Experimental Study on Tribological Properties of Coated Surface and Textured Surface under Seawater Lubrication Conditions

Abstract

:1. Introduction

2. Materials and Methods

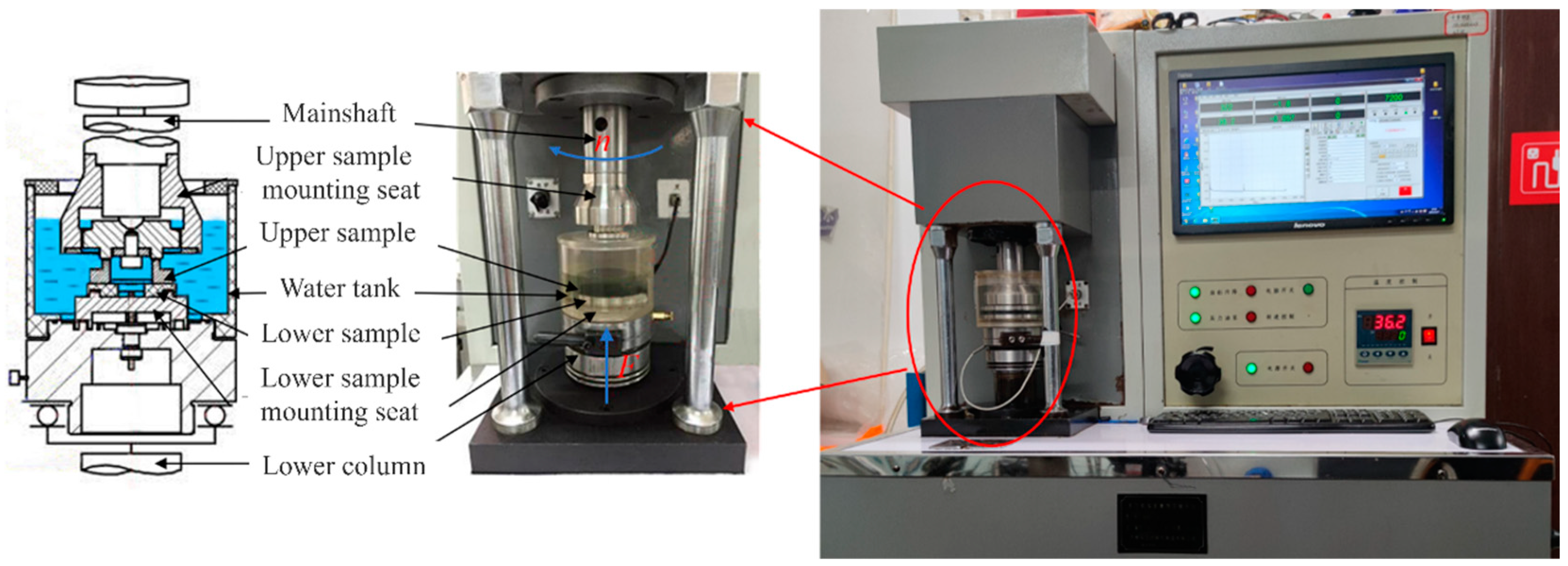

2.1. Experimental Set-Up

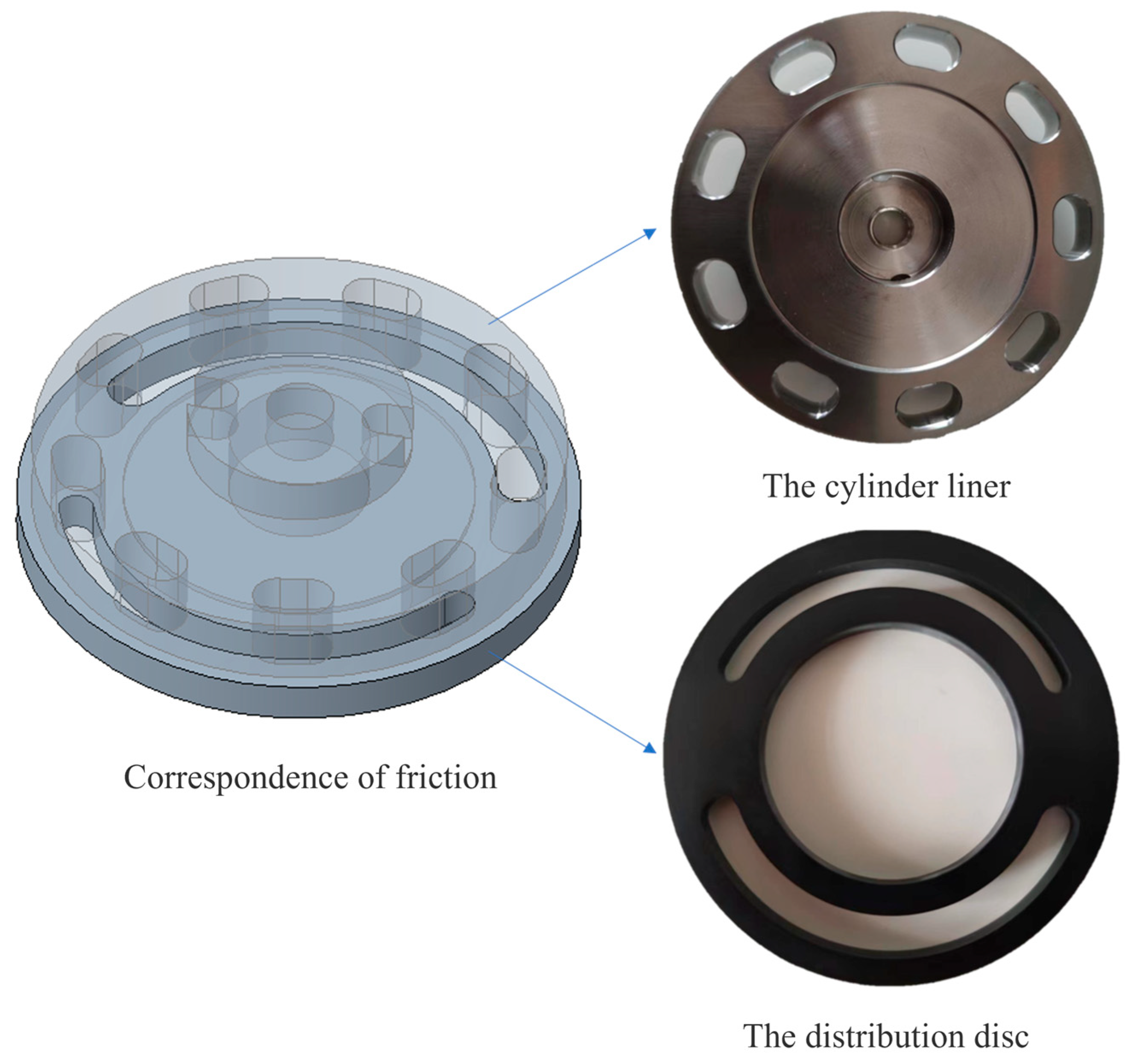

