Erosion Behavior of Stellite-6 and WC-12Co Coatings on SA213-T22 Boiler Steel

Abstract

:1. Introduction

2. Experimental Section

2.1. Materials and Coating Process

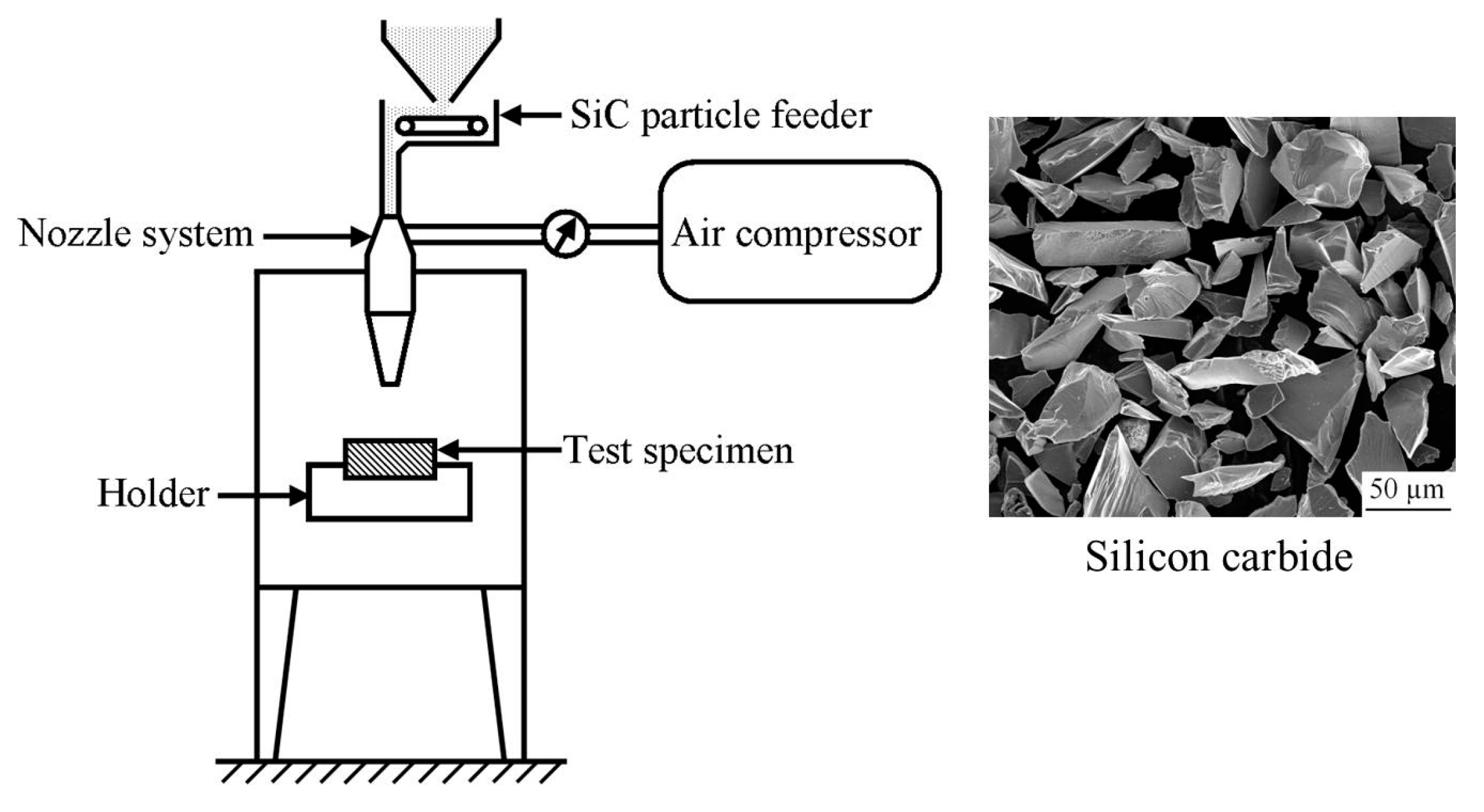

2.2. Erosion Experiments

2.3. Characterization

3. Results and Discussion

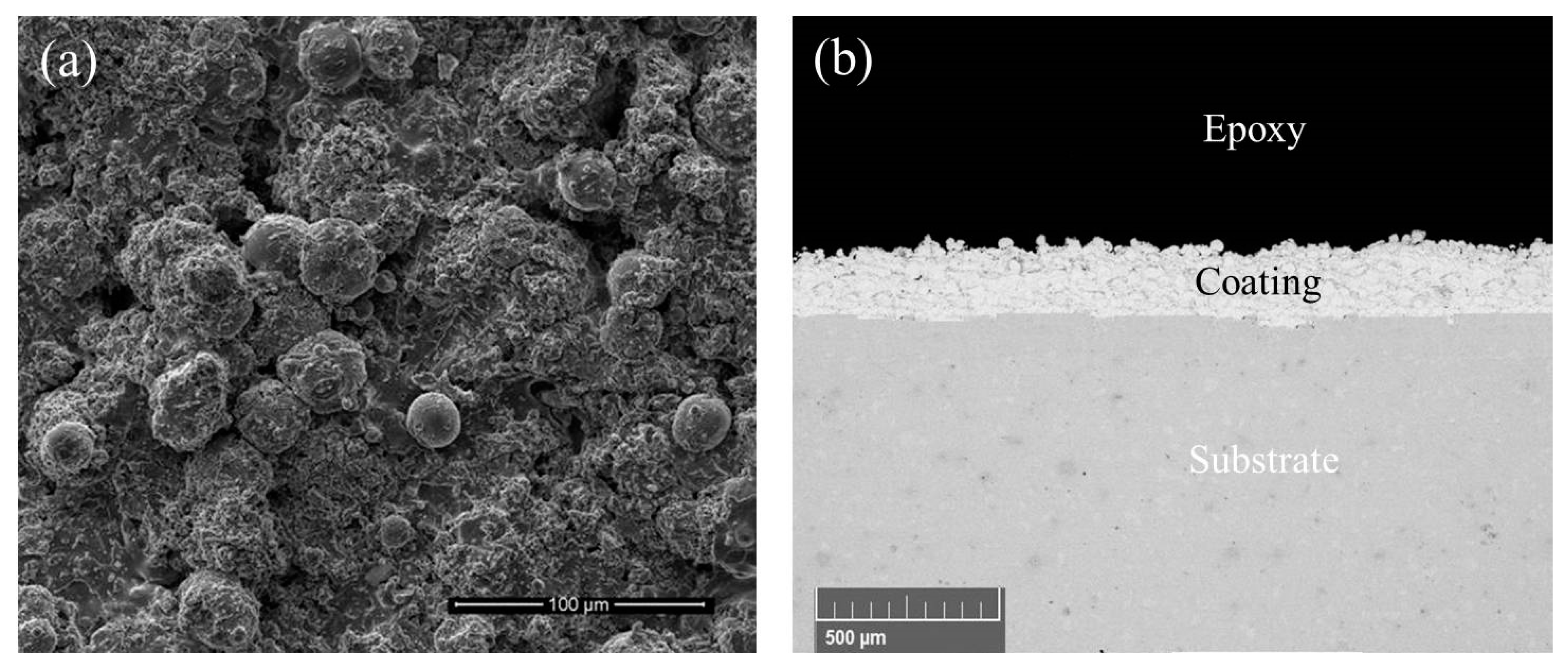

3.1. Characterization

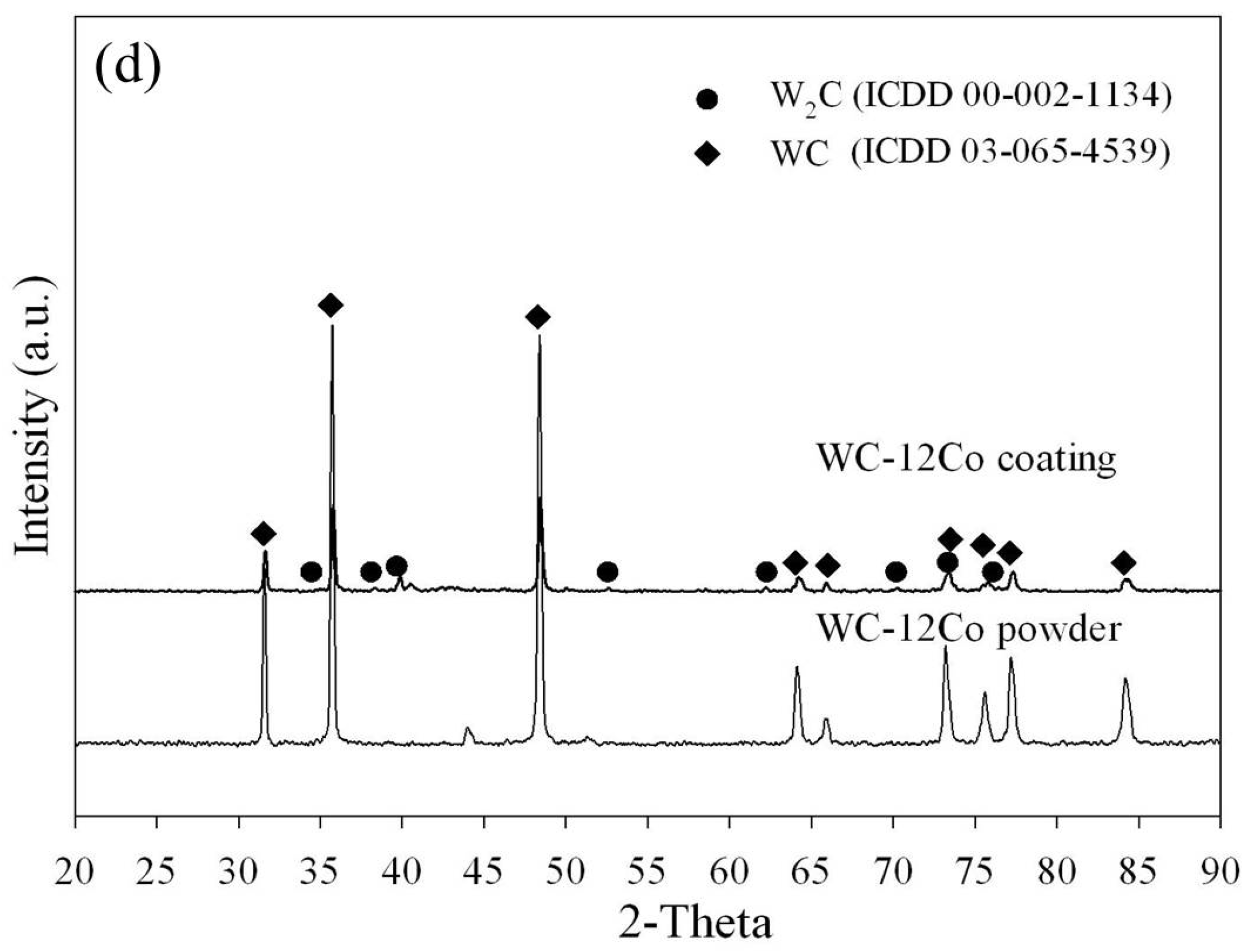

3.1.1. SEM/EDS and X-ray Diffraction Analysis

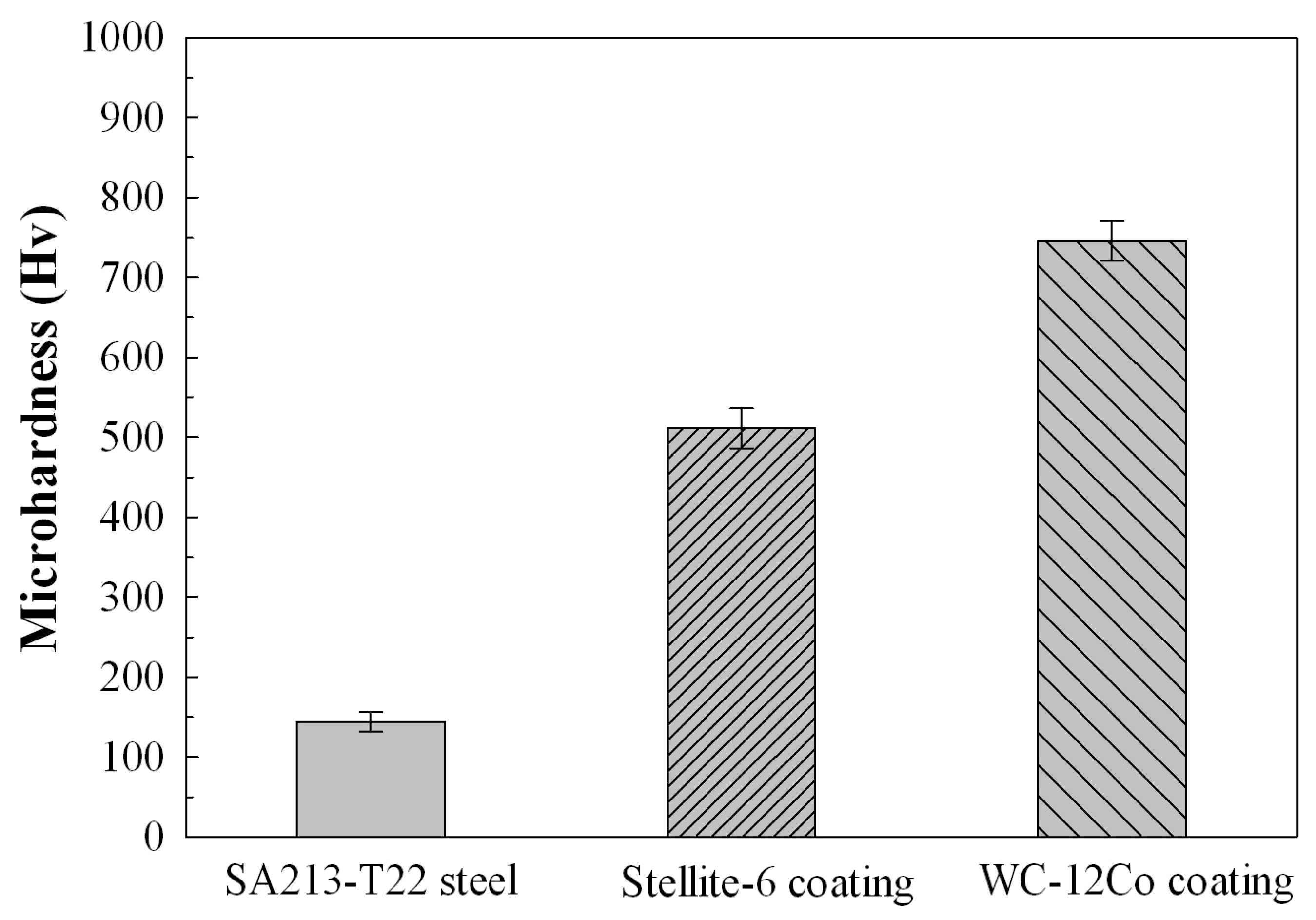

3.1.2. Hardness

3.2. Erosion Test

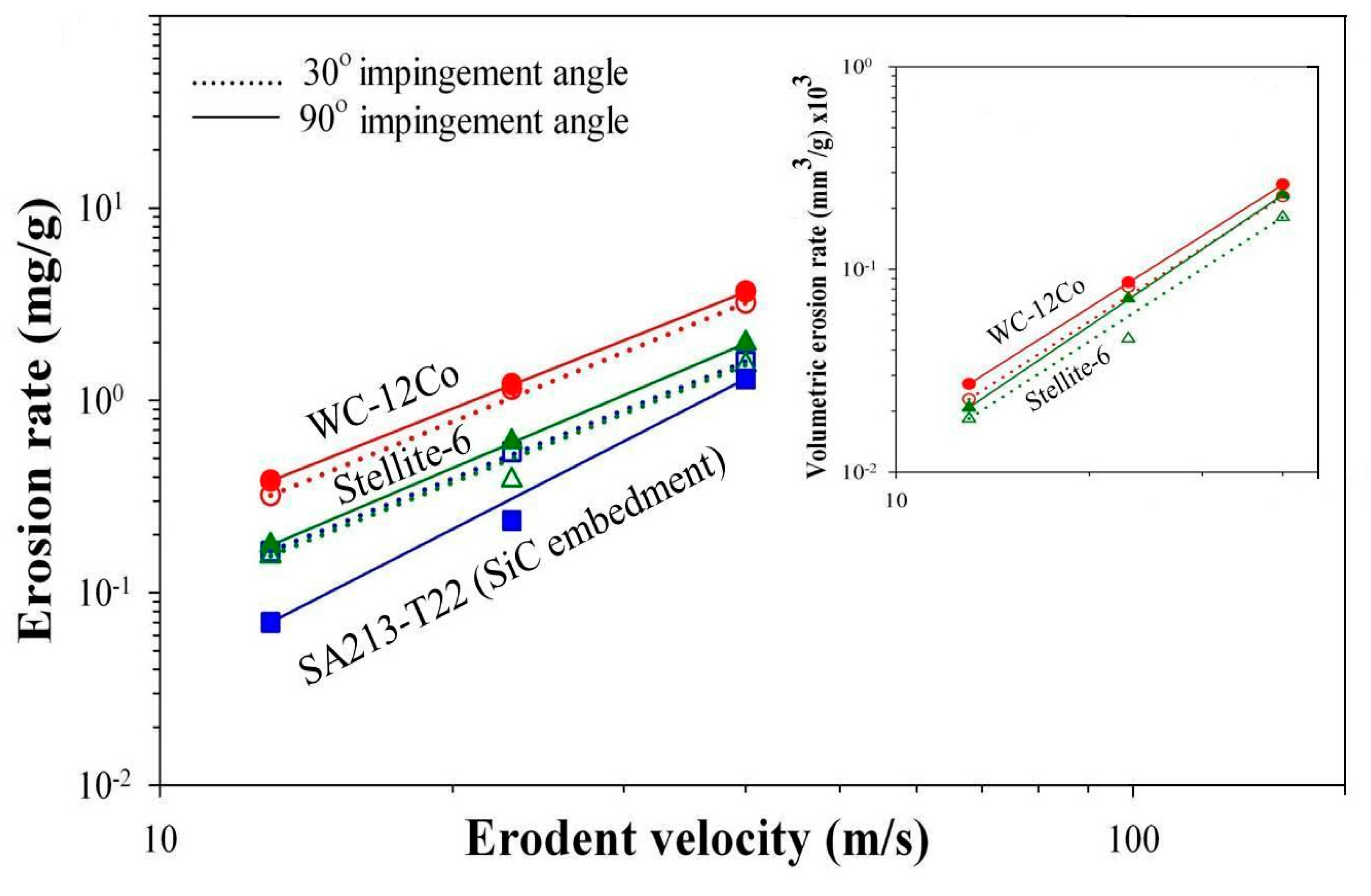

3.2.1. Erosion Rate and Velocity Exponent

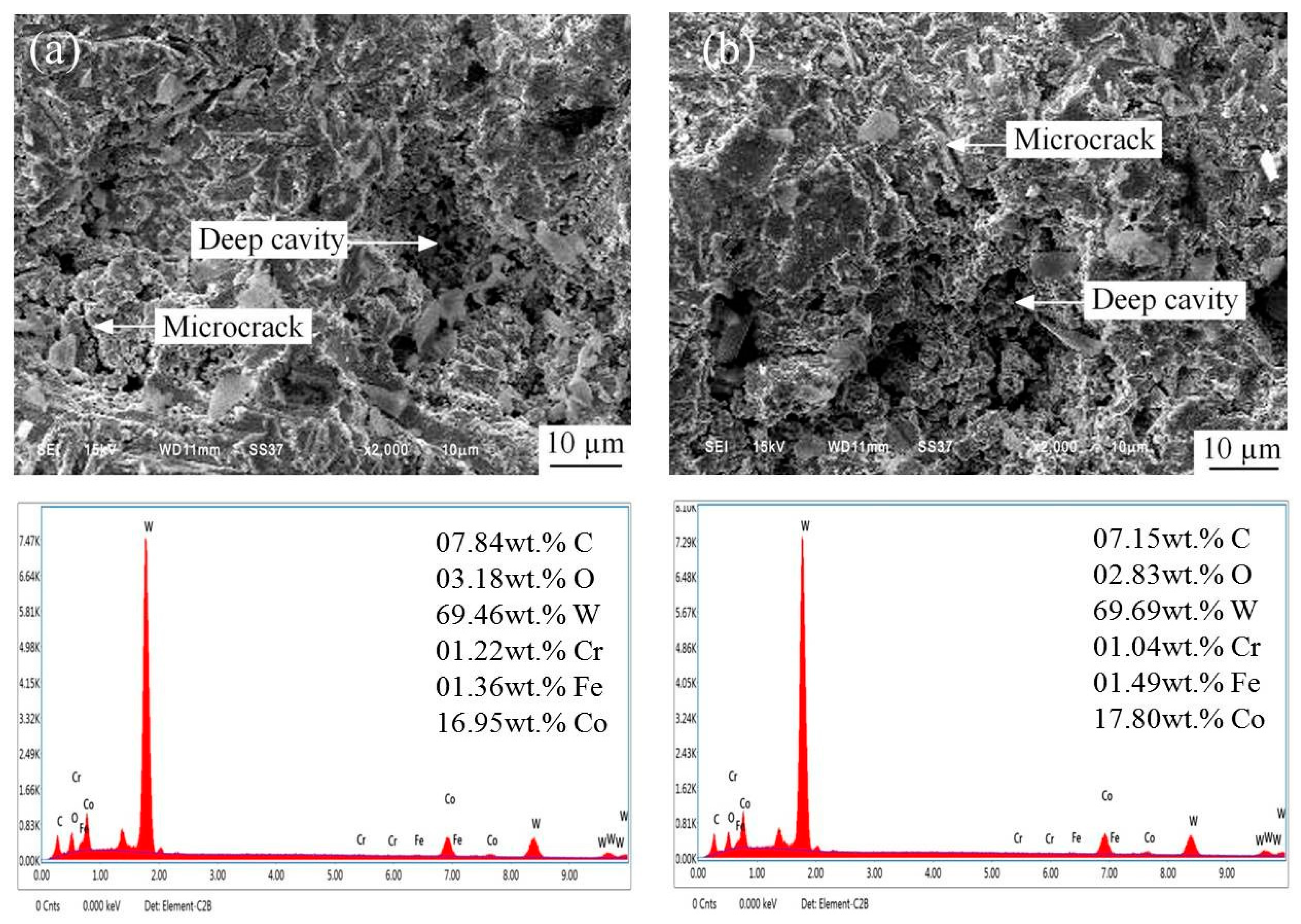

