MXene Coatings Based on Electrophoretic Deposition for the High-Temperature Friction Reduction of Graphite for Mechanical Seal Pairs

Abstract

1. Introduction

2. Experimental Details

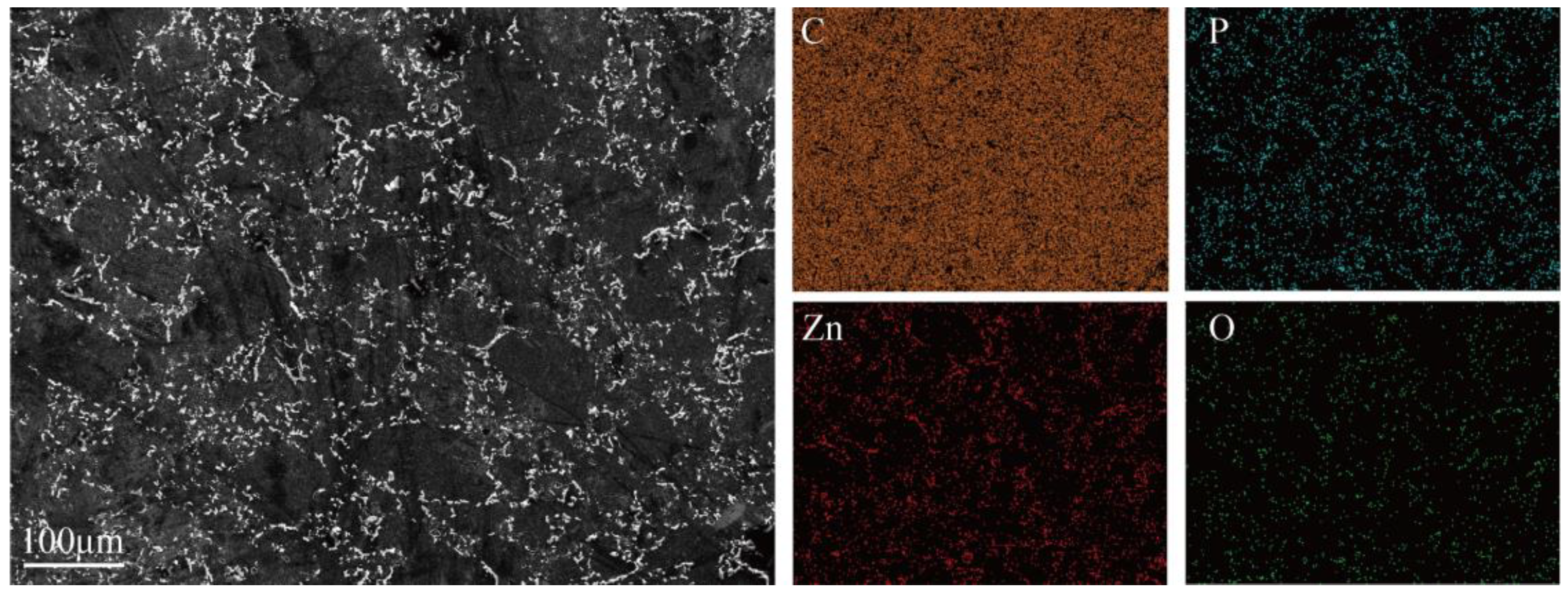

2.1. Composition and Performance of the Impregnated Zinc Phosphate Graphite

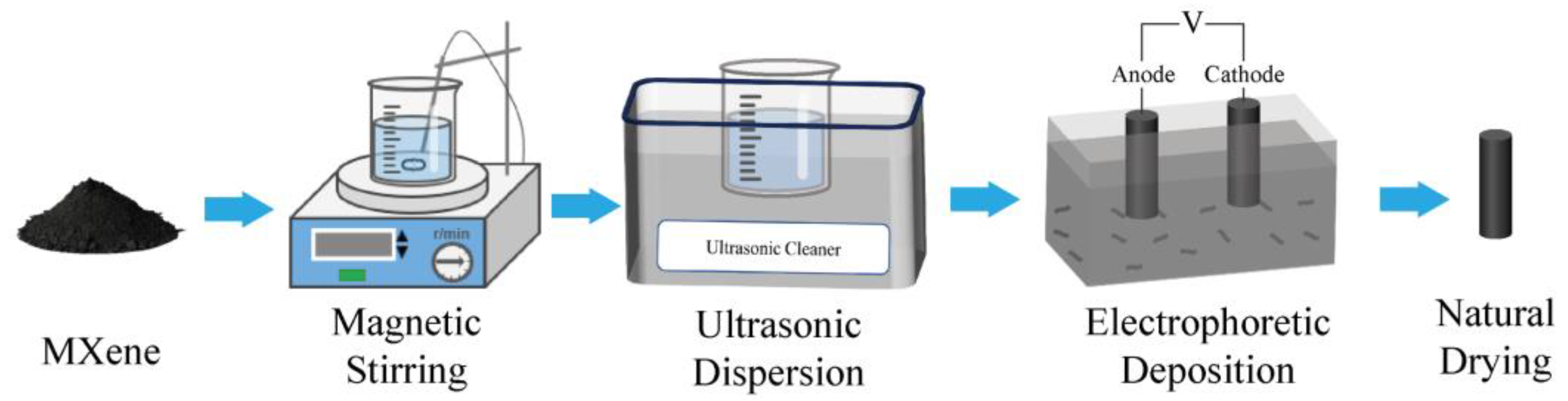

2.2. Preparation of the MXene Coatings

2.3. The Microstructure Characterization and Tribological Properties of the MXene Coatings

3. Results and Discussion

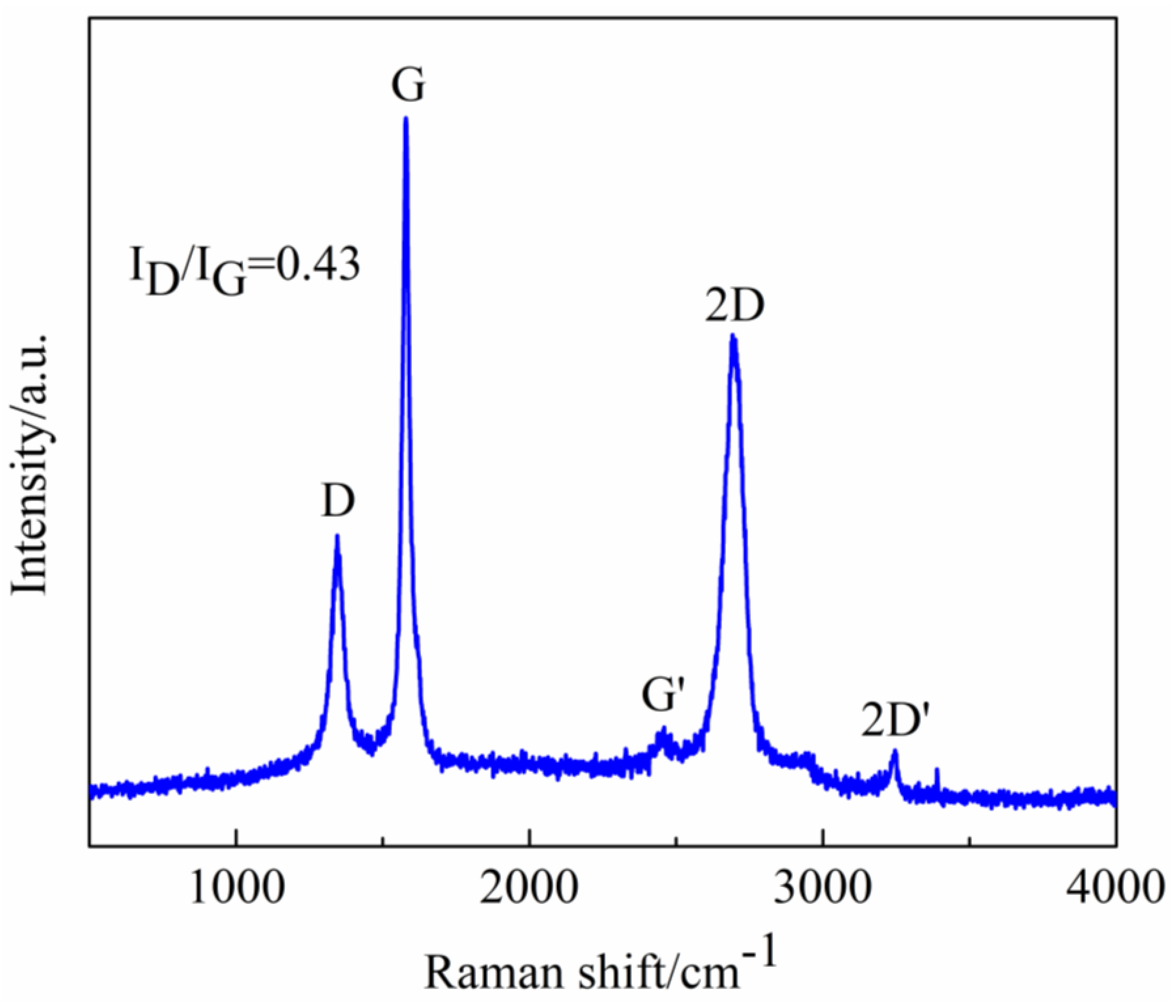

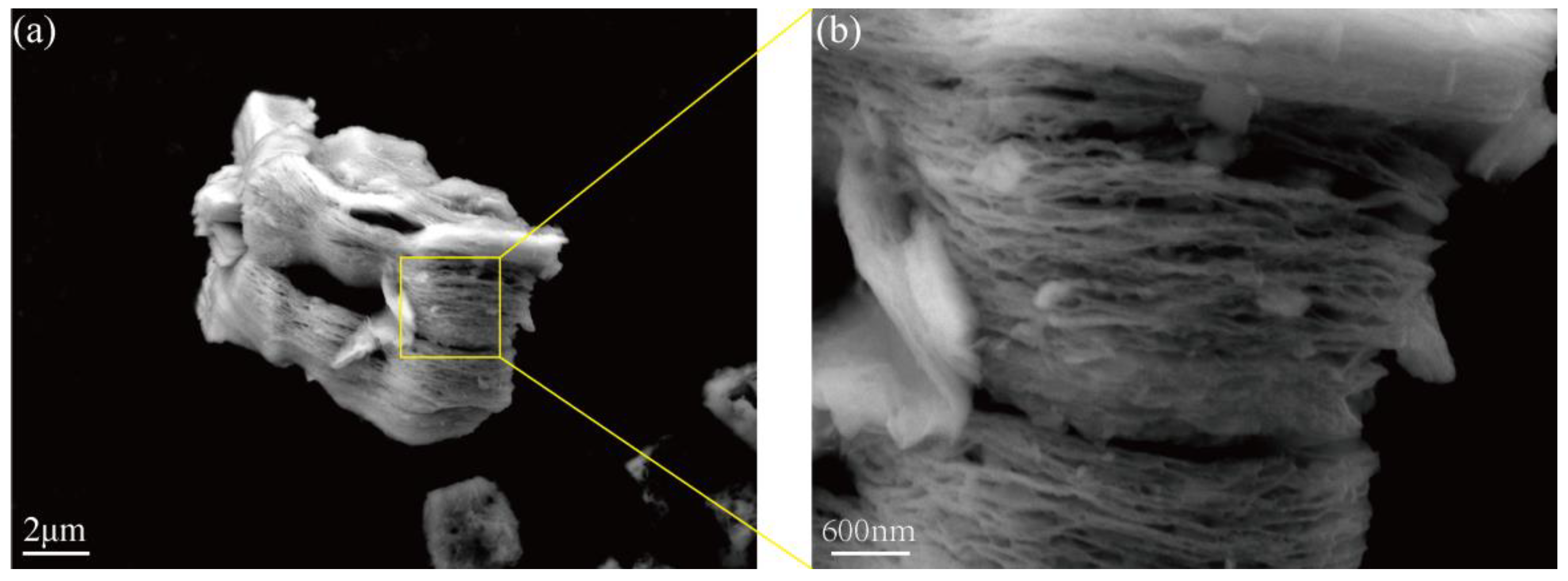

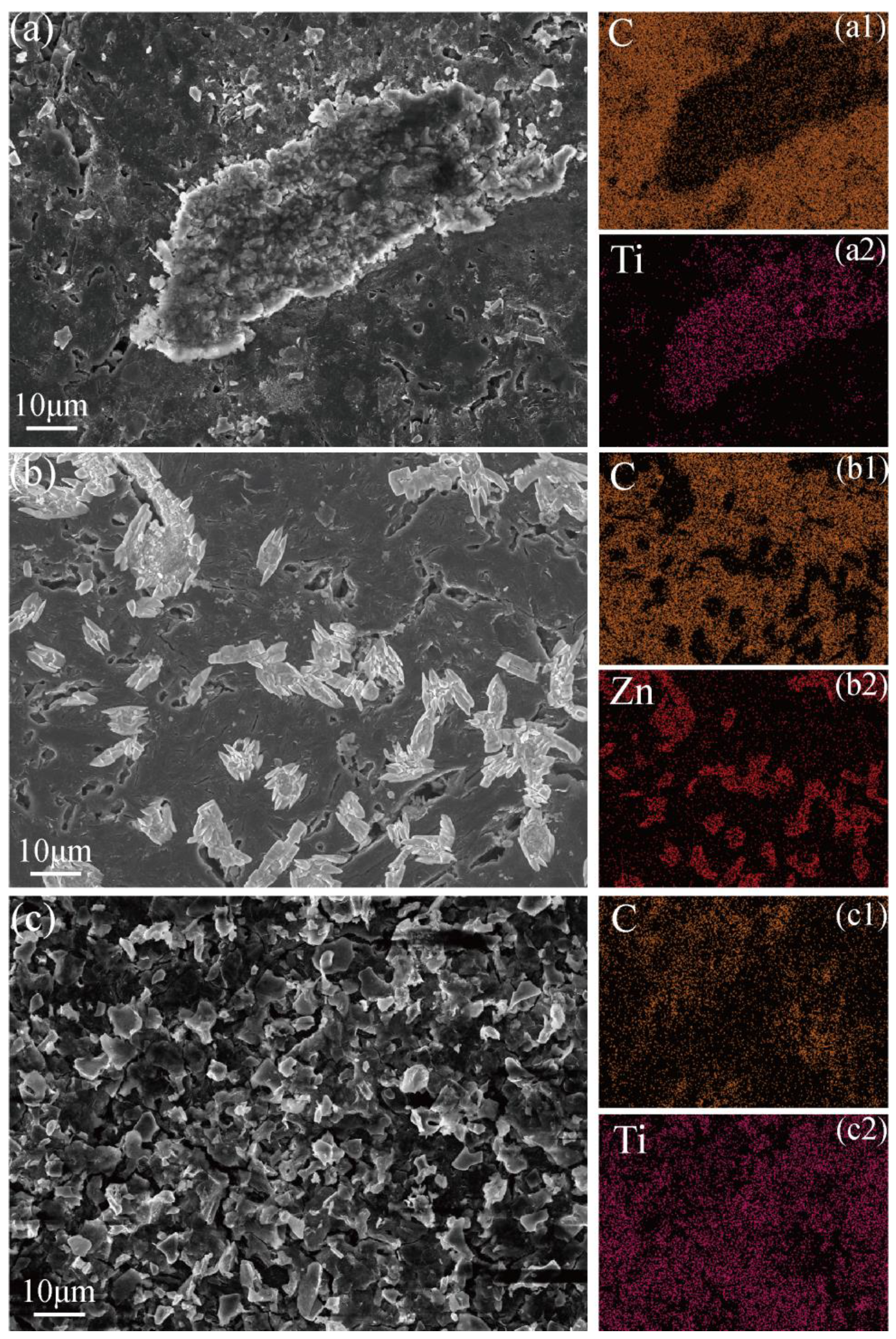

3.1. Microstructure of Graphite and Ti3C2Tx

3.2. Characterization of MXene Coatings

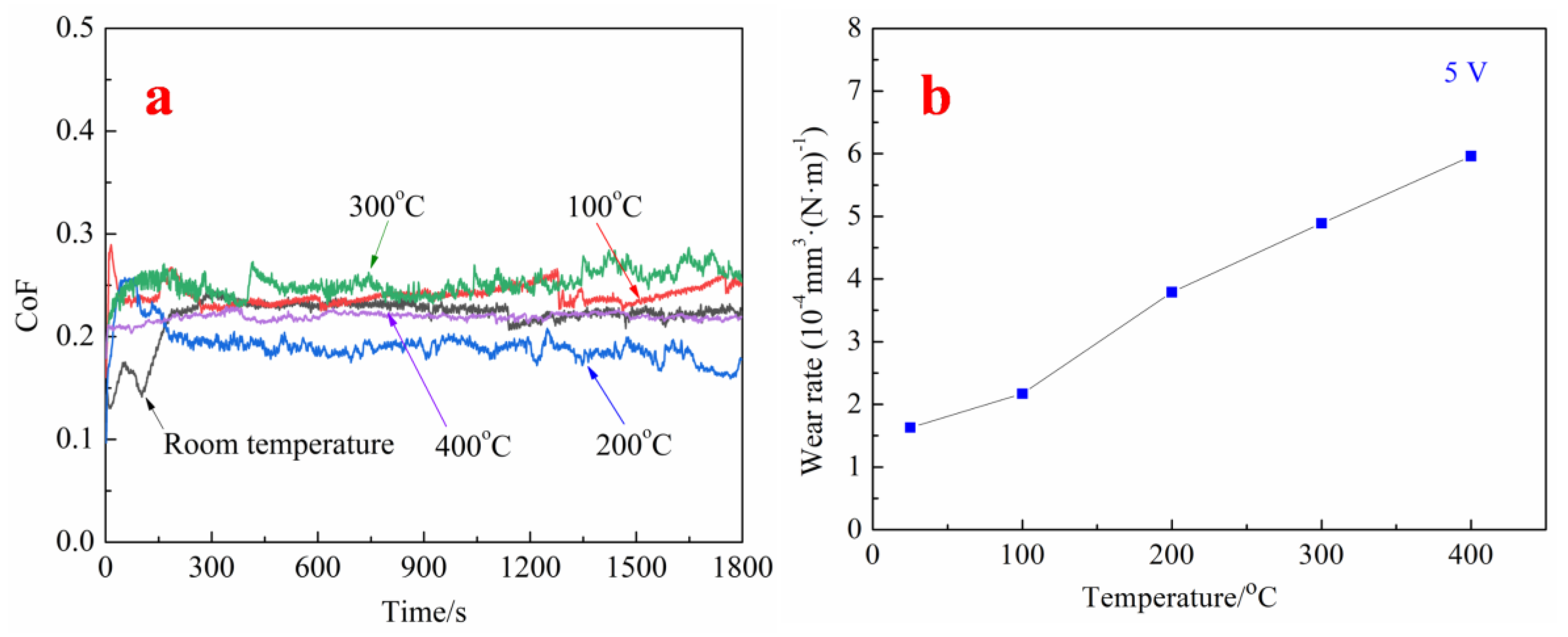

