The Characteristics of Ancient Residence Wood from the Qing Dynasty in Yunnan Province

Abstract

:1. Introduction

2. Materials and Methods

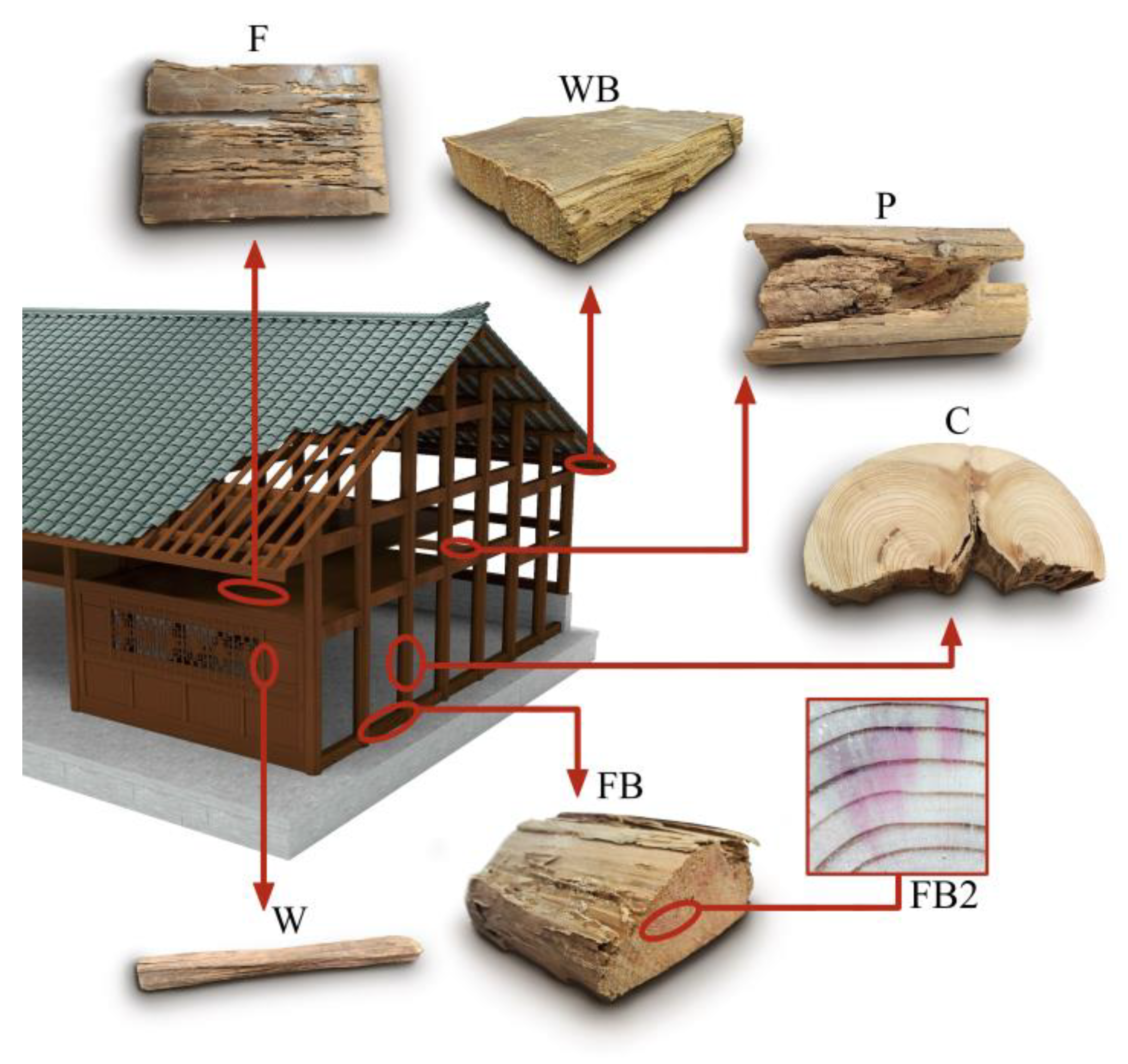

2.1. Samples of Ancient Wooden Components

2.2. Wood Anatomy

2.3. Physical Properties and Chemical Composition

2.3.1. Measurement of Physical Properties

2.3.2. Main Chemical Components Analysis

2.3.3. X-ray Diffraction

2.3.4. Infrared Spectral Analysis

2.3.5. Thermogravimetric Analysis

3. Results

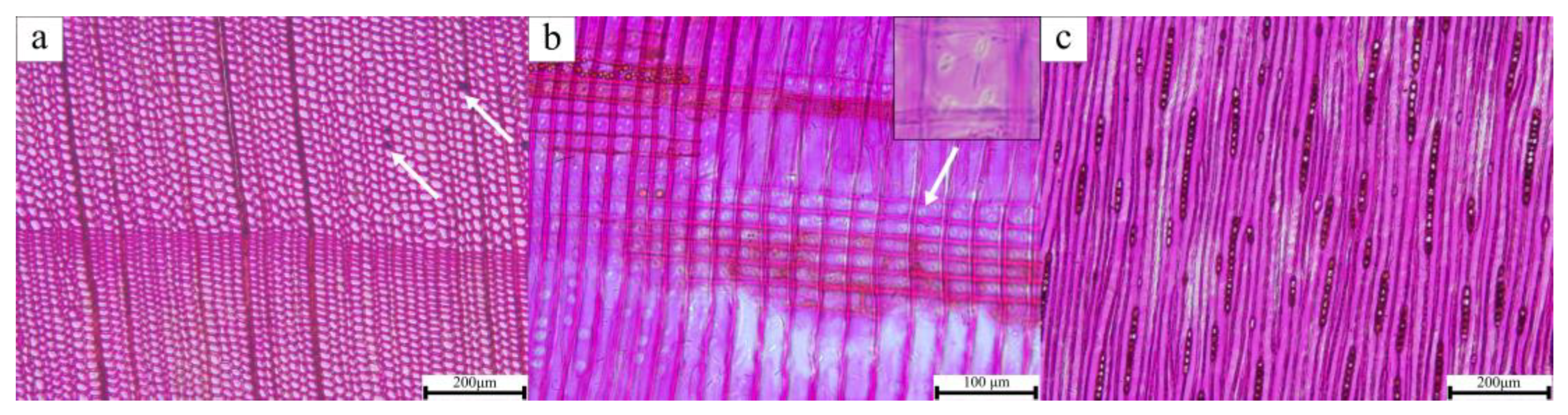

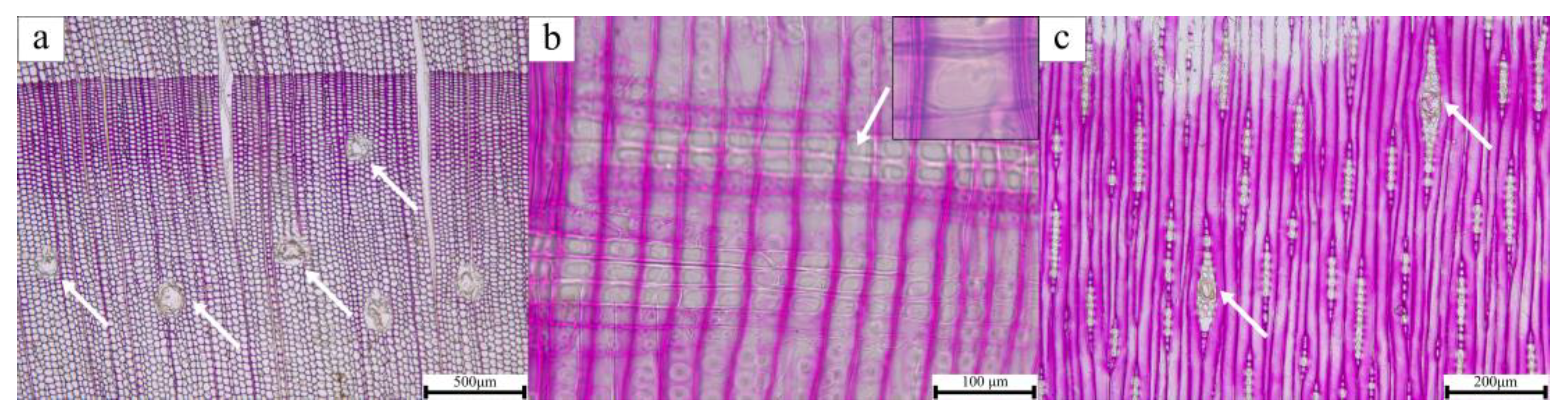

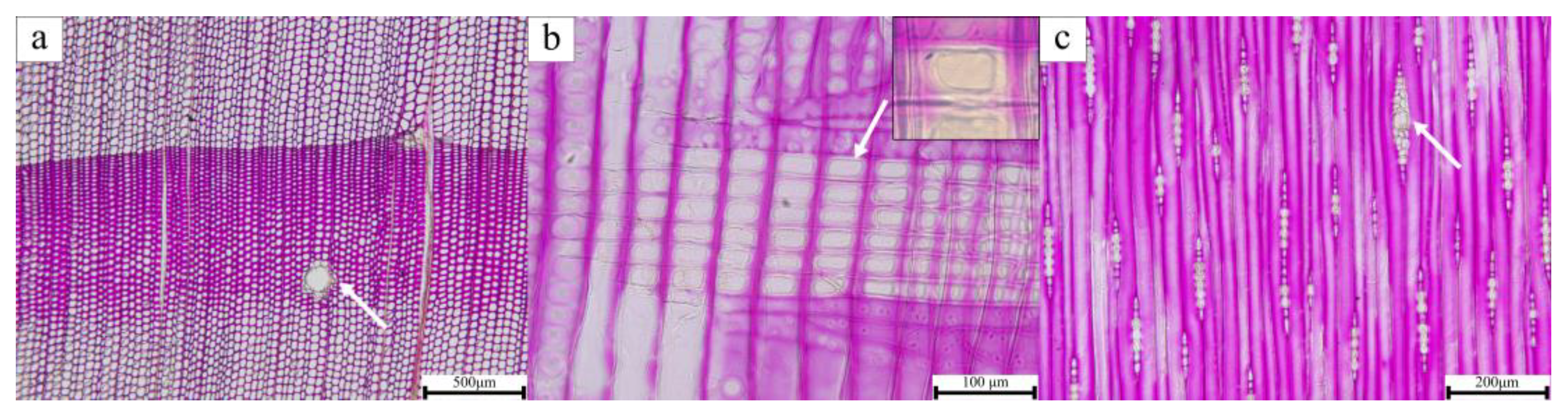

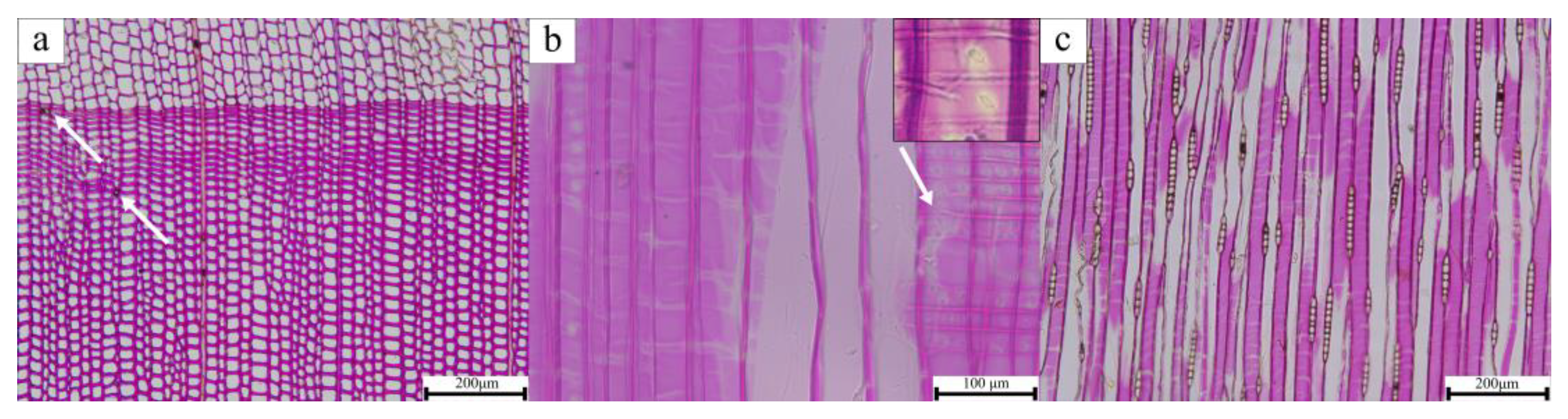

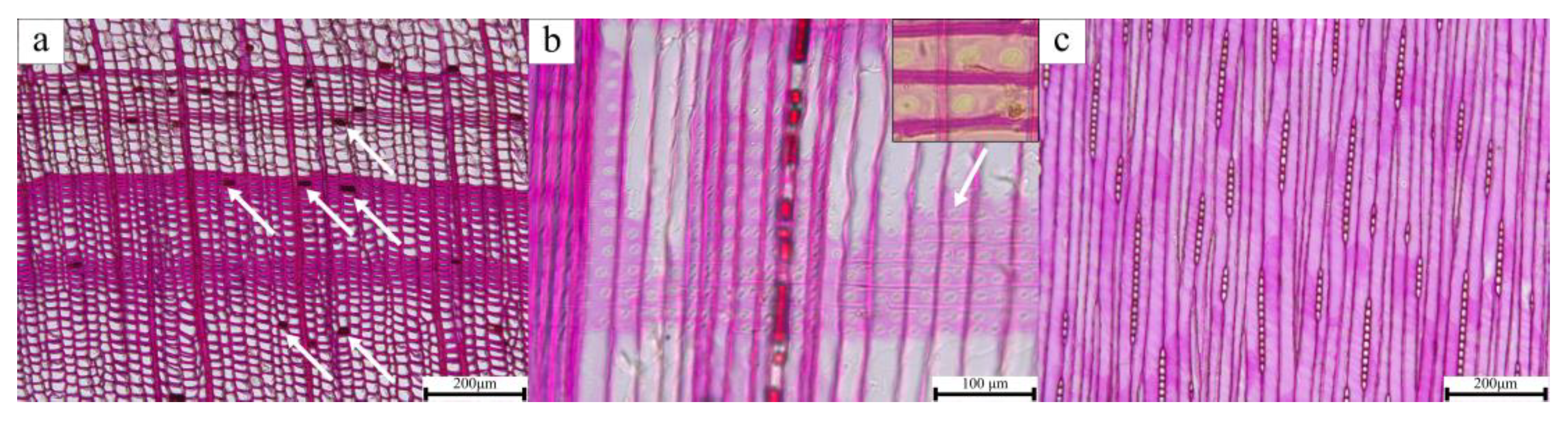

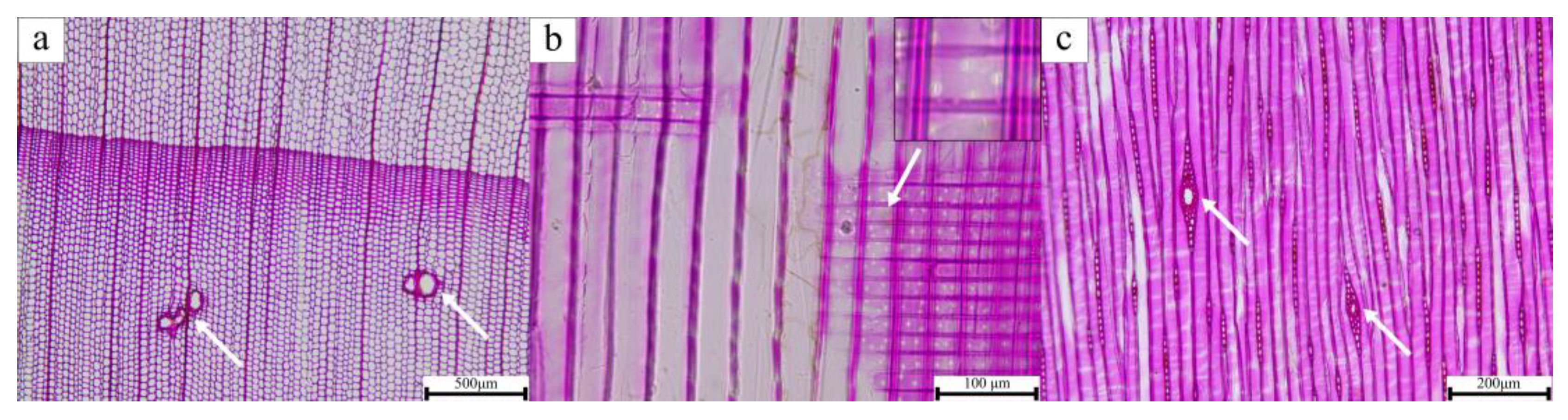

