Pyrocarbon Coating on Granular Al2O3 for HTGR-Type Power Reactor

Abstract

:1. Introduction

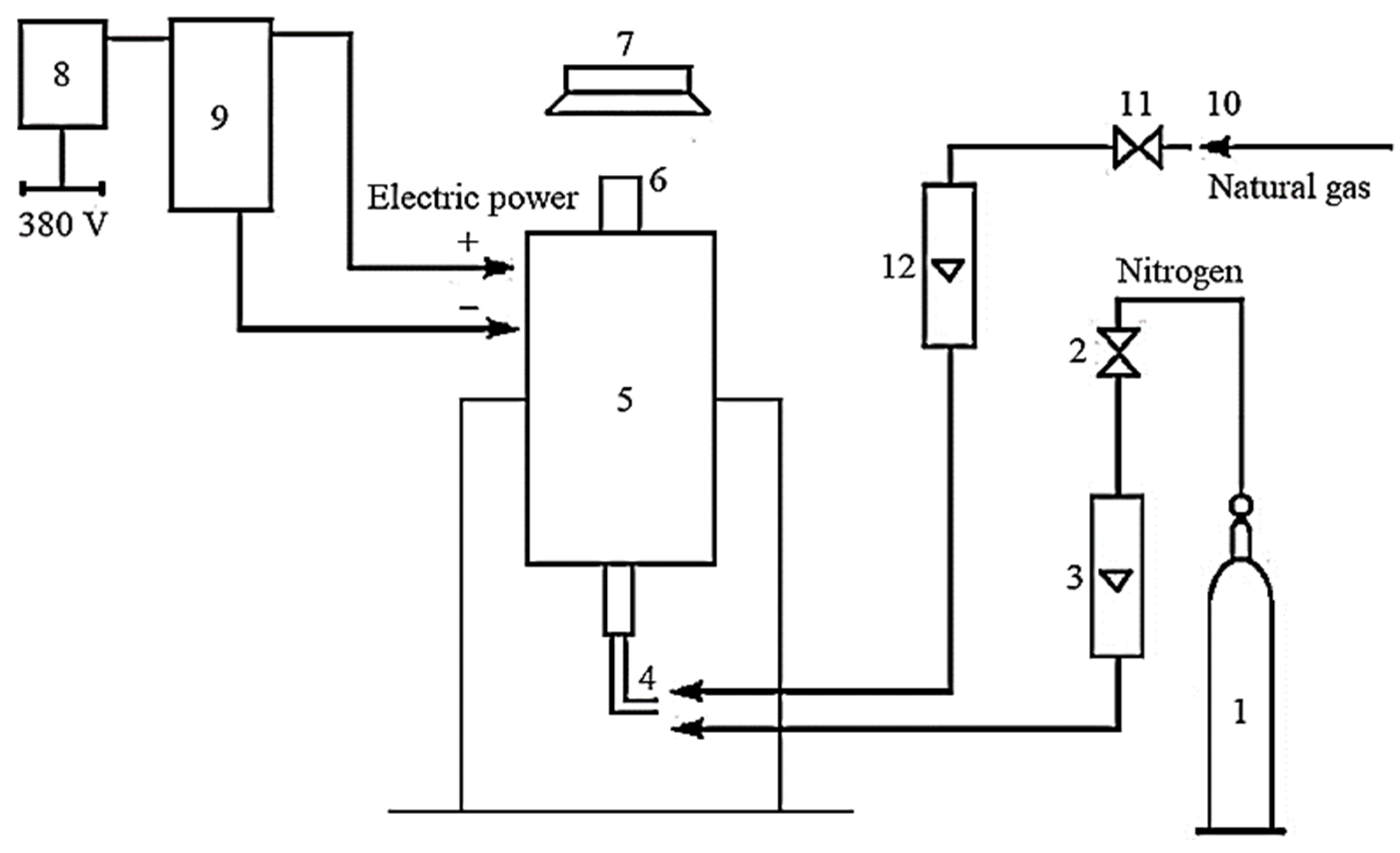

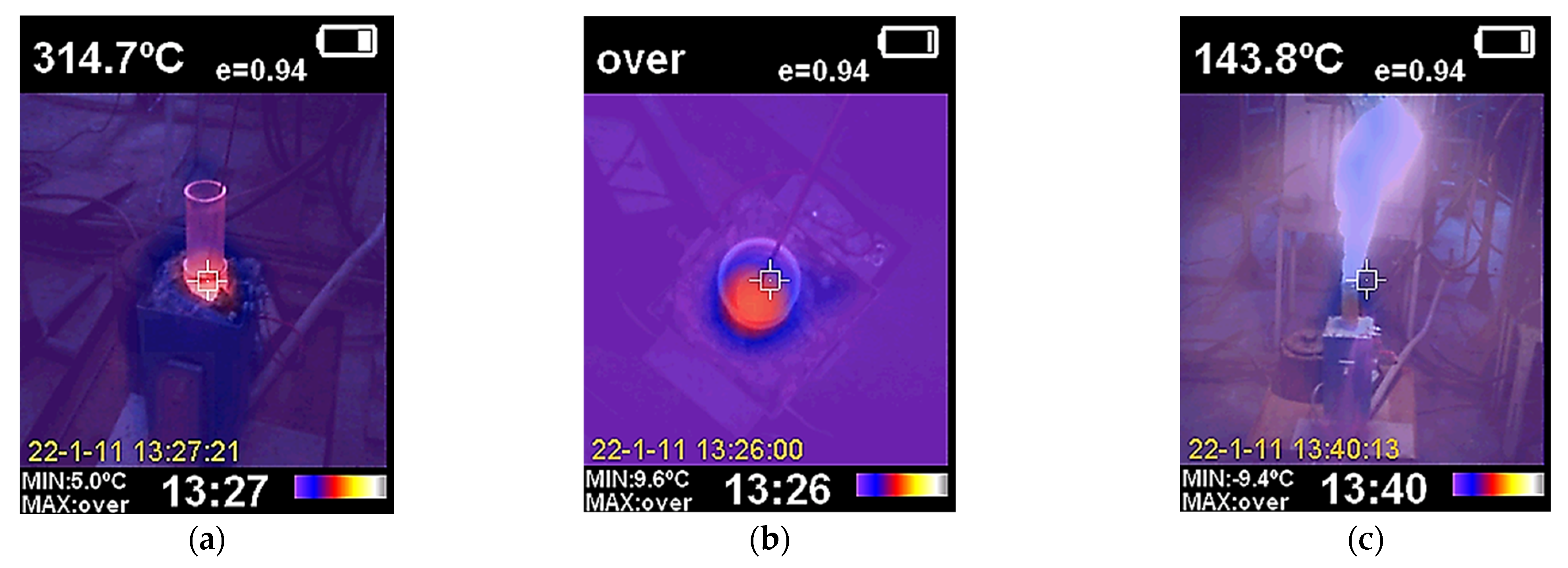

2. Materials and Methods

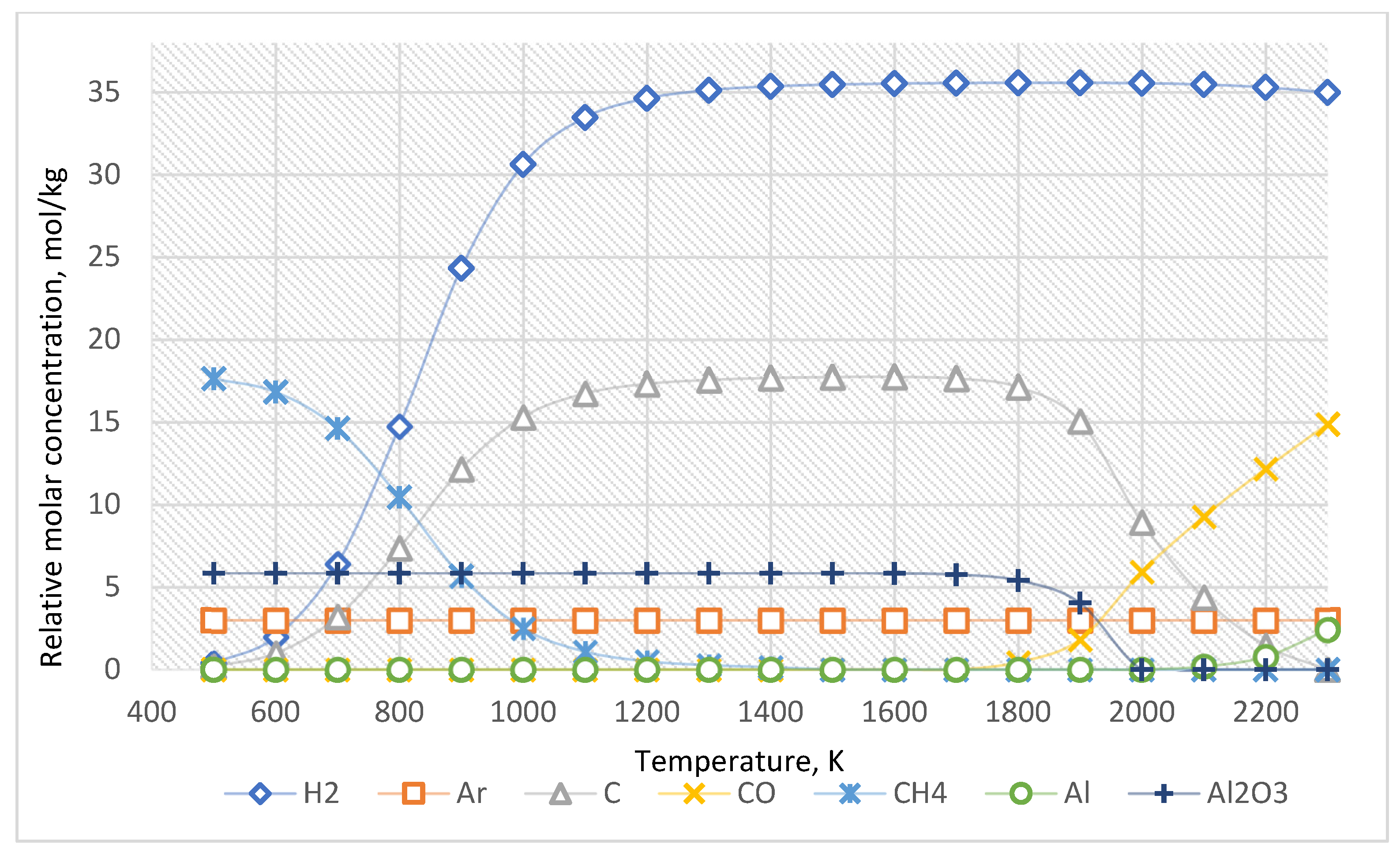

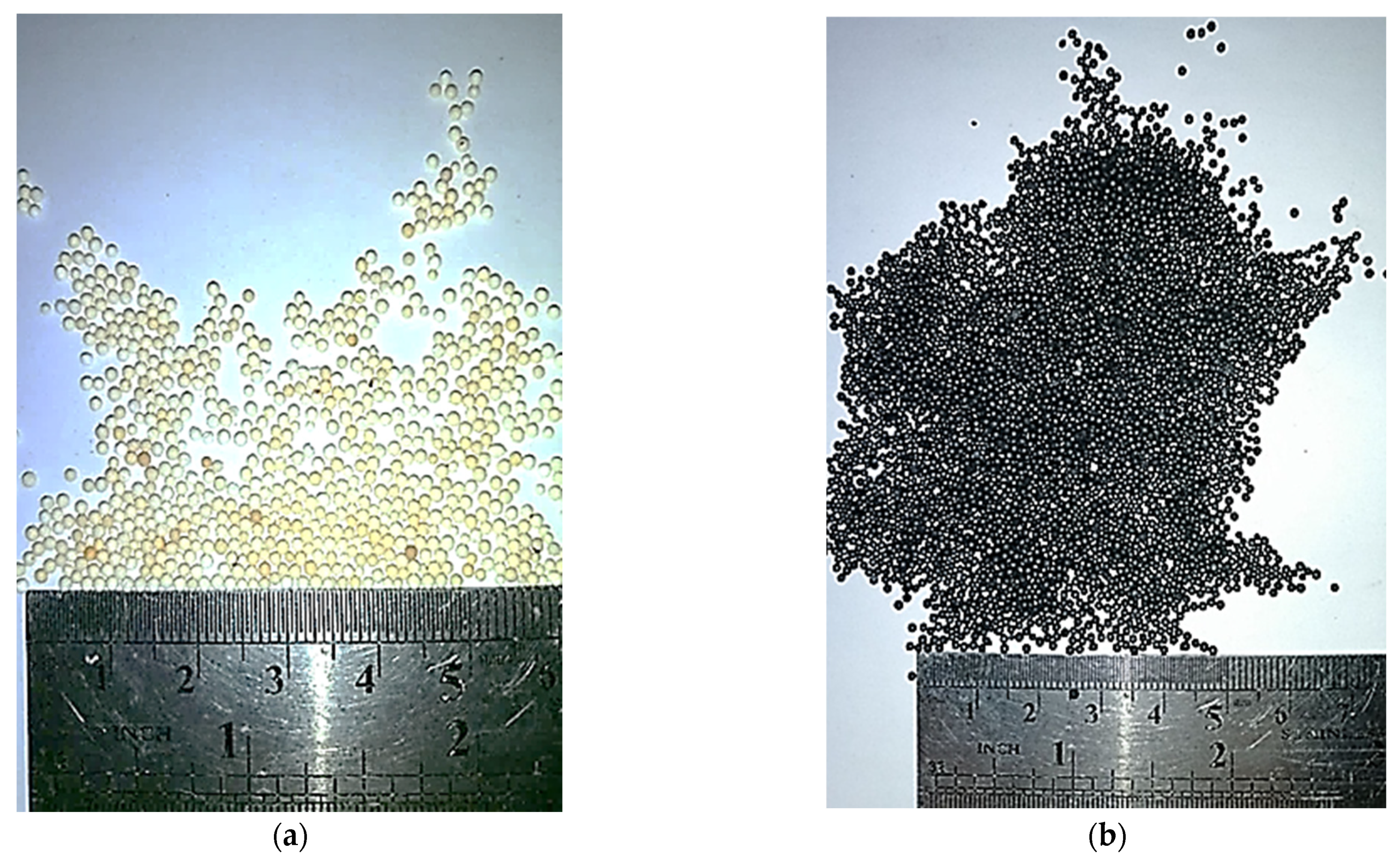

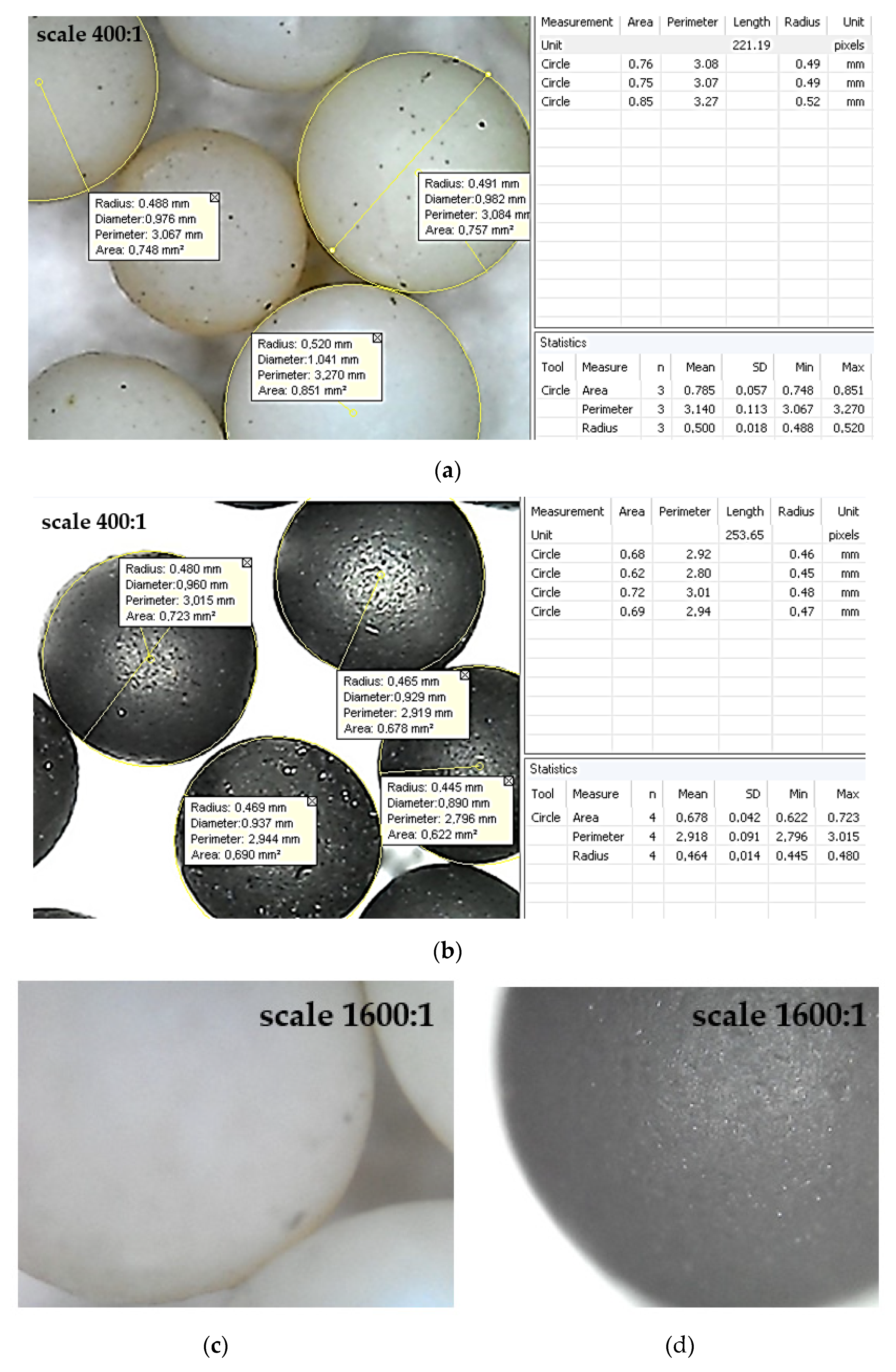

3. Results

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Nomenclature

| Abbreviations | |

| HTGR | high-temperature gas-cooled reactor; |

| NPP | nuclear power plant. |

| Symbols | |

| d | diameter of granules, m |

| h | thickness of the pyrocarbon coating, m |

| m1 | the mass of batches of granules before coating, kg |

| m2 | the mass of batches of granules after coating, kg; |

| X | the mass fraction of pyrocarbon coating, % |

| ρ0 | density of Al2O3 granules, kg/m3 |

| ρc | density of pyrocarbon coating, kg/m3 |

References

- Cao, J.; Cohen, A.; Hansen, J.; Lester, R.; Peterson, P.; Xu, H. China-U.S. cooperation to advance nuclear power. Science 2016, 353, 547–548. [Google Scholar] [CrossRef] [PubMed]

