Study on Cavitation Corrosion Properties of Titanium Alloy Radiation Rod with Different Roughnesses for Ultrasonic Casting

Abstract

:1. Introduction

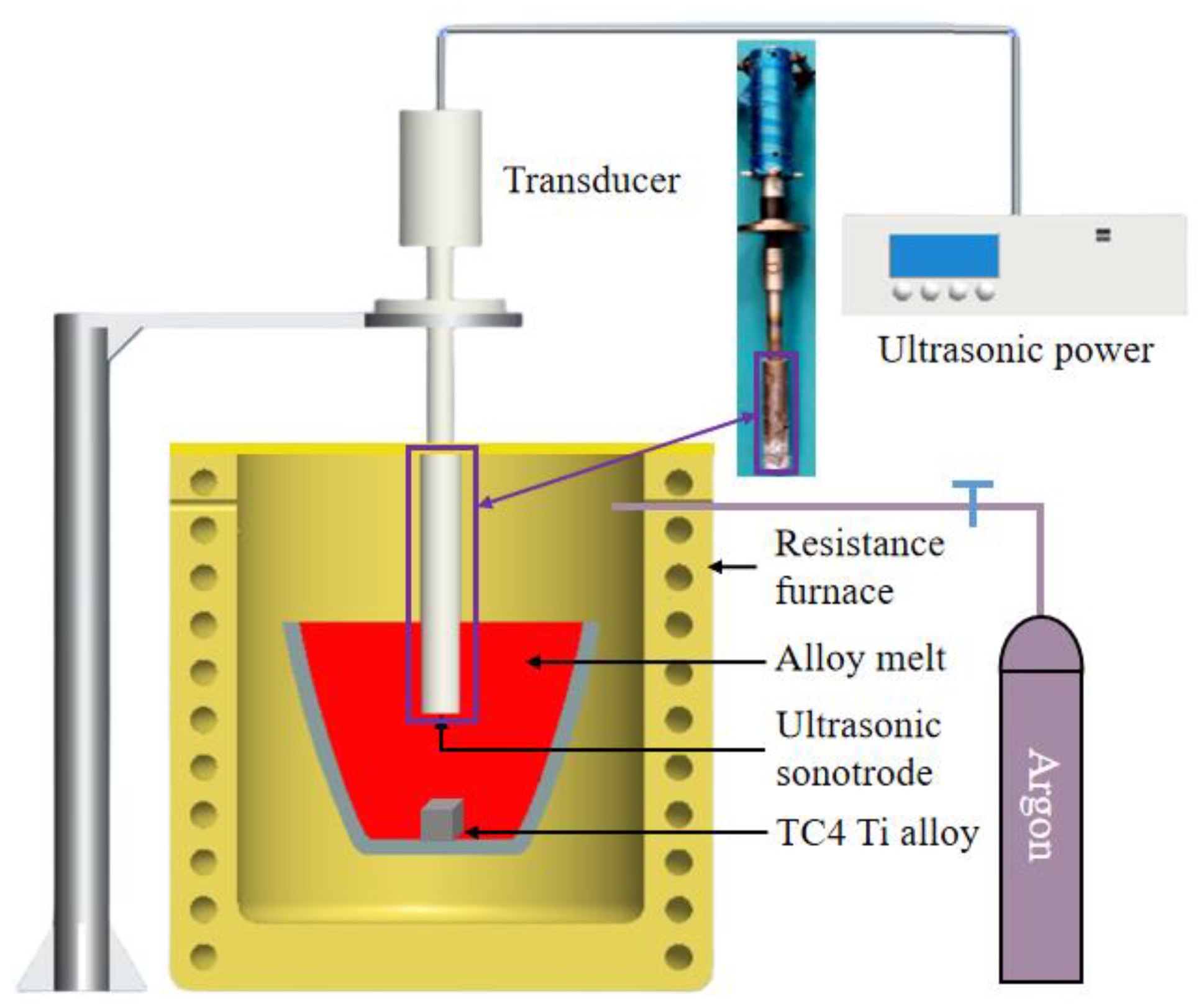

2. Experimental Details

2.1. Materials

2.2. Sample Preparation

2.3. Microstructural Characterization

3. Results and Discussion

3.1. Weight Loss Rate/Cavitated Area

