Modified Graphene Micropillar Array Superhydrophobic Coating with Strong Anti-Icing Properties and Corrosion Resistance

Abstract

:1. Introduction

2. Experiment

2.1. Materials

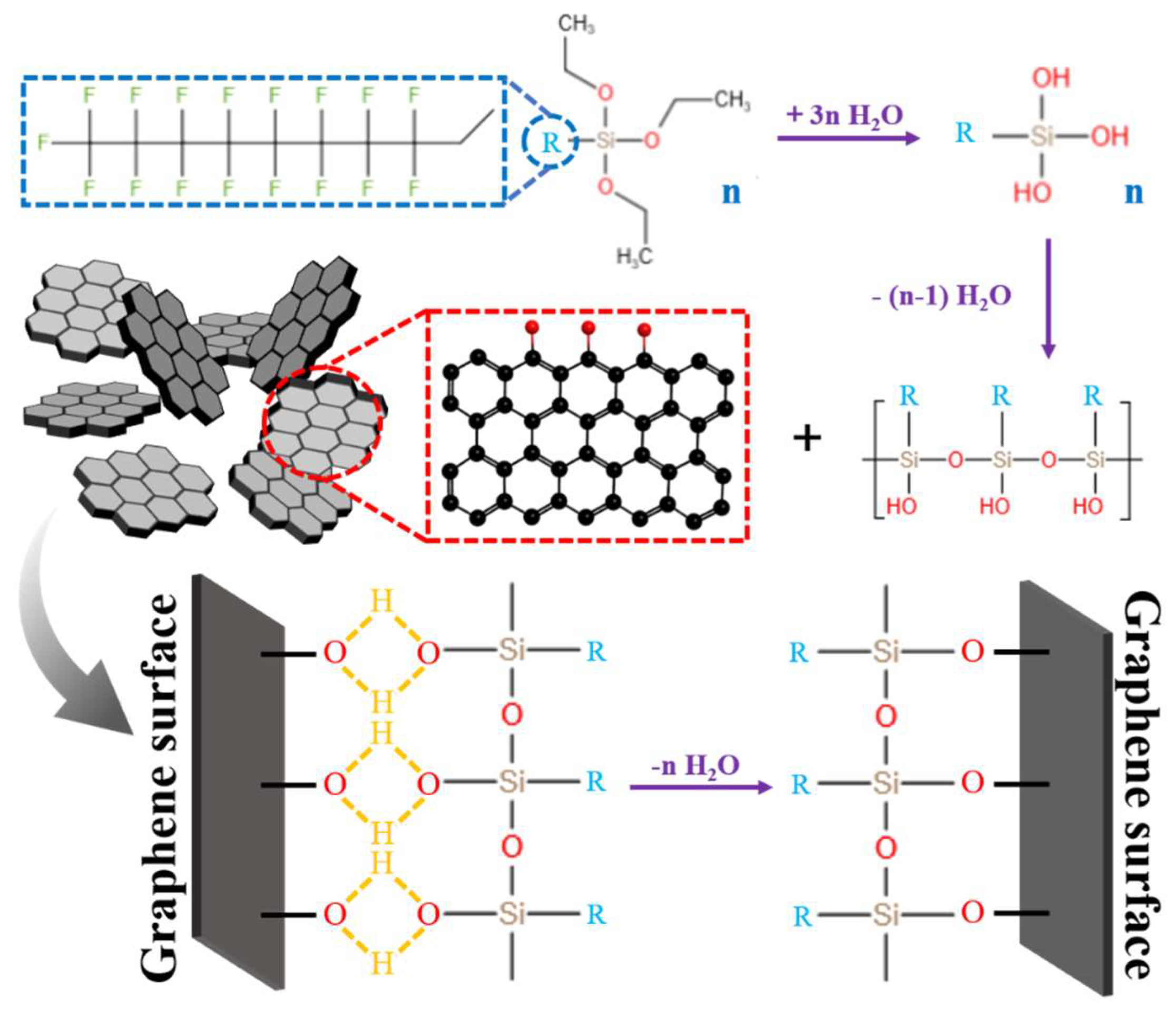

2.2. Preparation of AC-FAS Modified Graphene Nanosheets

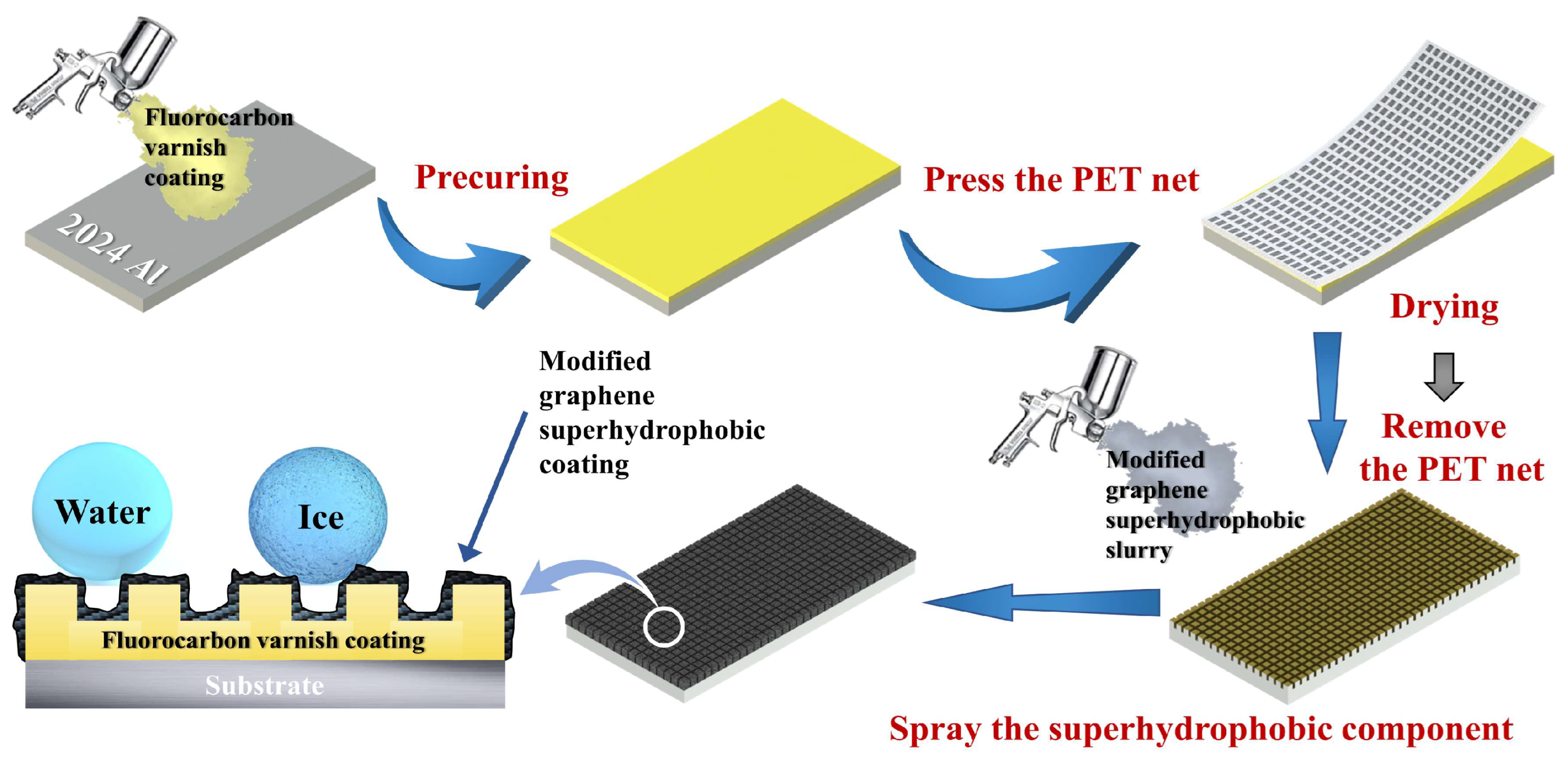

2.3. Preparation of Modified Graphene Micropillar Array Superhydrophobic Coating

2.4. Characterization

3. Results and Discussion

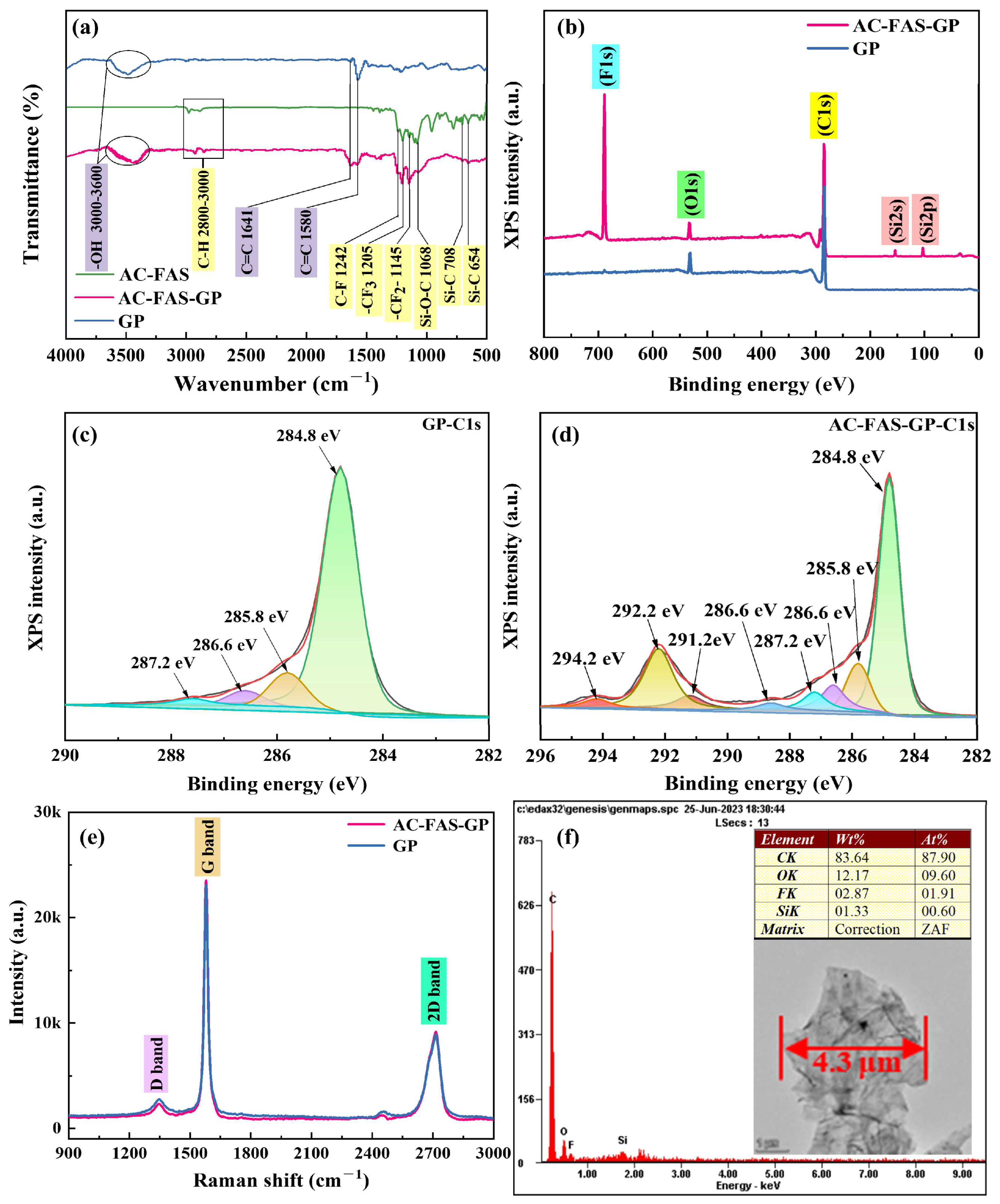

3.1. Characterization of AC-FAS-GP