- Kalinowski, B.; Włodarski, R.; Szterk, L. Studies on Obtaining Pyrocarbon Coatings on Spherical Particles of Uranium Materials. Report “P”—No. 1631/IV/C. Polish–Italian Seminar of Some Chemical, Ceramic and Metallurgical Aspects of Nuclear Fuels; Institute of Nuclear Research: Zakopane, Poland, 1971. [Google Scholar]

- Long, E.L.; Tiegs, T.N.; Robbins, J.M.; Kania, M.J. Performance of HTGR Fertile Particles Irradiated in HFIR Capsule HT-32. Contract No. W-7405-eng-26. Metals and Ceramics Division. HTGR Base Technology Program. Fueled Graphite Development (189a 01330); Oak Ridge National Laboratory: Oak Ridge, TN, USA, 1980. [Google Scholar]

- Tepest, P.A. A direct measurement of bacon anisotropy factors on pyrocarbon coatings deposited on fuel particles for the high temperature reactor. Carbon 1978, 16, 171–174. [Google Scholar] [CrossRef]

- Y Leon, S.B.; Lindberg, J.C.H. The Humanitarian Atom: The Role of Nuclear Power in Addressing the United Nations Sustainable Development Goals. In Nuclear Law; T.M.C. Asser Press: Hague, The Netherlands, 2022; pp. 71–298. [Google Scholar] [CrossRef]

- Kerlin, T.W.; Upadhyaya, B.R. Dynamics and Control of Nuclear Reactors; Academic Press: Cambridge, MA, USA, 2019. [Google Scholar] [CrossRef]

- Chen, F.; Han, Z. Steady-state thermal fluids analysis for the HTR-PM equilibrium core. Int. J. Adv. Nucl. React. Des. Technol. 2021, 3, 11–17. [Google Scholar] [CrossRef]

- Knol, S.; De Groot, S.; Salama, R.V.; Best, J.; Bakker, K.; Bobeldijk, I.; Westlake, J.R.; Fütterer, M.A.; Laurie, M.; Tang, C.; et al. HTR-PM fuel pebble irradiation qualification in the high flux reactor in Petten. Nucl. Eng. Des. 2018, 329, 82–88. [Google Scholar] [CrossRef]

- Pratama, A.L.; Irwanto, D. Study on fissile material usage for 50 MWt high temperature gas reactor using (Pu-U)O2 fuel. J. Phys. Conf. Ser. 2021, 1772, 012004. [Google Scholar] [CrossRef]

- Horvath, A.; Rachlew, E. Nuclear power in the 21st century: Challenges and possibilities. Ambio 2016, 45, 38–49. [Google Scholar] [CrossRef]

- Taryo, T. The development of HTGR-TRISO coated fuels in the globe: Challenging of Indonesia to be an HTGR fuel producer. J. Phys. Conf. Ser. 2019, 1198, 022062. [Google Scholar] [CrossRef]

- Ivanov, A.S.; Rusinkevich, A.A. The kinetics of fission products release from microfuel taking into account the trapped fraction and limited solubility effects. Nucl. Eng. Des. 2016, 306, 47–51. [Google Scholar] [CrossRef]

- Ivanov, A.S.; Rusinkevich, A.A.; Taran, M.D. The “trapped fraction” and interfacial jumps of concentration in fission products release from coated fuel particles. J. Nucl. Mater. 2018, 498, 395–399. [Google Scholar] [CrossRef]

- Ivanov, A.S.; Rusinkevich, A.A.; Taran, M.D. Simulation of fission product release from microfuel particles taking into account the effects of trapped fraction and concentration jumps at the interfaces. Phys. At. Nucl. 2019, 82, 1214–1218. [Google Scholar] [CrossRef]

