transition temperatures of the solid solution of (1−x) (Bi0.5Na0.5)TiO3−xSrTiO3. J. Eur. Ceram. Soc. 2010, 30, 1827–1832. [Google Scholar] [CrossRef]

- Duong, T.A.; Han, H.S.; Hong, Y.H.; Park, Y.S.; Nguyen, H.T.K.; Dinh, T.H.; Lee, J.S. Dielectric and piezoelectric properties of Bi1/2Na1/2TiO3-SrTiO3 lead-free ceramics. J. Electroceram. 2018, 41, 73–79. [Google Scholar] [CrossRef]

- Acosta, M.; Jo, W.; Rödel, J. Temperature and frequency-dependent properties of the 0.75Bi1/2Na1/2TiO3-0.25SrTiO3 lead-free incipient piezoceramic. J. Am. Ceram. Soc. 2014, 97, 1937–1943. [Google Scholar] [CrossRef]

- Acosta, M.; Schmitt, L.A.; Luna, L.M.; Scherrer, M.C.; Brilz, M.; Webber, K.G.; Deluca, M.; Kleebe, H.J.; Rödel, J.; Donner, W. Core-shell lead-free piezoelectric ceramics: Current status and advanced characterization of the Bi1/2Na1/2TiO3-SrTiO3 system. J. Am. Ceram. Soc. 2015, 98, 3405–3422. [Google Scholar] [CrossRef]

- Li, H.L.; Liu, Q.; Zhou, J.J.; Wang, K.; Li, J.F.; Liu, H.; Fang, J.Z. Grain size dependent electrostrain in Bi1/2Na1/2TiO3-SrTiO3 incipient piezoceramics. J. Eur. Ceram. Soc. 2016, 36, 2849–2853. [Google Scholar] [CrossRef]

- Kim, S.H.; Lee, S.H.; Han, H.S.; Lee, J.S. Piezoelectric characteristics of lead-free 0.74(Bi0.5Na0.5)TiO3-0.26SrTiO3 ceramics according to calcination temperature. J. Korean Inst. Electr. Electron. Mater. Eng. 2019, 32, 35–39. [Google Scholar]

- Koruza, J.; Rojas, V.; Molina-Luna, L.; Kunz, U.; Duerrschnabel, M.; Kleebe, H.J.; Acosta, M. Formation of the core-shell microstructure in lead-free Bi1/2Na1/2TiO3-SrTiO3 piezoceramics and its influence on the electromechanical properties. J. Eur. Ceram. Soc. 2016, 36, 1009–1016. [Google Scholar] [CrossRef]

- Zhu, Y.; Zhang, Y.; Xie, B.; Fan, P.; Marwat, M.A.; Ma, W.; Wang, C.; Yang, B.; Xiao, J.; Zhang, H. Large electric field-induced strain in AgNbO3-modified 0.76Bi0.5Na0.5TiO3-0.24SrTiO3 lead-free piezoceramics. Ceram. Int. 2018, 44, 7851–7857. [Google Scholar] [CrossRef]

- Hong, Y.H.; Han, H.S.; Jeong, G.H.; Park, Y.S.; Dinh, T.H.; Ahn, C.W.; Lee, J.S. High electromechanical strain properties by the existence of nonergodicity in LiNbO3-modified Bi1/2Na1/2TiO3–SrTiO3 relaxor ceramics. Ceram. Int. 2018, 44, 21138–21144. [Google Scholar] [CrossRef]

- Pan, H.; Zhang, J.; Jia, X.; Xing, H.; He, J.; Wang, J.; Wen, F. Large electrostrictive effect and high optical temperature sensing in Bi0.5Na0.5TiO3-BaTiO3-(Sr0.7Bi0.18Er0.02)TiO3 luminescent ferroelectrics. Ceram. Int. 2018, 44, 5785–5789. [Google Scholar] [CrossRef]

- Yu, D.; Zhou, C.; Chen, J.; Li, Q.; Li, L.; Yuan, C.; Xu, J.; Rao, G. Large electrostriction-like strain by tailoring relaxor degree in BNT-based ceramics. J. Mater. Sci. Mater. Electron. 2023, 34, 1153. [Google Scholar] [CrossRef]

- Yao, K.; Zhou, C.; Li, Q.; Xiao, Z.; Yuan, C.; Xu, J.; Chen, G.; Rao, G. Large electrostrictive coefficient with optimized Electro-Strain in BNT-based ceramics with ergodic state. Mater. Sci. Eng. B 2022, 283, 115828. [Google Scholar] [CrossRef]