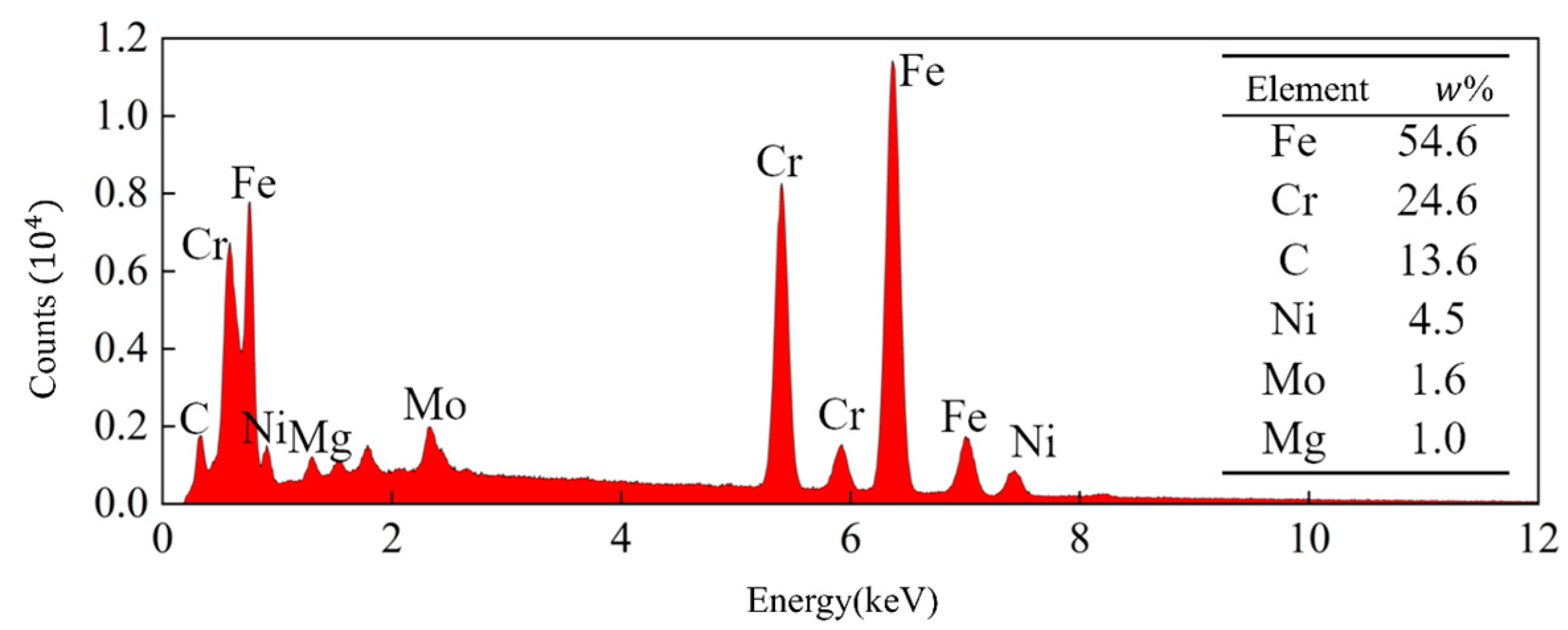

2.2. Test Specimen

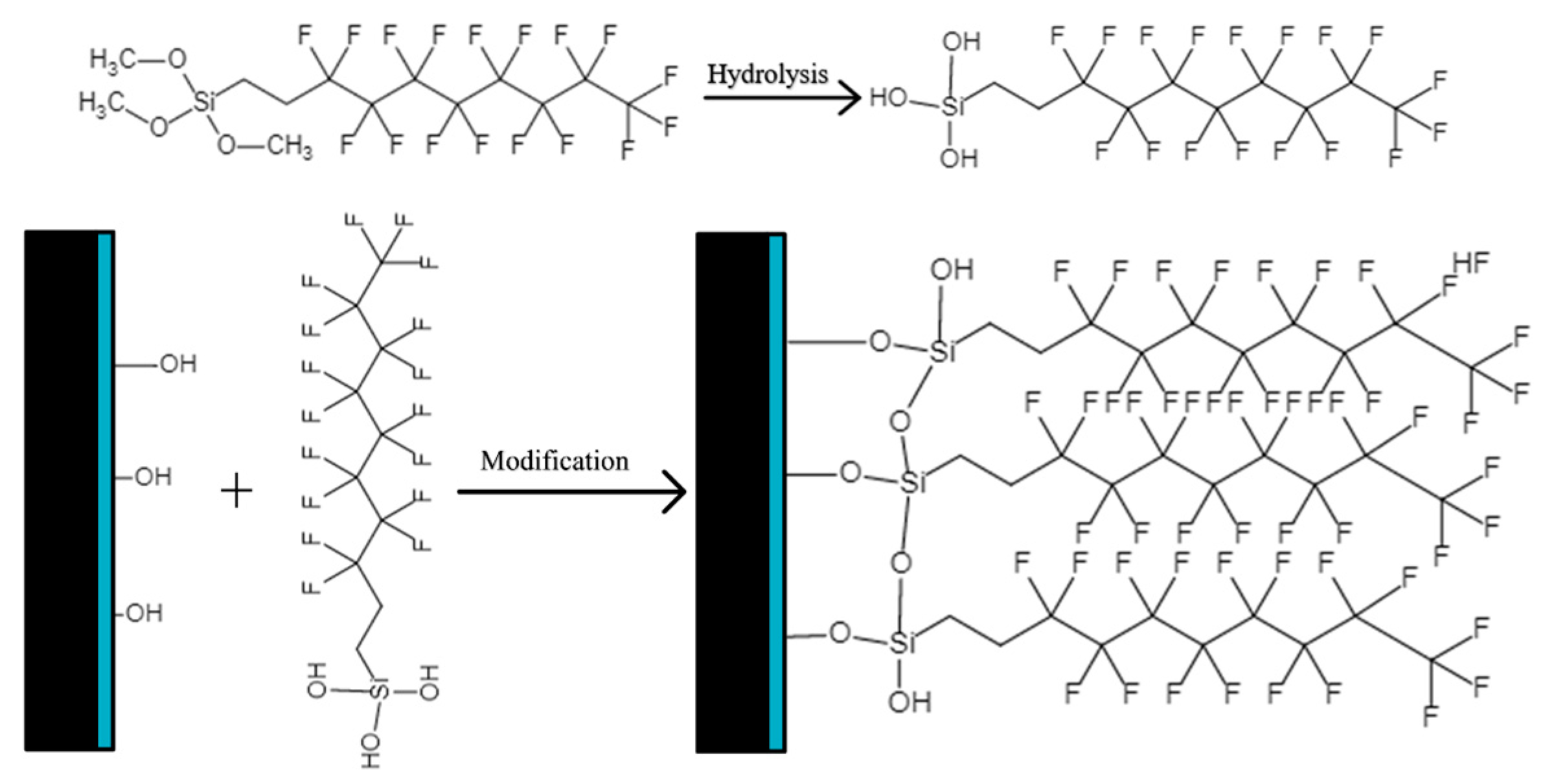

2.2.1. Surface Coating Sample Processing

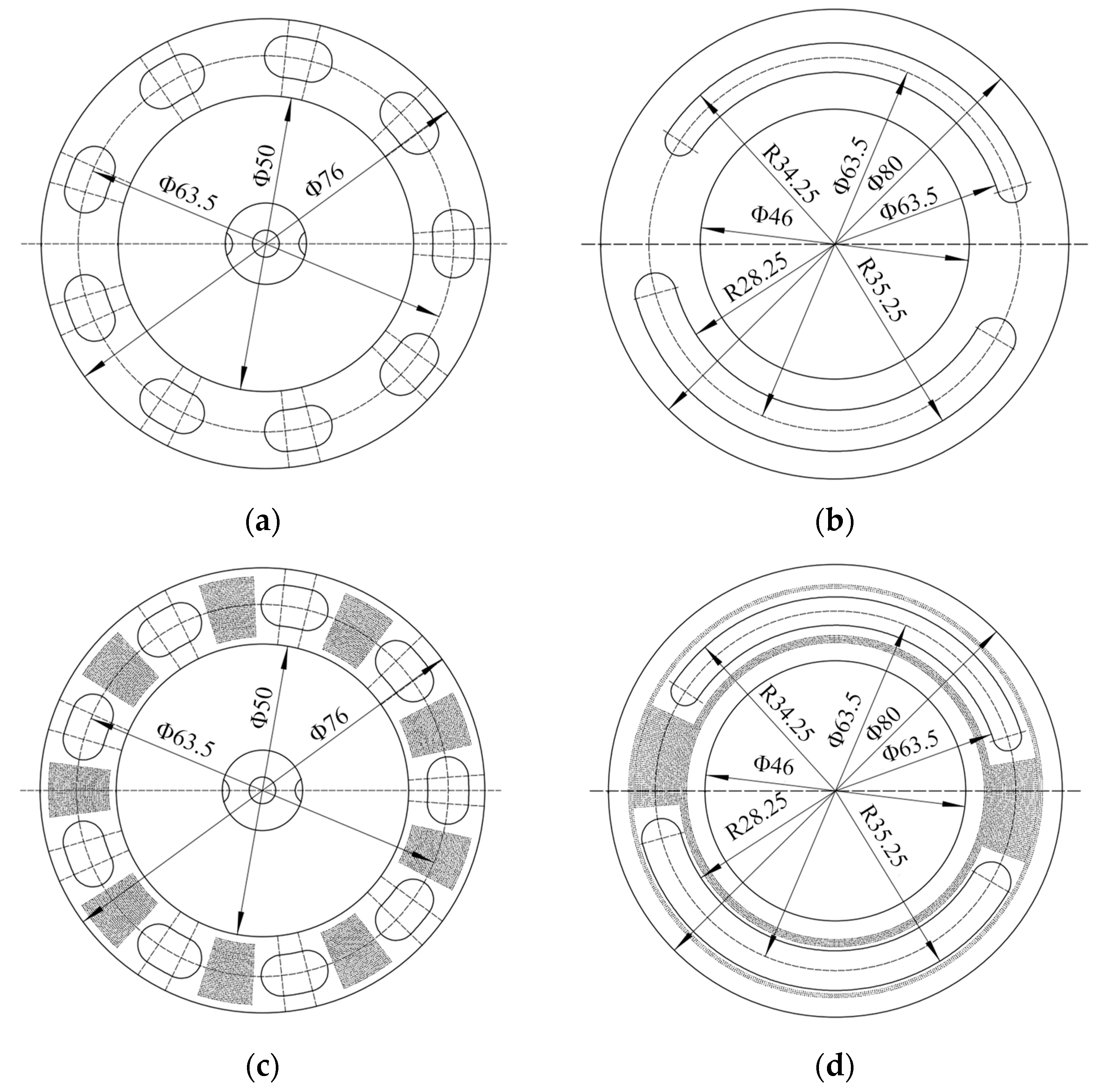

2.2.2. Surface Texture Sample Processing

2.3. Lubricating Medium

2.4. Test Scheme

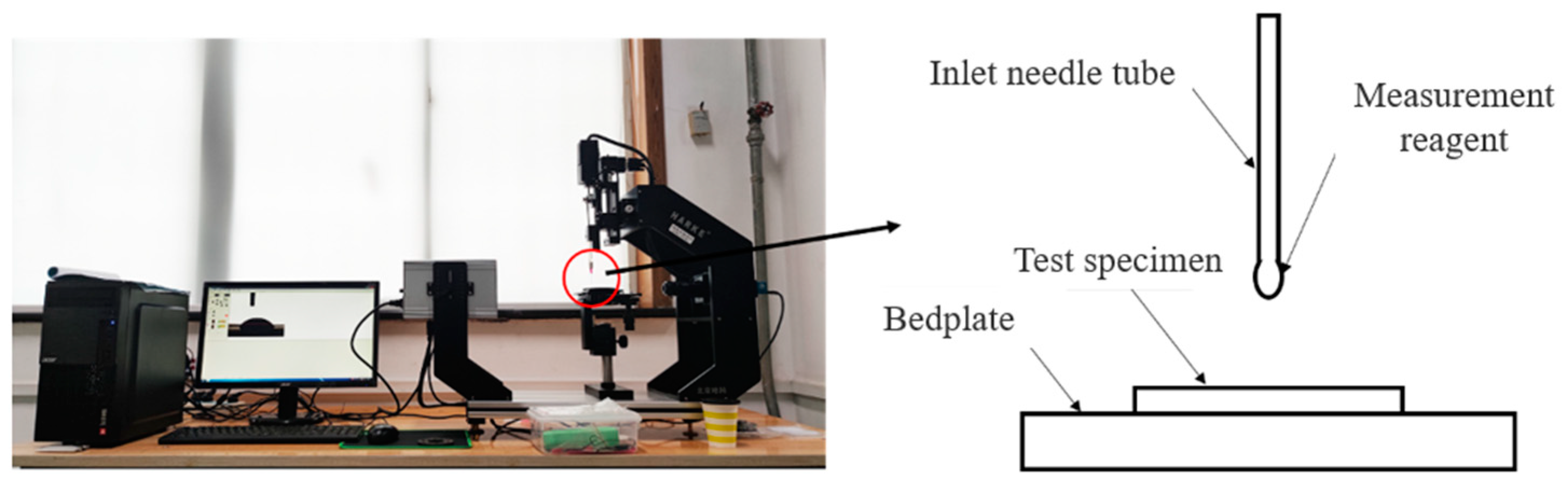