3.2.2. Surface Morphology and Chemical Composition Analysis

4. Conclusions

- The erosion of uncoated SA213-T22 steel showed a ductile mode with a ploughing and microcutting morphology and SiC embedment on the surface. The erosion rates were lower than the intrinsic values due to the change in the surface condition from metal to composite. Thus, an evaluation of the erosion for materials with extremely low hardness, less than SiC, will result in errors. In the case of high hardness materials such as Stellite-6 and WC-12Co, SiC embedment did not occur on the surface. This made it possible to apply SiC as an erodent particle for erosion testing.

- The velocity exponent indicates erosion sensitivity. In the case of uncoated SA213-T22 steel with SiC embedment, the change in velocity exponent from 2.3 to a value exceeding 3 showed a drastic change in the surface condition, while the Stellite-6 and WC-12Co coatings had values of 2, which corresponded to the traditional literature [3,27,42].

- Stellite-6 is a metal matrix composite, whereas WC-12Co coating is a cermet composite. As a result, erosion will behave differently. In the case of a cermet composite, WC-12Co coating showed only brittle erosion, while Stellite-6 showed a morphology with some evidence of ductile erosion such as lips on the coating surface. Thus, its erosion behavior exhibited predominantly brittle erosion.

- The evaluation results showed better wear resistance from the Stellite-6 than from the WC-12Co coating. This contributed to the strength and toughness of the metal matrix composite structure and the lower porosity of the coating. In the case of the WC-12Co coating, the porosity was double that of the Stellite-6 coating. However, due to the higher hardness of WC-12Co, it has high potential to be optimized to achieve even better coatings if it could reduce its porosity and W2C brittle phase.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Ramesh, M.; Prakash, S.; Nath, S.; Sapra, P.K.; Venkataraman, B. Solid particle erosion of HVOF sprayed WC-Co/NiCrFeSiB coatings. Wear 2010, 269, 197–205. [Google Scholar] [CrossRef]

- Sundararajan, G. The solid particle erosion of metallic materials: The rationalization of the influence of material variables. Wear 1995, 186, 129–144. [Google Scholar] [CrossRef]

- Sundararajan, G.; Roy, M. Solid particle erosion behaviour of metallic materials at room and elevated temperatures. Tribol. Int. 1997, 30, 339–359. [Google Scholar] [CrossRef]

