An Optimized Dip Coating Approach for Metallic, Dielectric, and Semiconducting Nanomaterial-Based Optical Thin Film Fabrication

Abstract

1. Introduction

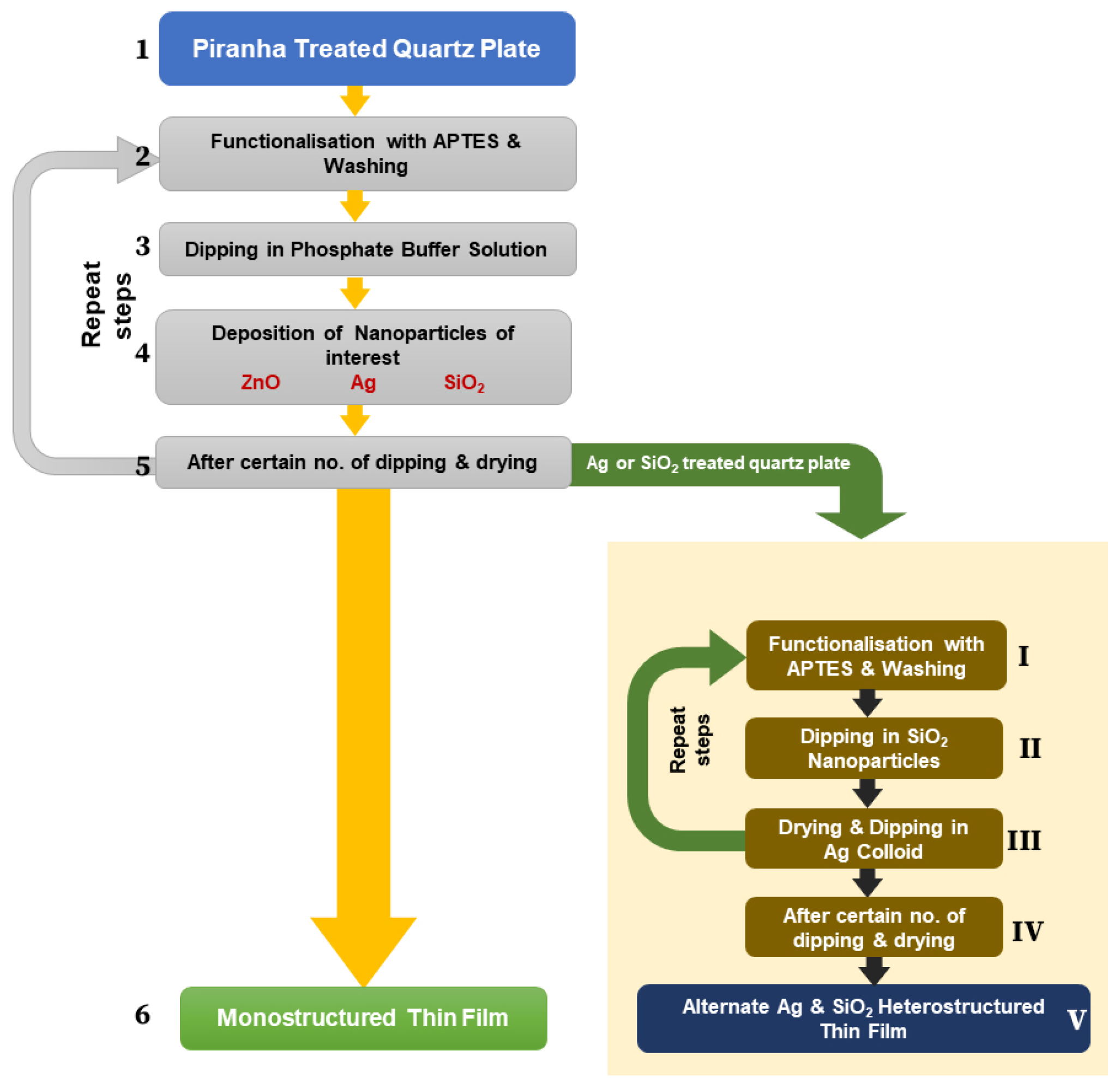

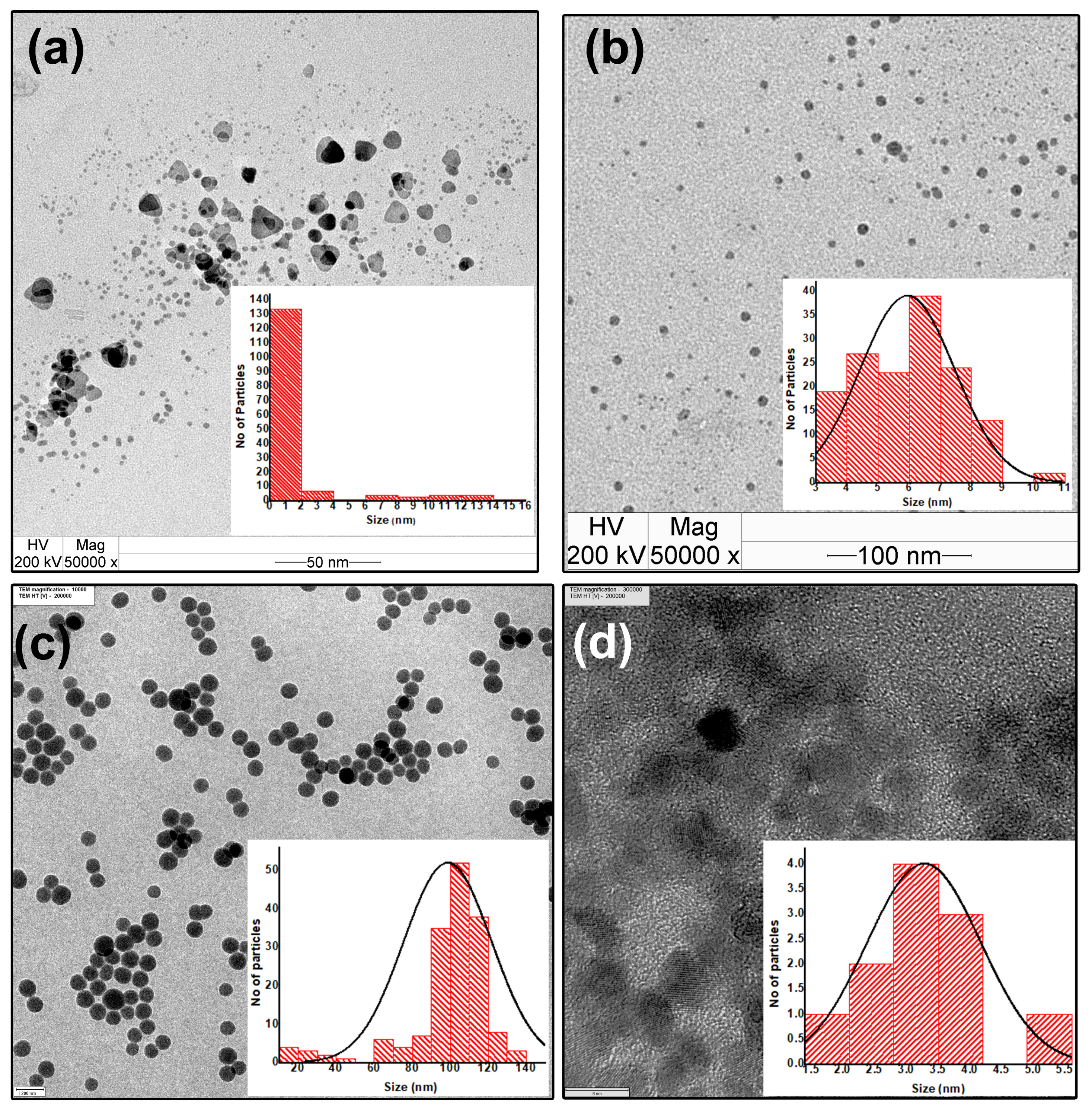

2. Materials and Methods

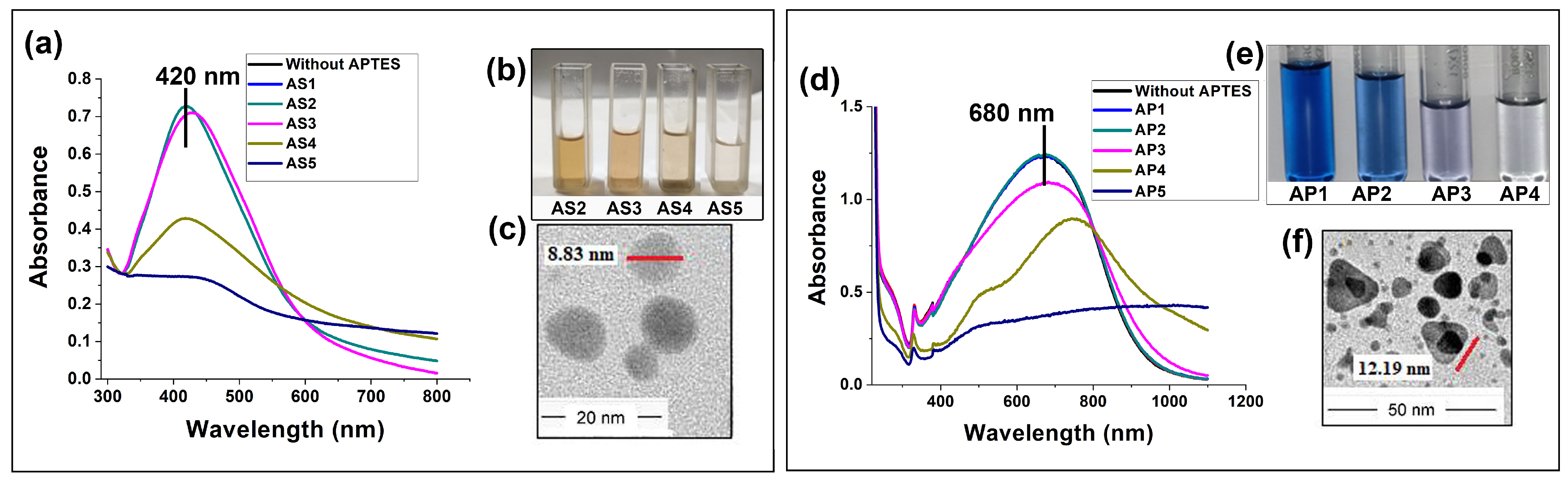

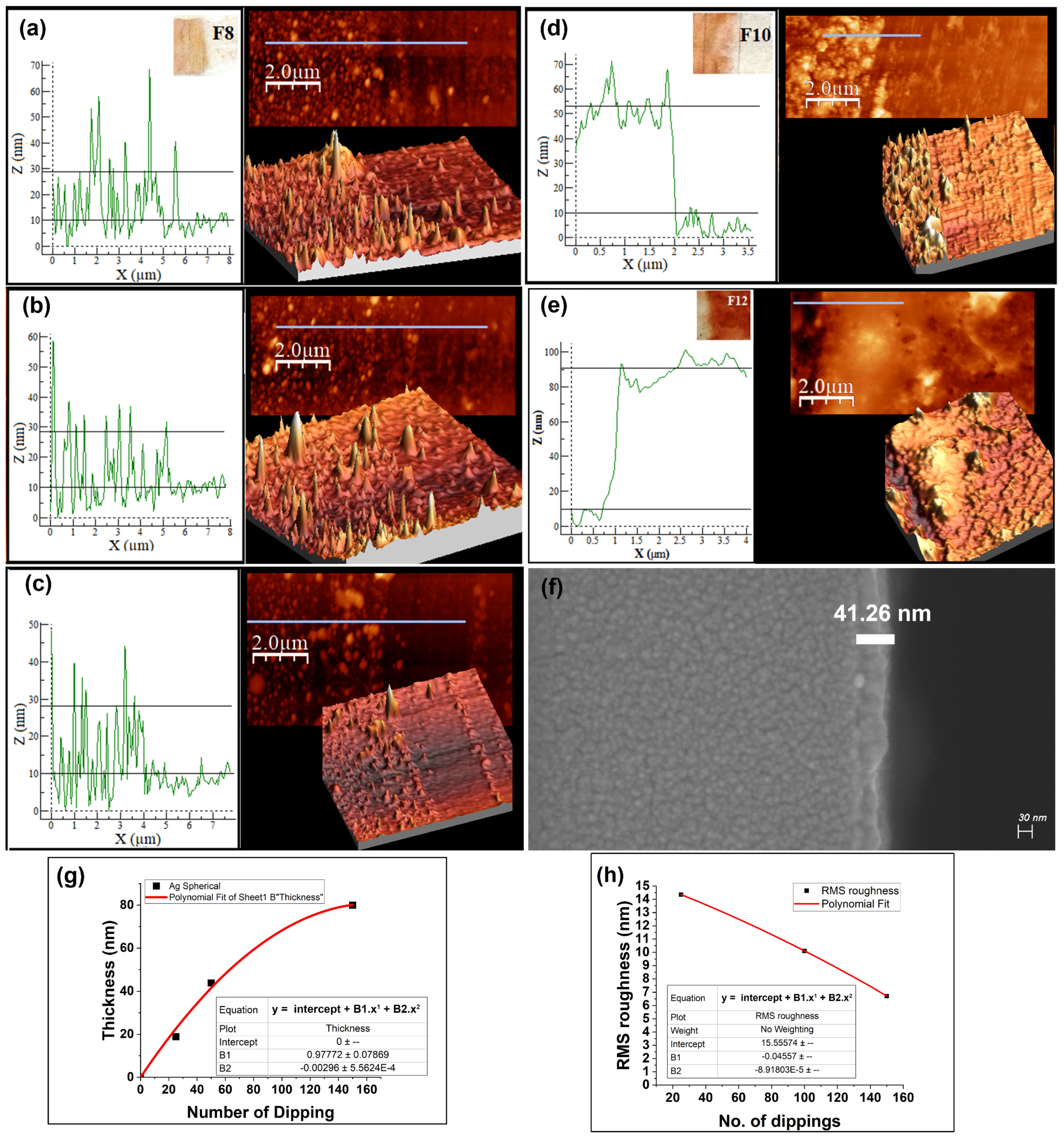

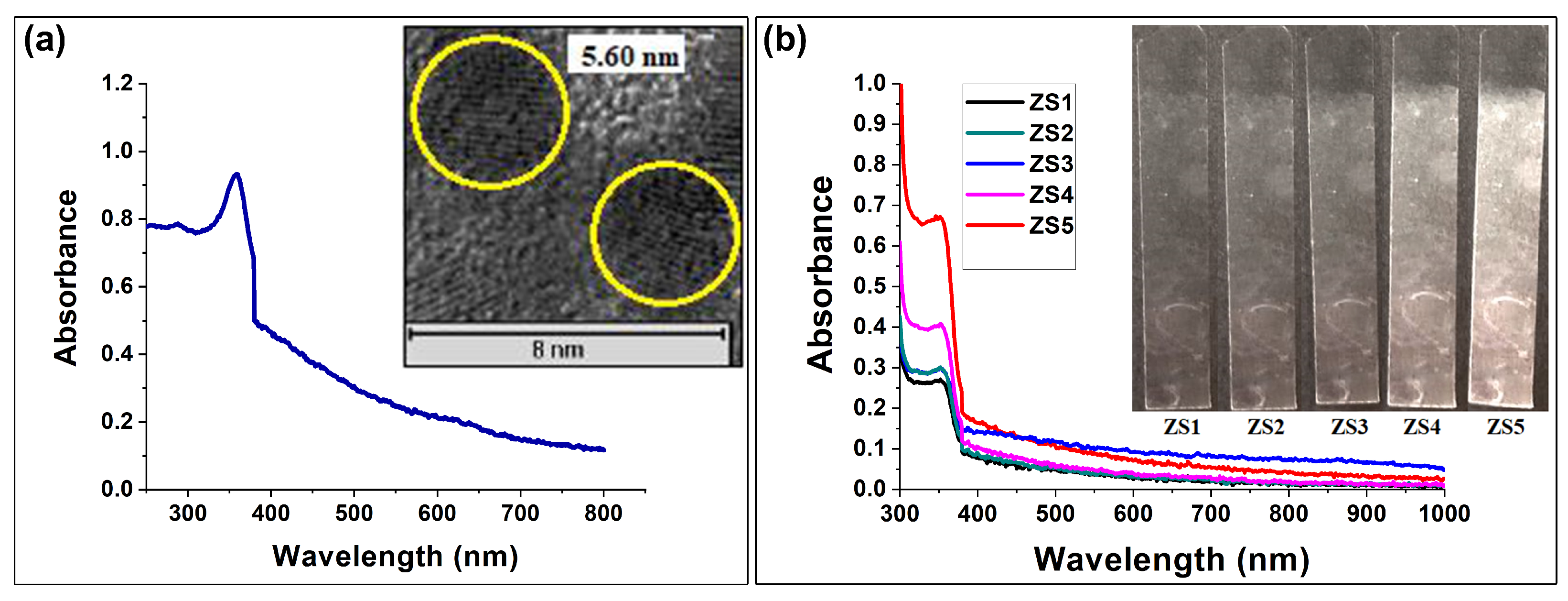

3. Results

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| viz. | Videlicet |