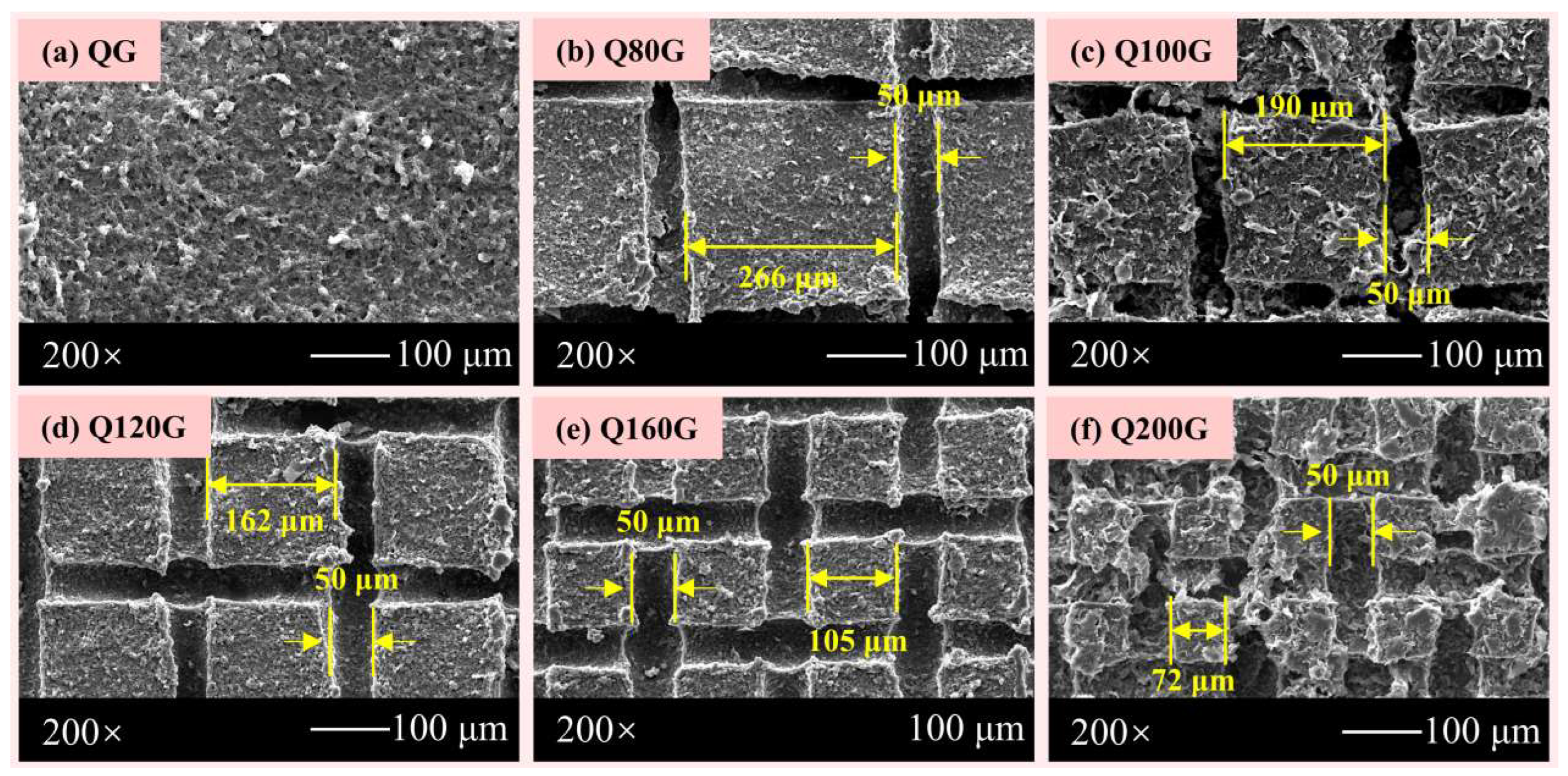

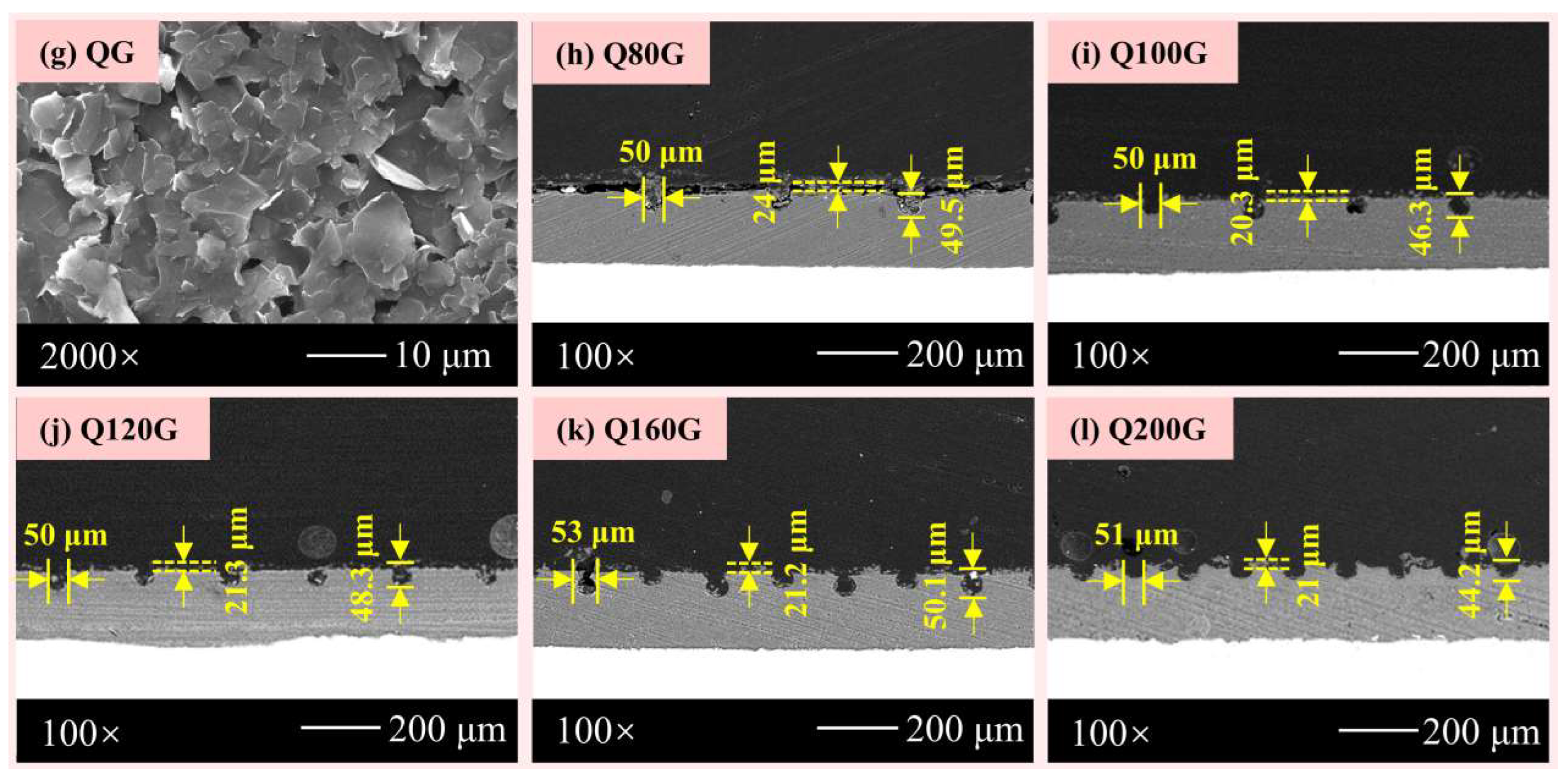

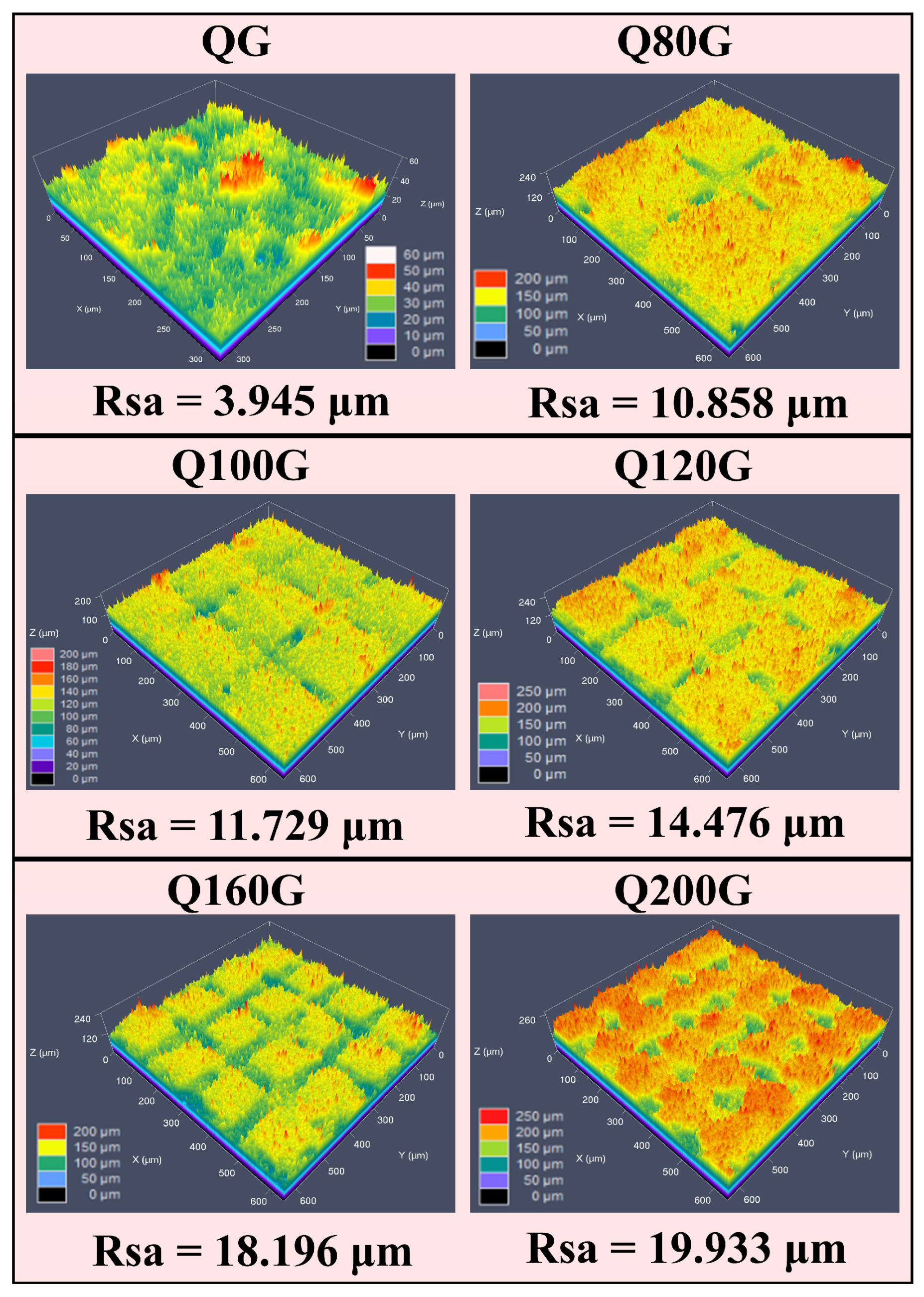

3.2. Morphologies of the Coatings

3.3. Water Contact Angles and Sliding Angles

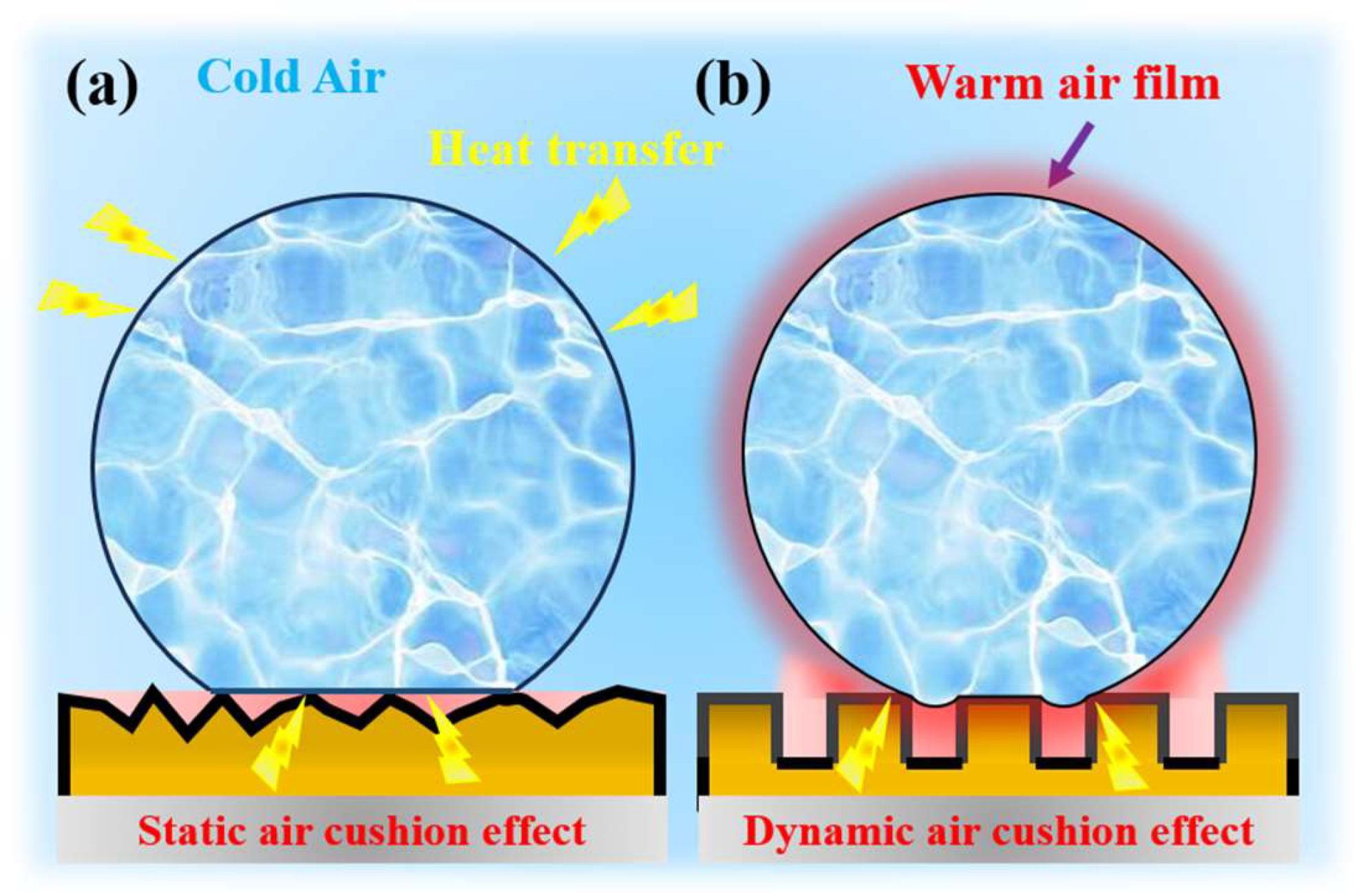

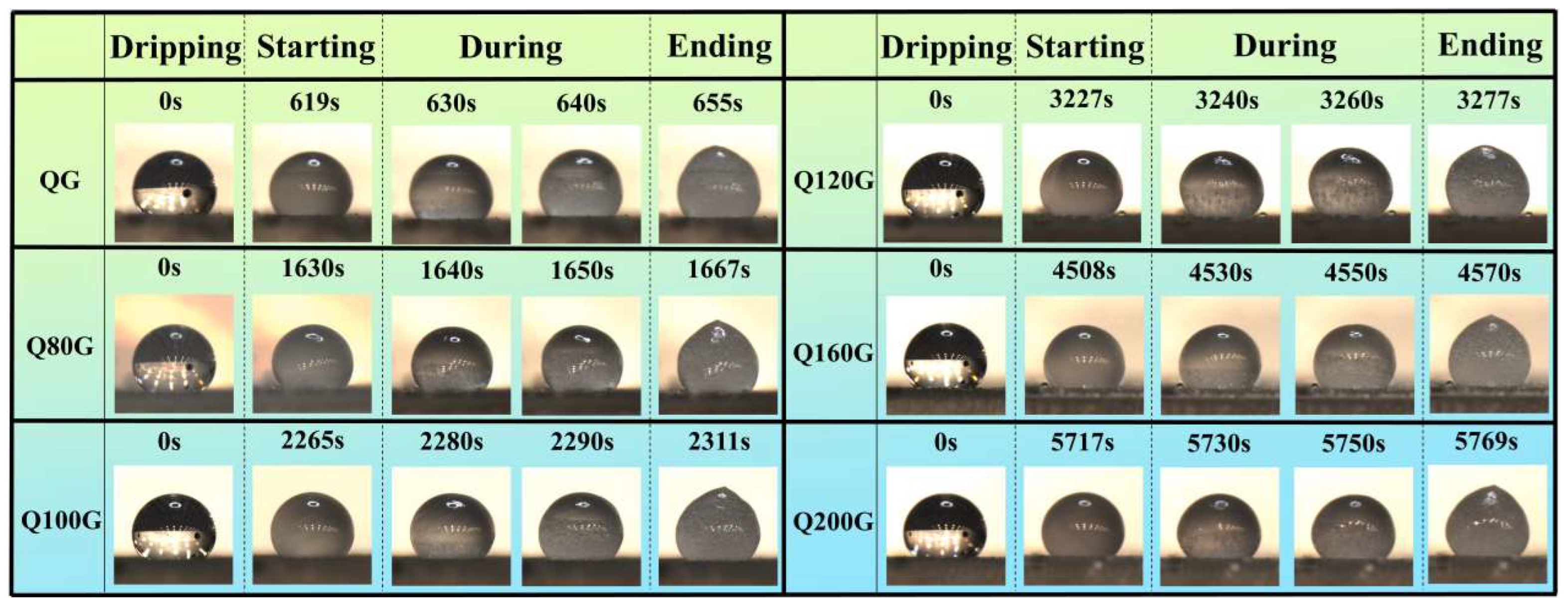

3.4. Anti-Icing Properties

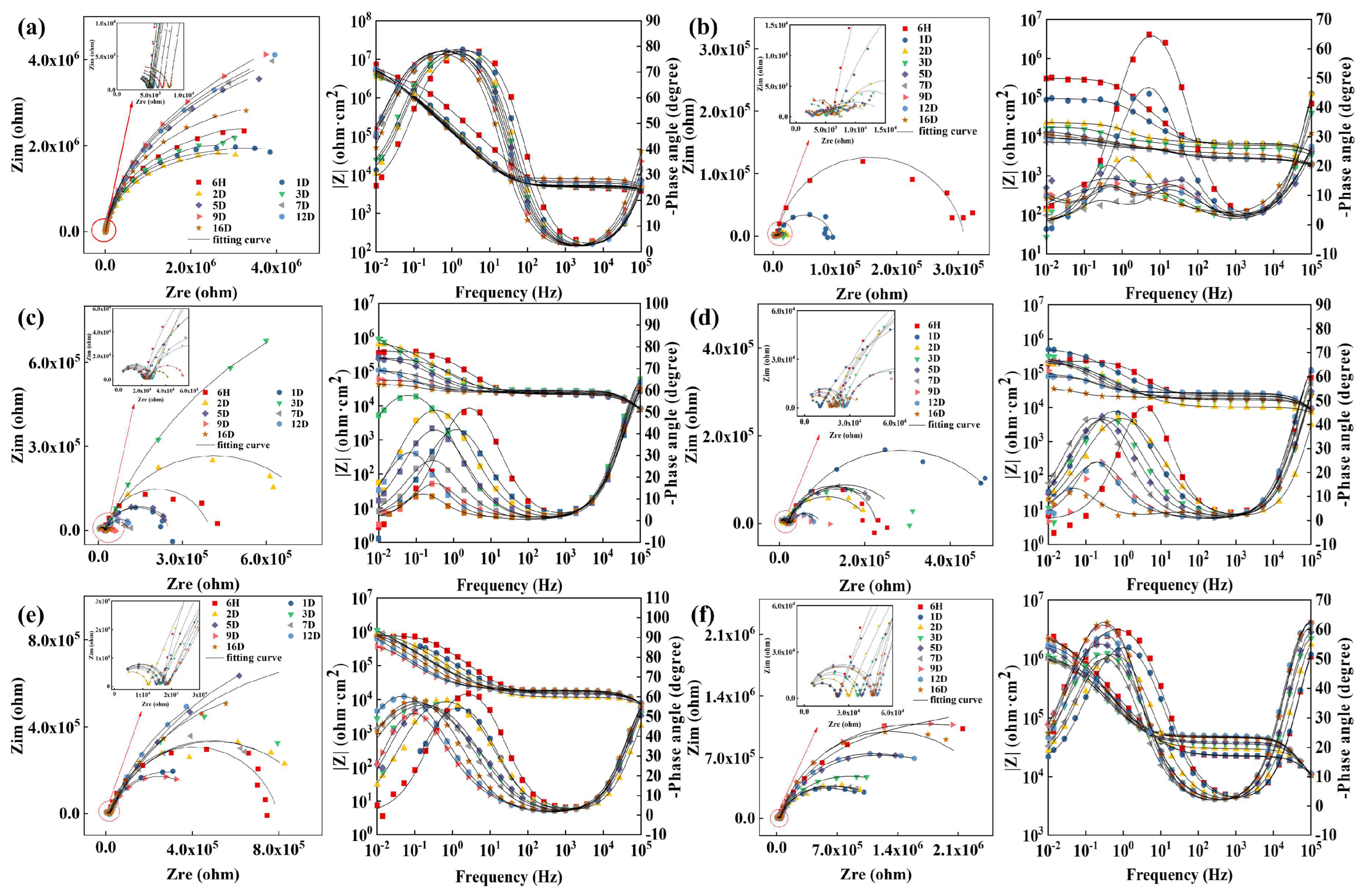

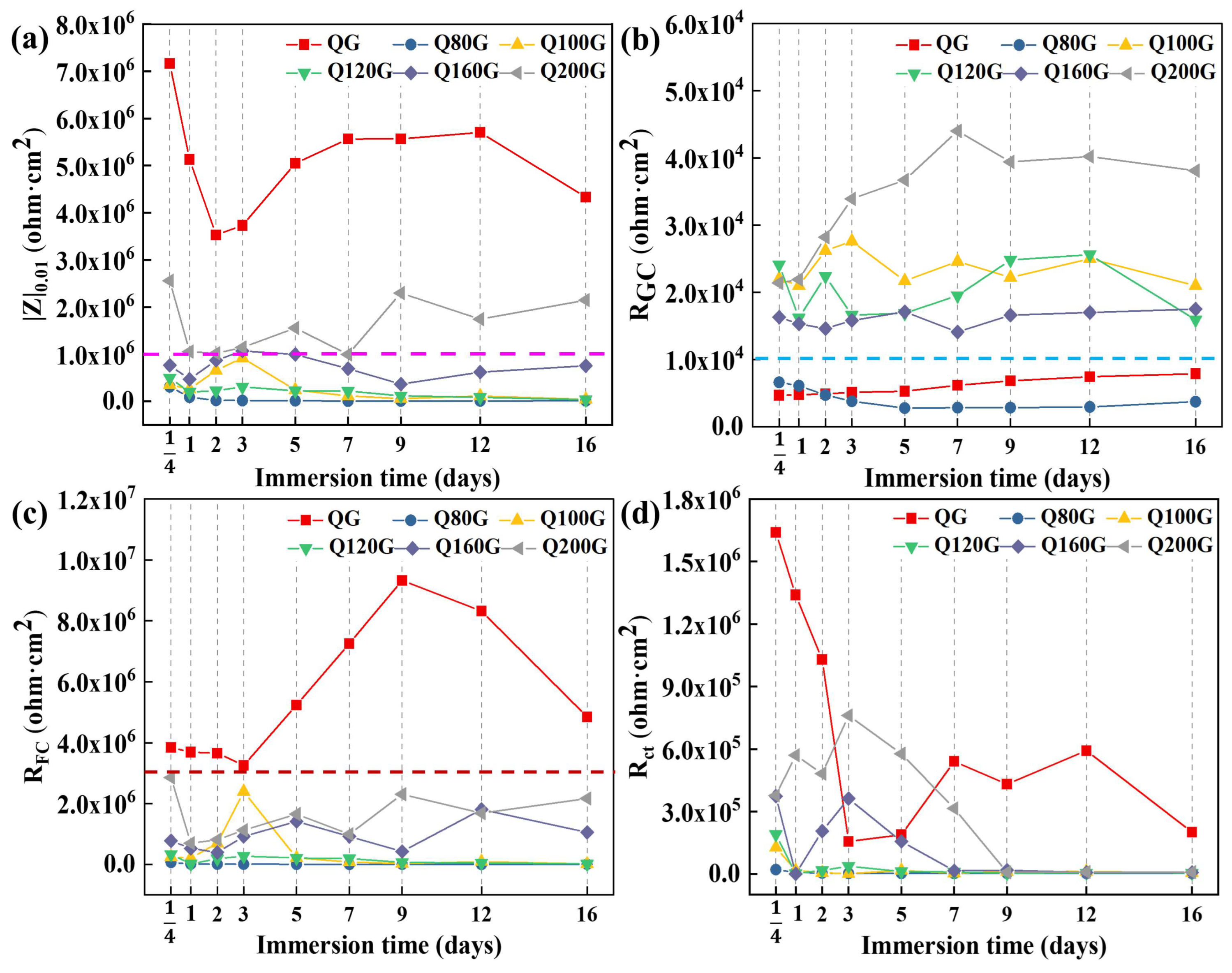

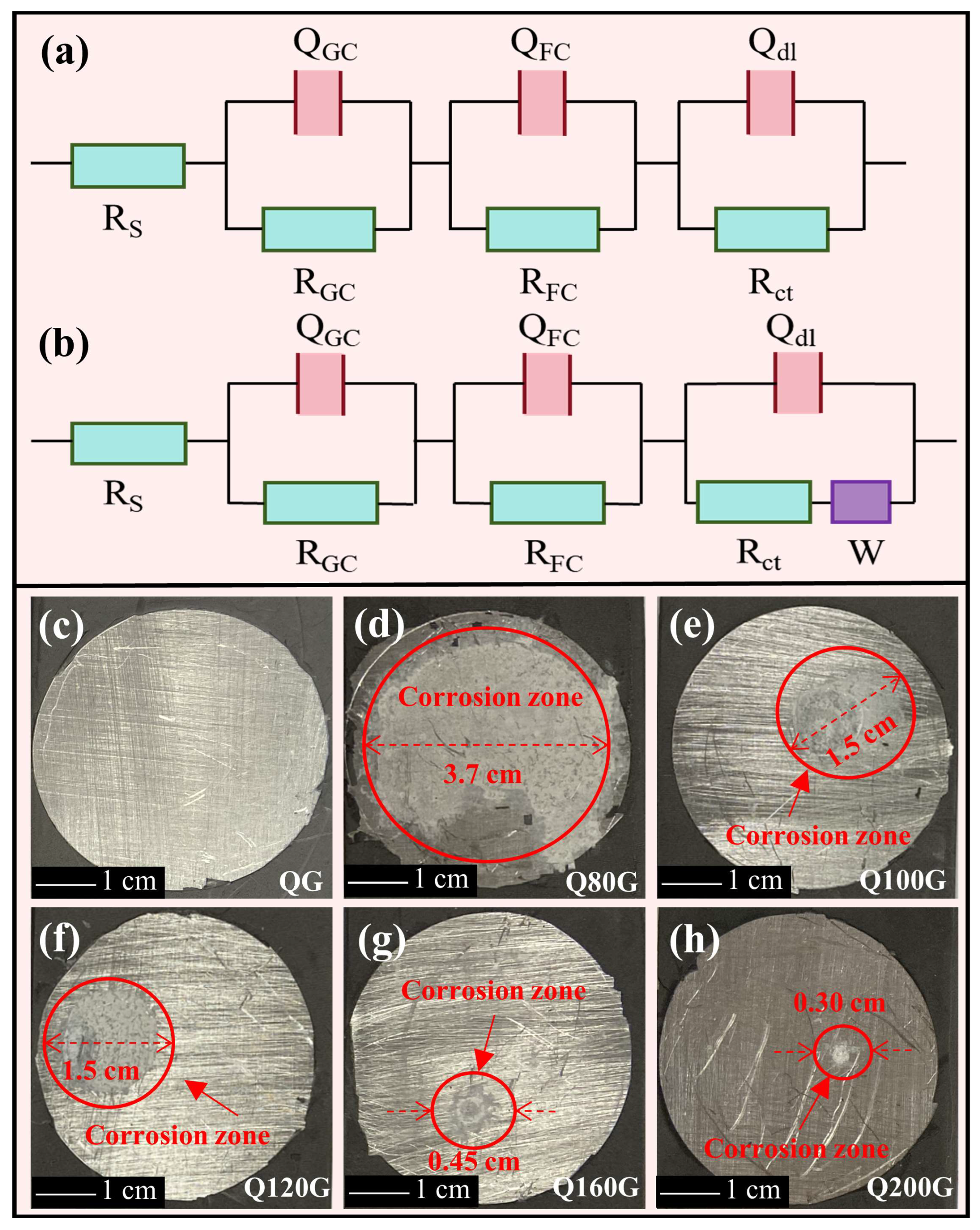

3.5. Corrosion Resistance

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Shen, Y.; Wu, X.; Tao, J.; Zhu, C.; Lai, Y.; Chen, Z. Icephobic