3.1. Wood Identification Results

3.2. Physical Property Analysis

3.3. Main Chemical Composition Analysis

3.4. XRD Analysis

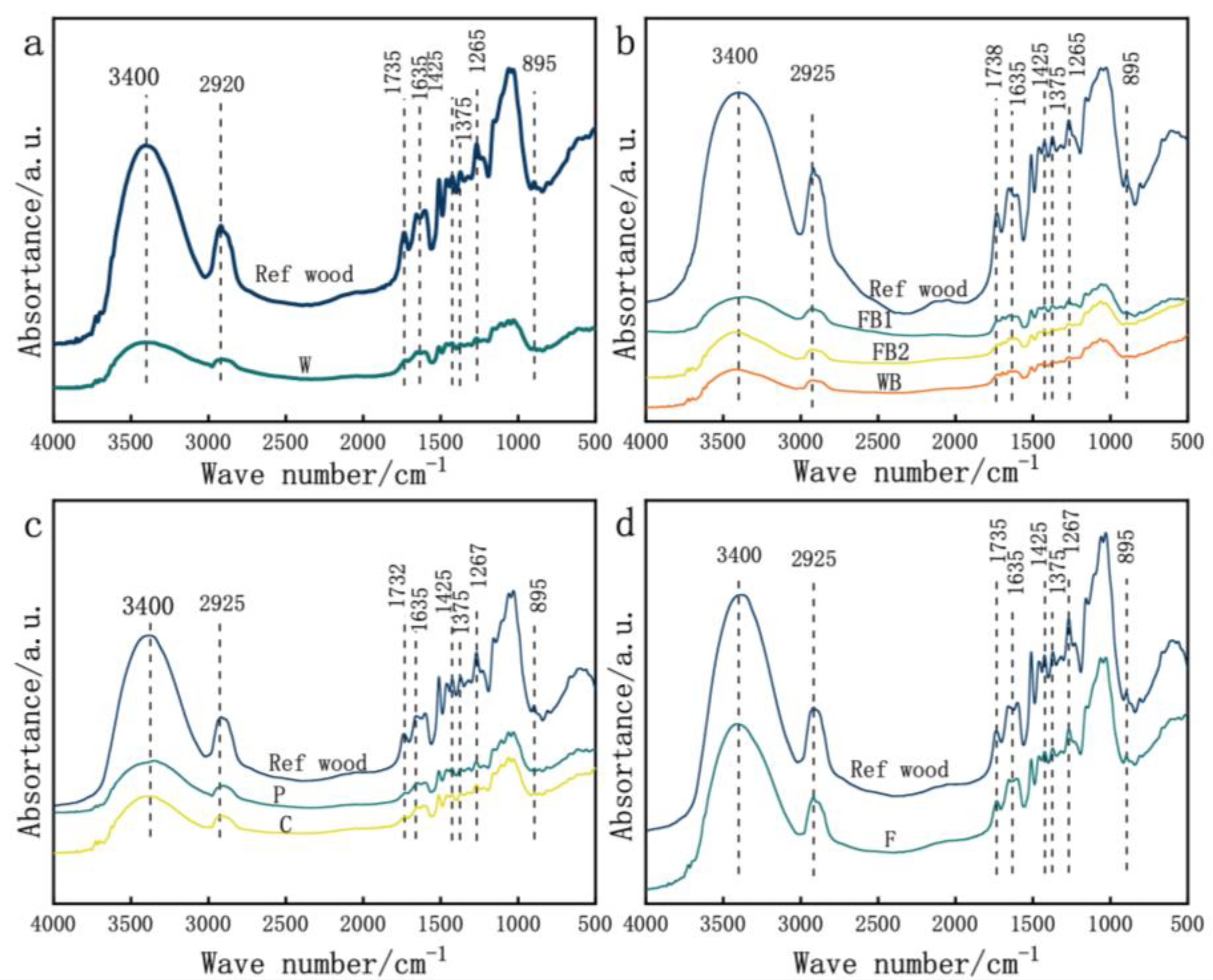

3.5. FTIR Spectroscopy Analysis

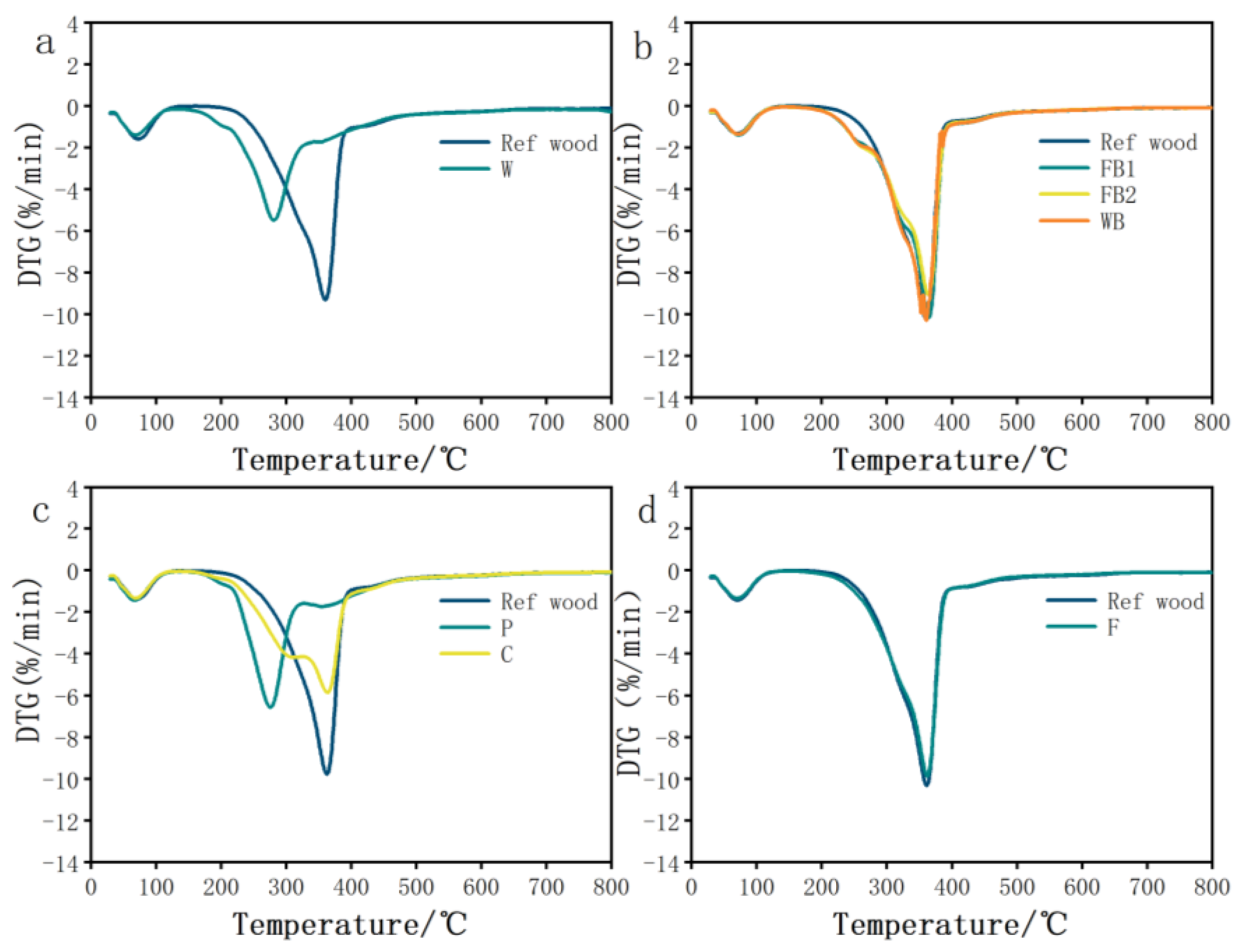

3.6. Thermogravimetric Analysis

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Dinulică, F.; Stanciu, M.D.; Savin, A. Correlation between Anatomical Grading and Acoustic–Elastic Properties of Resonant Spruce Wood Used for Musical Instruments. Forests 2021, 12, 1122. [Google Scholar] [CrossRef]

- Zhenzhong, G.; Mengjie, C.; Shuqi, C.; Jin, S. Investigation into the Deterioration of Castanopsis Hystrix Buried Wood by Anatomical, Chemical and Thermal Analysis. Mater. Res. Express 2022, 9, 095602. [Google Scholar] [CrossRef]

