Road Surface Texture Evaluation and Relation to Low-Speed Skid Resistance for Different Types of Mixtures

Abstract

:1. Introduction

2. Scope and Objectives

- Common texture evaluation indices included in this research were determined. The commonly used macro-texture indices MTD and MPD were obtained. The statistical index RMS was calculated and included as an amplitude-related indicator due to its strong correlation with the skid resistance [14,36]. Namely, three common texture indices, MTD, MPD and RMS were included.

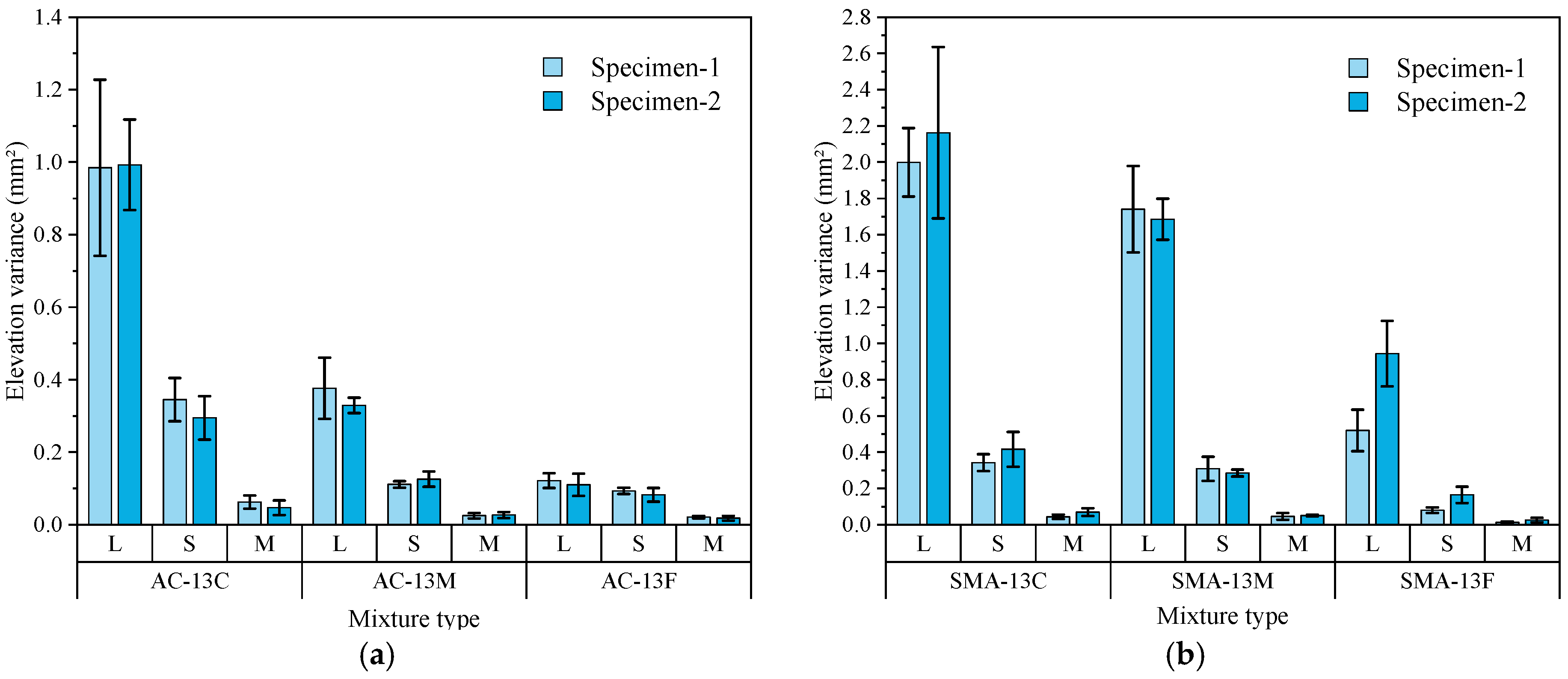

- Elevation variances with three different wavebands were calculated by signal filtering. Elevation variances for micro-texture with wavelengths from 0.024 mm to 0.5 mm was achieved, and even macro-texture was also divided into long and short groups by 5 mm to better understand the texture components with different wavelengths.

