Abstract

The good mechanical properties of metal nitrides make them ideal surface coatings for cutting tools and mold components. Conventional TiN coatings have largely been replaced by AlTiN due to their superior mechanical properties and resistance to high temperatures. In this study, we investigated the application of bias voltage to the substrate to enhance ion bombardment during the synthesis of protective AlTiN coatings using high-power impulse magnetron sputtering (HiPIMS) with synchronous trigger-direct current (ST-DC) bias voltage. The ST-DC parameters included the duty cycle duration (3%, 6%, 12%, 18%) and turn-on time, which included synchronous (TD0) or a trigger delay of 50 μs (TD50). Scanning electron microscope images revealed that the highest deposition rate (22.1 nm/min) was achieved using TD50 with a duty cycle of 3%. The results obtained using an electron probe microanalyzer and X-ray diffractometer revealed the formation of an h-AlN structure when the Al/Ti ratio was between 0.71 and 0.74. Transmission electron microscopy and nanoindentation results revealed that transforming DC bias into synchronous bias to boost the bias output time (i.e., increasing the duty cycle) increased AlTiN grain refinement (from ~100 nm to ~55 nm) with a corresponding increase in hardness (from 22.7 GPa to 24.7 GPa) as well as an increase in residual stress within the AlTiN coating (from 0.16 GPa to −51 GPa). The excellent adhesion performance of the coatings provided further evidence indicating the importance of duty cycle and trigger delay when using pulsed-DC bias in HiPIMS.

1. Introduction

By adjusting the processing conditions to achieve a high metal ionization rate, it is possible to create high-density coatings with excellent mechanical properties [1,2]. Kouznetsov et al. introduced the idea of increasing the high-power impulse magnetron sputtering (HiPIMS) ionization rate to 70% [3]. Note that their work focused on a Cu target; however, the same approach has since been applied to other metals, such as Cr and Ti [4,5,6]. HiPIMS technology can be used to overcome the disadvantages inherent to other PVD technologies, such as direct current (DC) magnetron sputtering (loose film structure due to low ionization rate) [7,8] and cathodic arc evaporation (particle formation on the coating surface, despite a high ionization rate) [9]. The operating principle of HiPIMS is to apply short pulses of ultrahigh power to a target using a low-duty cycle (less than 10%) at a frequency of less than 2 kHz [10]. This ensures an ultrahigh peak power density (at the kW⋅cm—2 scale) [11] and a high ion fraction of sputtered species (e.g., 80% for Ti) [12]. Researchers have demonstrated the efficacy of substrate pretreatment via HiPIMS (metal ion bombardment and implantation) technology to enhance film adhesion [13]. This has led to the adoption of HiPIMS technology in a variety of fields [14,15,16], especially industrial cutting tools [17,18].

The application of a high-hardness coating to prevent direct contact between the cutting tool and workpiece is the most effective approach to enhancing the life cycle of cutting tools [19]. HiPIMS technology can be used to create high-hardness coatings of high density, particularly when a bias voltage is applied to the substrate to increase the kinetic energy of bombarding ions [20,21]. Unfortunately, all positive ions in the plasma gas (helpful as well as unhelpful) are attracted by DC bias voltage. Bombarding the workpiece with argon ions has proven effective in enhancing the compactness of the film structure; however, it tends to reduce coating adhesion by increasing internal stress [22]. The number and type of ions that are generated within a cycle vary with the characteristics of the pulsed power supply. It is possible to enhance the mechanical properties of the coating simply by adjusting the pulse characteristics in conjunction with the biasing system.

The quantity and types of gaseous ions generated during the HiPIMS pulse-on phase have been extensively studied [23,24]. Researchers have reported that the ion flux of Ar+ is higher than that of Ti+ under a short pulse-on time (0 to 25 μs), whereas the ion flux of Ti+ is higher under a longer pulse-on time (25 to 50 μs) [25]. It has also been reported that Ar+ ions account for the main ion current during the first 20 μs, while Al+ accounts for the main ion current between 20 and 100 μs, beyond which the main ion current switches back to Ar+ [26]. This has prompted speculation that HiPIMS could be combined with a synchronous bias to reduce residual stress in coatings. Cemin et al. [27] posited that by controlling the bias voltage opening time during HiPIMS deposition, it should be possible to reduce the bombardment effects of multiply charged ions on the coating and thereby reduce residual stress.

The binary metal nitride (i.e., TiN, AlN, CrN) coatings exhibit an improved lifetime of working components compared to conventional metals. However, the ternary nitride (i.e., AlTIN, AlCrN) coatings have replaced the binary coatings due to better mechanical properties at higher temperatures. The better mechanical characteristic of AlTiN coating can be altered by adjusting the parameters, including power, pressure, and bias voltage. Zhang et al. [28] reported that the hybrid AlTiN coating with lower stress can be achieved by increasing the power of DCMS via a hybrid technique combining cathodic arc evaporation and DCMS. Beake et al. [29] reported that the AlTiN PVD coating with higher Al content exhibits resistance to fracture in the nano-impact test. Li et al. [30] reported an increase in the hardness of AlTiN coatings from 28 to 31 GPa by increasing the DC bias voltage.

Researchers have had considerable success in implementing HiPIMS in conjunction with synchronous bias using a single metal target for the deposition of binary compound coatings [31,32]. Note that the composition ratio of dissociated metal and gas ions in the metal target differed from that in the alloy target. In the current study, we used an Al/Ti alloy target for the deposition of AlTiN coatings under synchronous or trigger delay-pulsed DC bias voltage with a duty cycle of 3%, 6%, 12%, or 18%. We evaluated the feasibility of the proposed bias technique by characterizing the properties of the AlTiN coatings for improving adhesion strength with lower residual stress and keeping higher hardness in cutting applications. We also studied the effects of the bias voltage duty cycle on current-time (I-T) and voltage-time (V-T) curves, as well as the microstructure, residual stress, hardness, and adhesion of the coatings.