- Roos, E.; Maile, K.; Berreth, K.; Lyutovich, A.; Weiss, R.; Perova, T.; Moore, A. Chemical vapour deposition of PyC–SixCy–SiC–Si3N4 multilayer with graded C…SiC transition. Surf. Coat. Technol. 2004, 180–181, 465–469. [Google Scholar] [CrossRef]

- Liu, N.; Guo, L.; Kou, G.; Li, Y.; Yin, X. Carbon nanotube reinforced pyrocarbon matrix composites with high coefficient of thermal expansion for self-adapting ultra-high-temperature ceramic coatings. Ceram. Int. 2022, 48, 15668–15676. [Google Scholar] [CrossRef]

- Xu, M.; Guo, L.; Fu, Y. Effect of pyrocarbon texture on the mechanical and oxidative erosion property of SiC coating for protecting carbon/carbon composites. Ceram. Int. 2021, 47, 32657–32665. [Google Scholar] [CrossRef]

- Xu, M.; Guo, L.; Huang, J.; Zhang, P. Microstructure and resistance to thermal shock of SiC coatings that are prepared on C/C-composite pyrocarbon matrices of various textures. Ceram. Int. 2021, 47, 9818–9826. [Google Scholar] [CrossRef]

- Duan, H.; Zhang, Z.; Li, L.; Li, W. Effect of pyrocarbon interphase texture and thickness on tensile damage and fracture in T-700™ carbon fiber–reinforced silicon carbide minicomposites. J. Am. Ceram. Soc. 2021, 3, 2171–2181. [Google Scholar] [CrossRef]

- Chernikov, A.S. HTGR fuel and fuel elements. Energy 1991, 16, 263–274. [Google Scholar] [CrossRef]

- López-Honorato, E.; Meadows, P.J.; Xiao, P.; Marsh, G.; Abram, T.J. Structure and mechanical properties of pyrolytic carbon produced by fluidized bed chemical vapor deposition. Nucl. Eng. Des. 2008, 238, 3121–3128. [Google Scholar] [CrossRef]

- Xu, J.; Guo, L.; Wang, H.; Li, K.; Wang, T.; Li, W. Mechanical property and toughening mechanism of 2.5D C/C-SiC composites with high textured pyrocarbon interface. Ceram. Int. 2021, 47, 29183–29190. [Google Scholar] [CrossRef]

- Kurbakov, S.D. Formation of multifunctional barriers to increase the radiochemical resistance of the protective coatings of HTGR fuel elements. At. Energy 2009, 106, 377–388. [Google Scholar] [CrossRef]

- Ilinich, G.N.; Kvon, R.I.; Ayupov, A.B.; Chumachenko, V.A.; Romanenko, A.V. Mesoporous alumina infiltrated with a very thin and complete carbon layer. Microporous Mesoporous Mater. 2015, 208, 120–128. [Google Scholar] [CrossRef]

- Opyatyuk, V.V.; Kozlov, I.L.; Karchev, K.D.; Vistiak, S.V.; Kozlov, O.I.; Turmanidze, R. Simulation of point defects formation in the fuel element of a nuclear power plant’s wave reactor. J. Eng. Sci. 2023, 10, F7–F10. [Google Scholar] [CrossRef]

- Yang, H.-C.; Park, H.-O.; Park, K.-T.; Kim, S.-J.; Kim, H.-J.; Eun, H.-C.; Lee, K. Development of carbonization and a relatively high-temperature halogenation process for the removal of radionuclides from spent ion exchange resins. Processes 2001, 9, 96. [Google Scholar] [CrossRef]

- Yang, H.-C.; Lee, M.-W.; Eun, H.-C.; Kim, H.-J.; Lee, K.; Seo, B.-K. Thermal decontamination of spent activated carbon contaminated with radiocarbon and tritium. Processes 2020, 8, 1359. [Google Scholar] [CrossRef]

- Li, Z.; Wang, J.; Huang, J.; Ding, M. Development and research of triangle-filter convolution neural network for fuel reloading optimization of block-type HTGRs. Appl. Soft Comput. 2023, 136, 110126. [Google Scholar] [CrossRef]

- Semeiko, K.V.; Kustovskyi, S.S.; Kupriyanchuk, S.V.; Chumak, R.E. Dependence of the pyrocarbon structure on the parameters of the process of pyrolysis of hydrocarbon gases in an electrothermal fluidized bed. J. Eng. Phys. Thermophys. 2020, 93, 677–684. [Google Scholar] [CrossRef]

- Meshcheryakov, E.P.; Reshetnikov, S.I.; Sandu, M.P.; Knyazev, A.S.; Kurzina, I.A. Efficient adsorbent-desiccant based on aluminium oxide. Appl. Sci. 2021, 11, 2457. [Google Scholar] [CrossRef]

- Attard, P. Entropy beyond the Second Law (Second Edition): Thermodynamics and Statistical Mechanics for Equilibrium, Non-Equilibrium, Classical, and Quantum Systems; IOP Publishing Ltd.: Bristol, UK, 2023; pp. 1–61. [Google Scholar] [CrossRef]

- Pelton, A.D. Thermodynamics and Phase Diagrams of Materials. Materials Science and Technology; Wiley Online Library: Hoboken, NJ, USA, 2013. [Google Scholar] [CrossRef]

- Fau, G.; Gascoin, N.; Steelant, J. Hydrocarbon pyrolysis with a methane focus: A review on the catalytic effect and the coke production. J. Anal. Appl. Pyrolysis 2014, 108, 1–11. [Google Scholar] [CrossRef]

- Blanco, R.E.; Cathers, G.I.; Ferris, L.M.; Gens, T.A.; Horton, R.W.; Nicholson, E.L. Processing of graphite reactor fuels containing coated particles and ceramics. Nucl. Sci. Eng. 2017, 20, 1964. [Google Scholar] [CrossRef]

