SrTiO3 Thin Films on Dielectric Substrates for Microwave Applications

Abstract

:1. Introduction

2. Experiment

2.1. Sample Preparation

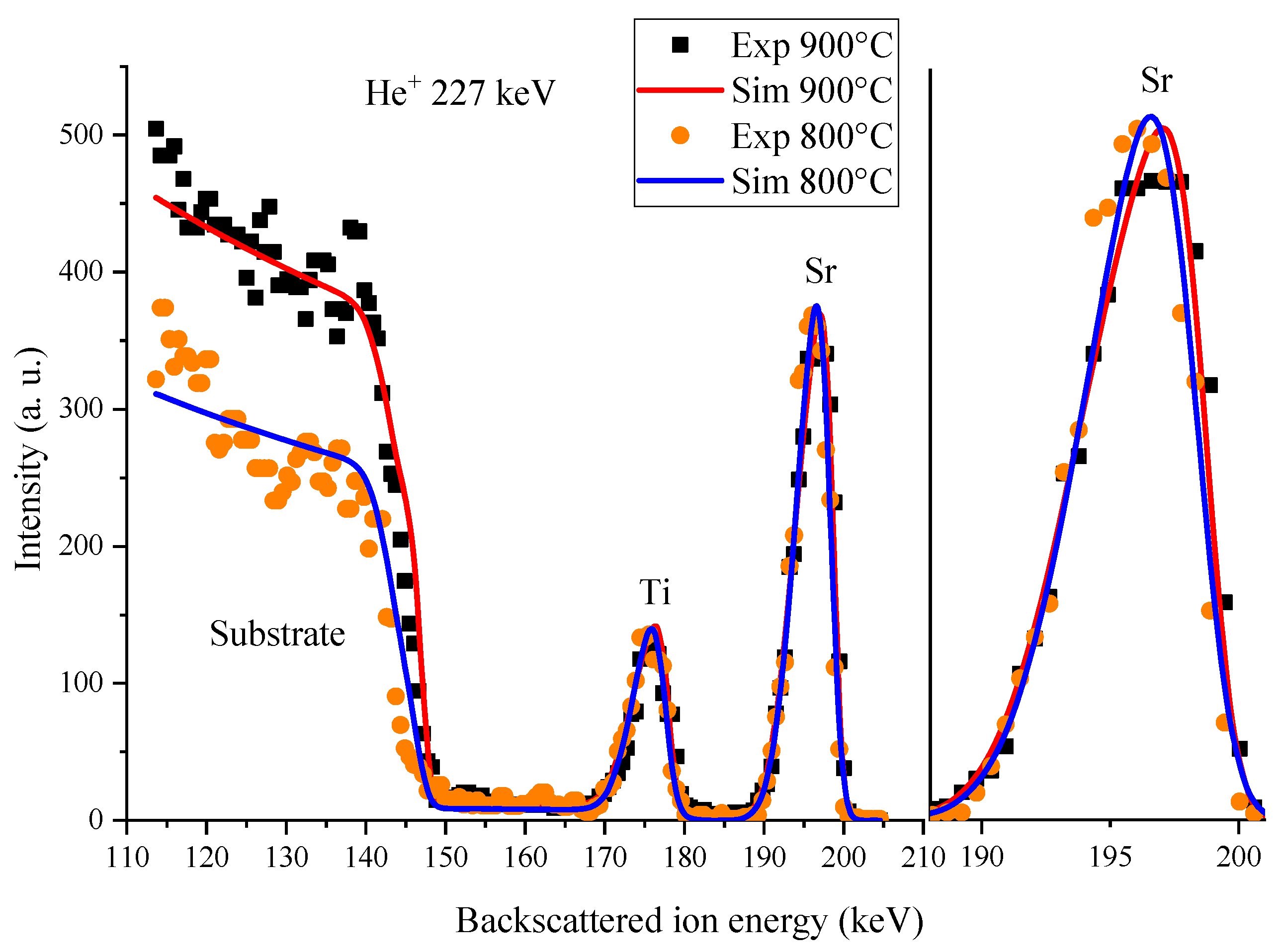

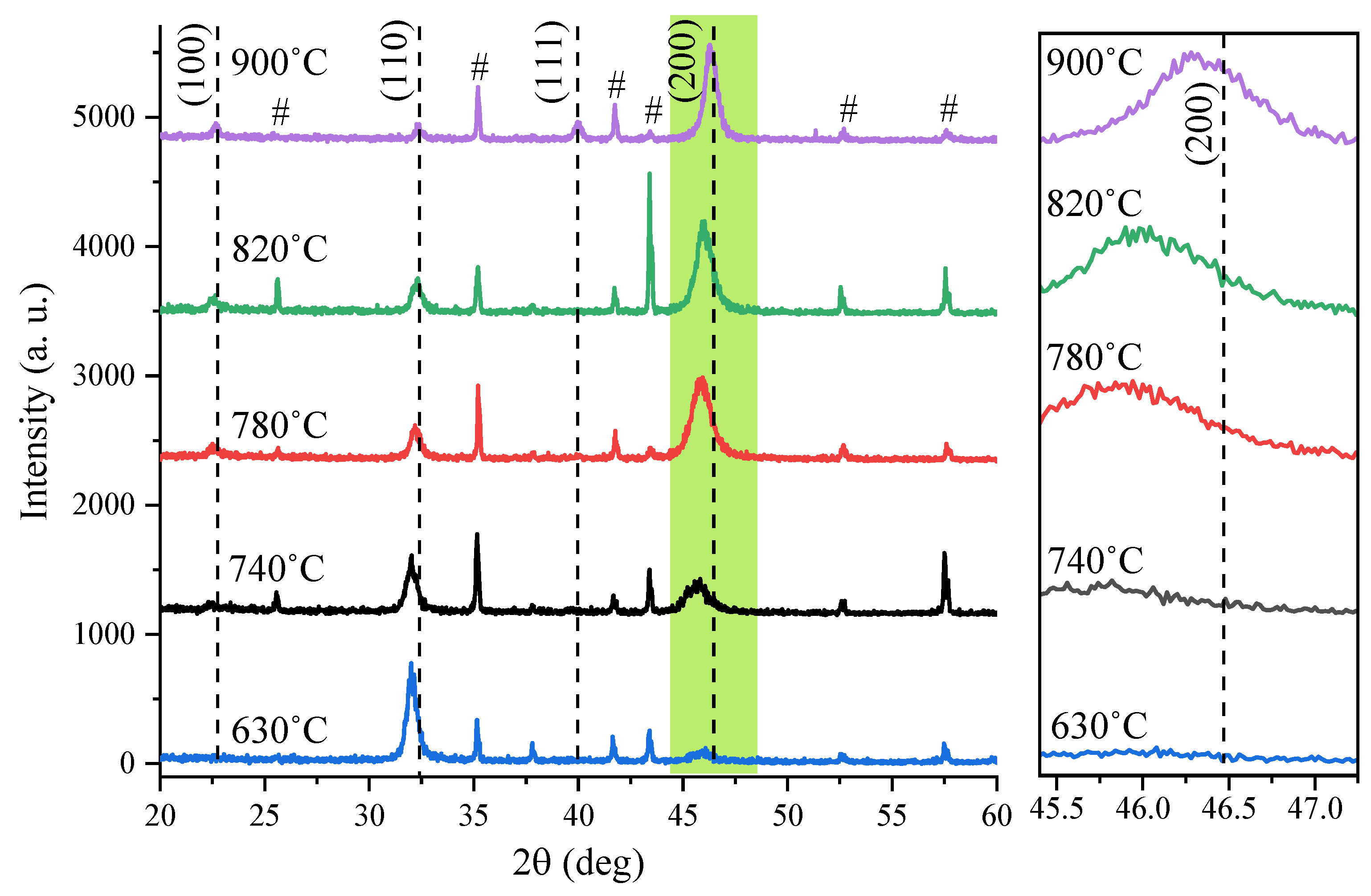