2. Experiment Details

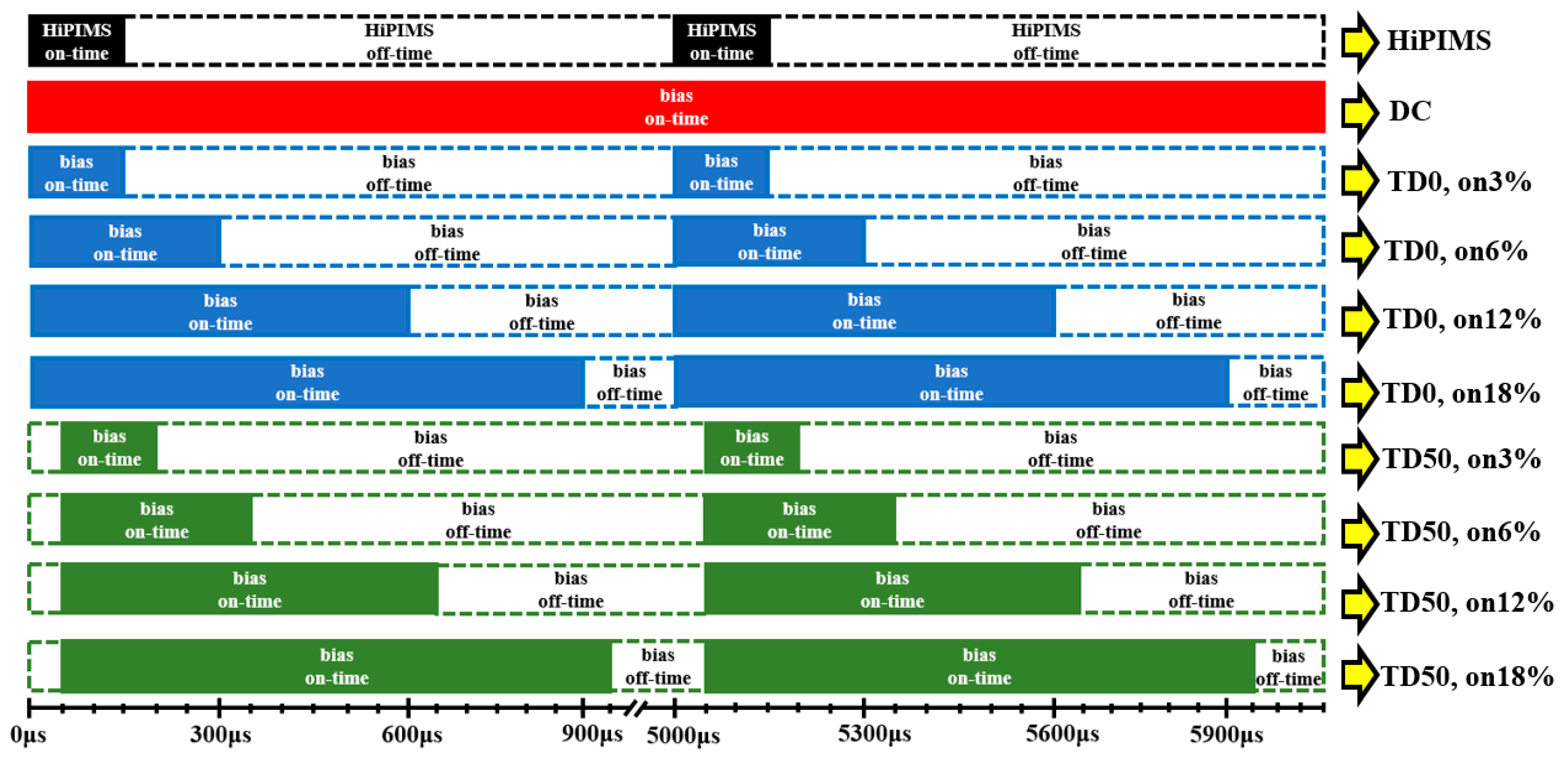

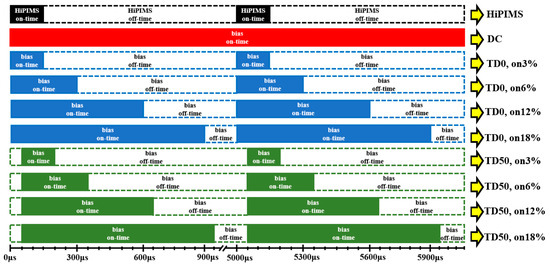

Prior to depositing the coating, the WC-Co substrate (WC, 92 at.%; Co, 8 at.%; diameter: 25 mm; thickness: 5 mm) was cleaned using an alkaline solution and plasma bombardment. The vacuum chamber (base pressure < 10−5 Pa) was equipped with a Ti target (area: 825 cm2, purity: 99.99%) for the deposition of a metallic Ti layer and an Al65Ti35 target (area: 825 cm2, purity: 99.995%) for the deposition of the main AlTiN layer. No substrate heating or rotation was used during deposition. The Ti layer deposition parameters were as follows: power (4 kW), pressure (0.4 Pa), bias voltage (−90 V), and deposition time (6 min). The AlTiN layer deposition parameters were as follows: power (4 kW), pressure (0.4 Pa), bias voltage (−45 V), and deposition time (126 min). HiPIMS power was supplied using a MAGPULS MP2-HC1000 (Germany) with a duty cycle of 3% (on/off time: 150 μs/4850 μs) and pulsed frequency of 200 Hz. Bias voltage (Hüttinger 4020, Germany) turn-on time was divided into synchronization (TD0) and a trigger delay of 50 μs (TD50) while varying the duty cycle. The names of the sample were derived from the duty cycle and trigger delay time, as follows: TD0 3%, TD0 6%, TD0 12%, TD0 18%, TD50 3%, TD50 6%, TD50 12% and TD50 18%. DC bias was applied in the control group. Figure 1 presents a schematic diagram illustrating the time sequence of the HiPIMS power supply and pulsed DC bias voltage. The black square indicates that the target power was on, and the dotted line indicates that the target power was off. The red square indicates the continuous output of DC bias voltage. The blue square indicates that the bias start time was synchronized with the target power supply, whereas the green square indicates a delay of 50 μs. Note that the size of the blue and green squares is proportional to the bias voltage duty cycle. The deposition parameters are listed in Table 1.

Figure 1.

Schematic diagram showing the time sequence of HiPIMS power supply and pulsed DC bias voltage.

Table 1.

HiPIMS parameters used in the deposition of AlTiN coatings.

I-T and V-T curves were obtained as a function of HiPIMS and bias power using an oscilloscope (GW Instek, GDS-2204E, New Taipei, Taiwan) equipped with current (GCP-020) and voltage probes (GDP-025). Field emission scanning electron microscopy (FE-SEM, JEOL, JSM-7610F, Tokyo, Japan) and transmission electron microscopy (TEM, JEOL, JEM-2100, Tokyo, Japan) were respectively used to observe the surface and cross-sectional morphology of the coatings. X-ray diffractometry (XRD, PANalytical, X’pert, Almelo, Netherlands) and selected area electron diffraction (SAED) were used to identify the crystalline structures. An electron probe microanalyzer (EPMA, JEOL, JXA-8500F, Tokyo, Japan) was used to determine the ratio of elements in the coatings. A nanoindenter (TI-900, Triboin-denter, Hysitron, Minneapolis, MN, USA) equipped with a Berkovich diamond indenter (radius of 100 nm) with a nominal tip was used to obtain the hardness and Young’s modulus of the coatings. Nanoindentation test conditions were as follows: load (4.4–7.0 mN) and indentation depth (<10% of the coating thickness). Note that nanoindentation results were averaged from no fewer than 10 tests in random locations. The Stoney equation was used in conjunction with the substrate curvature method to calculate the residual stress in the coatings. This involved measuring the thickness of the coatings and the curvature of the Si wafer before and after deposition. Details pertaining to the process of coating deposition and analysis measurements can be found in previous studies [5,6].