2.4.1. Contact Angle Measurement

2.4.2. Friction and Wear Test

3. Results and Discussion

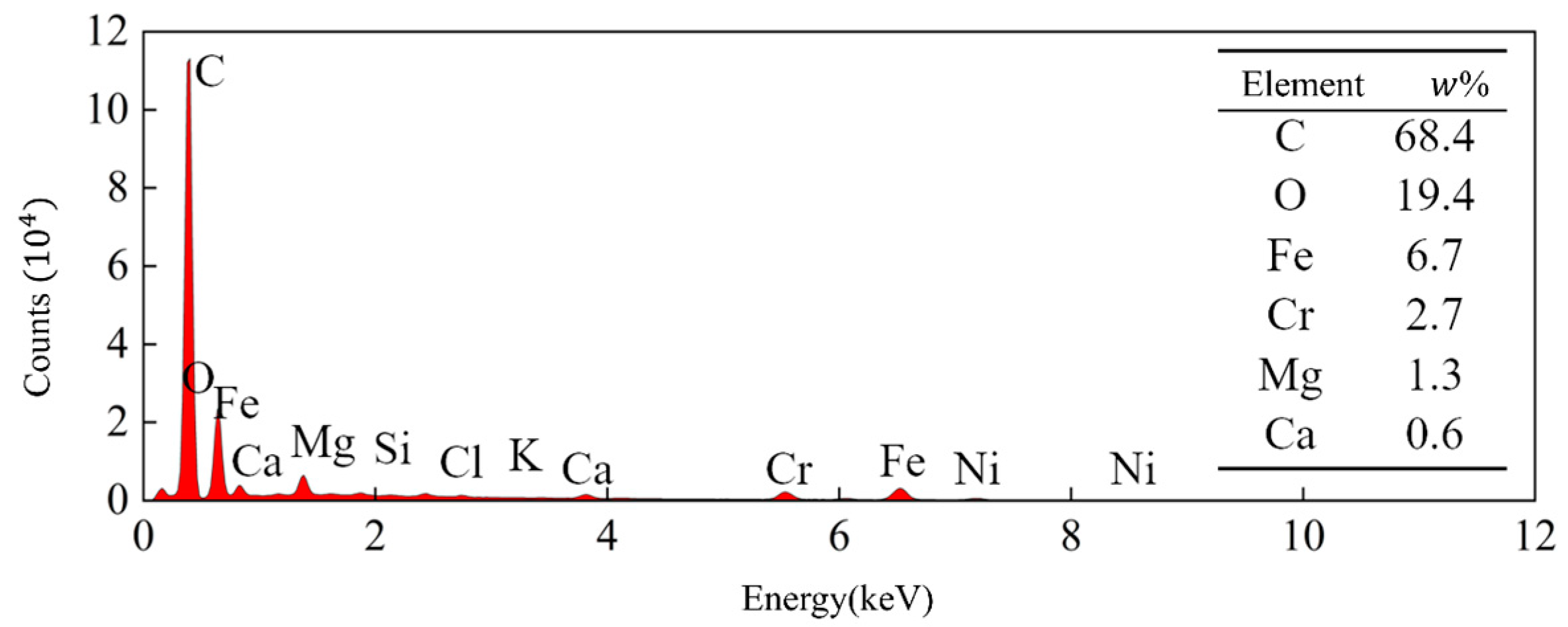

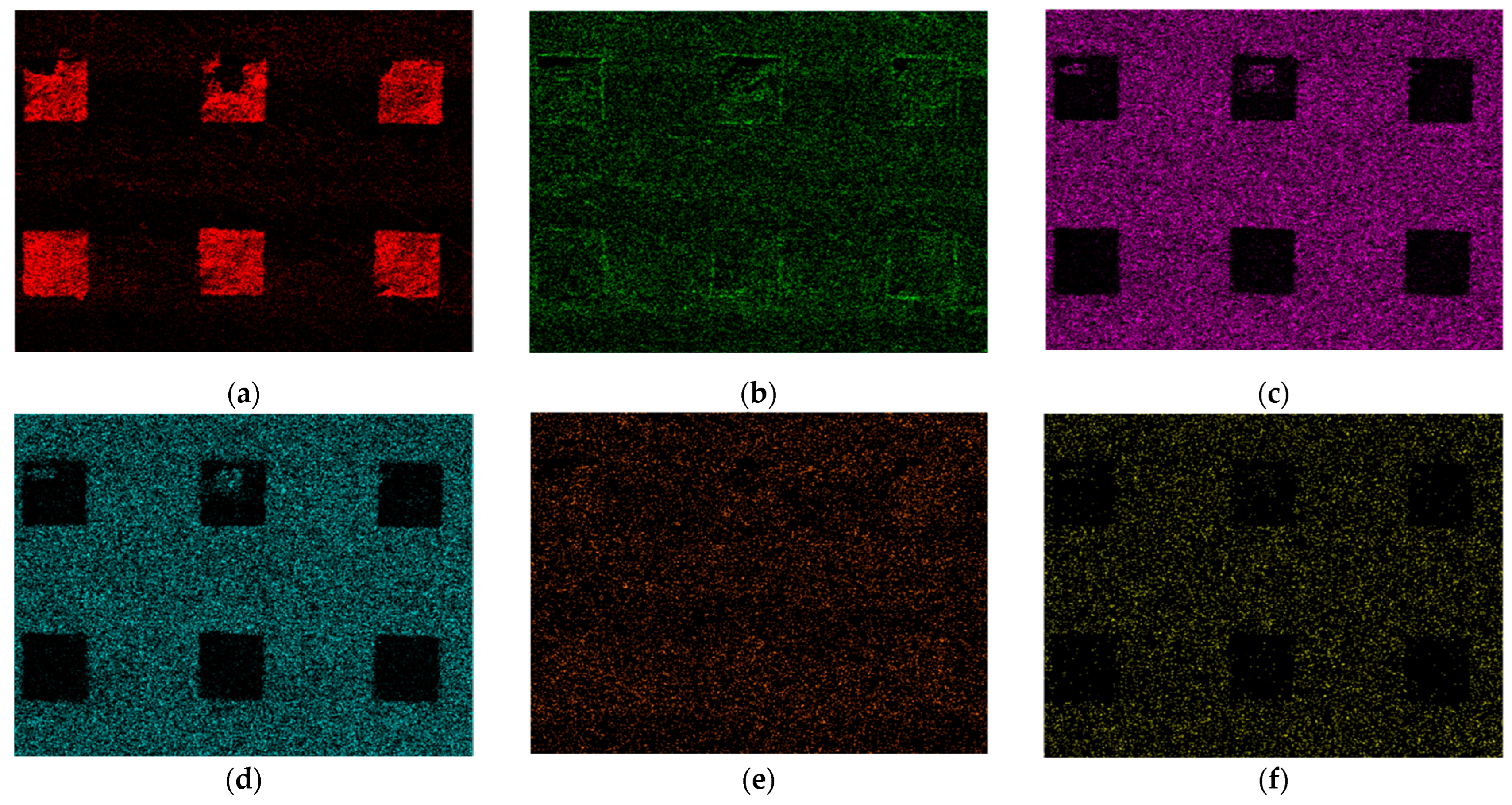

3.1. Surface Coating

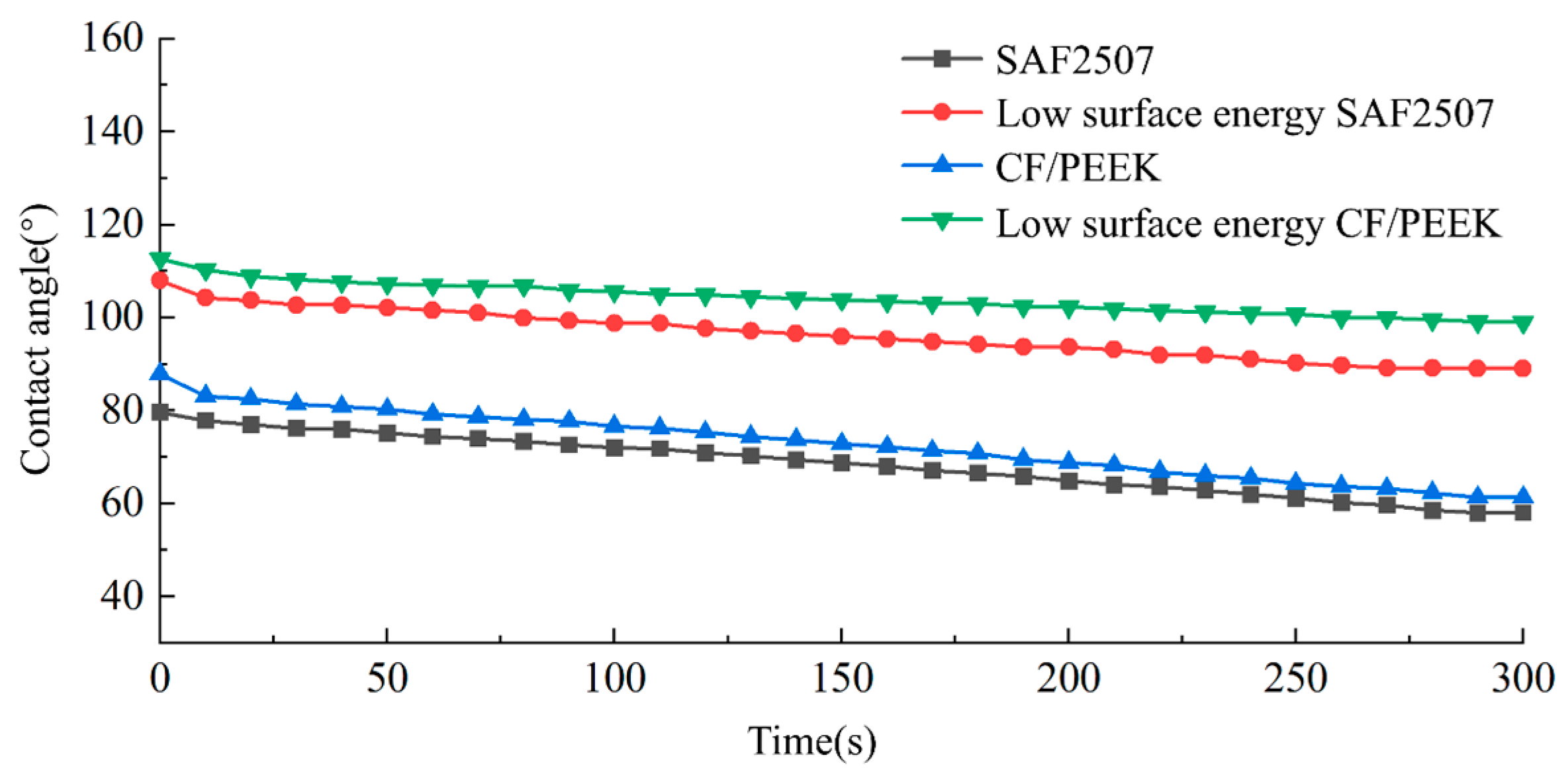

3.1.1. Surface Wettability

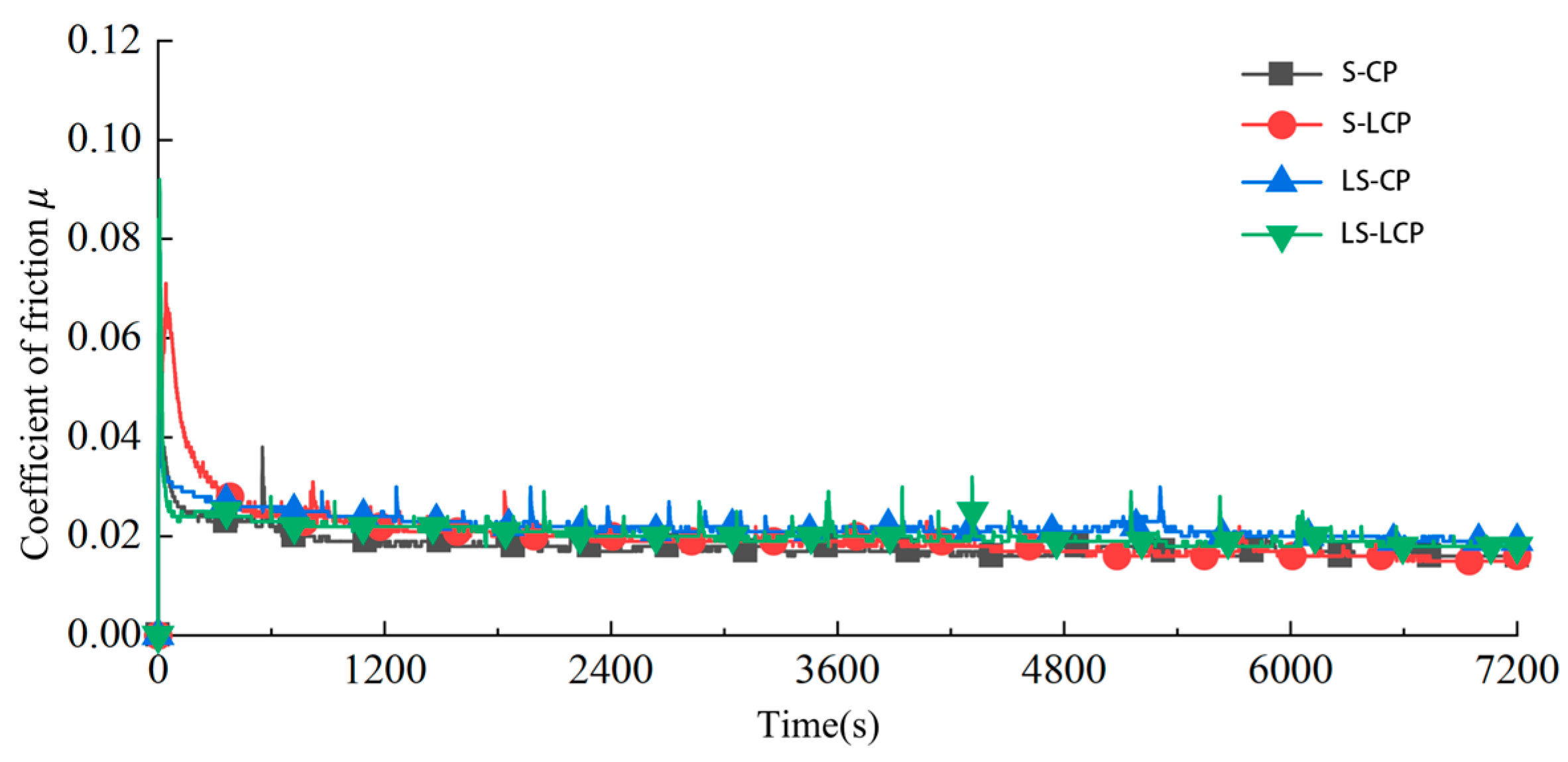