3.2. Corrosion Morphology and Corrosion Products

3.2.1. Corrosion Morphology

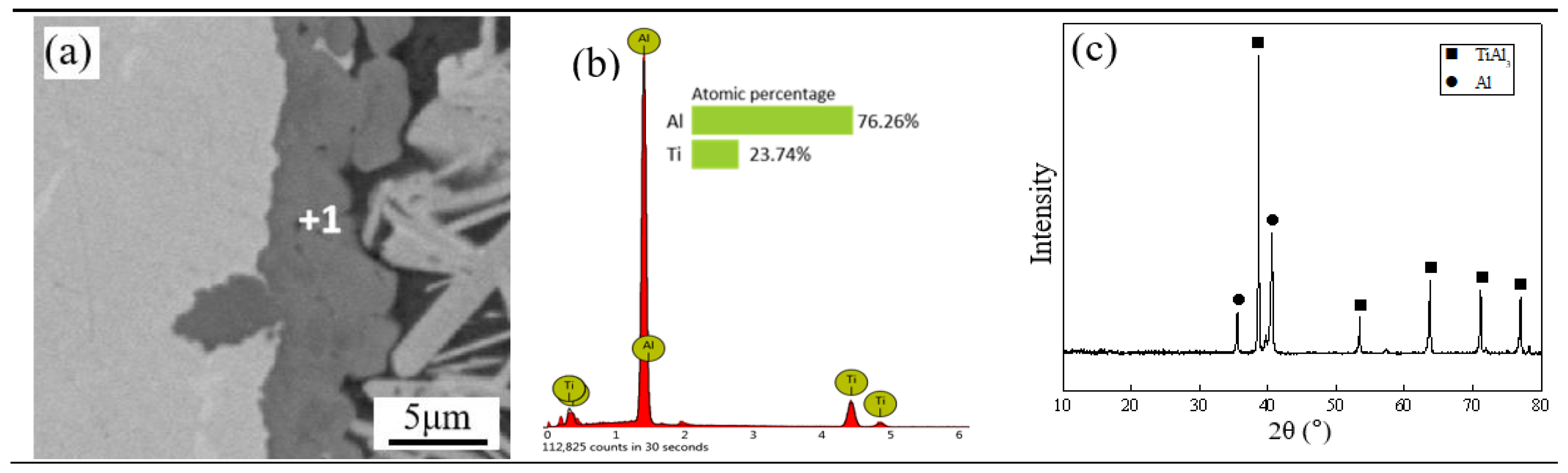

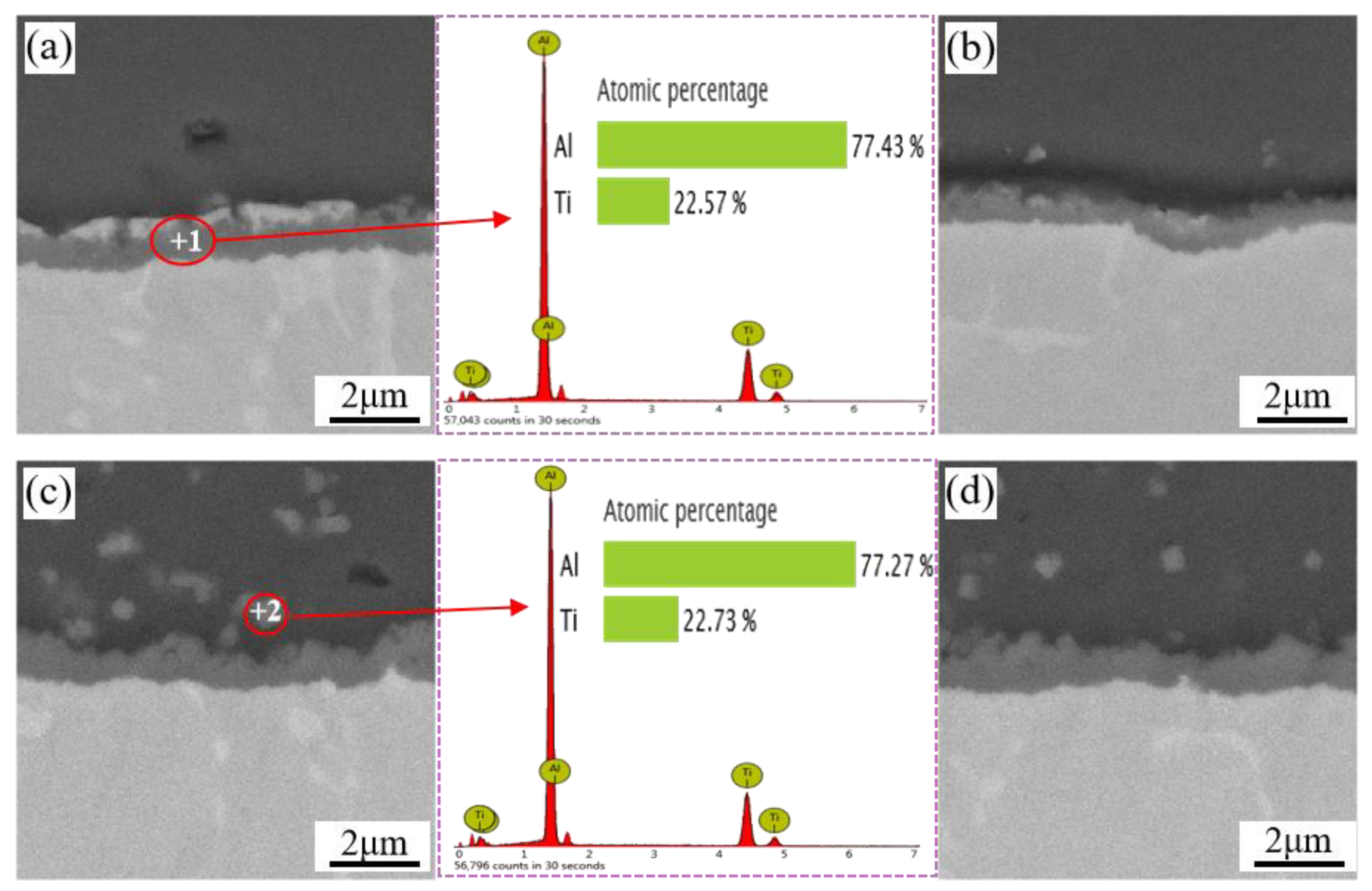

3.2.2. Corrosion Product

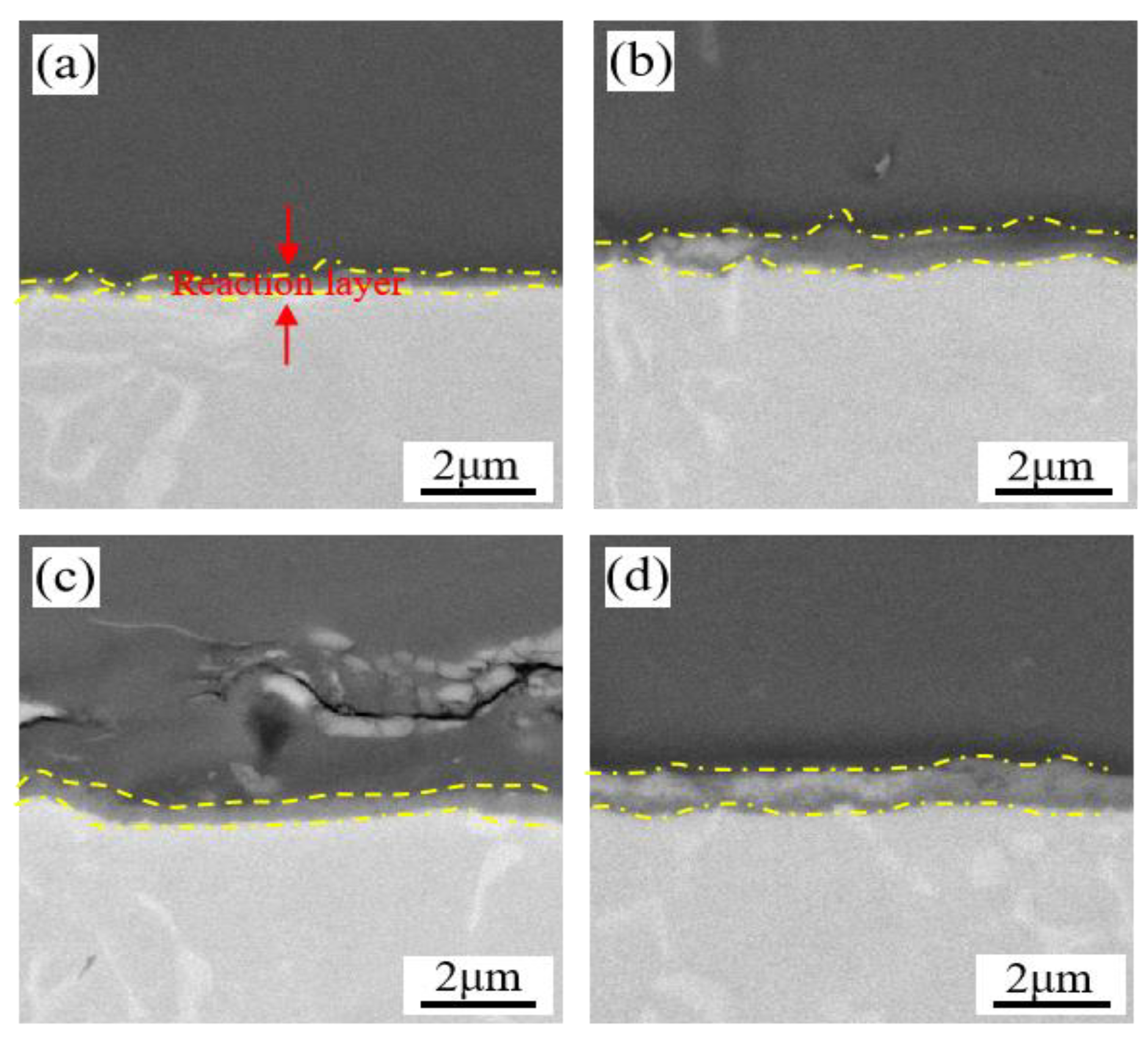

3.3. Reaction Layer Morphology

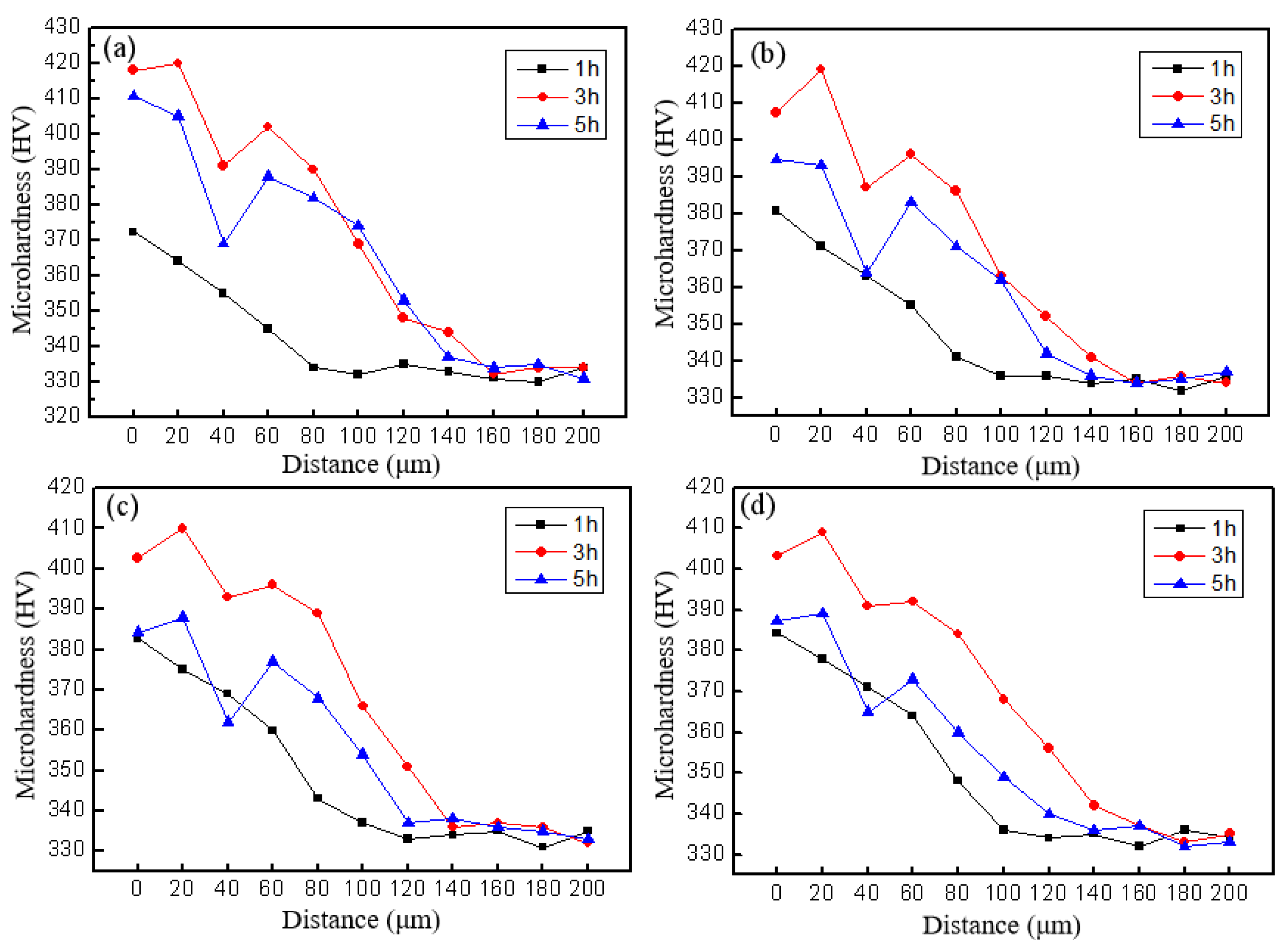

3.4. Profile Microhardness

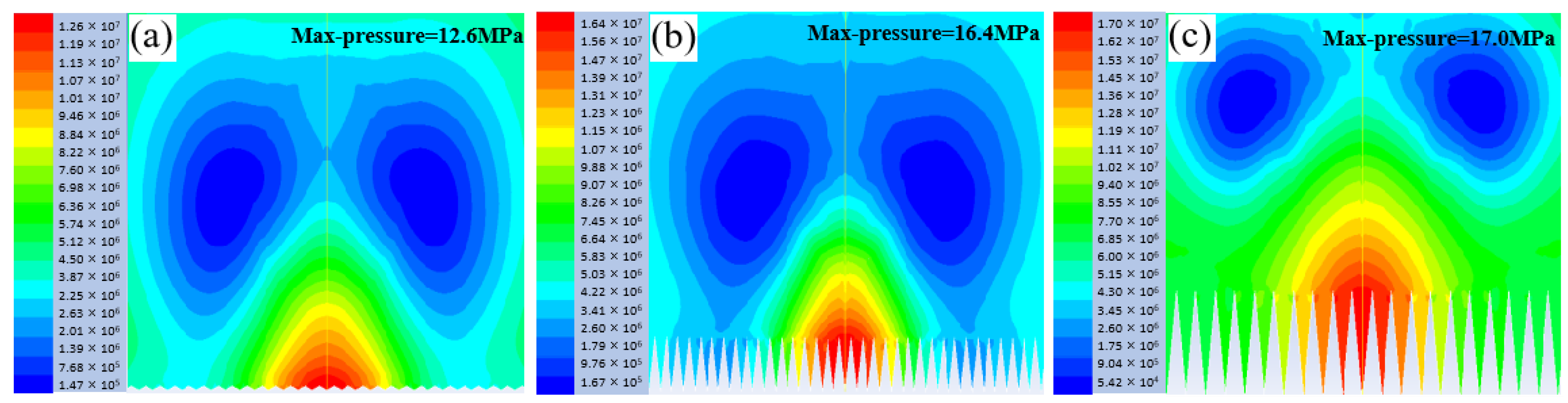