3. Results and Discussion

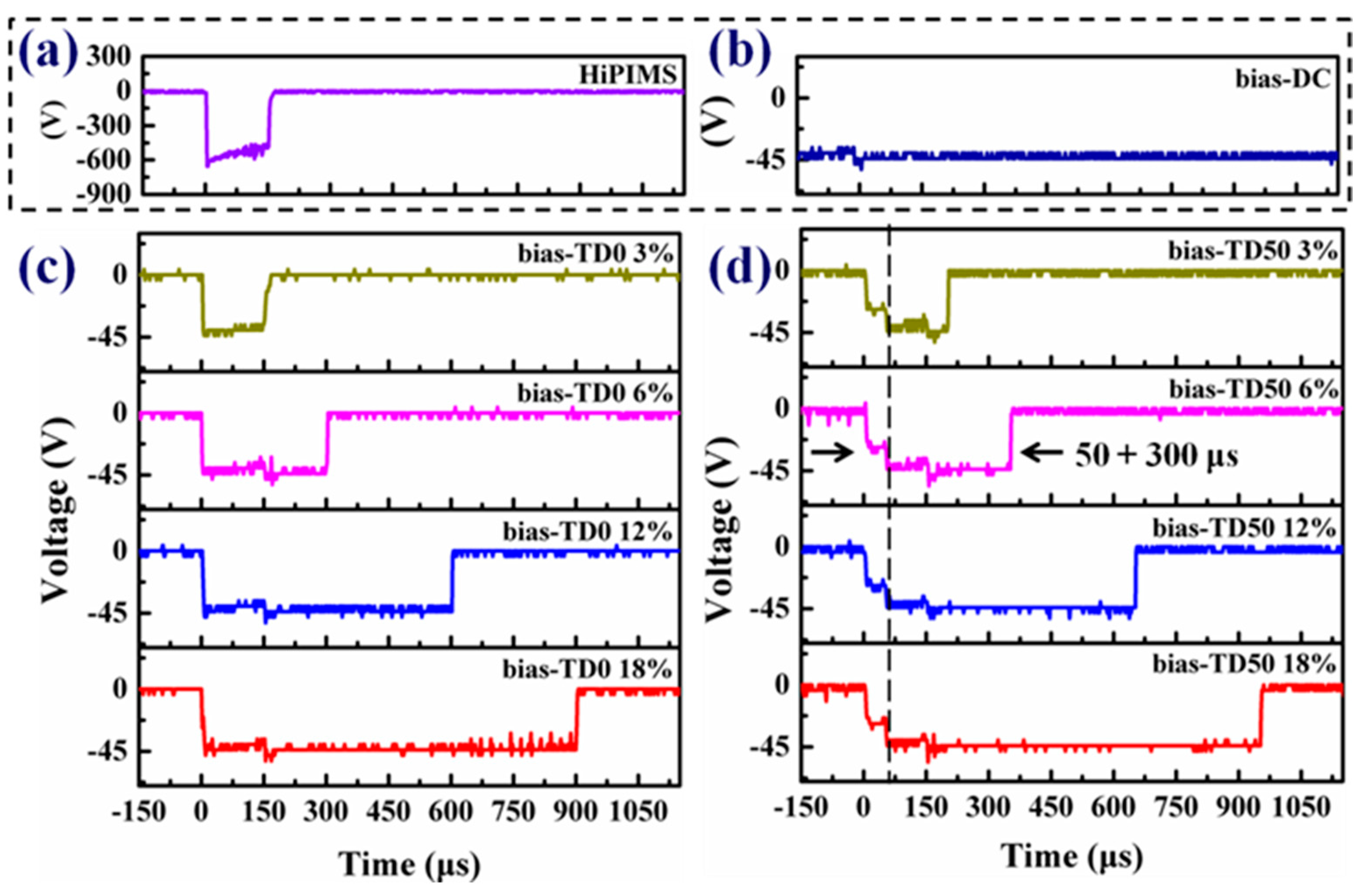

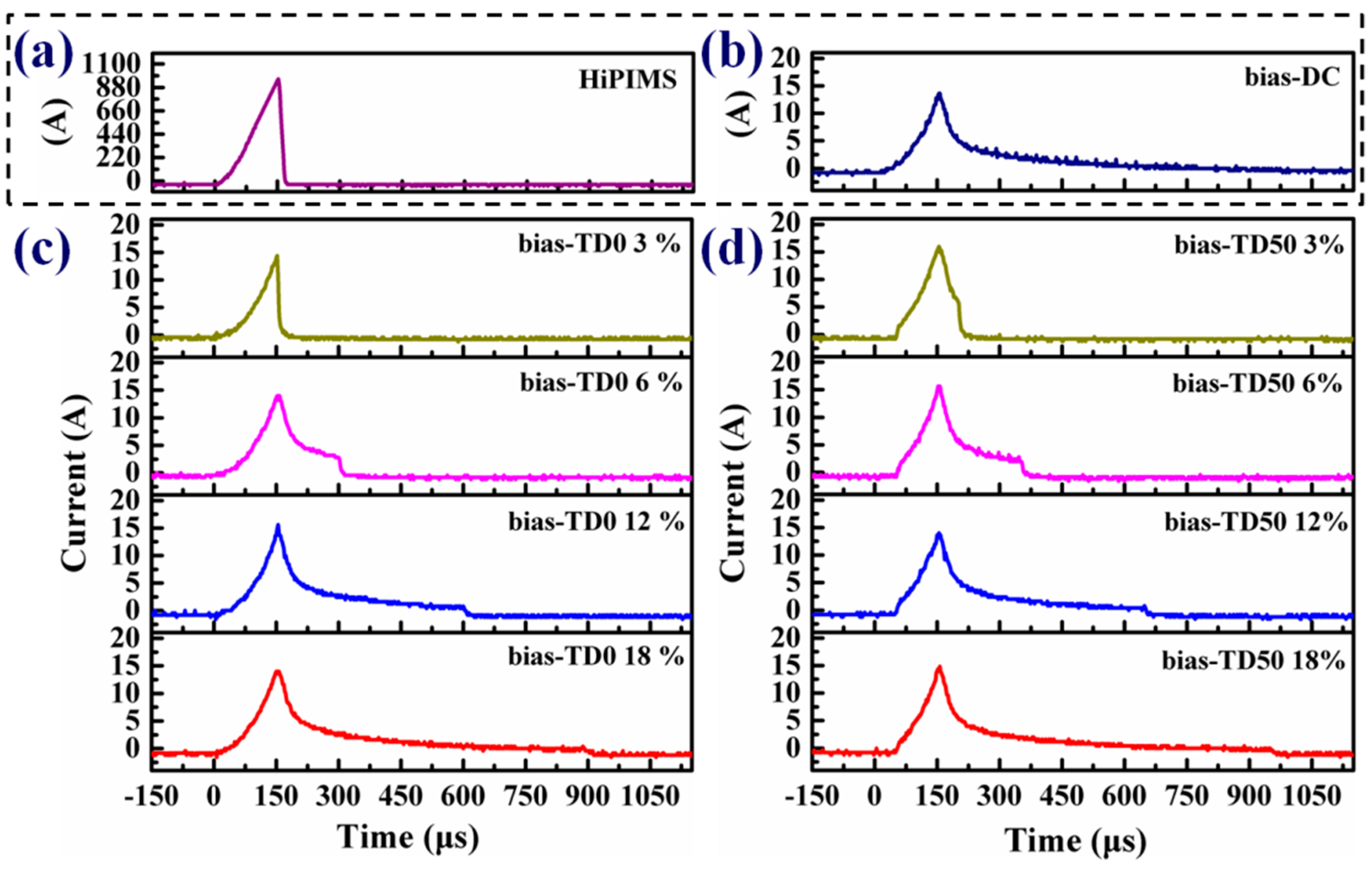

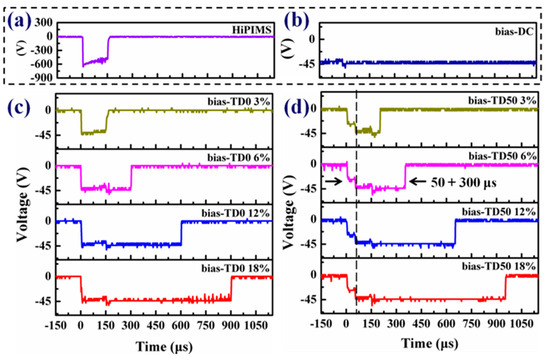

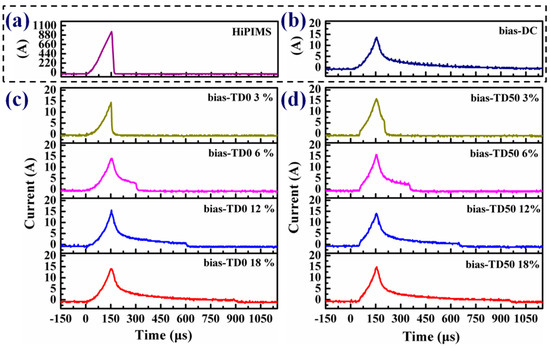

I-T and V-T curves were measured using an oscilloscope to determine the output current and voltage of the target and substrate bias. Figure 2a presents a square wave output typical of HiPIMS voltage during the pulse-on period. Figure 2b illustrates the stability of output bias (−45 V) in DC mode during the application of HiPIMS power to the target. As shown in Figure 2c, the substrate voltage in synchronous mode (TD0) was maintained at −45 V, and the bias on time was extended from 150 to 900 μs as the duty cycle was increased from 3% to 18%. As shown in Figure 2d, the substrate bias output time in TD50 mode was delayed by 50 μs, while a smaller bias output (this smaller voltage is maintained at about −23 V) was observed in the HiPIMS on-time from 0–50 μs (bias voltage is off). It has been reported that non-zero voltage values are caused by differences in floating potential on the substrate [27,33]. Figure 3a,b presents the current curves of the target in HiPIMS and substrate in DC mode. Figure 3c,d presents the current curves of the substrate in TD0 and TD50 modes while varying the duty cycle (3%, 6%, 12%, 18%). Note that varying the bias output mode altered the patterns related to substrate current. As shown in Figure 3c, the observed increase in bias current (0 to 15A) was consistent with HiPIMS output (when the turn-on time was increased from 0 to 150 μs). Current values appeared at 150 μs after the pulsed DC bias was turned on (duty cycle: 6%, 12%, 18%). Figure 3d presents the substrate current values recorded at 0 A during the 0–50 μs period with the pulsed DC bias turned off (due to a bias voltage being delayed by 50 μs), while the substrate current was observed when the pulsed DC bias turned on.

Figure 2.

Voltage waveform as a function of duty cycle: (a) Measured at the cathode in HiPIMS; (b) measured at substrate holder in DC bias; (c,d) pulsed-DC bias as a function of duty cycle under TD0 and TD50, respectively.

Figure 3.

Current waveforms as a function of duty cycle: (a) Measured at the cathode in HiPIMS; (b) measured at substrate holder in DC bias; (c,d) pulsed-DC bias as a function of duty cycle under TD0 and TD50, respectively.

Table 2 lists the peak current and average power delivered to the substrate in DC mode or pulsed DC bias (duty cycle of TD0-TD50). Note that the average values were obtained from values captured at 0–1000 μs. The higher average power (71.9 W/μs) observed in DC mode can be attributed to the DC bias voltage output during coating deposition. Note that the average power under TD0, 18% (75.2 W/μs), and TD50, 18% (74.5 W/μs), exceeded that in DC mode, indicating that bias voltage had no practical effect without sufficient ion flow. Previous studies have reported that there is a delay in the generation of metal ions following HiPIMS initiation [25]. For example, the highest flux of Ti1+ occurs roughly 25 μs after current discharge, whereas the highest flux of Al+ occurs roughly 40 μs later [23,26]. It was observed that when using a duty cycle of 3%–12%, the peak current was higher under TD50 (15.6–16.8 A) than under TD0 (15.6–14.4 A). The observed decrease in peak current can be attributed to the extended bias voltage output duration, which increased the mobility of gaseous atoms in the plasma, thereby reducing the probability of metal ions reaching the substrate [34]. Table 3 presents the element concentrations in AlTiN coatings as a function of the bias voltage duty cycle. In all samples, the Al/Ti ratio was roughly 3:1, while the Al+Ti/N was roughly 1:1, and the concentration of O was below 3 at.%. These findings confirm the formation of stoichiometric metal nitride coatings under an ultra-low oxygen environment. Note that increasing the duty cycle led to an increase in Al content, whereas decreasing the duty cycle led to an increase in Ti content. This can be attributed to differences in the time required for the dissemination of bulk dissociated Al and Ti ions [23,26].

Table 2.

Peak current and average power as functions of bias output mode.

Table 3.

Chemical composition and ratio of Al/(Al+Ti) and N/(Al+Ti) in AlTiN films as a function of bias voltage mode.

