Effect of Three Kinds of Aloe Emodin Microcapsules Prepared by SDBS, OP-10 and TWEEN-80 Emulsifiers on Antibacterial, Optical and Mechanical Properties of Water-Based Coating for MDF

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Preparation Method of the Aloe Emodin Microcapsules

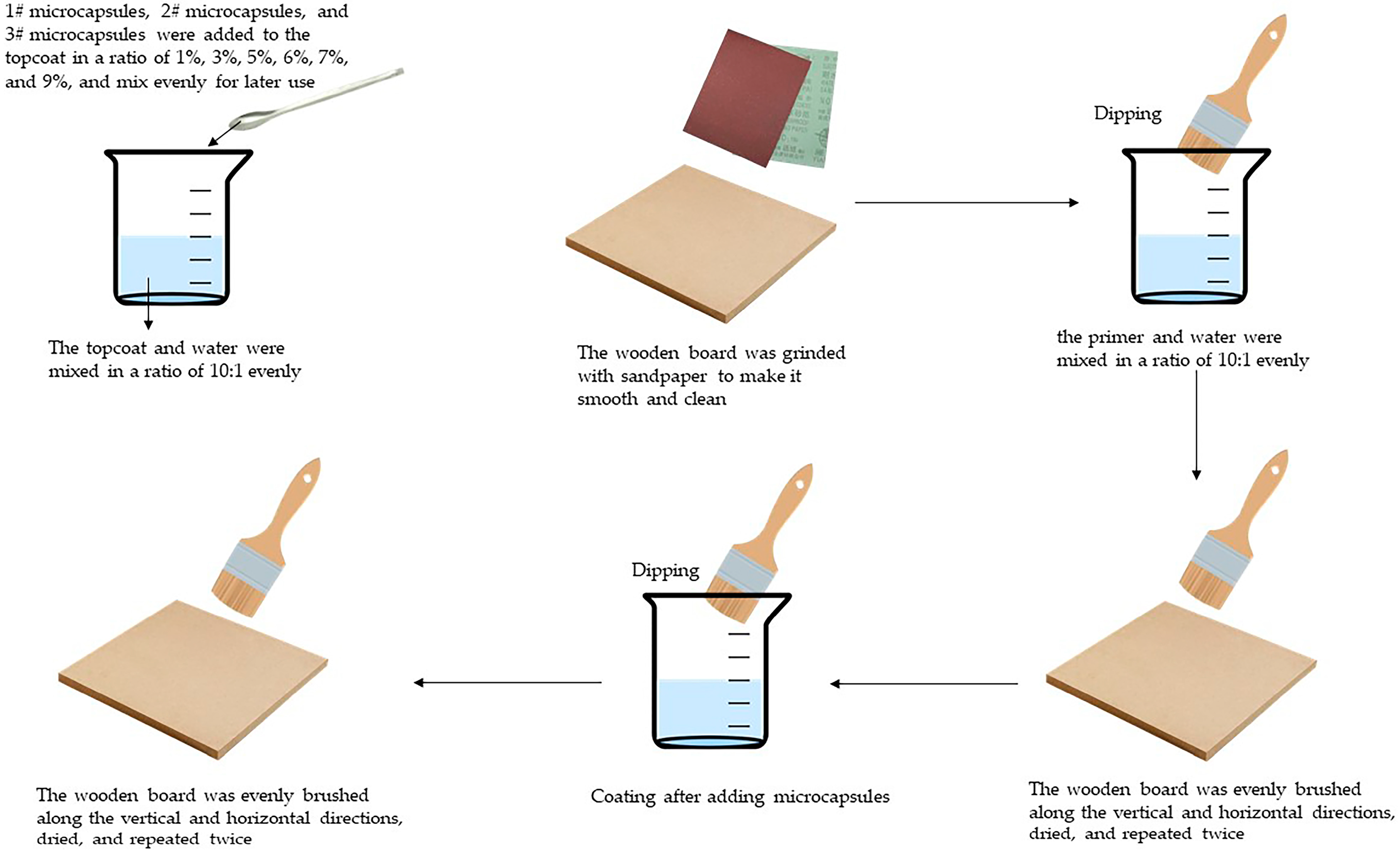

2.3. Preparation of Coatings

2.4. Testing and Characterization

2.4.1. Microscopic Morphology and Chemical Composition

2.4.2. Antibacterial Properties

2.4.3. Optical Performance

2.4.4. Mechanical Property

2.4.5. Roughness

3. Results and Discussion

3.1. MDF Surface Topography Analysis

3.2. Chemical Composition Analysis of Coatings

3.3. Analysis of Antibacterial Performance of Coating on MDF

3.4. Analysis of Optical Properties of Coating on MDF

3.5. Analysis of Mechanical Properties of Coating on MDF

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Mai, C.; Schmitt, U.; Niemz, P. A brief overview on the development of wood research. Holzforschung 2022, 76, 102–119. [Google Scholar] [CrossRef]

- Yan, X.X.; Zhao, W.T.; Wang, L. Preparation and performance of thermochromic and self-repairing dual function paint film with lac resin microcapsules and fluorane microcapsules. Polymers 2021, 13, 3109. [Google Scholar] [CrossRef]

- Hu, W.G.; Yu, R.Z. Mechanical and acoustic characteristics of four wood species subjected to bending load. Maderas-Cienc. Tecnol. 2023, 25, 39. [Google Scholar]

- Wei, X.Y.; Niu, X.T. Recent Advances in Superhydrophobic Surfaces and Applications on Wood. Polymers 2023, 15, 1682. [Google Scholar] [CrossRef]

