Organic Patinas on Small Historical Bronzes: From Mock-Ups to Actual Artworks

Abstract

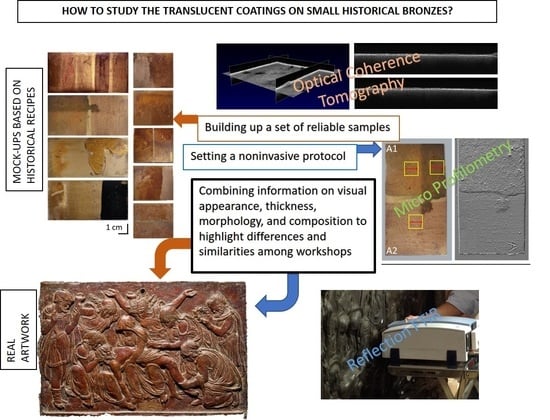

1. Introduction

2. Materials and Methods

2.1. Mock-Ups Simulating Historical Reconstructions and Renaissance Relief

2.2. Fourier Transform Infrared Spectroscopy (FTIR)

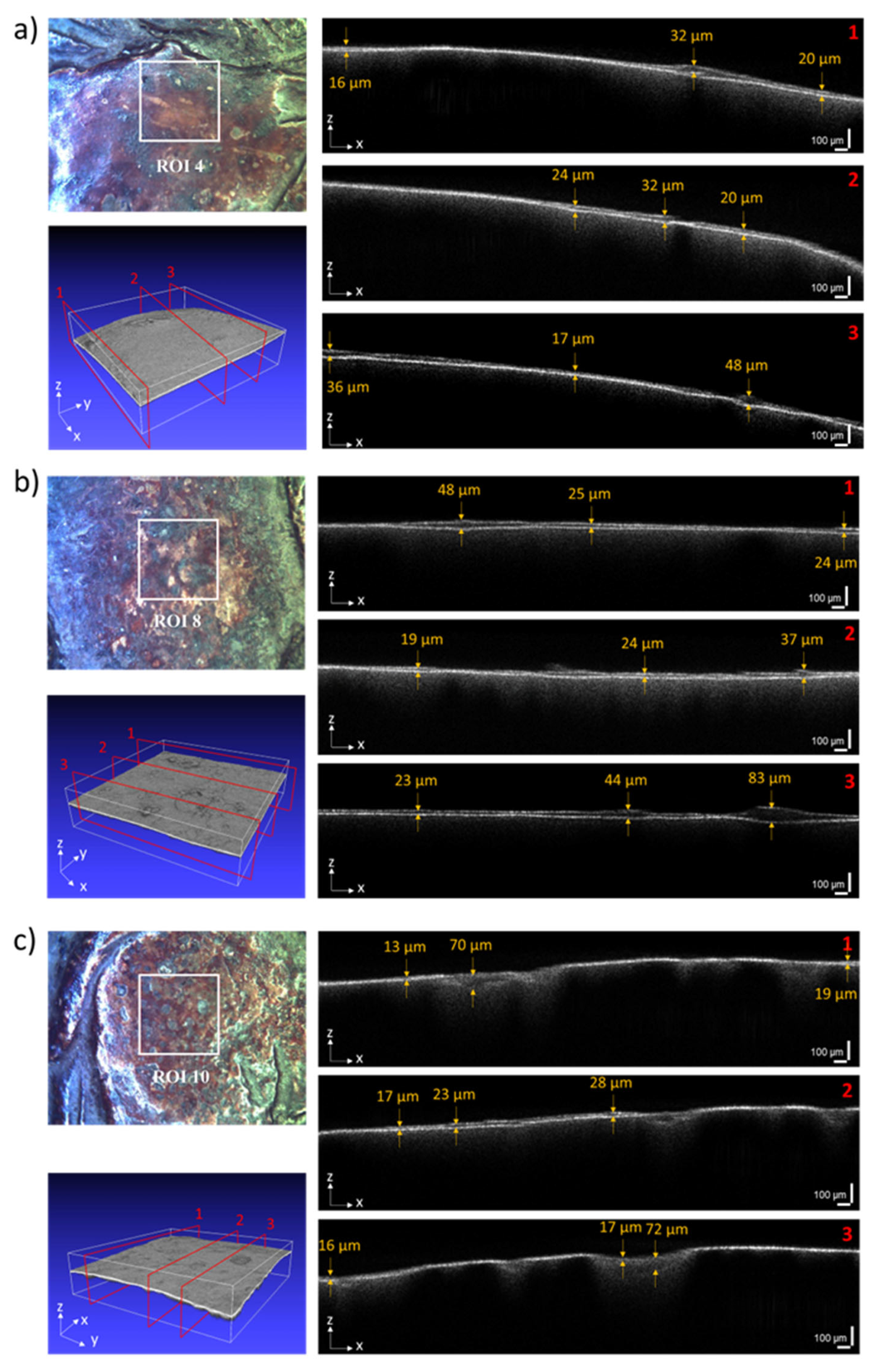

2.3. Optical Coherence Tomography (OCT)

