Friction Evolution of Graphite Bearing Impregnated with Polymer Subjected to Vibration Fretting at High Temperature

Abstract

:1. Introduction

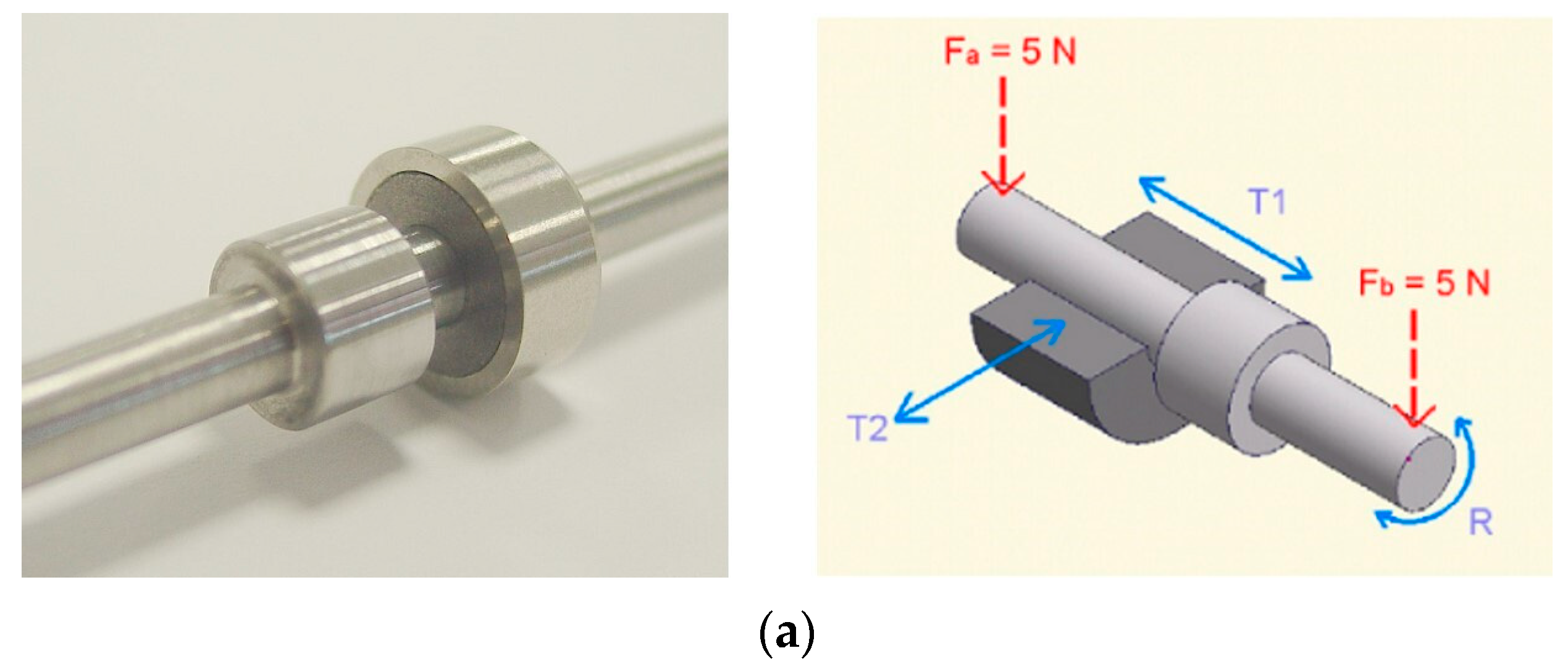

2. Materials and Methods

2.1. Materials of the Study

- A graphite bearing with an internal diameter of 4.02 mm and a length of 8 mm, either impregnated or not with polymer. The mechanical characteristics of the graphite are outlined in Table 1;

- The shaft, with a diameter of 3.97 mm and a 7 mm diameter stop, which was precision-machined from AISI 304L austenitic stainless steel. It possesses a Young’s Modulus of approximately 190 GPa, and its Vickers Hardness is 180 HV.

