Research Progress of Surface Treatment Technologies on Titanium Alloys: A Mini Review

Abstract

:1. Introduction

- (1)

- Surface biochemical treatment of biomedical titanium alloys.

- (2)

- Surface nitriding and nitrocarburizing on titanium alloys.

- (3)

- Hybrid surface modification (HSM) on titanium alloys.

- (4)

- Electrochemical/chemical surface treatment of titanium alloys.

- (5)

- Laser surface modification of titanium alloys.

- (6)

- Surface mechanical treatment on titanium alloys.

2. Recent Developments of Surface Treatment Technologies for Titanium Alloys

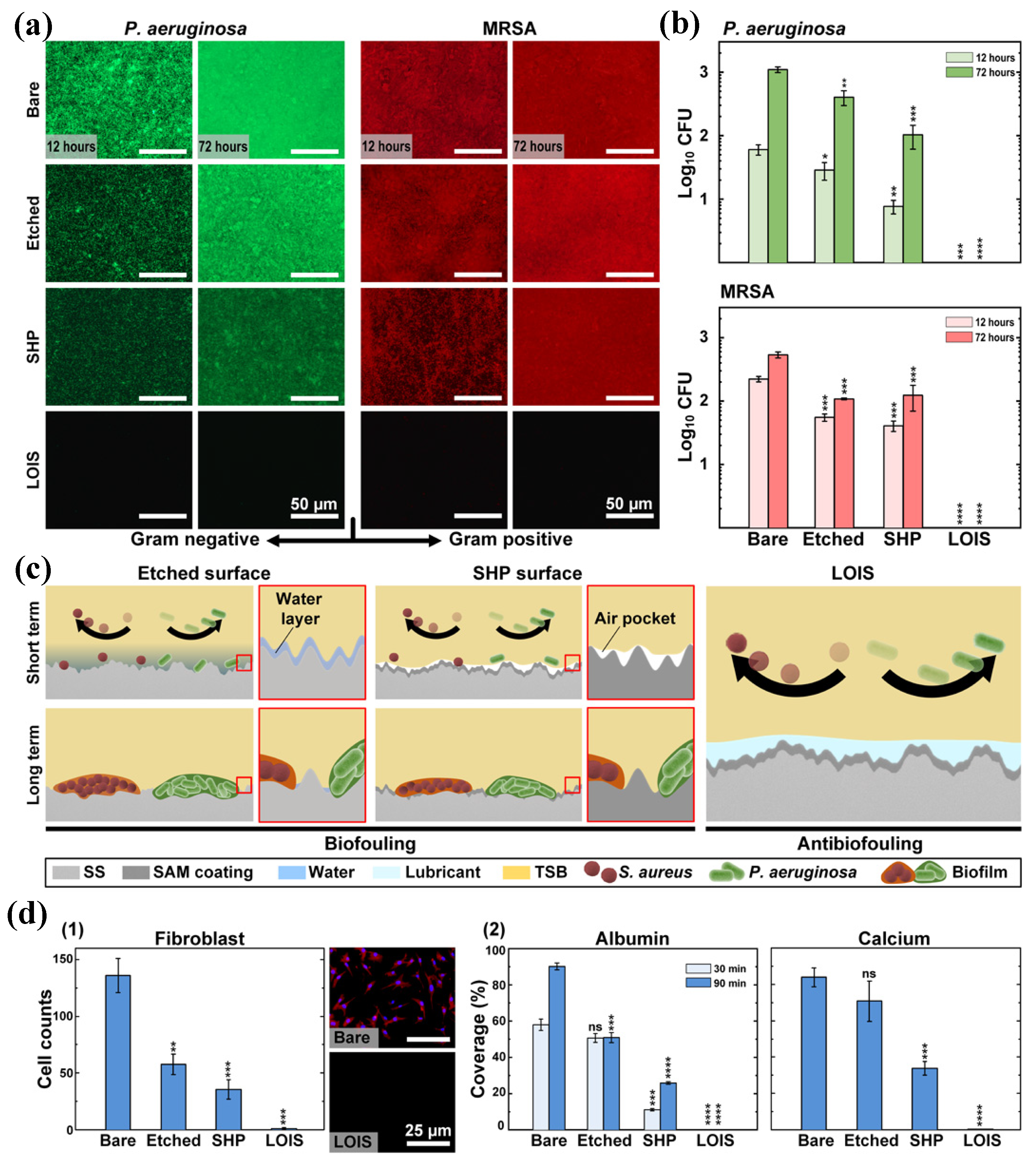

2.1. Surface Biochemical Treatment of Biomedical Titanium Alloys

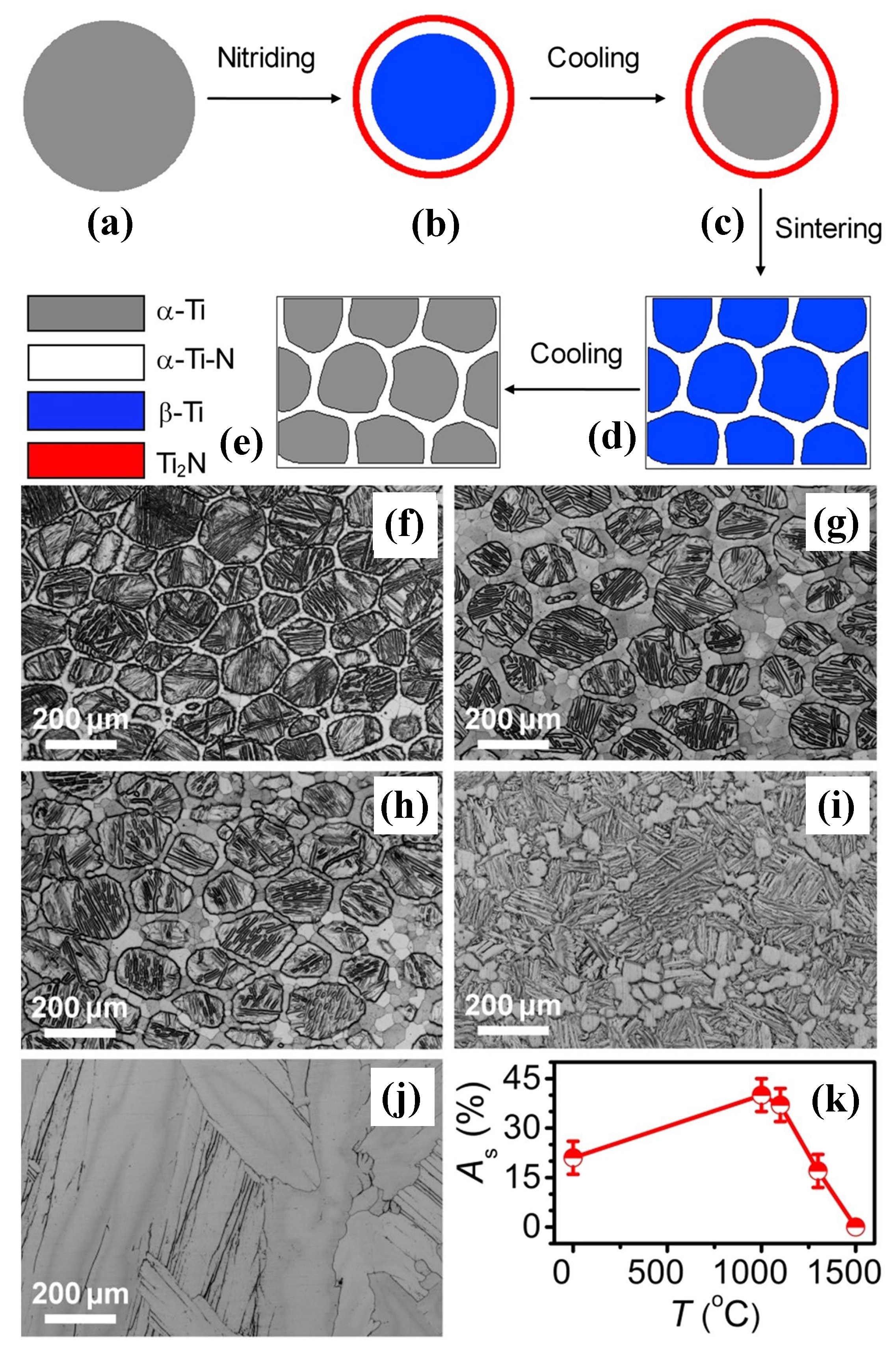

2.2. Surface Nitriding and Nitrocarburizing on Titanium Alloys