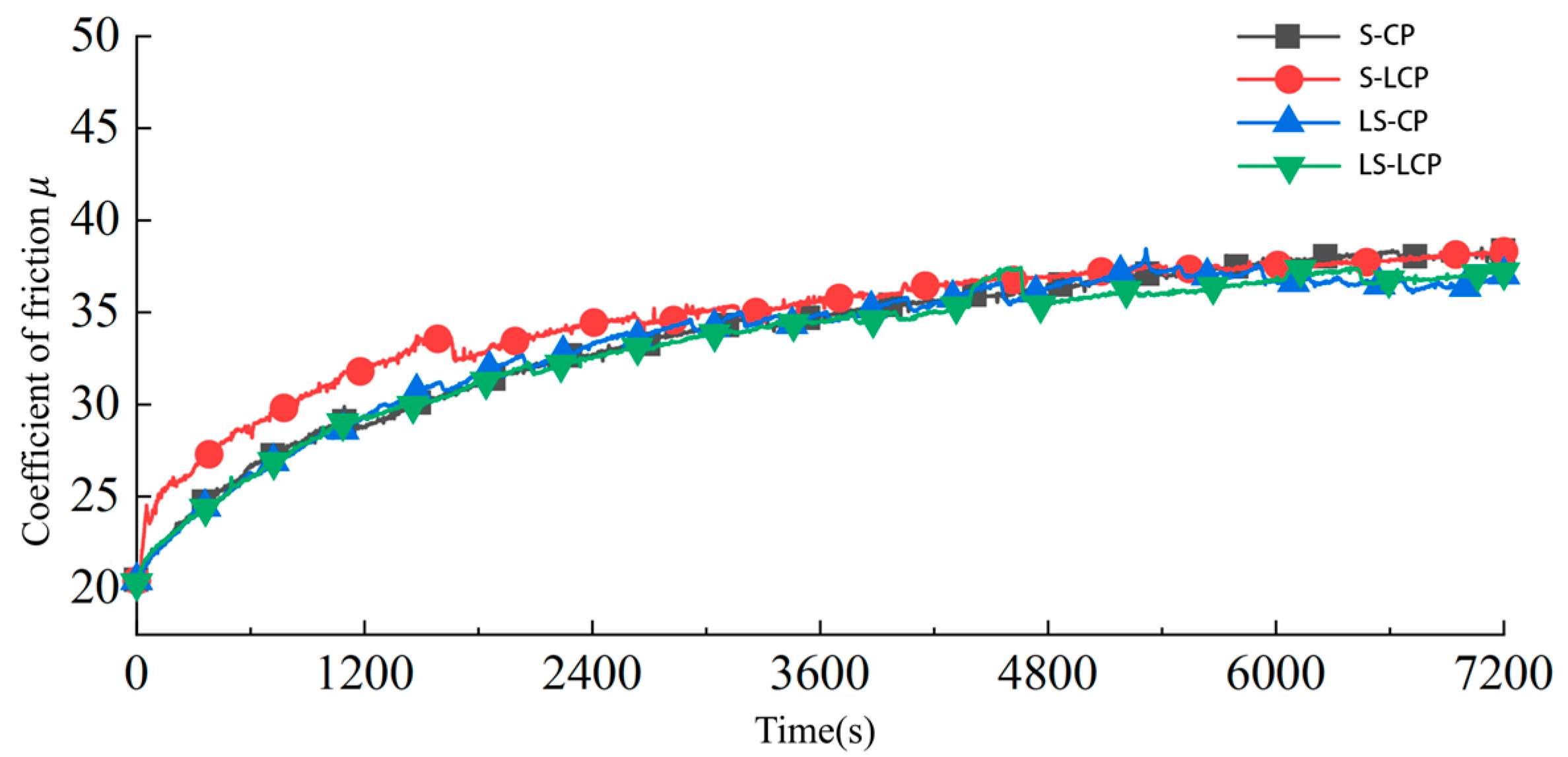

3.1.2. Frictional Characteristic

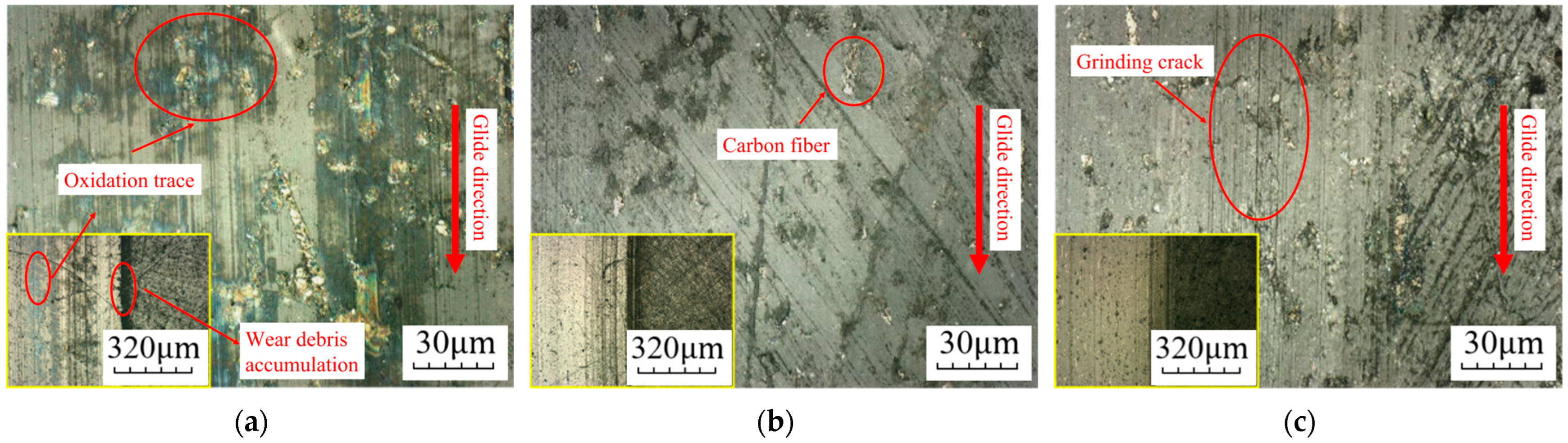

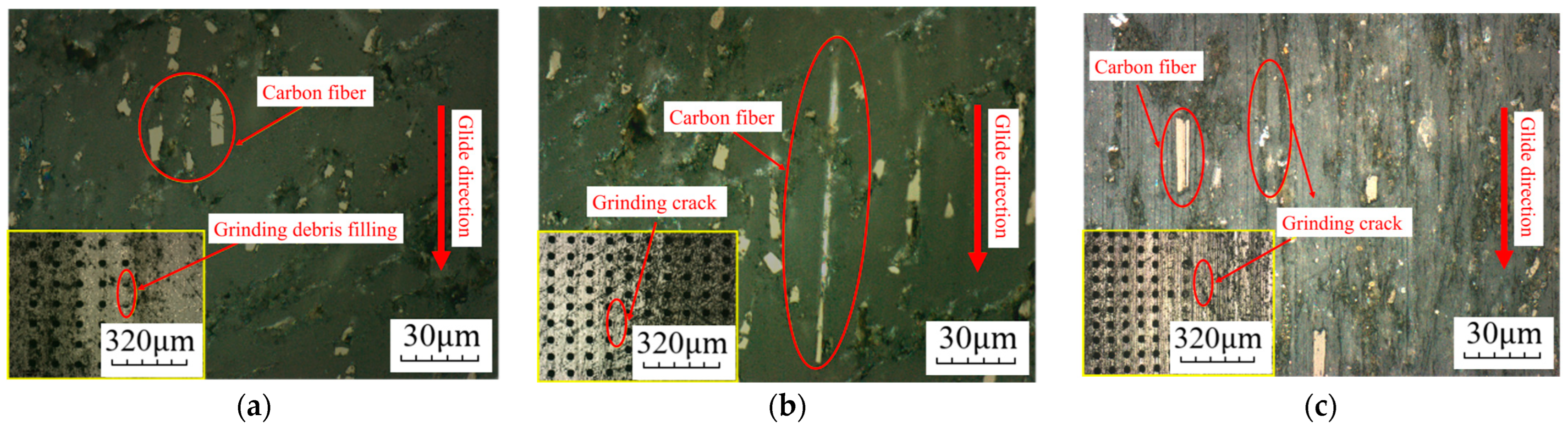

3.1.3. Wear Morphology

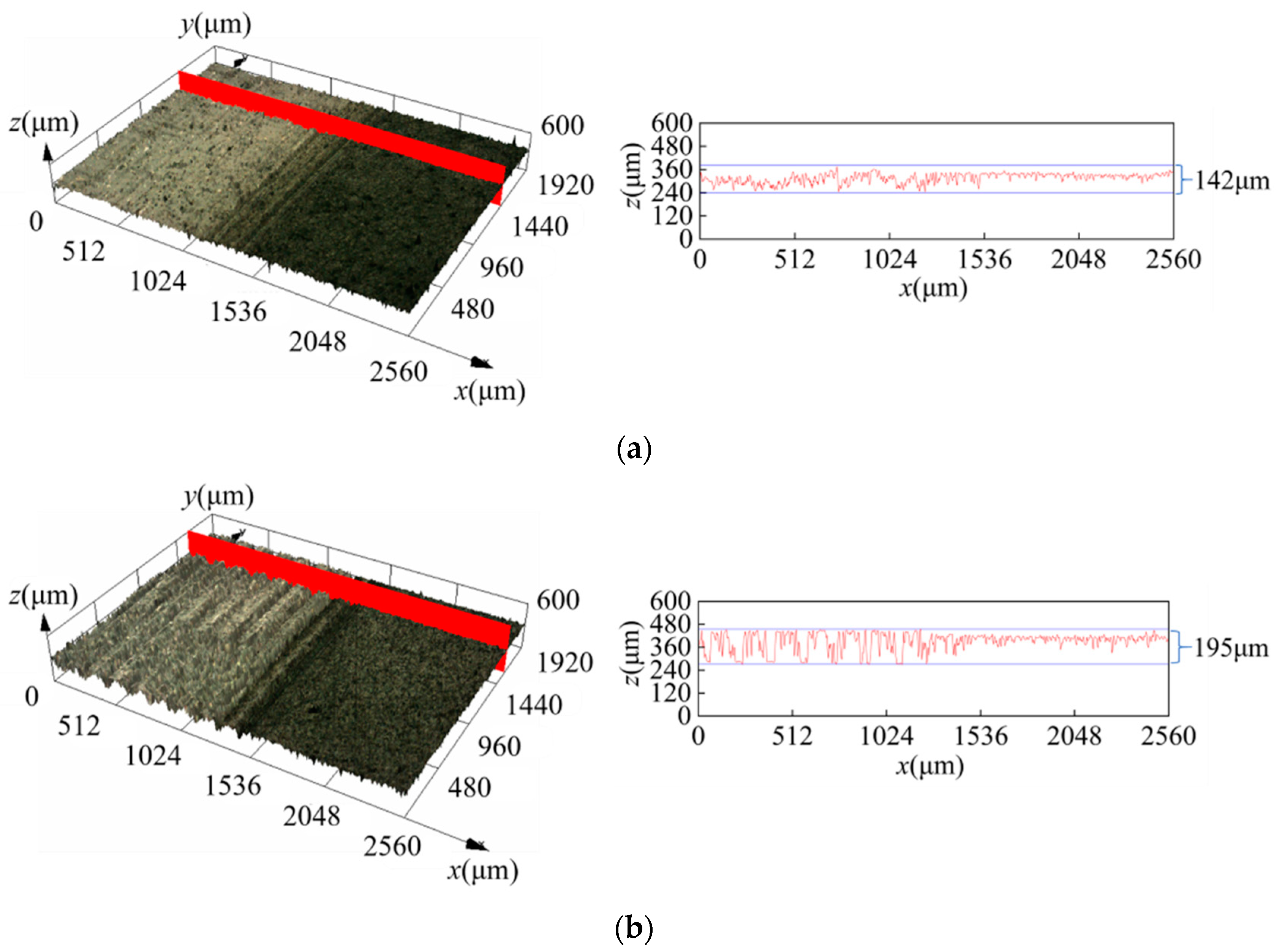

3.2. Surface Texture

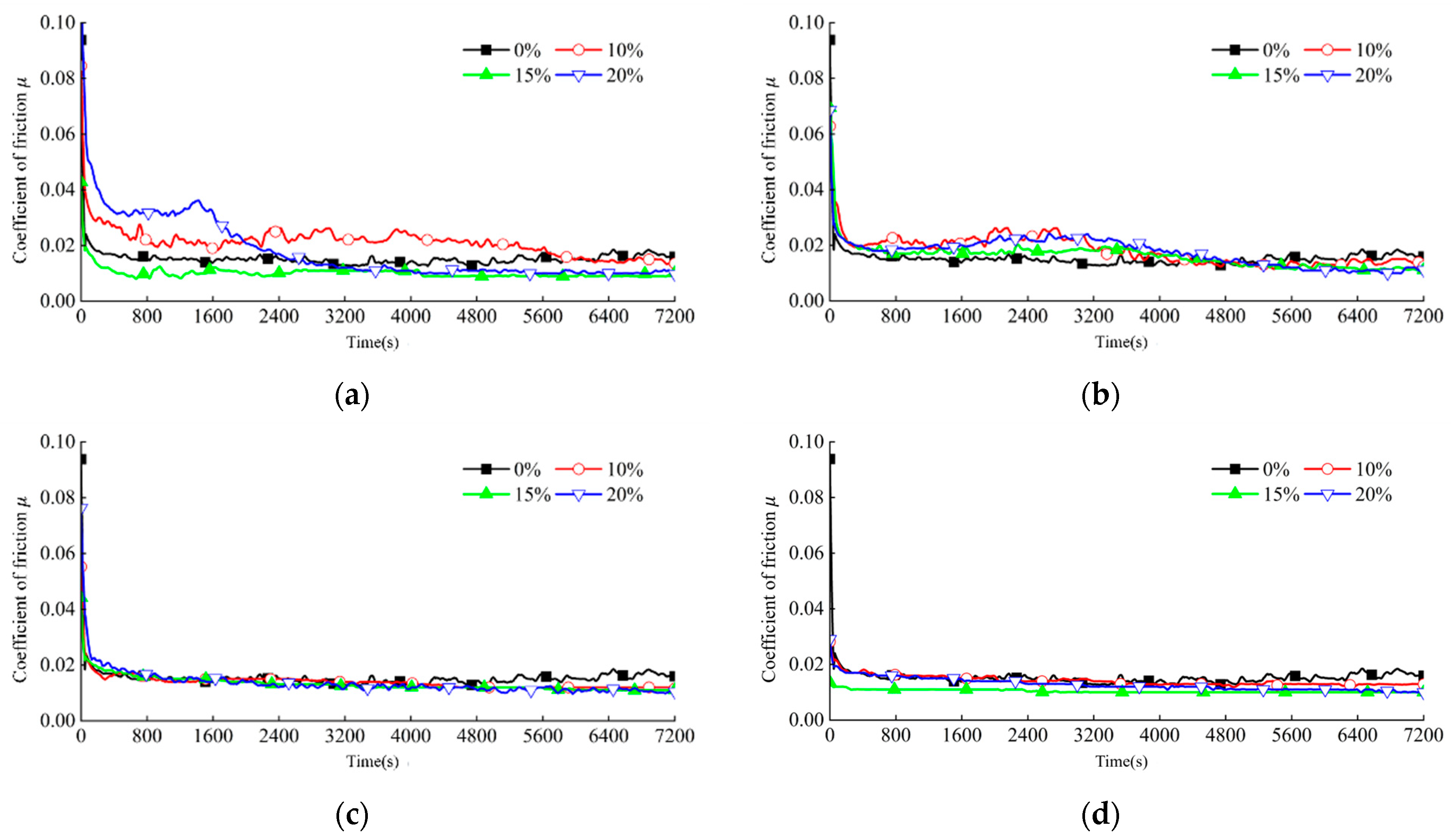

3.2.1. Texture Shape and Area Ratio