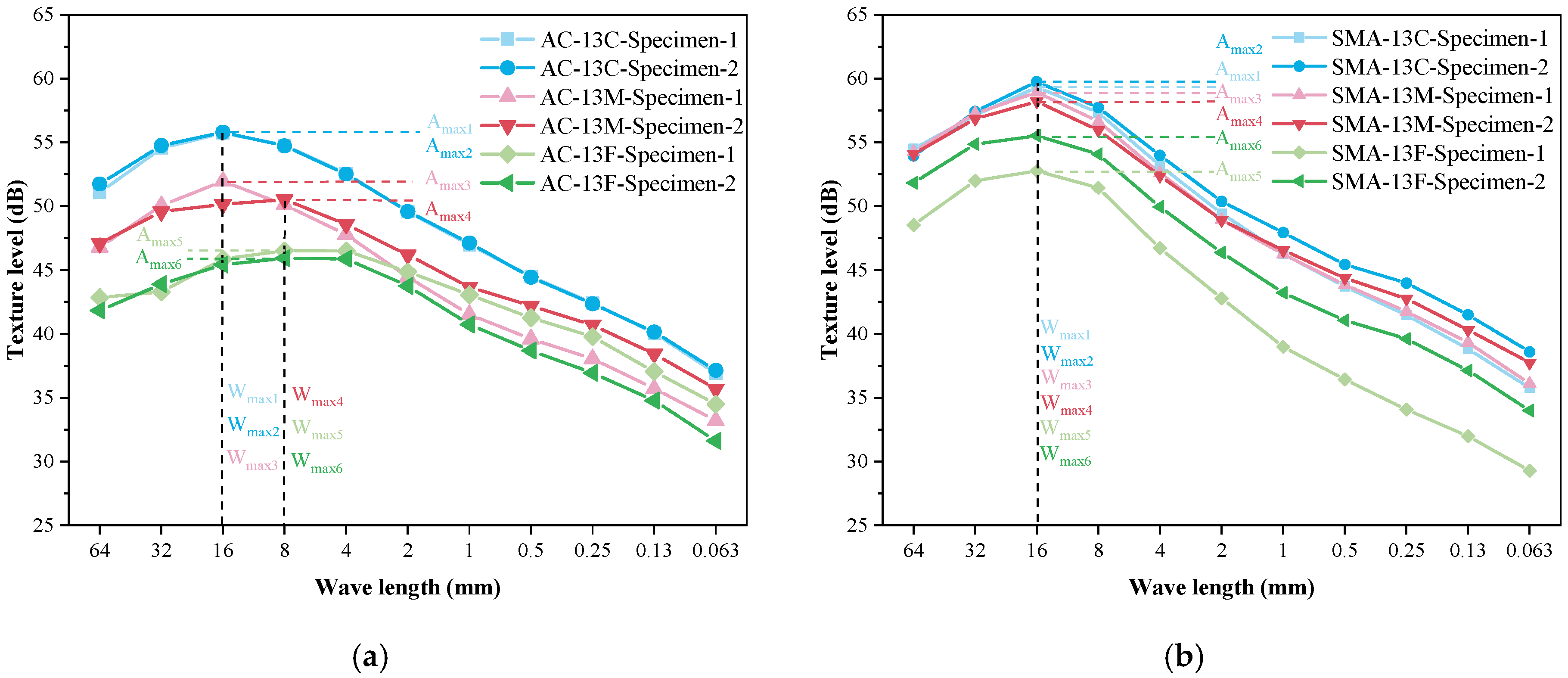

- Texture spectrums was obtained by signal processing and spectral analysis was conducted to analyze the texture distribution considering the general shape, peak value and corresponding wavelengths. The effects of aggregates gradating on the texture spectrums were also explained.

- Based on the above-mentioned texture and BPN for two types of asphalt mixtures, multiple linear regression was carried out to establish a prediction model of BPN from the surface texture considering the multicollinearity between different texture indices. The possible use of macro-texture and micro-texture to estimate BPN by linear regression was investigated.