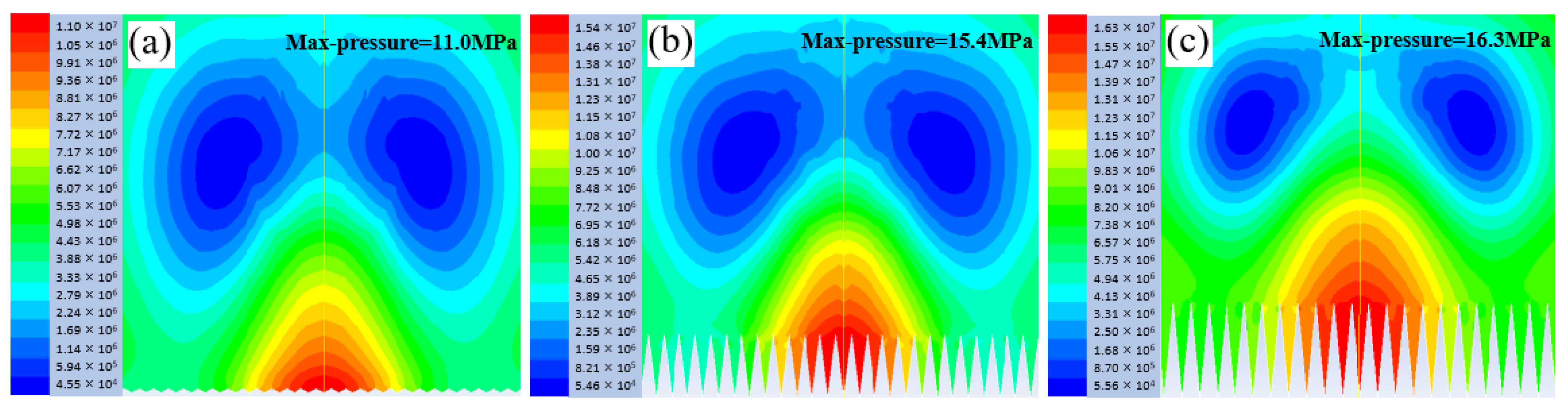

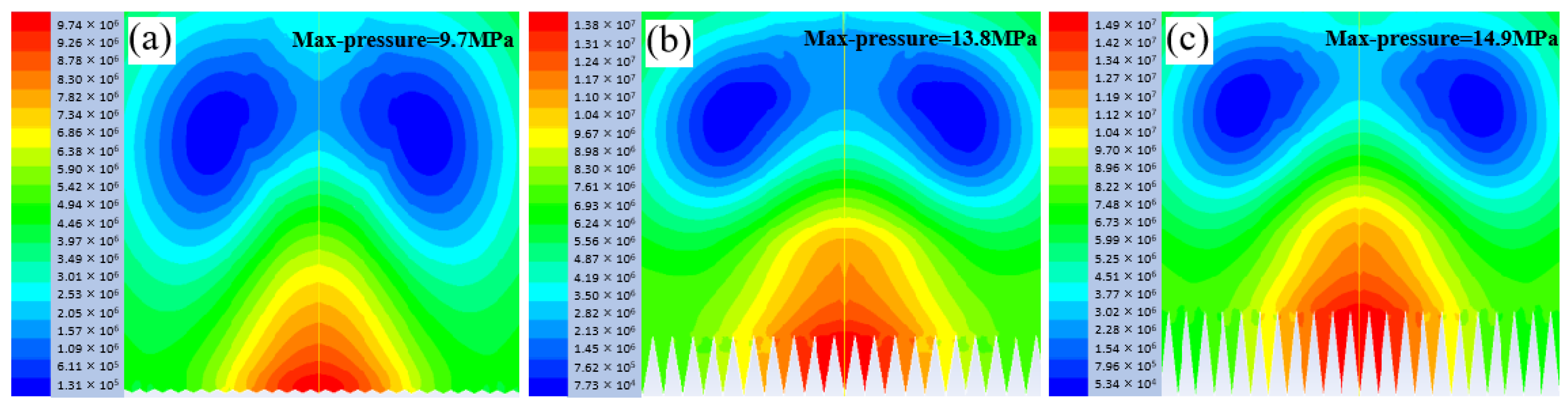

3.5. Simulation of the Collapse Impact of Cavitation Bubbles near the Wall

3.5.1. Boundary

3.5.2. Parameter

3.5.3. Simulation Result

4. Conclusions

- (1)

- The corrosion rule of titanium alloy in aluminum melt was that the greater the roughness, the greater the weight loss rate/cavitated area. The weight loss/cavitated area of titanium alloy caused by cavitation effect accounted for 6.4%~8.6% of the total weight loss/cavitated area. The corrosion product was the intermetallic compound TiAl3. These reactants appeared at the Al/Ti solid–liquid interface of samples with different roughness in about 4 min, and the reaction layer was formed in 10 min.

- (2)

- With the increase of cavitation erosion time, the thickness of the work hardening layer on the surface of the material increased first and then decreased. The maximum thickness could reach 160 μm. The evolution of the hardened layer depended on the stripping rate of the surface material caused by cavitation corrosion and the work hardening rate of the surface layer.