- Wang, J.; Ning, L.; Gao, Q.; Zhang, S.; Chen, Q. The Identification and Characteristics of Phoebe Zhennan Buried Wood. IAWA J. 2019, 40, 804–819. [Google Scholar] [CrossRef]

- Haag, V.; Koch, G.; Richter, H.-G.; Evans, R.; Guzmán, J.A.S.; Schmitt, U. Wood Anatomical and Topochemical Analyses to Characterize Juvenile and Adult Wood of Lesser-Known Species from Central America (Mexico). IAWA J. 2019, 40, 785–803. [Google Scholar] [CrossRef]

- Meko, D.; Touchan, R.; Kherchouche, D.; Slimani, S. Direct Versus Indirect Tree Ring Reconstruction of Annual Discharge of Chemora River, Algeria. Forests 2020, 11, 986. [Google Scholar] [CrossRef]

- Liu, J.; Yang, B.; Huang, K.; Sonechkin, D. Annual Regional Precipitation Variations from a 700 Year Tree-ring Record in South Tibet, Western China. Clim. Res. 2012, 53, 25–41. [Google Scholar] [CrossRef]

- Dong, G.; Zhang, B.; Qi, J.; Yuan, H.; Zhou, Y.; Luo, B.; Deng, S.; Xia, Y. The Deterioration State and Degradation Mechanism of Historical Timber Structures from the Yunnan Military Academy. Wood Mater. Sci. Eng. 2023, 18, 1878–1887. [Google Scholar] [CrossRef]

- Han, L.; Xi, G.; Dai, W.; Zhou, Q.; Sun, S.; Han, X.; Guo, H. Influence of Natural Aging on the Moisture Sorption Behaviour of Wooden Structural Components. Molecules 2023, 28, 1946. [Google Scholar] [CrossRef] [PubMed]

- Kim, J.S.; Kim, M.; Lim, J.W.; Cha, M.Y.; Lee, K.H.; Yoon, Y.H.; Kim, Y.S. Characterization of Microbial Decay and Microbial Communities in Waterlogged Archaeological Rosewood (Dalbergia Species). Forests 2023, 14, 1992. [Google Scholar] [CrossRef]

- Macchioni, N.; Sozzi, L.; Fidanza, G.B. The Relationship between Carving Work and Timber Features: A Database for the Italian Wooden Statuary. Forests 2022, 13, 517. [Google Scholar] [CrossRef]

- Lee, S.-B.; Tong, R.L.; Kim, S.-H.; Im, I.G.; Su, N.-Y. Potential Pest Status of the Formosan Subterranean Termite, Coptotermes Formosanus Shiraki (Blattodea: Isoptera: Rhinotermitidae), in Response to Climate Change in the Korean Peninsula. Fla. Entomol. 2021, 103, 431–437. [Google Scholar] [CrossRef]

