Abstract

The thermionic vacuum discharge method is very effective in that the films obtained using this technology are characterised by a very high degree of adhesion, density and purity because the deposition technique is carried out in high, very high or, if possible, in ultra-very high vacuum conditions with no gas present. When the substrate is placed in vacuum, no heat transfer particles are present, the substrate being heated only by the ion incident on the surface. This advantage recommends the TVD method for deposits on plastics or other thermally sensitive materials. Additionally, this slow heat transfer reduces energy loss, making the deposition method industrially competitive. The paper aims to present theoretical aspects of this type of discharge, compared to typical or more popular plasmas but also to present the achievements of this method and its utility in the thin films production, layers that have specific imposed properties. The practical depositions and applications presented are in the nuclear fusion-related material science and also for obtaining materials for granular structures, used as magneto-resistive coatings.

1. Introduction

A tremendous endeavour in scientific and industrial activities is dedicated nowadays to coatings, surface treatments, as well as to thin film production for a large domain of applications.

The following opportunities are indicative of the high level of interest in surface science phenomena:

The possibility to study the elementary particle interactions at the two-dimensional level of the deposited film.

The ability to drastically change the physical-chemical properties of solid surfaces such as:

- -

- surface colour change;

- -

- improvement of the surface tribological properties;

- -

- surface passivation to environmental corrosion agents;

- -

- surface mechanical hardening;

- -

- surface electronic, luminous changes;

- -

- development of new unique material structures, etc.

As a result, one can save and protect expensive materials, extend the life of various device components, save energy, obtain new sources of energy, particularly through solar energy conversion, obtain the most sophisticated layers for automation and IT components, and push up new ways to obtain energy from thermonuclear devices, among other things.

Many deposition and surface treatment technologies are in use nowadays due to their importance in both economic and research activity.

Among these, the following ones are worth being mentioned:

- a.

- Sputtering of cathode material by ion bombardment during the electrical discharges in noble gases, mostly argon;

- b.

- Chemical and plasma assisted chemical vapor deposition method where the electrical discharges in chemical gases can produce active chemical reaction on the surfaces and as a result, can cover them with different thin coatings, such as evaporations by material heating and subsequent deposition, evaporation by laser surface bombardment followed by material deposition, plasma jet deposition, anodic vacuum arc (AVA) deposition and thermionic vacuum arc deposition (TVA).

Of course, there are additional deposition techniques, but we will only be focusing on the last coating method within the scope of this review article because it has highly fascinating qualities that are less well recognized in the scientific community. There are some observations that must be made from the very beginning of this presentation concerning even the denomination and these are the following: after this deposition process was discovered in the eighth decade of the past century, it was given the current name, the thermionic vacuum arc deposition method. However, this method can be used with discharges ranging from modest currents of roughly a hundred mA to proper arc discharges with currents of tens or even hundreds of amperes.

As will be demonstrated on the following pages of this work, it is possible to maintain the vacuum discharge at low currents due to cathode heating by a special external source that ensures sufficient thermo-electron emission from the cathode, capable of igniting and maintaining the small current vacuum discharge, even in high vacuum conditions. Therefore, a more proper denomination of this method would be the thermionic vacuum discharge (TVD) method which includes both small current-high voltage discharges and the high current, small voltage ones. These two modes of discharges, as it will be revealed further, are able to be used when increasing the injected power into the plasma.

When treating the subject throughout this review article, the term “TVD” will be used instead of “TVA” which, as will be seen, represents only a particular domain of the more general one, namely TVD.

2. General Description of the TVD Method

The TVD method consists of a discharge that runs in an atmosphere of pure vapours generated by the anode which in turn, is heated by the energetic action of the electrons coming both from the heated cathode and from the plasma.

The thermo-electrons first emitted by the cathode are accelerated in high vacuum conditions towards the anode on which a high positive potential is applied. This way, the anode material, heated by energetic electron bombardment, is evaporated, and a pure vapor atmosphere is created around the anode whose pressure increases and the necessary conditions appear for plasma ignition by electron-vapor particle collisions. These space particles, neutral or ionized, are expanding in the surrounding vacuum, and are deposited on the probe substrates. Due to the thermo-electrons emitted by the externally heated cathode, the plasma can be started, maintained and changed beginning with very low discharge currents and high anode voltages (tens of milliamps-and kilovolts, respectively) and continued up to hundreds of A and some volts.

In order to have a more detailed introspective view into the physical phenomena, firstly, some general considerations over the cathode, anode and plasma events must be considered further.

2.1. Cathode Phenomena

Imagine a tungsten filament intensely heated by a low voltage, high current electrical source. The energy electron distribution function (Fermi distribution) within a solid at the equilibrium can be simply obtained as follows [1,2]:

Let w1 and w2 be two discrete energy levels inside the solid which are occupied by two electrons which are colliding with each other. After the collision, they are transferred on the new energy levels, w′1 and w′2.

Let p(w) be the probability for an energy level, w, to be occupied by an electron. Then, due to quantum effect, the probability for that energy level to be free is given by 1 − p(w) so that the probability for that energy level to be occupied or non-occupied is p(w) + 1 − p(w) = 1 = certitude.

The probability to have a collision between two electrons having energies w1 and w2, is proportional with the product p(w1). p(w2)[1 − p(w1′)][1 − p(w2′)] states that the levels w1 and w2 must be occupied and the levels w1′ and w2′ must be free for such a collision to appear. Similarly, the inverse collision can be produced proportionally with the probability p(w1′) p(w2′)[1 − p(w1)][1 − p(w2)]. At the equilibrium, the two expressions are equal, and dividing both members of the obtained equation by the product p(w1) p(w2)p(w1′)p(w2′), one obtains:

where the energy conservation w1 + w2 = w1′ + w2′ was considered, Δw being given by |w1 − w1′| = |w2′ − w2| = Δw.

A solution of this equation, as directly seen, is [1/p(w) − 1] = a1exp(a2w). Finally, the probability for the energy level w to be occupied is given by [2].

Now, the constant a1 can be written in a different, more convenient way as a1 = exp(−wF/kT), and a2 as 1/kT. The Fermi-–Dirac distribution that prescribes the number of electrons having the energy w, within a unit space of the solid, is given by:

Here, n is the total number of electrons found within a unit space of solid and this formula shows that the number of electrons with energy w is given by the product of total number of electrons existent in the unit space volume multiplied by the probability to find an electron with that energy [p(w)]. It must be underlined that the constant a2 was chosen to obtain the usual Maxwell–Boltzmann distribution function for the high energy values (w >> wF) when the discrete energy spectrum tends to be continuous and when

Now, the expression of the emission current from the unit surface of the emitter is obtained from Jx = ∫ef(w)g(w)vx(w)dw. Here, x denotes the perpendicular axis on the emitter surface, and g(w) is the density (per unit energy interval) of the possible energetic states for the electrons inside the solid [3].

To evaluate this energy state density, the simplest energetic scheme within the metal, which is that of free electrons, will be considered further.

The corresponding single-dimensional (x) Schrodinger equation is with Ψ as the wave function, as the Plank constant, m as the electron mass and w as the total electron energy. Its solution is a sum of sine and cosine functions and must be zero at the solid boundaries. From these conditions, the arbitrary coefficient of the cosine part of the solution disappears while from the sine part, one obtains that the wave number, kx, must be given by kx = nx π/L with nx—an integer, and L—the maximum length of the solid along the x direction. This relation says that kx can have only discrete values separated from one another by the π/L value. Then the total number of levels existent for a given k2 = kx2 + ky2 + kz2 is obtained as N = 2.4/3πk3(1/8) (π/L)−3 where the volume of only one eighth part of the k space, together with the levels splitting due to the electron spin orientation, were considered [3]. This volume was divided by the k space volume corresponding to an energy state, namely (π/L)3 to obtain the total number of states for a fixed k2 value.

The density of states on the unit energy interval is readily obtained by deriving this expression with respect to the energy (that is dN/dw = (dN/dk)(dk/dw)). Considering that w(k) = 2k2/2m, finally the energy state density is given by g(w) = .

Therefore, the expression of the Jx current can be obtained from:

Here, the transition from the energy-space to velocity-space was made and the condition (w − wF) >> kT was considered. The vx,min is the minimum x component of electron speed value, necessary to overcome the solid energy barrier, (Φ = work function) and to escape into the free space. Performing the well-known integrals appearing here, one obtains the expression for the electron emitted current from the unit solid surface as [4]:

where e is the elementary charge, m is the electron mass, k is the Boltzmann constant, h is the Planck constant, T is the filament temperature and Φ is the barrier encountered by the electron on his way out of metal, which is the minimum energy. A particle of unit electric charge must have to be able to exit the solid and become a free particle. This energy is usually denoted by a work function and is a characteristic value for an electron emitting solid [5].

One can see the exponential increase of the emitted current with the filament temperature. To generate a considerable thermo-emission current, the filament must be heated to a significant temperature, but this temperature must not exceed the melting point of the electron emitting material under the obvious conditions.

The well-known materials that meet these requirements are tungsten, rhenium and carbon, with the first being the most utilized. There are also other metals with high enough melting points, but their high commercial prices forbid their industrial use for thermo-emission purposes.

Here, it must be underlined that different particles of other material adsorbed on the emitter surface contribute to emitter work function; (Φ) changes and it exponentially influences the thermo-emitted current value, as seen from the relation (3).

Usually, a high intensity thermo-electron emission is desired.

A possible way to improve this parameter is to use a thorium-tungsten alloy; when heated, the thorium metal migrates towards the tungsten filament surface and contributes to a work function decrease (Φw = 4.5 eV, Φth = 3.71 eV) and consequently, to a thermo-electron increase.

Assuming an “atmosphere” of vapours generated of other material is present near the emitter surface, these vapours could appear when the anode material is evaporated by electronic bombardment. To appreciate the phenomena taking place in this case, the following considerations will be made.

The evaporated atoms are adsorbed on the solid emitter surface, where they remain for a period before being incorporated by the adsorbing material or leaving the surface by thermal desorption. The atom (molecule) desorption rate from the solid surface can be described by the Equation (5):

where Nads is the total number of the adsorbed particles on a unit surface of the solid, f is a special term closely related to the vibration frequency of the adsorbed particles [5], H is the desorption energy barrier that an adsorbed particle must surpass when leaving the solid surface and Tfil is the filament (solid surface) temperature.

At equilibrium, this particle flux directed away from the surface must be balanced by the oncoming chaotic particle flux from the adjacent space on a unit solid surface.

If the space particle density is Ng, in the condition of chaotic particle movement, half of them have a speed component oriented towards the solid surface, the other half having the speed oriented away from the solid. The space mean value of this unidirectional speed component is also a half of the thermal mean particle velocity because it is comprised between zero and the maximal value of the cosine function. Therefore, the oncoming flux is .

However, the mean thermal speed value, , can be obtained when using the Maxwell distribution function [6,7,8] and is given by the expression vg = , Tg being the space vapour temperature.

At last, the following equation for the oncoming flux towards the unit surface of the emitting metal is derived (which is equal with the flux leaving the unit metal surface at thermal equilibrium (4)): .

where M is the mass of the adsorbed particle and k is the Planck constant. At thermal equilibrium, this incoming particle flux is equal with the number of desorbed particles per unit time and one can write for the adsorbed particle number on the unit surface of the solid surface:

Now, if Nw is the total adsorbing sites existing on the solid surface unity, the occupancy degree of sites on the solid unit surface is given by:

Normally, the energy barrier, H, depends on this coverage degree too, but at higher temperatures of the emitter, it can be assumed that the coverage ratio is low enough and does not influence the barrier value.

The weighted solid work function, φm, influenced by this coverage degree may be written as [9]:

φm = (1 − θ)φw + θφads = φw + θ(φads − φw)

Here, φw is the work function of the solid clean surface (filament = tungsten in the present case), φads—the work function of the adsorbed material.

This relation shows that the greater H, Tg and Ng values are, and the lower Tfil is, the greater the change of the work function for a filament material—adsorbed metal combination.

If φads > φw, then the adsorbed material increases the work function of the solid (filament) and adsorbed material combination (and consequently decreases the thermo-emission) while, when φads < φw, the combination work function decreases (as in the case of a tungsten-thorium combination) and the thermo-emission current increases.

These considerations are useful to be aware of in TVD deposition processes [7].

2.2. Anode Phenomena

When a high positive potential is applied to the emitter potential (which is assumed to be zero), the electrons produced by the heated cathode move through the vacuum space towards the anode and bombard it with high energy. The anode material is thus evaporated. Now, certain considerations will be made in order to better understand the phenomena that have emerged in this case. Suppose a thermal equilibrium existent between the two phases of the evaporating anode material, one being the solid phase and the other one the vapor phase.

Considering the free enthalpy for the unit mass as given elsewhere [10]:

where μ is the free enthalpy, u is the internal energy, p is pressure, v is volume, T is temperature in K and s is entropy. From the free enthalpy expression, it immediately results:

Μ = u + pv − Ts

dμ = du + pdv + vdp − Tds − sdT = vdp − sdT

Here, the principle of thermodynamics, dq = Tds = du + pdv, was considered.