- (3)

- The greater the roughness of the solid interface, the greater the maximum pressure at that point. When the roughness was constant, the smaller the ratio coefficient was and the closer the cavity was to the solid interface, the maximum pressure increased. The greater the surface roughness, the wider the influence range of the high pressure zone, and the greater the degree of corrosion.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Lin, R.; Liu, B.; Zhang, J.J.; Zhang, S.G. Microstructure evolution and properties of 7075 aluminum alloy recycled from scrap aircraft aluminum alloys. J. Mater. Res. Technol. 2022, 19, 354–367. [Google Scholar] [CrossRef]

- Wan, Z.D.; Wang, Q.; Zhao, Y.; Zhao, T.Y.; Shan, J.G.; Meng, D.Y.; Song, J.L.; Wu, A.P.; Wang, G.Q. Improvement in tensile properties of 2219-T8 aluminum alloy TIG welding joint by PMZ local properties and stress distribution. Mater. Sci. Eng. A 2022, 839, 142863. [Google Scholar] [CrossRef]

- Zhang, J.F.; Zhou, D.S.; Pang, X.Y.; Zhang, B.W.; Li, Y.; Sun, B.H.; Valiev, R.S.; Zhang, D.L. Deformation-induced concurrent formation of 9R phase and twins in a nanograined aluminum alloy. Acta. Mater. 2023, 244, 118540. [Google Scholar] [CrossRef]

- Safyri, M.; Moshtaghi, M.; Hojo, T.; Akiyama, E. Mechanisms of hydrogen embrittlement in high-strength aluminum alloys containing coherent or incoherent dispersoids. Corros. Sci. 2022, 194, 109895. [Google Scholar] [CrossRef]

- Miao, J.S.; Sutton, S.; Luo, A.A. Deformation microstructure and thermomechanical processing maps of homogenized AA2070 aluminum alloy. Mater. Sci. Eng. A 2022, 834, 142619. [Google Scholar] [CrossRef]

- Guo, X.P.; Li, H.J.; Xue, P. Microstructure and mechanical properties of 600 MPa grade ultra-high strength aluminum alloy fabricated by wire-arc additive manufacturing. J. Mater. Sci. Technol. 2023, 149, 56–66. [Google Scholar] [CrossRef]

- Balasubramani, N.; Venezuela, J.; Yang, N.; Wang, G.; Stjohn, D.; Dargusch, M. An overview and critical assessment of the mechanisms of microstructural refinement during ultrasonic solidification of metals. Ultrason. Sonochem. 2022, 89, 106151. [Google Scholar] [CrossRef]

- Eskin, D.G.; Tzanakis, I.; Wang, F.; Lebon, G.S.B.; Subroto, T.; Pericleous, K.; Mi, J. Fundamental studies of ultrasonic melt processing. Ultrason. Sonochem. 2019, 52, 455–467. [Google Scholar] [CrossRef]

- Priyadarshi, A.; Khavari, M.; Shahrani, B.; Subroto, T.; Yusuf, L.A.; Conte, M.; Pretice, P.; Pericleous, K.; Eskin, D.; Tzanakis, L. In-situ observations and acoustic measurements upon fragmentation of free-floating intermetallics under ultrasonic cavitation in water. Ultrason. Sonochem. 2021, 80, 105820. [Google Scholar] [CrossRef]

- Xu, N.X.; Yu, Y.; Zhai, W.; Wang, J.Y.; Wei, B.B. A high-temperature acoustic field measurement and analysis system for determining cavitation intensity in ultrasonically solidified metallic alloys. Ultrason. Sonochem. 2023, 94, 106343. [Google Scholar] [CrossRef]

- Lu, D.H.; Jiang, Y.H.; Guan, G.S.; Zhou, R.F.; Li, Z.H.; Zhou, R. Refinement of primary Si in hypereutectic Al-Si alloy by electromagnetic stirring. J. Mater. Process. Tech. 2007, 189, 13–18. [Google Scholar] [CrossRef]

- Cho, W.G.; Kang, C.G. Mechanical properties and their microstructure evaluation in the thixoforming process of semi-solid aluminum alloys. J. Mater. Process. Tech. 2000, 105, 269–277. [Google Scholar] [CrossRef]

- Wang, T.; Huang, Y.F.; Ma, Y.Z.; Wu, L.; Yan, H.Y.; Liu, C.; Liu, Y.; Liu, B.; Liu, W.S. Microstructure and mechanical properties of powder metallurgy 2024 aluminum alloy during cold rolling. J. Mater. Res. Technol. 2021, 15, 3337–3348. [Google Scholar] [CrossRef]

- Liu, T.; Wang, Q.D.; Sui, Y.D.; Wang, Q.G.; Ding, W.J. An investigation into aluminum-aluminum bimetal fabrication by squeeze casting. Mater. Design 2015, 68, 8–17. [Google Scholar] [CrossRef]

- Martin, J.H.; Yahata, B.; Hundly, J.M.; Mayer, J.A.; Schaedler, T.A.; Pollock, T.M. 3D printing of high-strength aluminium alloys. Nature 2017, 549, 365–369. [Google Scholar] [CrossRef]

- Yuan, D.; Shao, S.; Guo, C.; Jiang, F.C.; Wang, J.D. Grain refining of Ti-6Al-4V alloy fabricated by laser and wire additive manufacturing assisted with ultrasonic vibration. Ultrason. Sonochem. 2021, 73, 105472. [Google Scholar] [CrossRef]

- Jiang, R.P.; Zhao, W.H.; Zhang, L.; Li, X.Q.; Guan, S.K. Microstructure and corrosion resistance of commercial purity aluminum sheet manufactured by continuous casting direct rolling after ultrasonic melt pre-treatment. J. Mater. Res. Technol. 2023, 22, 1522–1532. [Google Scholar] [CrossRef]