- Jin, L.; Pang, J.; Jing, R.; Lan, Y.; Wang, L.; Li, F.; Hu, Q.; Du, H.; Guo, D.; Wei, X.; et al. Ultra-slim pinched polarization-electric field hysteresis loops and thermally stable electrostrains in lead-free sodium bismuth titanate based solid solutions. J. Alloys Compd. 2019, 788, 1182–1192. [Google Scholar] [CrossRef]

- Shi, J.; Fan, H.Q.; Liu, X.; Bell, A.J. Large electrostrictive strain in (Bi0.5Na0.5)TiO3-BaTiO3-(Sr0.7Bi0.2)TiO3 solid solutions. J. Am. Ceram. Soc. 2014, 97, 848–853. [Google Scholar] [CrossRef]

- Lu, X.; Hou, L.; Jin, L.; Wang, D.; Hu, Q.; Alikin, D.O.; Turygin, A.P.; Wang, L.; Zhang, L.; Wei, X. Origin of composition-insensitive electrostrictive coefficient and continuous decrease of domain wall density in (1−x)NaNbO3−xBaTiO3 lead-free ferroelectrics. J. Eur. Ceram. Soc. 2018, 38, 3127–3135. [Google Scholar] [CrossRef]

- Shvartsman, V.V.; Lupascu, D.C. Lead-free relaxor ferroelectrics. J. Am. Ceram. Soc. 2012, 95, 1–26. [Google Scholar] [CrossRef]

- He, H.Y.; Lu, X.; Li, M.C.; Wang, Y.M.; Li, Z.R.; Lu, Z.G.; Lu, L. Thermal and compositional driven relaxor ferroelectric behaviours of lead-free (Bi0.5Na0.5)TiO3-SrTiO3 ceramics. J. Mater. Chem. C 2020, 8, 2411. [Google Scholar] [CrossRef]

- Fan, P.Y.; Zhang, Y.Y.; Xie, B.; Zhu, Y.W.; Ma, W.G.; Wang, C.; Yang, B. Large electric-field-induced strain in B-site complex-ion (Fe0.5Nb0.5)4+-doped Bi1/2 (Na0.82K0.12)1/2TiO3 lead-free piezoceramics. Ceram. Int. 2018, 44, 3211–3217. [Google Scholar] [CrossRef]

- Cheng, R.F.; Xu, Z.J.; Chu, R.Q.; Hao, J.G.; Du, J.; Li, G.R. Electric field-induced ultrahigh strain and large piezoelectric effect in Bi1/2Na1/2TiO3-based lead-free piezoceramics. J. Eur. Ceram. Soc. 2016, 36, 489–496. [Google Scholar] [CrossRef]

- Jin, L.; Luo, W.; Hou, L.; Tian, Y.; Hu, Q.; Wang, L.; Zhang, L.; Lu, X.; Du, H.; Wei, X.; et al. High electric field-induced strain with ultra-low hysteresis and giant electrostrictive coefficient in barium strontium titanate lead-free ferroelectrics. J. Eur. Ceram. Soc. 2019, 39, 295–304. [Google Scholar] [CrossRef]

- Deng, A.; Wu, J. Optimized strain properties with small hysteresis in BNT-based ceramics with ergodic relaxor state. J. Eur. Ceram. Soc. 2021, 41, 5147–5154. [Google Scholar] [CrossRef]

- Lee, H.B.; Heo, D.J.; Malik, R.A.; Yoon, C.H.; Han, H.S.; Lee, J.S. Lead-free Bi1/2(Na0.82K0.18)1/2TiO3 ceramics exhibiting large strain with small hysteresis. Ceram. Int. 2013, 39, 5705–5708. [Google Scholar] [CrossRef]

- Malik, R.A.; Hussain, A.; Maqbool, A.; Zaman, A.; Ahn, C.W.; Rahman, J.U.; Song, T.K.; Kim, W.J.; Kim, M.H. Temperature-insensitive high strain in lead-free Bi0.5(Na0.84K0.16)0.5TiO3-0.04SrTiO3 ceramics for actuator applications. J. Am. Ceram. Soc. 2015, 98, 3842–3848. [Google Scholar] [CrossRef]

- Xi, H.; Yu, L.X.; Qian, H.; Chen, F.J.; Mao, M.M.; Liu, Y.F.; Lyu, Y.N. Large strain with low hysteresis in Sn-modified Bi0.5(Na0.75K0.25)0.5TiO3 lead-free piezoceramics. J. Mater. Sci. 2020, 55, 1388–1398. [Google Scholar] [CrossRef]

- Gozuacik, N.K.; Bayir, M.C.; Alkoy, E.M.; Alkoy, S. Origin of the large field-induced strain and enhanced energy storage response of rare-earth-doped lead-free 0.854BNT-0.12BKT-026BT ceramics, IEEE Trans. Ultrason. Ferroelectr. Freq. Control. 2021, 68, 2576–2584. [Google Scholar] [CrossRef]