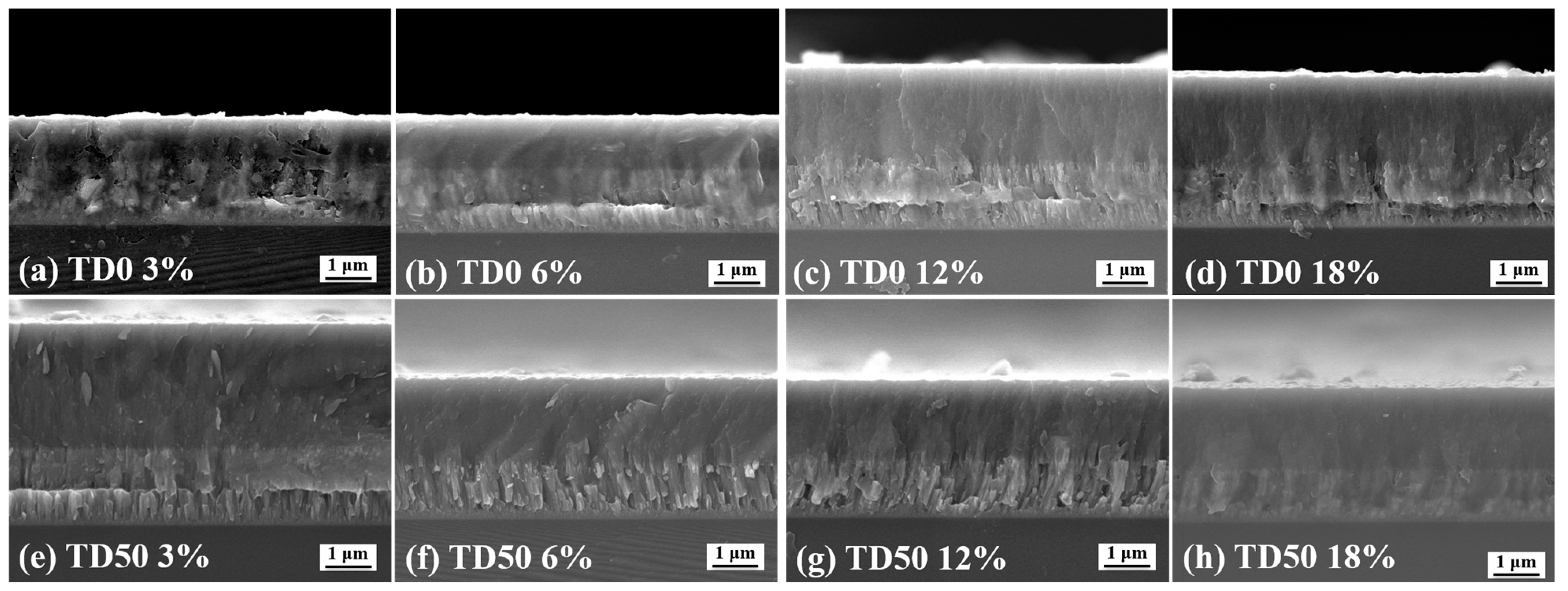

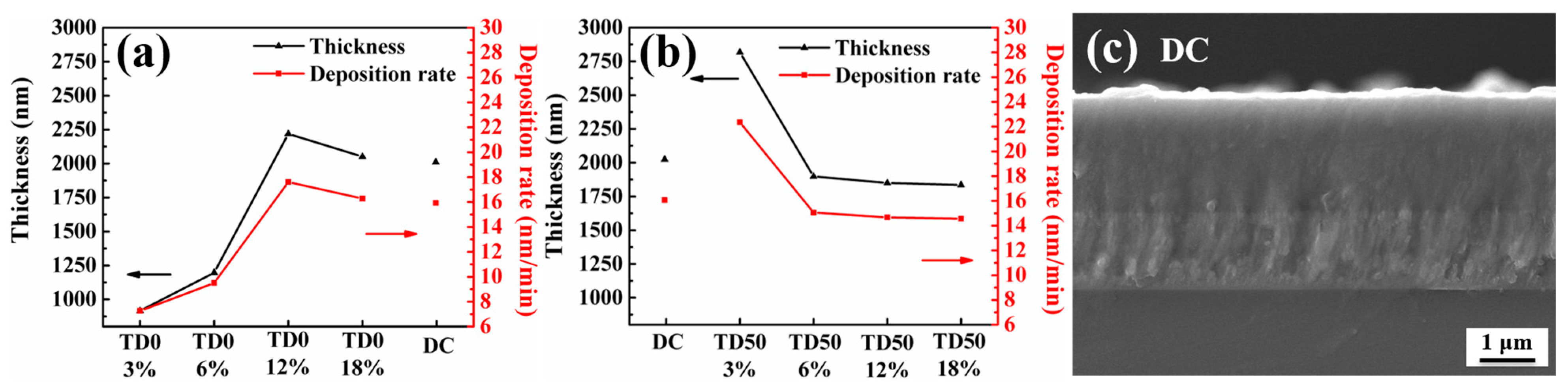

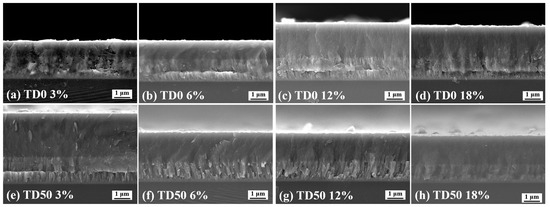

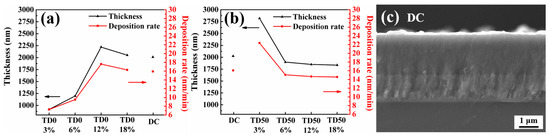

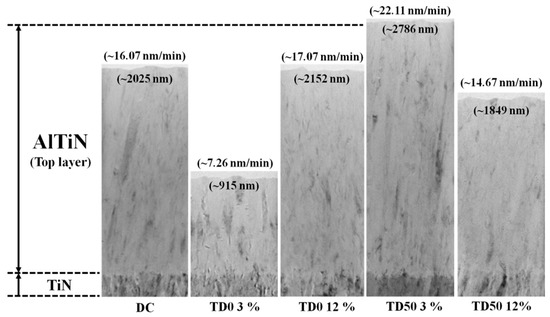

Figure 4 and Figure 5 present SEM images and the rate of AlTiN deposition under DC, TD0, and TD50 as a function of the bias voltage duty cycle. As shown in Figure 5c, AlTiN film was deposited under DC bias (deposition rate = 16.07 nm/min) as a control sample. In TD0 mode, increasing the duty cycle from 3% to 12% was shown to increase the deposition rate of AlTiN film from 7.26 to 17.07 nm/min (see Figure 4a–c and Figure 5a). In TD0 mode, the extended bias voltage turn-on time was shown to increase the rate of deposition by increasing the number of metal ions attracted to the substrate. Increasing the duty cycle beyond a critical value (12%) was shown to promote the attraction of noble gas ions to the substrate with a corresponding decrease in the rate of deposition. A further increase in duty cycle to 18% decreased the rate of deposition to 16.28 nm/min (see Figure 4d), which altered the crystal structure of AlTiN coating, as evidenced by a weaker (200) plane (see Figure 6a). The highest deposition rate in TD50 mode was observed under a duty cycle of 3% due to the on-time of the bias voltage corresponding to the generation time of a large flow of metal ions, resulting in the dissociated nitrogen and metal ions being accelerated to the substrate (see Figure 4e). Increasing the duty cycle from 3% to 18% led to a decrease in the rate of deposition from 22.11 to 14.56 nm/min (see Figure 4e–h and Figure 5b) due to an increase in the number of inert gaseous ions attracted to the substrate.

Figure 4.

SEM images of AlTiN coatings deposited under various duty cycle bias voltage modes: TD0 and TD50.

Figure 5.

(a,b) Rate of AlTiN deposition under DC, TD0, and TD50 as a function of duty cycle bias voltage mode; (c) SEM images of AlTiN coatings fabricated under DC bias voltage.

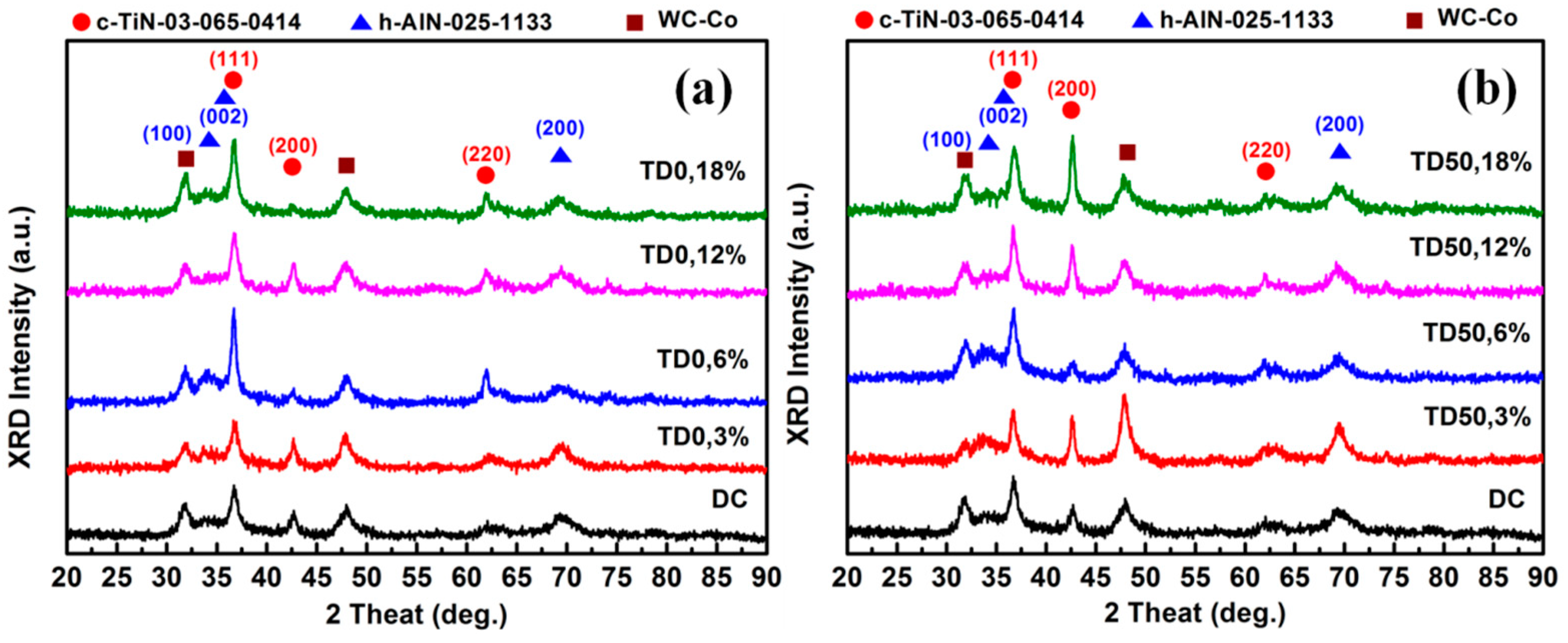

Figure 6.

(a,b) XRD patterns from AlTiN coatings deposited under TD0 and TD50 conditions as a function of duty cycle bias voltage mode.

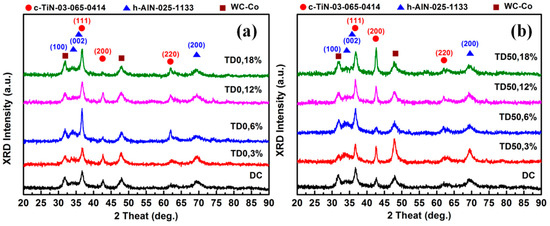

Figure 6 presents XRD patterns of AlTiN coatings deposited under DC, TD0, and TD50 modes as a function of duty cycle bias voltage modes. The 2θ diffraction peaks of 36.50°, 42.44°, and 61.50° correspond to the (111), (200) and (220) planes in c-TiN, which is consistent with JCPDS No.03-065-0414. The 2θ diffraction peaks at 33.48°, 35.91°, and 70.16° correspond to the (100), (002) and (200) planes in h-AlN, which is consistent with JCPDS No.025-1133. The h-AlN structure observed in all samples can be attributed to a stable hexagonal ZnS structure with an Al/(Ti+Al) ratio exceeding 0.7 (see Table 3) [35,36]. Note that the peak position (69.54°) of AlN (200) shifted to an angle below that of the JCPDS card (70.16°) due to lattice distortion and increased interplanar spacing within the h-AlN structure resulting from the replacement of Al atoms by larger Ti atoms [37,38]. Pelleg et al. [39] reported that the preferred orientation of TiN can be determined in terms of strain and surface energy. The dominant mechanisms determining surface energy and strain energy are film thickness and the energy of ion bombardment. Note that we are unable to discuss the differences in XRD intensities of various crystal planes due to a lack of fixed parameters.