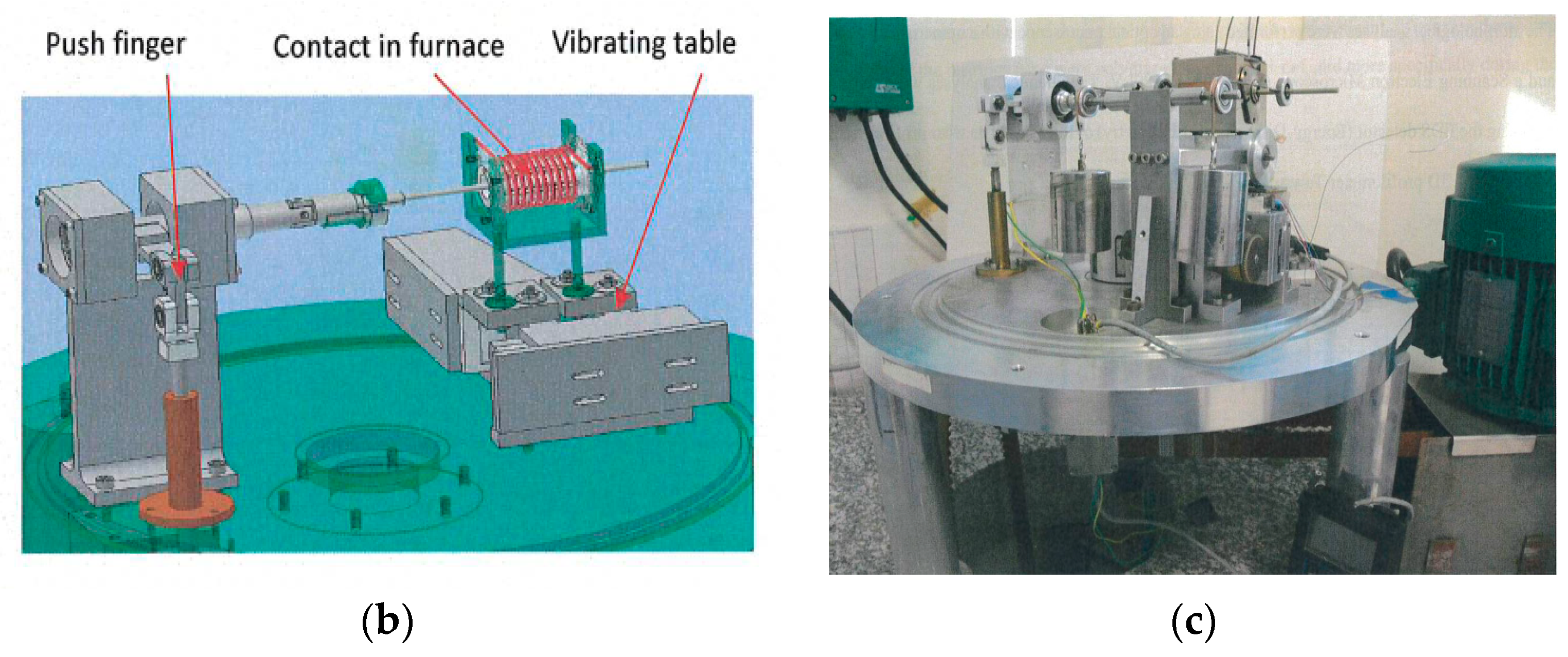

2.2. Experimental Setup

- In the first, labeled as “vibration tests”, all mechanical stresses were applied, and the friction torque was measured periodically (over 10 min intervals) at various stages of the tests.

- In the second, referred to as “vibration-free tests”, the T1 and T2 stresses were not applied, and the friction torque is continuously measured throughout the tests.