- Zhao, W.L.; Zuo, R.Z.; Li, F.; Li, L.T. Structural, dielectric, ferroelectric and strain properties in CaZrO3-modified Bi(Mg0.5Ti0.5)O3-PbTiO3 solid solutions. J. Alloys Compd. 2014, 591, 218–223. [Google Scholar] [CrossRef]

- Dinh, T.H.; Kang, J.K.; Lee, J.S.; Khansur, N.H.; Daniels, J.; Lee, H.Y.; Yao, F.Z.; Wang, K.; Li, J.F.; Han, H.S.; et al. Nanoscale ferroelectric/relaxor composites: Origin of large strain in lead-free Bi-based incipient piezoelectric ceramics. J. Eur. Ceram. Soc. 2016, 36, 3401–3407. [Google Scholar] [CrossRef]

- Chen, N.; Yao, W.; Liang, C.; Xiao, S.; Hao, J.; Xu, Z.; Chu, R. Phase structure, ferroelectric properties, and electric field-induced large strain in lead-free 0.99[(1−x)(Bi0.5Na0.5)TiO3−x(Bi0.5K0.5)TiO3]-0.01Ta piezoelectric ceramics. Ceram. Int. 2016, 42, 9660–9666. [Google Scholar] [CrossRef]

- Tran, V.D.N.; Ullah, A.; Dinh, T.H.; Lee, J.S. Large field induced strain properties of Sr (K0.25Nb0.75)O3-modified Bi1/2(Na0.82K0.18)1/2TiO3 lead-free piezoelectric ceramics. J. Electron. Mater. 2016, 45, 2627–2631. [Google Scholar] [CrossRef]

- He, H.Y.; Lu, W.H.; Oh, J.A.S.; Li, Z.R.; Lu, X.; Zeng, K.Y.; Lu, L. Probing the coexistence of ferroelectric and relaxor states in Bi0.5Na0.5TiO3-based ceramics for enhanced piezoelectric performance. ACS Appl. Mater. Interfaces 2020, 12, 30548–30556. [Google Scholar] [CrossRef]

- Yin, J.; Wang, Y.M.; Zhang, Y.X.; Wu, B.; Wu, J.G. Thermal depolarization regulation by oxides selection in lead-free BNT/oxides piezoelectric composites. Acta Mater. 2018, 158, 269–277. [Google Scholar] [CrossRef]

- Viola, G.; McKinnon, R.; Koval, V.; Adomkevicius, A.; Dunn, S.; Yan, H. Lithium-induced phase transitions in lead-free Bi0.5Na0.5TiO3 based ceramics. J. Phys. Chem. C. 2014, 118, 8564–8570. [Google Scholar] [CrossRef]

- Zhang, H.B.; Xu, P.W.; Patterson, E.; Zang, J.D.; Jiang, S.L.; Rödel, J. Preparation and enhanced electrical properties of grain oriented (Bi1/2Na1/2)TiO3-based lead-free incipient piezoceramics. J. Eur. Ceram. Soc. 2015, 35, 2501–2512. [Google Scholar] [CrossRef]

- Li, F.; Jin, L.; Xu, Z.; Zhang, S.J. Electrostrictive effect in ferroelectrics: An alternative approach to improve Piezoelectricity. Appl. Phys. Rev. 2014, 1, 011103. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, H.; Gao, J.; Li, M.; Zhang, Q.; Zhang, Y. Optimized Strain Response in (Co0.5Nb0.5)4+-Doped 76Bi0.5Na0.5TiO3-24SrTiO3 Relaxors. Coatings 2023, 13, 1331. https://doi.org/10.3390/coatings13081331

Li H, Gao J, Li M, Zhang Q, Zhang Y. Optimized Strain Response in (Co0.5Nb0.5)4+-Doped 76Bi0.5Na0.5TiO3-24SrTiO3 Relaxors. Coatings. 2023; 13(8):1331. https://doi.org/10.3390/coatings13081331

Chicago/Turabian StyleLi, Hui, Jingxia Gao, Mingyang Li, Qingfeng Zhang, and Yangyang Zhang. 2023. "Optimized Strain Response in (Co0.5Nb0.5)4+-Doped 76Bi0.5Na0.5TiO3-24SrTiO3 Relaxors" Coatings 13, no. 8: 1331. https://doi.org/10.3390/coatings13081331

APA StyleLi, H., Gao, J., Li, M., Zhang, Q., & Zhang, Y. (2023). Optimized Strain Response in (Co0.5Nb0.5)4+-Doped 76Bi0.5Na0.5TiO3-24SrTiO3 Relaxors. Coatings, 13(8), 1331. https://doi.org/10.3390/coatings13081331