| SEM | Scanning electron microscopy |

| TEM | Transmission electron microscopy |

| UV-vis | Ultraviolet-visible spectroscopy |

| APTES | 3-aminopropyltriethoxysilane |

| NPs | Nanoparticles |

| SPR | Surface plasmon resonance |

| AFM | Atomic force microscopy |

Appendix A

Appendix A.1

Appendix A.2

Appendix B

References

- Căilean, A.M.; Dimian, M. Current challenges for visible light communications usage in vehicle applications: A survey. IEEE Commun. Surv. Tutor. 2017, 19, 2681–2703. [Google Scholar] [CrossRef]

- Pimenta, S.; Cardoso, S.; Miranda, A.; De Beule, P.; Castanheira, E.; Minas, G. Design and fabrication of SiO2/TiO2 and MgO/TiO2 based high selective optical filters for diffuse reflectance and fluorescence signals extraction. Biomed. Opt. Express 2015, 6, 3084–3098. [Google Scholar] [CrossRef]

- Kim, D.; Woo, H.K.; Lee, Y.M.; Kim, Y.; Choi, J.H.; Oh, S.J. Controllable doping and passivation of ZnO thin films by surface chemistry modification to design low-cost and high-performance thin film transistors. Appl. Surf. Sci. 2020, 509, 145289. [Google Scholar] [CrossRef]

- Yu, R.; Mazumder, P.; Borrelli, N.F.; Carrilero, A.; Ghosh, D.S.; Maniyara, R.A.; Baker, D.; García de Abajo, F.J.; Pruneri, V. Structural coloring of glass using dewetted nanoparticles and ultrathin films of metals. ACS Photonics 2016, 3, 1194–1201. [Google Scholar] [CrossRef]

- Shaukat, A.; Noble, F.; Arif, K.M. Nanostructured color filters: A review of recent developments. Nanomaterials 2020, 10, 1554. [Google Scholar] [CrossRef]

- Ge, P.; Liang, X.; Wang, J.; Zhao, C.; Gao, X.; Ding, Z. Optical filter designs for multi-color visible light communication. IEEE Trans. Commun. 2018, 67, 2173–2187. [Google Scholar] [CrossRef]