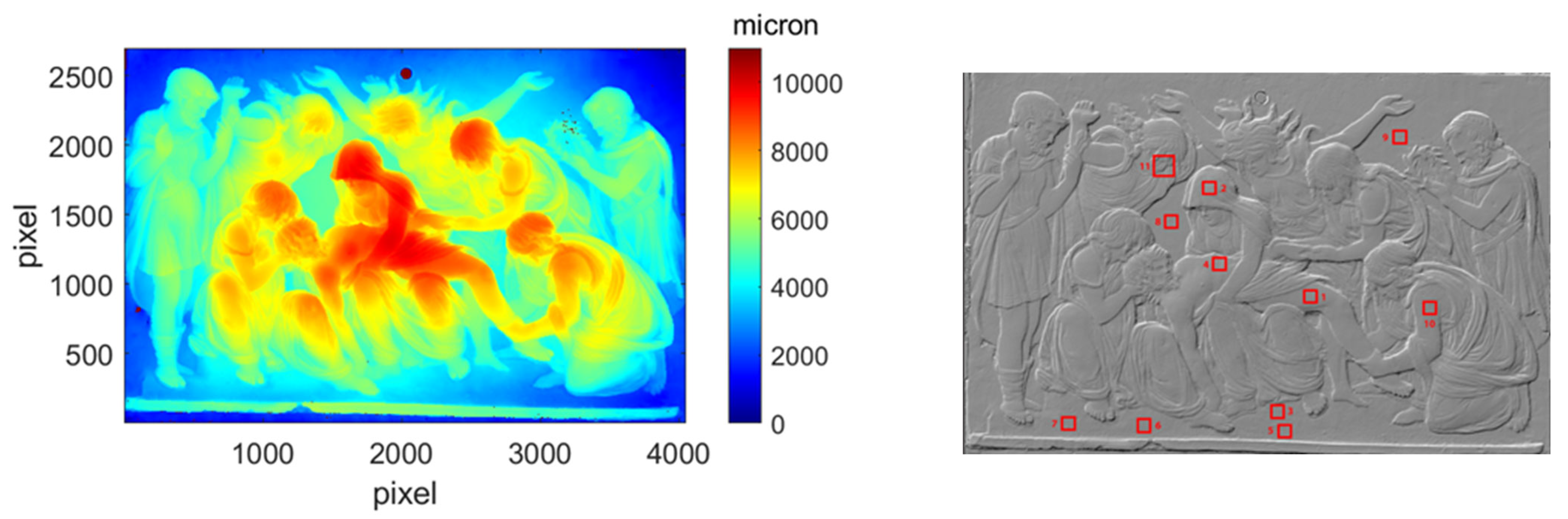

2.4. Microprofilometry (MP)

2.5. Eddy Currents (EC) Gauge

2.6. Scanning Electron Microscopy (SEM)

3. Results and Discussion

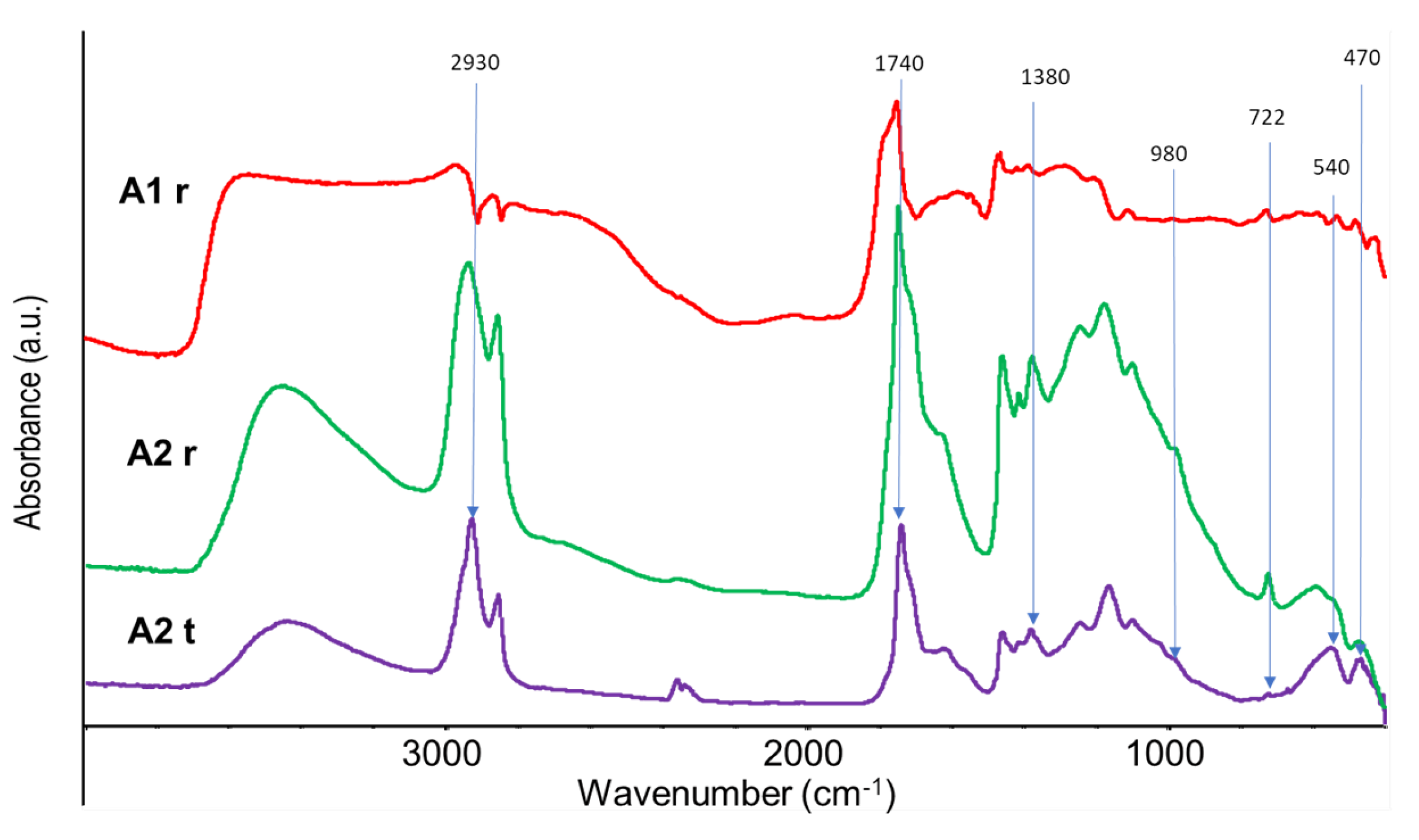

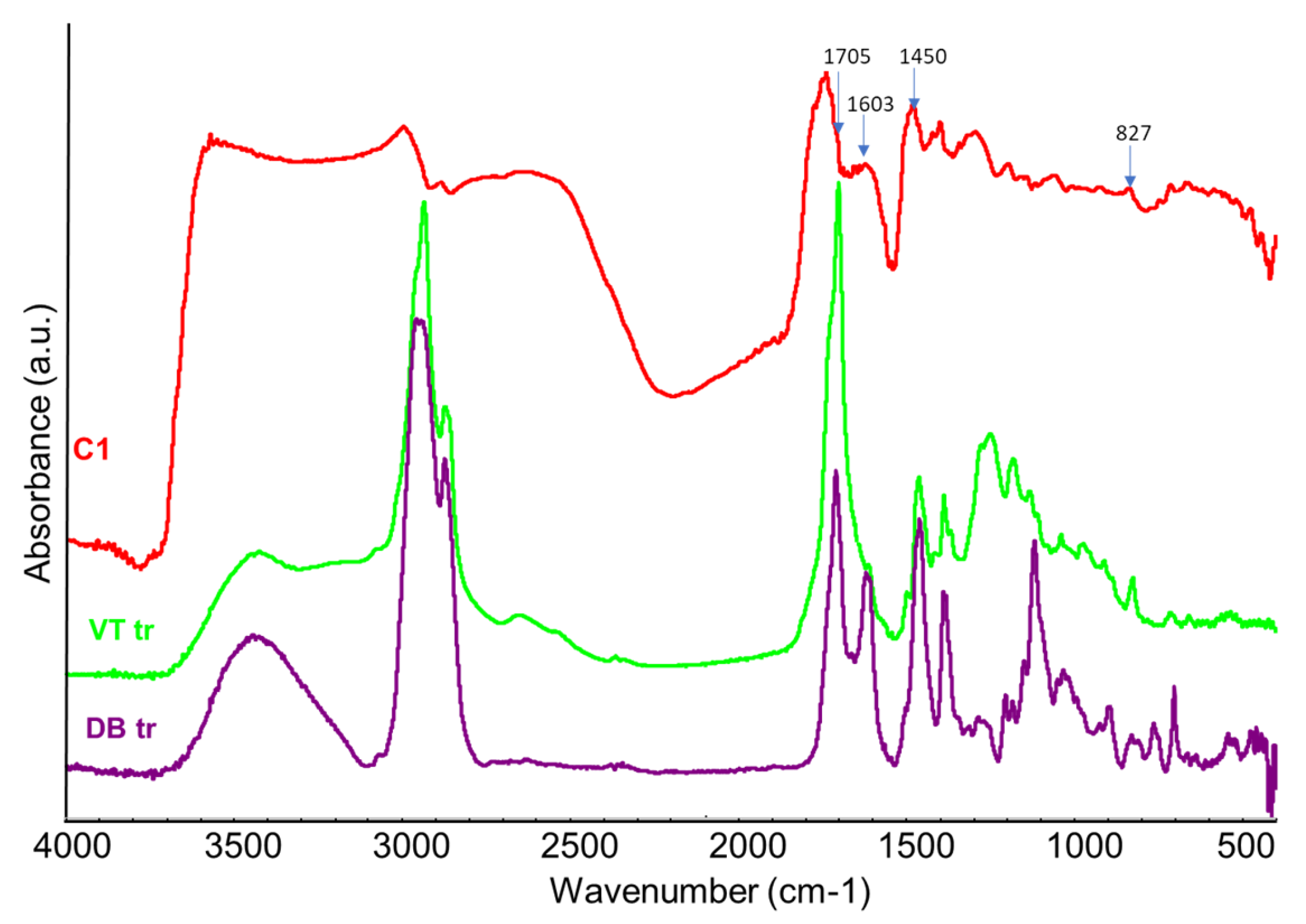

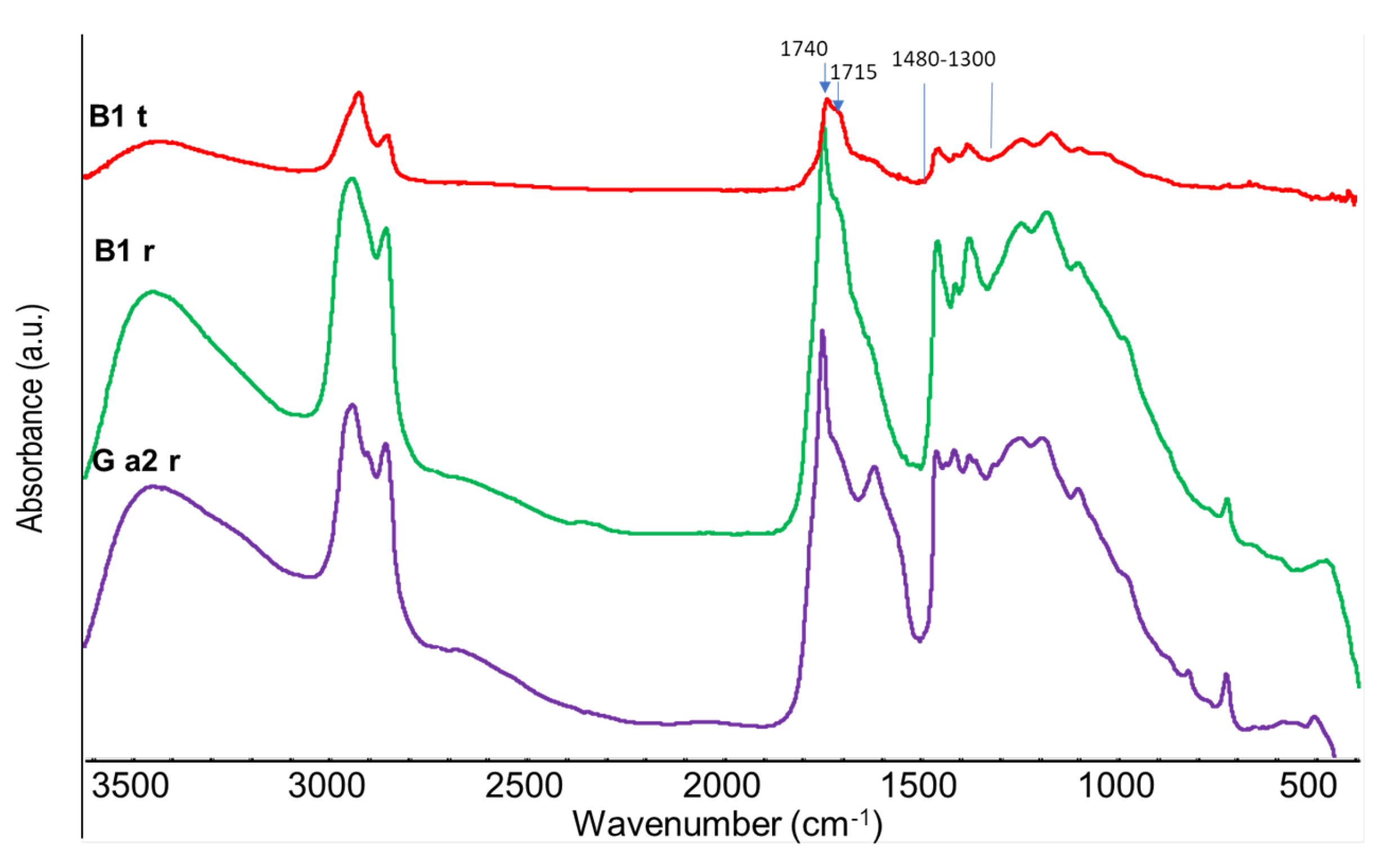

3.1. Mock-Ups

3.2. Bertoldo’s Relief

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A. Materials and Methods for the Preparation of the Mock-Ups

| Name | Ingredients | Preparation | Notes and Comments |

|---|---|---|---|

| 0 | Linseed oil; Mastic; Spirit of turpentine | See Appendix A | |

| 1 | Linseed oil; Mastic; Spirit of turpentine; Madder lake; Rock alum; Potassium carbonate | 0.2 g of madder lake prepared as in [38] in about 10 mL of oil–mastic varnish (Appendix A) | |

| 4 | Linseed oil; Mastic; Spirit of turpentine; Hematite | 0.2 g of hematite in 2 mL of oil–mastic varnish (Appendix A) | |

| A1 | Linseed oil; Mastic; Spirit of turpentine; Madder lake; Rock alum; Potassium carbonate | 0.2 g of madder lake prepared as in [38] in about 10 mL of oil–mastic varnish (Appendix A) | 30 min of heating in a ventilated oven at 130 °C |