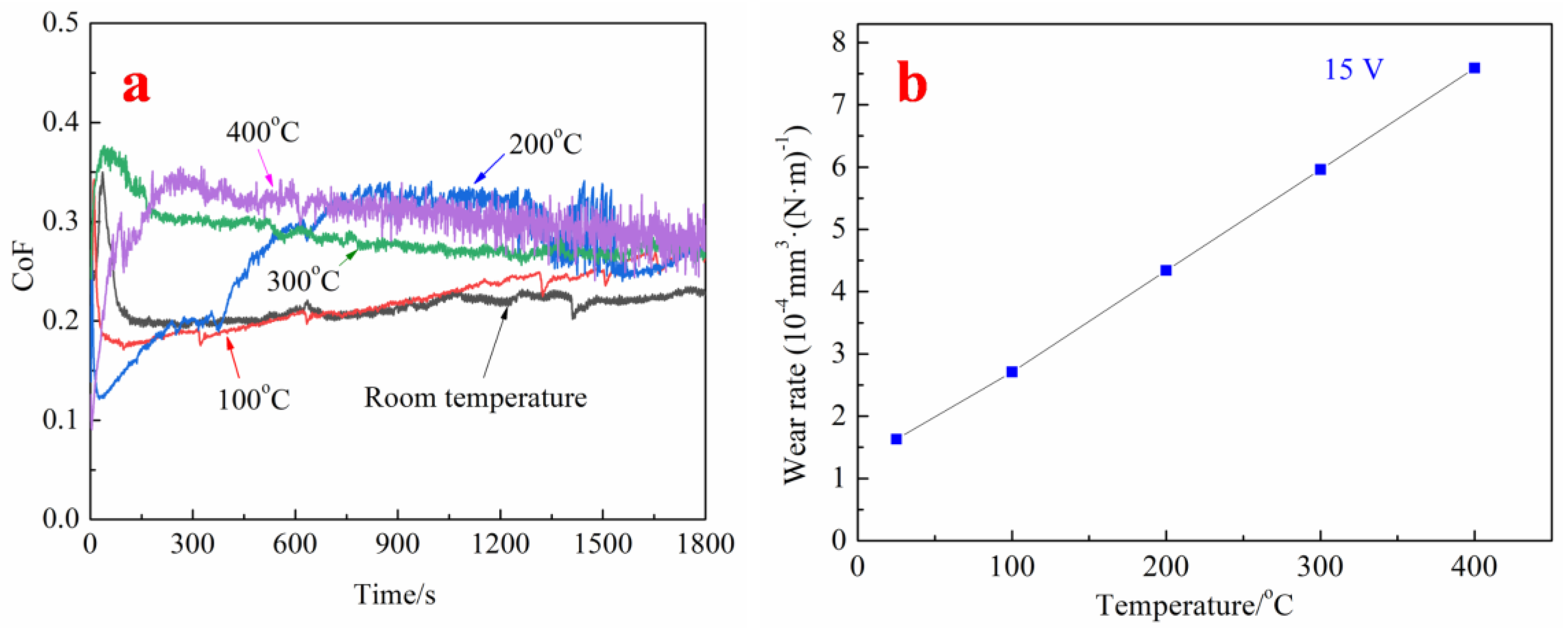

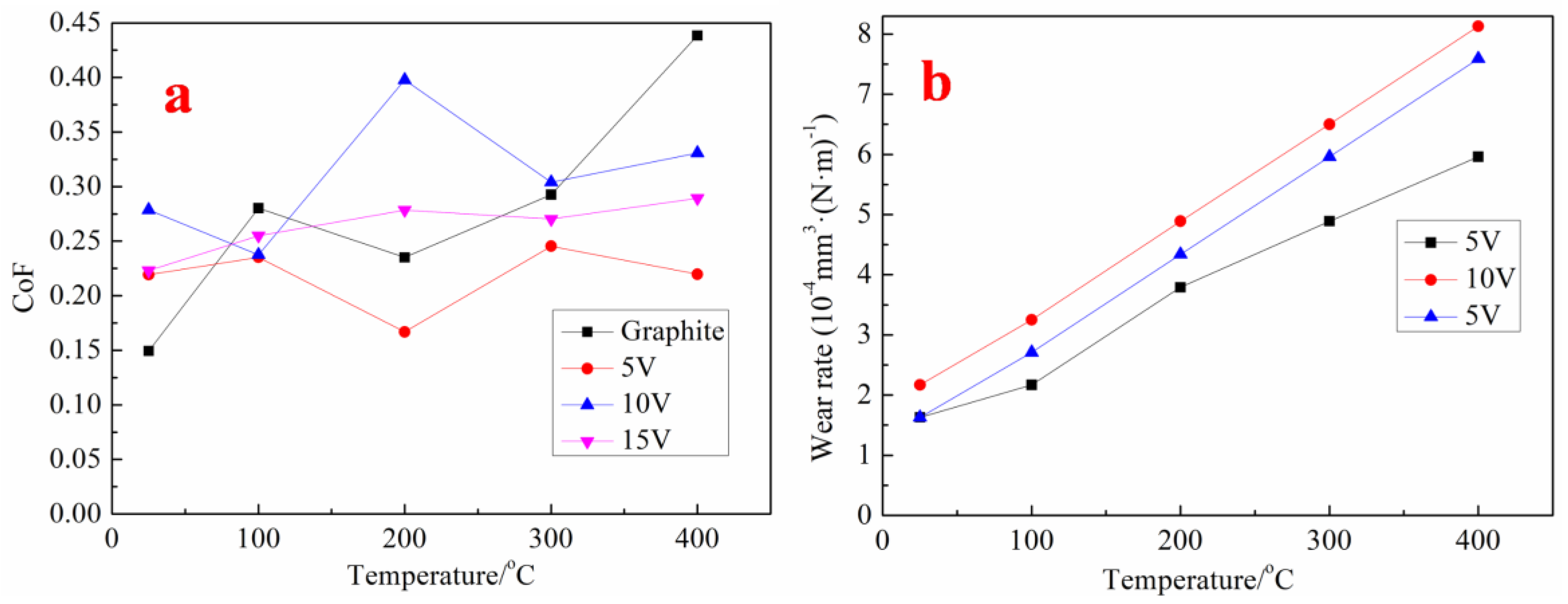

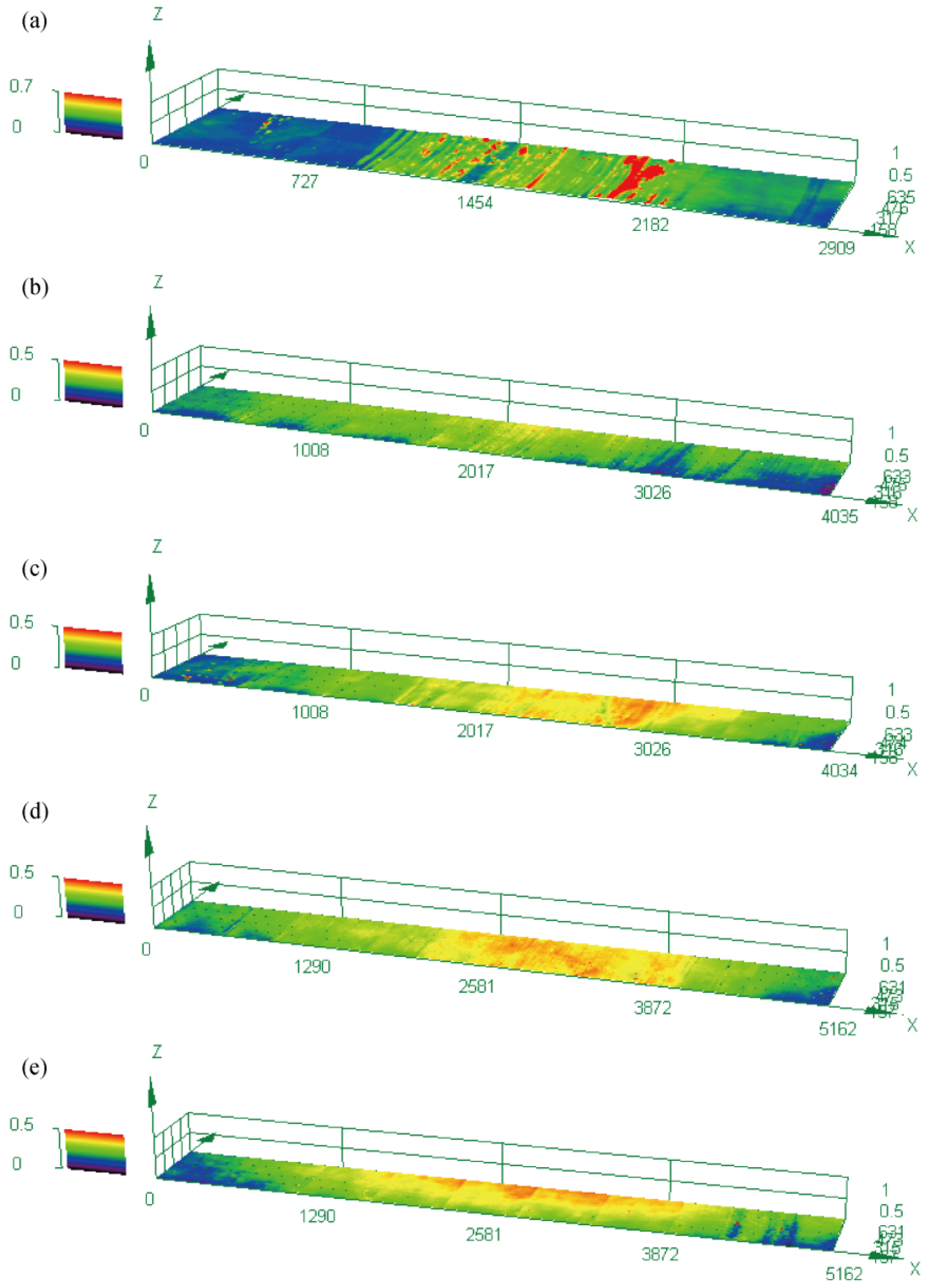

3.3. The Tribological Properties of MXene Coatings

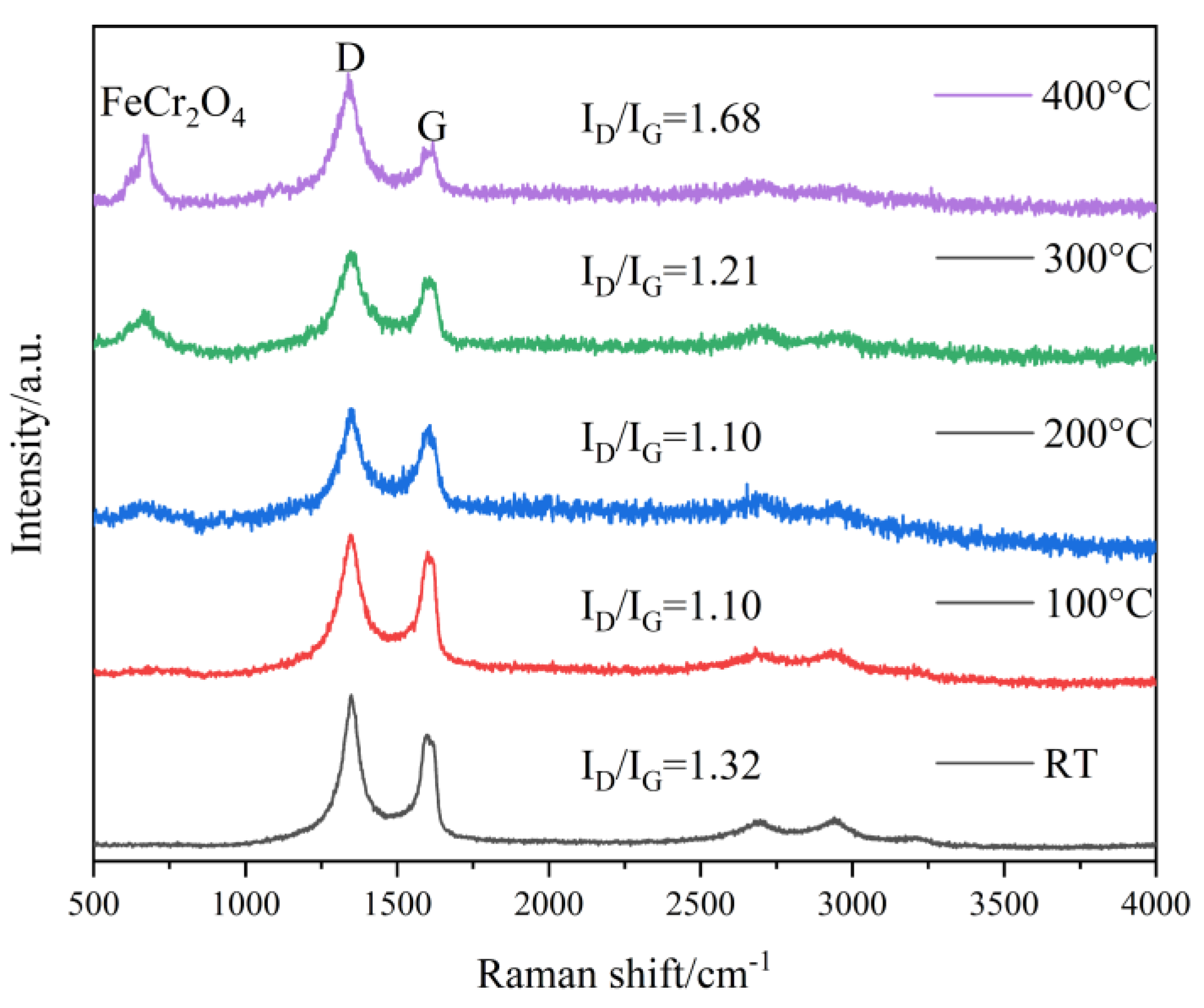

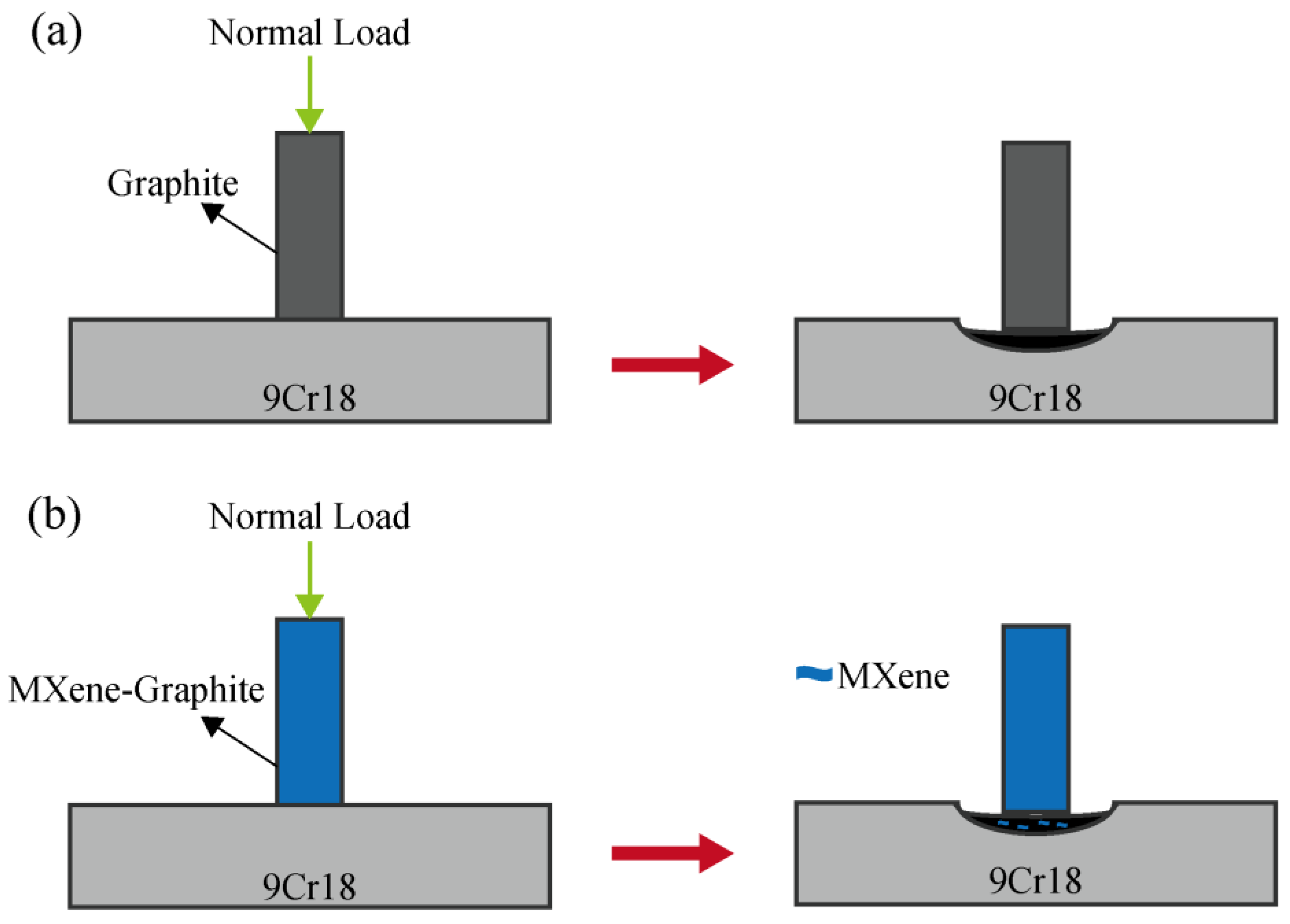

3.4. The Wear Mechanism of MXene Coatings

4. Conclusions

- (1)

- The Ti3C2Tx coatings deposited at 5 V are relatively smooth, and the Ti3C2Tx coatings partially cover the surface of the graphite, which helps to form a lubricating film with the graphite. The Ti3C2Tx coatings deposited at 10 V may lead to the crystallization of the impregnated zinc phosphate in the pores of the graphite surface and destroy the original structure of the graphite. There is