2.2. Structure Investigation

2.3. Electrical Measurements

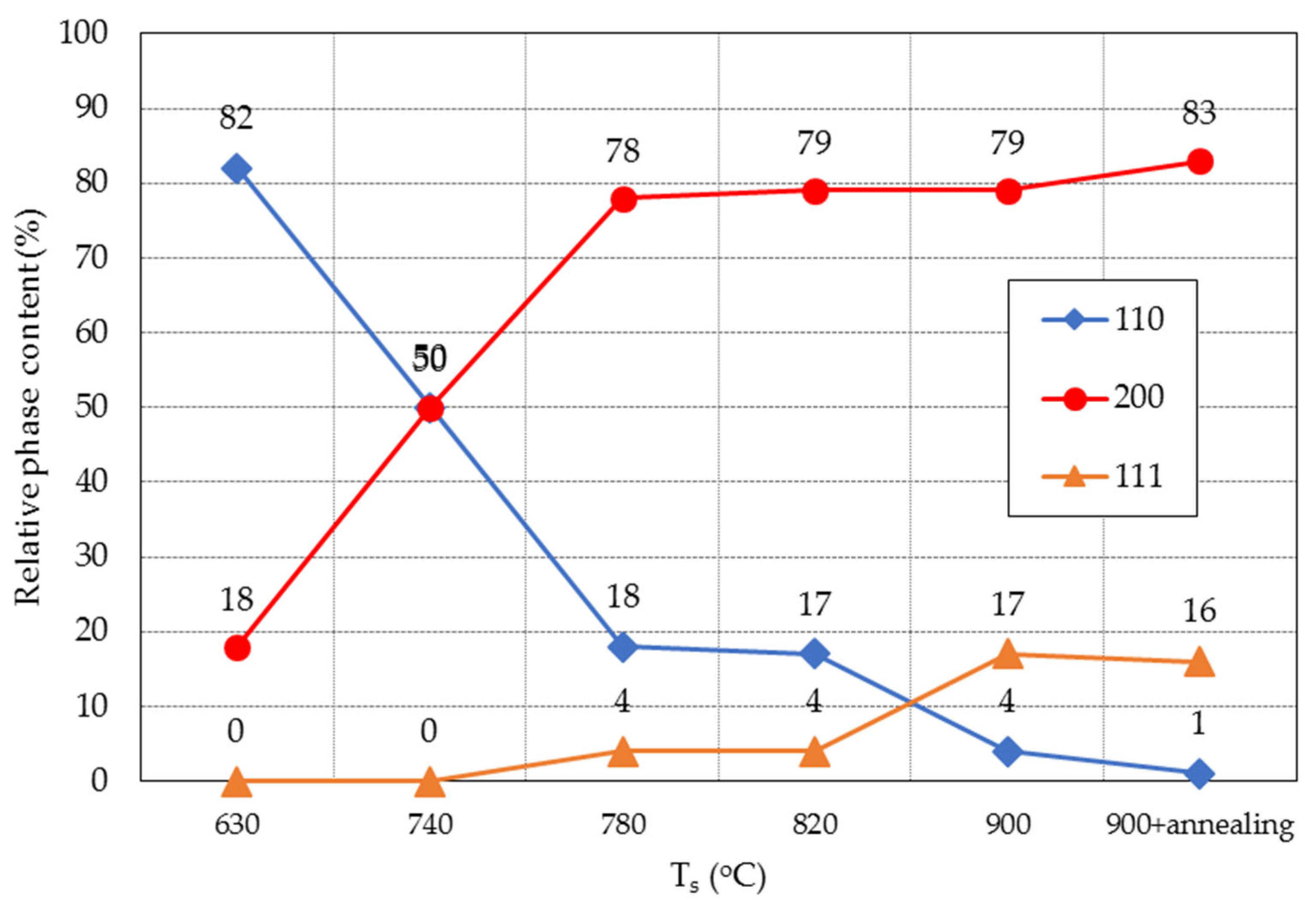

3. Results

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Martin, L.W.; Rappe, A.M. Thin-film ferroelectric materials and their applications. Nat. Rev. Mater. 2016, 2, 16087. [Google Scholar] [CrossRef]

- Xu, Y. Ferroelectric Materials and Their Applications; Elsevier Science Publishers: Amsterdam, The Netherlands, 2013. [Google Scholar]