- Sowman, H.G.; Surver, R.L.; Johnson, J.R. The development of spherical pyrolytic-carbon-coated UC2 and UThC2 fuel particles. Nucl. Sci. Eng. 2017, 20, 1964. [Google Scholar] [CrossRef]

- Ashok, J.; Raju, G.; Reddy, P.S.; Subrahmanyam, M.; Venugopal, A. Catalytic decomposition of CH4 over NiO-Al2O3-SiO2 catalysts: Influence of catalyst preparation conditions on the production of H2. Int. J. Hydrog. Energy 2008, 33, 4809–4818. [Google Scholar] [CrossRef]

- Guan, Z.; Zou, K.; Wang, X.; Deng, Y.; Chen, G. The synergistic effect of P-doping and carbon coating for boosting electrochemical performance of TiO2 nanospheres for sodium-ion batteries. Chin. Chem. Lett. 2021, 32, 3847–3851. [Google Scholar] [CrossRef]

- Yang, J.; Bai, S.; Sun, J.; Wu, H.; Sun, S.; Wang, S.; Li, Y.; Ma, W.; Tang, X.; Xu, D. Microstructural understanding of the oxidation behavior of cr-coated alloy 800H in supercritical water. Corros. Sci. 2023, 211, 110910. [Google Scholar] [CrossRef]

- Yang, J.; Shang, L.; Sun, J.; Bai, S.; Wang, S.; Liu, J.; Yun, D.; Ma, D. Restraining the cr-zr interdiffusion of Cr-coated Zr alloys in high temperature environment: A Cr/CrN/Cr coating approach. Corros. Sci. 2023, 214, 111015. [Google Scholar] [CrossRef]

| Parameter | Unit | Value (Range) |

|---|---|---|

| The volume of the reaction zone | m3 | 8.0 × 10–5 |

| Type of the gas distribution device | – | Dip-free lattice |

| Type of electric current between electrodes | – | Variable |

| Amperage | A | 2.0–3.8 |

| Voltage | V | 95–190 |

| Process temperature | K | 1073–1273 |

| Process pressure | MPa | 0.1 |

| Material treatment duration | h | 1.0 |

| Gas consumption in a mixture of the natural gas | m3/h | 0.005 |

| Gas consumption during the reactor’s heating | m3/h | 0.050 |

| Natural gas consumption | m3/h | 0.060–0.070 |

| Temperature, K | H | H2 | C | CO | CH4 | Al | Al2O3 |

|---|---|---|---|---|---|---|---|

| 400 | 1.93 × 10–22 | 3.80 × 10–2 | 1.90 × 10–2 | 1.93 × 10–22 | 20.20 | 1.93 × 10–22 | 6.63 |

| 500 | 1.99 × 10–20 | 0.41 | 0.20 | 1.93 × 10–22 | 20.01 | 0.01 × 10–28 | 6.63 |

| 600 | 3.07 × 10–16 | 2.08 | 1.04 | 0.01 × 10–28 | 19.18 | 1.16 × 10–21 | 6.63 |

| 700 | 3.21 × 10–13 | 6.82 | 3.41 | 1.93 × 10–22 | 16.81 | 0.01 × 10–28 | 6.63 |

| 800 | 6.15 × 10–11 | 15.96 | 7.98 | 5.03 × 10–15 | 12.24 | 0.01 × 10–28 | 6.63 |

| 900 | 3.52 × 10–9 | 26.89 | 13.46 | 3.94 × 10–14 | 6.77 | 3.44 × 10–16 | 6.63 |

| 1000 | 8.14 × 10–8 | 34.34 | 17.17 | 0.49 × 10–10 | 3.05 | 0.01 × 10–28 | 6.63 |

| 1100 | 9.95 × 10–7 | 37.78 | 18.89 | 1.83 × 10–8 | 1.33 | 1.37 × 10–10 | 6.63 |

| 1200 | 0.78 × 10–5 | 39.20 | 19.60 | 7.29 × 10–7 | 0.62 | 4.65 × 10–9 | 6.63 |

| 1300 | 0.44 × 10–4 | 39.80 | 19.90 | 0.16 × 10–4 | 0.31 | 9.05 × 10–8 | 6.63 |

| 1400 | 0.20 × 10–3 | 40.08 | 20.04 | 0.23 × 10–3 | 0.17 | 1.14 × 10–6 | 6.63 |

| 1500 | 0.71 × 10–3 | 40.22 | 20.11 | 0.23 × 10–2 | 0.10 | 0.01×10–3 | 6.62 |

| 1600 | 0.22 × 10–2 | 40.30 | 20.12 | 1.70 × 10–2 | 6.70 × 10–2 | 0.69 × 10–4 | 6.61 |

| 1700 | 0.60 × 10–2 | 40.34 | 20.02 | 9.60 × 10–2 | 4.50 × 10–2 | 0.37 × 10–3 | 6.53 |

| 1800 | 1.50 × 10–2 | 40.35 | 19.49 | 0.46 | 3.10 × 10–2 | 0.17 × 10–2 | 6.17 |

| 1900 | 3.30 × 10–2 | 40.35 | 17.33 | 1.90 | 2.20 × 10–2 | 0.65 × 10–2 | 4.75 |

| 2000 | 7.10 × 10–2 | 40.33 | 10.14 | 6.71 | 1.50 × 10–2 | 2.60 × 10–2 | 0.15 × 10–22 |