If the two phases are in equilibrium, the free enthalpy variation when passing from one phase to the other one is zero.

This means, when identifying the solid phase with index “2” and the gaseous phase with index “1”, that one can write:

v1dp − s1dT = v2dp − s2dT and therefore (v1 − v2)dp = (s1 − s2)dT

However, from the second law of thermodynamics [11], s1 − s2 = ∫dqrev/T, where qrev is the reversibly transferred heat, when passing from a phase to another one.

In this particular case, the phase change is made by vaporization or condensation and the heat change can be calculated by considering the heat of transformation, usually denoted by λ which can be assumed constant in a first approximation (which really, is not quite exact [12]). Then passing from a solid state to a gaseous one, s1 − s2 = ∫dqrev/T = λ/T and if λ is considered constant, one can write:

which is just the Clausius–Clapeyron Equation (10).

dp/dT = λ/(v1 − v2)T

However, the solid volume (v2) subjected to transition is by far less than the corresponding gaseous one (v1) which in turn is subjected to the universal low of gases, namely pv1 = γNavkT, with γ denoting the number of molls per mass unity, and Nav denoting Avogadro’s number [12].

In conclusion, the following relations could be derived:

which leads to the expression for the gaseous phase pressure value lnp = lnC − λ/γNavkT, or

dp/dT = λp/(γNavkT2)

p = C. exp(−w/kT).

Here, w = λ/γNav is the heat involved when a particle passes from a phase to another and C a constant appearing after integration.

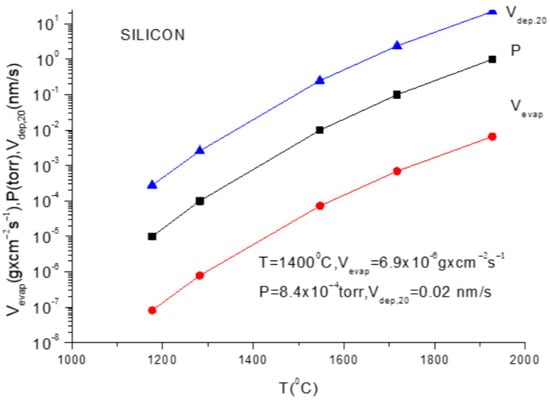

This is the principal dependence form of vapor pressure against the temperature. The true experimental dependence is given in the literature [10], and it is expressed as follows:

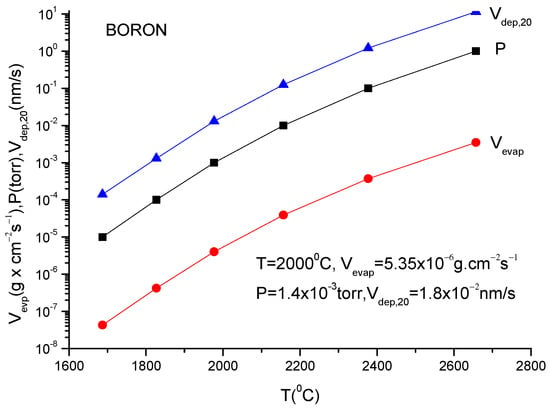

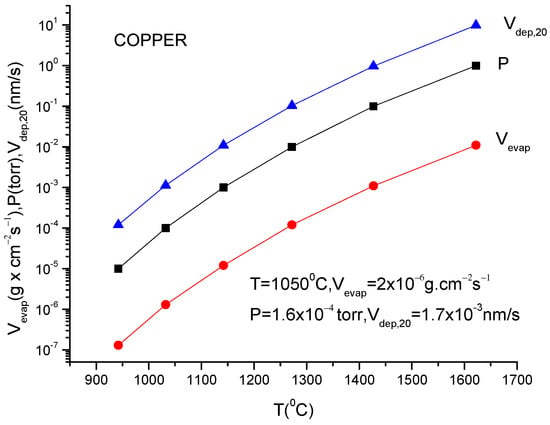

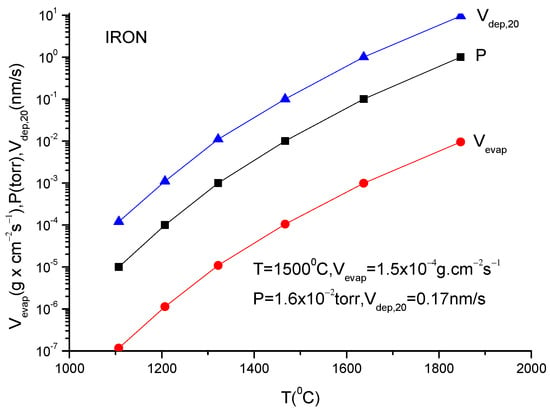

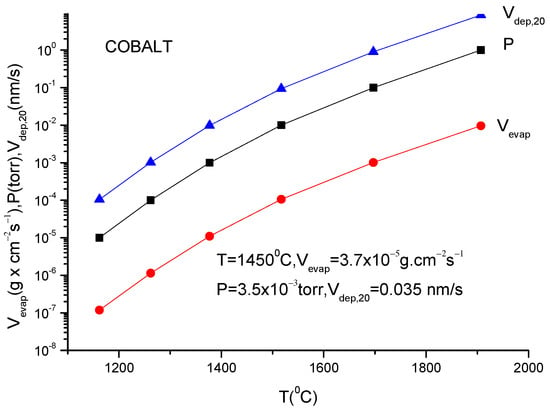

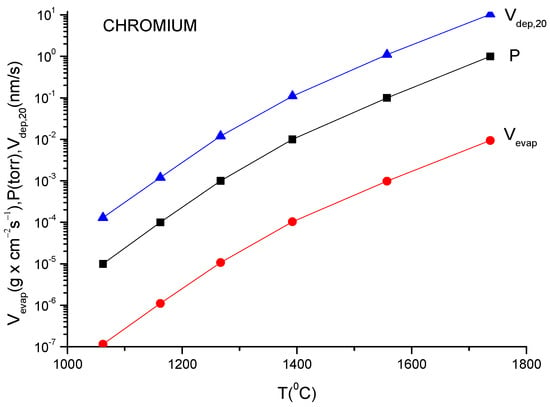

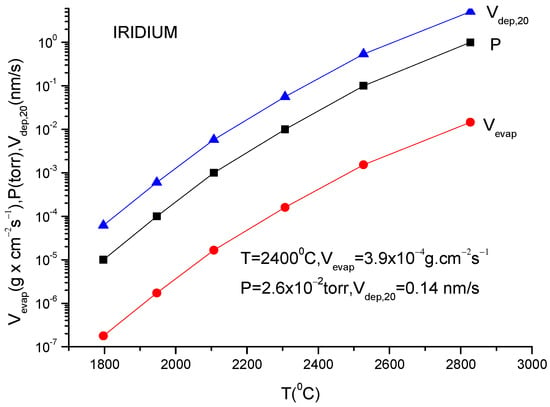

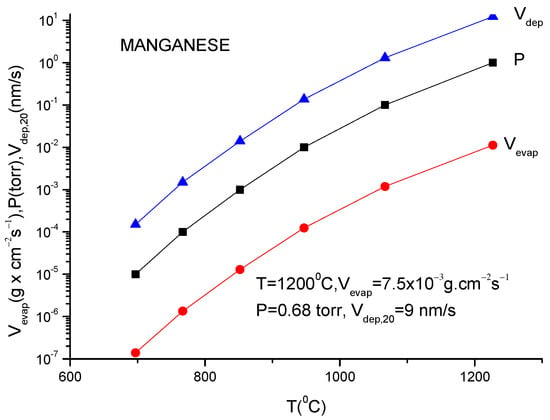

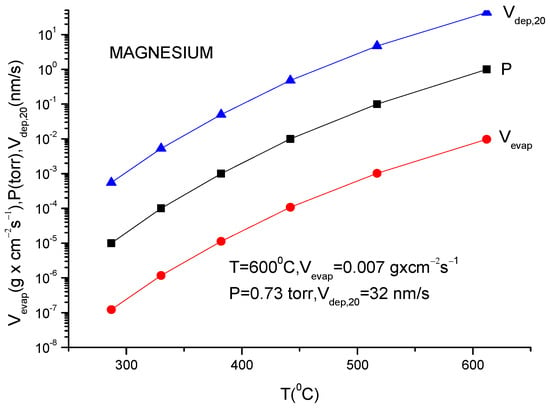

where A and B are two constants, characteristic to each substance as suggested by Equation (10). Additionally, a lot of graphs are given elsewhere [13], representing the temperature dependence of the vapor pressure.

p = A exp (−B/T)

As known from statistical mechanics, p = nkT [6], with n being the particle space density. One can conclude that nkT = C.exp(−w/kT).

Whence the vapor gas is formed, a particle flux appears, expanding from the anode to the vacuum space. In this case, that flux continues to travel until it reaches a solid surface where the particles are deposited and do not return to the anode.

Therefore, in stationary conditions, this flux must be sustained by the evaporation rate. However, as presented above (Equation (5)), this flux for equilibrium condition can be expressed as:

or after some arithmetic,

φ = 1/4 n [8kT/(πm)]1/2 = p/(4 kT).[8kT/(πm)]1/2

φ = p(2πmkT)1/2

This is in fact the evaporation rate of the solid phase to vapor phase measured in the number of particles leaving a solid unit surface during a unit time.

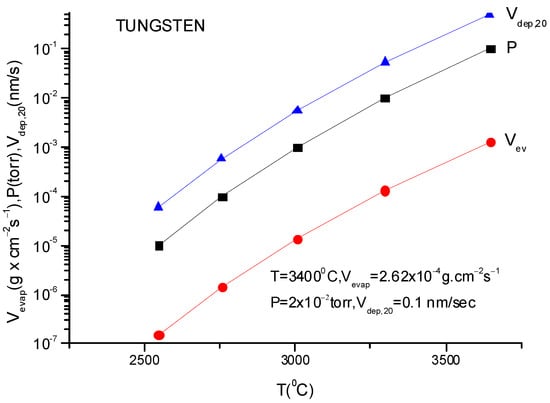

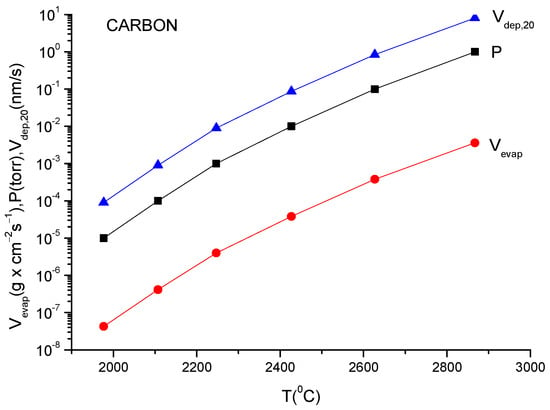

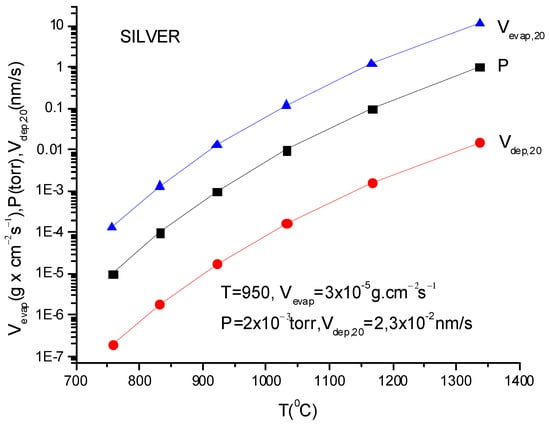

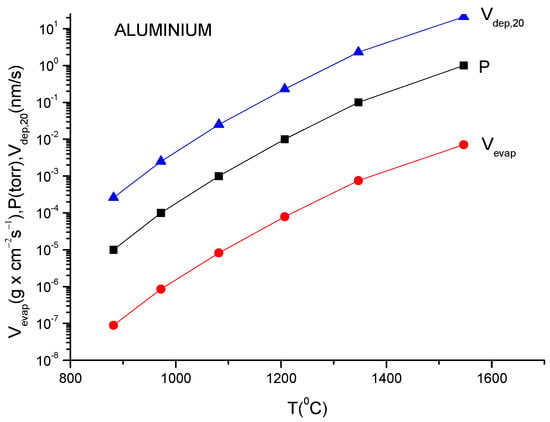

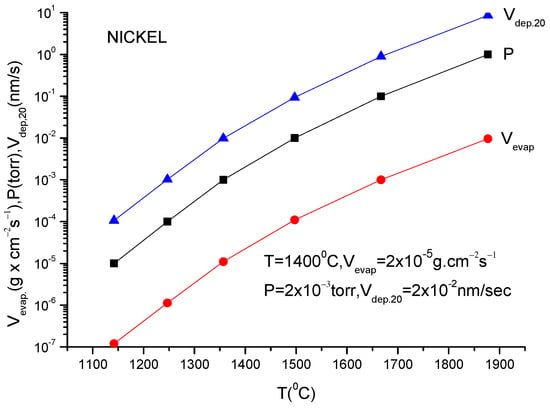

For practical reasons, the above given relation must be transformed to a relation which contains the mass quantity evaporated within a second from a square centimetre of anode surface. This is necessary to evaluate the deposition rate which is usually measured by the quartz balance gauges.