- Huang, J.; Gao, X.; MacManus-Driscoll, J.L.; Wang, H. Ferroelectric thin films and nanostructures: Current and future. In Nanostructures in Ferroelectric Films for Energy Applications; Elsevier: Amsterdam, The Netherlands, 2019; pp. 19–39. [Google Scholar]

- Tagantsev, A.K.; Sherman, V.O.; Astafiev, K.F.; Venkatesh, J.; Setter, N. Ferroelectric materials for microwave tunable applications. J. Electroceramics 2003, 11, 5–66. [Google Scholar] [CrossRef]

- Liu, X.; Tu, J.; Li, H.; Tian, J.; Zhang, L. Research progress of double perovskite ferroelectric thin films. Appl. Phys. Rev. 2023, 10, 021315. [Google Scholar] [CrossRef]

- Kong, L.B.; Li, S.; Zhang, T.S.; Zhai, J.W.; Boey, F.C.; Ma, J. Electrically tunable dielectric materials and strategies to improve their performances. Prog. Mater. Sci. 2010, 55, 840–893. [Google Scholar] [CrossRef]

- Vendik, I.B.; Vendik, O.G.; Kollberg, E.L. Commutation quality factor of two-state switchable devices. IEEE Trans. Microw. Theory Tech. 2000, 48, 802–808. [Google Scholar] [CrossRef]

- Vendik, O.G. Ferroelectrics find their “niche” among microwave control devices. Phys. Solid State 2009, 51, 1529–1534. [Google Scholar] [CrossRef]

- Setter, N.; Setter, N.; Damjanovic, D.; Eng, L.; Fox, G.; Gevorgian, S.; Hong, S.; Streiffer, S. Ferroelectric thin films: Review of materials, properties, and applications. J. Appl. Phys. 2006, 100, 051606. [Google Scholar] [CrossRef]

- Winiger, J.; Winiger, J.; Keller, K.; Moor, D.; Baumann, M.; Kim, D.; Chelladurai, D.; Leuthold, J. PLD Epitaxial Thin-Film BaTiO3 on MgO−Dielectric and Electro-Optic Properties. Adv. Mater. Interfaces 2023, 2300665. [Google Scholar] [CrossRef]

- Chen, C.L.; Shen, J.; Chen, S.Y.; Luo, G.P.; Chu, C.W.; Miranda, F.A.; Chang, H.Y. Epitaxial growth of dielectric Ba0.6Sr0.4TiO3 thin film on MgO for room temperature microwave phase shifters. Appl. Phys. Lett. 2006, 78, 652–654. [Google Scholar] [CrossRef]

- Lin, J.; Guo, X.; Li, C.; Hong, Z.; Wu, Y.; Huang, Y. Manipulation of phase transitions and electrical properties of Ba1-xSrxTiO3 thin films through orientation engineering. Acta Mater. 2003, 261, 119360. [Google Scholar] [CrossRef]

- Jackson, T.J.; Jones, I.P. Nanoscale defects and microwave properties of (BaSr)TiO3 ferroelectric thin films. J. Mater. Sci. 2009, 44, 5288–5296. [Google Scholar] [CrossRef]

- Harris, D.T.; Lam, P.G.; Burch, M.J.; Li, J.; Rogers, B.J.; Dickey, E.C.; Maria, J.P. Ultra-high tunability in polycrystalline Ba1−xSrxTiO3 thin films. Appl. Phys. Lett. 2014, 105, 072904. [Google Scholar] [CrossRef]

- Razumov, S.; Tumarkin, A.; Gaidukov, M.; Gagarin, A.; Kozyrev, A.; Vendik, O.; Ivanov, A.; Buslov, O.; Keys, V.; Sengupta, L.C.; et al. Characterisation of quality of BaxSr1-xTiO3 thin film by the commutation quality factor measured at microwaves. Appl. Phys. Lett. 2002, 81, 1675–1677. [Google Scholar] [CrossRef]

- Kozyrev, A.B.; Soldatenkov, O.I.; Ivanov, A.V. Switching time of planar ferroelectric capacitors using strontium titanate and barium strontium titanate films. Tech. Phys. Lett. 1998, 24, 755–757. [Google Scholar] [CrossRef]