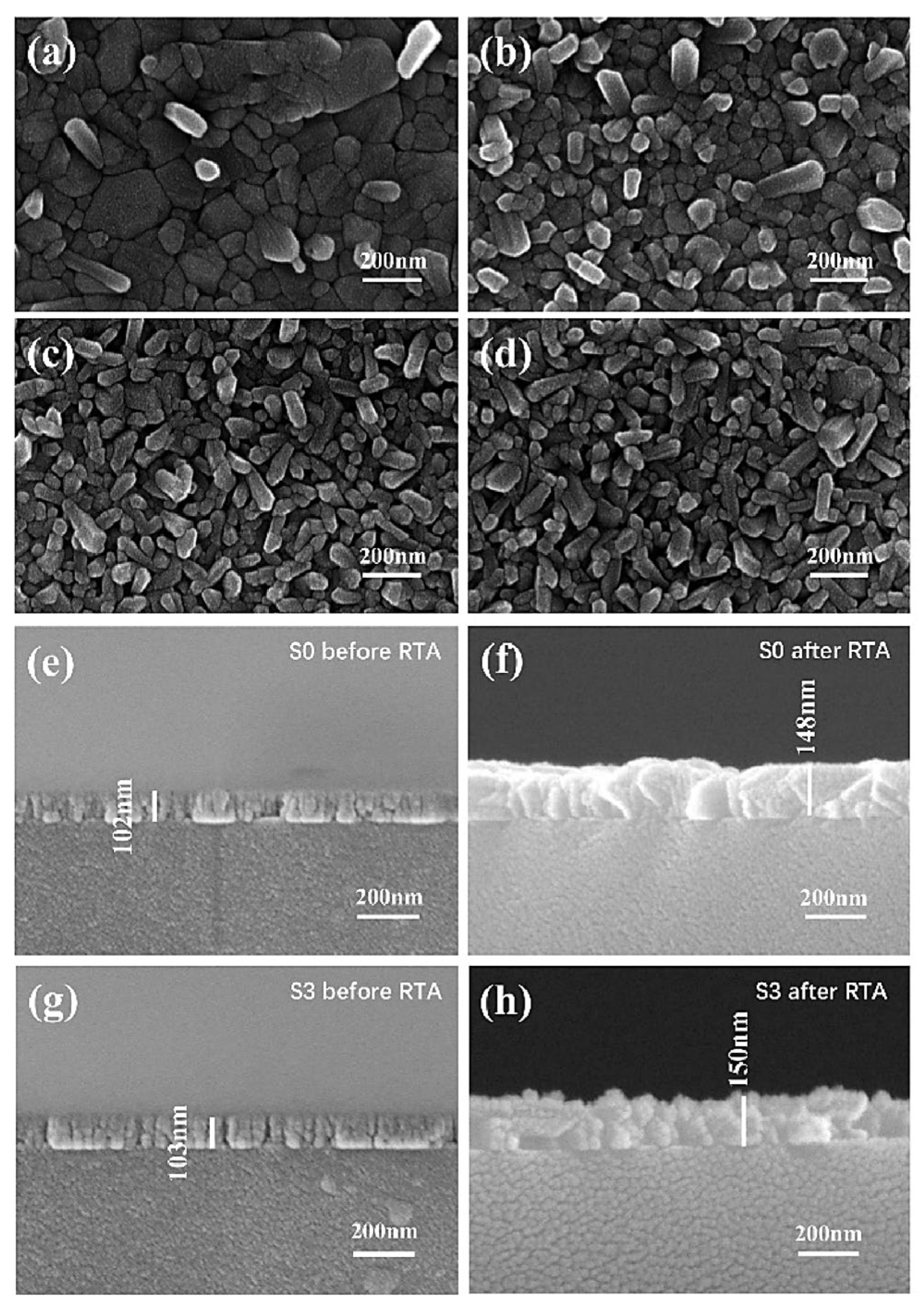

2.3. Hybrid Surface Modification (HSM) on Titanium Alloys

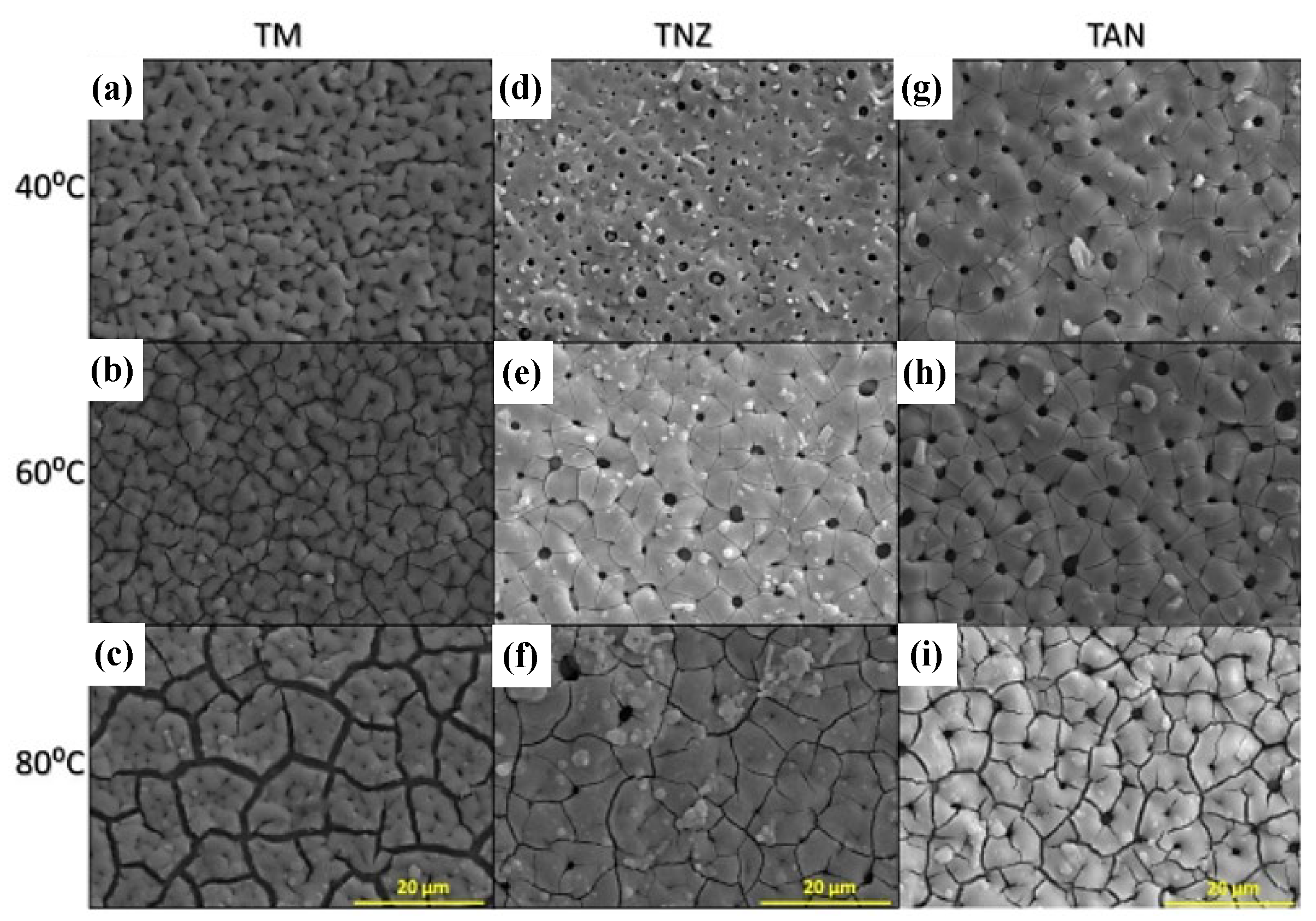

2.4. Electrochemical/Chemical Surface Treatment of Titanium Alloys

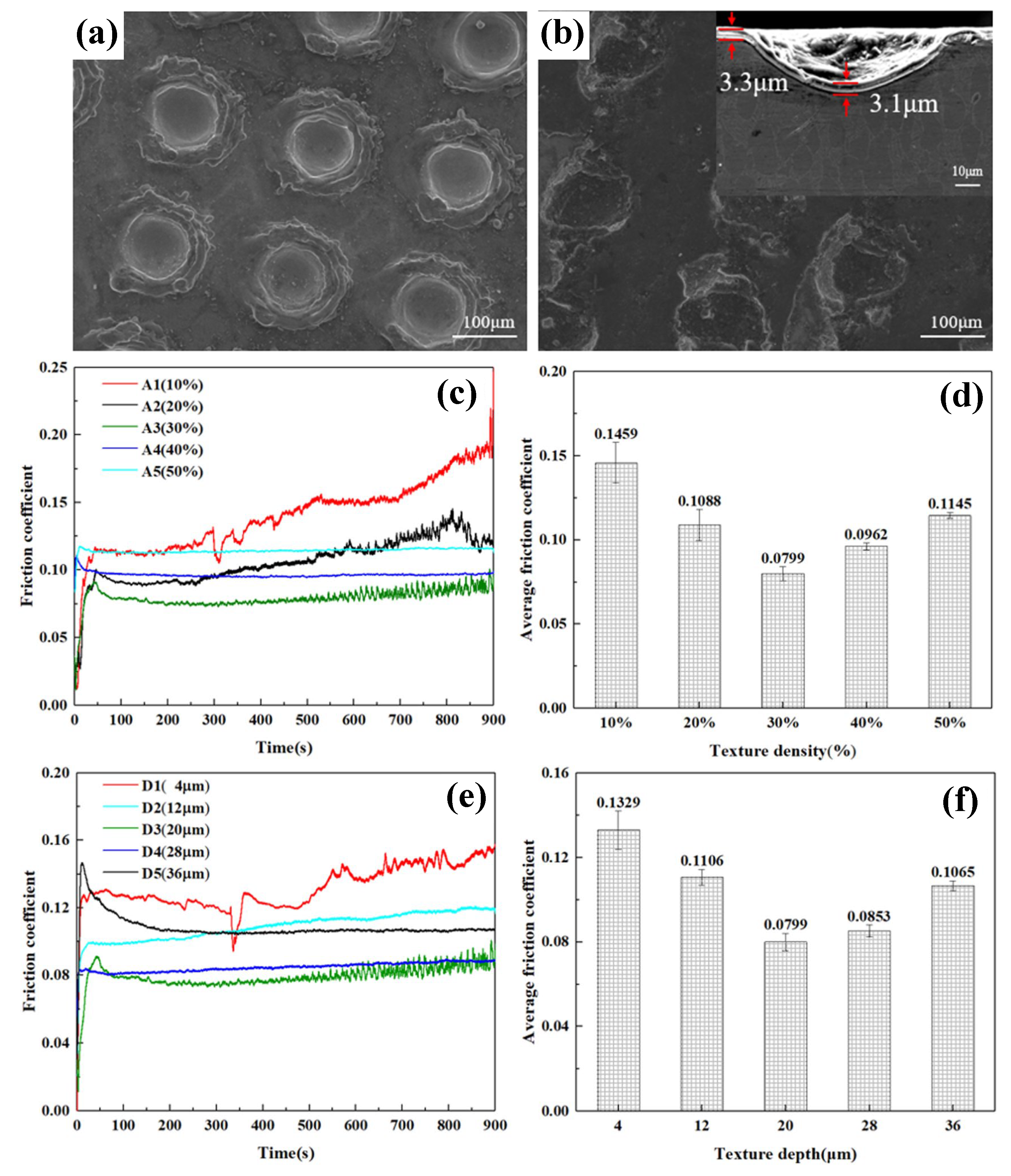

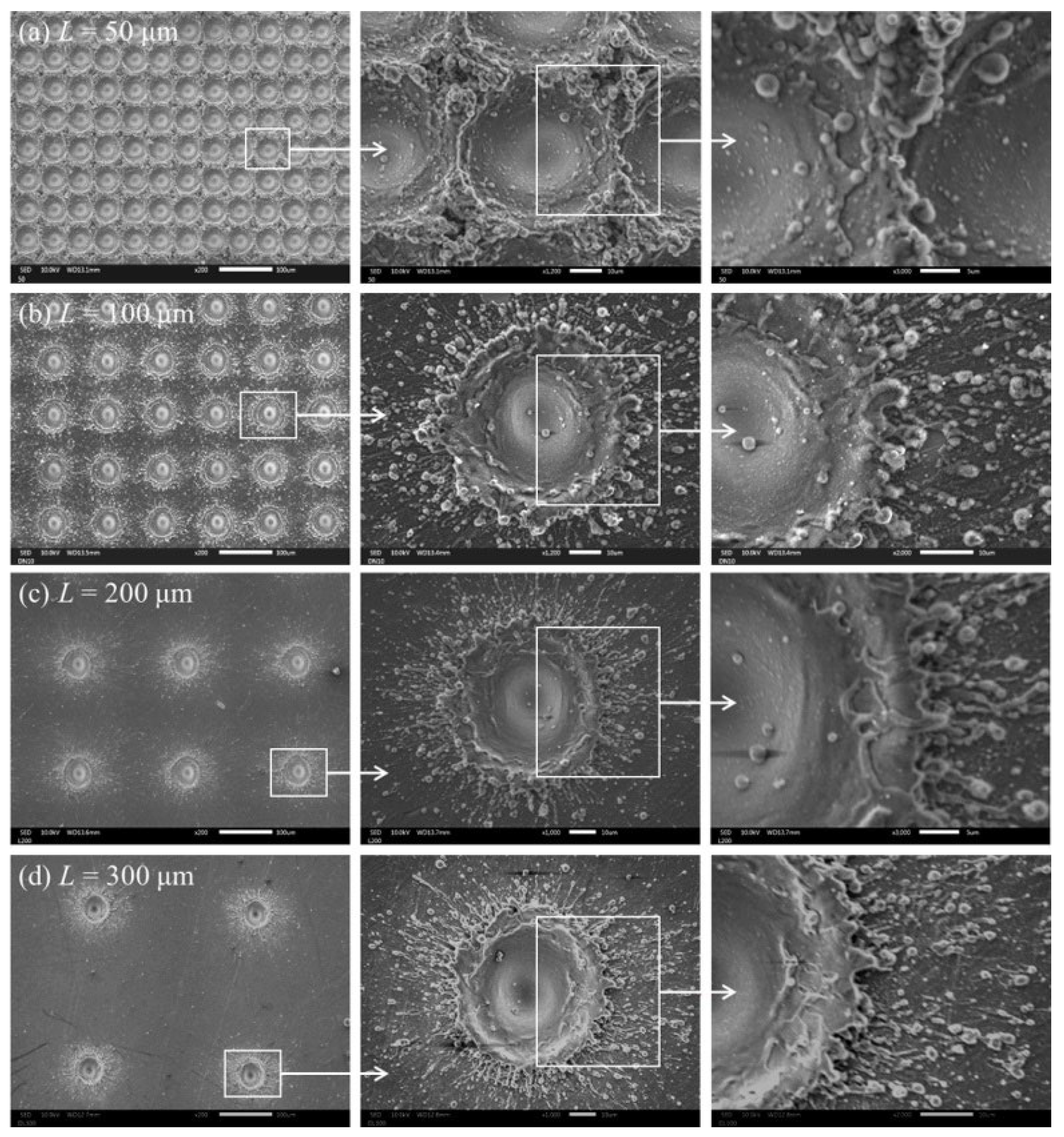

2.5. Laser Surface Modification of Titanium Alloys

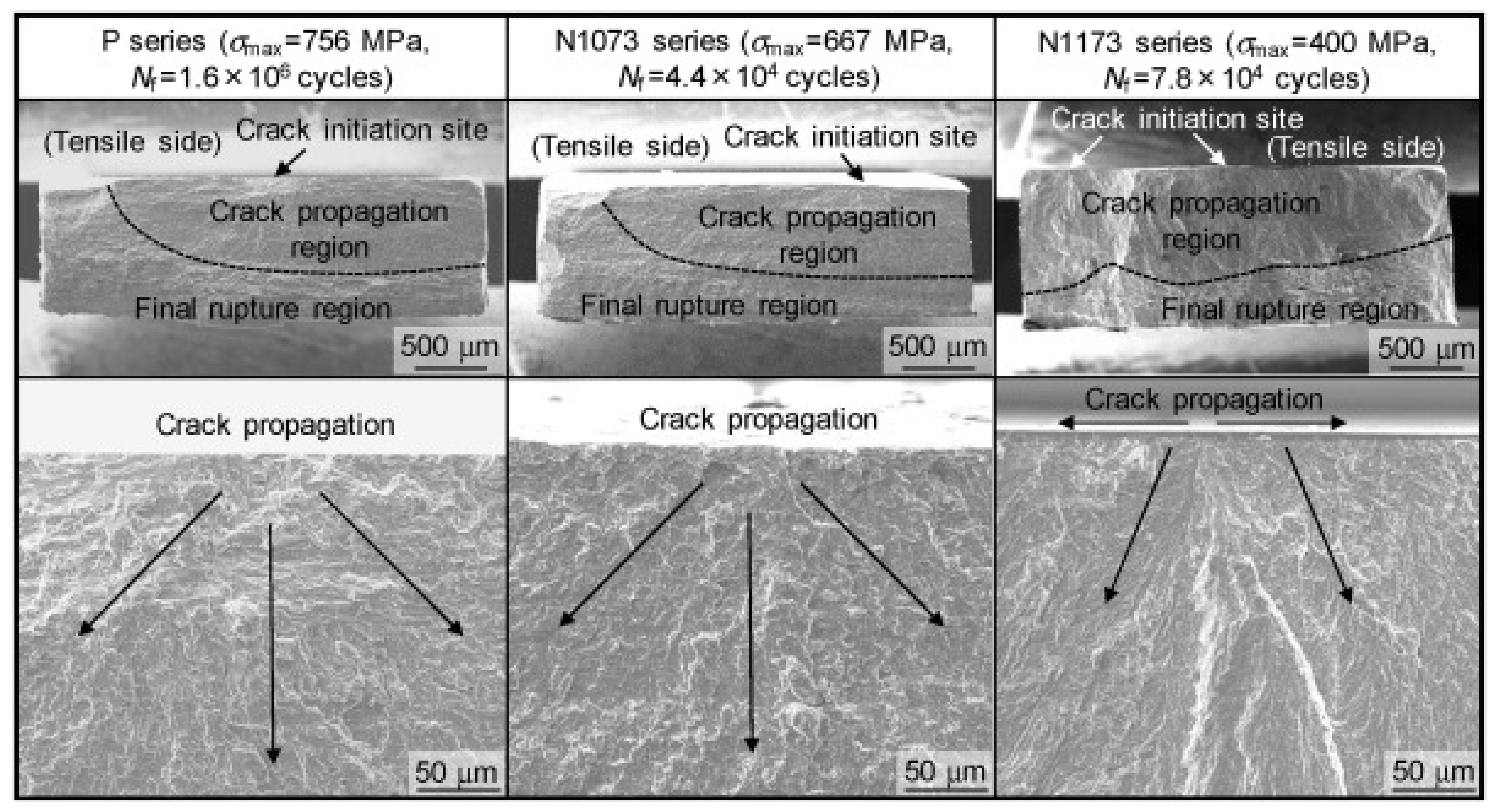

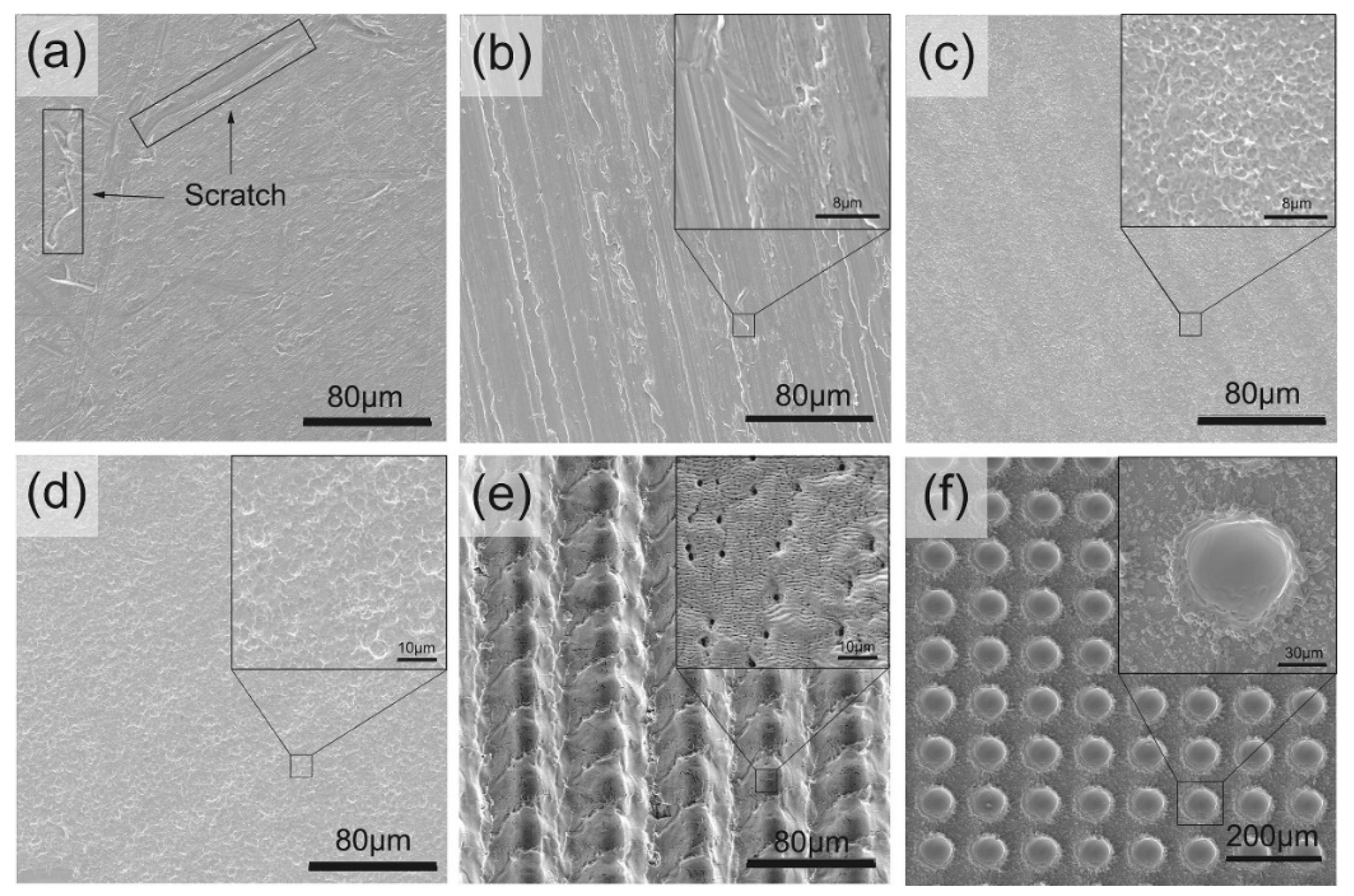

2.6. Surface Mechanical Treatment of Titanium Alloys

3. Conclusions and Prospects

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Lu, W.; Zhang, D.; Zhang, X.; Wu, R.; Sakata, T.; Mori, H. Microstructural characterization of TiB in in situ synthesized titanium matrix composites prepared by common casting technique. J. Alloys Compd. 2001, 327, 240–247. [Google Scholar] [CrossRef]