more Ti3C2Tx in the coatings deposited at 15 V. During the deposition process, there is a severe reaction of electrolytic water, resulting in bubbles at the electrode. The bursting bubbles destroy the structure of the coatings.

- (2)

- The Ti3C2Tx coatings deposited at 5 V can effectively reduce the CoF of the friction pair of the impregnated zinc phosphate graphite and 9Cr18 steel at high temperatures, and the friction curve is relatively stable. The Ti3C2Tx coatings prepared at 10 V exhibit a high-temperature CoF. The Ti3C2Tx coatings deposited at 15 V also have high friction during the friction process.

- (3)

- The Ti3C2Tx coatings deposited at 5 V were covered in a transfer film from the graphite during the sliding, which plays a lubricating role. At room temperature, the Ti3C2Tx coatings improve the lubrication behaviors due to the good self-lubricating behaviors of the graphite. With the increase in temperature, the graphite particles in the transfer film are oxidized in the ambient air, but the Ti3C2Tx coatings in the transfer film can still play a lubricating role with the graphite in the transfer film and indicate the good tribological properties of graphite.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Dinc, S.; Demiroglu, M.; Turnquist, N.; Mortzheim, J.; Goetze, G.; Maupin, J.; Hopkins, J.; Wolfe, C.; Florin, M. Fundamental Design Issues of Brush Seals for Industrial Applications. J. Turbomach. 2002, 124, 293–300. [Google Scholar]