3. Materials and Methods

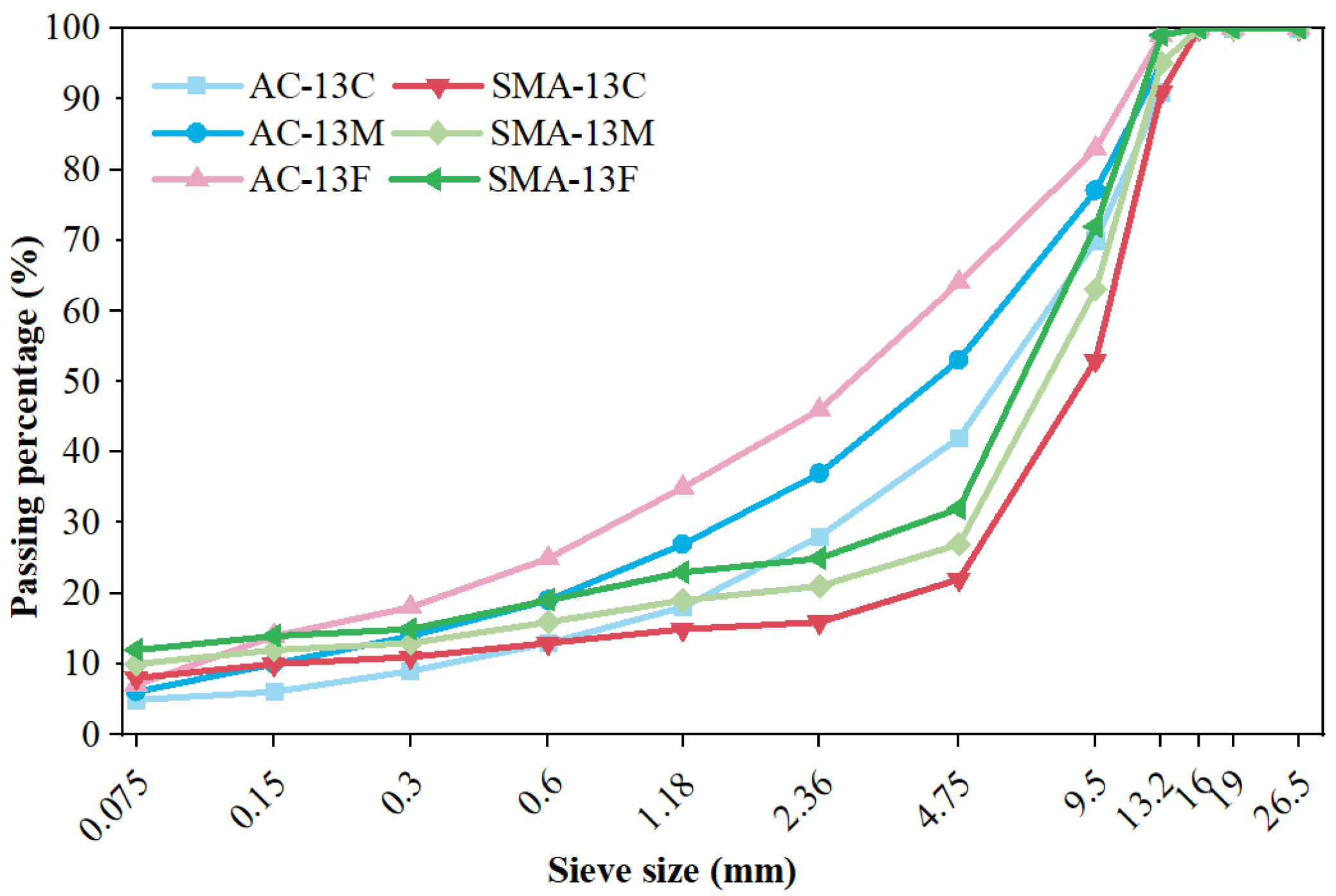

3.1. Materials and Specimen Fabrication

3.2. Test Programme

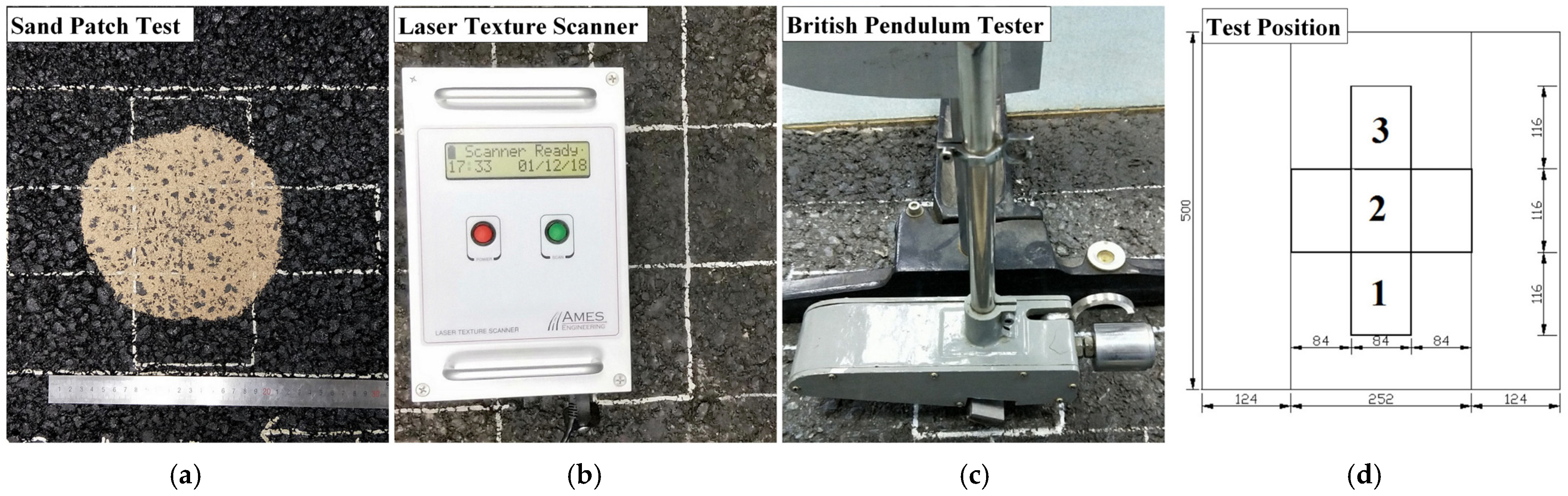

3.2.1. Measurement Devices and Test Positions

3.2.2. Road Surface Texture Evaluation

4. Results and Discussion

4.1. Road Surface Texture Analysis for Different Mixtures

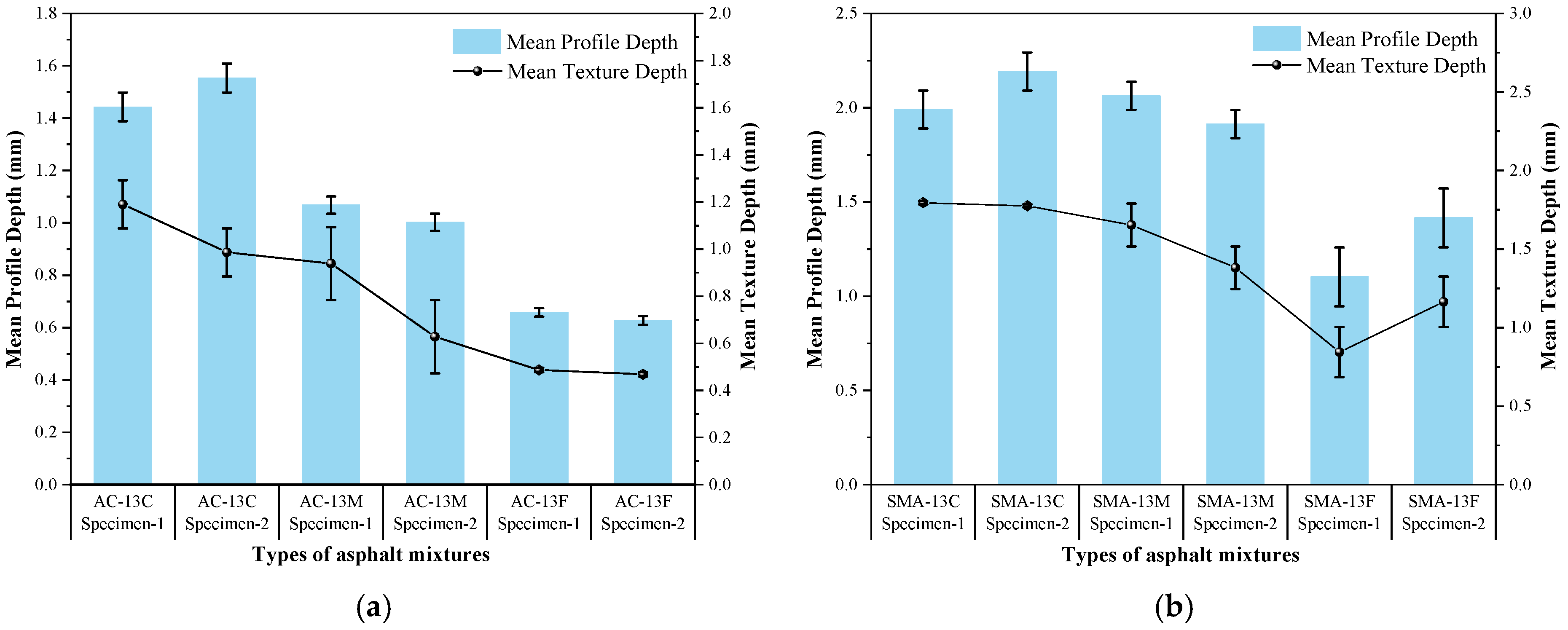

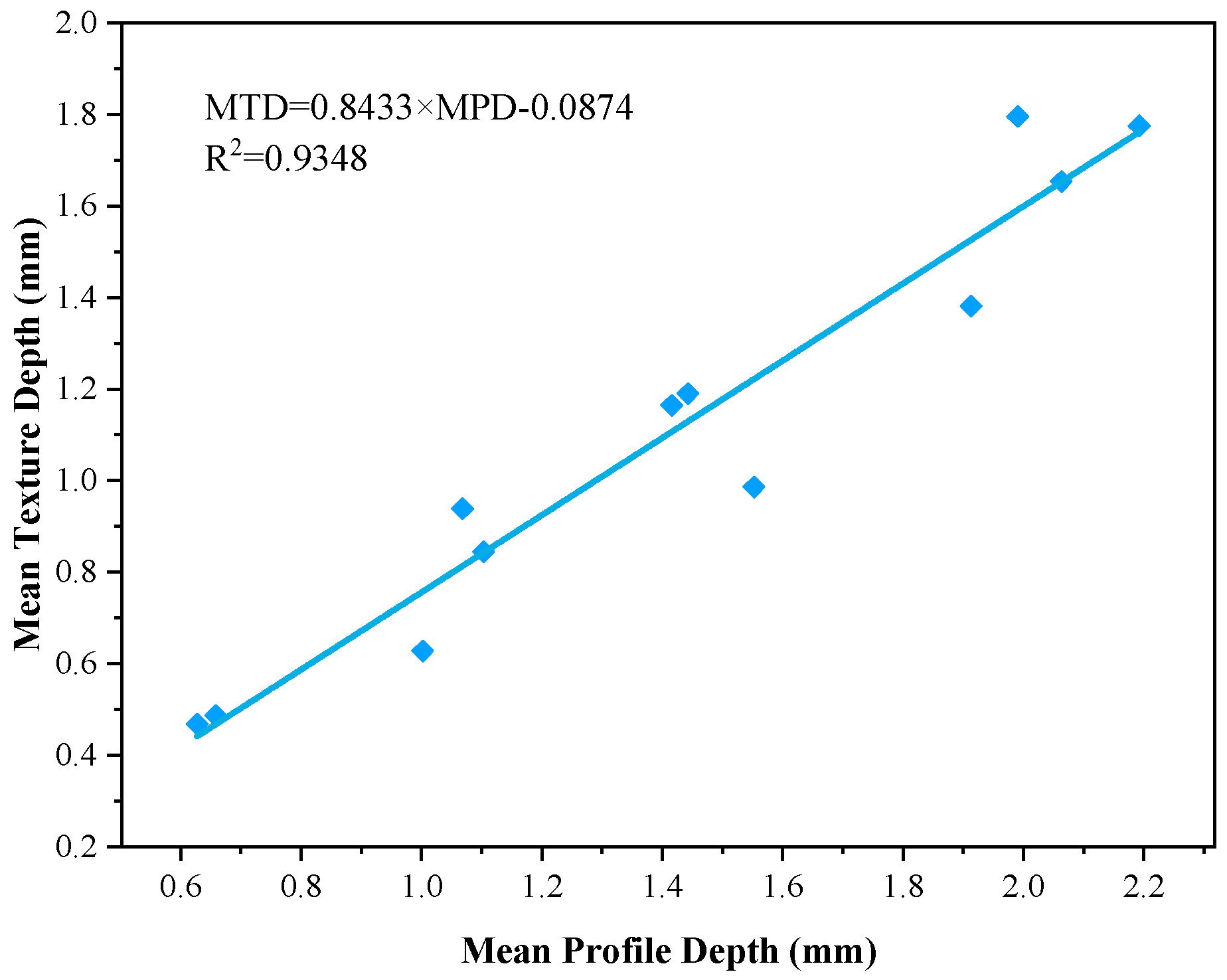

4.1.1. Texture Depth for Different Mixtures

4.1.2. Root Mean Square (RMS) for Different Mixtures

4.1.3. Variances with Regard to Different Wavelength Ranges for Different Mixtures

4.1.4. Texture Spectral Analysis for Different Mixtures

4.2. Prediction of BPN from Road Surface Texture

4.2.1. BPN and Its Linear Regression with a Single Road Surface Index

4.2.2. Relation Establishing Between Road Surface and BPN

4.2.3. Verification of the Skid Resistance Prediction

5. Summary and Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Najafi, S.; Flintsch, G.W.; Medina, A. Linking roadway crashes and tire–pavement friction: A case study. Int. J. Pavement Eng. 2017, 18, 119–127. [Google Scholar] [CrossRef]

- Kumar, A.; Tang, T.; Gupta, A.; Anupam, K. A state-of-the-art review of measurement and modelling of skid resistance: The perspective of developing nation. Case Stud. Constr. Mater. 2023, 18, e02126. [Google Scholar] [CrossRef]

- Mataei, B.; Zakeri, H.; Zahedi, M.; Nejad, F.M. Pavement friction and skid resistance measurement methods: A literature review. Open J. Civ. Eng. 2016, 6, 537–565. [Google Scholar] [CrossRef]