| A2 | Linseed oil; Mastic; Spirit of turpentine; Hematite | 0.2 g of hematite in 2 mL of oil–mastic varnish (Appendix A) | 30 min heating in a ventilated oven at 130 °C |

| B1 | Linseed oil; Mastic | Finely ground mastic mixed with linseed oil (50:50 ratio); the blend was heated up to 130 °C for 30 min | |

| B2 | Venetian turpentine | The resin was gently warmed for better application | 30 min heating in a ventilated oven at 130 °C |

| C1 | Venetian turpentine; Dragon’s blood | 1 g of dragon’s blood in 4 g of turpentine, warmed in a water bath and stirred until dissolved | Since the application of the varnish on the cold surface turned out not fluent, the metal was gently heated |

| C2 | Venetian turpentine; Dragon’s blood; Spirit of turpentine | 1 g of dragon’s blood in 4 g of turpentine, addition of spirit of turpentine until the dissolution of the dragon’s blood | Since the application of the varnish on the cold surface turned out not fluent, the metal was gently heated |

| E2 | Linseed oil; Hematite | 28 wt % of hematite was added to linseed oil | First coat applied with circular brushes; second coat made with pure linseed oil (without hematite) |

| F1 | Linseed oil; Mastic; Spirit of turpentine; Madder lake | 0.2 g of madder lake [38] were added to 10 mL of oil–mastic varnish (Appendix A) | The sample was let dry in a vented oven for 3 h at 130 °C. However, it was not completely dry after this time |

| F2 | Linseed oil; Mastic; Spirit of turpentine; Madder lake; Burgundy pitch | Burgundy pitch was added to the mixture of sample F1 as 2 wt % and dissolved upon gentle warming in water bath. The varnish was brushed warm on the metal | Burgundy pitch was suggested by Stone [1] based on analytical evidence on real objects; historical references to this resin are found in De la maniere de graverà l’eau forte et au burin, et de la gravure en manière noire (1645) by Abraham Bosse [13], in the “Vernice dura” recipe. The sample was dried at 130 °C in a ventilated oven for 3 h. The addition of burgundy pitch affected the drying rate and the final compactness and shininess of the film |

| G a1 | Linseed oil; Hematite | About 2 wt % of hematite was dispersed in linseed oil. Three coats: first one applied with circular brushstrokes, two further applied with crisscrossed brushstrokes | The substrate was filed and ground, then treated with a 5% caustic soda solution applied with cotton swabs, rinsed with demineralized water, and air-dried (common process in the Florentine craft tradition). Subsequent application of the swabs turned the surface colour from yellow to blue shades |

| G a2 | Linseed oil; Hematite | About 2 wt % of hematite was dispersed in linseed oil. One coat applied with a small brush and little circular brushstrokes | |

| G b1 | Linseed oil; Hematite | About 2 wt % of hematite was dispersed in linseed oil. One coat applied with tight brushstrokes in order to obtain a thin layer | |

| G b2 | Linseed oil; Hematite; Litharge | About 2 wt % of hematite and 20 wt % of litharge were dispersed in linseed oil. One coat applied with tight brushstrokes in order to obtain a thin layer |

References

- Stone, R. Organic patinas on small bronzes of the Italian Renaissance. Metrop. Mus. J. 2010, 45, 107–124. [Google Scholar] [CrossRef][Green Version]

- Pitthard, V.; Stone, R.; Stanek, S.; Griesser, M.; Gersch, C.; Hanzer, H. Organic patinas on Renaissance and Baroque bronzes–Interpretation of compositions of the original patination by using a set of simulated varnished bronze coupons. J. Cult. Herit. 2011, 12, 44–53. [Google Scholar] [CrossRef]

- Stone, R.E.; White, R.; Indictor, N. Surface composition of some Italian Renaissance bronzes. In Proceedings of the ICOM, 9th Triennial Meeting, Dresden, Germany, 26–31 August 1990; ICOM Committee for Conservation: Los Angeles, CA, USA, 1999; pp. 568–573. [Google Scholar]

- Pitthard, V.; Stanek, S.; Griesser, M.; Hanzer, H.; Kryza-Gersch, C. Comprehensive investigation of the ‘organic patina’ on Renaissance and Baroque indoor bronze sculptures from the collection of the Kunsthistorisches Museum, Vienna. In Proceedings of the Conservation Science 2007, Milan, Italy, 10–11 May 2007; Archetype Publications: London, UK, 2008; pp. 49–55. [Google Scholar]

- Basso, E.; Pozzi, F.; Day, J.; Borsch, L. Unmasking a wild man: Scientific analysis of Bertoldo di Giovanni’s Shield Bearer in the Frick Collection. Herit. Sci. 2020, 8, 109. [Google Scholar] [CrossRef]

- Invernizzi, C.; Fiocco, G.; Iwanicka, M.; Kowalska, M.; Targowski, P.; Blümich, B.; Rehorn, C.; Gabrielli, V.; Bersani, D.; Licchelli, M.; et al. Non-invasive mobile technology to study the stratigraphy of ancient Cremonese violins: OCT, NMR-MOUSE, XRF and reflection FT-IR spectroscopy. Microchem. J. 2020, 155, 104754. [Google Scholar] [CrossRef]

- Boon, J.; Van Langh, R. Comprehensive studies of patinas on Renaissance bronze statuettes with laboratory, synchrotron and neutron-aided techniques. In Proceedings of the ICOM-CC 17th Triennial Conference Preprints, Melbourne, Australia, 15–19 September 2014; pp. 1–7. [Google Scholar]

- Handwerker, P. Untersuchung und Konzepterstellung zur Oberflächengestaltung des Reliefs “Grablegung Christi” von. Giambologna. Dissertation, thesis at Technische Universität of München, Germany. WS 2017/2018 (Ms.).