3. Results

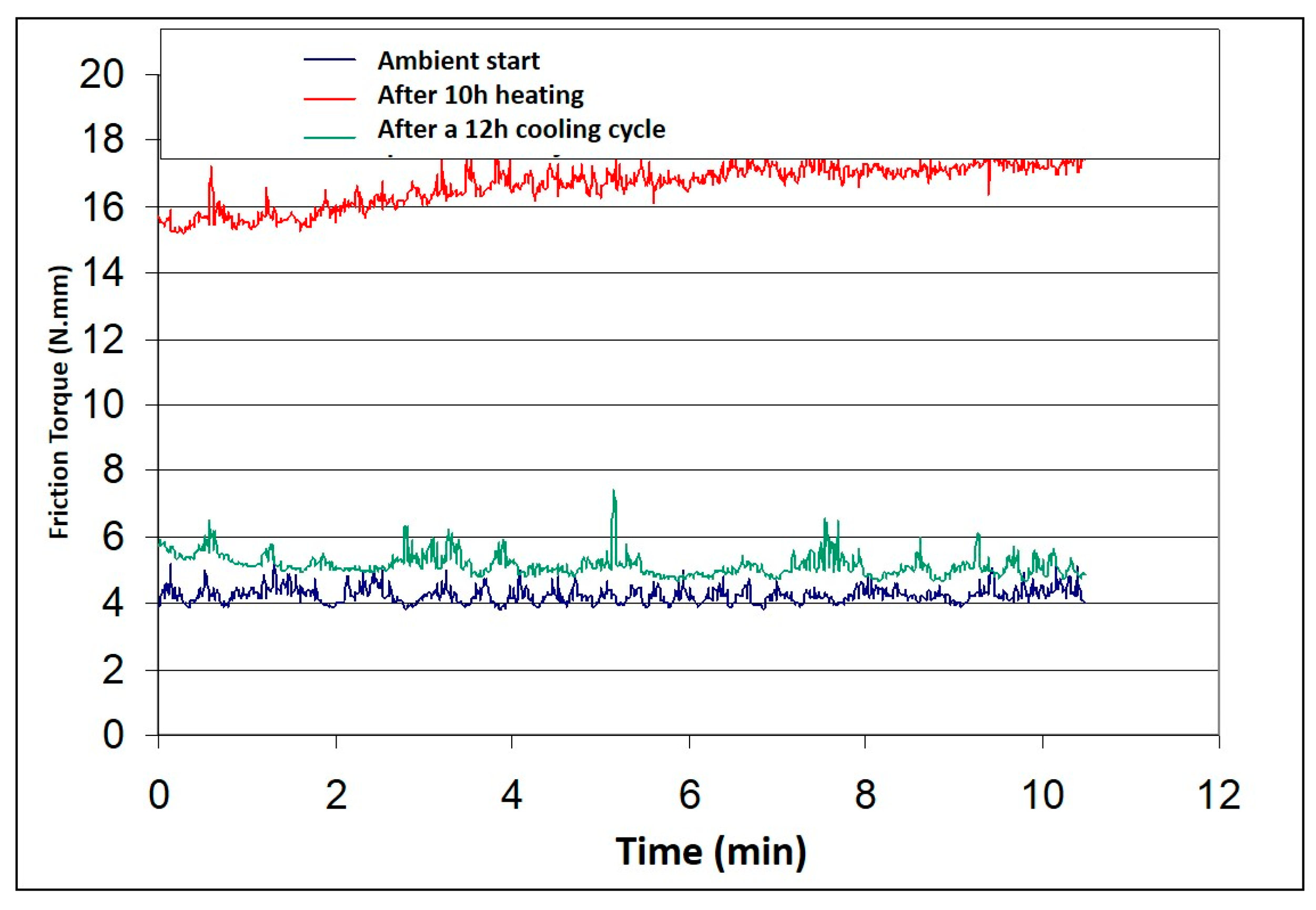

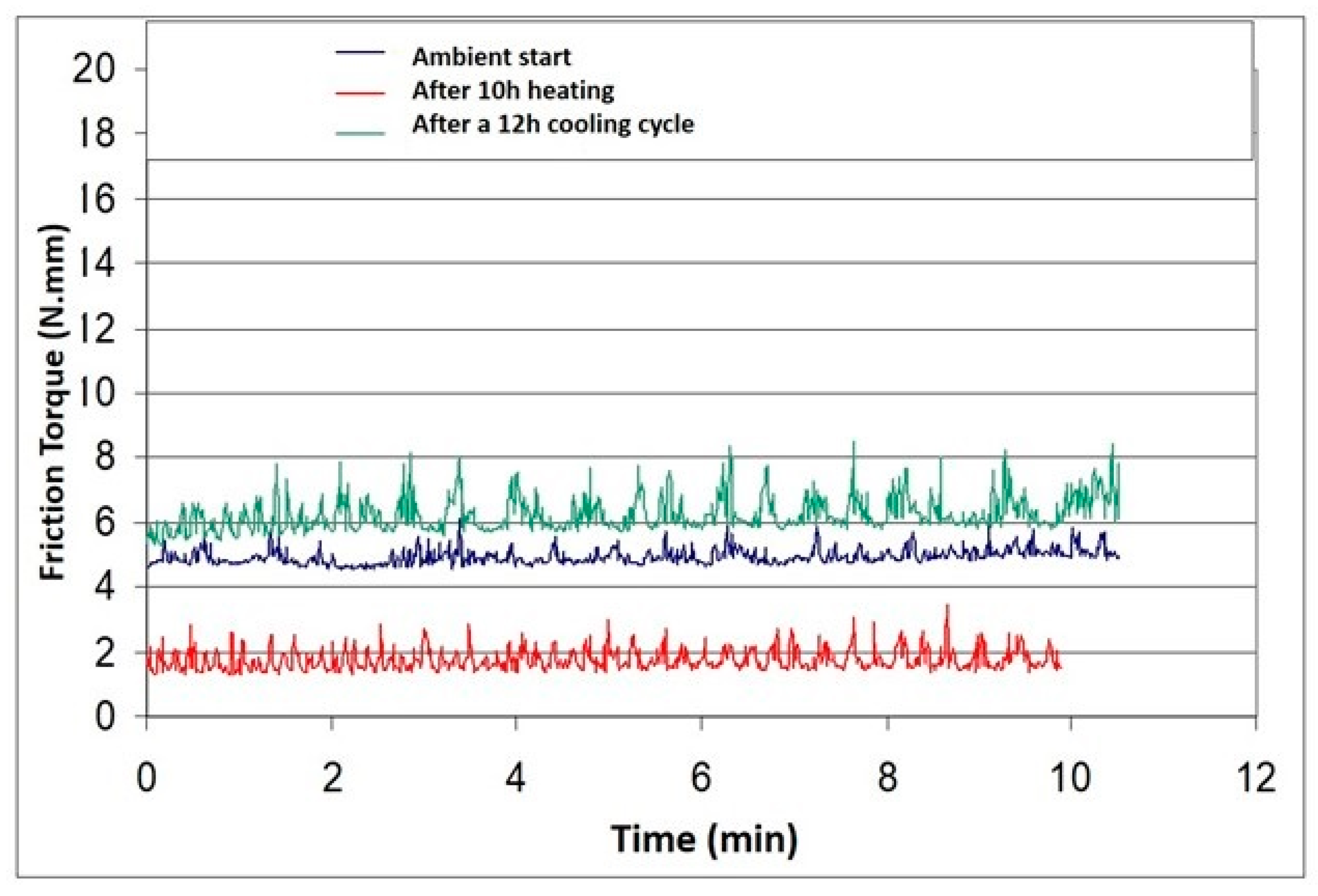

3.1. Vibration Tests: Friction

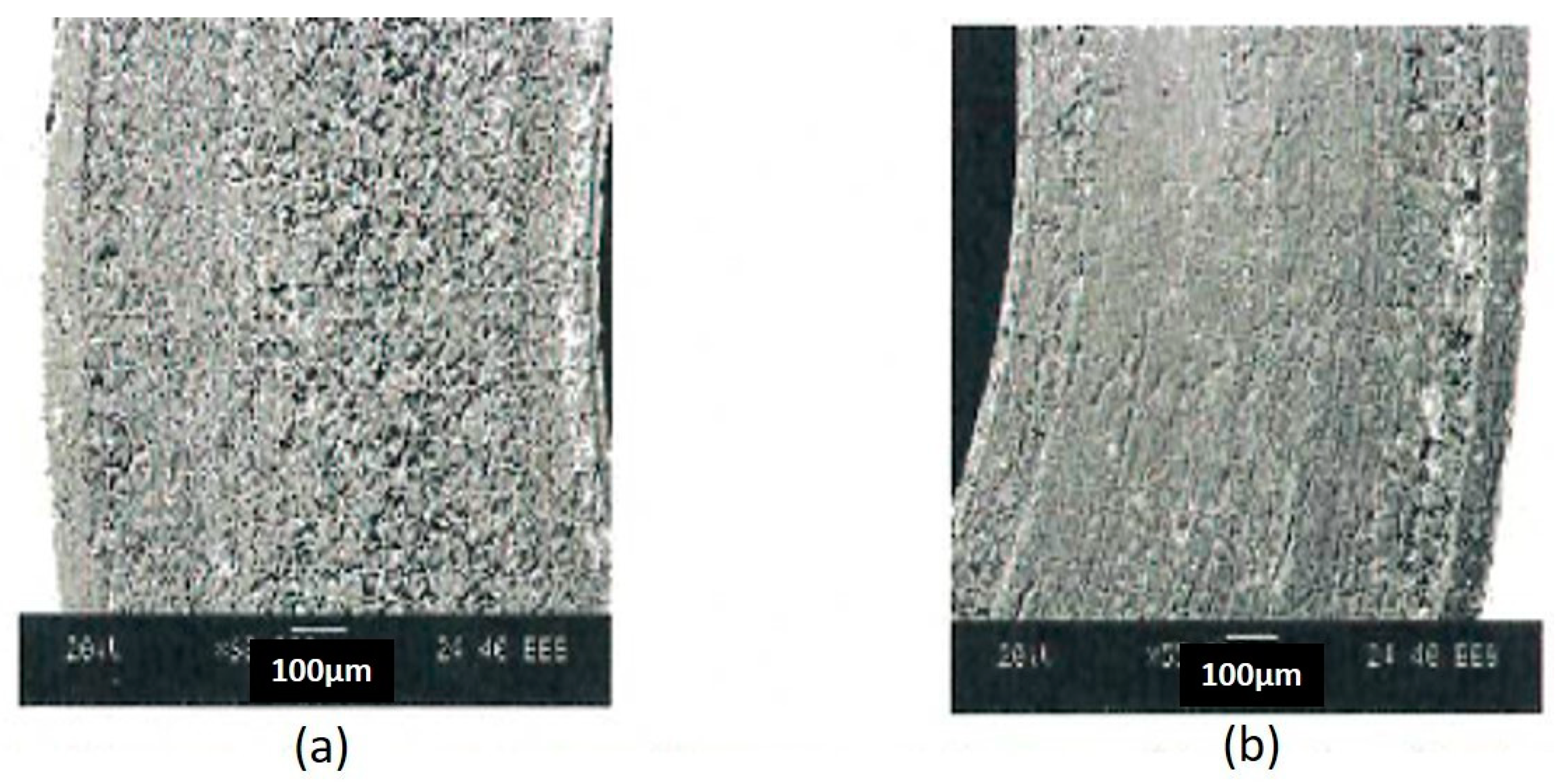

3.2. Vibration Tests: Wear and Damage

- The contact zone between the bearing and the cylindrical bearing surface of the shaft, constituting a permanent contact.