- Xu, H.D.; Li, Q.Z.; Xu, Q.; Bao, Z.Y.; Wang, L.H.; Xing, T. Effects of Brown-rot Decay on the Electrical Resistance of Wood and its Mechanism. Bioresources 2019, 14, 6134–6145. [Google Scholar] [CrossRef]

- Goldhahn, C.; Cabane, E.; Chanana, M. Sustainability in wood materials science: An opinion about current material development techniques and the end of lifetime perspectives. Philos. Trans. Royal Soc. A 2021, 379, 20200339. [Google Scholar] [CrossRef]

- Luo, Z.Y.; Xu, W.; Wu, S.S. Performances of Green Velvet Material (PLON) Used in Upholstered Furniture. Bioresources 2023, 18, 5108–5119. [Google Scholar] [CrossRef]

- Zigon, J.; Kovac, J.; Petric, M. The influence of mechanical, physical and chemical pre-treatment processes of wood surface on the relationships of wood with a waterborne opaque coating. Prog. Org. Coat. 2022, 162, 106574. [Google Scholar] [CrossRef]

- Luo, Y.R.; Xu, W. Optimization of Panel Furniture Plates Rework Based on Intelligent Manufacturing. Bioresources 2023, 18, 5198–5208. [Google Scholar] [CrossRef]

- Bakhshandeh, E.; Bastani, S.; Saeb, M.R.; Croutxe-Barghorn, C.; Allonas, X. High-performance water-based UV-curable soft systems with variable chain architecture for advanced coating applications. Prog. Org. Coat. 2019, 130, 99–113. [Google Scholar] [CrossRef]

- Kong, X.F.; Meng, X.Z. Application of Chemical Technology of Water-Based Acrylic Dipping Paint in Art Painting Creation. J. Chem. 2022, 2022, 7715011. [Google Scholar] [CrossRef]

- Wang, X.J.; Sun, W.P.; Li, W.G.; Zuo, C.L.; Jiang, Y.; Wang, S.X. Development of Waterborne Heavy-Duty Anticorrosive Coatings with Modified Nanoscale Titania. Coatings 2022, 12, 1651. [Google Scholar] [CrossRef]