In addition, because the vapor pressure dependency on temperature is frequently provided in the literature as measured in torr, a correction factor must be inserted in Equation (11) to allow for this pressure unit translation. Suppose one wants to obtain a formula which gives the evaporation rate in . Equation (11) gives the number of particles evaporated from a square centimetre of evaporating material during a second and in order to transform it in , one must multiply ϕ by M/NA because ϕNA gives the evaporation rate in the number of moles and Mϕ/NA gives the evaporation rate given in since M represents the molar mass which is given in grams.

Multiplying the right side of Equation (11) with this factor, one obtains:

V (in g × cm−2 s−1) = (2πκNA)−1/2 p (in dyn/cm−2) (M/T)1/2

Taking the value of the Boltzmann constant as 1.381 × 10−16 erg/K and the value of NA = 6.022 × 1023, the (2πκNA)1/2 = 22.8 × 103 erg/K.

Now, if p is taken from the literature with its value in torr, it is necessary to multiply this value with the correction factor to express p in dyn/cm2, as determined by the measuring units considered in Equation (11).

This can be carried out by taking the mercury density as 13.53 g/cm3, the earth gravity as 981 cm/s2 and the height of a mercury column of 0.1 cm; the pressure correction factor is readily obtained as 1327.3 [dyn/cm2] per torr.

Introducing all these data in the above equation, one obtains for the evaporation rate from a unit anode surface heated to a temperature T(K):

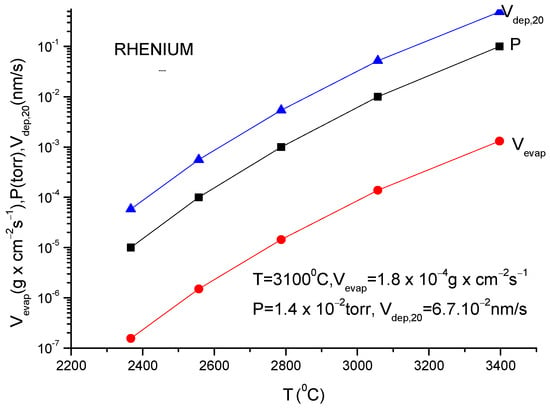

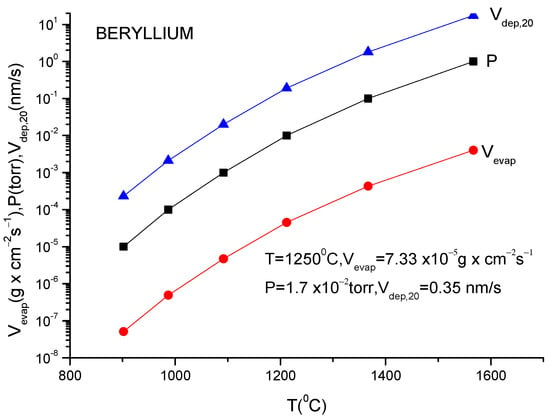

In conclusion knowing the anode temperature, T, and the evaporated particle molar mass, M, the vapor pressure together with evaporation rate can be obtained computationally or from the graphs plotted for a certain material [14]. Conversely, measuring the evaporation rate, the anode temperature together with vapor pressure can be derived.

These values can then be used in the TVD deposition technology.

Indeed, knowing the evaporation rate and the vapor pressure, it is possible to derive the deposition rate on a substrate mounted on a holder which is positioned just above the anode evaporating material (specifically the anode).

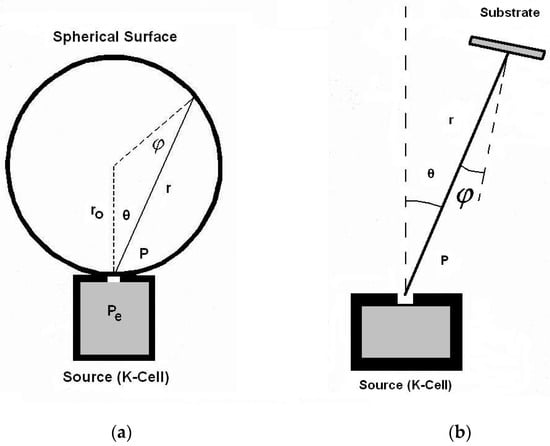

The evaporate quantity indicated by Equation (12) expands isotopically in the surrounding vacuum space, generating spheres of increasing radius through which the vapor particles pass every second. This is due to flux conservation, as there are no additional sources or sinks between the punctual anodic source and the chamber’s wall. As a result, the evaporated substance leaving the anode at the rate provided by Equation (12) passes later via a sphere on which the substrate and source are positioned, as shown in Figure 1a.

As a comparison, all of this happens as when blowing the air through a tube with soap and a sphere is formed at the tube tip, or as when inflating a spherical balloon.

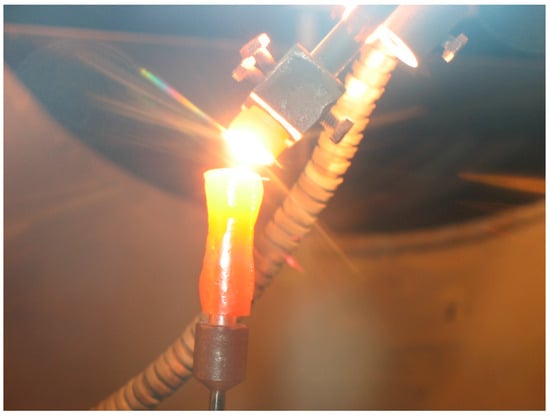

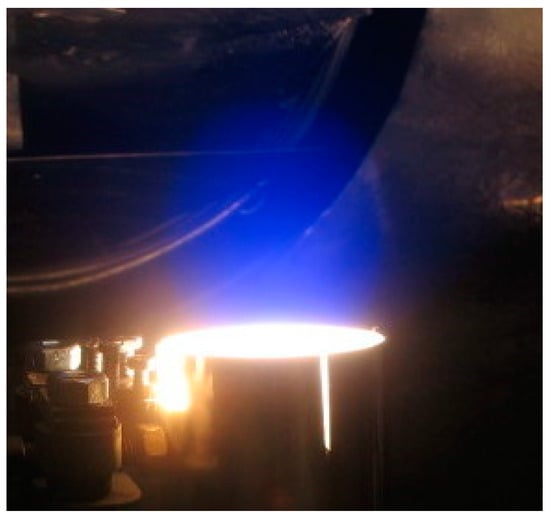

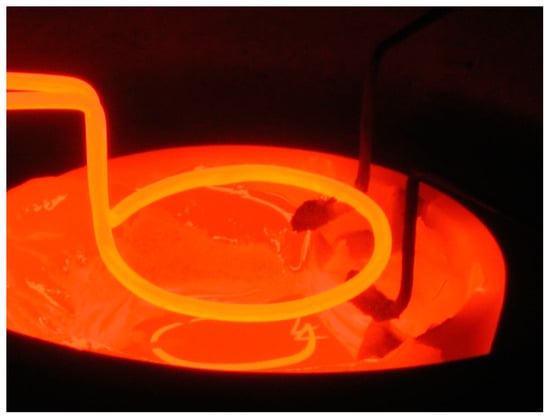

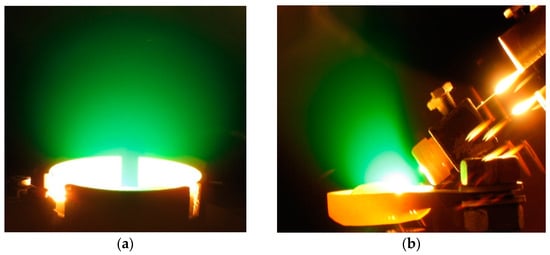

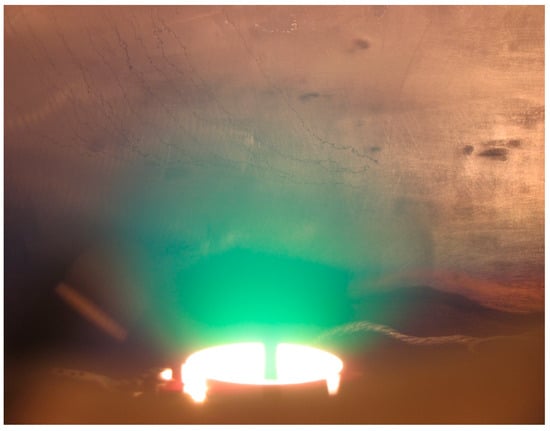

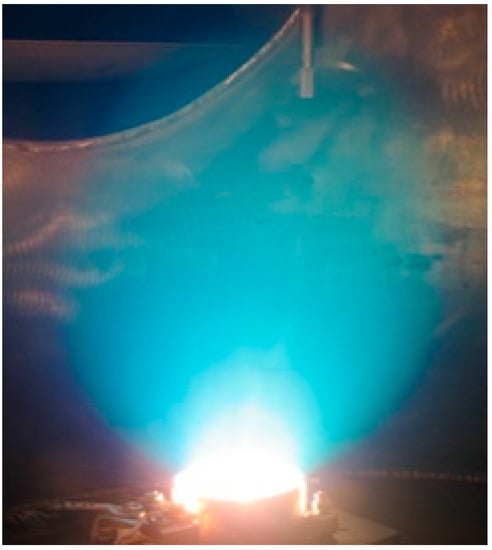

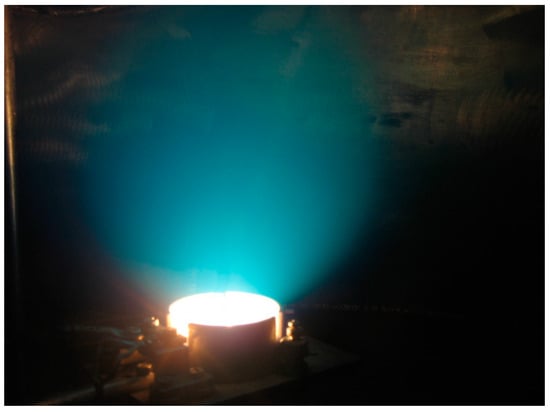

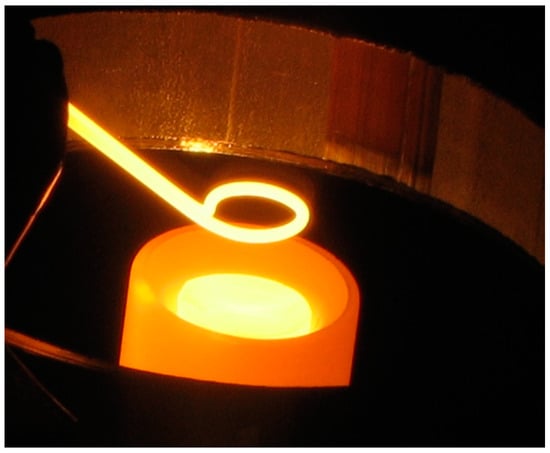

The image of this sphere is given in the Figure 1, and it can also be seen in the discharge photo given in the Figure 2, which is obtained when igniting TVD in copper vapours. (This sphere seems to be a little bit elongated along the vertical direction due to the influence of electric fields upon the charged particles but not upon the neutral ones).

In this case, one can write (considering the particle conservation in space):

S.v = 5.83 × 10−2S. p(M/T)1/2 g/s = 4πr02q

Here, S is the anode-emitting surface and q is the weight of the evaporated material which crosses during unit time, the unit surface of the sphere on which the substrate is mounted having its normal pointing to the centre of the respective sphere (of uniform coating, as found by Knudsen [15]).

From Equation (13), the deposition rate can readily be found for the mentioned position of the substrate, namely:

d = q/ρ = 1.85 × 10−2 S(M/T)1/2p/(4r02 ρ) = 1.85 × 10−2S(M/T)1/2p/(r2ρ) (m/s)

Here, the deposition rate is given, d (in m/s), at a distance r = 2r0 from the anode (taken along the vertical just above the anode in cm), function of the anode temperature, T (K), molar weight of the anode material, M (g/mol), vapor pressure, p (torr), and density of the depositing material, ρ (g/cm3). This deposition rate is the same all over a sphere which passes through the source (anode) and substrate as proved experimentally by Knudsen and has the radius r0 [16], as shown in the Figure 1. The Knudsen formula also contains the base pressure (which is the minimum gas pressure allowed by the vacuum pump system) which is subtracted from vapor pressure, but in this case, this pressure is negligible in comparison with the pressures of the vapours of the anode material used in deposition. In fact, the Knudsen formula is:

Here, besides the above presented magnitudes and those shown on Figure 1b, the base vacuum pressure pb appears too. From Figure 1a, one can see that r = 2r0 cosθ cosφ (θ = φ) so that for a substrate mounted perpendicularly on the sphere radius r0, no matter its position on that sphere, Rm/ρ is given, as in Equation (14), with r being the distance from the anode to any substrate position on the sphere. When the substrate is positioned nearer to the source, what gains by the distance shortening loses due to the tilting angle.