- Kaiser, N. Review of the fundamentals of thin-film growth. Appl. Opt. 2002, 41, 3053–3060. [Google Scholar] [CrossRef] [PubMed]

- Barber, Z.; Blamire, M. High throughput thin film materials science. Mater. Sci. Technol. 2008, 24, 757–770. [Google Scholar] [CrossRef]

- Kumar, A.K.S.; Zhang, Y.; Li, D.; Compton, R.G. A mini-review: How reliable is the drop casting technique? Electrochem. Commun. 2020, 121, 106867. [Google Scholar] [CrossRef]

- Mustafa, H.A.M.; Jameel, D.A. Modeling and the main stages of spin coating process: A review. J. Appl. Sci. Technol. Trends 2021, 2, 91–95. [Google Scholar] [CrossRef]

- Safi, I. Recent aspects concerning DC reactive magnetron sputtering of thin films: A review. Surf. Coat. Technol. 2000, 127, 203–218. [Google Scholar] [CrossRef]

- Affinito, J.; Martin, P.; Gross, M.; Coronado, C.; Greenwell, E. Vacuum deposited polymer/metal multilayer films for optical application. Thin Solid Film. 1995, 270, 43–48. [Google Scholar] [CrossRef]

- Wasa, K.; Kanno, I.; Kotera, H. Handbook of Sputter Deposition Technology: Fundamentals and Applications for Functional Thin Films, Nano-Materials and MEMS; William Andrew Publishing: Norwich, NY, USA, 2012. [Google Scholar]

- Khan, Z.R.; Khan, M.S.; Zulfequar, M.; Khan, M.S. Optical and structural properties of ZnO thin films fabricated by sol-gel method. Mater. Sci. Appl. 2011, 2, 340–345. [Google Scholar] [CrossRef]

- Tian, W.; Vahid Mohammadi, A.; Wang, Z.; Ouyang, L.; Beidaghi, M.; Hamedi, M.M. Layer-by-layer self-assembly of pillared two-dimensional multilayers. Nat. Commun. 2019, 10, 2558. [Google Scholar] [CrossRef]

- Suchikova, Y.; Kovachov, S.; Bohdanov, I.; Popova, E.; Moskina, A.; Popov, A. Characterization of CdxTeyOz/CdS/ZnO Heterostructures Synthesized by the SILAR Method. Coatings 2023, 13, 639. [Google Scholar] [CrossRef]

- Butt, M.A. Thin-film coating methods: A successful marriage of high-quality and cost-effectiveness—A brief exploration. Coatings 2022, 12, 1115. [Google Scholar] [CrossRef]

- Samha, H.; DeArmond, M.K. Multilayer sol-gel films using the Langmuir-Blodgett deposition method. Langmuir 1993, 9, 1927–1929. [Google Scholar] [CrossRef]

- Kitsomboonloha, R.; Ngambenjawong, C.; Mohammed, W.; Chaudhari, M.; Hornyak, G.; Dutta, J. Plasmon resonance tuning of gold and silver nanoparticle-insulator multilayered composite structures for optical filters. Micro Nano Lett. 2011, 6, 342–344. [Google Scholar] [CrossRef]

- Higashi, N.; Takagi, T.; Koga, T. Layer-by-layer fabrication of well-packed gold nanoparticle assemblies guided by a β-sheet peptide network. Polym. J. 2010, 42, 95–99. [Google Scholar] [CrossRef]

- Rivero, P.J.; Goicoechea, J.; Matias, I.R.; Arregui, F.J. A comparative study of two different approaches for the incorporation of silver nanoparticles into layer-by-layer films. Nanoscale Res. Lett. 2014, 9, 301. [Google Scholar] [CrossRef]

- Rivero, P.J.; Goicoechea, J.; Arregui, F.J. Layer-by-layer nano-assembly: A powerful tool for optical fiber sensing applications. Sensors 2019, 19, 683. [Google Scholar] [CrossRef]