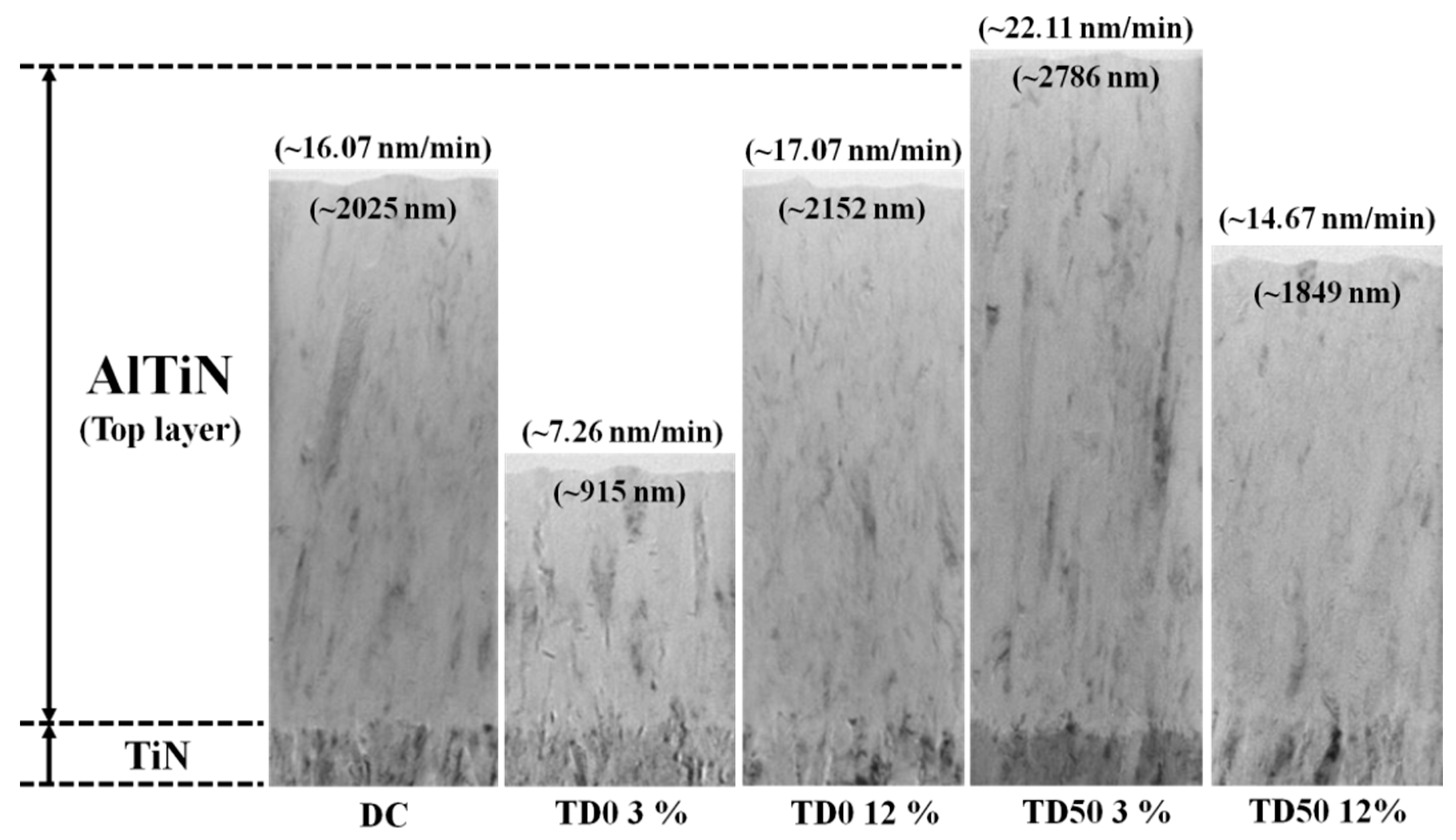

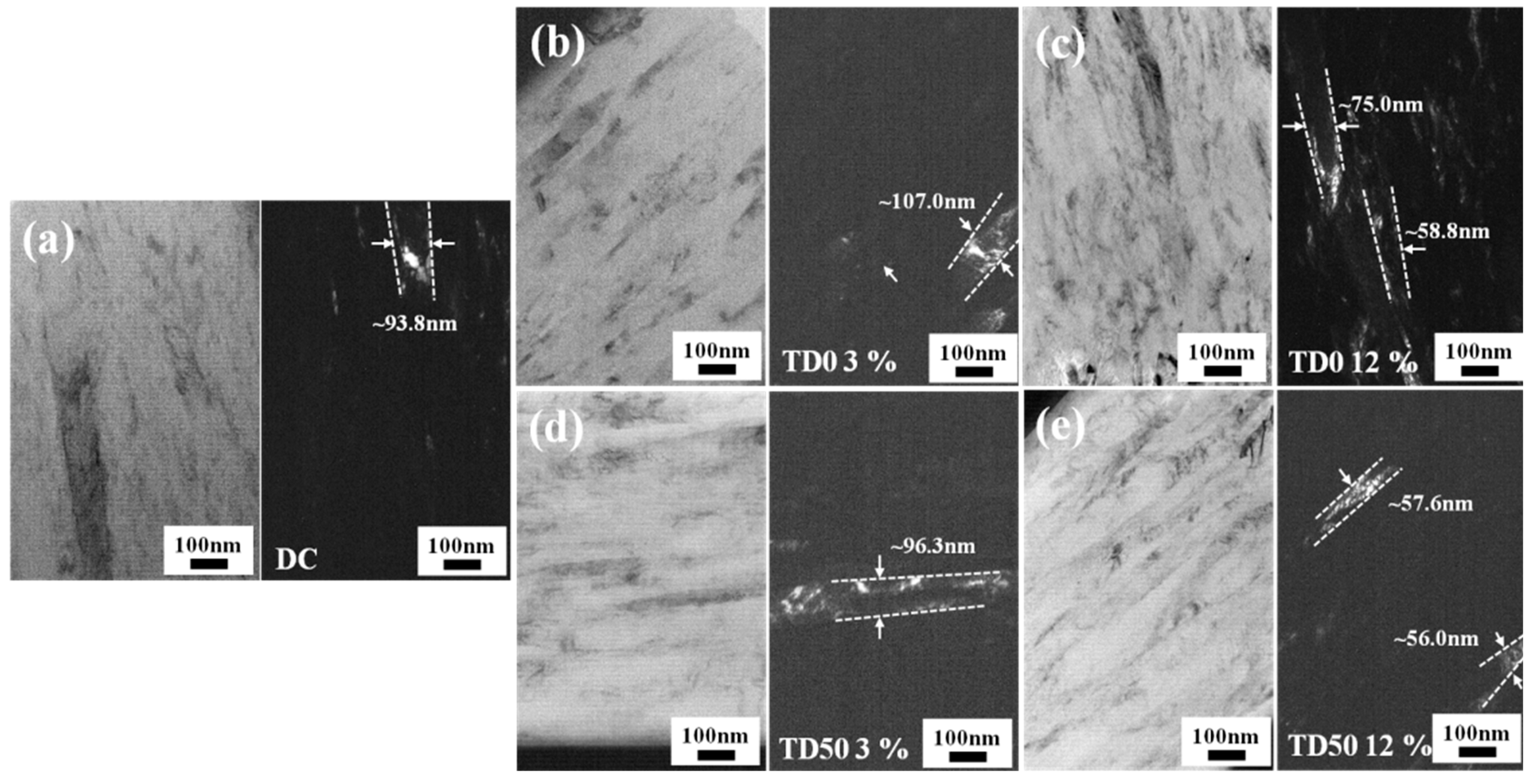

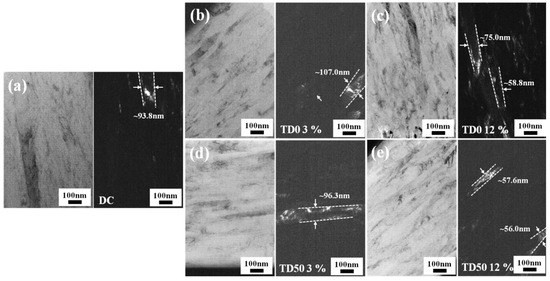

The mechanical properties of a coating are closely related to the compactness of the structure and the size of the columnar crystals [6,40]. Figure 7 presents cross-sectional TEM images and the corresponding deposition rates under DC, TD0, and TD50 with a duty cycle of 3% or 12%. The TEM images are consistent with the SEM results in terms of AlTiN film thickness and deposition rate. Larger columnar grains were observed in AlTiN films deposited in DC mode. High-magnification bright-field and dark-field TEM images of AlTiN films were used to measure the size of the columnar crystals (see Figure 8). Larger columnar grains were observed in AlTiN films deposited in DC mode. In both TD0 and TD50 bias voltage modes, the largest AlTiN columnar crystals were obtained under a duty cycle of 3%. Overall, the size of the columnar crystals was inversely proportional to the duty cycle. Crystal size is generally proportional to film thickness; however, in the current study, crystal size was inversely proportional to film thickness. We posit that this can be attributed to discrepancies in the energy of argon ion bombardment and the output time of bias voltage. The energy of ion bombardment is determined by the applied bias, which causes the ions to accelerate by generating an electric field between the plasma and the biased substrate during deposition. Increasing ion bombardment energy promotes grain size refinement [41]. In TD0 3% samples, the abbreviated turn-on bias resulted in the lowest rate of deposition, which in turn hindered columnar crystal growth. In TD0 12% samples, the longer bias turn-on time resulted in fine columnar crystals (30~40 nm) due to the thinning effect of the inert gas ions during film growth [32]. Similar results were obtained under TD50 conditions.