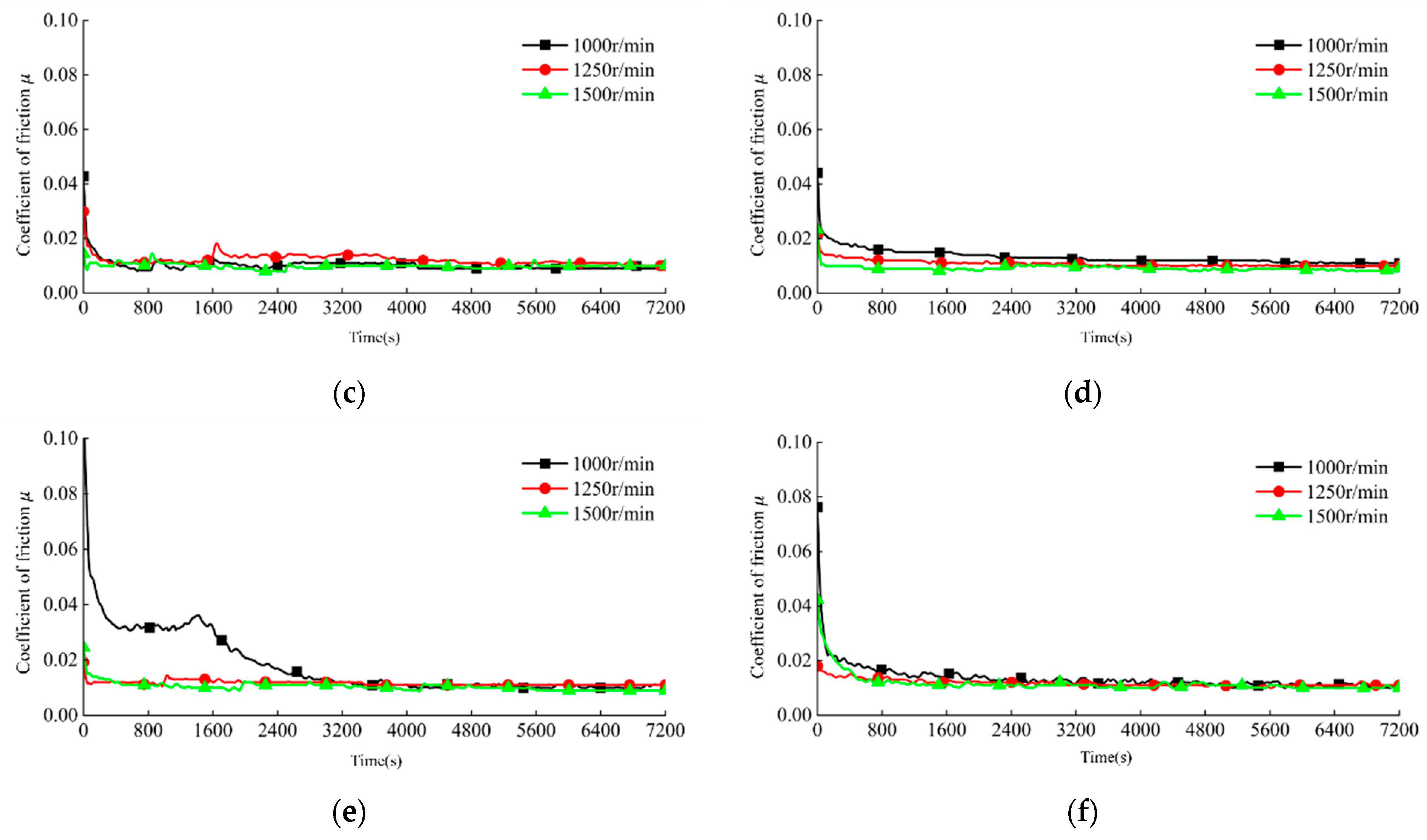

3.2.2. Rotational Speed

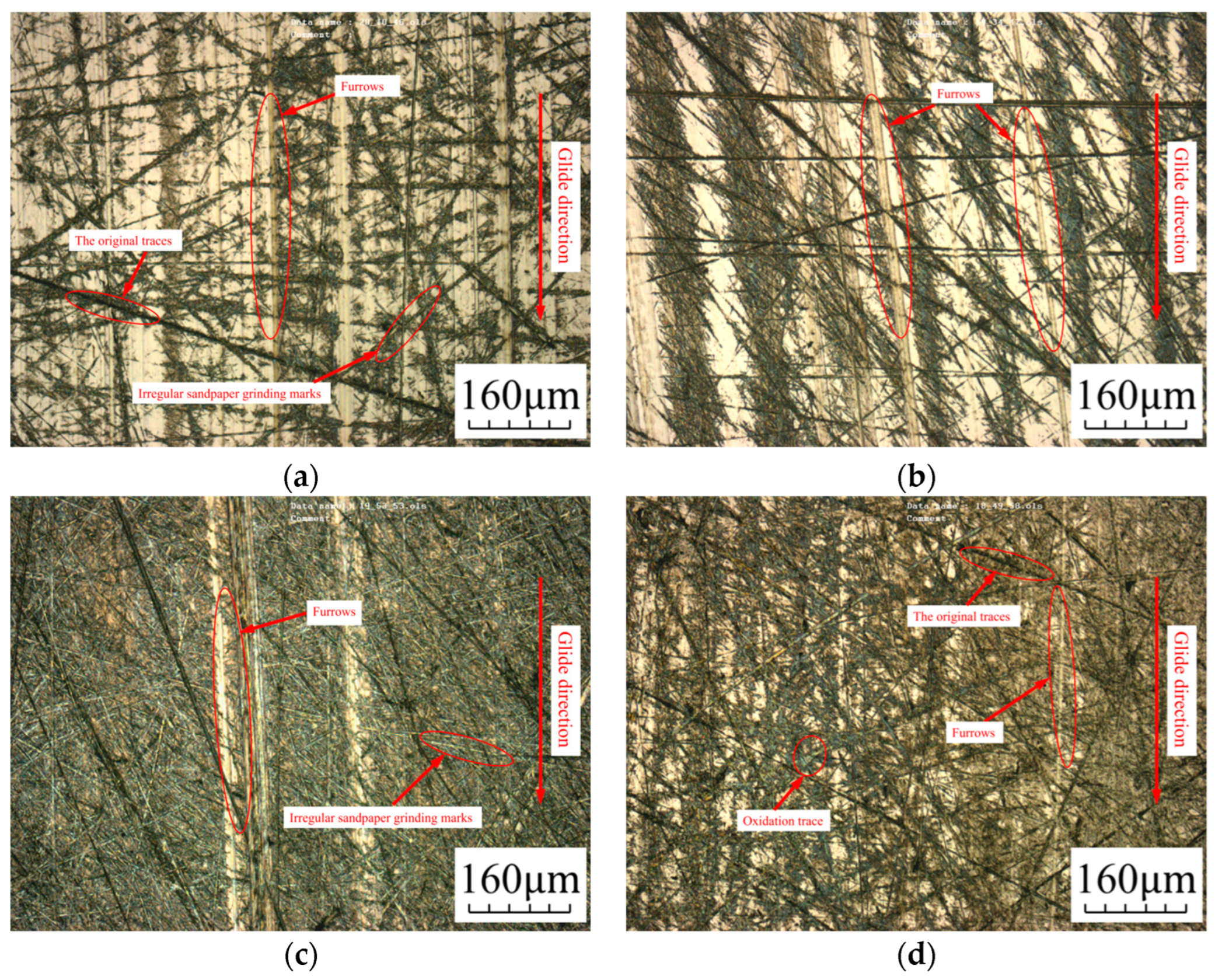

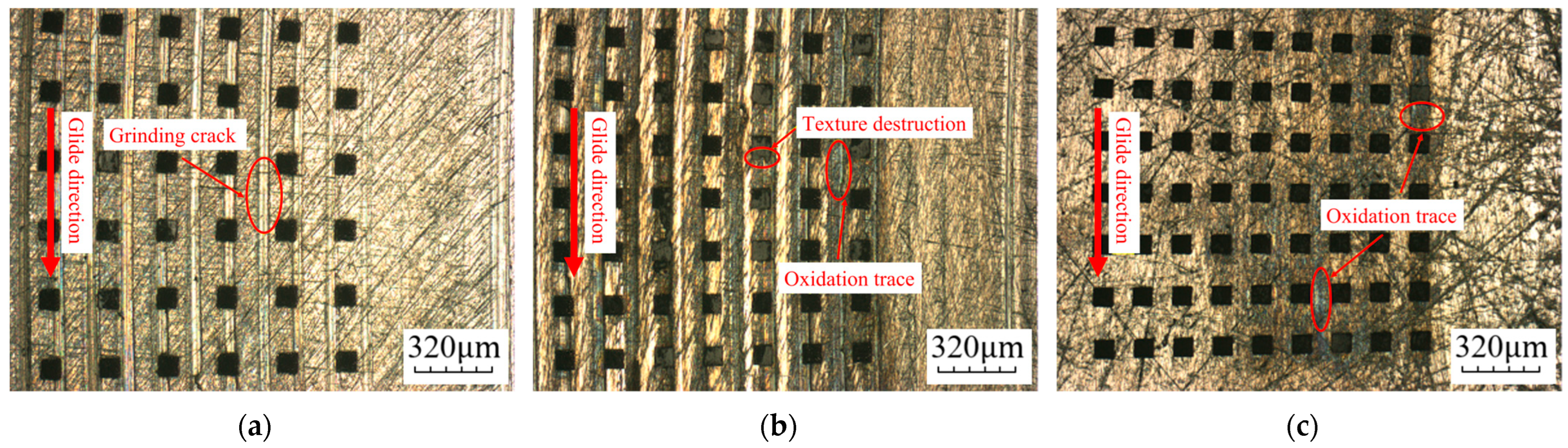

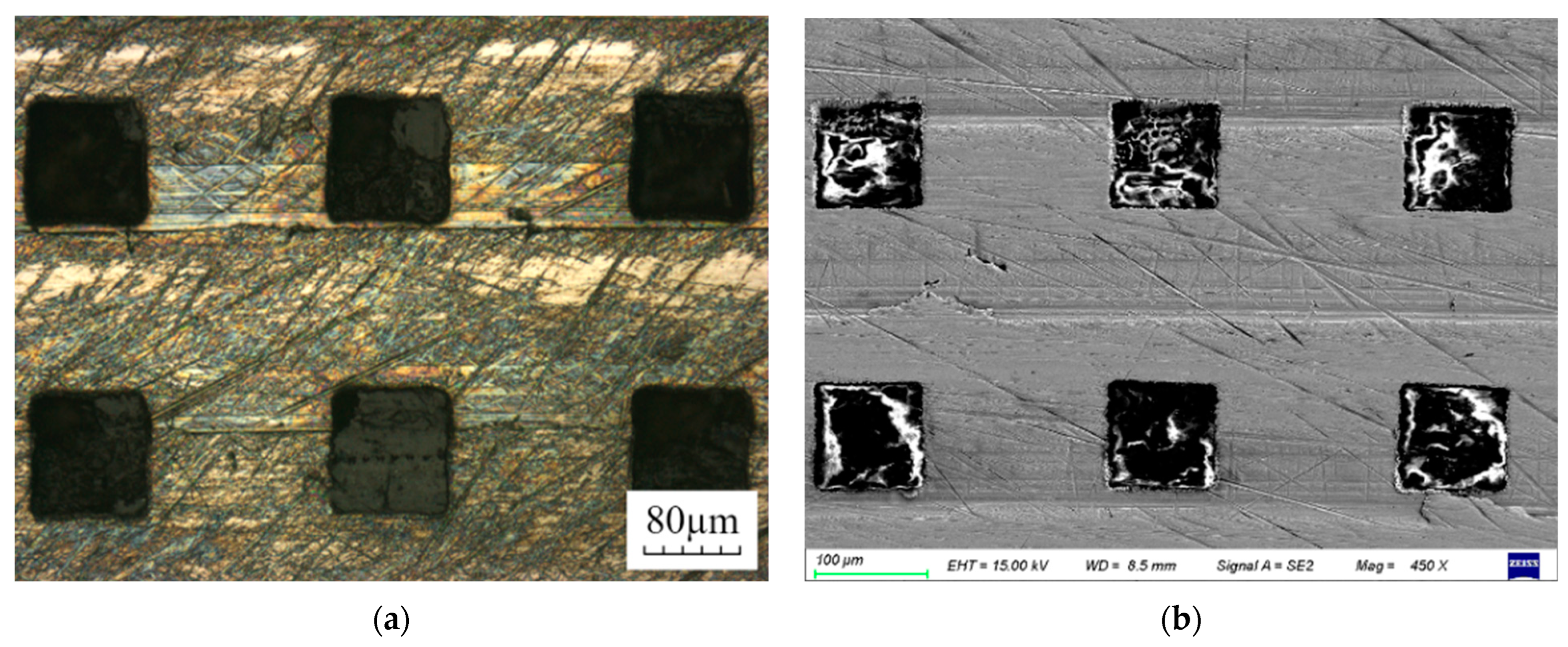

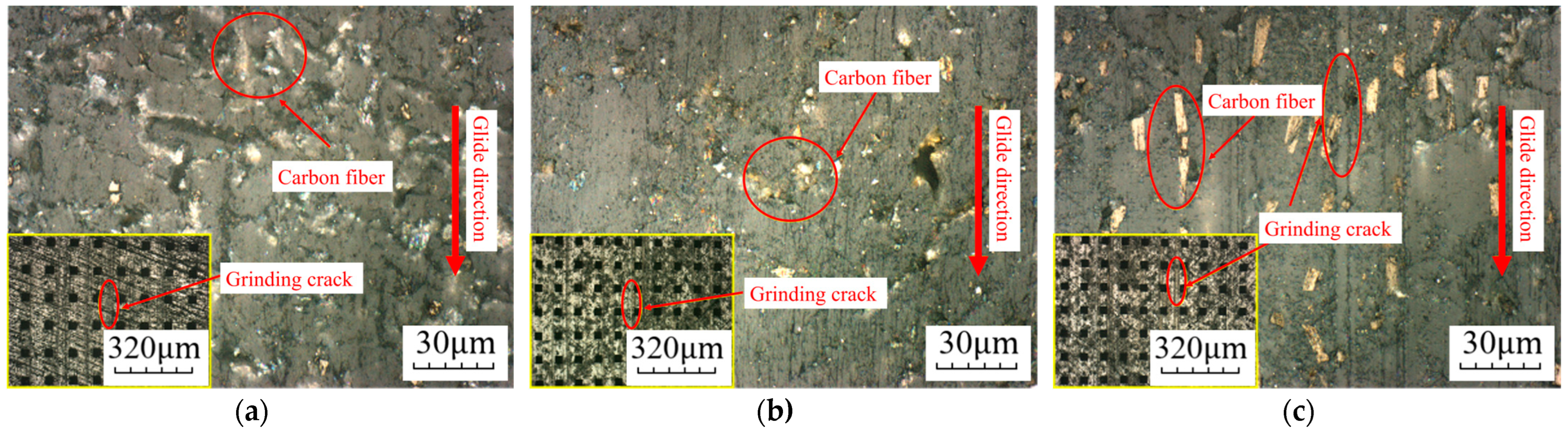

3.2.3. Wear Morphology

4. Conclusions

- Under the condition of a 1000 r/min rotational speed, the friction coefficient of the double-hydrophobic flow distribution pair is not the smallest, but, from the stability of the wear process, the temperature change of the lubricating medium, and the wear surface morphology, the friction and wear performance of the double-hydrophobic surface is the best. This is because the surface free energy of the double-hydrophobic surface is low, which is beneficial to the occurrence of boundary slip, and the velocity slip is generated between the solid–liquid interface, which greatly reduces the friction force and plays a wear-reducing effect.