Figure 1.

Geometry of the deposition from a schematic anode considered similar with Knudsen cell. (a) the spherical surface expansion; (b) with a substrate placed within the sphere. Reprinted/adapted with permission from Ref. [16]. © 2007, Wiley Online Library.

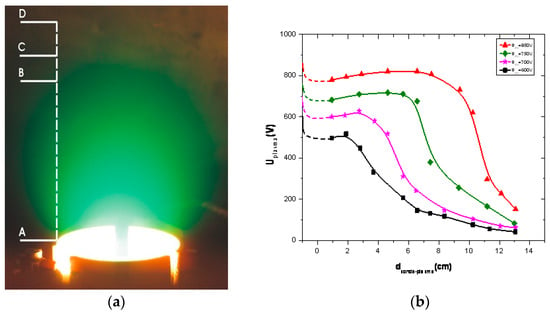

Figure 2.

Plasma image (a) and spatial distribution of plasma potentials for different discharge voltages (b) [12].

In Figure 1 the deposition geometry together with the uniform deposition sphere determined by the anode position and by the substrate position are shown.

For the case of other substrate orientations, the cosine rule must be considered as shown in the given Knudsen Formula (15).

2.3. The Inter Electrode Phenomena

Now, if the anode material temperature is sufficiently high, the vapor pressure increases to a value able to allow for plasma formation (above the anode) by electron-vapor particle ionizing collisions.

The potential of just formed plasma, which is a conductive medium in intimate contact with the anode, will follow the anode potential increase or decrease. However, the plasma potential will always be smaller than the anode potential (at least for discharge currents used in TVD technology), as it will be shown later in this review article.

That means that near the anode, a positive potential jump will appear, which ensures the plasma electron acceleration to produce the continuous evaporation of the anode and to maintain the stationary function of the discharge.

In Figure 2a, TVD plasma is shown together with the line along which the plasma potentials were measured using an electron emission probe. In the right figure, the measured plasma potentials are given for different anode potentials, namely 850 V (red), 750 V (green), 700 V(pink) and 600 V (black). The space origin was chosen as the anode position.

From the potential distribution curves experimentally measured, it is clearly seen that a positive potential jump is formed near the anode in order to accelerate the plasma electrons towards the anode, as mentioned above.

When increasing the anode potential, the plasma density and conductivity will also increase. This increases the plasma current and number of electrons flowing towards the anode. In turn, it will decrease the anode potential fall necessary to maintain the evaporation rate because in this case, the number of electrons is increased.

Furthermore, the plasma potential is seen to be of the order of hundreds of volts and is practically constant along a vast discharge space in the inter electrode gap.

As will be presented further, a lot of interesting peculiarities of this kind of discharge appear.

By this technology, one can see that a continuous deposition of the chosen anode material is processed in high vacuum conditions, being assisted by a high energy ionic bombardment of the just-forming layer.

It is worth noting that the nature of the ions is identical to that of the evaporated particles, and that no gas is present in the deposition chamber. Furthermore, as previously stated, the energy of these ions can be easily adjusted by adjusting the anode potential. More details will be given later.

3. Different Arrangements of TVD Components

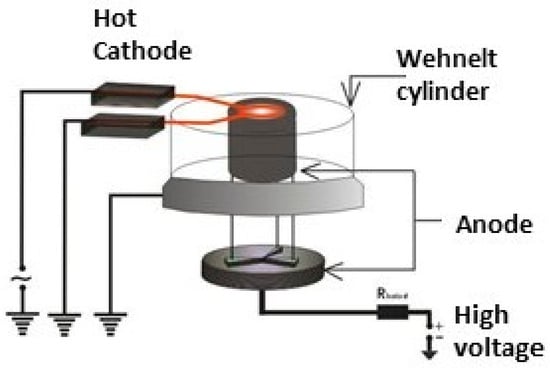

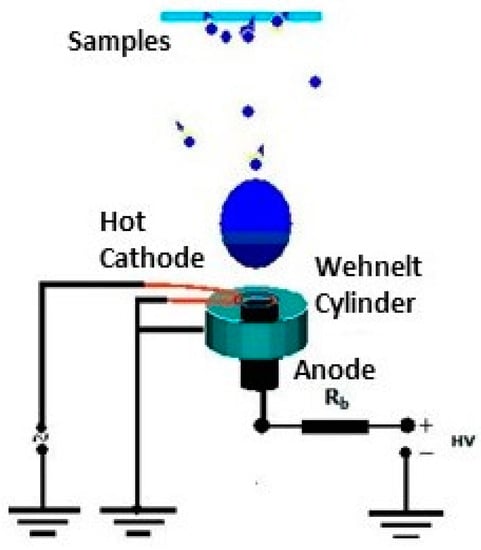

3.1. Electron Gun Arrangement for TVD

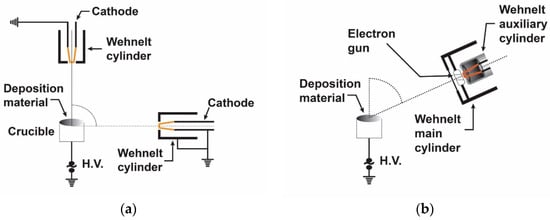

Figure 3 shows the standard experimental setup, where an electron gun is used as a cathode which is mounted and tilted at an angle with respect to the vertical traced up from the anode.

Figure 3.

Electron gun TVD arrangement with different cathode positions: (a) the cathode angle is 90° and (b) the cathode tilt angle is greater than 0°.

The discharge parameters together with the deposition efficiency drastically depend on this cathode tilt angle relative to the vertical line. The plasma burning conditions are better at low tilt angles, but the open space available for deposition is limited. On the contrary, high tilt angles result in harsher burning conditions (higher discharge voltages), but more open space for deposition.

The substrates to be covered with deposited material are placed above the anode when the cathode tilt angle, ά, is greater than 0° Figure 3b.

The possibility to tilt the cathode position allows the heated anode to be exposed to the electron bombardment of the filament but also to have a geometry that allows the plasma and the particles to expand towards the sample holder.

One can see a Whenelt cylinder around the filament dedicated to providing an easier discharge breakdown in anode vapours due to its electron lens action on the anode surface.

Indeed, the role of this cylinder is to facilitate a good electron concentration on the anode surface before the discharge ignition. This way, the electron heating is concentrated on a small anode area and the evaporation becomes more effective, as in the case when the Whenelt cylinder is not present and the electron beam spreads over the greater area.

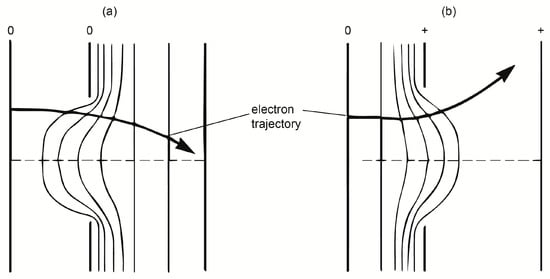

To understand the electron concentrating action of a hole as that of the Whenelt cylinder, in Figure 4, an oversimplified action is schematically presented (on the electrons) of a potential electric field combination determined by a metal hole, situated between two electrodes, all being mounted in vacuum space.

Figure 4.

Schematic potential (a) and electric field distribution (b) around an aperture.

The constant potential lines are marked together with the electron paths, as determined by the electric forces, when different potentials are applied on the cathode, aperture and anode. A deeper look inside the study of the electron optics phenomena can be found in [9,17,18].

As seen from the above presented scheme of the electron gun arrangement, the Whenelt cylinder can be considered as being the focusing hole given in Figure 4, with the filament as the grounded cathode, and anode as the positive electrode shown on the right side of the same figure.

From Figure 4, one can see that, depending on the potential applied on the Whenelt, when the filament is earthen and the anode is at a high positive voltage, the electrons can be concentrated on the surface of the anode, or diverged, just before the discharge is started. The concentration action acts only when it is necessary to concentrate the electrons on the anode to decrease the breaking down potential. Following that point, plasma substantially perturbs this potential distribution and its concentrating impact; however, this effect is no longer required because the discharge burns at lower voltages.

From these considerations, when the Whenelt cylinder is mounted insulated from the filament and a particular voltage is applied on it, the thermo-emitted electron beam can be concentrated at different distances from the filament where the anode is fixed.

In this case, the ignition moment can be optimized for lower anode voltages, and this can lessen the construction conditions imposed to the discharge source. This way, its maximum voltage can be lowered.

In addition, the ignition voltages can be reduced by increasing the cathode heating current, as discussed further in this review article.

Further considerations concerning the electron movement in the electrical fields in vacuum can be found in [9].

3.2. Ring Cathode TVD Arrangement

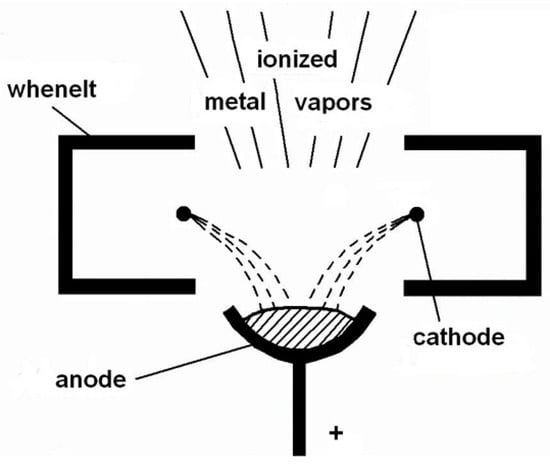

Another TVD arrangement is presented in Figure 5 which is known as ring cathode TVD. This arrangement was first described in [11].

Figure 5.

Old ring cathode TVD (TVA) arrangement. Reprinted/adapted with permission from Ref. [11]. © 1996, European Physical Society.

Here the previously described electron gun arrangement was replaced by a tungsten ring mounted just above the anode material.

The Whenelt cylinder was replaced by a complicated piece, described in Figure 5.

The subsequent versions of ring cathodes, as shown in Figure 6, utilized a simpler Whenelt cylinder, allowing for a much more practical opening space in front of the probe substrates.

Figure 6.

The new ring cathode structure.

This allowed for a higher deposition rate with this geometry.

The evaporated atoms and generated ions pass through the cathode ring and are deposited on the above mounted substrates.

The deposition rates are greater this time, compared with those obtained by the electron gun arrangement.

Here, the plasma flows through the cathode ring towards the substrates which is different from plasma jets generated in a usual plasmatron type installation, where the plasma flows through the hole drilled through the anode.

Two main technological differences appear directly when using these two structures:

- In the case of the electron gun structure, the highly positive anode is openly “seen” by the earthen probe substrate. As plasma potential is situated near the anode potential, as mentioned above, the plasma ions coming to the probes are accelerated towards and bombard them with energy of the order of eVp which frequently, can be situated around one keV. This will contribute to building up a good, structured coating on the substrates.

However, because plasma ions are mostly directed to the cathode, when the ionization rate increases in comparison to the particle evaporation rate, some unusual behavior of the deposition rate appears, as seen below.

Indeed, the deposition rate can decrease when increasing the power introduced into the plasma.

- 2.

- In the case of ring cathode structure, the probe substrates are directly “seen” by the anode and the ions are guided this time towards the probes contributing aside with atoms to a continuous increase in the deposition rate as the introduced power in the plasma is increased.

On the other hand, because the earthen cathode ring is now positioned between the anode and probe substrate (at zero voltage), a partial electrical screening between anode and substrate develops. This in turn will decrease the energy of ions coming to the forming deposition.

To summarize, the gun cathode configuration ensures a higher ion energy bombardment of probes whereas the ring cathode geometry gives a higher deposition rate with lower ion energy.

However, in the case of conducting substrates, the ion energy can be increased by applying a negative bias on them.