- Li, J.; Nagaraj, B.; Liang, H.; Cao, W.; Lee, C.H.; Ramesh, R. Ultrafast polarization switching in thin-film ferroelectrics. Appl. Phys. Lett. 2004, 84, 1174–1176. [Google Scholar] [CrossRef]

- Cole, M.W. Temperature Stabilization of BST Thin Films: A Critical Review. Ferroelectrics 2014, 470, 67–89. [Google Scholar] [CrossRef]

- Gaidukov, M.M.; Tumarkin, A.V.; Gagarin, A.G.; Kozyrev, A.B. Thermostabilization of the properties of multilayer ferroelectric variconds for microwave applications. Tech. Phys. Lett. 2014, 40, 337–339. [Google Scholar] [CrossRef]

- Mantese, J.V.; Alpay, S.P. Graded Ferroelectrics, Transpacitors and Transponents; Springer: New York, NY, USA, 2005. [Google Scholar]

- Müller, K.A.; Burkard, H. SrTiO3: An intrinsic quantum paraelectric below 4 K. Phys. Rev. B 1979, 19, 3593. [Google Scholar] [CrossRef]

- Yang, F.; Zhang, Q.; Yang, Z.; Gu, J.; Liang, Y.; Li, W.; Wang, W.; Jin, K.; Gu, L.; Guo, J. Room-temperature ferroelectricity of SrTiO3 films modulated by cation concentration. Appl. Phys. Lett. 2015, 107, 082904. [Google Scholar] [CrossRef]

- Biegalski, M.D.; Jia, Y.; Schlom, D.G.; Trolier-McKinstry, S.; Streiffer, S.K.; Sherman, V.; Uecker, R.; Reiche, P. Relaxor ferroelectricity in strained epitaxial SrTiO3 thin films on DyScO3 substrates. Appl. Phys. Lett. 2006, 88, 192907. [Google Scholar] [CrossRef]

- Haeni, J.H.; Irvin, P.; Chang, W.; Uecker, R.; Reiche, P.; Li, Y.L.; Choudhury, S.; Tian, W.; Hawley, M.E.; Craigo, B.; et al. Room-temperature ferroelectricity in strained SrTiO3. Nature 2004, 430, 758–761. [Google Scholar] [CrossRef]

- Tkach, A.; Okhay, O.; Reaney, I.M.; Vilarinho, P.M. Mechanical strain engineering of dielectric tunability in polycrystalline SrTiO3 thin films. J. Mater. Chem. C 2018, 6, 2467–2475. [Google Scholar] [CrossRef]

- Pertsev, N.A.; Tagantsev, A.K.; Setter, N. Phase transitions and strain-induced ferroelectricity in SrTiO3 epitaxial thin films. Phys. Rev. B 2000, 61, R825. [Google Scholar] [CrossRef]

- Sbrockey, N.M.; Tompa, G.S.; Kalkur, T.S.; Zhang, J.; Alpay, S.; Cole, M.W. Voltage induced acoustic resonance in metal organic chemical vapor deposition SrTiO3 thin film. J. Vac. Sci. Technol. B 2012, 30, 061202. [Google Scholar] [CrossRef]

- Jia, J.; Zhao, G.; Lei, L.; Wang, X. Preparation of LaNiO3/SrTiO3/LaNiO3 capacitor structure through sol–gel process. Ceram. Int. 2016, 42, 9762–9768. [Google Scholar] [CrossRef]

- Kozyrev, A.; Keis, V.; Buslov, O.; Ivanov, A.; Soldatenkov, O.; Loginov, V.; Graul, J. Microwave properties of ferroelectric film planar varactors. Integr. Ferroelectr. 2001, 34, 271–278. [Google Scholar] [CrossRef]

- Sulong, T.A.T.; Osman, R.A.M.; Idris, M.S. Trends of microwave dielectric materials for antenna application. In AIP Conference Proceedings; AIP Publishing: Melville, NY, USA, 2016. [Google Scholar]

- Kozyrev, A.B.; Soldatenkov, O.I.; Samoilova, T.B.; Ivanov, A.V.; Mueller, C.H.; Rivkin, T.V.; Koepf, G.A. Response time and power handling capability of tunable microwave devices using ferroelectric films. Integr. Ferroelectr. 1998, 22, 329–340. [Google Scholar] [CrossRef]