- Liu, X.; Zhang, D.K.; Guo, Z.G. A Facile Modifier-free Approach to Fabricate Antistatic Superhydrophobic Composite Coatings with Remarkable Thermal Stability and Corrosion Resistance. J. Bionic. Eng. 2020, 17, 421–435. [Google Scholar] [CrossRef]

- Yan, X.X.; Zhao, W.T.; Wang, L. Mechanism of Thermochromic and Self-Repairing of Waterborne Wood Coatings by Synergistic Action of Waterborne Acrylic Microcapsules and Fluorane Microcapsules. Polymer 2022, 14, 56. [Google Scholar] [CrossRef] [PubMed]

- Sharaf, M.H.; Nagiub, A.M.; Salem, S.S.; Kalaba, M.H.; El Fakharany, E.M.; Abd El-Wahab, H. A new strategy to integrate silver nanowires with waterborne coating to improve their antimicrobial and antiviral properties. Pigm. Resin Technol. 2022, 52, 490–501. [Google Scholar] [CrossRef]

- Siritongsuk, P.; Thammawithan, S.; Srichaiyapol, O.; Nasompag, S.; Pongha, S.; Daduang, S.; Klaynongsruang, S.; Patramanon, R. Synthesis and application of AgNPs-Chitosan composite as a self-disinfecting coating in water-based polyurethane. Coatings 2022, 12, 1832. [Google Scholar] [CrossRef]

- Hu, W.G.; Luo, M.Y.; Hao, M.M.; Tang, B.; Wan, C. Study on the Effects of Selected Factors on the Diagonal Tensile Strength of Oblique Corner Furniture Joints Constructed by Wood Dowel. Forests 2023, 14, 1149. [Google Scholar] [CrossRef]

- Hu, W.G.; Yu, R.Z.; Luo, M.Y.; Konukcu, A.C. Study on tensile strength of single dovetail joint: Experimental, numerical, and analytical analysis. Wood Mater. Sci. Eng. 2022, 17, 2155875. [Google Scholar] [CrossRef]

- Abd El-Gawad, W.M.; Ahmed, N.M.; Mohamed, W.S.; Souaya, E.R. A novel approach for new cost-saving durable anticorrosive and antibacterial coatings. J. Coat. Technol. Res. 2019, 16, 1263–1281. [Google Scholar] [CrossRef]

- Ren, Y.X.; Hao, P.W. Modification mechanism and enhanced low-temperature performance of asphalt mixtures with graphene-modified phase-change microcapsules. Constr. Build. Mater. 2022, 320, 126301. [Google Scholar] [CrossRef]

- Xiao, Z.B.; Liu, H.Q.; Zhao, Q.X.; Niu, Y.W.; Chen, Z.Q.; Zhao, D. Application of microencapsulation technology in silk fibers. J. Appl. Polym. Sci. 2022, 139, e52351. [Google Scholar] [CrossRef]

- Peng, W.W.; Yan, X.X. Preparation of tung oil microcapsule and its effect on wood surface coating. Polymers 2022, 14, 1536. [Google Scholar] [CrossRef] [PubMed]

- Shahabudin, N.; Yahya, R.; Gan, S.N. Microcapsules of poly(urea-formaldehyde) (PUF) containing alkyd from palm oil. Mater. Today-Proc. 2016, 3, S88–S95. [Google Scholar] [CrossRef]

- Oumer, A.; Bisrat, D.; Mazumder, A.; Asres, K. A New Antimicrobial Anthrone from the Leaf Latex of Aloe trichosantha. Nat. Prod. Commun. 2014, 9, 949–952. [Google Scholar] [CrossRef]

- Chiang, H.M.; Lin, Y.T.; Hsiao, P.L.; Su, Y.H.; Tsao, H.T.; Wen, K.C. Determination of Marked Components -aloin and aloe-emodin-in Aloe vera before and after hydrolysis. J. Food Drug. Anal. 2012, 20, 646–652. [Google Scholar]