- Panigrahi, A.; Bönisch, M.; Waitz, T.; Schafler, E.; Calin, M.; Eckert, J.; Skrotzki, W.; Zehetbauer, M. Phase transformations and mechanical properties of biocompatible Ti–16.1Nb processed by severe plastic deformation. J. Alloys Compd. 2015, 628, 434–441. [Google Scholar] [CrossRef]

- Attar, H.; Prashanth, K.G.; Chaubey, A.K.; Calin, M.; Zhang, L.C.; Scudino, S.; Eckert, J. Comparison of wear properties of commercially pure titanium prepared by selective laser melting and casting processes. Mater. Lett. 2015, 142, 38–41. [Google Scholar] [CrossRef]

- Haghighi, S.E.; Lu, H.B.; Jian, G.Y.; Cao, G.H.; Habibi, D.; Zhang, L.C. Effect of α″ martensite on the microstructure and mechanical properties of beta-type Ti–Fe–Ta alloys. Mater. Des. 2015, 76, 47–54. [Google Scholar] [CrossRef]

- Calin, M.; Zhang, L.C.; Eckert, J. Tailoring of microstructure and mechanical properties of a Ti-based bulk metallic glass-forming alloy. Scr. Mater. 2007, 57, 1101–1104. [Google Scholar] [CrossRef]

- De los Rios, E.R.; Walley, A.; Milan, M.T.; Hammersley, G. Fatigue crack initiation and propagation on shot-peened surfaces in A316 stainless steel. Int. J. Fatigue 1995, 17, 493–499. [Google Scholar] [CrossRef]

- Torres, M.A.S.; Voorwald, H.J.C. An evaluation of shot peening, residual stress and stress relaxation on the fatigue life of AISI 4340 steel. Int. J. Fatigue 2002, 24, 877–886. [Google Scholar] [CrossRef]

- Kobayashi, M.; Matsui, T.; Murakami, Y. Mechanism of creation of compressive residual stress by shot peening. Int. J. Fatigue 1998, 20, 351–357. [Google Scholar] [CrossRef]

- Fu, Y.; Loh, N.L.; Batchelor, A.W.; Liu, D.; Zhu, X.; He, J.; Xu, K. Improvement in fretting wear and fatigue resistance of Ti6Al4V by application of several surface treatments and coatings. Surf. Coat. Technol. 1998, 106, 193–197. [Google Scholar] [CrossRef]

- Nalla, R.K.; Altenberger, I.; Noster, U.; Liu, G.Y.; Scholtes, B.; Ritchie, R.O. On the influence of mechanical surface treatments—Deep rolling and laser shock peening—On the fatigue behavior of Ti6Al4V at ambient and elevated temperatures. Mater. Sci. Eng. A 2003, 355, 216–230. [Google Scholar] [CrossRef]

- Golden, P.J.; Hutson, A.; Sundaram, V.; Arps, J.H. Effect of surface treatments on fretting fatigue of Ti6Al4V. Int. J. Fatigue 2007, 29, 1302–1310. [Google Scholar] [CrossRef]

- Liu, C.; Bi, Q.; Matthews, A. Tribological and electrochemical performance of PVD TiN coatings on the femoral head of Ti6Al4V artificial hip joints. Surf. Coat. Technol. 2003, 163–164, 597–604. [Google Scholar] [CrossRef]

- Warren, J.; Hsiung, L.M.; Wadley, H.N.G. High temperature deformation behavior of physical vapor deposited Ti6Al4V. Acta Metall. Mater. 1995, 43, 2773–2787. [Google Scholar] [CrossRef]

- Perry, S.S.; Ager, J.W., III; Somorjai, G.A.; McClelland, R.J.; Drory, M.D. Interface characterization of chemically vapor deposited diamond on titanium and Ti-6Al-4V. J. Appl. Phys. 1993, 74, 7542–7550. [Google Scholar] [CrossRef]

- Baek, S.H.; Mihec, D.F.; Metson, J.B. The Deposition of Diamond Films by Combustion Assisted CVD on Ti and Ti6Al4V. Chem. Vap. Depos. 2002, 8, 29–34. [Google Scholar] [CrossRef]

- Tsipas, S.A.; Vázquez-Alcázar, M.R.; Navas, E.M.R.; Gordo, E. Boride coatings obtained by pack cementation deposited on powder metallurgy and wrought Ti and Ti6Al4V. Surf. Coat. Technol. 2010, 205, 2340–2347. [Google Scholar] [CrossRef]

- Çelikkan, H.; Öztürk, M.K.; Aydin, H.; Aksu, M.L. Boriding titanium alloys at lower temperatures using electrochemical methods. Thin Solid Films 2007, 515, 5348–5352. [Google Scholar] [CrossRef]

- Sanders, A.P.; Tikekar, N.; Lee, C.; Chandran, K.S.R. Surface Hardening of Titanium Articles with Titanium Boride Layers and its Effects on Substrate Shape and Surface Texture. J. Manuf. Sci. Eng. 2009, 131, 031001. [Google Scholar] [CrossRef]

- Wang, Z.M.; Ezugwu, E.O. Performance of PVD-Coated Carbide Tools When Machining Ti6Al4V©. Tribol. Trans. 1997, 40, 81–86. [Google Scholar] [CrossRef]

- Senthil Selvan, J.; Subramanian, K.; Nath, A.K.; Kumar, H.; Ramachandra, C.; Ravindranathan, S.P. Laser boronising of Ti6Al4V as a result of laser alloying with pre-placed BN. Mater. Sci. Eng. A 1999, 260, 178–187. [Google Scholar] [CrossRef]

- Wilson, A.D.; Leyland, A.; Matthews, A. A comparative study of the influence of plasma treatments, PVD coatings and ion implantation on the tribological performance of Ti6Al4V. Surf. Coat. Technol. 1999, 114, 70–80. [Google Scholar] [CrossRef]

- Hutchings, R.; Oliver, W.C. A study of the improved wear performance of nitrogen-implanted Ti6Al4V. Wear 1983, 92, 143–153. [Google Scholar] [CrossRef]

- Vreeling, J.A.; Ocelík, V.; De Hosson, J.T.M. Ti6Al4V strengthened by laser melt injection of WCp particles. Acta Mater. 2002, 50, 4913–4924. [Google Scholar] [CrossRef]

- Man, H.C.; Zhao, N.Q.; Cui, Z.D. Surface morphology of a laser surface nitrided and etched Ti6Al4V alloy. Surf. Coat. Technol. 2005, 192, 341–346. [Google Scholar] [CrossRef]

- Kloosterman, A.B.; Kooi, B.J.; De Hosson, J.Th.M. Electron microscopy of reaction layers between SiC and Ti6Al4V after laser embedding. Acta Mater. 1998, 46, 6205–6217. [Google Scholar] [CrossRef]

- Lee, H.; Mall, S. Stress relaxation behavior of shot-peened Ti6Al4V under fretting fatigue at elevated temperature. Mater. Sci. Eng. A 2004, 366, 412–420. [Google Scholar] [CrossRef]

- John, R.; Buchanan, D.J.; Jha, S.K.; Larsen, J.M. Stability of shot-peen residual stresses in an α+β titanium alloy. Scr. Mater. 2009, 61, 343–346. [Google Scholar] [CrossRef]

- Liu, K.K.; Hill, M.R. The effects of laser peening and shot peening on fretting fatigue in Ti6Al4V coupons. Tribol. Int. 2009, 42, 1250–1262. [Google Scholar] [CrossRef]

- Wang, G.; Wang, S.; Yang, X.; Yu, X.; Wen, D.; Chang, Z.; Zhang, M. Fretting wear and mechanical properties of surface-nanostructural titanium alloy bone plate. Surf. Coat. Technol. 2021, 405, 126512. [Google Scholar] [CrossRef]