- Carlson, C.M.; Rivkin, T.V.; Parilla, P.A.; Perkins, J.D.; Ginley, D.S.; Kozyrev, A.B.; Oshadchy, V.N.; Pavlov, A.S. Large dielectric constant (ε/ε> 6000) Ba0.4Sr0.6TiO3 thin films for high-performance microwave phase shifters. Appl. Phys. Lett. 2000, 76, 1920–1922. [Google Scholar] [CrossRef]

- Abe, K.A.K.; Komatsu, S.K.S. Measurement and thermodynamic analyses of the dielectric constant of epitaxially grown SrTiO3 films. Jpn. J. Appl. Phys. 1993, 32, L.1157–L.1159. [Google Scholar]

- Loginov, V.E.; Tumarkin, A.V.; Sysa, M.V.; Buslov, O.U.; Gaidukov, M.M.; Ivanov, A.I.; Kozyrev, A.B. The influence of synthesis temperature on structure properties of SrTiO3 ferroelectric films. Integr. Ferroelectr. 2001, 39, 375–381. [Google Scholar] [CrossRef]

- Kozyrev, A.B.; Kozyrev, A.B.; Samoilova, T.B.; Golovkov, A.A.; Hollmann, E.K.; Kalinikos, D.A.; Loginov, V.E.; Koepf, G.A. Nonlinear properties of SrTiO3 films at microwave frequencies. Integr. Ferroelectr. 1997, 17, 263–271. [Google Scholar] [CrossRef]

- Kužel, P.; Kadlec, F.; Petzelt, J.; Schubert, J.; Panaitov, G. Highly tunable SrTiO3/DyScO3 heterostructures for applications in the terahertz range. Appl. Phys. Lett. 2007, 91, 232911. [Google Scholar] [CrossRef]

- Chang, W.; Kirchoefer, S.W.; Bellotti, J.A.; Qadri, S.B.; Pond, J.M.; Haeni, J.H.; Schlom, D.G. In-plane anisotropy in the microwave dielectric properties of SrTiO3 films. J. Appl. Phys. 2005, 98, 024107. [Google Scholar] [CrossRef]

- Afrosimov, V.V.; Il’in, R.N.; Sakharov, V.I.; Serenkov, I.T.; Yanovskii, D.V.; Karmanenko, S.F.; Semenov, A.A. Study of YBa2Cu3O7−x films at various stages of their growth by medium-energy ion scattering. Phys. Solid State 1999, 41, 527–533. [Google Scholar] [CrossRef]

- Tumarkin, A.V.; Serenkov, I.T.; Sakharov, V.I.; Afrosimov, V.V.; Odinets, A.A. Influence of the substrate temperature on the initial stages of growth of barium strontium titanate films on sapphire. Phys. Solid State 2016, 58, 364–369. [Google Scholar] [CrossRef]

- Niu, G.; Saint-Girons, G.; Vilquin, B.; Delhaye, G.; Maurice, J.L.; Botella, C.; Robach, Y.; Hollinger, G. Molecular beam epitaxy of SrTiO3 on Si (001): Early stages of the growth and strain relaxation. Appl. Phys. Lett. 2009, 95, 062902. [Google Scholar] [CrossRef]

- Schmelzer, J.W. Nucleation Theory and Applications; Strauss GmbH: Mörlenbach, Germany, 2004. [Google Scholar]

- Kukushkin, S.A.; Osipov, A.V. Theory of phase transformations in the mechanics of solids and its applications for description of fracture, formation of nanostructures and thin semiconductor films growth. Key Eng. Mater. 2013, 528, 145–164. [Google Scholar] [CrossRef]

- Kukushkin, S.A.; Osipov, A.V. Nucleation kinetics of nanofilms. In Encyclopedia of Nanoscience and Nanotechnology; American Scientific Publishers: Valencia, CA, USA, 2004; Volume 8, pp. 113–136. [Google Scholar]

- Kukushkin, S.A. Evolution processes in multicomponent and multiphase films. Thin Solid Film. 1992, 207, 302–312. [Google Scholar] [CrossRef]