- Sanchez, M.; Gonzalez-Burgos, E.; Iglesias, I.; Gomez-Serranillos, M.P. Pharmacological Update Properties of Aloe Vera and its Major Active Constituents. Molecules 2020, 25, 1324. [Google Scholar] [CrossRef]

- Kahramanoglu, I.; Chen, C.Y.; Chen, J.Y.; Wan, C.P. Chemical Constituents, Antimicrobial Activity, and Food Preservative Characteristics of Aloe vera Gel. Agronomy 2020, 9, 831. [Google Scholar] [CrossRef]

- Li, T.; Lu, Y.; Zhang, H.; Wang, L.; Beier, R.C.; Jin, Y.J.; Wang, W.J.; Li, H.R.; Hou, X.L. Antibacterial Activity and Membrane-Targeting Mechanism of Aloe-Emodin against Staphylococcus epidermidis. Front. Microbiol. 2021, 12, 621866. [Google Scholar] [CrossRef]

- Mahajan, K.; Kumar, S.; Bhat, Z.F.; Naqvi, Z.; Mungure, T.E.; Bekhit, A.E.A. Functionalization of carrageenan based edible film using Aloe vera for improved lipid oxidative and microbial stability of frozen dairy products. Food Biosci. 2021, 43, 101336. [Google Scholar] [CrossRef]

- Ding, L.J.; Wang, H.; Liu, D.; Zheng, Z.N. Surface attachment of natural antimicrobial coatings onto conventional polypropylene nonwoven fabric and its antimicrobial performance assessment. J. Food Protect. 2018, 81, 172–177. [Google Scholar] [CrossRef]

- Hu, X.K.; Ma, Y.; Liu, Z.D.; Zhao, M.X.; Dong, S.M.; Yang, H.; Dai, C.M. Microcalorimetric evaluation of the effects of three anthraquinone derivatives from Chinese Rhubarb and the synergistic effect of the mixture on Staphylococcus aureus. J. Therm. Anal. Calorim. 2020, 141, 739–749. [Google Scholar] [CrossRef]

- Fiedler, J.O.; Carmona, O.G.; Carmona, C.G.; Lis, M.J.; Plath, A.M.S.; Samulewski, R.B.; Bezerra, F.M. Application of Aloe vera microcapsules in cotton nonwovens to obtain biofunctional textiles. J. Text. Inst. 2019, 111, 68–74. [Google Scholar] [CrossRef]

- Adnan, M.; Moses, J.J. Performance and Characterization of Aloe Vera Microcapsules on Silk/Lyocell Blended Fabric. Tekst. Konfeksiyon 2020, 29, 317–321. [Google Scholar] [CrossRef]

- Huang, N.; Yan, X.X. Preparation of Aloe-Emodin Microcapsules and Its Effect on Antibacterial and Optical Properties of Water-Based Coating. Polymers 2023, 15, 1728. [Google Scholar] [CrossRef]

- GB/T 21866-2008; Test Method and Effect for Antibacterial Capability of Paints Film. Standardization Administration of the China: Beijing, China, 2008.

- GB/T 4789.2-2022; National Food Safety Standard for Microbiological Examination of Food—Determination of Total Colony Count. Standardization Administration of the China: Beijing, China, 2022.

- GB/T 11186.3-1989; Methods for Measuring the Color of Paint Films—Part 3: Calculation of Color Differences. Standardization Administration of the China: Beijing, China, 1989.

- GB/T 4893.6-2013; Test of Surface Coatings of Furniture—Part 6: Determination of Gloss Value. Standardization Administration of the China: Beijing, China, 2013.

- 20211076-T-606; Paints and Varnishes—Determination of Film Hardness by Pencil Test. Standardization Administration of the China: Beijing, China, 2021.

- GB/T 4893.4-2013; Test of Surface Coatings of Furniture—Part 4: Determination of Adhesion-Cross Cut. Standardization Administration of the China: Beijing, China, 2013.