4. TVD Considerations from the Electrical Point of View

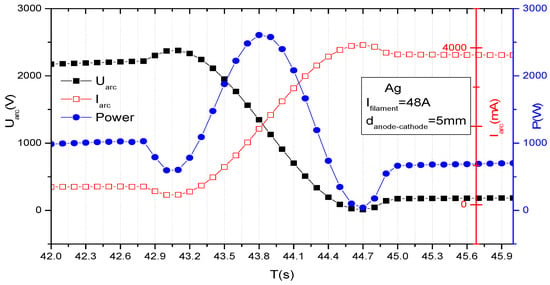

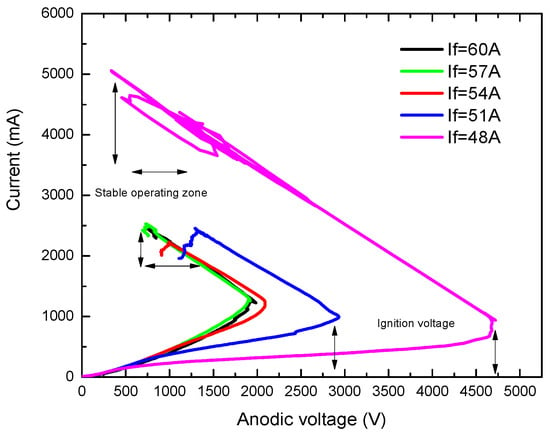

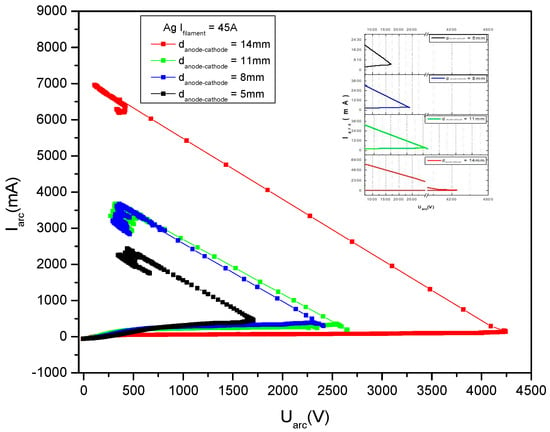

In order to evaluate the temporal evolution of the discharge electrical parameters during the TVD ignition for a silver plasma, keeping the cathode-anode distance constant at 5 mm and the filament current at 48 A, we acquired the inter-electronic current and voltage as it is plotted, along with the discharge power in Figure 7, previously published in [12].

Figure 7.

Example of temporal evolution of current, voltage and power during TVD ignition.

Starting with cathode filament heating that ensures a thermos-electron current of the order of 0.1 A. in high vacuum conditions, when applying high positive voltage on the anode of the order of kilovolts, the current, voltage and power vary as time passes. Here, one can see that the maximum power is obtained (at t = 43.8 s) after the plasma ignition moment (t = 43 s) and becomes smaller after the stationary plasma conditions are attained (t > 450 s).

A possible explanation of time variations of the voltage applied between the anode and cathode, and of the discharge current, may be given as follows:

For the time, t, running in the domain interval, 42 s < t < 42.75 s. the applied voltage, Udisc, together with electron current, Idisc, coming from the heated cathode (there is no plasma yet) are practically constant. That means that the applied voltage can sweep all the electrons thermo-emitted by the cathode. The electron bombardment of the anode creates an atmosphere of vapours around the anode which can create a slowdown of electrons by the newly appeared electron-atom collisions, and temporarily decrease the electron current (no ions are yet produced). The discharge current decrease causes a voltage decrease on the load resistance mounted in series with the discharge and a voltage applied on the discharge increases, as shown on the figure. In this circumstance, the vapor ionization can blow-up, resulting in an increase in the discharge current. Therefore, the voltage applied on the load resistance increases and the remaining voltage available from the source, which is applied in series with burning plasma, decreases. During these transient phenomena, the applied power attains maximum value at approximately 43.8 s, when the space atom density is increasing. The discharge current continues to increase and consequently the applied voltage continues to decrease, attaining its maximum (minimum) value at t = 44.7 s. when the power on plasma becomes minimum. Here, the evaporation rate is expected to decrease, and the ionization rate is expected to decrease too. Consequently, the discharge current decreases and the discharge voltage increases, leading to a slight increase in discharge power until t = 45 s when the stationary state of the discharge is obtained. For t > 45 s, the plasma voltage, current and power are stationary, as seen on the curve.

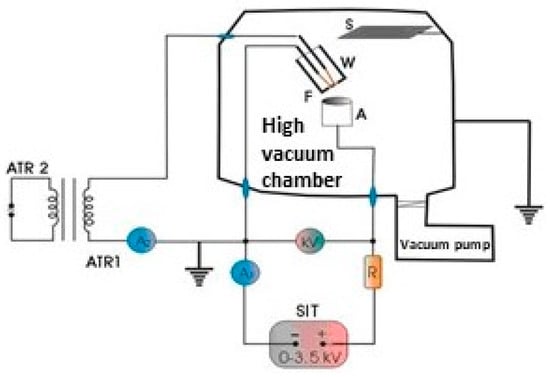

The used electrical circuitry is presented in the Figure 8. The discharge chamber, as well as the electron gun and anode setup, are sketched. The electrical circuitry for ring cathode filament is similar but the filament, anode and Whenelt positions are changed in a way which will be shown later.

Figure 8.

The electrical circuitry.

The voltage is measured between the anode and the cathode while the current corresponds to that flowing through the discharge, load resistance, R and the high voltage source.

The temporal discharge evolution V-I characteristics presented in Figure 7, show that the discharge current steadily increases with applied voltage up to the usual knee of the curve, where the voltage begins to decline, accompanied by a rapid current increase. From the knee further, the plasma is ignited in the evaporated atmosphere formed above the anode. Visually, one can see firstly a bright spot just over the anode which extends out around the anode in the neighbouring vacuum space. That means that the ionized or excited anode particles formed by their collision with the electrons are expanding around the anode.

There, a remark must be made, namely the plasma is formed in the anode-evaporated particles, the rest gaze pressure being made low enough as to impede any stray gas discharge in the discharge chamber.

Additionally, the possible cathode sputtering is very low since the discharge current is still low and the filament tungsten material has a very low sputtering yield.

This regime of discharge can be labelled the glow discharge, sustained by a cathode filament external heating.

For example, in an electrical discharge burning in copper evaporated atoms and having currents lower that 4 A, when decreasing the cathode heating, the electrical discharge extinguishes. That means that for these currents, the plasma burning is only feasible when the filament cathode is externally heated.

For discharge current values over 4 A, if one tries to decrease the cathode heating current, firstly, a slight discharge current decreasing accompanied by a plasma voltage increasing is observed, which is followed by a rapid discharge current self-increase.

Then, the cathode filament becomes white bright and even the Whenelt begins to radiate a light which becomes whiter in time. The discharge current increases and plasma voltage decreases. This behavior can be explained as follows:

Before plasma ignition, the thermo-electrons are produced only by external cathode heating, no other charged particles being present between anode and cathode yet.

After the anode heating, the early formed vapours give the possibility for plasma ignition and for the plasma ions to be accelerated towards the cathode. Their bombardment contributes to an additional heating of the cathode.

For low discharge currents (under approximately 4 A), this contribution is not sufficient to maintain the discharge when reducing the external heating of the cathode, and this was also experimentally proved.

In the case of copper vapours, at discharge currents of 4 A, the contribution of plasma ion bombardment to cathode heating (if the Whenelt is at zero potential, its temperature increases even if it is not externally heated) becomes dominant, and the discharge is no longer extinguished experimentally, even when the filament heating is removed. Initially, for the discharge currents greater than 4A, when decreasing the external cathode heating and maintaining a constant high voltage applied from the source, the discharge current slightly decreases which leads to discharge voltage, Vpl, increasing as can be seen from Equation (16):

where Esour is the voltage applied from the high voltage source, Id is the discharge current, Rload is the load resistance and Vpl is the positive potential applied on the anode.

Esour = IdRload + Vpl

That means that the number of incoming ions decreases but the energy of each singular ion increases. As a result, the energy introduced into the cathode by the plasma ions bombardment can overall increase. The filament temperature rises, as does the electron emission. As a results, the discharge current increases, which continues even after the external heating of the cathode is turned off.

Visually, the cathode filament’s light emission intensifies, with the radiated spectrum shifting from a reddish to a bright white colour. Furthermore, if the Whenelt cylinder is earthen and can receive ions from the plasma, it will glow until white, contributing to an increase in total cathode electron emission and a quick plasma discharge explosion. From now on, the discharge current would indefinitely increase if no load resistance were provided.

This is the proper self-maintained arc discharge, that is the real TVA. These considerations suggest using the thermionic vacuum discharge (TVD) terminology which, as can be inferred from the above presented considerations, includes the old used thermionic vacuum arc discharge (TVA) denomination.

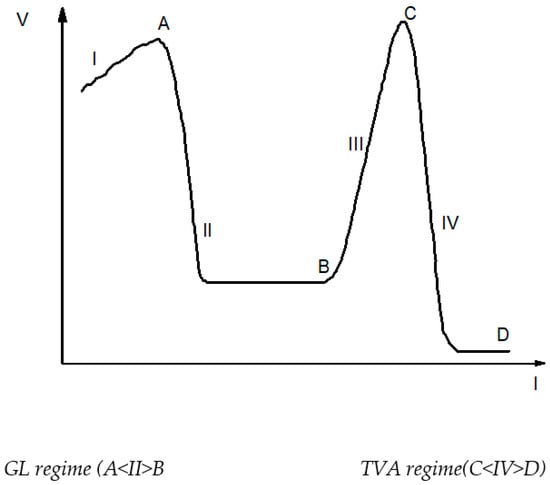

In conclusion, two discharge distinct regimes appear within the TVD discharges:

- -

- Glow-like (GL) regime for low current-high voltage discharge with the voltages of hundreds of volts and with 0.1 to about 4 A discharge currents (for copper vapor discharge), when the plasma burning decisively depends on the external cathode heating. As will be presented below, this regime will allow for good enough deposition rates but in the presence of high energy plasma ions that bombard the forming deposition layers.

- -

- Thermionic vacuum arc (TVA) regime when low voltages are applied on the discharge and the plasma currents are higher. Depending on the geometry of the electrode arrangement and the plasma parameters, the deposition rate can be greater in the TVA regime than that obtained in the GL regime. The reason for this is that very high-density plasma expands in the surrounding vacuum space, but the energy of plasma ions is low due to the plasma potential, which is also low, with the anode potential being in the order of ten volts and the discharge current varying from 5 A to hundreds of A, as also reported in [19]. A qualitative behaviour of the TVD is presented in Figure 9 for different discharge currents [20].

Figure 9. The two TVD regimes for different plasma parameters.

Figure 9. The two TVD regimes for different plasma parameters.

From the above so far presented description, one can derive the following characteristics of the TVD technology:

- -

- The film deposition must take place only in high vacuum conditions. If the rest gas pressure is not low enough, a stray auxiliary discharge can be ignited in the rest gas, and this will make the anode evaporation generation difficult and also it allows for the deposition material poisoning.

- -

- The cathode material must be tungsten, the material with the highest melting point which allows for high electron emission when heated to temperatures below the melting point. If one considers the low tungsten sputter yield and the low discharge currents in the GL regime, the net advantage of using a tungsten thermally heated cathode for high purity thin layers deposition becomes obvious.

- -

- The discharge currents can be varied in a large domain from some tens of milliamps to some hundreds of A as desired.

- -

- The anode evaporation is induced by electron bombardment of its surface which deliver their energies to the solid anode and induces its evaporation;

- -

- The deposited layer is formed in the condition of genuine ion bombardment with variable energy (of order of hundreds eV) as it will be shown later on;

- -

- The deposition rates can be varied in a very large domain since one can use both GLD and TVA regimes by discharge parameters variation;

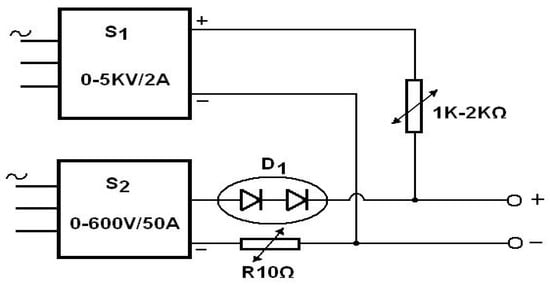

In this case the anode voltage source must furnish both low current, high voltages and high current, low voltages. A simple possible electrical scheme also used by the authors of the present review article can be similar with that presented in Figure 10.

Figure 10.

S1 is a low current, high voltage source and S2 is a high current, low voltage source.

The above scheme can be expanded in a similar way with another source having higher current, lower voltage capabilities for arc discharges generation and high-speed deposition of layers for different industrial purposes.

The discharge variable parameters are the filament heating, the anode potential, the anode-cathode distance, cathode tilt with respect to the anode vertical (in the electron gun cathode case) and ballast resistance as well. All these parameters can be altered to monitor the deposition processes in a manner dictated by the real necessities.

5. Deposition Rates Obtained with Different Geometries

5.1. Electron Gun Geometry

In this section, the deposition rate dependence on filament heating current, discharge current, voltage and amount of electrical power introduced in plasma is highlighted as presented in [21,22].

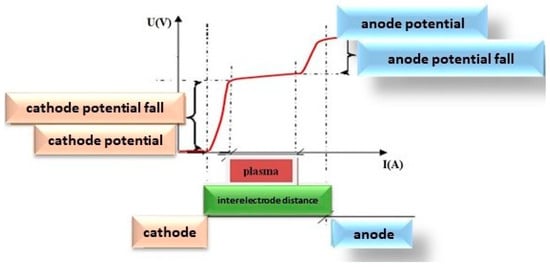

To better understand the deposition phenomena, firstly it is worthwhile to present the general potential change along the anode-cathode distance as it resulted from many measurements carried out with an emission electrical probe and given in Figure 11.