- Jang, H.S.; Lee, G.H.; Jeon, J.B.; Choi, Y.S.; Shin, S.M. Effect of ultrasonic melt treatment conditions on melt quality of Al–Mg alloy. J. Mater. Res. Technol. 2022, 19, 2645–2656. [Google Scholar] [CrossRef]

- Xiong, Z.F.; Jiang, Y.; Yang, M.; Zhang, Y.; Lei, L. Achieving superior strength and ductility in 7075 aluminum alloy through the design of multi-gradient nanostructure by ultrasonic surface rolling and aging. J. Alloys Compd. 2022, 918, 165669. [Google Scholar] [CrossRef]

- Sui, D.S.; Han, Q.Y. Ultrasound-assisted cast-on method: Obtaining high-quality metallurgical bonds between a bare steel insert and A354 aluminum alloy within a composite casting. J. Mater. Process. Tech. 2023, 311, 117783. [Google Scholar] [CrossRef]

- Eskin, G.I. Principles of Ultrasonic Treatment: Application for Light Alloys Melts. Adv. Perform. Mater. 1997, 4, 223–232. [Google Scholar] [CrossRef]

- Li, J.Y.; Pan, Y.; Yan, Z.X.; Lu, S.L.; Zhao, D.J.; Guo, W.; Wu, S. Effects of Li content on microstructure evolution and mechanical properties of squeeze-cast Al-5Cu-xLi alloy assisted with ultrasonic treatment. J. Alloys Compd. 2023, 961, 171083. [Google Scholar] [CrossRef]

- Guang, F.; Jiang, W.M.; Wang, J.L.; Li, G.Y.; Zhang, Z.; Fan, Z.T. Development of high strength Mg/Al bimetal by a novel ultrasonic vibration aided compound casting process. J. Mater. Process. Tech. 2022, 300, 117441. [Google Scholar] [CrossRef]

- Moussa, M.E.; Waly, M.A.; Amin, M. Effect of high intensity ultrasonic treatment on microstructural modification and hardness of a nickel-aluminum bronze alloy. J. Alloys Compd. 2018, 741, 804–813. [Google Scholar] [CrossRef]

- Dong, F.; Li, X.Q.; Zhang, L.H. Cavitation erosion mechanism of titanium alloy radiation rods in aluminum melt. Ultrason. Sonochem. 2016, 31, 150–156. [Google Scholar] [CrossRef]

- Jiao, L.; Zhao, Y.T.; Li, H.; Shang, H.; Zhang, Z.Z.; Xia, T.F. A High-Temperature Aluminum Liquid Corrosion Resistant Ultrasonic Amplitude Transformer and a Preparation Method Thereof. China Patent CN201210467584.4, 19 November 2012. [Google Scholar]

- Maula, M.I.; Winarni, T.I.; Tauviqirrahman, M.; Maula, M.I.; Winarni, T.I.; Tauviqirrahman, M.; Akbar, I.; Basri, H.; Heide, E.V.D.; Jamari, J. Tresca Stress Simulation of Metal-on-Metal Total Hip Arthroplasty during Normal Walking Activity. Materials 2021, 14, 7554. [Google Scholar]

- Thakur, A.; Kaya, S.; Kumar, A. Recent Trends in the Characterization and Application Progress of Nano-Modified Coatings in Corrosion Mitigation of Metals and Alloys. Appl. Sci. 2023, 13, 730. [Google Scholar] [CrossRef]

- Thakur, A.; Sharma, S.; Ganjoo, R.; Assad, H.; Kumar, A. Anti-Corrosive Potential of the Sustainable Corrosion Inhibitors Based on Biomass Waste: A Review on Preceding and Perspective Research. J. Phys. Conf. Ser. 2022, 2267, 012079. [Google Scholar] [CrossRef]

- Tian, Y.; Liu, Z.L.; Li, X.Q.; Zhang, L.H.; Li, R.Q.; Jiang, R.P.; Dong, F. The cavitation erosion of ultrasonic sonotrode during large-scale metallic casting: Experiment and simulation. Ultrason. Sonochem. 2018, 43, 29–37. [Google Scholar] [CrossRef]

- Hong, S.; Wu, Y.P.; Zhang, J.F.; Zheng, Y.G.; Zheng, Y.; Lin, J.R. Synergistic effect of ultrasonic cavitation erosion and corrosion of WC–CoCr and FeCrSiBMn coatings prepared by HVOF spraying. Ultrason. Sonochem. 2016, 31, 563–569. [Google Scholar] [CrossRef]

- Man, H.C.; Cui, Z.D.; Yue, T.M.; Cheng, F.T. Cavitation erosion behavior of laser gas nitrided Ti and Ti6Al4V alloy. Mater. Sci. Eng. A 2003, 355, 167–173. [Google Scholar] [CrossRef]

- Li, D.; Kang, Y.; Wang, X.C.; Ding, X.L.; Fang, Z.L. Effects of nozzle inner surface roughness on the cavitation erosion characteristics of high speed submerged jets. Exp. Therm. Fluid Sci. 2016, 74, 444–452. [Google Scholar] [CrossRef]

- Pitt, F.; Ramulu, M. Influence of grain size and microstructure on oxidation rates in titanium alloy Ti-6Al-4V under superplastic forming conditions. J. Mater. Eng. Perform. 2004, 13, 727–734. [Google Scholar] [CrossRef]