- GB/T 4893.9-2013; Test of Surface Coatings of Furniture—Part 9: Determination of Resistance to Impact. Standardization Administration of the China: Beijing, China, 2013.

| Material | Molecular Formula | Mw (g/mol) | CAS No. | Concentration (%) |

|---|---|---|---|---|

| urea | CH4N2O | 60.06 | 57-13-6 | 99.0 |

| formaldehyde solution | - | - | - | 37.0 |

| triethanolamine | C6H15NO3 | 149.19 | 102-71-6 | 99.9 |

| polyvinyl alcohol | [C2H4O]n | - | 9002-89-5 | |

| aloe emodin | C15H10O5 | 270.2369 | 481-72-1 | 98.0 |

| citric acid monohydrate | C6H10O8 | 210.14 | 5949-29-1 | 99.9 |

| anhydrous ethanol | C2H6O | 46.07 | 64-17-5 | 99.9 |

| waterborne acrylic resin | - | - | 9003-01-4 | - |

| Escherichia coli | - | - | - | - |

| Staphylococcus aureus | - | - | - | - |

| nutrient agar medium | - | - | - | - |

| nutritional broth | - | - | - | - |

| sodium chloride | NaCl | 58.4428 | 7647-14-5 | 99.5 |

| silicon dioxide | SiO2 | 60.084 | 14808-60-7 | 99.5 |

| polyethylene film | - | - | - | - |

| petri dish | - | - | - | - |

| sodium dodecylbenzene sulfonate (SDBS) | C18H29NaO3S | 348.48 | 25155-30-0 | 99.0 |

| Octylphenol polyoxyethylene ether-10 (OP-10) | ether-(C2H4O)n·C14H22O | 602.797 | 9002-93-1 | 99.0 |

| Polyoxyethylene dehydrated sorbitan monooleate (TWEEN-80) | C24H44O6 | 428.60 | 9005-65-6 | 99.0 |

| Name of Emulsifier | HLB Value | Type of Emulsifier |

|---|---|---|

| SDBS | 10.6 | Anionic type |

| OP-10 | 13.4 | Non-ionic |

| TWEEN-80 | 15.0 | Non-ionic |

| Sample (#) | Types of Emulsifiers | Emulsifier Concentration (%) | n (Urea):n (Formaldehyde) | m (Core Material):m (Wall Material) | Temperature (°C) | Stirring Speed (rpm) |

|---|---|---|---|---|---|---|

| 1 | SDBS | 3 | 1:1.2 | 1:15 | 50 | 600 |

| 2 | OP-10 | 3 | 1:1.2 | 1:15 | 50 | 600 |

| 3 | TWEEN-80 | 3 | 1:1.2 | 1:15 | 50 | 600 |

| Sample | Urea (g) | Formaldehyde Solution (g) | Wall Material (g) | Polyvinyl Alcohol (g) | Aloe Emodin (g) | Deionized Water (g) | Emulsifier (g) | NaCl (g) | SiO2 (g) |

|---|---|---|---|---|---|---|---|---|---|

| 1 | 10.00 | 16.22 | 16.00 | 0.10 | 1.07 | 227.95 | 7.05 | 1.28 | 1.28 |

| 2 | 10.00 | 16.22 | 16.00 | 0.10 | 1.07 | 227.95 | 7.05 | 1.28 | 1.28 |

| 3 | 10.00 | 16.22 | 16.00 | 0.10 | 1.07 | 227.95 | 7.05 | 1.28 | 1.28 |

| Content of the Microcapsules (%) | Microcapsule Weight (g) | Coating Weight (g) |

|---|---|---|

| 0 | 0 | 1.00 |

| 1.0 | 0.01 | 0.99 |

| 3.0 | 0.03 | 0.97 |

| 5.0 | 0.05 | 0.95 |

| 6.0 | 0.06 | 0.94 |

| 7.0 | 0.07 | 0.93 |

| 9.0 | 0.09 | 0.91 |

| Characteristic Peak (cm−1) | Chemical Groups |

|---|---|

| 2950 | C–H (sp3) |

| 1144 | C–O |

| 1730 | C=O |

| 1247 | C–N, or N–H |

| 1380 | aryl-O–H |

| 1450 | C–H with CH2 or CH3 |

| Coating | Microcapsule Content (%) | Actual Number of Viable Bacteria for Escherichia coli (CFU·Tablets−1) | Antibacterial Rate for Escherichia coli (%) | Actual Number of Viable Bacteria for Staphylococcus aureus (CFU·Tablets−1) | Antibacterial Rate for Staphylococcus aureus (%) |