Figure 11.

Schematic dependence of electric potential in different points of anode-cathode gap.

As in other common gas discharge scenarios, a cathode potential jump forms in front of the cathode, accelerating electrons and ions towards the cathode. Then follows the plasma region which is a conducting medium, and the anode potential jump which accelerates electrons towards the anode, this way ensuring the necessary anode heating which in turn ensures maintaining a constant level of the anode evaporation because, otherwise, the discharge would extinguish due to the lack of “of gas”.

Indeed, the vapors present a special kind of gas since this “gas” condenses on the walls of the discharge chamber and on any other cold solid surface present within the deposition chamber (this way disappearing as a gas phase) and consequently, it must be continuously replenished.

An extensive study of the deposition behavior in TVD technology was carried out in copper vapor discharge [22].

Namely, the deposition rate, and the plasma ion energy dependences on discharge parameters when using TVD technology are to be presented below, especially when the electron gun cathode arrangement is used.

It is indeed very important to know how plasma parameters can influence the deposition rate to properly monitor and optimize the deposition process.

The main parameters that were changed during the deposition process are the cathode heating current, the discharge current and the positive high voltage applied on the anode. Another parameter influencing the deposition conditions is the anode-cathode distance which also can be changed during the process, but it will not be presented here.

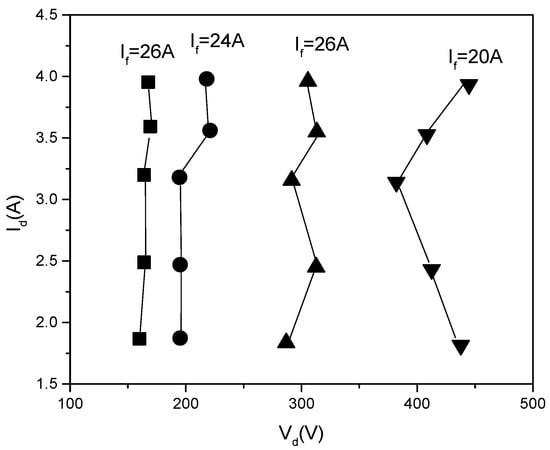

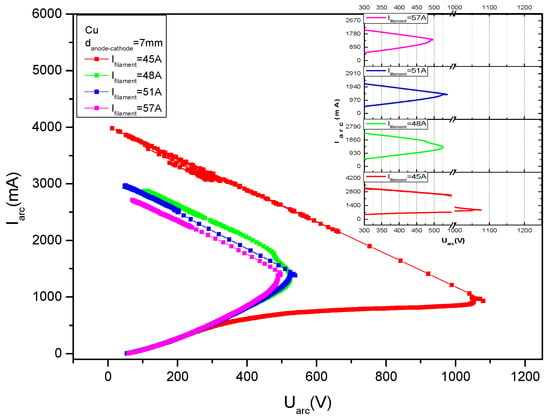

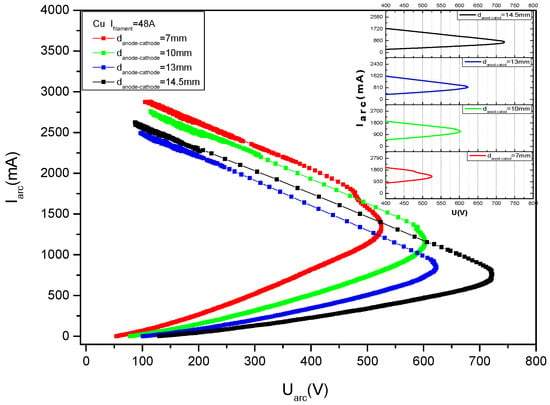

Figure 12 gives some V-I characteristics measured in copper vapors for different cathode filament heating currents, namely 20 A, 22 A, 24 A and 26 A.

Figure 12.

V-I characteristics measured in copper vapors, for different filament heating currents values, If, marked on the figure.

One can immediately see that the discharge current, Id, increases practically at a constant discharge voltage, Vd, except for the curve for the lowest filament heating current, say If = 20 A.

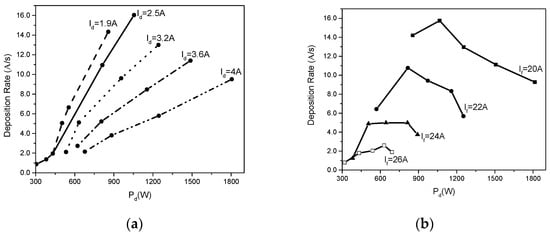

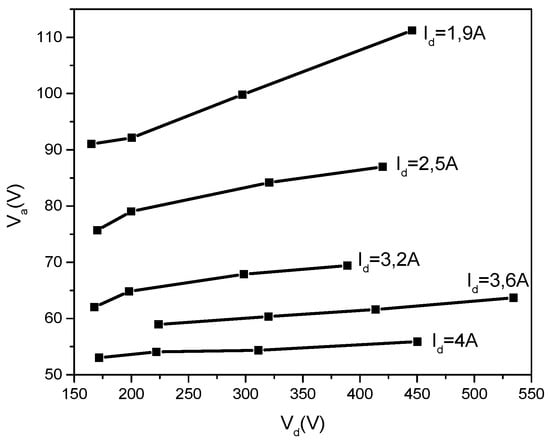

In Figure 13, previously published by the authors in [22], the deposition rates against the power applied on the discharge, Pd, are plotted for different discharge currents, namely Id = 1.9 A, 2.5 A, 3.2 A, 3.6 A and 4 A, and for different cathode heating currents with the same values as in Figure 12.

Figure 13.

(a) Deposition rate dependence on the discharge power for different discharge currents shown on the curves and (b) deposition rate dependence on the discharge power for different cathode heating currents, marked on the curves.

When measuring these data, a certain filament heating current was first chosen and by changing the anode potential, the discharge currents were measured together with the deposition rate on the probes.

Multiplying the voltage with the discharge current, the applied power was obtained, and the deposition rate was drawn as shown in Figure 13.

From these curves it is obvious that the deposition rate increases with the discharge power for the same discharge current but decreases when the discharge current increases (Figure 13a).

In Figure 13b, one can see that the deposition rate decreases when the cathode heating filament is increased, and for the same filament heating current, first the deposition rate increases with applied power, attains an apex and then decreases.

This apex is displaced to higher power values when the cathode heating current value is decreased.

Further on, a possible explanation of these special comportments will be presented.

Experimental measurements were taken for both deposition rates and plasma ion energies and for different plasma parameters shown above.

The deposition rates were recorded by a Cresington quartz balance while the ion energies were measured by a retarding field device mounted near the probes to be covered.

Let some general considerations be made concerning the behavior of the ion current variation against the positive potential applied on the collector of the ion energy measuring device.

It must be underlined here that the plasma electrons are impeded to arrive to the device by the plasma device (earthen) retarding potential and by a grid negatively charged, mounted in the face of the variable positive ion collector [23,24].

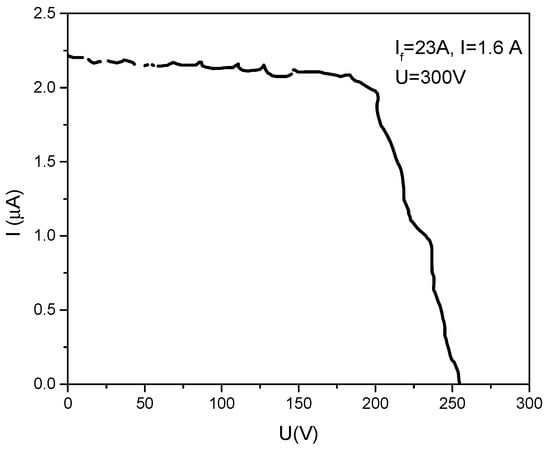

A typical recorded curve of the ion current coming from the plasma against the retarding potential applied on the collector of the ion energy measuring device is given in Figure 14.

Figure 14.

Typical recorder curve for ion energy measurement. If is the filament heating current; Id = discharge current; applied positive potential on the anode = 300 V.

The ion current arriving to the device is practically constant until the retarding voltage begins to repel the lowest energy ions coming from the plasma. Here, some more considerations must be made.

Each ion gains energy within the plasma zone and gains additional energy when it escapes from that region on the direction to the grounded substrate, due to the potential difference between positive plasma and substrate potential of substrates and of the measuring on energy device. The last source of energy is the same for all the ions, while the first one (therefore within plasma) depends on the energy distribution of ions in the plasma.

For this reason, the collector current remains practically constant until the common energy gained by all the ions from the plasma-substrate potential difference is annihilated. From that potential, the number of plasma ions decreases until the last most energetic plasma ions can attain the positive ion collecting electrode, when the collected current becomes zero. The graphic derivative of the descending curve can furnish some information concerning the ion energy distribution in plasma.

According to Figure 14, one can see that the applied anode potential being 300 V, and the middle point of the descending curve appearing around 225 V, an electron accelerating anode fall of about 75 V is formed in front of the anode. This anode potential jump ensures the electron energy needed to evaporate the anode and maintain the plasma together with particle deposition during the discharge.

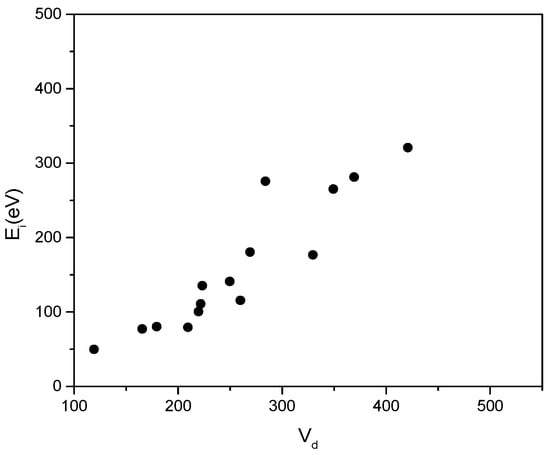

In the recorded curve, one can see that the plasma ion energy bombarding an earthen substrate is of the order of some hundreds of eV in the presented case (Figure 15).

Figure 15.

The measured plasma ion energy dependence against the anode potential Vd.

If decreasing the cathode heating current, and trying to maintain the same discharge current, one must increase the anode potential to higher values. This draws up the plasma potential too and increases the ion energy available for a more efficient ion bombardment of the forming deposition.

It is now obvious how the energy of plasma ions which bombard the substrate could be changed, namely by simply changing the cathode heating current combined with positive anode potential changing when maintaining the same discharge current.

These curves could be considered as proof of the potential variation from the cathode (zero potential) to the anode where an electron accelerating anode fall is formed, as previously stated.

The dependence of plasma ions energy, Ei = eVp, on the anode potential, Vd, as experimentally inferred, is given in Figure 15.

The measurement of this dependence can be considered as being near a linear one.

The fact that the points are slightly scattered apart can be explained by the highly different conditions of plasma potential generation, which will be discussed further.

These measurements show that, when increasing the anode potential, the plasma potential increases too as if these two values were coupled with each other.

Therefore, it is to be supposed that when a more energetic ion flux is desired to come from the plasma region towards the substrate, one must increase the anode potential.

As mentioned above, a rapid potential variation jump is formed near the anode in order to maintain the anode material evaporation. The plasma is generated by electron-anode particle (toms or molecules) ionizing collisions.

Let Vp be the plasma potential near the anode and Vd the anode potential. Because the discharge current is exclusively carried by electrons, the energy introduced into the evaporating material can be written as:

where Id is the discharge current and Va = Vd − Vp.

Eev = Id(Vd − Vp) = IdVa

Here, it must be added that the electrons possess a thermal energy within the plasma which is of the order of an electron volt that is too low to generate the anode evaporation and to be considered.

This electric energy is balanced by anode thermal radiation, anode support thermal conduction and the anode particle evaporation (atoms or molecules of the solid material).

From these three energy loss mechanisms, the second one can be reduced to a negligible value by choosing the support of the anode as a thin tungsten wire (of order of one mm diameter) introduced in a hole drilled into the anode. In fact, there is a justified interest in lessening this kind of thermal loss as much as possible.

Therefore, one can write for energy balance in front of the anode:

where Id is the discharge current considered to be formed by the electron hitting the anode (the ions are repelled there), Va is the anode potential jump which accelerates the electrons towards the anode, N is the number of the particles evaporated from the anode per second, λ is the necessary energy to evaporate a particle from the anode material, β is constant containing the thermal emissivity of the composed anode material, anode radiating surface, S, and the Stefan–Boltzmann constant σ, and T is the absolute anode temperature [10].

IdVa = Nλ + ΒT4

Among the evaporated particles, the electron–particle collisions generate a certain number of ions.