- Tumarkin, A.V.; Gaidukov, M.M.; Razumov, S.V.; Gagarin, A.G. Capacitor structures based on strontium titanate films. Phys. Solid State 2012, 54, 968–971. [Google Scholar] [CrossRef]

- Chang, W.; Bellotti, J.A.; Kirchoefer, S.W.; Pond, J.M. Strain tensor effects on SrTiO3 incipient ferroelectric phase transition. J. Electroceramics 2006, 17, 487–494. [Google Scholar] [CrossRef]

- Chang, W.; Kirchoefer, S.W.; Pond, J.M.; Bellotti, J.A.; Qadri, S.B.; Haeni, J.H.; Schlom, D.G. Room-temperature tunable microwave properties of strained SrTiO3 films. J. Appl. Phys. 2004, 96, 6629–6633. [Google Scholar] [CrossRef]

- Tumarkin, A.V.; Gaidukov, M.M.; Gagarin, A.G.; Samoilova, T.B.; Kozyrev, A.B. Ferroelectric strontium titanate thin films for microwave applications. Ferroelectrics 2012, 439, 49–55. [Google Scholar] [CrossRef]

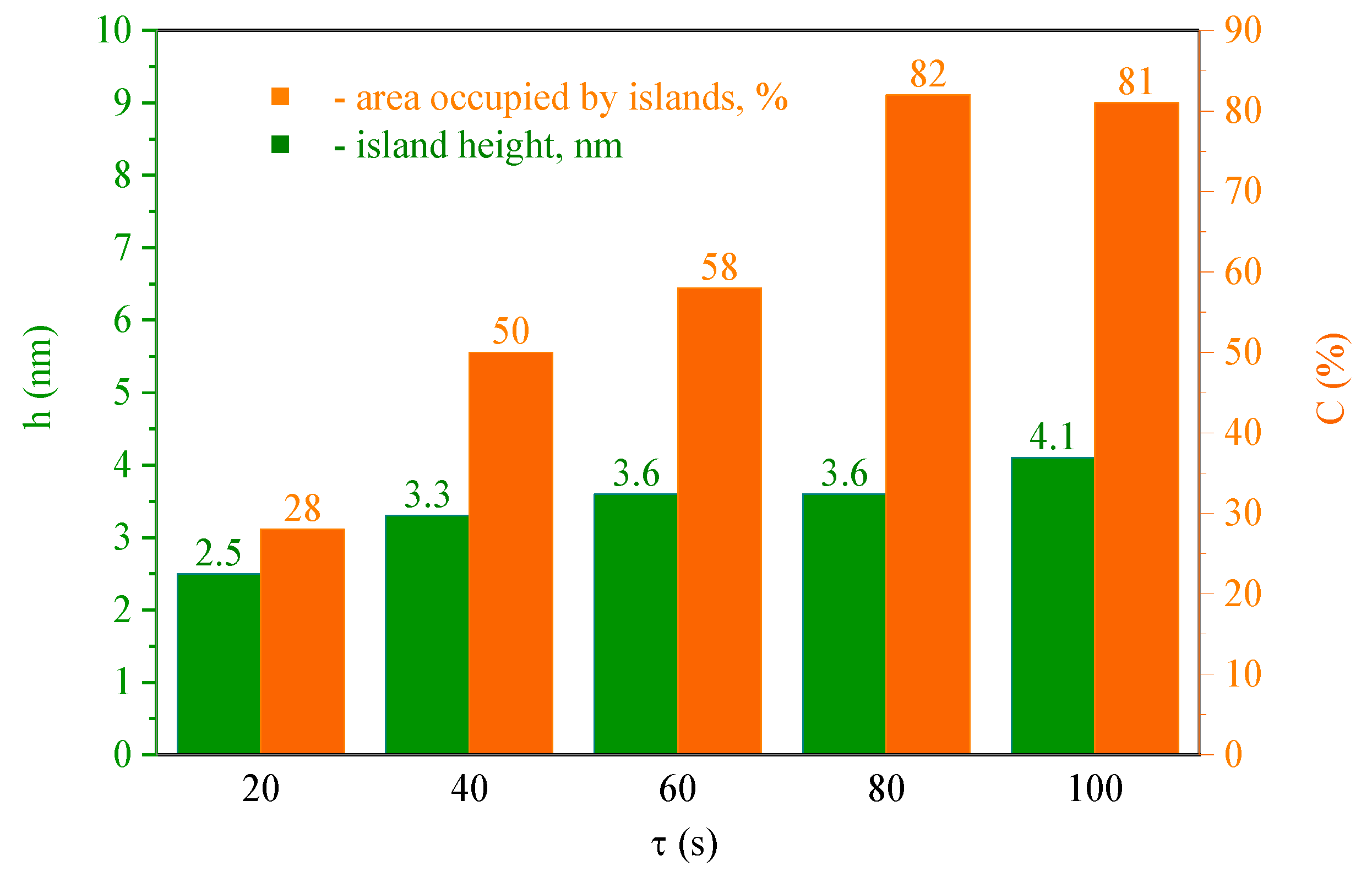

| Sample | Substrate | Ts (°C) | τ (s) | h (nm) | σ (nm) | σ/h | C (%) | M |

|---|---|---|---|---|---|---|---|---|

| B-379a | alumina | 800 | 20 | 2.5 | 1.4 | 0.56 | 28 | 5.1 |

| B-380a | alumina | 800 | 40 | 3.3 | 2.0 | 0.6 | 50 | 12.2 |

| B-378a | alumina | 800 | 60 | 3.6 | 1.6 | 0.43 | 58 | 15.4 |

| B-381a | alumina | 800 | 80 | 3.6 | 1.6 | 0.43 | 82 | 21.7 |

| B-398a | alumina | 800 | 100 | 4.1 | 1.6 | 0.39 | 81 | 24.5 |

| Substrate | Design | f (GHz) | n (%) | tanδ (U0) | tanδ (Umax) | CQF | Ref. |

|---|---|---|---|---|---|---|---|