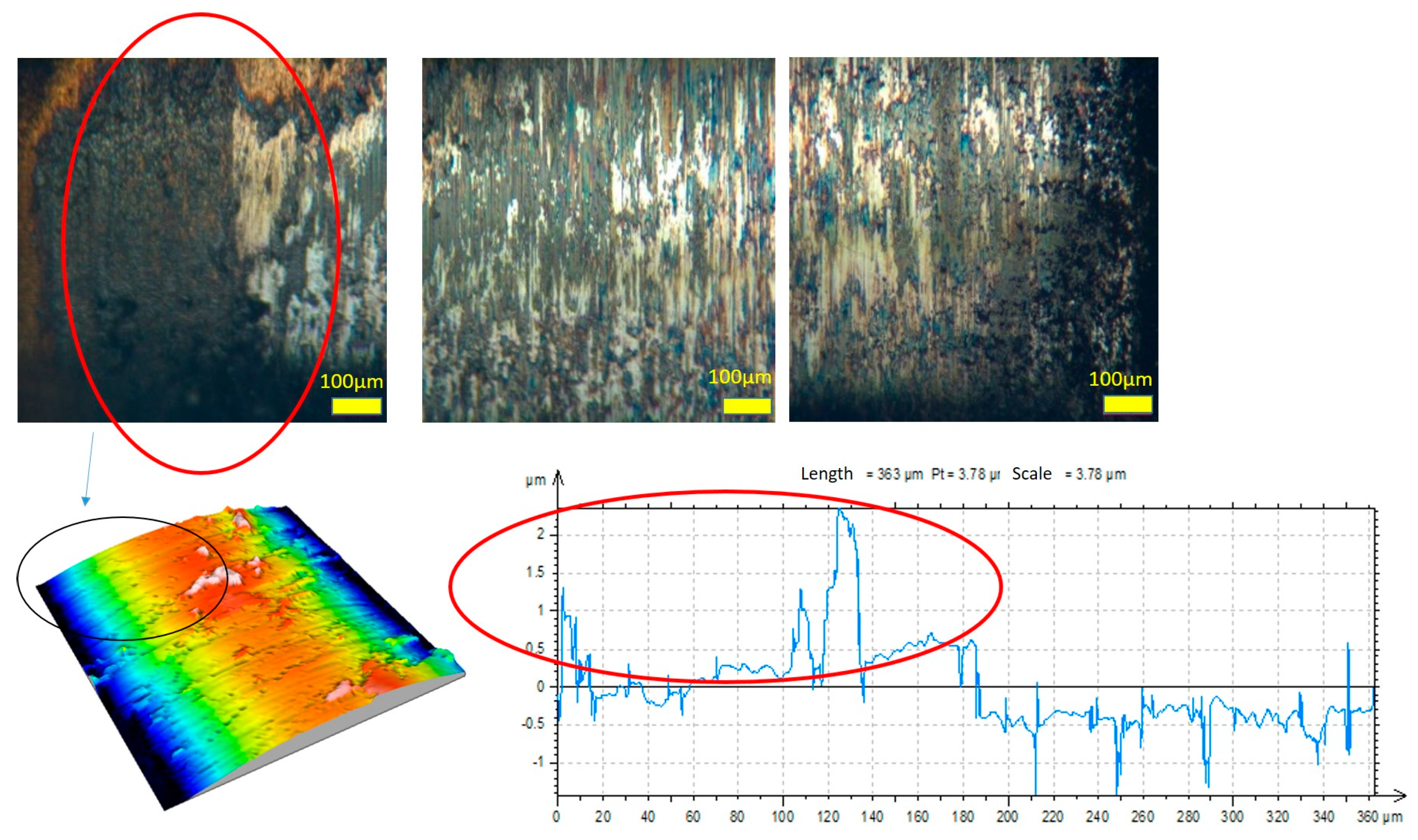

- The contact zone between the graphite bearing and the metal thrust of the shaft, characterized by non-permanent contact. This area is subjected to fretting impact stresses in conjunction with the rotational movements of the shaft.