- Tan, T.; Zhao, Q.; Kuwae, H.; Ueno, T.; Chen, P.; Tsutsumi, Y.; Mizuno, J.; Hanawa, T.; Wakabayashi, N. Surface properties and biocompatibility of sandblasted and acid-etched titanium–zirconium binary alloys with various compositions. Dent. Mater. J. 2022, 41, 266–272. [Google Scholar] [CrossRef]

- Liu, P.; Hao, Y.; Zhao, Y.; Yuan, Z.; Ding, Y.; Cai, K. Surface modification of titanium substrates for enhanced osteogenetic and antibacterial properties. Colloids Surf. B Biointerfaces 2017, 160, 110–116. [Google Scholar] [CrossRef] [PubMed]

- Chae, K.; Jang, W.Y.; Park, K.; Lee, J.; Kim, H.; Lee, K.; Lee, C.K.; Lee, Y.; Lee, S.H.; Seo, J. Antibacterial infection and immune-evasive coating for orthopedic implants. Sci. Adv. 2020, 6, eabb0025. [Google Scholar] [CrossRef] [PubMed]

- Bai, H.; Zhong, L.; Kang, L.; Liu, J.; Zhuang, W.; Lv, Z.; Xu, Y. A review on wear-resistant coating with high hardness and high toughness on the surface of titanium alloy. J. Alloys Compd. 2021, 882, 160645. [Google Scholar] [CrossRef]

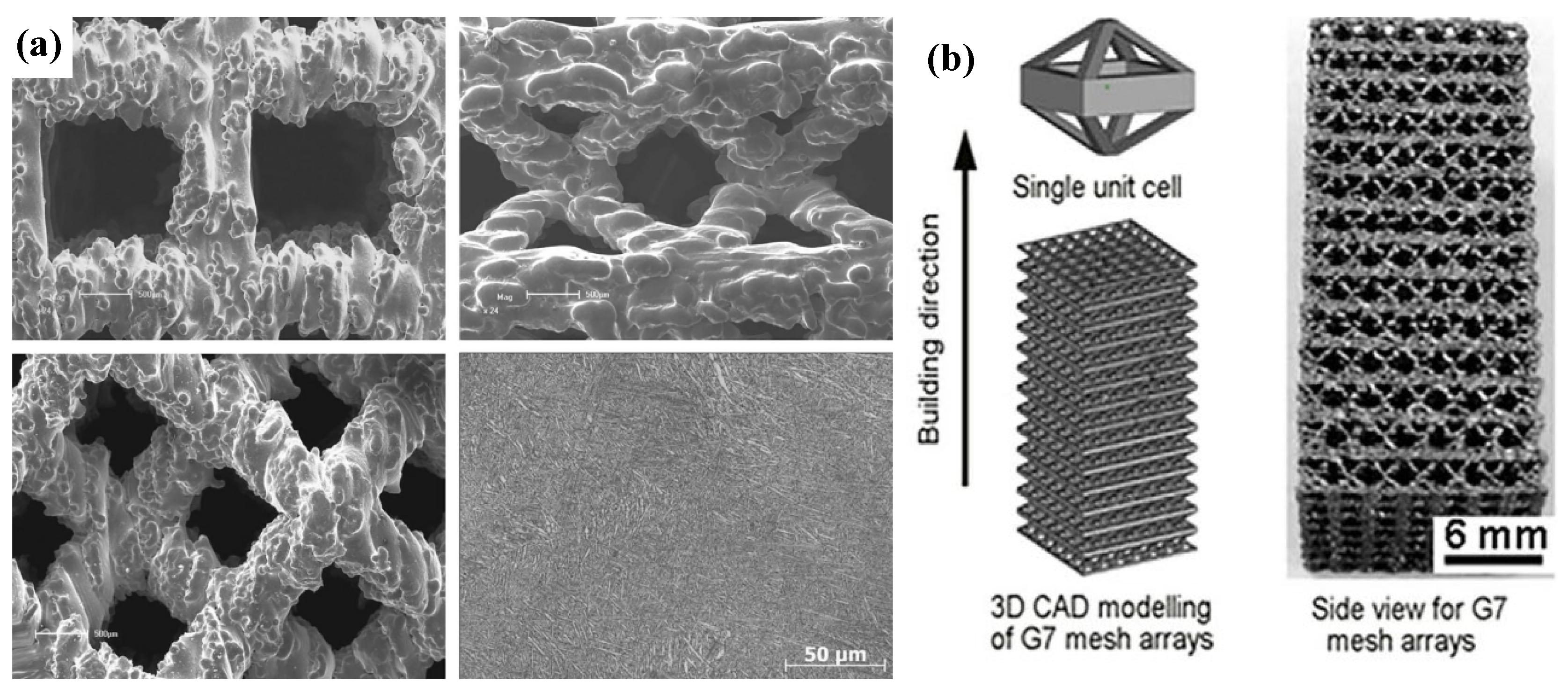

- Ren, B.; Wan, Y.; Liu, C.; Wang, H.; Yu, M.; Zhang, X.; Huang, Y. Improved osseointegration of 3D printed Ti6Al4V implant with a hierarchical micro/nano surface topography: An in vitro and in vivo study. Mater. Sci. Eng. C 2021, 118, 111505. [Google Scholar] [CrossRef] [PubMed]

- Peng, R.; Zhang, P.; Tian, Z.; Zhu, D.; Chen, C.; Yin, B.; Hua, X. Effect of textured DLC coatings on tribological properties of titanium alloy under grease lubrication. Mater. Res. Express 2020, 7, 066408. [Google Scholar] [CrossRef]

- Todea, M.; Vulpoi, A.; Popa, C.; Berce, P.; Simon, S. Effect of different surface treatments on bioactivity of porous titanium implants. J. Mater. Sci. Technol. 2019, 35, 418–426. [Google Scholar] [CrossRef]

- Zhang, L.-C.; Chen, L.-Y.; Wang, L. Surface Modification of Titanium and Titanium Alloys: Technologies, Developments, and Future Interests. Adv. Eng. Mater. 2020, 22, 1901258. [Google Scholar] [CrossRef]

- Cui, W.; Niu, F.; Tan, Y.; Qin, G. Microstructure and tribocorrosion performance of nanocrystalline TiN graded coating on biomedical titanium alloy. Trans. Nonferrous Met. Soc. China 2019, 29, 1026–1035. [Google Scholar] [CrossRef]

- Takesue, S.; Kikuchi, S.; Misaka, Y.; Morita, T.; Komotori, J. Rapid nitriding mechanism of titanium alloy by gas blow induction heating. Surf. Coat. Technol. 2020, 399, 126160. [Google Scholar] [CrossRef]

- Zhang, Y.S.; Zhao, Y.H.; Zhang, W.; Lu, J.W.; Hu, J.J.; Huo, W.T.; Zhang, P.X. Core-shell structured titanium-nitrogen alloys with high strength, high thermal stability and good plasticity. Sci. Rep. 2017, 7, 40039. [Google Scholar] [CrossRef]

- Li, J.; Pang, X.; Fan, A.; Zhang, H. Friction and wear behaviors of Ti/Cu/N coatings on titanium alloy surface by DC magnetron sputtering. J. Wuhan Univ. Technol. Mater Sci. Ed. 2017, 32, 140–146. [Google Scholar] [CrossRef]

- Takesue, S.; Kikuchi, S.; Akebono, H.; Morita, T.; Komotori, J. Characterization of surface layer formed by gas blow induction heating nitriding at different temperatures and its effect on the fatigue properties of titanium alloy. Results Mater. 2020, 5, 100071. [Google Scholar] [CrossRef]

- Seo, D.M.; Hwang, T.W.; Moon, Y.H. Carbonitriding of Ti6Al4V alloy via laser irradiation of pure graphite powder in nitrogen environment. Surf. Coat. Technol. 2019, 363, 244–254. [Google Scholar] [CrossRef]