- Chawla, V.; Chawla, A.; Puri, D.; Prakash, S.; Gurbuxani, P.G.; Sidhu, B.S. Hot corrosion & erosion problems in coal based power plants in India and possible solutions–a review. J. Met. Mater. Miner. 2011, 10, 367. [Google Scholar]

- Levy, A. Erosion and erosion-corrosion of metals. Corrosion 1995, 51, 872–883. [Google Scholar] [CrossRef]

- Shipway, P.; Hutchings, I. The role of particle properties in the erosion of brittle materials. Wear 1996, 193, 105–113. [Google Scholar] [CrossRef]

- Wichianrat, P.; Dateraksa, K.; Sujirote, K.; Chumphu, A. Wear behaviour of alumina nozzles by sand blasting. J. Met. Mater. Miner. 2010, 20, 15–18. [Google Scholar]

- Vite-Torres, M.; Laguna-Camacho, J.R.; Baldenebro-Castillo, R.E.; Gallardo-Hernández, E.A.; Vera-Cárdenas, E.E.; Vite-Torres, J. Study of solid particle erosion on AISI 420 stainless steel using angular silicon carbide and steel round grit particles. Wear 2013, 301, 383–389. [Google Scholar] [CrossRef]

- Ball, A. The mechanisms of wear, and the performance of engineering materials. J. S. Afr. Inst. Min. Metall. 1986, 86, 1–13. [Google Scholar]

- Wellman, R.; Nicholls, J. High temperature erosion–oxidation mechanisms, maps and models. Wear 2004, 256, 907–917. [Google Scholar] [CrossRef]

- Bonu, V.; Barshilia, H.C. High-Temperature Solid Particle Erosion of Aerospace Components: Its Mitigation Using Advanced Nanostructured Coating Technologies. Coatings 2022, 12, 1979. [Google Scholar] [CrossRef]

- Mangla, A.; Chawla, V.; Singh, G. Comparative study of hot corrosion behavior of HVOF and plasma sprayed Ni20Cr coating on SA213 (T22) boiler steel in Na2SO4-60% V2O5 environment. Int. J. Eng. Sci. Res. Technol. 2017, 4, 2348–8034. [Google Scholar]

- Sapate, S.; Roy, M. Solid particle erosion of thermal sprayed coatings. In Thermal Sprayed Coatings and Their Tribological Performances; IGI Global: Hershey, PA, USA, 2015; pp. 193–226. [Google Scholar]

- Singh, P.K.; Mishra, S. Erosion performance of detonation gun deposited WC–12Co, Stellite 6 and Stellite 21 coatings on SAE213-T12 steel. Tribol.-Mater. Surf. Interfaces 2020, 14, 229–239. [Google Scholar] [CrossRef]

- Kumar, M.; Singh, H.; Singh, N.; Joshi, R.S. Erosion–corrosion behavior of cold-spray nanostructured Ni–20Cr coatings in actual boiler environment. Wear 2015, 332, 1035–1043. [Google Scholar] [CrossRef]

- Sidhu, H.S.; Sidhu, B.S.; Prakash, S. Mechanical and microstructural properties of HVOF sprayed WC–Co and Cr3C2–NiCr coatings on the boiler tube steels using LPG as the fuel gas. J. Mater. Process. Technol. 2006, 171, 77–82. [Google Scholar] [CrossRef]

- Kim, H.J.; Hwang, S.Y.; Lee, C.H.; Juvanon, P. Assessment of wear performance of flame sprayed and fused Ni-based coatings. Surf. Coat. Technol. 2003, 172, 262–269. [Google Scholar] [CrossRef]

- Sharma, A.; Goel, S. Erosion behaviour of WC–10Co–4Cr coating on 23-8-N nitronic steel by HVOF thermal spraying. Appl. Surf. Sci. 2016, 370, 418–426. [Google Scholar]

- Sierens, A.; Vanvooren, J.; Deplus, K.; Faes, K.; De Waele, W. Review on the possible tool materials for friction stir welding of steel plates. In Sustainable Construction and Design; Laboratory Soete, Ghent University: Ghent, Belgium, 2014; Volume 5. [Google Scholar]

- Peat, T.; Galloway, A.; Toumpis, A.; McNutt, P.; Iqbal, N. The erosion performance of particle reinforced metal matrix composite coatings produced by co-deposition cold gas dynamic spraying. Appl. Surf. Sci. 2017, 396, 1623–1634. [Google Scholar] [CrossRef]

- Suckling, M.; Allen, C. Critical variables in high temperature erosive wear. Wear 1997, 203, 528–536. [Google Scholar] [CrossRef]

- Hejwowski, T.; Szala, M. Wear-Fatigue Study of Carbon Steels. Adv. Sci. Technol. Res. J. 2021, 15, 179–190. [Google Scholar] [CrossRef]

- Weronski, A.; Hejwowski, T. Effect of stress on abrasive and erosive wear of steels and sprayed coatings. Vacuum 2008, 83, 229–233. [Google Scholar] [CrossRef]

- ASTM G76-05; Standard Practice for Conducting Erosion Tests by Solid Particle Impingement Using Gas Jets. ASTM International West Conshohocken: Conshohocken, PA, USA, 1983.