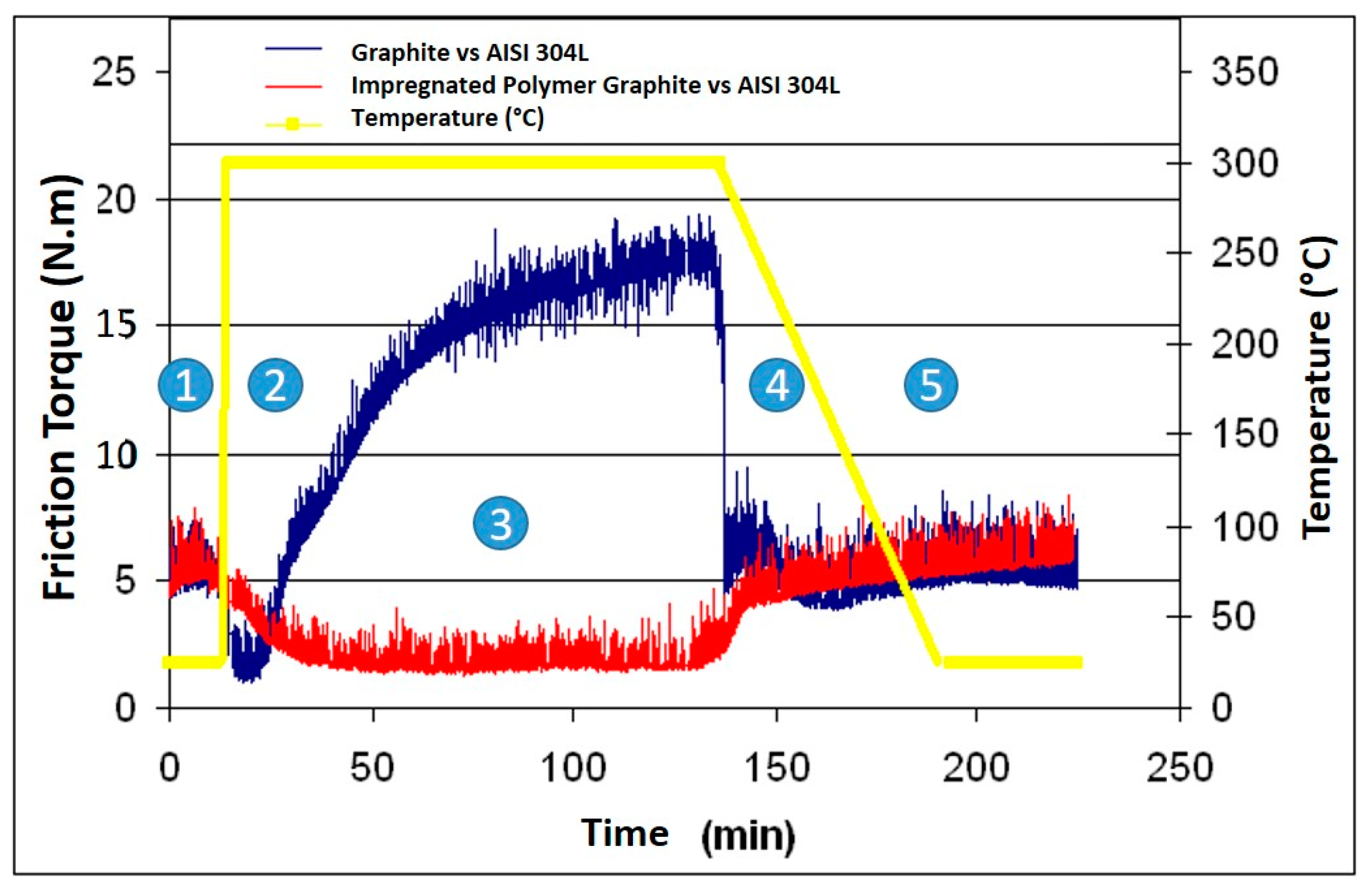

3.3. Vibration-Free Testing

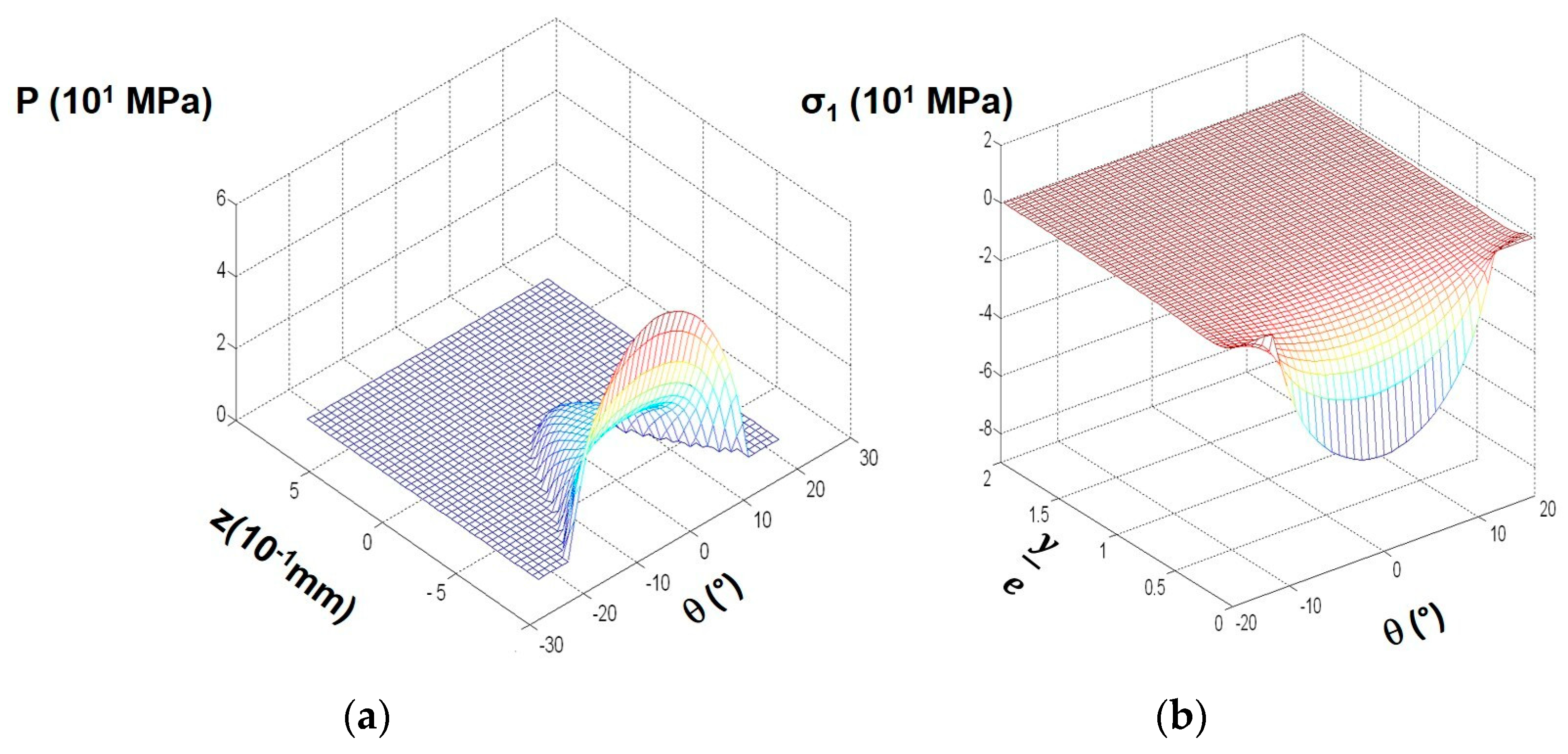

4. Contact Pressure and Stress Fields

- θ is the angle defining the angular position of the point where we wish to calculate h.