| 2100 | 0.14 | 40.24 | 6.14 | 9.70 | 1.10 × 10–2 | 0.19 | 0.01 × 10–28 |

| 2200 | 0.27 | 40.05 | 1.57 | 13.77 | 0.77 × 10–2 | 0.80 | 0.01 × 10–28 |

| 2300 | 0.49 | 39.71 | 0,67 | 16.84 | 0.54 × 10–2 | 2.60 | 0.01 × 10–28 |

| Temperature, K | H2 | N2 | C | CO | CH4 | Al | Al2O3 |

|---|---|---|---|---|---|---|---|

| 300 | 0.82 × 10–3 | 3.08 | 0.14 × 10–2 | 4.46 × 10–23 | 18.47 | 1.93 × 10–22 | 6.05 |

| 400 | 3.70 × 10–2 | 3.08 | 2.10 × 10–2 | 0.01 × 10–28 | 18.45 | 1.93 × 10–22 | 6.05 |

| 500 | 0.40 | 3.08 | 0.20 | 0.01 × 10–28 | 18.26 | 1.93 × 10–22 | 6.05 |

| 600 | 2.04 | 3.08 | 1.03 | 5.99 × 10–19 | 17.44 | 1.93 × 10–22 | 6.05 |

| 700 | 6.64 | 3.08 | 3.33 | 0.11 × 10–9 | 15.14 | 1.93 × 10–22 | 6.05 |

| 800 | 15.27 | 3.08 | 7.64 | 1.89 × 10–8 | 10.83 | 1.93 × 10–22 | 6.05 |

| 900 | 25.21 | 3.08 | 12.61 | 1.04 × 10–6 | 5.86 | 1.93 × 10–22 | 6.05 |

| 1000 | 31.74 | 3.08 | 15.87 | 0.25 × 10–4 | 2.60 | 0.48 × 10–19 | 6.05 |

| 1100 | 34.69 | 3.08 | 17.35 | 0.32 × 10–3 | 1.12 | 5.82 × 10–17 | 6.05 |

| 1200 | 35.89 | 3.08 | 17.94 | 0.27 × 10–2 | 0.52 | 2.07 × 10–14 | 6.05 |

| 1300 | 36.40 | 3.08 | 18.19 | 1.60 × 10–2 | 0.27 | 2.94 × 10–12 | 6.05 |

| 1400 | 36.64 | 3.06 | 18.24 | 7.10 × 10–2 | 0.15 | 2.04 × 10–10 | 6.03 |

| 1500 | 36.75 | 2.99 | 18.11 | 0.26 | 8.80 × 10–2 | 8.06 × 10–9 | 5.97 |

| 1600 | 36.81 | 2.80 | 17.58 | 0.80 | 5.60 × 10–2 | 2.06 × 10–7 | 5.79 |

| 1700 | 36.84 | 2.37 | 16.30 | 2.08 | 3.70 × 10–2 | 3.86 × 10–6 | 5.37 |

| 1800 | 36.84 | 1.56 | 13.88 | 4.49 | 2.50 × 10–2 | 0.61 × 10–4 | 4.56 |

| 1900 | 36.84 | 0.60 | 10.10 | 7.38 | 1.70 × 10–2 | 0.98 × 10–3 | 3.59 |

| 2000 | 36.82 | 0.12 | 9.44 | 8.92 | 1.30 × 10–2 | 1.70 × 10–2 | 3,07 |

| 2100 | 36.75 | 8.20 × 10–2 | 4.44 | 12.52 | 0.92 × 10–2 | 0.14 | 0.01 × 10–28 |