- Zammit, A.; Attard, M.; Subramaniyan, P.; Levin, S.; Wagner, L.; Cooper, J.; Espitalier, L.; Cassar, G. Enhancing surface integrity of titanium alloy through hybrid surface modification (HSM) treatments. Mater. Chem. Phys. 2022, 279, 125768. [Google Scholar] [CrossRef]

- Zhang, M.-X.; Miao, S.-M.; Shi, Y.-N. A Novel Surface Treatment Technique for Titanium Alloys. JOM 2020, 72, 4583–4593. [Google Scholar] [CrossRef]

- Liu, R.; Yuan, S.; Lin, N.; Zeng, Q.; Wang, Z.; Wu, Y. Application of ultrasonic nanocrystal surface modification (UNSM) technique for surface strengthening of titanium and titanium alloys: A mini review. J. Mater. Res. Technol. 2021, 11, 351–377. [Google Scholar] [CrossRef]

- Baris, N.M.; Golkovsky, M.G.; Tushinsky, L.I. SR-study of coatings obtained by complex electron-beam alloying of titanium alloys and steels. In Proceedings of the Proceedings KORUS 2000. The 4th Korea-Russia International Symposium on Science and Technology, Ulsan, Republic of Korea, 27 June–1 July 2000; Volume 3, pp. 407–410. [Google Scholar]

- Casadei, F.; Pileggi, R.; Valle, R.; Matthews, A. Studies on a combined reactive plasma sprayed/arc deposited duplex coating for titanium alloys. Surf. Coat. Technol. 2006, 201, 1200–1206. [Google Scholar] [CrossRef]

- Li, Y.; Zhou, Q.; Liu, M. Effect of novel surface treatment on corrosion behavior and mechanical properties of a titanium alloy. Baosteel Technol. Res. 2021, 15, 11–19. [Google Scholar] [CrossRef]

- Tarbokov, V.A.; Pavlov, S.K.; Remnev, G.E.; Nochovnaya, N.A.; Eshkulov, U.É. Titanium Alloy Surface Complex Modification. Metallurgist 2019, 62, 1187–1193. [Google Scholar] [CrossRef]

- Takesue, S.; Kikuchi, S.; Misaka, Y.; Morita, T.; Komotori, J. Combined Effect of Gas Blow Induction Heating Nitriding and Post-Treatment with Fine Particle Peening on Surface Properties and Wear Resistance of Titanium Alloy. Mater. Trans. 2021, 62, 1502–1509. [Google Scholar] [CrossRef]

- Zammit, A.; Attard, M.; Subramaniyan, P.; Levin, S.; Wagner, L.; Cooper, J.; Espitalier, L.; Cassar, G. Investigations on the adhesion and fatigue characteristics of hybrid surface-treated titanium alloy. Surf. Coat. Technol. 2022, 431, 128002. [Google Scholar] [CrossRef]

- Song, C.; Liu, M.; Deng, Z.-Q.; Niu, S.-P.; Deng, C.-M.; Liao, H.-L. A novel method for in-situ synthesized TiN coatings by plasma spray-physical vapor deposition. Mater. Lett. 2018, 217, 127–130. [Google Scholar] [CrossRef]

- Hou, F.; Gorthy, R.; Mardon, I.; Tang, D.; Goode, C. Low voltage environmentally friendly plasma electrolytic oxidation process for titanium alloys. Sci. Rep. 2022, 12, 6037. [Google Scholar] [CrossRef]

- Kazek-Kęsik, A.; Leśniak, K.; Zhidkov, I.S.; Korotin, D.M.; Kukharenko, A.I.; Cholakh, S.O.; Kalemba-Rec, I.; Suchanek, K.; Kurmaev, E.Z.; Simka, W. Influence of Alkali Treatment on Anodized Titanium Alloys in Wollastonite Suspension. Metals 2017, 7, 322. [Google Scholar] [CrossRef]

- Rudawska, A.; Zaleski, K.; Miturska, I.; Skoczylas, A. Effect of the Application of Different Surface Treatment Methods on the Strength of Titanium Alloy Sheet Adhesive Lap Joints. Materials 2019, 12, 4173. [Google Scholar] [CrossRef] [PubMed]

- Vlcak, P.; Fojt, J.; Koller, J.; Drahokoupil, J.; Smola, V. Surface pre-treatments of Ti-Nb-Zr-Ta beta titanium alloy: The effect of chemical, electrochemical and ion sputter etching on morphology, residual stress, corrosion stability and the MG-63 cell response. Results Phys. 2021, 28, 104613. [Google Scholar] [CrossRef]

- Khodaei, M.; Amini, K.; Valanezhad, A.; Watanabe, I. Surface treatment of titanium dental implant with H2O2 solution. Int. J. Miner. Metall. Mater. 2020, 27, 1281–1286. [Google Scholar] [CrossRef]

- Zhao, J.; Chen, D.; Hao, C.; Mi, W.; Zhou, L. The optimization and role of Ti surface doping in thermochromic VO2 film. Opt. Mater. 2022, 133, 112960. [Google Scholar] [CrossRef]

- Zhao, G.; Xia, L.; Zhong, B.; Wu, S.; Song, L.; Wen, G. Effect of alkali treatments on apatite formation of microarc-oxidized coating on titanium alloy surface. Trans. Nonferrous Met. Soc. China 2015, 25, 1151–1157. [Google Scholar] [CrossRef]

- Luo, Q.; Yin, S.; Sun, X.; Tang, Y.; Feng, Z.; Dai, X. Density functional theory study on the adsorption properties of SO2 gas on graphene, N, Ti, and N–Ti doped graphene. Micro Nanostruct. 2022, 171, 207401. [Google Scholar] [CrossRef]

- Shirazi, H.A.; Chan, C.-W.; Lee, S. Elastic-plastic properties of titanium and its alloys modified by fibre laser surface nitriding for orthopaedic implant applications. J. Mech. Behav. Biomed. Mater. 2021, 124, 104802. [Google Scholar] [CrossRef]

- Guo, C.; Zhang, M.; Hu, J. Fabrication of hierarchical structures on titanium alloy surfaces by nanosecond laser for wettability modification. Opt. Laser Technol. 2022, 148, 107728. [Google Scholar] [CrossRef]

- Wang, Y.; Yu, Z.; Li, K.; Hu, J. Effects of surface properties of titanium alloys modified by grinding, sandblasting and acidizing and nanosecond laser on cell proliferation and cytoskeleton. Appl. Surf. Sci. 2020, 501, 144279. [Google Scholar] [CrossRef]

- Pan, X.; Wang, X.; Tian, Z.; He, W.; Shi, X.; Chen, P.; Zhou, L. Effect of dynamic recrystallization on texture orientation and grain refinement of Ti6Al4V titanium alloy subjected to laser shock peening. J. Alloys Compd. 2021, 850, 156672. [Google Scholar] [CrossRef]

- Yao, X.; Shi, Y.; Li, T.; Wensheng, L. Forming Characteristics and Analysis of Nitrided Layers During the Laser Nitriding Titanium Alloy. Rare Met. Mater. Eng. 2019, 48, 4060–4067. [Google Scholar]

- Dong, B.; Guo, X.; Zhang, K.; Zhang, Y.; Li, Z.; Wang, W.; Cai, C. Combined effect of laser texturing and carburizing on the bonding strength of DLC coatings deposited on medical titanium alloy. Surf. Coat. Technol. 2022, 429, 127951. [Google Scholar] [CrossRef]

- Han, J.; Zhang, G.; Chen, X.; Cai, Y.; Luo, Z.; Zhang, X.; Su, Y.; Tian, Y. High strength Ti alloy fabricated by directed energy deposition with in-situ Cu alloying. J. Mater. Process. Technol. 2022, 310, 117759. [Google Scholar] [CrossRef]

- Pan, X.; He, W.; Cai, Z.; Wang, X.; Liu, P.; Luo, S.; Zhou, L. Investigations on femtosecond laser-induced surface modification and periodic micropatterning with anti-friction properties on Ti6Al4V titanium alloy. Chin. J. Aeronaut. 2022, 35, 521–537. [Google Scholar] [CrossRef]