materials: Fundamentals, performance evaluation, and applications. Prog. Mater. Sci. 2019, 103, 509–557. [Google Scholar] [CrossRef]

- Quaia, S.; Marchesin, A.; Rampazzo, D.; Mancuso, C. Anti-icing measures in the Italian power system. IET Gener. Transm. Distrib. 2019, 13, 5577–5585. [Google Scholar] [CrossRef]

- Zeng, D.; Li, Y.; Liu, H.; Yang, Y.; Peng, L.; Zhu, C.; Zhao, N. Superhydrophobic coating induced anti-icing and deicing characteristics of an airfoil. Colloids Surfaces A Physicochem. Eng. Asp. 2023, 660, 130824. [Google Scholar] [CrossRef]

- Zhou, L.; Liu, R.; Yi, X. Research and development of anti-icing/deicing techniques for vessels: Review. Ocean Eng. 2022, 260, 112008. [Google Scholar] [CrossRef]

- Li, N.; Jiang, J.; Yang, M.; Wang, H.; Ma, Y.; Li, Z.; Tang, G. Anti-icing mechanism of combined active ethanol spraying and passive surface wettability. Appl. Therm. Eng. 2023, 220, 119805. [Google Scholar] [CrossRef]

- Zhao, W.; Xiao, L.; He, X.; Cui, Z.; Fang, J.; Zhang, C.; Li, X.; Li, G.; Zhong, L.; Zhang, Y. Moth-eye-inspired texturing surfaces