- Heath, G.; Stack, M.; Rehberg, M.; Kammer, P. The Erosion of Functionally Graded Coatings under Fluidized Bed Conditions; Presses Polytechniques et Universitaires Romandes: Lausanne, Switzerland, 1995. [Google Scholar]

- Promdirek, P.; Chandra-Ambhom, S.; Prasong, R.; Riittirat, S.; Pompaisansakul, N. Influence of gas tungsten arc welding parameters on the high-temperature erosion-corrosion resistance of Incoloy 800 cladded by Stellite 12 for the application as thermowell. Mater. Sci. Forum 2011, 696, 248–253. [Google Scholar] [CrossRef]

- Promdirek, P.; Chandra-Ambhom, S.; Tongtae, C.; Anantawirun, C.; Buaphuen, C. Characterization and Failure Analysis of Incoloy 800 Used as Thermowell Subjected to High Temperature Erosion-Corrosion. Mater. Sci. Forum 2008, 595–598, 673–680. [Google Scholar] [CrossRef]

- Finnie, I. Erosion of surfaces by solid particles. Wear 1960, 3, 87–103. [Google Scholar] [CrossRef]

- Liu, Z.; Wan, S.; Nguyen, V.; Zhang, Y. A numerical study on the effect of particle shape on the erosion of ductile materials. Wear 2014, 313, 135–142. [Google Scholar] [CrossRef]

- Tabakoff, W.; Shanov, V. Erosion rate testing at high temperature for turbomachinery use. Surf. Coat. Technol. 1995, 76, 75–80. [Google Scholar] [CrossRef]

- ASTM G76-13; Standard Test Method for Conducting Erosion Tests by Solid Particle Impingement Using Gas Jets. ASTM International West Conshohocken: Conshohocken, PA, USA, 2018.

- ASTM A213 T22; 2.25Cr-1Mo Steel for Boiler and Heat Exchanger Seamless Tubes (STBA 24). ASTM International West Conshohocken: Conshohocken, PA, USA, 2023. Available online: https://www.matweb.com (accessed on 11 August 2023).

- Cinca, N.; Lopez, E.; Dosta, S.; Guilemany, J. Study of stellite-6 deposition by cold gas spraying. Surf. Coat. Technol. 2013, 232, 891–898. [Google Scholar] [CrossRef]

- Ma, N.; Guo, L.; Cheng, Z.; Wu, H.; Ye, F.; Zhang, K. Improvement on mechanical properties and wear resistance of HVOF sprayed WC-12Co coatings by optimizing feedstock structure. Appl. Surf. Sci. 2014, 320, 364–371. [Google Scholar] [CrossRef]

- Berget, J. Influence of Powder and Spray Parameters on Erosion and Corrosion Properties of HVOF Sprayed WC-Co-Cr Coatings. Ph.D. Thesis, Department of Machine Design and Materials Technology, Norwegian University of Science and Technology, Trondheim, Norway, 1998. [Google Scholar]

- Yuan, J.; Zhan, Q.; Huang, J.; Ding, S.; Li, H. Decarburization mechanisms of WC–Co during thermal spraying: Insights from controlled carbon loss and microstructure characterization. Mater. Chem. Phys. 2013, 142, 165–171. [Google Scholar] [CrossRef]

- Ding, X.; Ke, D.; Yuan, C.; Ding, Z.; Cheng, X. Microstructure and cavitation erosion resistance of HVOF deposited WC-Co coatings with different sized WC. Coatings 2018, 8, 307. [Google Scholar] [CrossRef]

- Kreye, H. Characteristics of coatings produced by high velocity flame spraying. Therm. Spray. 1989, 2, 24. [Google Scholar]

- Mirshekari, G.; Daee, S.; Bonabi, S.F.; Tavakoli, M.; Shafyei, A.; Safaei, M. Effect of interlayers on the microstructure and wear resistance of Stellite 6 coatings deposited on AISI 420 stainless steel by GTAW technique. Surf. Interfaces 2017, 9, 79–92. [Google Scholar] [CrossRef]

- Stack, M.; Mathew, M. Transitions in microabrasion mechanisms for WC-Co (HVOF) coated steel, Proceedings of the Institution of Mechanical Engineers. Part J J. Eng. Tribol. 2005, 219, 49–57. [Google Scholar] [CrossRef]

- Jonda, E.; Szala, M.; Sroka, M.; Łatka, L.; Walczak, M. Investigations of cavitation erosion and wear resistance of cermet coatings manufactured by HVOF spraying. Appl. Surf. Sci. 2023, 608, 155071. [Google Scholar] [CrossRef]

- Jonda, E.; Latka, L. Comparative analysis of mechanical properties of WC-based cermet Coatings sprayed by HVOF onto AZ31 magnesium alloy substrates. Adv. Sci. Technol. Res. J. 2021, 15, 57–64. [Google Scholar] [CrossRef]

- Roy, M.; Ray, K.; Sundararajan, G. An analysis of the transition from metal erosion to oxide erosion. Wear 1998, 217, 312–320. [Google Scholar] [CrossRef]