Figure 7.

TEM images of AlTiN coatings deposited under DC, TD0, and TD50 with a duty cycle of 3% or 12%.

Figure 8.

Bright-field and dark-field TEM images of AlTiN coatings as a function of bias mode: (a) DC (b) TD0 3% (c) TD0 12% (d) TD50 3% (e) TD50 12%.

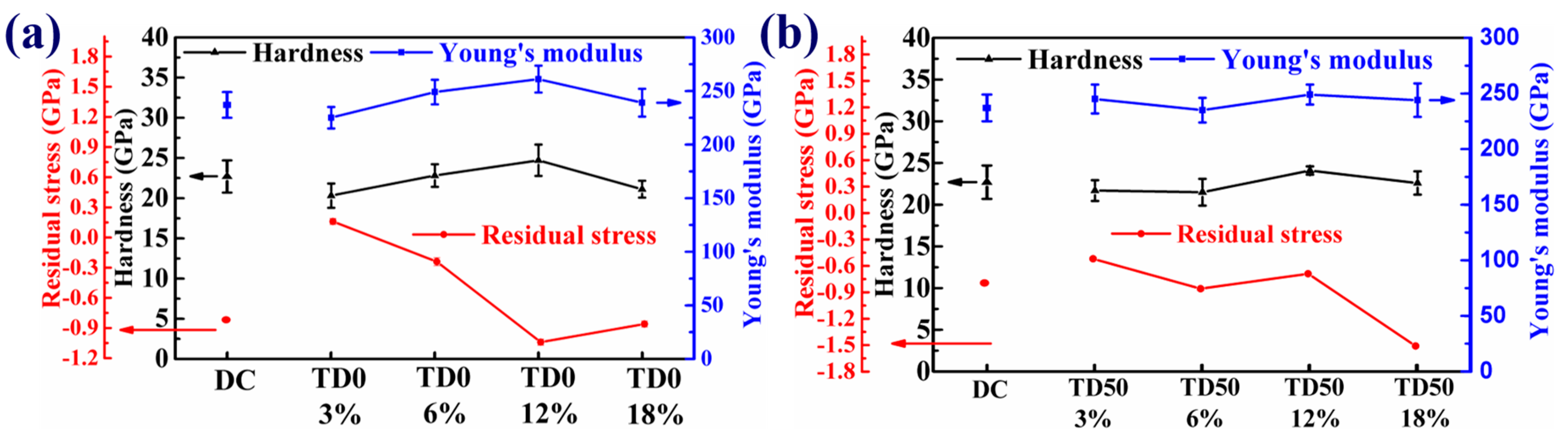

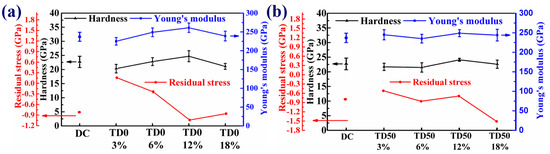

Figure 9a,b and Table 4 present the hardness, Young’s modulus, and residual stress in AlTiN coatings synthesized under TD0 and TD50 with various duty cycle bias voltage modes. The hardness of AlTiN coatings deposited in DC mode (control group) was 22.7 GPa, while Young’s modulus was 237 GPa, and residual stress was −0.81 GPa. The hardness of samples synthesized in TD0 mode was as follows (see Figure 9a): 3% (20.3 GPa), 12% (24.1 GPa), and 18% (21.1 GPa). The hardness of samples synthesized in TD50 mode were as follows (see Figure 9b): 3% (21.7 GPa), 12% (24.7 GPa), and 18% (22.6 GPa). The high hardness values can be attributed to a reduction in the size of the columnar crystals under Ar ion bombardment. Note that these findings are consistent with the grain size results obtained in TEM analysis (see Figure 8). As reported in a previous study [42], smaller grains (<10 nm) provide more grain boundaries, which can lead to the accumulation of positive or negative edge dislocations, resulting in reverse repulsion. The low hardness values observed under a duty cycle of 3% can be attributed to a lack of high-energy argon ion bombardment while the bias was off. Intuitively, residual stress (proportional to microstructure compactness) was correlated with average bias, average power, and hardness (see Table 2). As shown in Table 5, these mechanical properties are in agreement with those observed in AlTiN coatings synthesized using other methods.

Figure 9.

(a,b) Hardness, Young’s modulus, and residual stress in AlTiN coatings deposited under TD0 and TD50 conditions as functions of duty cycle and bias voltage.

Table 4.

Mechanical properties of AlTiN coatings deposited under various bias voltage modes.

Table 5.

Mechanical properties of AlTiN coatings in current study and previous works.

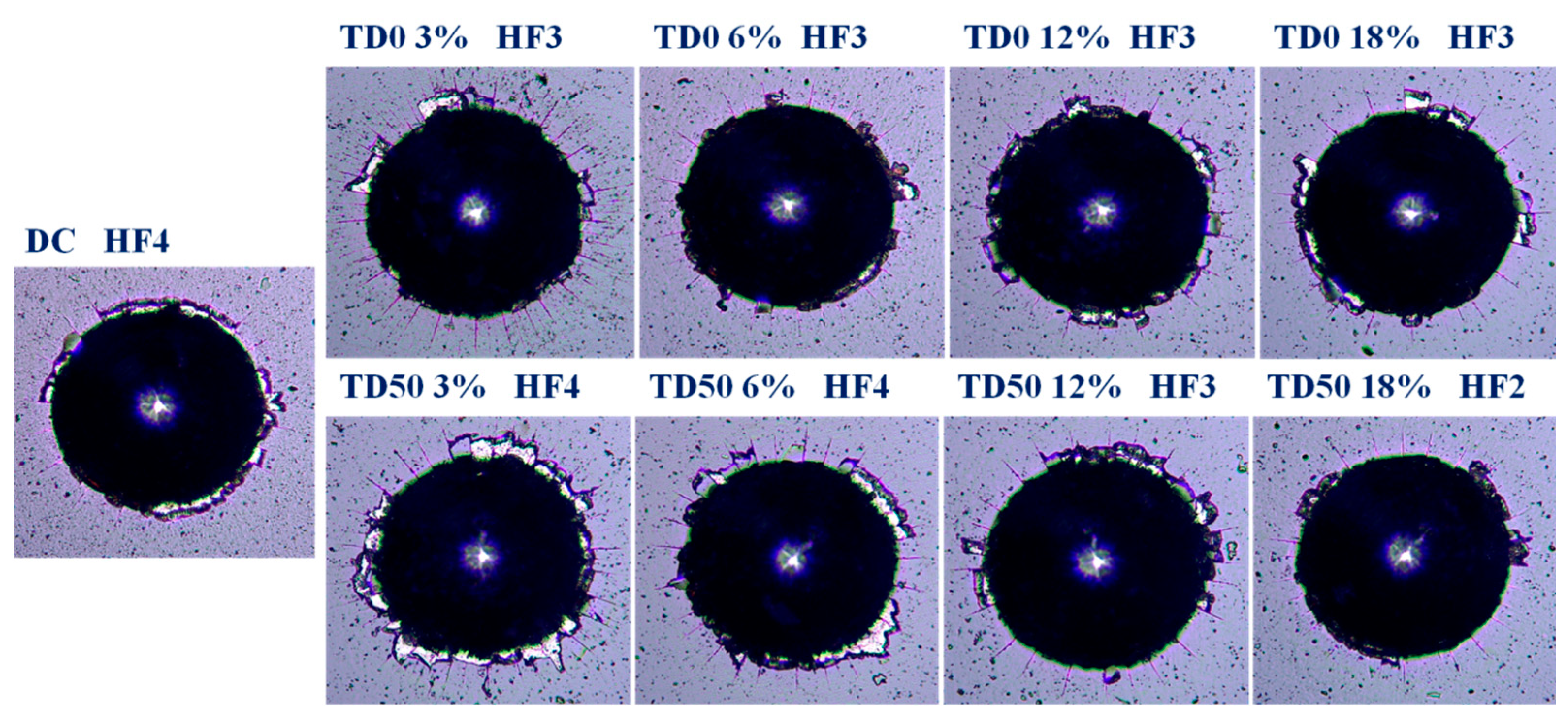

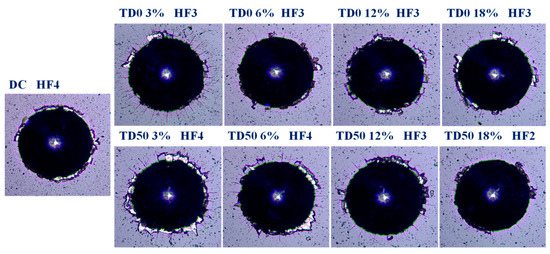

Figure 10 presents the results of Rockwell adhesion tests of AlTiN coatings deposited on WC-Co substrates based on DIN4856:2018-02 specifications, in which adhesion strength is classified into six levels (HF1-HF6). HF1 to HF4 are deemed acceptable adhesion, and HF5 and HF6 are deemed unacceptable. The adhesion strength in all coatings fell between HF2 and HF4 (i.e., acceptable). Differences in adhesion strength can be attributed to multiple factors, including the mechanical properties of the coatings, the substrate surface properties, and the design of the interface layer. The high degree of consistency in adhesion performance can be attributed to the fact that all samples shared the same interlayer design (AlTiN/TiN/TixNy/Ti/substrate). The crack resistance of the coatings was determined by calculating the deformation relative to yielding (H/E) and resistance to plastic indentation (H3/E2) ratios based on the nanoindentation values, the results of which are summarized in Table 4. Generally, the H/E and H3/E2 ratios are proportional to plastic deformation resistance [47,48]. Large areas of the TD0–18% and TD50–3% samples were subject to film peeling, which can be attributed to lower H/E and H3/E2 ratios and a thicker AlTiN layer. We speculate that the film peeling observed in the DC samples was due to the relatively large columnar crystals and higher residual stress, which prevented the dispersal and release of forces applied during the Rockwell indentation measurements. Note that the TD0–3% sample also had large columnar crystals; however, the adhesion performance was far better due to the positive residual stress offsetting a portion of the normal force.