- Sayma, A.I.; Bré ard, C.; Vahdati, M.; Imregun, M. Aeroelasticity Analysis of Air-Riding Seals for Aero-Engine Applications. J. Tribol. 2002, 124, 607–616. [Google Scholar] [CrossRef]

- Zhao, Y.; Zhang, G.; Wang, J.; Wang, H.; Zhao, W.; Zeng, Q. Tribological properties of low-temperature time-dependent pretreated graphite for mechanical seal pairs in high-speed turbopump. Friction 2023, 12, 305–318. [Google Scholar]

- Zeng, Q.; Deng, Z.; Li, J.; Zhang, W. Advances in magnetic fluid seal and structures. J. Magn. Magn. Mater. 2024, 603, 172232. [Google Scholar]

- Torres, H.; Podgornik, B.; Jovičević-Klug, M.; Ripoll, M.R. Compatibility of graphite, hBN and graphene with self-lubricating coatings and tool steel for high temperature aluminium forming. Wear 2022, 490, 204187. [Google Scholar]

- Omrani, E.; Dorri Moghadam, A.; Menezes, P.L. New emerging self-lubricating metal matrix composites for tribological applications. In Ecotribology: Materials Forming, Machining and Tribology; Springer: Cham, Switzerland, 2016; pp. 63–103. [Google Scholar]

- Wang, R.; Zhang, F.; Yang, K.; Xiao, N.; Tang, J.; Xiong, Y.; Zhang, G.; Duan, M.; Chen, H. Important contributions of carbon materials in tribology: From lubrication abilities to wear mechanisms. J. Alloys Compd. 2024, 979, 173454. [Google Scholar]

- Zhao, W.; Zhang, G.; Dong, G. Friction and wear behavior of different seal materials under water-lubricated conditions. Friction 2020, 9, 697–709. [Google Scholar]