- Im, I.-G.; Cha, H.-S.; Kang, W.-C.; Lee, S.-B.; Han, G.-S. The Status of Damage and Monitoring of Subterranean Termite (Reticulitermes Spp.) (Blattodea: Rhinotermitidae) for Wooden Cultural Heritage in Korea. J. Conserv. Sci. 2021, 37, 191–208. [Google Scholar] [CrossRef]

- Novita, N.; Amiruddin, H.; Ibrahim, H.; Jamil, T.M.; Syaukani, S.; Oguri, E.; Eguchi, K. Investigation of Termite Attack on Cultural Heritage Buildings: A Case Study in Aceh Province, Indonesia. Insects 2020, 11, 385. [Google Scholar] [CrossRef]

- Zukowski, J.; Su, N.-Y. A Comparison of Morphology among Four Termite Species with Different Moisture Requirements. Insects 2020, 11, 262. [Google Scholar] [CrossRef] [PubMed]

- Svora, P.; Pawelkowicz, S.S.; Prošek, Z. Microscopic Studies of Irradiated Wood by UV Light. Microsc. Microanal. 2019, 25, 2408–2409. [Google Scholar] [CrossRef]

- Cogulet, A.; Blanchet, P.; Landry, V. Wood Degradation under UV Irradiation: A Lignin Characterization. J. Photochem. Photobiol. B Biol. 2016, 158, 184–191. [Google Scholar] [CrossRef]

- Mattonai, M.; Watanabe, A.; Shiono, A.; Ribechini, E. Degradation of Wood by UV Light: A Study by EGA-MS and Py-GC/MS with online Irradiation System. J. Anal. Appl. Pyrolysis 2019, 139, 224–232. [Google Scholar] [CrossRef]

- Guo, J.; Zhou, H.; Stevanic, J.S.; Dong, M.; Yu, M.; Salmén, L.; Yin, Y. Effects of Ageing on the Cell Wall and Its Hygroscopicity of Wood in Ancient Timber Construction. Wood Sci. Technol. 2018, 52, 131–147. [Google Scholar] [CrossRef]

- Liu, X.; Xu, X.; Tu, X.; Ma, W.; Huang, H.; Varodi, A.M. Characteristics of Ancient Ship Wood from Taicang of the Yuan Dynasty. Materials 2022, 16, 104. [Google Scholar] [CrossRef]

- Bernabei, M.; Brunetti, M.; Macchioni, N.; Nocetti, M.; Micheloni, M. Surveying and Dating the Wooden Roof Structure of St Francis of Assisi Church in Valletta, Malta. Int. J. Archit. Herit. 2021, 15, 1886–1894. [Google Scholar] [CrossRef]

- GB/T 50165—2020; Ministry of Housing and Urban Rural Development of the People’s Republic of China. Technical Standard for Maintenance and Strengthening of Historic Timber Building. China Architecture and Building Press: Beijing, China, 2020.

- Kolář, T.; Dobrovolný, P.; Szabó, P.; Mikita, T.; Kyncl, T.; Kyncl, J.; Sochová, I.; Rybníček, M. Wood Species Utilization for Timber Constructions in the Czech Lands over the Period 1400–1900. Dendrochronologia 2021, 70, 125900. [Google Scholar] [CrossRef]

- GB/T 29894—2013; State Administration of Quality Supervision, Inspection and Quarantine, Standardization Administration of China. General Principles of Wood Identification Methods. Standards Press of China: Beijing, China, 2014.

- GB/T 1927.5—2021; State Administration of Quality Supervision, Inspection and Quarantine, Standardization Administration of China. Test Methods for Physical and Mechanical Properties of Small Clear Wood Specimens—Part 5: Determinarion of Density. Standards Press of China: Beijing, China, 2021.

- GB/T 1927.4—2021; State Administration of Quality Supervision, Inspection and Quarantine, Test Methods for Physical and Mechanical Properties of Small Clear Wood Specimens—Part 4: Determinarion of Moisture Content. Standards Press of China: Beijing, China, 2021.

- Mertz, M.; Gupta, S.; Hirako, Y.; Azevedo, P.D.; Sugiyama, J. Wood Selection of Ancient Temples in the Sikkim Himalayas. IAWA J. 2014, 35, 444–462. [Google Scholar] [CrossRef]

- Zhao, C.; Zhang, X.; Liu, L.; Yu, Y.; Zheng, W.; Song, P. Probing Chemical Changes in Holocellulose and Lignin of Timbers in Ancient Buildings. Polymers 2019, 11, 809. [Google Scholar] [CrossRef]

- Andersson, S.; Serimaa, R.; Paakkari, T.; SaranpÄÄ, P.; Pesonen, E. Crystallinity of Wood and the Size of Cellulose Crystallites in Norway Spruce (Picea Abies). J. Wood Sci. 2003, 49, 531–537. [Google Scholar] [CrossRef]

- de Almeida, T.H.; Sardela, M.; Lahr, F.A.R. X-Ray Diffraction on Aged Brazilian Wood Species. Mater. Sci. Eng. B 2019, 246, 96–103. [Google Scholar] [CrossRef]

- Lentz, D.L.; Hockaday, B. Tikal Timbers and Temples: Ancient Maya Agroforestry and the End of Time. J. Archaeol. Sci. 2009, 36, 1342–1353. [Google Scholar] [CrossRef]

- Xu, Y.; Chen, B. Investigation of Thermodynamic Parameters in the Pyrolysis Conversion of Biomass and Manure to Biochars Using Thermogravimetric Analysis. Bioresour. Technol. 2013, 146, 485–493. [Google Scholar] [CrossRef] [PubMed]

- Inside Wood. Available online: https://insidewood.lib.ncsu.edu (accessed on 24 October 2022).