enabled self-cleaning aluminum to achieve photothermal anti-icing. Opt. Laser Technol. 2021, 141, 107115. [Google Scholar] [CrossRef]

- Zhang, K.; Li, J.; Wang, Y.; Lin, C.; Zhao, J.; Liu, Y.; Chen, S. Anti-icing of solid surfaces based on droplet dynamics. Mod. Phys. Lett. B 2023, 37, 2330002. [Google Scholar] [CrossRef]

- Xie, Z.; Wang, H.; Geng, Y.; Li, M.; Deng, Q.; Tian, Y.; Chen, R.; Zhu, X.; Liao, Q. Carbon-based photothermal superhydrophobic materials with hierarchical structure enhances the anti-icing and photothermal deicing properties. ACS Appl. Mater. Interfaces 2021, 13, 48308–48321. [Google Scholar] [CrossRef]

- Pan, R.; Zhang, H.; Zhong, M. Triple-scale superhydrophobic surface with excellent anti-icing and icephobic performance via ultrafast laser hybrid fabrication. ACS Appl. Mater. Interfaces 2021, 13, 1743–1753. [Google Scholar] [CrossRef]

- He, Y.; Wang, L.; Wu, T.; Wu, Z.; Chen, Y.; Yin, K. Facile fabrication of hierarchical textures for substrate-independent and durable superhydrophobic surfaces. Nanoscale 2022, 14, 9392–9400. [Google Scholar] [CrossRef]