- Grosso, P.; Bongiorno, V.; Piccardo, P.; Magnani, L. Virtues of Giambologna from Grimaldi Chapel archaeometrical characterization. J. Miner. Met. Mater. Soc. 2014, 66, 802–807. [Google Scholar] [CrossRef]

- Baruffetti, M.; Agnoletti, S.; Galeotti, M. L’intervento su due bronzetti tardorinascimentali: Studio del soggetto, della tecnica di realizzazione e spunti di ricerca sulle finiture superficiali come linee-guida per la comprensione e il restauro. In Proceedings of the XIV Congresso Nazionale IGIIC—Lo Stato dell’Arte—Accademia Di Belle Arti di L’Aquila, L’Aquila, Italy, 20–22 October 2016; pp. 311–318. [Google Scholar]

- Ronchetti, G. Manuale per i Dilettanti di Pittura a Olio, Acquarello, Miniatura, Guazzo, Tempera, Encausto, Pastello, Fotopittura ecc.; Hoepli Editore: Milano, Italy, 1970. [Google Scholar]

- Van de Graaf, J.A. Het De Mayerne Manuscript Als Bron Voor de Schildertechniek van de Barok; British Museum: Sloane, UK, 1958. [Google Scholar]

- Bosse, A. De la Maniere de Graver à L’eau Forte et au Burin, et de la Gravure en Manière Noire: Avec la Façon de Construire les Presses Modernes, et D’imprimer en Taille-Douce;A Paris, rue Dauphine; Chez Charles-Antoine Jombert: Parigi, France, 1758. [Google Scholar]

- Masschelein-Kleiner, L. Ancient Binding Media, Varnishes and Adhesives; ICCROM: Roma, Italy, 1995. [Google Scholar]

- Lenormand, L.S.; Molard, F.É.; Francœur, L.B.; Payen, M.A.; Robiquet, P. Nuovo Dizionario Universale Tecnologico o di arti e mestieri e della economia industriale e commerciante; Giuseppe Antonelli Editore: Venezia, Italy, 1830; pp. 1831–1859. [Google Scholar]

- Scott, D.A. Copper and Bronze in Art: Corrosion, Colorants, Conservation; Getty Publications: Los Angeles, CA, USA, 2002; p. 331. [Google Scholar]

- Giumlia-Mair, A. Colouring treatments on ancient copper-alloys. Rev. Métall. 2001, 98, 767–776. [Google Scholar] [CrossRef]

- Targowski, P.; Rouba, B.; Wojtkowski, M.; Kowalczyk, A. The application of optical coherence tomography to non destructive examination of museum objects. Stud. Conserv. 2004, 49, 107–114. [Google Scholar] [CrossRef]

- Liang, H.; Cid, M.G.; Cucu, R.G.; Dobre, G.M.; Podoleanu, A.G.; Pedro, J.; Saunders, D. Enface optical coherence tomography—A novel application of non-invasive imaging to art conservation. Opt. Express 2005, 13, 6133–6144. [Google Scholar] [CrossRef]

- Callewaert, T.; Guo, J.; Harteveld, G.; Vandivere, A.; Eisemann, E.; Dik, J.; Kalkman, J. Multi-scale optical coherence tomography imaging and visualization of Vermeer’s Girl with a Pearl Earring. Opt. Express 2020, 28, 26239–26256. [Google Scholar] [CrossRef]

- Targowski, P.; Iwanicka, M.; Tyminska-Widmer, L.; Sylwestrzak, M.; Kwiatkowska, E.A. Structural examination of easel paintings with optical coherence tomography. Acc. Chem. Res. 2010, 43, 826–836. [Google Scholar] [CrossRef]

- Targowski, P.; Gòra, M.; Wojtkowski, M. Optical coherence tomography for artwork diagnostics. Laser Chem. 2006, 35373. [Google Scholar] [CrossRef][Green Version]

- Liang, H.; Mari, M.; Cheung, C.S.; Kogou, S.; Johnson, P.; Filippidis, G. Optical coherence tomography and non-linear microscopy for paintings–a study of the complementary capabilities and laser degradation effects. Opt. Express 2017, 25, 19640–19653. [Google Scholar] [CrossRef]

- Daffara, C.; Mazzocato, S.; Marchioro, G. Multiscale roughness analysis by microprofilometry based on conoscopic holography: A new tool for treatment monitoring in highly reflective metal artworks. Eur. Phys. J. Plus 2022, 137, 430. [Google Scholar] [CrossRef]