- Abdulkareem AlMashhadani, H.; Khadom, A.A.; Khadhim, M.M. Effect of Polyeugenol coating on surface treatment of grade 23 titanium alloy by micro arc technique for dental application. Results Chem. 2022, 4, 100555. [Google Scholar] [CrossRef]

- Zhang, L.-C.; Liu, Y.; Li, S.; Hao, Y. Additive Manufacturing of Titanium Alloys by Electron Beam Melting: A Review. Adv. Eng. Mater. 2018, 20, 1700842. [Google Scholar] [CrossRef]

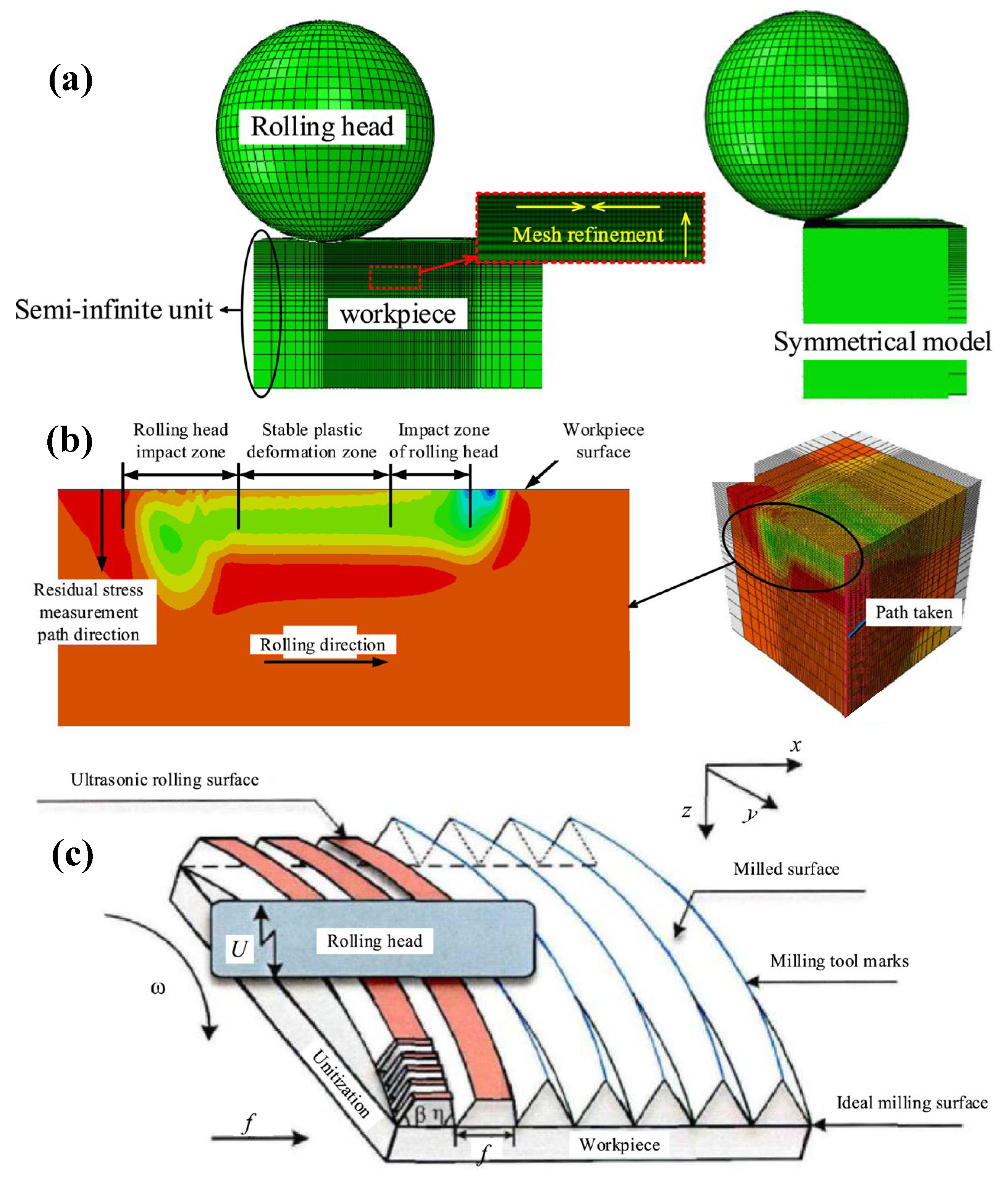

- Ren, Z.; Li, Z.; Zhou, S.; Wang, Y.; Zhang, L.; Zhang, Z. Study on surface properties of Ti6Al4V titanium alloy by ultrasonic rolling. Simul. Model. Pract. Theory 2022, 121, 102643. [Google Scholar] [CrossRef]

- Du, Z.; He, Q.; Chen, R.; Liu, F.; Zhang, J.; Yang, F.; Zhao, X.; Cui, X.; Cheng, J. Rolling reduction-dependent deformation mechanisms and tensile properties in a β titanium alloy. J. Mater. Sci. Technol. 2022, 104, 183–193. [Google Scholar] [CrossRef]

- Pu, D.; Chen, X.; Ding, Y.; Sun, Y.; Feng, B.; Zheng, K.; Pan, F. Effect of Ti particles size on the microstructure and mechanical properties of TiP/VW94 composites. Mater. Sci. Eng. A 2022, 858, 144140. [Google Scholar] [CrossRef]

- Wang, N.; Zhu, J.; Liu, B.; Zhang, X.; Zhang, J.; Tu, S. Influence of Ultrasonic Surface Rolling Process and Shot Peening on Fretting Fatigue Performance of Ti6Al4V. Chin. J. Mech. Eng. 2021, 34, 90. [Google Scholar] [CrossRef]

- Zhang, Y.-L.; Lai, F.-Q.; Qu, S.-G.; Liu, H.-P.; Jia, D.-S.; Du, S.-F. Effect of ultrasonic surface rolling on microstructure and rolling contact fatigue behavior of 17Cr2Ni2MoVNb steel. Surf. Coat. Technol. 2019, 366, 321–330. [Google Scholar] [CrossRef]

- Klimenov, V.A.; Vlasov, V.A.; Borozna, V.Y.; Klopotov, A.A. Ultrasonic Surface Treatment of Titanium Alloys. The Submicrocrystalline State. IOP Conf. Ser. Mater. Sci. Eng. 2015, 91, 012040. [Google Scholar] [CrossRef]

- Li, L.; Sun, L.; Li, M. Diffusion bonding of dissimilar titanium alloys via surface nanocrystallization treatment. J. Mater. Res. Technol. 2022, 17, 1274–1288. [Google Scholar] [CrossRef]

- Urtekin, L.; Aydin, Ş.; Sevim, A.L.I.; GÖK, K.; Uslan, İ. Experimental Determination of Biofilm and Mechanical Properties of Surfaces Obtained by CO2 Laser Gas-Assisted Nitriding of Ti6Al4V Alloy. Surf. Rev. Lett. 2022, 29, 2250154. [Google Scholar] [CrossRef]

- Urtekin, L.; Keleş, Ö. Investigation of Mechanical Properties of TiN-coated Ti6Al4V Alloy for Biomedical Applications. J. Def. Sci. 2019, 18, 91–108. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xie, B.; Gao, K. Research Progress of Surface Treatment Technologies on Titanium Alloys: A Mini Review. Coatings 2023, 13, 1486. https://doi.org/10.3390/coatings13091486

Xie B, Gao K. Research Progress of Surface Treatment Technologies on Titanium Alloys: A Mini Review. Coatings. 2023; 13(9):1486. https://doi.org/10.3390/coatings13091486

Chicago/Turabian StyleXie, Bingyu, and Kai Gao. 2023. "Research Progress of Surface Treatment Technologies on Titanium Alloys: A Mini Review" Coatings 13, no. 9: 1486. https://doi.org/10.3390/coatings13091486

APA StyleXie, B., & Gao, K. (2023). Research Progress of Surface Treatment Technologies on Titanium Alloys: A Mini Review. Coatings, 13(9), 1486. https://doi.org/10.3390/coatings13091486