- Zhang, F.; Yin, P.; Zeng, Q.; Wang, J. Insights on the Formation Mechanism of Ultra-Low Friction of Phenolic Resin Graphite at High Temperature. Coatings 2021, 12, 6. [Google Scholar] [CrossRef]

- Zeng, Q.; Zhang, W. A Systematic Review of the Recent Advances in Superlubricity Research. Coatings 2023, 13, 1989. [Google Scholar] [CrossRef]

- Roe, M.; Torrance, A. The surface failure and wear of graphite seals. Tribol. Int. 2008, 41, 1002–1008. [Google Scholar]

- Shi, D.; Cai, L.; Zhang, C.; Chen, D.; Pan, Z.; Kang, Z.; Liu, Y.; Zhang, J. Fabrication methods, structure design and durability analysis of advanced sealing materials in proton exchange membrane fuel cells. Chem. Eng. J. 2023, 454, 139995. [Google Scholar] [CrossRef]

- Zhao, J.; Li, Q.; Li, S.; Li, S.; Chen, G.; Liu, X.; He, Y.; Luo, J. Influence of a carbon-based tribofilm induced by the friction temperature on the tribological properties of impregnated graphite sliding against a cemented carbide. Friction 2020, 9, 686–696. [Google Scholar] [CrossRef]

- Gao, R.; Huang, Y.; Zhou, X.; Ma, G.; Jin, G.; Li, T.; Wang, H.; Liu, M. Material system and tribological mechanism of plasma sprayed wear resistant coatings: Overview. Surf. Coat. Technol. 2024, 483, 130758. [Google Scholar] [CrossRef]

- Zhao, J.; Liu, Y.; Liu, D.; Gu, Y.; Zheng, R.; Ma, R.; Li, S.; Wang, Y.; Shi, Y. The tribological performance of metal-/resin-impregnated graphite under harsh condition. Lubricants 2021, 10, 2. [Google Scholar] [CrossRef]

- Mahto, N.K.; Tyagi, R.; Mishra, S. Sliding Wear of Copper-Impregnated Carbo-Graphite Under Different Conditions. J. Mater. Eng. Perform. 2024, 1–14. [Google Scholar] [CrossRef]

- Berman, D.; Erdemir, A.; Sumant, A.V. Approaches for Achieving Superlubricity in Two-Dimensional Materials. ACS Nano 2018, 12, 2122–2137. [Google Scholar] [CrossRef]

- Li, H.; Wang, J.; Gao, S.; Chen, Q.; Peng, L.; Liu, K.; Wei, X. Superlubricity between MoS2 monolayers. Adv. Mater. 2017, 29, 1701474. [Google Scholar] [CrossRef]

- Ramezani, M.; Ripin, Z.M.; Jiang, C.-P.; Pasang, T. Superlubricity of Materials: Progress, Potential, and Challenges. Materials 2023, 16, 5145. [Google Scholar] [CrossRef]

- Yi, S.; Li, J.; Rao, J.; Ma, X.; Zhang, Y. Alkyl-functionalized black phosphorus nanosheets triggers macroscale superlubricity on diamond-like carbon film. Chem. Eng. J. 2022, 449, 137764. [Google Scholar] [CrossRef]

- Gao, K.; Bin, W.; Berman, D.; Ren, Y.; Luo, J.; Xie, G. Self-Adaptive Macroscale Superlubricity Based on the Tribocatalytic Properties of Partially Oxidized Black Phosphorus. Nano Lett. 2023, 23, 6823–6830. [Google Scholar] [CrossRef]

- Tang, G.; Wu, Z.; Su, F.; Wang, H.; Xu, X.; Li, Q.; Ma, G.; Chu, P.K. Macroscale Superlubricity on Engineering Steel in the Presence of Black Phosphorus. Nano Lett. 2021, 21, 5308–5315. [Google Scholar] [CrossRef] [PubMed]

- Zeng, Q.; Ning, Z.; Pang, Z.; Wang, Z.; Zheng, C. Self-assembled multilayer WS2/GO films on amorphous silicon coating for enhancing the lubricating properties. Appl. Surf. Sci. 2023, 624, 157184. [Google Scholar] [CrossRef]

- Zeng, Q. High Temperature Low Friction Behavior of h-BN Coatings against ZrO2. Coatings 2022, 12, 1772. [Google Scholar] [CrossRef]

- Zeng, Q. Influence of CePO4 on high temperature anti-friction and anti-wear behaviors of nickel-based h-BN composite coatings. Diam. Relat. Mater. 2024, 148, 111421. [Google Scholar] [CrossRef]

- Naguib, M.; Kurtoglu, M.; Presser, V.; Lu, J.; Niu, J.; Heon, M.; Hultman, L.; Gogotsi, Y.; Barsoum, M.W. Two-dimensional nanocrystals produced by exfoliation of Ti3AlC2. Adv. Mater. 2011, 23, 4248–4253. [Google Scholar] [CrossRef]

- Huang, S.; Mutyala, K.; Sumant, A.; Mochalin, V. Achieving superlubricity with 2D transition metal carbides (MXenes) and MXene/graphene coatings. Mater. Today Adv. 2021, 9, 100133. [Google Scholar] [CrossRef]

- Rodriguez, A.; Jaman, M.; Acikgoz, O.; Wang, B.; Yu, J.; Grützmacher, P.G.; Rosenkranz, A.; Baykara, M.Z. The potential of Ti3C2Tx nano-sheets (MXenes) for nanoscale solid lubrication revealed by friction force microscopy. Appl. Surf. Sci. 2021, 535, 147664. [Google Scholar] [CrossRef]

- Chhattal, M.; Rosenkranz, A.; Kaihuan, Y.; Grützmacher, P.; Gong, Z.; Zhang, J. Comparative analysis of the solid lubrication performance-Ti3AlC2 versus Ti3C2Tx coatings. Ceram. Int. 2024, 50, 26391–26401. [Google Scholar] [CrossRef]

- Rosenkranz, A.; Wang, B.; Zambrano, D.; Henríquez, J.; Aguilar-Hurtado, J.; Marquis, E.; Restuccia, P.; Wyatt, B.; Righi, M.; Anasori, B. Solid-lubrication performance of Ti3C2Tx-Effect of tribo-chemistry and exfoliation. Mater. Today Nano 2024, 25, 100464. [Google Scholar] [CrossRef]

- Liu, X.; Le, K.; Wang, J.; Lin, H.; Liu, Y.; Jiang, F.; Yang, Z.; Li, H.; Xu, S.; Liu, W. Synergistic lubrication of multilayer Ti3C2Tx@ MoS2 composite coatings via hydrothermal synthesis. Appl. Surf. Sci. 2024, 668, 160400. [Google Scholar] [CrossRef]