- Rivero, P.J.; Urrutia, A.; Goicoechea, J.; Arregui, F. Optical fiber humidity sensors based on Localized Surface Plasmon Resonance (LSPR) and Lossy-mode resonance (LMR) in overlays loaded with silver nanoparticles. Sens. Actuator B Chem. 2012, 173, 244–249. [Google Scholar] [CrossRef]

- Yuehui, W.; Xing, Y. High-reflection optical thin films based on SiO2/TiO2 nanoparticles multilayers by dip coating. Micro Nano Lett. 2018, 13, 1349–1351. [Google Scholar] [CrossRef]

- Shibraen, M.H.; Yagoub, H.; Zhang, X.; Xu, J.; Yang, S. Anti-fogging and anti-frosting behaviors of layer-by-layer assembled cellulose derivative thin film. Appl. Surf. Sci. 2016, 370, 1–5. [Google Scholar] [CrossRef]

- Saffar, M.A.; Eshaghi, A.; Dehnavi, M.R. Fabrication of superhydrophobic, self-cleaning and anti-icing ZnO/PTFE-SiO2 nano-composite thin film. Mater. Chem. Phys. 2021, 259, 124085. [Google Scholar] [CrossRef]

- Rivero, P.J.; Urrutia, A.; Goicoechea, J.; Matias, I.; Arregui, F. A Lossy Mode Resonance optical sensor using silver nanoparticles-loaded films for monitoring human breathing. Sens. Actuator B Chem. 2013, 187, 40–44. [Google Scholar] [CrossRef]

- Michel, M.; Toniazzo, V.; Ruch, D.; Ball, V. Deposition mechanisms in layer-by-layer or step-by-step deposition methods: From elastic and impermeable films to soft membranes with ion exchange properties. ISRN Mater. Sci. 2012, 2012, 701695. [Google Scholar] [CrossRef]

- Scherino, L.; Giaquinto, M.; Micco, A.; Aliberti, A.; Bobeico, E.; La Ferrara, V.; Ruvo, M.; Ricciardi, A.; Cusano, A. A time-efficient dip coating technique for the deposition of microgels onto the optical fiber tip. Fibers 2018, 6, 72. [Google Scholar] [CrossRef]

- Wu, L.; Yang, D.; Fei, L.; Huang, Y.; Wu, F.; Sun, Y.; Shi, J.; Xiang, Y. Dip-coating process engineering and performance optimization for three-state electrochromic devices. Nanoscale Res. Lett. 2017, 12, 390. [Google Scholar] [CrossRef] [PubMed]

- Eshaghi, A.; Aghaei, A.A.; Zabolian, H.; Jannesari, M.; Firoozifar, A. Transparent superhydrophilic SiO2/TiO2/SiO2 tri-layer nanostructured antifogging thin film. Ceram. Silik. 2013, 57, 210–214. [Google Scholar]

- Szeghalmi, A.; Helgert, M.; Brunner, R.; Heyroth, F.; Gösele, U.; Knez, M. Atomic layer deposition of Al2O3 and TiO2 multilayers for applications as bandpass filters and antireflection coatings. Appl. Opt. 2009, 48, 1727–1732. [Google Scholar] [CrossRef] [PubMed]

- Shelemin, A.; Baloukas, B.; Zabeida, O.; Klemberg-Sapieha, J.E.; Martinu, L. Fabrication of plasmonic Ag nanoparticles for optical coating applications. In Proceedings of the Optical Interference Coatings Conference (OIC 2022), Whistler, BC, Canada, 19–24 June 2022; Optica Publishing Group: Washington, DC, USA, 2022; p. MD-3. [Google Scholar]

- Park, C.; Kim, T.; Kim, Y.I.; Lee, M.W.; An, S.; Yoon, S.S. Supersonically sprayed transparent flexible multifunctional composites for self-cleaning, anti-icing, anti-fogging, and anti-bacterial applications. Compos. Part B Eng. 2021, 222, 109070. [Google Scholar] [CrossRef]