|---|---|---|---|---|---|

| 1# Microcapsule Added to the Coating | 0 | 297 | - | 247 | - |

| 1.0 | 260 | 12.5 | 200 | 19.0 | |

| 3.0 | 213 | 28.3 | 180 | 27.1 | |

| 5.0 | 139 | 53.2 | 129 | 47.8 | |

| 6.0 | 101 | 66.0 | 108 | 56.3 | |

| 7.0 | 97 | 67.3 | 101 | 59.1 | |

| 9.0 | 77 | 74.1 | 84 | 66.0 | |

| 2# Microcapsule Added to the Coating | 0 | 297 | - | 247 | - |

| 1.0 | 283 | 4.7 | 224 | 9.3 | |

| 3.0 | 265 | 10.8 | 205 | 17.0 | |

| 5.0 | 160 | 46.1 | 145 | 41.3 | |

| 6.0 | 145 | 51.2 | 123 | 50.2 | |

| 7.0 | 123 | 58.6 | 113 | 54.3 | |

| 9.0 | 89 | 70.0 | 92 | 62.8 | |

| 3# Microcapsules Added to the Coating | 0 | 297 | - | 247 | - |

| 1.0 | 270 | 9.1 | 223 | 9.7 | |

| 3.0 | 246 | 17.2 | 198 | 19.8 | |

| 5.0 | 168 | 43.4 | 137 | 44.5 | |

| 6.0 | 144 | 51.5 | 121 | 51.0 | |

| 7.0 | 134 | 54.9 | 105 | 57.5 | |

| 9.0 | 98 | 67.0 | 94 | 61.9 |

| Coating | Microcapsule Content (%) | L | a | b | ΔE |

|---|---|---|---|---|---|

| MDF with 1# Microcapsule Added to the Coating | 0 | 48.66 ± 0.70 | 13.29 ± 1.00 | 25.59 ± 0.70 | - |

| 1.0 | 49.45 ± 0.90 | 10.76 ± 0.90 | 29.65 ± 0.80 | 4.85 | |

| 3.0 | 49.48 ± 0.70 | 12.55 ± 1.00 | 33.62 ± 1.50 | 8.11 | |

| 5.0 | 49.18 ± 0.90 | 14.33 ± 0.30 | 33.87 ± 1.10 | 8.37 | |

| 6.0 | 49.75 ± 1.50 | 13.94 ± 0.20 | 33.87 ± 0.50 | 8.38 | |

| 7.0 | 48.42 ± 1.20 | 15.18 ± 0.40 | 34.52 ± 1.50 | 9.14 | |

| 9.0 | 52.64 ± 1.70 | 11.67 ± 0.20 | 35.66 ± 0.60 | 10.95 | |

| MDF with 2# Microcapsule Added to the Coating | 0 | 48.66 ± 0.70 | 13.29 ± 1.00 | 25.59 ± 0.70 | - |

| 1.0 | 48.95 ± 0.60 | 12.86 ± 0.90 | 25.30 ± 0.60 | 0.59 | |

| 3.0 | 50.57 ± 0.90 | 11.12 ± 0.40 | 29.23 ± 1.10 | 4.65 | |

| 5.0 | 52.15 ± 1.60 | 11.99 ± 0.40 | 29.63 ± 0.60 | 5.50 | |

| 6.0 | 51.28 ± 1.80 | 11.45 ± 0.80 | 30.38 ± 0.70 | 5.77 | |

| 7.0 | 51.60 ± 1.80 | 12.62 ± 0.20 | 30.84 ± 1.20 | 6.06 | |

| 9.0 | 52.68 ± 1.10 | 12.12 ± 0.50 | 31.45 ± 0.90 | 7.21 | |

| MDF with 3# Microcapsule Added to the Coating | 0 | 48.66 ± 0.70 | 13.29 ± 1.00 | 25.59 ± 0.70 | - |