- z is the axial position of the point where we wish to calculate h.

- L is the length of the bearing.

- C is the radial clearance defined by C = Rbearing − Rshaft.

- e is the eccentricity in the center plane of the bearing (distance between the center of the bearing O0 and that of the shaft C0).

- φ is the wedge angle representing the angle between the center line (O0 C0) and the direction of the load N.

- −δ is the relative misalignment, with δ, where d is the magnitude of the misalignment characterized by the modulus of the projection of the segment C1C2 in a straight section of the bearing. C1 and C2 are the positions of the shaft center at both ends of the bearing.

- β is the misalignment angle between the line of centers C1C2 and the direction of load N (Figure 9).

5. Discussion

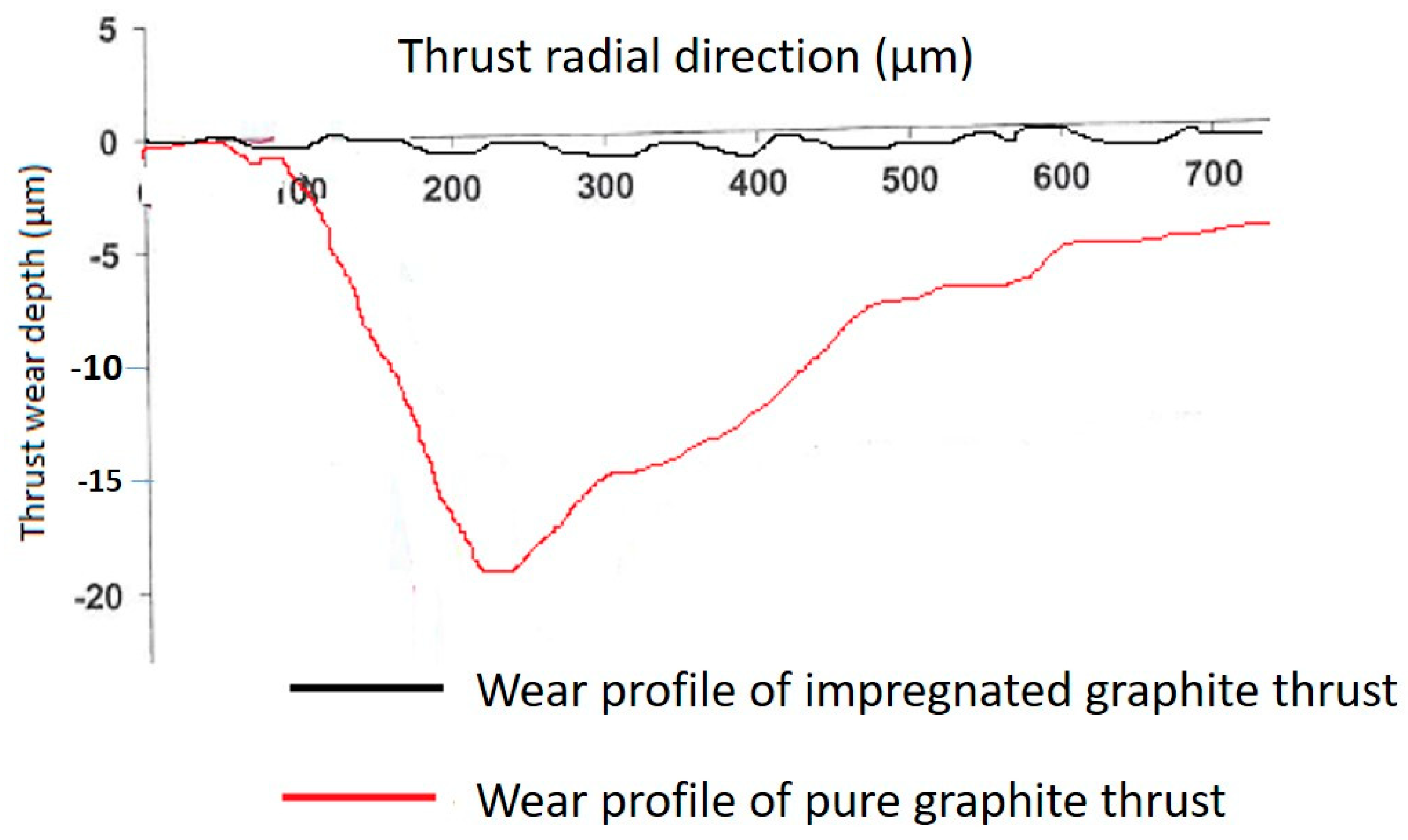

5.1. Thrust Behavior Analysis

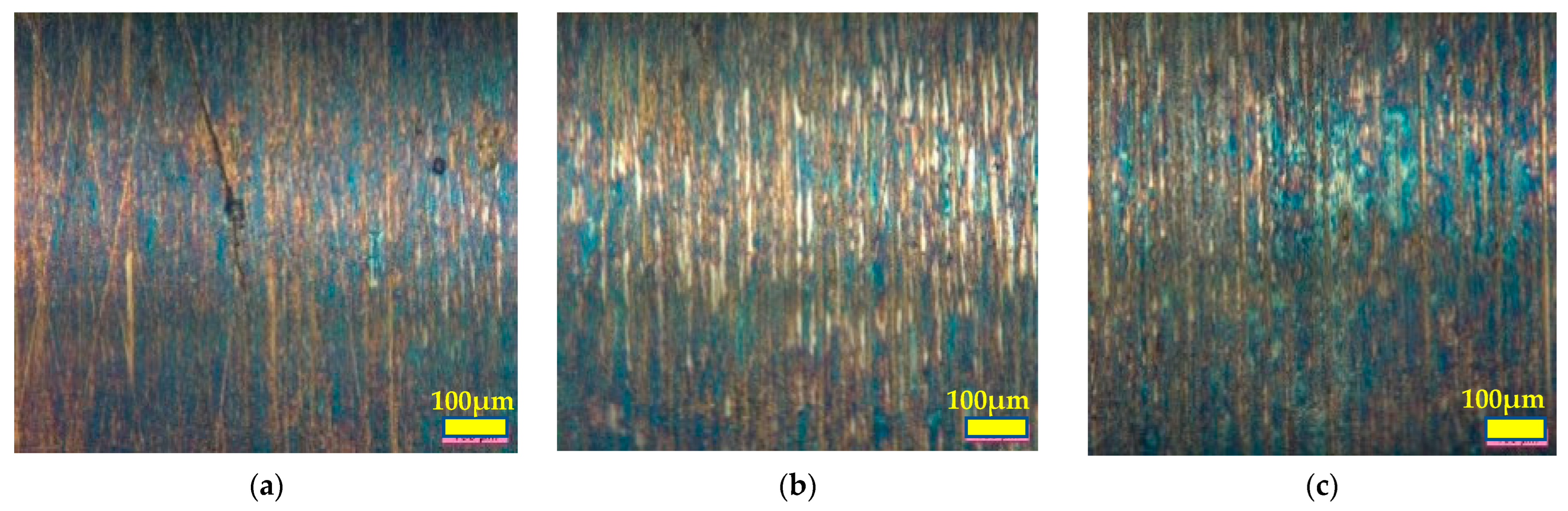

5.2. Bore Behavior Analysis

5.3. Influence of the Temperature on the Impregnated Graphite Behavior

6. Conclusions

- At room temperature and up to 150 °C, both materials exhibit identical tribological behavior. The frictional torque resistance is approximately 5 N·mm, and the bearing wear profiles are similar.

- However, at elevated temperatures above 150 °C, the frictional torque of pure graphite increases by more than threefold, and the wear profile of the thrust bearing becomes almost 100 times deeper than that measured at room temperature. In contrast, the friction torque of polymer-impregnated graphite is halved, and the wear profile of the thrust bearing remains comparable to that measured at ambient temperature.

- Under contact pressure, the melting temperature of the polymer decreases, initiating polymer diffusion through the graphite porosity to the contact zone starting from 150 °C. The formation of a thin fluid film of polymer on the asperities of the contact lubricates the interface, resulting in a friction torque that is half that of ball bearings, as the Teflon film exhibits anti-adhesive properties.

- The spectral analysis of the fretting friction signal displays the first peak at frequency f of the periodic fretting signal and a second peak at frequency 3.f. This frequency signature indicates a hydrodynamic shaft/bearing oscillation, revealing liquid-lubricated friction above 270 °C. Additionally, optical visualization of the impregnated graphite wear tracks illustrates the accumulation of polymer plates on the surfaces.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Ramadanoff, D.; Glass, S.W. High-altitude brush problems. Trans. AIEE 1944, 63, 825–829. [Google Scholar]