- Zeng, Q.; Zhou, H.; Huang, J.; Guo, Z. Review on the recent development of durable superhydrophobic materials for practical applications. Nanoscale 2021, 13, 11734–11764. [Google Scholar] [CrossRef] [PubMed]

- Chen, H.; Wang, F.; Fan, H.; Hong, R.; Li, W. Construction of MOF-based superhydrophobic composite coating with excellent abrasion resistance and durability for self-cleaning, corrosion resistance, anti-icing, and loading-increasing research. Chem. Eng. J. 2021, 408, 127343. [Google Scholar] [CrossRef]

- Li, X.; Yan, J.; Yu, T.; Zhang, B. Versatile nonfluorinated superhydrophobic coating with self-cleaning, anti-fouling, anti-corrosion and mechanical stability. Colloids Surfaces A Physicochem. Eng. Asp. 2022, 642, 128701. [Google Scholar] [CrossRef]

- Lou, C.; Zhang, R.; Lu, X.; Zhou, C.; Xin, Z. Facile fabrication of epoxy/polybenzoxazine based superhydrophobic coating with enhanced corrosion resistance and high thermal stability. Colloids Surfaces A Physicochem. Eng. Asp. 2019, 562, 8–15. [Google Scholar] [CrossRef]

- Han, X.; Ren, L.; Ma, Y.; Gong, X.; Wang, H. A mussel-inspired self-repairing superhydrophobic coating with good anti-corrosion and photothermal properties. Carbon 2022, 197, 27–39. [Google Scholar] [CrossRef]

- Ye, Z.; Li, S.; Zhao, S.; Deng, L.; Zhang, J.; Dong, A. Textile coatings configured by double-nanoparticles to optimally couple superhydrophobic and antibacterial properties. Chem. Eng. J. 2021, 420, 127680. [Google Scholar] [CrossRef]

- Yu, H.; Wu, M.; Duan, G.; Gong, X. One-step fabrication of eco-friendly superhydrophobic fabrics for high-efficiency oil/water separation and oil spill cleanup. Nanoscale 2022, 14, 1296–1309. [Google Scholar] [CrossRef]

- Nyholm, N.; Espallargas, N. Functionalized carbon nanostructures as lubricant additives—A review. Carbon 2023, 201, 1200–1228. [Google Scholar] [CrossRef]

- Chu, Z.; Jiao, W.; Huang, Y.; Yan, M.; Zheng, Y.; Wang, R.; He, X. Smart superhydrophobic films with self-sensing and anti-icing properties based on silica nanoparticles and graphene. Adv. Mater. Interfaces 2020, 7, 2000492. [Google Scholar] [CrossRef]

- Bai, Z.-G.; Zhang, B. Fabrication of a mechanically-stable anti-icing graphene oxide-diatomaceous earth/epoxy coating. Mater. Res. Express 2019, 6, 085090. [Google Scholar] [CrossRef]

- Zheng, Z.; Liao, C.; Xia, Y.; Chai, W.; Xie, C.; Zhang, W.; Liu, Y. Facile fabrication of robust, biomimetic and superhydrophobic polymer/graphene-based coatings with self-cleaning, oil-water separation, anti-icing and corrosion resistance properties. Colloids Surfaces A Physicochem. Eng. Asp. 2021, 627, 127164. [Google Scholar] [CrossRef]

- Uzoma, P.C.; Liu, F.; Xu, L.; Zhang, Z.; Han, E.-H.; Ke, W.; Arukalam, I. Superhydrophobicity, conductivity and anticorrosion of robust siloxane-acrylic coatings modified with graphene nanosheets. Prog. Org. Coatings 2019, 127, 239–251. [Google Scholar] [CrossRef]

- Du, X.Q.; Liu, Y.W.; Chen, Y. Enhancing the corrosion resistance of aluminum by superhydrophobic silane/graphene oxide coating. Appl. Phys. A 2021, 127, 580. [Google Scholar] [CrossRef]

- Wu, X.H.; Liew, Y.K.; Lim, W.M.; Mai, C.; Then, Y.Y. Blood compatible and noncytotoxic superhydrophobic graphene/titanium dioxide coating with antibacterial and antibiofilm properties. J. Appl. Polym. Sci. 2023, 140, e53629. [Google Scholar] [CrossRef]

- Li, C.; Chen, H.; Fan, Y.; Fu, K.; Liu, C.; Ren, X.; Yang, H.; Lin, S. Functionalized graphene modified styrene-divinylbenzene copolymer as a superhydrophobic catalyst carrier for hydrogen-water liquid phase catalytic exchange. Int. J. Hydrogen Energy 2023, 48, 3520–3533. [Google Scholar] [CrossRef]

- Li, Z.-T.; Wu, H.-T.; Chen, W.-Y.; He, F.-A.; Li, D.-H. Preparation of magnetic superhydrophobic melamine sponges for effective oil-water separation. Sep. Purif. Technol. 2019, 212, 40–50. [Google Scholar] [CrossRef]

- Choi, Y.S.; Lee, J.S.; Jin, S.B.; Han, J.G. Super-hydrophobic coatings with nano-size roughness prepared with simple PECVD method. J. Phys. D Appl. Phys. 2013, 46, 315501. [Google Scholar] [CrossRef]

- Hu, L.; Deng, J.; Xie, Y.; Qian, F.; Dong, Y.; Xu, C. In situ growth of graphene on polyimide for high-responsivity flexible PbS–graphene photodetectors. Nanomaterials 2023, 13, 1339. [Google Scholar] [CrossRef]

- Teng, T.-P.; Chang, S.-C.; Chen, Z.-Y.; Huang, C.-K.; Tseng, S.-F.; Yang, C.-R. High-yield production of graphene flakes using a novel electrochemical/mechanical hybrid exfoliation. Int. J. Adv. Manuf. Technol. 2019, 104, 2751–2760. [Google Scholar] [CrossRef]

- Nguyen, V.T.; Le, H.D.; Ngo, T.T.T.; Le, D.Q.; Nguyen, X.N.; Phan, N.M. Synthesis of multi-layer graphene films on copper tape by atmospheric pressure chemical vapor deposition method. Adv. Nat. Sci. Nanosci. Nanotechnol. 2013, 4, 035012. [Google Scholar] [CrossRef]

- Yan, Q.; Zhou, S.; Ma, L.; Wan, S.; Zhu, X. Approach to excellent superhydrophobicity and corrosion resistance of carbon-based films by graphene and cobalt synergism. Surf. Interface Anal. 2018, 51, 152–163. [Google Scholar] [CrossRef]

- Li, R.; Chen, C.; Li, J.; Xu, L.; Xiao, G.; Yan, D. A facile approach to superhydrophobic and superoleophilic graphene/polymer aerogels. J. Mater. Chem. A 2014, 2, 3057. [Google Scholar] [CrossRef]

- Vanithakumari, S.; Jena, G.; Sofia, S.; Thinaharan, C.; George, R.; Philip, J. Fabrication of superhydrophobic titanium surfaces with superior antibacterial properties using graphene oxide and silanized silica nanoparticles. Surf. Coatings Technol. 2020, 400, 126074. [Google Scholar] [CrossRef]

- Li, D.; Lu, Y.; Zhang, C. Superhydrophobic and electrochemical performance of CF2-modified g-C3N4/graphene composite film deposited by PECVD. Nanomaterials 2022, 12, 4387. [Google Scholar] [CrossRef]