| 1.0 | 50.61 ± 0.20 | 9.33 ± 0.30 | 30.01 ± 0.20 | 6.25 | |

| 3.0 | 50.13 ± 0.40 | 9.55 ± 0.30 | 31.79 ± 1.30 | 7.39 | |

| 5.0 | 51.11 ± 1.90 | 9.53 ± 0.40 | 32.38 ± 1.40 | 8.14 | |

| 6.0 | 52.43 ± 1.80 | 10.04 ± 0.10 | 33.56 ± 1.80 | 9.40 | |

| 7.0 | 55.21 ± 1.60 | 9.49 ± 0.50 | 36.01 ± 0.70 | 12.89 | |

| 9.0 | 55.49 ± 1.30 | 9.82 ± 0.30 | 37.72 ± 0.60 | 14.35 |

| Coating | Microcapsule Content (%) | Gloss at 20° (GU) | Gloss at 60° (GU) | Gloss at 85° (GU) | Light Loss Rate (%) |

|---|---|---|---|---|---|

| MDF with 1# Microcapsule Added to the Coating | 0 | 50.15 ± 1.30 | 82.15 ± 2.10 | 95.6 ± 1.40 | - |

| 1.0 | 20.65 ± 0.30 | 48.70 ± 1.60 | 53.3 ± 1.90 | 40.7 | |

| 3.0 | 5.80 ± 0.50 | 21.70 ± 0.40 | 19.1 ± 1.10 | 73.6 | |

| 5.0 | 2.58 ± 0.20 | 12.38 ± 0.70 | 7.2 ± 0.30 | 84.9 | |

| 6.0 | 1.70 ± 0.20 | 8.88 ± 0.50 | 4.7 ± 0.50 | 89.2 | |

| 7.0 | 1.10 ± 0.10 | 5.85 ± 0.10 | 2.0 ± 0.10 | 92.9 | |

| 9.0 | 0.85 | 3.60 ± 0.20 | 1.0 ± 0.10 | 95.6 | |

| MDF with 2# Microcapsule Added to the Coating | 0 | 50.15 ± 2.50 | 82.15 ± 1.60 | 95.6 ± 1.40 | - |

| 1.0 | 18.23 ± 2.10 | 42.93 ± 1.10 | 45.7 ± 2.10 | 47.7 | |

| 3.0 | 4.05 ± 0.20 | 15.98 ± 0.60 | 9.6 ± 0.60 | 80.6 | |

| 5.0 | 1.10 ± 0.10 | 6.00 ± 0.20 | 1.9 ± 0.10 | 92.7 | |

| 6.0 | 0.98 ± 0.10 | 4.03 ± 0.20 | 0.8 ± 0.10 | 95.1 | |

| 7.0 | 0.75 ± 0.20 | 3.23 ± 0.10 | 0.8 ± 0.10 | 96.1 | |

| 9.0 | 0.63 ± 0.10 | 2.08 ± 0.10 | 0.6 ± 0.10 | 97.5 | |

| MDF with 3# Microcapsule Added to the Coating | 0 | 50.15 ± 3.70 | 82.15 ± 1.60 | 95.6 ± 1.40 | - |