Figure 10.

Rockwell indentation results of AlTiN coatings deposited under various bias voltage modes.

4. Conclusions

This study sought to elucidate the effects of synchronous bias under TD0 (3%, 6%, 12%, 18%) and TD50 (3%, 6%, 12%, 18%) on the properties of AlTiN coatings synthesized using HiPIMS. The values and action positions of substrate current and voltage were determined using an oscilloscope. Under TD0, increasing the bias voltage output duration increased the peak current from 14.4 to 16.4 A. Under TD50, increasing the bias voltage output duration decreased the peak current from 16.8 to 15.2 A. This result confirms the difference in the distribution time of different metal ions. EPMA results revealed that increasing the duty cycle led to an increase in Al content, whereas decreasing the duty cycle led to an increase in Ti content. XRD results revealed the formation of an h-AlN structure when the Al/Ti ratio was between 0.71 and 0.74. TEM and nanoindentation results revealed that the transformation of DC bias into synchronous bias to boost the bias output time (increased duty cycle) led to AlTiN grain refinement from roughly ~100 to ~55 nm with an increase in hardness from 22.7 to 24.7 GPa and an increase in residual stress within the AlTiN coating from 0.16 to −1.51 GPa. The adhesion strength in all coatings was deemed acceptable.

To summarize, the differences among synchronous pulse bias (TD0), trigger delay pulse bias (TD50), and conventional DC bias systems in terms of AlTiN coating characteristics are as follows: (1) The highest deposition rate (22.11 nm/min) was achieved in the TD50–3% samples, which increased production efficiency by 38.6% compared to DC bias. (2) The highest surface hardness value (24.7 GPa) was achieved in the TD0-12% samples, exceeding that of DC bias by 8.8%. (3) The residual stress of sample TD-03% exceeded that of DC bias by 120%. By controlling the time of substrate bias output, it is possible to adjust the residual stress, deposition rate, and mechanical properties of the coating; however, the corresponding decrease in ion bombardment energy limits grain refinement. Based on these results, the next study will apply the sequential synchronous matching process of multiple target sources to understand whether the mechanical and adhesion properties of the film can be further improved for precise components.

Author Contributions

Data curation, S.-Y.H.; Investigation, S.-Y.H.; Methodology, I.-H.C. and G.-L.S.; Supervision, C.-L.C.; Writing—original draft, J.-F.T.; Writing—review & editing, J.-F.T. and C.-L.C. All authors have read and agreed to the published version of the manuscript.

Funding

The authors would like to extend their deepest thanks to the National Science and Technology Council, Taiwan, R.O.C, for financially supporting this research project under grant No. NSTC 110-2221-E-131-006, NSTC 111-2622-E-131-007 and NSTC 110-2222-E-262-002-MY3.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Not applicable.

Acknowledgments

The authors would like to extend heartfelt thanks for the use of the FE-EPMA (JXA-iHP200F) apparatus at the Instrument Center of National Tsing Hua University. The authors would also like to gratefully acknowledge the use of the TEM (JEOL, JEM-2100 Plus) apparatus at the Advanced Instrument Center of the National Yunlin University of Science and Technology.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Velicu, I.-L.; Tiron, V.; Porosnicu, C.; Burducea, I.; Lupu, N.; Stoian, G.; Popa, G.; Munteanu, D. Enhanced properties of tungsten thin films deposited with a novel HiPIMS approach. Appl. Surf. Sci. 2017, 424, 397–406. [Google Scholar] [CrossRef]

- Kumar, A.; Bauri, R.; Naskar, A.; Chattopadhyay, A. Characterization of HiPIMS and DCMS deposited TiAlN coatings and machining performance evaluation in high speed dry machining of low and high carbon steel. Surf. Coat. Technol. 2021, 417, 127180. [Google Scholar] [CrossRef]

- Kouznetsov, V.; Macak, K.; Schneider, J.M.; Helmersson, U.; Petrov, I. A novel pulsed magnetron sputter technique utilizing very high target power densities. Surf. Coat. Technol. 1999, 122, 290–293. [Google Scholar] [CrossRef]

- Ehiasarian, A.; New, R.; Münz, W.-D.; Hultman, L.; Helmersson, U.; Kouznetsov, V. Influence of high power densities on the composition of pulsed magnetron plasmas. Vacuum 2002, 65, 147–154. [Google Scholar] [CrossRef]

- Chang, C.-L.; Huang, C.-H.; Lin, C.-Y.; Yang, F.-C.; Tang, J.-F. Mechanical properties of amorphous and crystalline CrN/CrAlSiN multilayer coating fabricated using HPPMS. Surf. Interfaces 2022, 31, 102064. [Google Scholar] [CrossRef]

- Chang, C.-L.; Luo, G.-J.; Yang, F.-C.; Tang, J.-F. Effects of duty cycle on microstructure of TiN coatings prepared using CAE/HiPIMS. Vacuum 2021, 192, 110449. [Google Scholar] [CrossRef]

- Sarakinos, K.; Alami, J.; Konstantinidis, S. High power pulsed magnetron sputtering: A review on scientific and engineering state of the art. Surf. Coat. Technol. 2010, 204, 1661–1684. [Google Scholar] [CrossRef]

- Gui, B.; Zhou, H.; Zheng, J.; Liu, X.; Feng, X.; Zhang, Y.; Yang, L. Microstructure and properties of TiAlCrN ceramic coatings deposited by hybrid HiPIMS/DC magnetron co-sputtering. Ceram. Int. 2021, 47, 8175–8183. [Google Scholar] [CrossRef]

- Alhafian, M.; Chemin, J.; Fleming, Y.; Bourgeois, L.; Penoy, M.; Useldinger, R.; Soldera, F.; Mücklich, F. Choquet. Comparison on the structural, mechanical and tribological properties of TiAlN coatings deposited by HiPIMS and Cathodic Arc Evaporation. Surf. Coat. Technol. 2021, 423, 127529. [Google Scholar] [CrossRef]

- Alami, J.; Maric, Z.; Busch, H.; Klein, F.; Grabowy, U.; Kopnarski, M.J.S. Enhanced ionization sputtering: A concept for superior industrial coatings. Surf. Coat. Technol. 2014, 255, 43–51. [Google Scholar] [CrossRef]

- Anders, A.J.S. Discharge physics of high power impulse magnetron sputtering. Surf. Coat. Technol. 2011, 205, S1–S9. [Google Scholar] [CrossRef]

- Bernátová, K.; Fekete, M.; Klein, P.; Hnilica, J.; Vašina, P.J.P.S.S. Ionisation fractions of sputtered titanium species at target and substrate region in HiPIMS. Plasma Sources Sci. Technol. 2020, 29, 055010. [Google Scholar] [CrossRef]

- Drábik, M.; Truchlý, M.; Ballo, V.; Roch, T.; Kvetková, L.; Kúš, P. Influence of substrate material and its plasma pretreatment on adhesion and properties of WC/aC: H nanocomposite coatings deposited at low temperature. Surf. Coat. Technol. 2018, 333, 138–147. [Google Scholar] [CrossRef]

- Zhao, M.-J.; Huang, J.; Zhang, J.-F.; Hsu, C.-H.; Wu, W.-Y.; Huang, P.-H.; Wei, S.-F.; Lien, S.-Y.; Zhu, W.-Z. Effect of oxygen flow rate ratio on crystalline phase and properties of copper oxide films prepared by room-temperature high-power impulse magnetron sputtering. Surf. Coat. Technol. 2022, 434, 128215. [Google Scholar] [CrossRef]

- Hsu, Y.-H.; Liu, H.-W.; Lien, S.-Y.; Wu, W.-Y. High-power impulse magnetron sputter deposition for enhanced optical transmittance and electrical conductivity of flexible coating. Thin Solid Film. 2022, 748, 139158. [Google Scholar] [CrossRef]

- Zhao, M.-J.; Chen, Z.-Z.; Shi, C.-Y.; Chen, Q.-Z.; Xu, M.; Wu, W.-Y.; Wuu, D.-S.; Lien, S.-Y.; Zhu, W.-Z.J.V. Modulation of carrier density in indium–gallium–zinc-oxide thin film prepared by high-power impulse magnetron sputtering. Vacuum 2023, 207, 111640. [Google Scholar] [CrossRef]

- Claver, A.; Randulfe, J.J.; Palacio, J.F.; de Ara, J.F.; Almandoz, E.; Montalá, F.; Colominas, C.; Cot, V.; García, J.A. Improved adhesion and tribological properties of AlTiN-TiSiN coatings deposited by DCMS and HiPIMS on nitrided tool steels. Coatings 2021, 11, 1175. [Google Scholar] [CrossRef]

- Singh, A.; Ghosh, S.; Aravindan, S. Flank wear and rake wear studies for arc enhanced HiPIMS coated AlTiN tools during high speed machining of nickel-based superalloy. Surf. Coat. Technol. 2020, 381, 125190. [Google Scholar] [CrossRef]

- Zhao, J.; Liu, Z. Influences of coating thickness on cutting temperature for dry hard turning Inconel 718 with PVD TiAlN coated carbide tools in initial tool wear stage. J. Manuf. Process. 2020, 56, 1155–1165. [Google Scholar] [CrossRef]