- Rasol, M.; Schmidt, F.; Ientile, S.; Adelaide, L.; Nedjar, B.; Kane, M.; Chevalier, C. Progress and monitoring opportunities of skid resistance in road transport: A critical review and road sensors. Remote Sens. 2021, 13, 3729. [Google Scholar] [CrossRef]

- Taher, M.; Aman, M.; Bujang, H. The effect of aggregate micro and macro texture on pavement skid resistance of Malaysia road network. IOP Conf. Ser. Earth Environ. Sci. 2024, 1347, 012054. [Google Scholar] [CrossRef]

- Serigos, P.A.; De Fortier Smit, A.; Prozzi, J.A. Incorporating surface microtexture in the prediction of skid resistance of flexible pavements. Transp. Res. Rec. 2014, 2457, 105–113. [Google Scholar] [CrossRef]

- Yu, M.; You, Z.; Wu, G.; Kong, L.; Liu, C.; Gao, J. Measurement and modeling of skid resistance of asphalt pavement: A review. Constr. Build. Mater. 2020, 260, 119878. [Google Scholar] [CrossRef]

- Yang, Y.; Zhu, X.; Jelagin, D.; Guarin, A.; Steyn, W.J. Numerical analysis concerning the skid resistance of rubber-contaminated runway grooves. Tribol. Int. 2021, 163, 107157. [Google Scholar] [CrossRef]

- Zhang, L.; Wang, R.; Zhou, H.; Wang, G. Estimation of the friction behaviour of rubber on wet rough road, and its application to tyre wet skid resistance, using numerical simulation. Symmetry 2022, 14, 2541. [Google Scholar] [CrossRef]

- ISO 13473-1:2019; Characterization of Pavement Texture by Use of Surface Profiles—Part 1: Mean Profile Depth. International Standards Organization (ISO): Geneva, Switzerland, 2019.

- Permanent International Association of Road Congresses (PIARC). Report of the committee on surface characteristics. In Proceedings of the XVIII World Road Congress, Brussels, Belgium, 13–19 September 1987. [Google Scholar]

- Snyder, M.B. Current Perspectives on Pavement Surface Characteristics. In R&T Update: Concrete Pavement Research and Technology; 2007; Available online: http://overlays.acpa.org/Downloads/RT/RT%208.02%20Current%20Perspectives%20on%20Pavement%20Surface%20Characteristics.pdf (accessed on 24 October 2024).

- Chen, S.; Liu, X.; Luo, H.; Yu, J.; Chen, F.; Zhang, Y.; Ma, T.; Huang, X. A state-of-the-art review of asphalt pavement surface texture and its measurement techniques. J. Road Eng. 2022, 2, 156–180. [Google Scholar] [CrossRef]

- Ji, J.; Jiang, T.; Ren, W.; Dong, Y.; Hou, Y.; Li, H. Precise characterization of macro-texture and its correlation with anti-skidding performance of pavement. J. Test. Eval. 2022, 50, 1934–1946. [Google Scholar] [CrossRef]

- ISO/TS 13473-4:2008; Characterization of Pavement Texture by Use of Surface Profiles–Part 4: Spectral Analysis of Surface Profiles. International Standards Organization (ISO): Geneva, Switzerland, 2008.

- Kanafi, M.M.; Kuosmanen, A.; Pellinen, T.K.; Tuononen, A.J. Macro- and micro-texture evolution of road pavements and correlation with friction. Int. J. Pavement Eng. 2015, 16, 168–179. [Google Scholar] [CrossRef]

- Miller, T.; Swiertz, D.; Tashman, L.; Tabatabaee, N.; Bahia, H.U. Characterization of asphalt pavement surface texture. Transp. Res. Rec. J. Res. Board 2012, 2295, 19–26. [Google Scholar] [CrossRef]

- Xiao, S.; Li, M.; Chen, B.; Zhou, X.; Xi, C.; Tan, Y. Understanding the pavement texture evolution of RIOH Track using multi-scale and spatiotemporal analysis. Tribol. Int. 2023, 184, 108492. [Google Scholar] [CrossRef]

- Xiao, S.; Zhou, X.; Tan, Y.; Li, J. Spatiotemporal evolution analysis of pavement texture depth on RIOH track using statistical and rescaled range approaches. Constr. Build. Mater. 2022, 338, 127560. [Google Scholar] [CrossRef]

- Rezaei, A.; Masad, E. Experimental-based model for predicting the skid resistance of asphalt pavements. Int. J. Pavement Eng. 2013, 14, 24–35. [Google Scholar] [CrossRef]