| 1.0 | 16.10 ± 1.50 | 40.40 ± 1.20 | 44.1 ± 1.50 | 50.8 | |

| 3.0 | 2.23 ± 0.20 | 11.18 ± 0.30 | 5.50 ± 0.30 | 86.4 | |

| 5.0 | 0.90 ± 0.10 | 4.38 ± 0.10 | 1.00 ± 0.10 | 94.7 | |

| 6.0 | 0.68 ± 0.10 | 2.98 ± 0.10 | 0.70 ± 0.10 | 96.4 | |

| 7.0 | 0.68 ± 0.10 | 2.23 | 0.50 ± 0.20 | 97.3 | |

| 9.0 | 0.50 ± 0.10 | 1.80 ± 0.10 | 0.40 ± 0.10 | 97.8 |

| Coating | Microcapsule Content (%) | Hardness | Adhesion (Grade) | Impact Resistance (kg·cm) | Roughness (μm) |

|---|---|---|---|---|---|

| MDF with 1# Microcapsule Added to the Coating | 0 | HB | 1 | 4 | 0.37 ± 0.10 |

| 1.0 | H | 1 | 4 | 0.79 | |

| 3.0 | 2H | 1 | 4 | 2.10 ± 0.20 | |

| 5.0 | 3H | 1 | 4 | 2.81 ± 0.30 | |

| 6.0 | 3H | 1 | 5 | 2.92 ± 0.10 | |

| 7.0 | 3H | 1 | 5 | 3.30 ± 0.10 | |

| 9.0 | 3H | 2 | 5 | 3.90 ± 0.10 | |

| MDF with 2# Microcapsule Added to the Coating | 0 | HB | 1 | 4 | 0.37 ± 0.10 |

| 1.0 | H | 1 | 4 | 1.55 | |

| 3.0 | 2H | 1 | 4 | 2.20 ± 0.10 | |

| 5.0 | 2H | 1 | 4 | 3.32 ± 0.20 | |

| 6.0 | 2H | 1 | 5 | 4.41 ± 0.10 | |

| 7.0 | 3H | 1 | 5 | 4.84 ± 0.20 | |

| 9.0 | 3H | 2 | 5 | 5.86 ± 0.10 | |

| MDF with 3# Microcapsule Added to the Coating | 0 | HB | 1 | 4 | 0.37 ± 0.10 |

| 1.0 | 2H | 1 | 4 | 1.16 ± 0.20 | |

| 3.0 | 2H | 1 | 4 | 3.09 ± 0.10 | |

| 5.0 | 2H | 1 | 4 | 4.28 ± 0.10 | |

| 6.0 | 2H | 1 | 5 | 4.75 ± 0.10 | |

| 7.0 | 3H | 1 | 5 | 5.74 | |

| 9.0 | 3H | 2 | 5 | 6.93 ± 0.10 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhu, Y.; Huang, N.; Yan, X. Effect of Three Kinds of Aloe Emodin Microcapsules Prepared by SDBS, OP-10 and TWEEN-80 Emulsifiers on Antibacterial, Optical and Mechanical Properties of Water-Based Coating for MDF. Coatings 2023, 13, 1477. https://doi.org/10.3390/coatings13091477

Zhu Y, Huang N, Yan X. Effect of Three Kinds of Aloe Emodin Microcapsules Prepared by SDBS, OP-10 and TWEEN-80 Emulsifiers on Antibacterial, Optical and Mechanical Properties of Water-Based Coating for MDF. Coatings. 2023; 13(9):1477. https://doi.org/10.3390/coatings13091477

Chicago/Turabian StyleZhu, Ye, Nan Huang, and Xiaoxing Yan. 2023. "Effect of Three Kinds of Aloe Emodin Microcapsules Prepared by SDBS, OP-10 and TWEEN-80 Emulsifiers on Antibacterial, Optical and Mechanical Properties of Water-Based Coating for MDF" Coatings 13, no. 9: 1477. https://doi.org/10.3390/coatings13091477

APA StyleZhu, Y., Huang, N., & Yan, X. (2023). Effect of Three Kinds of Aloe Emodin Microcapsules Prepared by SDBS, OP-10 and TWEEN-80 Emulsifiers on Antibacterial, Optical and Mechanical Properties of Water-Based Coating for MDF. Coatings, 13(9), 1477. https://doi.org/10.3390/coatings13091477