- Kuang, S.; Wang, J.; Wang, L.; Huang, W.; Zhou, Z. Improvement of the mechanical and the tribological properties of CrNbTiMoZr coatings through the incorporation of carbon and the adjustment of the substrate bias voltage. Surf. Coat. Technol. 2021, 412, 127064. [Google Scholar] [CrossRef]

- Fan, Q.; Zhang, S.; Ma, D.; Wu, Z.; Cao, F.; Liu, Y.; Wang, T. Bias voltage optimization and cutting performance of AlCrN coatings deposited by a hybrid technology. Vacuum 2022, 204, 111348. [Google Scholar] [CrossRef]

- Wei, H.; Xia, J.; Zhou, W.; Zhou, L.; Hussain, G.; Li, Q.; Ostrikov, K.K. Adhesion and cohesion of epoxy-based industrial composite coatings. Compos. Part B Eng. 2020, 193, 108035. [Google Scholar] [CrossRef]

- Hsu, T.-W.; Greczynski, G.; Boyd, R.; Kolozsvári, S.; Polcik, P.; Bolz, S.; Bakhit, B.; Odén, M. Influence of Si content on phase stability and mechanical properties of TiAlSiN films grown by AlSi-HiPIMS/Ti-DCMS co-sputtering. Surf. Coat. Technol. 2021, 427, 127661. [Google Scholar] [CrossRef]

- Das, C.R.; Rangwala, M.; Ghosh, A. Influence of substrate bias voltage on microstructure and mechanical characteristics of TiAlSiN coating deposited by High Power Impulse Magnetron Sputtering (HiPIMS). Surf. Coat. Technol. 2023, 458, 129351. [Google Scholar] [CrossRef]

- Bohlmark, J.; Lattemann, M.; Gudmundsson, J.; Ehiasarian, A.; Gonzalvo, Y.A.; Brenning, N.; Helmersson, U. The ion energy distributions and ion flux composition from a high power impulse magnetron sputtering discharge. Thin Solid Film. 2006, 515, 1522–1526. [Google Scholar] [CrossRef]

- Greczynski, G.; Lu, J.; Jensen, J.; Petrov, I.; Greene, J.E.; Bolz, S.; Kölker, W.; Schiffers, C.; Lemmer, O.; Hultman, L. Metal versus rare-gas ion irradiation during Ti1− x Al x N film growth by hybrid high power pulsed magnetron/dc magnetron co-sputtering using synchronized pulsed substrate bias. J. Vac. Sci. Technol. A Vac. Surf. Film. 2012, 30, 061504. [Google Scholar] [CrossRef]

- Cemin, F.; Abadias, G.; Minea, T.; Lundin, D. Tuning high power impulse magnetron sputtering discharge and substrate bias conditions to reduce the intrinsic stress of TiN thin films. Thin Solid Film. 2019, 688, 137335. [Google Scholar] [CrossRef]

- Zhang, Q.; Wu, Z.; Xu, Y.X.; Wang, Q.; Chen, L.; Kim, K.H.J.S. Improving the mechanical and anti-wear properties of AlTiN coatings by the hybrid arc and sputtering deposition. Surf. Coat. Technol. 2019, 378, 125022. [Google Scholar] [CrossRef]

- Beake, B.; Smith, J.; Gray, A.; Fox-Rabinovich, G.; Veldhuis, S.; Endrino, J.J.S. Investigating the correlation between nano-impact fracture resistance and hardness/modulus ratio from nanoindentation at 25–500° C and the fracture resistance and lifetime of cutting tools with Ti1− xAlxN (x= 0.5 and 0.67) PVD coatings in milling operations. Surf. Coat. Technol. 2007, 201, 4585–4593. [Google Scholar]

- Li, B.; Xu, Y.; Rao, G.; Wang, Q.; Zheng, J.; Zhu, R.; Chen, Y.J.C. Tribological properties and cutting performance of AlTiN coatings with various geometric structures. Coatings 2023, 13, 402. [Google Scholar] [CrossRef]

- Tang, J.-F.; Huang, S.-Y.; Lin, J.-H.; Yang, F.-C.; Chang, C.-L. Mechanical properties of TiN deposited in synchronous bias mode through high-power impulse magnetron sputtering. Surf. Coat. Technol. 2022, 434, 128201. [Google Scholar] [CrossRef]

- Vavassori, D.; Mirani, F.; Gatti, F.; Dellasega, D.; Passoni, M. Role of magnetic field and bias configuration on HiPIMS deposition of W films. Surf. Coat. Technol. 2023, 458, 129343. [Google Scholar] [CrossRef]

- Greczynski, G.; Lu, J.; Jensen, J.; Bolz, S.; Kölker, W.; Schiffers, C.; Lemmer, O.; Greene, J.E.; Hultman, L. A review of metal-ion-flux-controlled growth of metastable TiAlN by HIPIMS/DCMS co-sputtering. Surf. Coat. Technol. 2014, 257, 15–25. [Google Scholar] [CrossRef]

- Salamania, J.; Johnson, L.; Schramm, I.; Calamba, K.; Boyd, R.; Bakhit, B.; Rogström, L.; Odén, M. Influence of pulsed-substrate bias duty cycle on the microstructure and defects of cathodic arc-deposited Ti1-xAlxN coatings. Surf. Coat. Technol. 2021, 419, 127295. [Google Scholar] [CrossRef]

- Tuilier, M.-H.; Pac, M.-J.; Covarel, G.; Rousselot, C.; Khouchaf, L. Structural investigation of thin films of Ti1− xAlxN ternary nitrides using Ti K-edge X-ray absorption fine structure. Surf. Coat. Technol. 2007, 201, 4536–4541. [Google Scholar] [CrossRef]

- Chen, L.; Paulitsch, J.; Du, Y.; Mayrhofer, P.H. Thermal stability and oxidation resistance of Ti–Al–N coatings. Surf. Coat. Technol. 2012, 206, 2954–2960. [Google Scholar] [CrossRef]

- Mendez, A.; Monclus, M.; Santiago, J.; Fernández-Martínez, I.; Rojas, T.C.; Garcia-Molleja, J.; Avella, M.; Dams, N.; Panizo-Laiz, M.; Molina-Aldareguia, J.M. Effect of Al content on the hardness and thermal stability study of AlTiN and AlTiBN coatings deposited by HiPIMS. Surf. Coat. Technol. 2021, 422, 127513. [Google Scholar] [CrossRef]

- Kimura, A.; Hasegawa, H.; Yamada, K.; Suzuki, T. Metastable Ti1-xAlxN films with different Al content. J. Mater. Sci. Lett. 2000, 19, 601–602. [Google Scholar] [CrossRef]

- Pelleg, J.; Zevin, L.; Lungo, S.; Croitoru, N.J.T.S.F. Reactive-sputter-deposited TiN films on glass substrates. Thin Solid Film. 1991, 197, 117–128. [Google Scholar] [CrossRef]

- Zhang, Z.; Zhang, L.; Yan, W.; Zhang, Y.; Yuan, H.; Shen, Y.; Liao, B.; Zhang, X.; Zhang, F.; Ouyang, X.J.M.C. Effect of self-ion with high-energy irradiation on the surface morphology, microstructure and mechanical properties of nanocrystalline TiAlN coating. Materials 2022, 190, 112041. [Google Scholar] [CrossRef]

- Xu, Y.; Li, G.; Li, G.; Gao, F.; Xia, Y.J.A.S.S. Effect of bias voltage on the growth of super-hard (AlCrTiVZr) N high-entropy alloy nitride films synthesized by high power impulse magnetron sputtering. Appl. Surf. Sci. 2021, 564, 150417. [Google Scholar] [CrossRef]

- Lesuer, D.; Syn, C.; Sherby, O. Nano-subgrain strengthening in ball-milled iron. Mater. Sci. Eng. A 2007, 463, 54–60. [Google Scholar] [CrossRef]

- Xian, G.; Xiong, J.; Fan, H.; Guo, Z.; Xian, L.; Sun, L.; Zhao, H.J.T.S.F. Effect of substrate pretreatments on the structure and properties of AlTiN coatings deposited on TiCN-based cermets. Thin Solid Film. 2023, 770, 139769. [Google Scholar] [CrossRef]

- Zhang, H.; Mei, F.; Yu, Y.; Lin, X.; Gao, J.J.S. Improvement on the mechanical, tribological properties and cutting performance of AlTiN-based coatings by compositional and structural design. Surf. Coat. Technol. 2021, 422, 127503. [Google Scholar] [CrossRef]

- Pang, X.; Yang, H.; Gao, K.; Wang, Y.; Volinsky, A.A.J.T.S.F. AlTiN layer effect on mechanical properties of Ti-doped diamond-like carbon composite coatings. Thin Solid Film. 2011, 519, 5353–5357. [Google Scholar] [CrossRef]

- Yang, F.-C.; Lin, C.-Y.; Tang, J.-F.; Chang, C.-L.J.S. Effect of mid-frequency pulse insertion on the microstructural and mechanical properties of AlTiN coatings prepared using superimposed HiPIMS process. Surf. Coat. Technol. 2020, 388, 125597. [Google Scholar] [CrossRef]

- Warcholinski, B.; Gilewicz, A.; Kuprin, A.; Tolmachova, G.; Ovcharenko, V.; Kuznetsova, T.; Zubar, T.; Khudoley, A.; Chizhik, S.J.V. Mechanical properties of Cr-ON coatings deposited by cathodic arc evaporation. Vacuum 2018, 156, 97–107. [Google Scholar] [CrossRef]

- Özkan, D.; Yılmaz, M.A.; Erdem, C.; Türküz, C.; Sulukan, E.; Yağcı, M.B.J.C.I. Wear and friction behavior of CrTiN/TiCN and CrTiN/CrCN multilayer composite coatings. Ceram. Int. 2022, 48, 13732–13747. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).