| DyScO3 | planar | 10 | 57 | 0.047 | 0.045 | 360 | [37] |

| LaNiO3 | MDM | 0.1 | 23 | 0.011 | 0.024 | 245 | [28] |

| Pt/MgO | MDM | 0.0001 | 71 | 0.02 | 0.015 | 5949 | [33] |

| Pt/Sapphire | 4 electrode | 30 | 53 | 0.041 | 0.022 | 690 | [34] |

| Pt/Sapphire | 4 electrode | 10 | 41 | 0.015 | 0.011 | 1730 | [29] |

| Pt/Sapphire | MDM | 5.6 | 43 | 0.1 | 0.027 | 120 | [27] |

| Pt/Sapphire | MDM | 1.5 | 50 | 0.016 | 0.021 | 1490 | [45] |

| DyScO3 | planar | 10 | 50 | 0.071 | 0.06 | 120 | [46] |

| DyScO3 | planar | 10 | 66 | 0.19 | 0.11 | 61 | [47] |

| Pt/Sapphire | MDM | 1.5 | 60 | 0.014 | 0.021 | 3000 | [48] |

| Alumina | planar | 2 | 46 | 0.009 | 0.014 | 3100 | This work |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tumarkin, A.; Sapego, E.; Gagarin, A.; Bogdan, A.; Karamov, A.; Serenkov, I.; Sakharov, V. SrTiO3 Thin Films on Dielectric Substrates for Microwave Applications. Coatings 2024, 14, 3. https://doi.org/10.3390/coatings14010003

Tumarkin A, Sapego E, Gagarin A, Bogdan A, Karamov A, Serenkov I, Sakharov V. SrTiO3 Thin Films on Dielectric Substrates for Microwave Applications. Coatings. 2024; 14(1):3. https://doi.org/10.3390/coatings14010003

Chicago/Turabian StyleTumarkin, Andrey, Eugene Sapego, Alexander Gagarin, Alexey Bogdan, Artem Karamov, Igor Serenkov, and Vladimir Sakharov. 2024. "SrTiO3 Thin Films on Dielectric Substrates for Microwave Applications" Coatings 14, no. 1: 3. https://doi.org/10.3390/coatings14010003