- Wilczewski, S.; Skórczewska, K.; Tomaszewska, J.; Osial, M.; Dąbrowska, A.; Nikiforow, K.; Jenczyk, P.; Grzywacz, H. Graphene modification by curcuminoids as an effective method to improve the dispersion and stability of PVC/graphene nanocomposites. Molecules 2023, 28, 3383. [Google Scholar] [CrossRef]

- Guo, C.; Liu, K.; Zhang, T.; Sun, P.; Liang, L. Development of flexible photothermal superhydrophobic microarray by photolithography technology for anti-icing and deicing. Prog. Org. Coat. 2023, 182, 107675. [Google Scholar] [CrossRef]

- Xiao, X.; Wei, X.; Wei, J.; Wang, J. Multifunctional Fe3O4-based photothermal superhydrophobic composite coating for efficient anti-icing/deicing. Sol. Energy Mater. Sol. Cells 2023, 256, 112313. [Google Scholar] [CrossRef]

- Oberli, L.; Caruso, D.; Hall, C.; Fabretto, M.; Murphy, P.I.; Evans, D. Condensation and freezing of droplets on superhydrophobic surfaces. Adv. Colloid Interf. Sci. 2014, 210, 47–57. [Google Scholar] [CrossRef] [PubMed]

- Li, Q.; Guo, Z. Fundamentals of icing and common strategies for designing biomimetic anti-icing surfaces. J. Mater. Chem. A 2018, 6, 13549–13581. [Google Scholar] [CrossRef]

- Wu, Y.; Shu, X.; Yang, Y.; She, W.; Dong, L.; Ran, Q. Fabrication of robust and room-temperature curable superhydrophobic composite coatings with breathable and anti-icing performance. Chem. Eng. J. 2023, 463, 142444. [Google Scholar] [CrossRef]

- Yin, X.; Mu, P.; Wang, Q.; Li, J. Superhydrophobic ZIF-8-based dual-layer coating for enhanced corrosion protection of Mg alloy. ACS Appl. Mater. Interfaces 2020, 12, 35453–35463. [Google Scholar] [CrossRef] [PubMed]

- Shen, X.; Mao, T.; Li, C.; Mao, F.; Xue, Z.; Xu, G.; Amirfazli, A. Durable superhydrophobic coatings based on CNTs-SiO2gel hybrids for anti-corrosion and thermal insulation. Prog. Org. Coat. 2023, 181, 107602. [Google Scholar] [CrossRef]

- Pei, Y.; Xing, Q.; Chen, A.; Xu, J.; Zhang, Y.; Huang, H.; Lei, C. Enhanced solar photothermal anti-/de-icing performance of microstructured polypropylene/graphene composite surfaces with diameter- and density-optimized nanopillars. Chem. Eng. Sci. 2023, 282, 119330. [Google Scholar] [CrossRef]

- Chen, Y.; Liu, Y.; Xie, Y.; Zhang, H.; Du, X.; Zhang, Z. Preparation of hydrophobic silane/graphene oxide composite coating implanted with benzotriazole to improve the anti-corrosion performance of copper. J. Alloys Compd. 2022, 893, 162305. [Google Scholar] [CrossRef]

| Q80G | Q100G | Q120G | Q160G | Q200G | |

|---|---|---|---|---|---|

| wg (μm) | 50 | 50 | 50 | 50 | 50 |

| wp (μm) | 266 | 198 | 165 | 112 | 72 |

| Φg (%) | 2.47 | 4.06 | 5.41 | 9.53 | 16.80 |

| Time (Days) | Rs (Ω·cm2) | QGC (10−10S·sα/cm2) | nGC | RGC (Ω·cm2) | QFC (10−6S·sα/cm2) | nFC | RFC (MΩ·cm2) | Qdl (10−6S·sα/cm2) | ndl | Rct (MΩ·cm2) | W (10−6S·sα/cm2) | CGC (10−11F·cm2) | CFC (10−7F·cm2) | Cdl (10−7F·cm2) |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 0.25 | 0.04012 | 8.07 | 0.883 | 4676 | 2.23 | 0.924 | 3.85 | 0.98 | 0.918 | 1.64 | —— | 3.3 | 5.9 | 2.1 |

| 1 | 0.01719 | 6.33 | 0.899 | 4748 | 2.60 | 0.923 | 3.69 | 1.36 | 0.925 | 1.34 | —— | 3.7 | 6.3 | 3.2 |

| 2 | 0.01002 | 6.41 | 0.902 | 4897 | 2.77 | 0.924 | 3.66 | 1.93 | 0.910 | 1.03 | —— | 3.9 | 6.6 | 3.3 |

| 3 | 0.01196 | 7.04 | 0.893 | 5106 | 1.48 | 0.954 | 3.26 | 4.88 | 0.878 | 0.16 | 2.1 | 3.3 | 6.2 | 4.8 |

| 5 | 0.03205 | 7.04 | 0.894 | 5280 | 1.60 | 0.950 | 5.24 | 5.36 | 0.878 | 0.19 | —— | 3.8 | 6.6 | 6.2 |

| 7 | 0.04475 | 6.75 | 0.900 | 6160 | 2.17 | 0.931 | 7.26 | 3.38 | 0.905 | 0.54 | —— | 4.6 | 6.6 | 6.5 |

| 9 | 0.02849 | 6.36 | 0.906 | 6831 | 1.89 | 0.939 | 9.33 | 5.04 | 0.891 | 0.43 | —— | 4.9 | 6.4 | 7.3 |

| 12 | 0.01000 | 5.92 | 0.902 | 7444 | 2.20 | 0.954 | 8.32 | 3.86 | 0.891 | 0.59 | —— | 3.6 | 9.3 | 4.8 |

| 16 | 0.05725 | 5.81 | 0.914 | 7881 | 1.89 | 0.950 | 4.85 | 6.37 | 0.844 | 0.20 | —— | 6.0 | 8.1 | 4.1 |

| Coatings | Freezing Delay Time (s) | Impedance Value (Ω·cm2) | Research |

|---|---|---|---|

| Untreated Al substrate | 10 | 6.2 × 102 | This work |

| MSODNS | 214 | / | Pei [43] |

| MN-FSGF | 498 | / | Chu [19] |

| GO-DE/EP | 2760 | / | Bai [20] |

| G-6 | 4595 | 3.0 × 105 | Zheng [21] |

| G25 | / | 1.1 × 104 | Paul [22] |

| silane/GO | / | 2.6 × 104 | Du [23] |

| BTAH-silane/GO | / | 5.7 × 106 | Chen [44] |

| Q200G | 5360 | 2.5 × 106 | This work |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, W.; Liu, F.; Li, Y.; Chen, T.; Nwokolo, I.K.; Ahmed, S.; Han, E.-H. Modified Graphene Micropillar Array Superhydrophobic Coating with Strong Anti-Icing Properties and Corrosion Resistance. Coatings 2024, 14, 247. https://doi.org/10.3390/coatings14030247

Zhang W, Liu F, Li Y, Chen T, Nwokolo IK, Ahmed S, Han E-H. Modified Graphene Micropillar Array Superhydrophobic Coating with Strong Anti-Icing Properties and Corrosion Resistance. Coatings. 2024; 14(3):247. https://doi.org/10.3390/coatings14030247

Chicago/Turabian StyleZhang, Wanyu, Fuchun Liu, Yushan Li, Tao Chen, Izuchukwu Kenneth Nwokolo, Sharjeel Ahmed, and En-Hou Han. 2024. "Modified Graphene Micropillar Array Superhydrophobic Coating with Strong Anti-Icing Properties and Corrosion Resistance" Coatings 14, no. 3: 247. https://doi.org/10.3390/coatings14030247