- Do, M.T.; Cerezo, V.; Ropert, C. Questioning the approach to predict the evolution of tire/road friction with traffic from road surface texture. Surf. Topogr. Metrol. Prop. 2020, 8, 024004. [Google Scholar] [CrossRef]

- Pomoni, M.; Plati, C.; Loizos, A.; Yannis, G. Investigation of pavement skid resistance and macrotexture on a long-term basis. Int. J. Pavement Eng. 2020, 23, 1060–1069. [Google Scholar] [CrossRef]

- Li, Q.J.; Zhan, Y.; Yang, G.; Wang, K.C. Pavement skid resistance as a function of pavement surface and aggregate texture properties. Int. J. Pavement Eng. 2020, 21, 1159–1169. [Google Scholar] [CrossRef]

- Li, P.; Yi, K.; Yu, H.; Xiong, J.; Xu, R. Effect of aggregate properties on long-term skid resistance of asphalt mixture. J. Mater. Civ. Eng. 2021, 33, 04020413. [Google Scholar] [CrossRef]

- Ergin, B.; Gökalp, İ.; Uz, V.E. Effect of aggregate microtexture losses on skid resistance: Laboratory-based assessment on chip seals. J. Mater. Civ. Eng. 2020, 32, 04020040. [Google Scholar] [CrossRef]

- Kane, M.; Edmondson, V. Modelling the bitumen scour effect: Enhancement of a dynamic friction model to predict the skid resistance of rubber upon asphalt pavement surfaces subjected to wear by traffic polishing. Wear 2018, 400, 100–110. [Google Scholar] [CrossRef]

- Vaiana, R.; Capiluppi, G.F.; Gallelli, V.; Iuele, T.; Minani, V. Pavement surface performances evolution: An experimental application. Procedia Social Behav. Sci. 2012, 53, 1149–1160. [Google Scholar] [CrossRef]

- ASTM E1911-19:2019; Standard Test Method for Measuring Surface Frictional Properties Using the Dynamic Friction Tester. ASTM International: West Conshohocken, PA, USA, 2019.

- ASTM E303-22:2022; Standard Test Method for Measuring Surface Frictional Properties Using the British Pendulum Tester. ASTM International: West Conshohocken, PA, USA, 2022.

- JTG 3450-2019:2019; Field Test Methods of Highway Subgrade and Pavement. China Communications Press Co., Ltd.: Beijing, China, 2019.

- Hall, J.; Smith, K.; Titus-Glover, T.; Wambold, J.; Yager, T.; Rado, Z. Guide for Pavement Friction; National Cooperative Highway Research Program (NCHRP) Project 01-43, Transportation Research Board of the National Academies: Washington, DC, USA, 2009. [Google Scholar]

- Xiao, S.; Sun, Z.; Tan, Y.; Li, J.; Lv, H. Hysteresis friction modelling of BPT considering rubber penetration depth into road surface. Int. J. Pavement Eng. 2023, 24, 2027415. [Google Scholar] [CrossRef]

- Leukel, J.; Scheurer, L.; Sugumaran, V. Machine learning models for predicting physical properties in asphalt road construction: A systematic review. Constr. Build. Mater. 2024, 440, 137397. [Google Scholar] [CrossRef]

- Jamhiri, B.; Jalal, F.E.; Chen, Y. Hybridizing multivariate robust regression analyses with growth forecast in evaluation of shear strength of zeolite–alkali activated sands. Multiscale Multidiscip. Model. Exp. Des. 2022, 5, 317–335. [Google Scholar] [CrossRef]

- Zuñiga Garcia, N. Predicting Friction with Improved Texture Characterization. Master’s Thesis, The University of Texas at Austin, Austin, TX, USA, 2017. [Google Scholar]

- Ji, J.; Ren, W.; Jiang, T.; Dong, Y.; Hou, Y.; Li, H. Establishment and Analysis of the Relationship Model between Macro-Texture and Skid Resistance Performance of Asphalt Pavement. Coatings 2022, 12, 1464. [Google Scholar] [CrossRef]

- JTG F40-2004:2004; Technical Specifications for Construction of Highway Asphalt Pavements. China Communications Press Co., Ltd.: Beijing, China, 2004.

- Ren, W.; Han, S.; He, Z.; Li, J.; Wu, S. Development and testing of a multivariable accelerated abrasion machine to characterize the polishing wear of pavement by tires. Surf. Topogr. Metrol. Prop. 2019, 7, 035006. [Google Scholar] [CrossRef]

- ASTM E965-15:2019; Standard Test Method for Measuring Pavement Macrotexture Depth Using a Volumetric Technique. ASTM International: West Conshohocken, PA, USA, 2019.