Unlike the neutral particles (atoms or molecules depending on the nature of the evaporating material) which are uniformly spread around the anode (as in the case of usual thermal evaporation), the ions are supposed to be under the influence of the electric field present between the positive anode and earthen cathode.

When the discharge vacuum chamber has earthen metallic walls, these can attract the ions from the positive plasma too.

However, the distance from the anode to the metallic walls is by far longer than the distance to the cathode. Therefore, the ionized particles are expected to be directed preponderantly towards the cathode positioned nearby.

Near the cathode, the discharge current can be considered as given especially by the ions, the thermally emitted electrons being directed towards the plasma, where they are drastically multiplied and where their density approaches the ion one. The experimental evaluations show that the saturated thermal electron emission of the cathode is of the order of 0.1 A while the discharge currents used in this experiment are of the order of some amperes.

Considering that a DC discharge current, as in the TVD case, is constant along the discharge [16,25], the conclusion is that near the cathode the main component of the discharge current is ionic. Consequently, one can write for the number of the ions entering the cathode during a second:

ni = Id/e

Here, “e” is the elementary charge (the ions are preponderantly once ionized), Id is the discharge current and ni is the number of ions entering the cathode per second.

As mentioned above, the neutral evaporated particles might be considered uniformly distributed around the anode tip as they are not being influenced by the electrical fields.

There are no particle sources or sinks between the anode and the surface on which the Cresington gauge, which measures the deposition rate, is attached, hence the particle current is conserved, allowing us to write:

Here, a is a constant depending on deposition geometry (see also the Equation (14) together with the Figure 1), R is the distance from the anode to the deposition rate measuring gauge, ρ is the density of the depositing material, D is the deposition rate given by the gauge which represents the rate of film thickness growth per second, NA is Avogadro’s number, M is the atom gram weight of the deposited material and nev is the total number of the particles arriving within a second at the spherical surface on which the deposition rate measuring device is mounted.

Besides these particles, the discharge ions entering the cathode must be added to obtain the total number of particles evaporated per second from the anode. In other words, the evaporation particle was considered as follows: the neutral ones together with a small number of ions coming there are preponderantly measured by the quartz balance while the ionized particles are considered to arrive mostly towards the cathode where they are registered as the discharge current.

In this case, the total number of the particle leaving the anode per second, N, is given by adding Equation (7) with Equation (8), that is,

On the other hand, for a given anode temperature, the evaporation rate is given by Equation (12).

A more usual formula for the evaporation rate which uses the data given in the literature for different materials is [14]:

lg(N/(Nav S) = lg p + 22.546 − 0.5lg(MT)

Here, S is the anode surface, Nav is Avogadro’s number, p is vapor pressure in torr, T is temperature in K and M is molecular weight of the evaporating material.

It must be underlined that this formula is the same as the one described in Equation (12), having different measuring units.

The Equations (21) and (22) combine to give:

Here, the relation log p = log(NkT) = A − B/T was used in order to use the experimental data given for pressure in the literature with A and B being characteristic for every material [13].

From the Equations (18), (21) and (22), the following relation can be found out:

The measured values of D, R, a and Id together with universal constants contained in the second term of Equation (22) can provide the anode temperature, T, and therefore the term βT4 once the constant value, β, is known.

The β value is difficult to quantify in the experimental scenario since the anodic materials are very different and have complicated geometry; however, it can be evaluated for current purposes as follows.

Let a Va particular value be determined from the plasma potential Vp value, as given by the ion energy measuring device (by an electrical retarding field, as announced above). This one can be written as: Va = Vd − Vp.

Once this value is determined, using the corresponding N given by the first Equation (21) (which is furnished by the experimental measurements of the total particle number arrived within a unit time at the surface where the deposition rate device is posted, together with a discharge current that arrived at the cathode of the discharge), and the corresponding anode temperature T, given by the second Equation (24) (which is theoretically derived from thermo-dynamical equilibrium considerations via the Clausius–Clapeyron Equation (10)), the β constant can be deduced from the Equation (11) with that particular measured Va value.

Further, this value can be used in Equation (23) for determining all Va values corresponding to other plasma currents, deposition rates and anode temperatures. The plasma potential Vp values can be determined from these Va values simply by writing Vp = Vd − Va and plotted against the anode potential (discharge voltages).

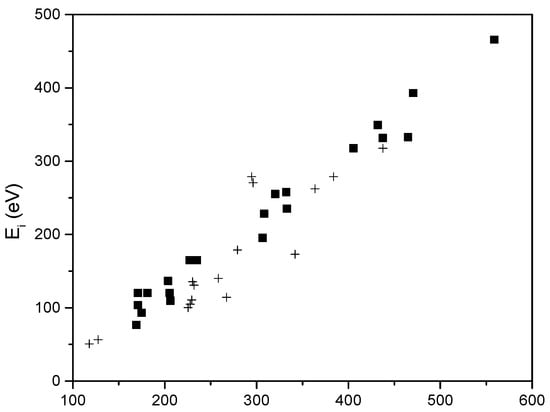

Taking all this into account, we can use Formula (17) and calculate the plasma ion energy as a function of Vd. The newly obtained values are plotted on Figure 16, along with the experimentally measured values of the energy, versus the plasma potential measured by the electric field retarding device previously presented in Figure 15 and corresponds to the retarding potential that annihilates the maximum value of the plasma ion current.

Figure 16.

The theoretical and experimental dependence of ion energy on the plasma potential. Black squares represent theoretical values while crosses represent the experimental ones.

This figure shows a good correlation between theoretical and experimental values, as well as the fact that both dependencies are linear.

Therefore, the plasma potential increases linearly with anode potential.

From the obtained data, it is interesting to plot the dependencies Va = f(Vd) and Vp = f(Vd) which can give an important inside look concerning the behavior of the TVD.

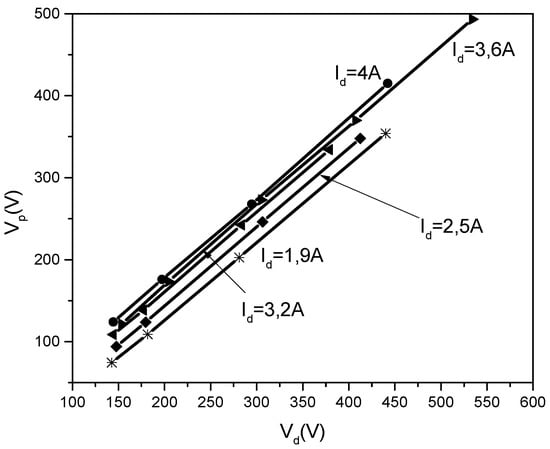

In Figure 17, one can see that the anode potential jump, Va, decreases for the same anode potential, Vd, when increasing the discharge current, Id. This seems to be logical because the greater the discharge current, the greater the electron number bombarding the anode and consequently the potential jump is allowed to decrease for a comparable anode heating energy to be obtained.

Figure 17.

Va = f(Vd) for different discharge currents (Id).

This anodic voltage jump, Va, seems to be almost constant against the discharge voltage, Vd, for the same discharge current value, especially for the higher discharge currents, while decreasing when Id increases.

On the other hand, taking a mean Va value for each curve and performing the corresponding IdVa products, one can see that all these are situated around the same power value, namely 200 W for all plots.

Considering that this power is responsible for anode heating, it is readily concluded that the anode temperature and therefore the corresponding evaporating rate is practically the same no matter what the discharge currents are.

This can suggest that the discharge current increases somehow similar to usual gas discharge cases when the gas pressure remains practically the same while increasing the glow discharge current.

Further on, one can conclude that when increasing the discharge current, that is, the evaporated particle ionization, a greater part of these evaporated particles are directed towards the cathode, forbidding them to travel towards the probes and to contribute to the deposition rate.

This explains the fact that the deposition rate decreases when the discharge current increases, as shown in the experimental data given in Figure 13a.

As for Figure 18, the Vp = f(Vd) dependencies, they are linear for the same discharge current, the higher current lines being situated above the lower ones.

Figure 18.

Vp = f(Vd) for different discharge currents (Id).

Here, it must be underlined that in the TVD case, there is the possibility to vary three parameters during the measurements, namely the anode potential (Vd), the discharge currents (Id) and the filament heating current, (If).

Accordingly, Figure 18 shows for a given anode potential, Vd, the plasma potential, Vp, increases when the discharge current increases. This creates a greater cathode potential jump which ensures greater electron acceleration across this jump and consequently an increased particle ionization rate necessary for a higher discharge current.

A particularly strange behavior revealed the deposition rate dependence as plotted against the electrical power introduced into the plasma, for a fixed filament heating current, shown in Figure 13b.

First, the deposition rate increases when the filament heating current decreases. This can be explained by the fact that when If is higher, a lower power is necessary to be introduced into the plasma for the same Id currents and consequently, the deposition rate is lower too.

However, the curiosity appears when choosing a certain If, and plotting the deposition rate against the plasma power (as given by the product Vd Id). Firstly, the deposition rate increases with plasma power, attains a maximum and then decreases with increasing plasma power. That means that the deposition efficiency decreases.

Next, a tentative explanation for this strange dependence will be presented, considering that in case of these special discharges, the « gas » generation (the evaporated atoms) and its ionization are simultaneously produced by the same agent, while the electrons are both emitted from the heated cathode and generated by electron-atom collision.

From Equation (18), the partial power spent for atom evaporation within a second is given by:

λN = IdVa − βT4

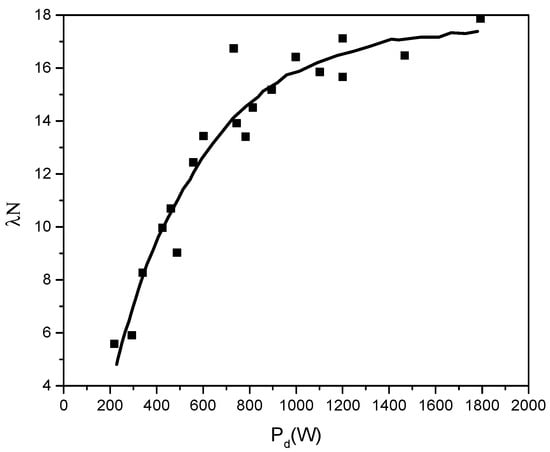

From the above presented data, this value can be calculated and plotted against the corresponding discharge power, Pd = IdVd.

This graph is drawn in Figure 19.

Figure 19.

Partial power λN = f(Pd) spent for evaporation during a second.

Figure 19 shows a rapid increase in the atom generation rate for lower discharge power, which decreases for higher discharge power.

On the other hand, from Equation (21) one can derive:

Here, in the second equation, the term Id = Pd/Vd, Vd was considered to be constant for a fixed filament heating current, as seen from the measured V-I characteristics.

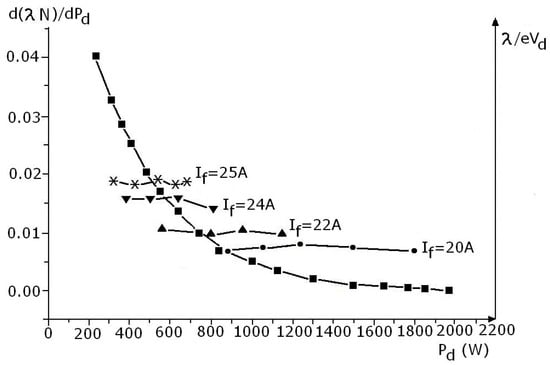

The second Equation (24) represents the derivative of the deposition rate against the discharge power. The term dN/dPd can be inferred by graphically derivation on Figure 19. Plotting the dN/DPd = f(Pd) dependence together with (1/eVd) values taken for different filament heating currents, the discharge powers corresponding to the points of intersection of these curves gives the maximum positions of the deposition rate dependence against the discharge power for a fixed cathode heating current, If.

Indeed, one can readily see that for different cathode heating currents, the maximum value of the deposition rate, D, is obtained from the condition dN/dPd = 1/(eVd) which annihilates the derivative of D with respect to discharge power, Pd, as described in Figure 20.

Figure 20.

d(λN)/dPd = f1 (Pd) and λ/eVd = f2(Pd).

It is readily seen that the maximum deposition rate is obtained at higher discharge power values for lower filament heating current values. That justifies the experimental dependencies shown in Figure 13b obtained for different filament heating currents.

All these highlight that there exists a competition between evaporation rate and ionization rate increase when increasing the discharge power:

For low discharge power, the evaporation rate increases faster with Pd, as compared with the ionization rate increasing and hence the deposition rate increases.

When Pd increases further, the evaporation rate increase diminishes while the ionization rate increases. This produces an increase in the discharge current and therefore a greater part of evaporated particles is evacuated through the electrodes and fails to arrive at the probes, mounted above the discharge gap. Finally, the net deposition rate decreases with increasing Pd, with the deposition efficiency decreasing.