- Halbus, A.F.; Horozov, T.S.; Paunov, V.N. Surface-modified zinc oxide nanoparticles for antialgal and antiyeast applications. ACS Appl. Nano Mater. 2020, 3, 440–451. [Google Scholar] [CrossRef]

- Huang, T.; Xu, X.H.N. Synthesis and characterization of tunable rainbow colored colloidal silver nanoparticles using single-nanoparticle plasmonic microscopy and spectroscopy. J. Mater. Chem. 2010, 20, 9867–9876. [Google Scholar] [CrossRef]

- Natte, K.; Behnke, T.; Orts-Gil, G.; Würth, C.; Friedrich, J.F.; Österle, W.; Resch-Genger, U. Synthesis and characterisation of highly fluorescent core–shell nanoparticles based on Alexa dyes. J. Nanopart. Res. 2012, 14, 680. [Google Scholar] [CrossRef]

- Baruah, S.; Rafique, R.F.; Dutta, J. Visible light photocatalysis by tailoring crystal defects in zinc oxide nanostructures. Nano 2008, 3, 399–407. [Google Scholar] [CrossRef]

| Thin Film | Depositing Nanoparticles | No. of Dips | Timing of Intermediate APTES Layer |

|---|---|---|---|

| F1 | Ag (prismatic) | 25 | - |

| F2 | 50 | - | |

| F3 | 100 | - | |

| F4 | 100 | After 50 dipping–drying cycles | |

| F5 | 50 * | - | |

| F6 | 100 * | - | |

| F7 | 150 | After every 50 dipping–drying cycles | |

| F8 | Ag (spherical) | 25 | - |

| F9 | 35 | - | |

| F10 | 50 | - | |

| F11 | 100 | After 50 dipping–drying cycles | |

| F12 | 150 | After every 50 dipping–drying cycles | |

| 3-4 F8R1 | 25 | - | |

| F8R2 | 25 | - | |

| F8R3 | 25 | - | |

| S1 | SiO2 | 1 | - |

| S2 | 2 | After the first dip | |

| S3 | 3 | ||

| S4 | 4 | After every dipping–drying cycle | |

| SFS1 | Both SiO2 and Ag (spherical) | Silica-1 | Silica—after every dipping–drying cycle |

| Ag-50 | |||

| SFS2 | Silica-2 | ||

| Ag-50 | |||

| SFS3 | Silica-2 | Ag—after every 50 dipping–drying cycles | |

| Ag-100 | |||

| SFS4 | Silica-3 | ||

| Ag-100 | |||

| ZS1 | ZnO | 50 | - |

| ZS2 | 100 | - | |

| ZS3 | 150 | - | |

| ZS4 | 100 | After 50 dipping–drying cycles | |

| ZS5 | 150 | After every 50 dipping–drying cycles |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sarkar, A.K.; Sarmah, D.; Baruah, S.; Datta, P. An Optimized Dip Coating Approach for Metallic, Dielectric, and Semiconducting Nanomaterial-Based Optical Thin Film Fabrication. Coatings 2023, 13, 1391. https://doi.org/10.3390/coatings13081391

Sarkar AK, Sarmah D, Baruah S, Datta P. An Optimized Dip Coating Approach for Metallic, Dielectric, and Semiconducting Nanomaterial-Based Optical Thin Film Fabrication. Coatings. 2023; 13(8):1391. https://doi.org/10.3390/coatings13081391

Chicago/Turabian StyleSarkar, Arnab Kumar, Devabrata Sarmah, Sunandan Baruah, and Pranayee Datta. 2023. "An Optimized Dip Coating Approach for Metallic, Dielectric, and Semiconducting Nanomaterial-Based Optical Thin Film Fabrication" Coatings 13, no. 8: 1391. https://doi.org/10.3390/coatings13081391

APA StyleSarkar, A. K., Sarmah, D., Baruah, S., & Datta, P. (2023). An Optimized Dip Coating Approach for Metallic, Dielectric, and Semiconducting Nanomaterial-Based Optical Thin Film Fabrication. Coatings, 13(8), 1391. https://doi.org/10.3390/coatings13081391