- Ren, W. Study on the Abrasion Characteristic of Surface Texture and Its Effect on Noise for Asphalt Pavements. Ph.D. Thesis, Chang’an University, Xi’an, China, 2019. [Google Scholar]

- ISO 13473-2:2002; Characterization of Pavement Texture by Use of Surface Profiles-Terminology and Basic Requirements Related to Pavement Texture Profile Analysis. International Standards Organization (ISO): Geneva, Switzerland, 2002.

- Fwa, T.; Choo, Y.; Liu, Y. Effect of aggregate spacing on skid resistance of asphalt pavement. J. Transp. Eng. 2003, 129, 420–426. [Google Scholar] [CrossRef]

- Lee, Y.P.K.; Fwa, T.F.; Choo, Y.S. Effect of pavement surface texture on British pendulum test. J. East. Asia Soc. Transp. Stud. 2005, 6, 1247–1257. [Google Scholar] [CrossRef]

| Surface Indicators | Linear Regression Equation | Correlation Coefficient R2 |

|---|---|---|

| Elevation variance L | BPN = −2.443 × L + 55.297 | 0.259 |

| Elevation variance S | BPN = −6.230 × S + 54.234 | 0.05 |

| Elevation variance M | BPN = −20.769 × M + 53.630 | 0.017 |

| MPD | BPN = −3.704 × MPD + 58.117 | 0.309 |

| RMS | BPN = −4.006 × RMS + 57.321 | 0.239 |

| LTX,0.06→0.5 | BPN = 0.027 × LTX,0.06→0.5 + 51.627 | 0.001 |

| LTX,0.5→32 | BPN = −0.434 × LTX,0.5→32 + 78.619 | 0.232 |

| Model No. | Linear Regression Equation | R2 | VIF | Durbin-Watson |

|---|---|---|---|---|

| No. 1 | BPN = 21.848 × S − 8.043 × MPD + 59.460 | 0.497 | 3.261/3.261 | 1.705 |

| No. 2 | BPN = −0.935 × LTX,64 + 0.997 × LTX,2 + 52.550 | 0.614 | 2.220/2.220 | 1.623 |

| No. 3 | BPN = −1.114 × LTX,64 + 1.97 × LTX,2 − 0.678 × LTX,0.25 + 42.765 | 0.670 | 3.089/12.501/7.719 | 1.623 |

| No. 4 | BPN = −0.99 × LTX,64 + 1.71 × LTX,2 − 92.464 × M + 25.214 | 0.684 | 2.287/6.685/4.722 | 2.012 |

| Measurement | Predicted BPN by Different Models | Measured BPN | Deviations for Different Models | ||||||

|---|---|---|---|---|---|---|---|---|---|

| No. 1 | No. 2 | No. 3 | No. 4 | No. 1 | No. 2 | No. 3 | No. 4 | ||

| 1 | 54 | 55 | 55 | 55 | 56 | 2 | 1 | 1 | 1 |

| 2 | 54 | 53 | 53 | 51 | 56 | 2 | 3 | 3 | 5 |

| 3 | 53 | 53 | 53 | 54 | 53 | 0 | 0 | 0 | 1 |

| 4 | 55 | 52 | 52 | 51 | 55 | 0 | 3 | 3 | 4 |

| 5 | 53 | 53 | 53 | 53 | 50 | 3 | 3 | 3 | 3 |

| 6 | 55 | 56 | 58 | 57 | 54 | 1 | 2 | 4 | 3 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ren, W.; Li, J.; Zhang, Y.; Wang, X.; Shao, R. Road Surface Texture Evaluation and Relation to Low-Speed Skid Resistance for Different Types of Mixtures. Coatings 2024, 14, 1367. https://doi.org/10.3390/coatings14111367

Ren W, Li J, Zhang Y, Wang X, Shao R. Road Surface Texture Evaluation and Relation to Low-Speed Skid Resistance for Different Types of Mixtures. Coatings. 2024; 14(11):1367. https://doi.org/10.3390/coatings14111367

Chicago/Turabian StyleRen, Wanyan, Jun Li, Yi Zhang, Xinya Wang, and Ruixue Shao. 2024. "Road Surface Texture Evaluation and Relation to Low-Speed Skid Resistance for Different Types of Mixtures" Coatings 14, no. 11: 1367. https://doi.org/10.3390/coatings14111367

APA StyleRen, W., Li, J., Zhang, Y., Wang, X., & Shao, R. (2024). Road Surface Texture Evaluation and Relation to Low-Speed Skid Resistance for Different Types of Mixtures. Coatings, 14(11), 1367. https://doi.org/10.3390/coatings14111367