- Kumar, K.; Kumar, S.; Singh, G.; Singh, J.P.; Singh, J. Erosion wear investigation of HVOF sprayed WC-10Co4Cr coating on slurry pipeline materials. Coatings 2017, 7, 54. [Google Scholar] [CrossRef]

- Arabnejad, H.; Mansouri, A.; Shirazi, S.; McLaury, B. Evaluation of solid particle erosion equations and models for oil and gas industry applications. In Proceedings of the SPE Annual Technical Conference and Exhibition, Houston, TX, USA, 27–30 September 2015. [Google Scholar]

- Basu, P.; Kefa, C.; Jestin, L. Boilers and Burners: Design and Theory; Springer Science & Business Media: Berlin/Heidelberg, Germany, 2012. [Google Scholar]

- Sapate, S.; RamaRao, A. Effect of erodent particle hardness on velocity exponent in erosion of steels and cast irons. Mater. Manuf. Process. 2003, 18, 783–802. [Google Scholar] [CrossRef]

- Keshavamurthy, R.; Naveena, B.; Sekhar, N. Thermal spray coatings for erosion-corrosion protection. In Production, Properties, and Applications of High Temperature Coatings; IGI Global: Hershey, PA, USA, 2018; pp. 246–267. [Google Scholar]

| Composition (wt%) | C | Mn | Si | S | P | Cr | Mo | Fe |

|---|---|---|---|---|---|---|---|---|

| T22 steel | 0.11 | 0.43 | 0.27 | 0.011 | 0.016 | 1.93 | 0.92 | Bal. |

| ASTM SA213-T22 | 0.15 | 0.3–0.6 | 0.5 | 0.03 | 0.03 | 1.9–2.6 | 0.87–1.13 | Bal. |

| Coating Powder | Average Particle Size (µm) | Composition (wt%) | ||||

|---|---|---|---|---|---|---|

| C | Si | Cr | Co | W | ||

| Stellite-6 | 11–45 µm, spherical | 1 | 1 | 28 | 66 | 4 |

| WC-12Co | 15–45 μm, spherical | 4 | - | - | 12 | 84 |

| Parameters | Values |

|---|---|

| Powder feed rate (g min−1) Oxygen flow rate (O2, L min−1) Propane flow rate (C3H8, L min−1) Air flow rate (L min−1) Spray distance (mm) Coating thickness (average, µm) Maximal heat source temperature (°C) | 25 50 20 400 200 200 2850 |

| Parameters | Values |

|---|---|

| Standoff distance (mm) Test gas Test duration (s) Nozzle diameter (mm) Test temperature | 20 Dry air 60 6 Room temperature |

| Particle velocity (m·s−1) Abrasive feed rate (g min−1) Angle of incidence (°) Air jet pressure (bar) | 12.8, 22.5 and 38.9 20 30, 90 5 |

| Sample | Impingement Angle (°) | Erodent Particle Velocity (m/s) | Erosion Rate (mg/g) | Velocity Exponent (n) | E90/E30 | Comment |

|---|---|---|---|---|---|---|

| SA213-T22 | 30 90 | 12.8 22.5 38.9 12.8 22.5 38.9 | 0.16 ± 0.02 0.54 ± 0.01 1.59 ± 0.13 0.07 ± 0.01 0.24 ± 0.02 1.29 ± 0.13 | 2.04 2.62 | 0.43 0.44 0.81 | ductile ductile ductile |

| Stellite-6 | 30 90 | 12.8 22.5 38.9 12.8 22.5 38.9 | 0.16 ± 0.01 0.38 ± 0.01 1.53 ± 0.18 0.18 ± 0.02 0.61 ± 0.04 1.98 ± 0.11 | 2.06 2.15 | 1.14 1.58 1.29 | brittle brittle brittle |

| WC-12Co | 30 90 | 12.8 22.5 38.9 12.8 22.5 38.9 | 0.32 ± 0.07 1.14 ± 0.12 3.20 ± 0.31 0.38 ± 0.07 1.21 ± 0.08 3.66 ± 0.19 | 2.07 2.04 | 1.19 1.06 1.14 | brittle brittle brittle |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kiatisereekul, A.; Siripongsakul, T.; Fakpan, K. Erosion Behavior of Stellite-6 and WC-12Co Coatings on SA213-T22 Boiler Steel. Coatings 2023, 13, 1444. https://doi.org/10.3390/coatings13081444

Kiatisereekul A, Siripongsakul T, Fakpan K. Erosion Behavior of Stellite-6 and WC-12Co Coatings on SA213-T22 Boiler Steel. Coatings. 2023; 13(8):1444. https://doi.org/10.3390/coatings13081444

Chicago/Turabian StyleKiatisereekul, Aumpava, Thamrongsin Siripongsakul, and Kittichai Fakpan. 2023. "Erosion Behavior of Stellite-6 and WC-12Co Coatings on SA213-T22 Boiler Steel" Coatings 13, no. 8: 1444. https://doi.org/10.3390/coatings13081444

APA StyleKiatisereekul, A., Siripongsakul, T., & Fakpan, K. (2023). Erosion Behavior of Stellite-6 and WC-12Co Coatings on SA213-T22 Boiler Steel. Coatings, 13(8), 1444. https://doi.org/10.3390/coatings13081444