Another important conclusion of the above given data can be the following one:

After heating the cathode filament and applying a high positive voltage to the anode, the thermo-emitted electrons are propelled towards the anode, they are heated, evaporation occurs and the discharge breaks down suddenly. Until the plasma occurrence, the ionizations are negligible, and all the electron energy is spent for evaporating anode material. After the breakdown, the evaporation is taken over by the plasma electrons accelerated across the anode fall Va. As suggested above, it seems that after the plasma breaking down, the evaporation rate of the anode material experiences a low increase, and the discharge behavior can be similar to that appearing in a usual gas. That means that the power spent on evaporation can be consider as being almost the same as that existent at the plasma initialization moment, at least for no very high discharge currents. In this case, the discharge power is spent mainly for electron vapor particles collisions of a different nature.

Now, let Vb be the breakdown voltage and Ib the corresponding initial discharge current which is mainly formed by the thermo-electrons elaborated by the cathode. If, after the breakdown, the evaporation rate remains the same, one can write:

where Va is the anode fall above mentioned which corresponds to the Id discharge current used during the deposition process.

VbIb ≈ VaId

Measuring the VbIb value just before the discharge ignition and the discharge current used during the deposition, the above relation can give the Va value. Knowing the anode potential, Vd, measured during the deposition process (for not very high discharge currents), the plasma potential is Vp = Vd − Va (see Figure 11), and the energy of the ions arriving to the earthen probe, eVp, can be deduced.

Experimental verification of these suppositions proved to be real and that gives the possibility to evaluate the ion energy, even when no such device is available due to different practical unfavorable situations.

As a conclusion of the above presented phenomena, one can say that this deposition method has three major independent parameters which can influence both the deposition rates and the genuine ion bombarding energy during the deposition process. These are the filament heating current, If, the anode potential, Vd, and the discharge current, Id.

The TVD technology possesses all the advantages of the thermal deposition as a possibility to localize the evaporation source and to use materials shaped as small pieces (even debris) but benefits the genuine ion energetic bombardment (of variable energies of the order of hundreds of eV) of the just-forming layers. When this energy is insufficient, the presence of ionized plasma allows the ions to be accelerated towards the substrate by applying a bias on it [26]. It is obvious that for thermal evaporation this facility is not applicable.

Moreover, while the thermal evaporation warms all quantity of evaporating material, the TVD method uses the electron bombardment of the material surface only, and sometimes it can allow for an energy saving or even can avoid the use of a crucible which can pollute the deposition purity, as will further be presented.

Indeed, when depositing tungsten, carbon, rhenium or other refractory materials, as further described when presenting the TVD technology for these materials, one can use the electronic bombardment of their surface only, to obtain a (superficial) suitable temperature for both evaporation and deposition with sufficient deposition rates, while the rest of the material is kept below its melting point.

In this case, the evaporation rate is not high, but this is in the benefit of deposition purity. Indeed, evaporation without a crucible avoids the possible contamination with the crucible material.

5.2. Ring Cathode Geometry

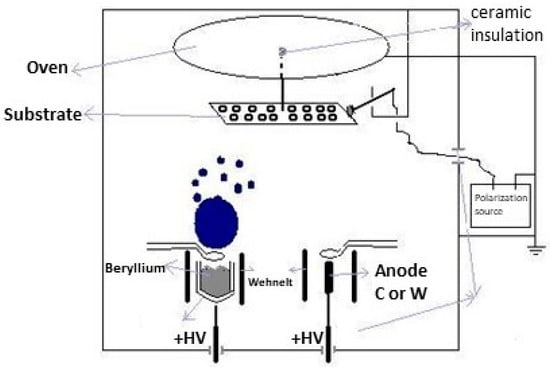

The new TVD arrangement uses a ring-like cathode filament, also made of tungsten and mounted just over the anode. The Whenelt type electric screen surrounds the filament this time, as shown in Figure 6.

As shown in Figure 6, the grounded filament allows the evaporated particles, no matter ions or neutrals, to travel towards the substrates intended to be covered. This time, the probes are mounted on the anode cathode direction and not at a tilt angle, as in the electron gun geometry assembly.

Therefore, the formed plasma and neutrals flow through the cathode and not through the anode, as in classical plasma jets devices (plasmatron, etc.).

When compared to the electron gun set-up, there is both a benefit and a disadvantage.

The advantage is that the ions are mostly directed towards the probes mounted above and which in turn helps in increasing the deposition rates with the power introduced into the plasma more efficiently because this time most of ions are directed towards the probe. Due to this fact, the deposition rate increases even when the discharge current increases.

In the electron gun arrangement, the deposition rate can decrease when the discharge currents increase, as presented above.

The drawback is that the position of grounded filament has a screening action with respect to the anode which can lower the energy of the ions bombarding the just-forming layer on the probes.

Opposite, in the electron gun geometry, the anode is completely open to the probes, the grounded cathode having a side position and this position introduces no screening between the anode and the probes.

Therefore, the amount of ions energy introduced into the bombarded probes is smaller in ring cathode configuration as compared with the case of the gun cathode.

Nevertheless, the ions can be independently accelerated or decelerated by applying a correspondent potential on the probes. These potentials proved out during different coating experiments carried out by the TVD technology to have a great importance, both for adherence and deposition structure.

The influence of ion bombardment on just forming deposition can be described broadly by the fact that ion energy leads to a local temperature increase, resulting in an increase in depositing particle mobility, which can improve particle arrangement in the new developing structure.

Additionally, when a deposited particle is loosely linked to the layer structure, it can be rapidly removed from that layer when hit by an energetic ion coming from the plasma.

This way, only the layer particles which are strongly connected with the neighboring ones will remain in the deposited structure after the action of plasma ion bombardment.

With other words, simultaneously with particle deposition, a slight sputtering effect takes place, and the layer structure is compacted and leveled at the same time.

6. Multiple Depositions by TVD Method

6.1. Simultaneous Depositions

As mentioned above, one of the advantages offered by TVD deposition technology is the possibility to easily obtain complex structured coatings due to its punctual character as an evaporation source.

Indeed, it is possible to obtain binary or ternary composed layers by igniting two or three simultaneous discharges with different discharge parameters, allowing for a large variety of previously programmed compositional depositions.

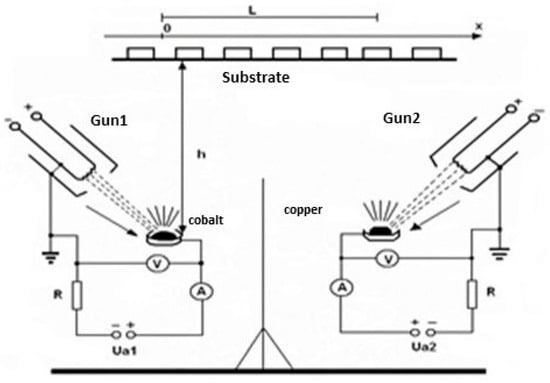

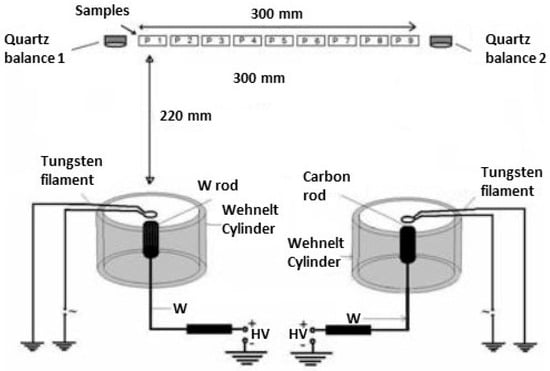

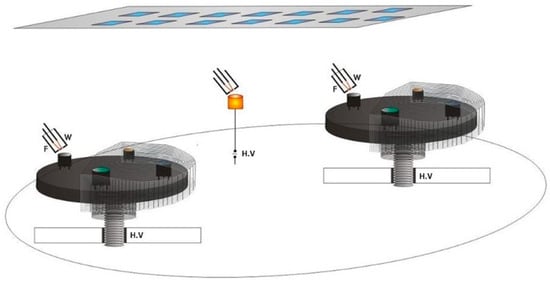

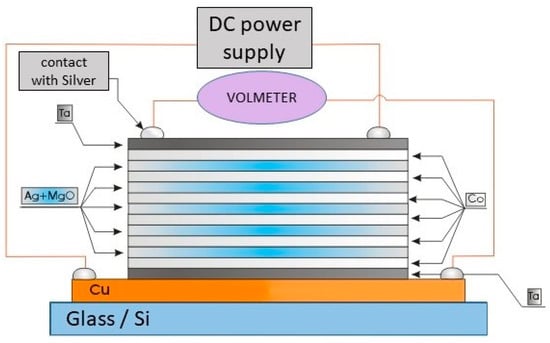

In Figure 21, an experimental arrangement used for a binary composite layer deposition is presented.

Figure 21.

Binary composite layer deposition scheme with two electron gun discharges.

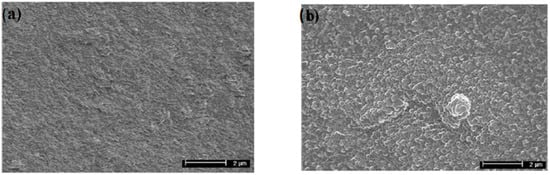

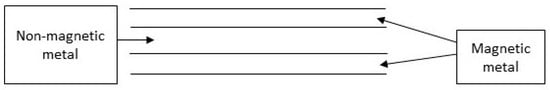

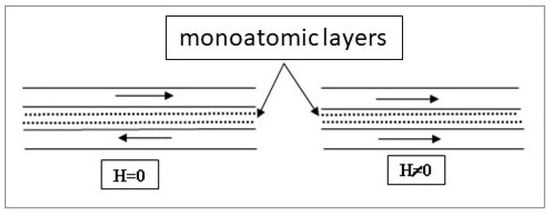

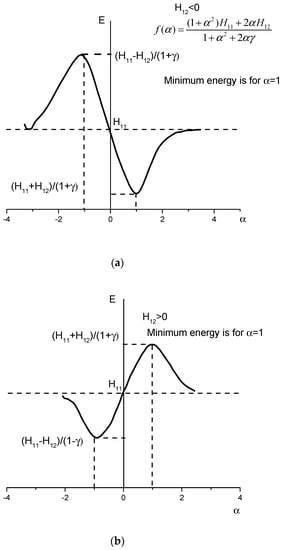

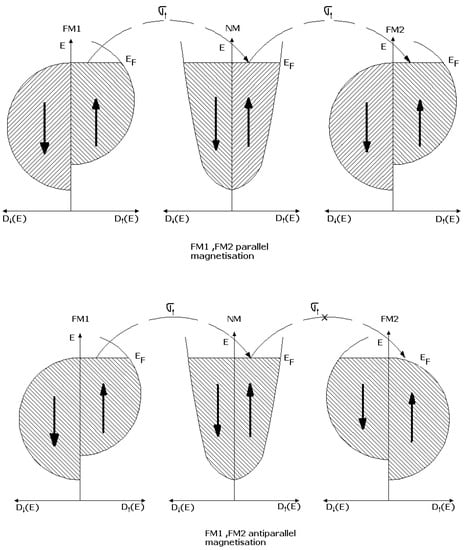

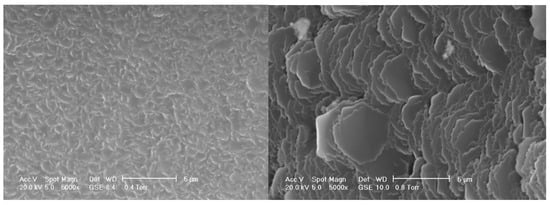

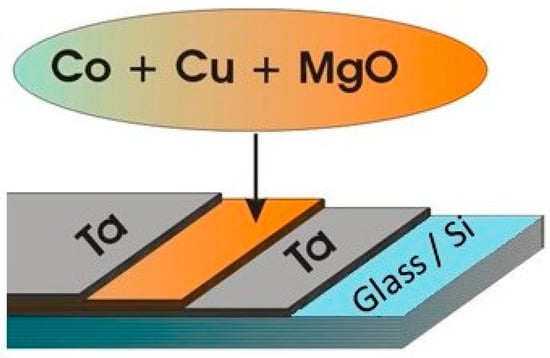

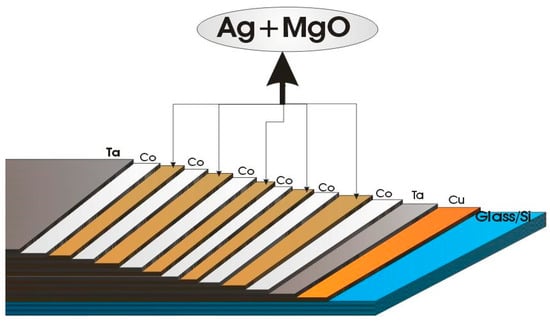

Each separate discharge uses its own high voltage source and cathode electron gun as well. To remove the mutual electrical influence between the two discharges, an electrical grounded screen is mounted between the two discharges. The screen height must be sufficient as to exclude the charges from one of the discharges to arrive in the space of the other one but not so high as to impede the evaporated particles (ionized or not) to arrive at the probes to be covered.