- Mazzocato, S.; Daffara, C. A Method for Spatially Registered Microprofilometry Combining Intensity-Height Datasets from Interferometric Sensors. Sensors 2023, 23, 4144. [Google Scholar] [CrossRef] [PubMed]

- Fontana, R.; Fovo, A.D.; Striova, J.; Pezzati, L.; Pampaloni, E.; Raffaelli, M.; Barucci, M. Application of noninvasive optical monitoring methodologies to follow and record painting cleaning processe. Appl. Phys. A 2015, 121, 957–966. [Google Scholar] [CrossRef]

- Eddy Current Testing at Level 2. Manual for the Syllabi. Contained in IAEA-Tec Doc-628. rev.2, Training Guidelines for Non-Destructive Testing Techniques; Training course series 48; IAEA Training Course Series; International Atomic Energy Agency: Venezia, Italy, 2011. [Google Scholar]

- Barra, V.; Daffara, C.; Porcinai, S.; Galeotti, M. Application of Coatings on Silver Studied with Punctual and Imaging Techniques: From Specimens to Real Cases; IOP Conference Series: Materials Science and Engineering; IOP Publishing: Bristol, UK, 2018. [Google Scholar]

- Texier, A.; Geffroy, A.M.; Syvilay, D.; Brocard-Rosa, T. Les cires microcristallines dans la protection de la statuaire en cuivre et alliages de cuivre exposée en extérieur. In Métal à Ciel Ouvert: La Sculpture Métallique D’extérieur du XIXe au Début du XXe Siècle: Identification, Conservation, Restauration; International Institute for Conservation of Historic and Artistic Works; Section Française: Champs-sur-Marne, France, 2014; pp. 163–175. ISBN 9782905430182. [Google Scholar]

- Ciofini, D.; Striova, J.; Camaiti, M.; Siano, S. Photo-oxidative kinetics of solvent and oil-based terpenoid varnishes. Polym. Degrad. Stab. 2015, 123, 47–61. [Google Scholar] [CrossRef]

- Invernizzi, C.; Rovetta, T.; Licchelli, M.; Malagodi, M. Mid and Near-Infrared Reflection database of natural organic materials in the cultural heritage field. Int. J. Anal. Chem. 2018, 2018, 7823248. [Google Scholar] [CrossRef]

- Daher, C.; Pimenta, V.; Bellot-Gurlet, L. Towards a non-invasive quantitative analysis of the organic components in museum objects varnishes by vibrational spectroscopies: Methodological approach. Talanta 2014, 129, 336–345. [Google Scholar] [CrossRef][Green Version]

- Salama, W.; El Aref, M.; Gaupp, R. Spectroscopic characterization of iron ores formed in different geological environments using FTIR, XPS, Mössbauer spectroscopy and thermoanalyses. Spectrochim. Acta Part A Mol. Biomol. Spectrosc. 2015, 136, 1816–1826. [Google Scholar] [CrossRef]

- Suëtaka, W. Surface Infrared and Raman Spectroscopy: Methods and Applications; Springer Science + Business Media: New York, NY, USA, 1995. [Google Scholar]

- Griffiths, P.R.; De Haseth, J.A. Fourier Transform Infrared Spectrometry; John Wiley & Sons: Hoboken, NJ, USA, 2007. [Google Scholar]

- Koperska, M.; Łojewski, T.; Łojewska, J. Vibrational spectroscopy to study degradation of natural dyes. Assessment of oxygen-free cassette for safe exposition of artefacts. Anal. Bioanal. Chem. 2011, 399, 3271–3283. [Google Scholar] [CrossRef]

- Font, J.; Salvadò, N.; Butì, E.J. Fourier transform infrared spectroscopy as a suitable technique in the study of the materials used in waterproofing of archeological amphorae. Anal. Chim. Acta 2007, 598, 119–127. [Google Scholar] [CrossRef]

- Kirby, J.; Van Bommel, M.; Verthecken, A. Natural Colorant for Dyeing and Lake Pigments: Practical Recipes and Their Theoric Sources; Archetype Publications: London, UK, 2014. [Google Scholar]