- EyeWood. Available online: http://woodlab.swfu.edu.cn/#/ (accessed on 24 October 2022).

- Jensen, P.; Gregory, D.J. Selected Physical Parameters to Characterize the State of Preservation of Waterlogged Archaeological Wood: A Practical Guide for Their Determination. J. Archaeol. Sci. 2006, 33, 551–559. [Google Scholar] [CrossRef]

- Lionetto, F.; Quarta, G.; Cataldi, A.; Cossa, A.; Auriemma, R.; Calcagnile, L.; Frigione, M. Characterization and Dating of Waterlogged Woods from an Ancient Harbor in Italy. J. Cult. Herit. 2014, 15, 213–217. [Google Scholar] [CrossRef]

- Babiński, L.; Izdebska-Mucha, D.; Waliszewska, B. Evaluation of the State of Preservation of Waterlogged Archaeological Wood Based on Its Physical Properties: Basic Density vs. Wood Substance Density. J. Archaeol. Sci. 2014, 46, 372–383. [Google Scholar] [CrossRef]

- Mi, X.; Li, Y.; Qin, X.; Li, J. Effects of Natural Weathering on Aged Wood from Historic Wooden Building: Diagnosis of the Oxidative Degradation. Herit. Sci. 2023, 11, 109. [Google Scholar] [CrossRef]

- Lionetto, F.; Del Sol, R.; Cannoletta, D.; Vasapollo, G.; Maffezzoli, A. Monitoring Wood Degradation during Weathering by Cellulose Crystallinity. Materials 2012, 5, 1910–1922. [Google Scholar] [CrossRef]

- Akgül, M.; Gümüşkaya, E.; Korkut, S. Crystalline Structure of Heat-Treated Scots Pine [Pinus Sylvestris L.] and Uludağ Fir [Abies Nordmanniana (Stev.) Subsp. Bornmuelleriana (Mattf.)] Wood. Wood Sci. Technol. 2007, 41, 281–289. [Google Scholar] [CrossRef]

- Howell, C.; Steenkjær Hastrup, A.C.; Goodell, B.; Jellison, J. Temporal Changes in Wood Crystalline Cellulose during Degradation by Brown Rot Fungi. Int. Biodeterior. Biodegrad. 2009, 63, 414–419. [Google Scholar] [CrossRef]

- Yang, Y.; Sun, H.; Li, B.; Han, L.; Wang, A.; Wang, W.; He, Y.; Zhao, R. Study on the Identification and the Extent of Decay of the Wooden Components in the Xichuan Guild Hall Ancient Architectures. Int. J. Archit. Herit. 2022, 16, 405–414. [Google Scholar] [CrossRef]

- Burgert, I.; Fratzl, P. Plants Control the Properties and Actuation of Their Organs through the Orientation of Cellulose Fibrils in Their Cell Walls. Integr. Comp. Biol. 2009, 49, 69–79. [Google Scholar] [CrossRef] [PubMed]

- Müller, U.; Rätzsch, M.; Schwanninger, M.; Steiner, M.; Zöbl, H. Yellowing and IR-Changes of Spruce Wood as Result of UV-Irradiation. J. Photochem. Photobiol. B Biol. 2003, 69, 97–105. [Google Scholar] [CrossRef] [PubMed]

- Pandey, K.K.; Pitman, A.J. FTIR Studies of the Changes in Wood Chemistry Following Decay by Brown-Rot and White-Rot Fungi. Int. Biodeterior. Biodegrad. 2003, 52, 151–160. [Google Scholar] [CrossRef]

- Thygesen, L.G.; Beck, G.; Nagy, N.E.; Alfredsen, G. Cell Wall Changes during Brown Rot Degradation of Furfurylated and Acetylated Wood. Int. Biodeterior. Biodegrad. 2021, 162, 105257. [Google Scholar] [CrossRef]

- García, E.L.; García, F.F.; Guindeo, A.C.; De Palacios, P.; Gril, J. Comparison of the Hygroscopic Behaviour of 205-Year-Old and Recently Cut Juvenile Wood from Pinus Sylvestris L. Ann. For. Sci. 2006, 63, 309–317. [Google Scholar] [CrossRef]

- Adeleke, A.A.; Odusote, J.K.; Lasode, O.A.; Ikubanni, P.P.; Madhurai, M.; Paswan, D. Evaluation of Thermal Decomposition Characteristics and Kinetic Parameters of Melina Wood. Biofuels 2022, 13, 117–123. [Google Scholar] [CrossRef]

- Tomassetti, M.; Campanella, L.; Tomellini, R. Thermogravimetric Analysis of Ancient and Fresh Woods. Thermochim. Acta 1990, 170, 51–65. [Google Scholar] [CrossRef]

- Burhenne, L.; Messmer, J.; Aicher, T.; Laborie, M.-P. The Effect of the Biomass Components Lignin, Cellulose and Hemicellulose on TGA and Fixed Bed Pyrolysis. J. Anal. Appl. Pyrolysis 2013, 101, 177–184. [Google Scholar] [CrossRef]