- Shi, C.; Wu, Y.J.; Mao, D.H.; Fan, G.F. Effect of Ultrasonic Bending Vibration Introduced by the L-shaped Ultrasonic Rod on Solidification Structure and Segregation of Large 2A14 Ingots. Materials 2020, 13, 807. [Google Scholar] [CrossRef]

- Li, R.Q.; Liu, Z.L.; Dong, F.; Li, X.Q.; Chen, P.H. Grain refinement of a large-scale Al alloy casting by introducing the multiple ultrasonic generators during solidification. Metall. Mater. Trans. A 2016, 47, 3790–3796. [Google Scholar] [CrossRef]

- Li, R.Q.; Liu, Z.L.; Chen, P.H.; Zhong, Z.T.; Li, X.Q. Investigation on the Manufacture of a Large-Scale Aluminum Alloy Ingot: Microstructure and Macrosegregation. Adv. Eng. Mater. 2017, 19, 1600375. [Google Scholar] [CrossRef]

- Zhou, Y.K.; Hammitt, F.G. Vibratory cavitation erosion in aqueous solutions. Wear 1983, 87, 163–171. [Google Scholar] [CrossRef]

- Chahine, G.L.; Kapahi, A.; Choi, J.K. Modeling of surface cleaning by cavitation bubble dynamics and collapse. Ultrason. Sonochem. 2016, 29, 528–549. [Google Scholar] [CrossRef]

- Kattner, U.R.; Lin, J.C.; Chang, Y.A. Thermodynamic Assessment and Calculation of the Ti-Al System. Metall. Mater. Trans. A 1992, 23, 2081–2090. [Google Scholar] [CrossRef]

- Kennedy, C.F.; Field, J.E. Damage threshold velocities for liquid impact. J. Mater. Sci. 2000, 35, 5331–5339. [Google Scholar] [CrossRef]

- Zhang, S.G.; Duncan, J.H.; Chahine, G.L. The final stage of the collapse of a cavitation bubble near a rigid wall. J. Fluid. Mech. 1993, 257, 147–181. [Google Scholar] [CrossRef]

- Tomia, Y.; Robinson, P.B.; Tong, R.P.; Blake, J.R. Growth and collapse of cavitation bubbles near a curved rigid boundary. J. Fluid. Mech. 2002, 466, 259–283. [Google Scholar] [CrossRef]

| Elements | Fe | C | N | H | O | Al | V | Ti |

|---|---|---|---|---|---|---|---|---|

| Content | ≤0.30 | ≤0.10 | ≤0.05 | ≤0.02 | ≤0.20 | 5.5~6.8 | 3.5~4.5 | Bal. |

| Sample | Ra (µm) | Initial Weight m(g) | Weight after 48 min m1(g) | Lost Weight/Cavitated Area (mg/cm2) |

|---|---|---|---|---|

| A | 0.4 | 27.0017 | 26.9936 | 8.1 |

| B | 7.2 | 27.0519 | 27.0392 | 12.7 |

| C | 9.5 | 27.2140 | 27.1968 | 17.3 |

| D | 9.8 | 26.9418 | 26.9264 | 15.4 |

| Number Rate (vt) | 12 min v1 (mg·min−1/cm2) | 24 min v2 (mg·min−1/cm2) | 36 min v3 (mg·min−1/cm2) | 48 min v4 (mg·min−1/cm2) |

|---|---|---|---|---|

| A | 0.168 | 0.152 | 0.185 | 0.169 |

| B | 0.304 | 0.260 | 0.273 | 0.265 |

| C | 0.460 | 0.349 | 0.421 | 0.359 |

| D | 0.334 | 0.266 | 0.347 | 0.320 |

| Roughness Time (t/h) | 1 | 3 | 5 |

|---|---|---|---|

| 0.4 Ra | 80 | 160 | 140 |

| 7.2 Ra | 90 | 150 | 130 |

| 9.5 Ra | 100 | 140 | 120 |

| 9.8 Ra | 100 | 150 | 130 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yang, Y.; Zhang, Y.; Liu, X.; Zhang, H. Study on Cavitation Corrosion Properties of Titanium Alloy Radiation Rod with Different Roughnesses for Ultrasonic Casting. Coatings 2023, 13, 1632. https://doi.org/10.3390/coatings13091632

Yang Y, Zhang Y, Liu X, Zhang H. Study on Cavitation Corrosion Properties of Titanium Alloy Radiation Rod with Different Roughnesses for Ultrasonic Casting. Coatings. 2023; 13(9):1632. https://doi.org/10.3390/coatings13091632

Chicago/Turabian StyleYang, Yilong, Ya Zhang, Xuhe Liu, and Haoming Zhang. 2023. "Study on Cavitation Corrosion Properties of Titanium Alloy Radiation Rod with Different Roughnesses for Ultrasonic Casting" Coatings 13, no. 9: 1632. https://doi.org/10.3390/coatings13091632

APA StyleYang, Y., Zhang, Y., Liu, X., & Zhang, H. (2023). Study on Cavitation Corrosion Properties of Titanium Alloy Radiation Rod with Different Roughnesses for Ultrasonic Casting. Coatings, 13(9), 1632. https://doi.org/10.3390/coatings13091632