- Savage, R.H. Graphite lubrication. J. Appl. Physic 1948, 19, 1–10. [Google Scholar] [CrossRef]

- Xue, X.; Jia, J.; Huo, Q.; Jia, J. Experimental investigation and prediction method of fretting wear in rack-plane spline couplings. Proc. Inst. Mech. Eng. Part J J. Eng. Tribol. 2020, 235, 1025–1037. [Google Scholar] [CrossRef]

- Zaidi, H.; Lepage, J. Influence de l’eau sur le comportement tribologique de matériaux carbonés. J. De Chim. Phys. 1987, 84, 325–329. [Google Scholar] [CrossRef]

- Zaidi, H.; Néry, H.; Paulmier, D. Stability of lubricating properties of graphite by orientation of the crystallites in the presence of water vapour. Appl. Surf. Sci. 1993, 70–71, 180–185. [Google Scholar] [CrossRef]

- Lancaster, J.K. Transitions in the friction and wear of carbons and graphites sliding against themselves. ASLE Trans. 1975, 18, 187–201. [Google Scholar] [CrossRef]

- Spreaborough, J. The frictional behaviour of graphite. Wear 1962, 5, 18–30. [Google Scholar] [CrossRef]

- Zhang, X.-Y.; Cai, Z.-B.; Peng, J.-F.; Liu, J.-H.; Du, R.; Ren, P.-D. Experimental study of the fretting wear behavior of Inconel 690 alloy under alternating load conditions. Proc. Inst. Mech. Eng. Part J J. Eng. Tribol. 2018, 232, 1343–1351. [Google Scholar] [CrossRef]

- Bhaskar, S.V.; Kudal, H.N. Tribology of nitrided-coated steel-a review. Arch. Mech. Technol. Mater. 2017, 37, 50–57. [Google Scholar] [CrossRef]

- Burris, D.L.; Sawyer, W.G. A low friction and ultra-low wear rate PEEK/PTFE composite. Wear 2006, 261, 410–418. [Google Scholar] [CrossRef]

- Ullah, S.; Haque, F.M.; Sidebottom, M.A. Maintaining low friction coefficient and ultralow wear in metallic filled PTFE composites. Wear 2022, 498–499, 204338. [Google Scholar] [CrossRef]

- Chang, Y.Y.; Amrutwar, S. Effect of Plasma Nitriding Pretreatment on the Mechanical Properties of AlCrSiN-Coated Tool Steels. Materials 2019, 12, 795. [Google Scholar] [CrossRef]

- Soto, J.; Jada, M.; Guyenro, N.; Delaunay, D. Thermal cycling aging of encapsulated phase change material—Compressed expanded natural graphite composite. Therm. Sci. Eng. Prog. 2021, 22, 100836. [Google Scholar] [CrossRef]

- Kim, Y.U.; Park, J.H.; Beom, Y.Y.; Sungwoong, Y.; Seunghwan, W.; Kim, S. Mechanical and thermal properties of artificial stone finishing materials mixed with PCM impregnated lightweight aggregate and carbon material. Constr. Build. Mater. 2021, 272, 121882. [Google Scholar] [CrossRef]

- Lu, F.; Liu, J. Experimental and numerical investigation on wear behavior of carbonfiber-reinforced carbon matrix composite used in rotary gas seals. Proc. Inst. Mech. Eng. Part J J. Eng. Tribol. 2020, 235, 575–587. [Google Scholar] [CrossRef]