| 2200 | 36.56 | 0.11 | 1.42 | 15.50 | 0.66 × 10–2 | 0.72 | 0.01 × 10–28 |

| 2300 | 36.22 | 0.32 | 1.34 | 16.05 | 0.50 × 10–2 | 2.05 | 0.01 × 10–28 |

| Temperature, K | H2 | Ar | C | CO | CH4 | Al | Al2O3 |

|---|---|---|---|---|---|---|---|

| 500 | 0.39 | 2.98 | 0.19 | 1.93 × 10–22 | 17.62 | 0.01 × 10–28 | 5.84 |

| 600 | 1.97 | 2.98 | 0.98 | 1.93 × 10–22 | 16.82 | 0.01 × 10–28 | 5.84 |

| 700 | 6.40 | 2.98 | 3.20 | 1.93 × 10–22 | 14.61 | 0.01 × 10–28 | 5.84 |

| 800 | 14.73 | 2.98 | 7.37 | 2.29 × 10–19 | 10.44 | 0.01 × 10–28 | 5.84 |

| 900 | 24.31 | 2.98 | 12.16 | 2.36 × 10–14 | 5.65 | 0.01 × 10–28 | 5.84 |

| 1000 | 30.61 | 2.98 | 15.30 | 2.69 × 10–11 | 2.50 | 0.01 × 10–28 | 5.84 |

| 1100 | 33.45 | 2.98 | 16.73 | 1.12 × 10–8 | 1.083 | 2.58 × 10–10 | 5.84 |

| 1200 | 34.61 | 2.98 | 17.31 | 6.97 × 10–7 | 0.50 | 4.45 × 10–9 | 5.84 |

| 1300 | 35.11 | 2.98 | 17.55 | 0.16 × 10–4 | 0.26 | 8.65 × 10–8 | 5.84 |

| 1400 | 35.34 | 2.98 | 17.67 | 0.22 × 10–3 | 0.14 | 1.09 × 10–6 | 5.84 |

| 1500 | 35.45 | 2.98 | 17.72 | 0.22 × 10–2 | 8.50 × 10–2 | 9.74 × 10–6 | 5.84 |

| 1600 | 35.51 | 2.98 | 17.73 | 1.60 × 10–2 | 5.40 × 10–2 | 0.66 × 10–4 | 5.83 |

| 1700 | 35.54 | 2.98 | 17.63 | 9.20 × 10–2 | 3.70 × 10–2 | 0.35 × 10–3 | 5.75 |

| 1800 | 35.55 | 2.98 | 17.12 | 0.44 | 2.50 × 10–2 | 0.16 × 10–2 | 5.40 |

| 1900 | 35.55 | 2.98 | 15.06 | 1.81 | 1.80 × 10–2 | 0.62 × 10–2 | 4.04 |

| 2000 | 35.53 | 2.98 | 8.93 | 5.92 | 1.20 × 10–2 | 2.60 × 10–2 | 3.47 × 10–24 |

| 2100 | 35.45 | 2.98 | 4.38 | 9.26 | 0.88 × 10–2 | 0.18 | 0.01 × 10–28 |

| 2200 | 35.28 | 2.98 | 1.46 | 12.17 | 0.64 × 10–2 | 0.77 | 0.01 × 10–28 |

| 2300 | 34.97 | 2.98 | 0.28 | 14.87 | 0.45 × 10–2 | 2.41 | 0.01 × 10–28 |

| Temperature, K | H2 | Ar | C | CO | CH4 | Al | Al2O3 |

|---|---|---|---|---|---|---|---|

| 400 | 4.90 × 10–2 | 2.50 | 2.43 × 10–2 | 1.16 × 10–21 | 24.91 | 1.93 × 10–22 | 4.90 |

| 500 | 0.52 | 2.50 | 0.26 | 0.01 × 10–28 | 24.67 | 1.93 × 10–22 | 4.90 |

| 600 | 2.68 | 2.50 | 1.34 | 0.01 × 10–28 | 23.59 | 1.93 × 10–22 | 4.90 |

| 700 | 8.75 | 2.50 | 4.37 | 0.01 × 10–28 | 20.56 | 1.93 × 10–22 | 4.90 |

| 800 | 20.26 | 2.50 | 10.13 | 1.11×10–17 | 14.80 | 0.28 × 10–19 | 4.90 |

| 900 | 33.71 | 2.50 | 16.85 | 2.55×10–14 | 8.08 | 2.46 × 10–16 | 4.90 |

| 1000 | 42.66 | 2.50 | 21.33 | 6.81×10–11 | 3.60 | 0.01 × 10–28 | 4.90 |

| 1100 | 46.74 | 2.50 | 23.37 | 1.39 × 10–8 | 1.56 | 3.97 × 10–10 | 4.90 |

| 1200 | 48.42 | 2.50 | 24.21 | 9.45 × 10–7 | 0.73 | 6.03 × 10–9 | 4.90 |

| 1300 | 49.13 | 2.50 | 24.56 | 0.21×10–4 | 0.37 | 1.17 × 10–7 | 4.90 |

| 1400 | 49.46 | 2.50 | 24.73 | 0.30 × 10–3 | 0.21 | 1.48 × 10–6 | 4.90 |

| 1500 | 49.62 | 2.50 | 24.81 | 2.90 × 10–3 | 0.12 | 0.13 × 10–4 | 4.90 |

| 1600 | 49.71 | 2.50 | 24.82 | 2.20 × 10–2 | 7.80 × 10–2 | 0.89 × 10–4 | 4.88 |

| 1700 | 49.75 | 2.50 | 24.69 | 0.12 | 5.30 × 10–2 | 0.48 × 10–3 | 4.78 |

| 1800 | 49.77 | 2.50 | 23.99 | 0.59 | 3.70 × 10–2 | 0.21 × 10–2 | 4.32 |

| 1900 | 49.77 | 2.50 | 21.20 | 2.46 | 2.60 × 10–2 | 0.84 × 10–2 | 2.47 |

| 2000 | 49.73 | 2.50 | 17.38 | 5.07 | 1.90 × 10–2 | 5.10 × 10–2 | 6.15 × 10–27 |

| 2100 | 49.63 | 2.50 | 10.57 | 9.98 | 1.30 × 10–2 | 0.26 | 0.01 × 10–28 |

| 2200 | 49.38 | 2.50 | 10.47 | 11.07 | 0.99 × 10–2 | 1.14 | 0.01 × 10–28 |

| 2300 | 49.00 | 2.50 | 10.44 | 12.54 | 0.75 × 10–2 | 2.86 | 0.01 × 10–28 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sklabinskyi, V.; Pitel, J.; Skydanenko, M.; Simeiko, K.; Liaposhchenko, O.; Pavlenko, I.; Ostroha, R.; Yukhymenko, M.; Mandryka, O.; Storozhenko, V. Pyrocarbon Coating on Granular Al2O3 for HTGR-Type Power Reactor. Coatings 2023, 13, 1462. https://doi.org/10.3390/coatings13081462

Sklabinskyi V, Pitel J, Skydanenko M, Simeiko K, Liaposhchenko O, Pavlenko I, Ostroha R, Yukhymenko M, Mandryka O, Storozhenko V. Pyrocarbon Coating on Granular Al2O3 for HTGR-Type Power Reactor. Coatings. 2023; 13(8):1462. https://doi.org/10.3390/coatings13081462

Chicago/Turabian StyleSklabinskyi, Vsevolod, Jan Pitel, Maksym Skydanenko, Kostiantyn Simeiko, Oleksandr Liaposhchenko, Ivan Pavlenko, Ruslan Ostroha, Mykola Yukhymenko, Oleksandr Mandryka, and Vitalii Storozhenko. 2023. "Pyrocarbon Coating on Granular Al2O3 for HTGR-Type Power Reactor" Coatings 13, no. 8: 1462. https://doi.org/10.3390/coatings13081462

APA StyleSklabinskyi, V., Pitel, J., Skydanenko, M., Simeiko, K., Liaposhchenko, O., Pavlenko, I., Ostroha, R., Yukhymenko, M., Mandryka, O., & Storozhenko, V. (2023). Pyrocarbon Coating on Granular Al2O3 for HTGR-Type Power Reactor. Coatings, 13(8), 1462. https://doi.org/10.3390/coatings13081462