| Sample | Region of Interest (ROI) | Thickness (μm) | |

|---|---|---|---|

| 0 |  | EC | 19.7 ± 0.9 |

| OCT | 19.6 ± 6.8 | ||

| Range OCT | 8.1–24.6 | ||

| 1 |  | EC | 35.9 ± 3.0 |

| OCT | 41.2 ± 18.2 | ||

| Range OCT | 18.5–71.1 | ||

| 3 |  | EC | 19.7 ± 1.0 |

| OCT | 13.8 ± 6.1 | ||

| Range OCT | 7.5–20.3 | ||

| 4 |  | EC | 25.1 ± 2.5 |

| OCT | 26.8 ± 6.9 | ||

| Range OCT | 18.3–35.3 | ||

| A1 left |  | EC | 54.6 ± 2.0 |

| OCT | 55.8 ± 14.9 | ||

| Range OCT | 38.9–71.2 | ||

| A1 right |  | EC | 101.0 ± 6.0 |

| OCT | 99.3 ± 18.0 | ||

| Range OCT | 78.0–123.6 | ||

| A2 |  | EC | 13.8 ± 2.2 |

| OCT | 14.35 ± 3.2 | ||

| Range OCT | 12.1–16.6 | ||

| B1 |  | EC | 33.8 ± 2.3 |

| OCT | 34.7 ± 10.5 | ||

| Range OCT | 21.9– 49.3 | ||

| B2 |  | EC | 257.0 ± 8.0 |

| OCT | 257.1 ± 12.2 | ||

| Range OCT | 245.9–276.3 | ||

| B2 bis |  | EC | 39.7 ± 1.0 |

| OCT | 38.5 ± 3.6 | ||

| Range OCT | 35.1–42.0 | ||

| C0 |  | EC | 180.0 ± 3.0 |

| OCT | 179.9 ± 2.5 | ||

| Range OCT | 174.3–182.6 | ||

| C1 |  | EC | 151.3 ± 9.5 |

| OCT | 125.5 ± 18.3 | ||

| Range OCT | 73.3–148.0 | ||

| C2 |  | EC | 40.4 ± 1.6 |

| OCT | 42.8 ± 6.2 | ||

| Range OCT | 30.2–48.6 | ||

| 18 up (E2) |  | EC | 21.9 ± 2.2 |

| OCT | 20.4 ± 5.3 | ||

| Range OCT | 12.9–25.6 | ||

| 18 down (E2) |  | EC | 18.6 ± 1.6 |

| OCT | 19.1 ± 3.7 * | ||

| Range OCT | 16.8–21.4 | ||

| 19 up (F1) |  | EC | 176.6 ± 1.3 |

| OCT | 173.8 ± 12.7 | ||

| Range OCT | 146.4–189.1 | ||

| 19 down (F1) |  | EC | 49.4 ± 4.6 |

| OCT | 41.1 ± 7.3 | ||

| Range OCT | 35.3–49.3 | ||

| 20 (F2) |  | EC | 66.7 ± 2.5 |

| OCT | 66.3 ± 4.4 | ||

| Range OCT | 64.0–67.9 | ||

| 21 sx (G-a1) |  | EC | 24.3 ± 1.1 |

| OCT | 26.1 ± 8.5 | ||

| Range OCT | 15.8–40.5 | ||

| 21 dx (G-a1) |  | EC | 24.4 ± 1.4 |

| OCT | 25.6 ± 6.2 | ||

| Range OCT | 18.8–37.6 | ||

| 22 (G-a2) |  | EC | 30.9 ± 0.7 |

| OCT | 28.5 ± 9.8 | ||

| Range OCT | 17.5–48.0 | ||

| 23 bottom (G-b2) |  | EC | 23.6 ± 2.9 |

| OCT | 25.2 ± 9.7 | ||

| Range OCT | 13.7–46.0 | ||

| 23 up (G-b2) |  | EC | 24.3 ± 1.6 |

| OCT | 30.6 ± 18.0 | ||

| Range OCT | 12.8–61.0 | ||

| Technique | Type | Noncontact | Spot Size Ø (mm) | Working Distance (mm) | Thickness Resolution (μm) | Sample Shape Requirements |

|---|---|---|---|---|---|---|

| r-FTIR | pointwise | ✓ | 5 | - | <10 | // |

| EC | pointwise | ✗ | 1 | 0 | 3–5 | Flat over 1 cm2 |

| OCT | imaging | ✓ | 0.013 | 25 | 5.5 in air * | Max gauge volume ** 10 × 10 × 3.5 mm3 |

| MP | imaging | ✓ | 0.020 | 43 | ~1 | Max gauge volume *** 300 × 300 × 8 mm3 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Galeotti, M.; Porcinai, S.; Cagnini, A.; Baruffetti, M.; Biondi, C.; Dal Fovo, A.; Fontana, R. Organic Patinas on Small Historical Bronzes: From Mock-Ups to Actual Artworks. Coatings 2024, 14, 212. https://doi.org/10.3390/coatings14020212

Galeotti M, Porcinai S, Cagnini A, Baruffetti M, Biondi C, Dal Fovo A, Fontana R. Organic Patinas on Small Historical Bronzes: From Mock-Ups to Actual Artworks. Coatings. 2024; 14(2):212. https://doi.org/10.3390/coatings14020212

Chicago/Turabian StyleGaleotti, Monica, Simone Porcinai, Andrea Cagnini, Maria Baruffetti, Caterina Biondi, Alice Dal Fovo, and Raffaella Fontana. 2024. "Organic Patinas on Small Historical Bronzes: From Mock-Ups to Actual Artworks" Coatings 14, no. 2: 212. https://doi.org/10.3390/coatings14020212

APA StyleGaleotti, M., Porcinai, S., Cagnini, A., Baruffetti, M., Biondi, C., Dal Fovo, A., & Fontana, R. (2024). Organic Patinas on Small Historical Bronzes: From Mock-Ups to Actual Artworks. Coatings, 14(2), 212. https://doi.org/10.3390/coatings14020212