- Amirat, M.; Zaidi, H.; Beloufa, A. Friction in vacuum and under different gaseous environment of magnetized sliding ferromagnetic contact. Proc. Inst. Mech. Eng. Part J J. Eng. Tribol. 2021, 235, 18–32. [Google Scholar] [CrossRef]

- Coscia, U.; Longo, A.; Palomba, M.; Sorrentino, A.; Barucca, G.; Di Bartolomeo, A.; Urban, F.; Ambrosone, G.; Carotenuto, G. Influence of the thermomechanical characteristics of low-density polyethylene substrates on the thermoresistive properties of graphite nanoplatelet coatings. Coatings 2021, 11, 332. [Google Scholar] [CrossRef]

- Khare, H.S.; Burris, D.L. The effects of environmental water and oxygen on the temperature-dependent friction of sputtered molybdenum disulfide. Tribol. Lett. 2013, 52, 485–493. [Google Scholar] [CrossRef]

- Zhu, Z.; Bai, S.; Wu, J.; Xu, L.; Li, T.; Ren, Y.; Liu, C. Friction and wear behavior of resin/graphite composite under dry sliding. J. Mater. Sci. Technol. 2015, 31, 325–330. [Google Scholar] [CrossRef]

- Xin, L.; Yang, B.B.; Li, J. Wear damage of Alloy 690TT in partial and gross slip fretting regimes at high temperature. Wear 2017, 390, 71–79. [Google Scholar] [CrossRef]

- Hojjati-Talemi, R.; Wahab, M.A.; Baets, P.D. Finite element simulation of phase difference effects on fretting fatigue crack nucleation behavior. Proc. Inst. Mech. Eng. Part J J. Eng. Tribol 2014, 228, 470–479. [Google Scholar] [CrossRef]

- Doyen, F.; Zaidi, H.; Rivière, J.P.; Leclercq, B.; Rocchi, J. Fretting contact study of stainless steel/graphite in a dry shaft/bearing contact with thrust. Wear 2007, 263, 508–517. [Google Scholar] [CrossRef]

- Zaidi, H.; Amirat, M.; Beloufa, A. Fretting study of an impregnated graphite bearing/nitrided s. steel in a dry contact submitted to severe thermo-vibratory loading. Proc. Inst. Mech. Eng. Part J J. Eng. Tribol. 2022, 236, 1707–1717. [Google Scholar] [CrossRef]

- Sylvestre, M.; Zaidi, H.; Rivière, J.P.; Eyidi, D.; Doyen, F. Fretting contact study of Ti-6Al-4 V/graphite couples in a dry shaft/bearing contact with thrust: Influence of plasma nitriding of the titanium alloy. Surf. Coat. Technol. 2010, 205, 1374–1380. [Google Scholar] [CrossRef]

- Delgado, A.; San Andrès, L. Identification of structural stiffness and damping coefficients of a shoes brush seals. In Proceedings of the ASME 2005 International Design Engineering Technical Conferences and Computers and Information in Engineering Conference, Long Beach, CA, USA, 24–28 September 2005; pp. 1–6. [Google Scholar]

- Djamai, A. Modélisation Tridimensionnelle et Etude du Rayage des Revêtements Fragiles: Identification des Endommagements par Résolution du Problème du Contact et du Champ des Contraintes. Ph.D. Thesis, Université de Poitiers, Poitiers, France, 2005. [Google Scholar]

- Arnaud, P.; Fouvry, S.; Garcin, S. Fretting wear rate impact on Ti-6Al-4V fretting crack risk: Experimental and numerical comparison between cylinder/plane and punch/plane contact geometries. Tribol. Int. 2016, 108, 32–47. [Google Scholar] [CrossRef]

- Sline, H.E. Solid lubricant materials for high temperatures—A review. Tribol. Int. 1982, 15, 303–315. [Google Scholar] [CrossRef]

- Allam, I.M. Solid lubricants for applications at elevated temperatures. J. Mater. Sci. 1991, 26, 3977–3984. [Google Scholar] [CrossRef]

- Prateek, M.; Mani, K.P.; Kishor, K.S.; Pallav, G. Structural, wear and thermal behavior of Cu–Al2O3–graphite hybrid metal matrix composites. Proc. Inst. Mech. Eng. Part L J. Mater. Des. Appl. 2020, 234, 1154–1164. [Google Scholar]

- Li, L.; Kang, L.; Ma, S.; Li, Z.; Ruan, X.; Cai, A. Finite element analysis of fretting wear considering variable coefficient of friction. Proc. Inst. Mech. Eng. Part J J. Eng. Tribol 2018, 233, 758–768. [Google Scholar] [CrossRef]

| Property | Graphite | PTFE (C2F4)n | Impregnation of Graphite at 10% |

|---|---|---|---|

| Density (g·cm−3) | 1,8 | 2.2 | 1.84 |

| Young’s Modulus (GPa) | 12 | 2 | 11 |

| Shore Hardness | 76 | 30 | 74 |

| Maximum Pressure for 0.05° Misalignment (MPa) | Maximum Von Mises Stress at Contact Edge (MPa) | Maximum Main Surface Stress (MPa) | |

|---|---|---|---|

| Graphite/AISI 304 SS | 55 | 18 | 65 |

| Polymer-impregnated graphite/ AISI 304 SS | 63 | 22 | 69 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zaïdi, H.; Tournis, S.; Deville, L.; Richard, C.; Aissa, M.; Bouguerra, K. Friction Evolution of Graphite Bearing Impregnated with Polymer Subjected to Vibration Fretting at High Temperature. Coatings 2024, 14, 207. https://doi.org/10.3390/coatings14020207

Zaïdi H, Tournis S, Deville L, Richard C, Aissa M, Bouguerra K. Friction Evolution of Graphite Bearing Impregnated with Polymer Subjected to Vibration Fretting at High Temperature. Coatings. 2024; 14(2):207. https://doi.org/10.3390/coatings14020207

Chicago/Turabian StyleZaïdi, Hamid, Stéphane Tournis, Leila Deville, Caroline Richard, Mohamed Aissa, and Kaouthar Bouguerra. 2024. "Friction Evolution of Graphite Bearing Impregnated with Polymer Subjected to Vibration Fretting at High Temperature" Coatings 14, no. 2: 207. https://doi.org/10.3390/coatings14020207