- Müller-Hagedorn, M.; Bockhorn, H.; Krebs, L.; Müller, U. A Comparative Kinetic Study on the Pyrolysis of Three Different Wood Species. J. Anal. Appl. Pyrolysis 2003, 68–69, 231–249. [Google Scholar] [CrossRef]

| Samples | Anatomical Features | Wood Species | ||||

|---|---|---|---|---|---|---|

| Tracheids | Longitudinal Parenchyma | Rays | Cross-Field Pitting | Resin Canals | ||

| W | The transverse section of earlywood tracheids circular, polygonal; tracheids length range 1262–4223 (2307) μm; bordered pits 1 row on the radial walls in earlywood. | Seldom, diffuse, few banded, end walls of parenchyma, with darker resign. | Uniseriate rays 1–26 plus cells; horizontal walls of ray parenchyma cells thin; end walls of ray parenchyma cells nodular absent; indentures distinct. | Cupressoid, 2–3 per cross field. | Absent. | Cupressus funebris Endl. |

| FB WB | The transverse section of earlywood tracheids oblong or polygonal; tracheids length range 1717–5579 (2770) μm; bordered pits 1 row on the radial walls in earlywood. | Absent. | 2 types including uniseriate and fusiform; ray tracheids marginal and interspersed, with deeply dentate edges. | All window-like (fenestriform), 1–2 (generally 1). | 2 types, axial and radical resin canals. | Pinus yunnanensis Franch. |

| P C | The transverse section of earlywood tracheids irregular, polygonal, and square; tracheids length range 1262–4318 (2148) μm; bordered pits 1 row on the radial walls in earlywood. | Diffuse and tangential band; end walls of parenchyma cells smooth with darker resign. | Uniseriate rays 1–21 plus cells; horizontal walls of ray parenchyma cells; ends walls of ray parenchyma cells smooth; indentures distinct; ray tracheids absent. | Taxodioid, 2–4 per cross field. | Absent. | Cunninghamia lanceolata (Lamb.) Hook |

| F | The transverse section of earlywood tracheids square oblong and polygonal; tracheids length range 1792–3814 (2280) μm; bordered pits 1 row on the radial walls in earlywood. | Absent. | 2 types including uniseriate and fusiform; uniseriate rays 1–22 plus cells; fusiform rays up to 2–11 plus cells. | Piceoid, 1–3 per cross field. | 2 types, axial and radical resin canals. | Picea brachytyla var complanata (Mast) Cheng |

| Samples | AD (g/cm3) | BD (g/cm3) | MWC (%) |

|---|---|---|---|

| W | 0.500 (0.014) | 0.417 (0.011) | 180.367% (0.023) |

| Ref cypress | 0.591–0.623 | 0.491–0.517 | 128.064%–138.306% |

| FB | 0.384 (0.002) | 0.327 (0.017) | 211.235% (0.055) |

| WB | 0.422 (0.002) | 0.357 (0.002) | 204.537% (0.032) |

| Ref pine | 0.599–0.638 | 0.498–0.529 | 123.830%–135.597% |

| P | 0.274 (0.046) | 0.239 (0.036) | 387.298% (0.021) |

| C | 0.305 (0.027) | 0.264 (0.021) | 344.243% (0.026) |

| Ref Chinese fir | 0.314–0.369 | 0.271–0.315 | 252.021%–303.062% |

| F | 0.394 (0.020) | 0.335 (0.16) | 160.040% (0.040) |

| Ref fir | 0.567–0.594 | 0.294–0.472 | 137.213%–146.405% |

| Samples | Holocellulose (%) | Cellulose (%) | Hemicellulose (%) | Lignin (%) | H/L a |

|---|---|---|---|---|---|

| W | 42.60 (0.35) | 30.80 (0.40) | 11.80 (0.75) | 34.60 (0.15) | 1.23 |

| Ref cypress | 45.90 (0.15) | 31.00 (0.12) | 14.90 (0.10) | 35.30 (0.21) | 1.30 |

| FB1 | 52.70 (0.21) | 34.20 (0.21) | 18.50 (0.38) | 34.70 (0.25) | 1.52 |

| FB2 | 54.40 (0.20) | 35.90 (0.45) | 18.50 (0.26) | 32.90 (0.15) | 1.65 |

| WB | 52.20 (0.20) | 34.20 (0.15) | 18.00 (0.21) | 33.70 (0.15) | 1.55 |

| Ref pine | 62.50 (0.36) | 43.80 (0.10) | 18.70 (0.26) | 26.00 (0.26) | 2.40 |

| P | 45.80 (0.36) | 34.80 (0.41) | 11.00 (0.75) | 39.60 (0.20) | 1.15 |

| C | 47.70 (0.40) | 36.30 (0.17) | 11.40 (0.41) | 40.20 (0.25) | 1.19 |

| Ref Chinese fir | 52.10 (0.15) | 38.60 (0.10) | 13.50 (0.06) | 35.00 (0.15) | 1.49 |

| F | 52.10 (0.45) | 36.80 (0.25) | 15.30 (0.61) | 30.40 (0.15) | 1.71 |

| Ref spruce | 53.90 (0.15) | 37.40 (0.10) | 16.50 (0.21) | 30.00 (0.42) | 1.80 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yang, X.; Li, C.; Wang, L.; Yang, C.; Zhang, S.; Gao, J.; Qiu, J. The Characteristics of Ancient Residence Wood from the Qing Dynasty in Yunnan Province. Coatings 2024, 14, 200. https://doi.org/10.3390/coatings14020200

Yang X, Li C, Wang L, Yang C, Zhang S, Gao J, Qiu J. The Characteristics of Ancient Residence Wood from the Qing Dynasty in Yunnan Province. Coatings. 2024; 14(2):200. https://doi.org/10.3390/coatings14020200

Chicago/Turabian StyleYang, Xiaorui, Changzhao Li, Liang Wang, Chunwang Yang, Shang Zhang, Jingran Gao, and Jian Qiu. 2024. "The Characteristics of Ancient Residence Wood from the Qing Dynasty in Yunnan Province" Coatings 14, no. 2: 200. https://doi.org/10.3390/coatings14020200