- Marian, M.; Song, G.; Wang, B.; Fuenzalida, V.; Krauß, S.; Merle, B.; Tremmel, S.; Wartzack, S.; Yu, J.; Rosenkranz, A. Effective usage of 2D MXene nanosheets as solid lubricant—Influence of contact pressure and relative humidity. Appl. Surf. Sci. 2020, 531, 147311. [Google Scholar]

- Yin, X.; Jin, J.; Chen, X.; Rosenkranz, A.; Luo, J. Ultra-Wear-Resistant MXene-Based Composite Coating via in Situ Formed Nanostructured Tribofilm. ACS Appl. Mater. Interfaces 2019, 11, 32569–32576. [Google Scholar] [PubMed]

- Lian, W.; Mai, Y.; Liu, C.; Zhang, L.; Li, S.; Jie, X. Two-dimensional Ti3C2 coating as an emerging protective solid-lubricant for tribology. Ceram. Int. 2018, 44, 20154–20162. [Google Scholar]

- Yi, S.; Li, J.; Liu, Y.; Ge, X.; Zhang, J.; Luo, J. In-situ formation of tribofilm with Ti3C2Tx MXene nanoflakes triggers macroscale superlubricity. Tribol. Int. 2021, 154, 106695. [Google Scholar]

- Wait, J.; Josephson, G.; Wyatt, B.; Anasori, B.; Çolak, A. Environmentally stable nanoscale superlubricity of multi-layered Ti3C2Tx MXene. Carbon 2023, 213, 118284. [Google Scholar] [CrossRef]

- Macknojia, A.; Ayyagari, A.; Zambrano, D.; Rosenkranz, A.; Shevchenko, E.V.; Berman, D. Macroscale Superlubricity Induced by MXene/MoS2 Nanocomposites on Rough Steel Surfaces under High Contact Stresses. ACS Nano 2023, 17, 2421–2430. [Google Scholar]

- Lu, X.; Gu, X.; Shi, Y. A review on the synthesis of MXenes and their lubrication performance and mechanisms. Tribol. Int. 2023, 179, 108170. [Google Scholar]

- Ferrari, A.C. Raman spectroscopy of graphene and graphite: Disorder, electron–phonon coupling, doping and nonadiabatic effects. Solid State Commun. 2007, 143, 47–57. [Google Scholar] [CrossRef]

- Zeng, Q.; Ning, Z. High-temperature tribological properties of diamond-like carbon films: A review. Rev. Adv. Mater. Sci. 2021, 60, 276–292. [Google Scholar]

- Xiong, D.; Li, X.; Bai, Z.; Lu, S. Recent advances in layered Ti3C2Tx MXene for electrochemical energy storage. Small 2018, 14, 1703419. [Google Scholar] [CrossRef]

- Hurtado, J.; Grützmacher, P.; Henríquez, J.; Zambrano, D.; Wang, B.; Rosenkranz, A. Solid lubrication performance of few—And multilayer Ti3C2Tx coatings. Adv. Eng. Mater. 2022, 24, 2200755. [Google Scholar]

- Jia, Y.; Wan, H.; Chen, L.; Zhou, H.; Chen, J. Effects of phosphate binder on the lubricity and wear resistance of graphite coating at elevated temperatures. Surf. Coat. Technol. 2017, 315, 490–497. [Google Scholar]

- Zhai, W.; Bai, L.; Zhou, R.; Fan, X.; Kang, G.; Liu, Y.; Zhou, K. Recent progress on wear-resistant materials: Designs, properties, and applications. Adv. Sci. 2021, 8, 2003739. [Google Scholar]

- Luo, X.; Robin, J.; Yu, S. Effect of temperature on graphite oxidation behavior. Nucl. Eng. Des. 2004, 227, 273–280. [Google Scholar]

- Morstein, C.E.; Dienwiebel, M. Graphite lubrication mechanisms under high mechanical load. Wear 2021, 477, 203794. [Google Scholar]

- Han, H.; Qian, Z.; Meng, F.; Cui, Z. Tribological performances of graphite–MoS2 coating at various high temperatures. Proc. Inst. Mech. Eng. Part J J. Eng. Tribol. 2019, 233, 1888–1902. [Google Scholar]

- Ma, W.; Li, T.; Fang, Z.; Li, W.; Tang, H.; Zhang, L.; Yu, Y.; Qiao, Z. Effect of Ti3C2Tx MXenes on tribological and rheological properties of greases. Tribol. Int. 2024, 191, 109137. [Google Scholar]

- Rosenkranz, A.; Grützmacher, P.G.; Espinoza, R.; Fuenzalida, V.M.; Blanco, E.; Escalona, N.; Gracia, F.J.; Villarroel, R.; Guo, L.; Kang, R.; et al. Multi-layer Ti3C2Tx-nanoparticles (MXenes) as solid lubricants–Role of surface terminations and intercalated water. Appl. Surf. Sci. 2019, 494, 13–21. [Google Scholar]

- Xue, L.; Xu, Q.; Meng, C.; Lei, S.; Zhang, G.; Tang, M.; Zhai, W.; Yu, H.; Liu, X.; Du, C. Achieving the ultra-low friction and wear rate of PEEK-PTFE composites by Ti3C2Tx MXene reinforcement. Tribol. Int. 2024, 199, 110030. [Google Scholar]

| Material | Hardness (HS) | Density (g/cm3) | Compressive Strength (MPa) | Flexural Strength (MPa) | Porosity (%) |

|---|---|---|---|---|---|

| Impregnated zinc phosphate graphite | 90 | 2.05 | 211 | 77.4 | 0.5 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zeng, Q.; Sun, S.; Gao, S.; Chen, J.; Zhang, F. MXene Coatings Based on Electrophoretic Deposition for the High-Temperature Friction Reduction of Graphite for Mechanical Seal Pairs. Coatings 2024, 14, 1567. https://doi.org/10.3390/coatings14121567

Zeng Q, Sun S, Gao S, Chen J, Zhang F. MXene Coatings Based on Electrophoretic Deposition for the High-Temperature Friction Reduction of Graphite for Mechanical Seal Pairs. Coatings. 2024; 14(12):1567. https://doi.org/10.3390/coatings14121567

Chicago/Turabian StyleZeng, Qunfeng, Shichuan Sun, Siyang Gao, Jianhang Chen, and Fan Zhang. 2024. "MXene Coatings Based on Electrophoretic Deposition for the High-Temperature Friction Reduction of Graphite for Mechanical Seal Pairs" Coatings 14, no. 12: 1567. https://doi.org/10.3390/coatings14121567

APA StyleZeng, Q., Sun, S., Gao, S., Chen, J., & Zhang, F. (2024). MXene Coatings Based on Electrophoretic Deposition for the High-Temperature Friction Reduction of Graphite for Mechanical Seal Pairs. Coatings, 14(12), 1567. https://doi.org/10.3390/coatings14121567