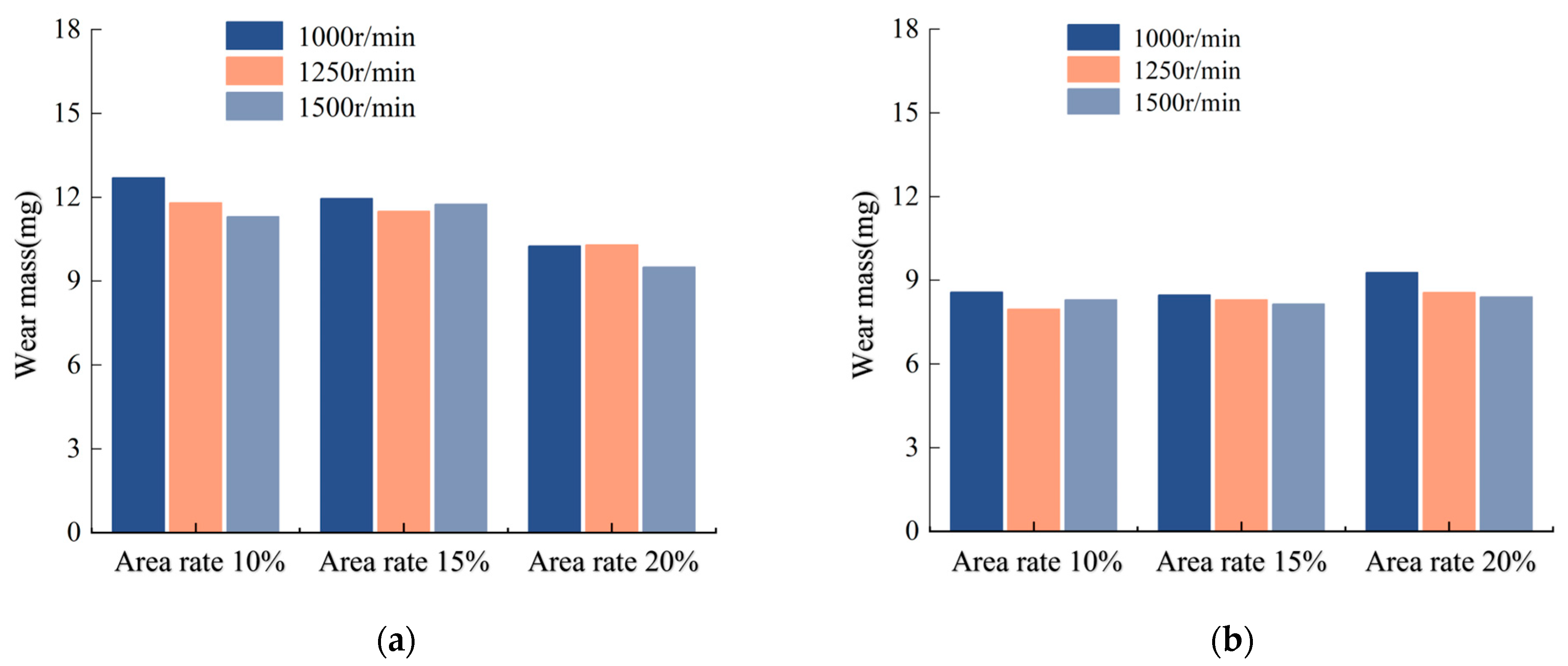

- The friction and wear properties of the combination of the smooth upper sample and the surface textured lower sample are better than the combination of the surface textured upper sample and the smooth lower sample, and the square cylindrical texture shows better anti-friction and wear resistance. The friction coefficient increases with the increase in the area ratio, and the friction coefficient increases with the increase in the rotational speed. Since the hardness of SAF2507 is higher than that of CF/PEEK, when the texture is processed on the upper sample, the texture edge will cut the softer surface of the lower sample during the relative motion process, causing certain damage to the surface of the lower sample. When the texture is processed in the lower sample, the texture edge will not have a cutting effect on the surface of the other sample, and it will not appear during the friction and wear process. The square cylindrical texture is superior to the cylindrical texture, because the fluid will flow along the cylindrical wall towards both sides after entering the cylindrical texture, so the dynamic pressure effect is not good, while the square cylindrical texture will not produce this phenomenon.

- Under seawater lubrication, the friction and wear reduction effect of the surface texture flow distribution pair is better than that of the surface coating. When the area ratio of texture on the sample is 10%, the wear is more serious. S-20% ST has better friction and wear performance.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Liang, Y.N.; Gao, D.R.; Chen, B. Friction and wear study on friction pairs with a biomimetic non-smooth surface of 316L relative to CF/PEEK under a seawater lubricated condition. Chin. J. Mech. Eng. 2019, 32, 66. [Google Scholar] [CrossRef]

- Cheng, B.X.; Duan, H.T.; Chen, Q. Effect of laser treatment on the tribological performance of polyetheretherketone (PEEK) under seawater lubrication. Appl. Surf. Sci. 2021, 566, 150668. [Google Scholar] [CrossRef]

- Ma, Z.H.; Nie, S.L.; Yin, F.L. Lifetime prediction of WC-6Ni/SiC friction pair under seawater lubrication using an Inverse Gaussian model. Ceram. Int. 2022, 48, 463–471. [Google Scholar] [CrossRef]

- Gheisari, R.; Polycarpou, A.A. Effect of surface microtexturing on seawater-lubricated contacts under starved and fully-flooded conditions. Tribol. Int. 2020, 148, 106339. [Google Scholar] [CrossRef]

- Pujar, V.; Devarajaiah, R.M.; Suresha, B.; Bharat, V. A review on mechanical and wear properties of fiber-reinforced thermoset composites with ceramic and lubricating fillers. Mater. Today Proc. 2021, 46, 7701–7710. [Google Scholar] [CrossRef]

- Hong, H.C.; Zhao, C.X.; Zhang, B. Flow Ripple Reduction of Axial-Piston Pump by Structure Optimizing of Outlet Triangular Damping Groove. Processes 2020, 8, 1664. [Google Scholar] [CrossRef]

- Jiang, J.H.; Wang, Z.B. Optimization and Influence of Micro-Chamfering on Oil Film Lubrication Characteristics of Slipper/Swashplate Interface within Axial Piston Pump. Energies 2021, 14, 1961. [Google Scholar] [CrossRef]

- Zhang, Z.H.; Nie, S.L.; Yuan, S.H. Comparative Evaluation of Tribological Characteristics of CF/PEEK and CF/PTFE/Graphite Filled PEEK Sliding against AISI630 Steel for Seawater Hydraulic Piston Pumps/Motors. Tribol. Trans. 2015, 58, 1096–1104. [Google Scholar] [CrossRef]

- Schuhler, G.; Jourani, A.; Bouvier, S. Efficacy of coatings and thermochemical treatments to improve wear resistance of axial piston pumps. Tribol. Int. 2018, 126, 376–385. [Google Scholar] [CrossRef]

- Zhao, J.G.; Fu, Y.L.; Wang, M.K. Experimental research on tribological characteristics of TiAlN coated valve plate in electro-hydrostatic actuator pumps. Tribol. Int. 2021, 155, 106782. [Google Scholar] [CrossRef]

- Wu, D.F.; Liu, Y.S.; Zhao, X.F. The Tribological Behaviors of Different Mass Ratio Al2O3-TiO2 Coatings in Water Lubrication Sliding against Si3N4. Tribol. Trans. 2016, 59, 352–362. [Google Scholar] [CrossRef]

- Fesanghary, M.; Khonsari, M.M. On the optimum groove shapes for load-carrying capacity enhancement in parallel flat surface bearings: Theory and experiment. Tribol. Int. 2013, 67, 254–262. [Google Scholar] [CrossRef]

- He, T.; Zhu, D.; Wang, J.X. Experimental and Numerical Investigations of the Stribeck Curves for Lubricated Counterformal Contacts. J. Tribol. 2017, 139, 021505. [Google Scholar] [CrossRef]

- Ryk, G.; Etsion, I. Testing piston rings with partial laser surface texturing for friction reduction. Wear 2006, 261, 792–796. [Google Scholar] [CrossRef]

- Zhang, H.; Zhang, D.Y.; Hua, M. A Study on the Tribological Behavior of Surface Texturing on Babbitt Alloy under Mixed or Starved Lubrication. Tribol. Lett. 2014, 56, 305–315. [Google Scholar] [CrossRef]

- Kovalchenko, A.; Ajayi, O.; Erdemir, A. The effect of laser surface texturing on transitions in lubrication regimes during unidirectional sliding contact. Tribol. Int. 2005, 38, 219–225. [Google Scholar] [CrossRef]

- Amanov, A.; Tsuboi, R.; Oe, H. The influence of bulges produced by laser surface texturing on the sliding friction and wear behavior. Tribol. Int. 2013, 60, 216–223. [Google Scholar] [CrossRef]

- Pettersson, U.; Jacobson, S. Influence of surface texture on boundary lubricated sliding contacts. Tribol. Int. 2003, 36, 857–864. [Google Scholar] [CrossRef]

- Gu, C.; Meng, X.; Xie, Y. Effects of surface texturing on ring/liner friction under starved lubrication. Tribol. Int. 2016, 94, 591–605. [Google Scholar] [CrossRef]

- Han, J.; Fang, L.; Sun, J. Hydrodynamic lubrication of microdimple textured surface using three-dimensional CFD. Tribol. Trans. 2010, 53, 860–870. [Google Scholar] [CrossRef]

- Vladescu, S.C.; Medina, S.; Olver, A.V. Lubricant film thickness and friction force measurements in a laser surface textured reciprocating line contact simulating the piston ring–liner pairing. Tribol. Int. 2016, 98, 317–329. [Google Scholar] [CrossRef]

- Zhang, J.; Meng, Y. Direct observation of cavitation phenomenon and hydrodynamic lubrication analysis of textured surfaces. Tribol. Lett. 2012, 46, 147–158. [Google Scholar] [CrossRef]

- Rosenkranz, A.; Costa, H.; Profito, F. Influence of surface texturing on hydrodynamic friction in plane converging bearings—An experimental and numerical approach. Tribol. Int. 2019, 134, 190–204. [Google Scholar] [CrossRef]

- Xing, Y.; Li, X.; Hu, R. Numerical analyses of rectangular micro-textures in hydrodynamic lubrication regime for sliding contacts. Meccanica 2021, 56, 365–382. [Google Scholar] [CrossRef]

- Liu, W.; Ni, H.; Chen, H. Numerical simulation and experimental investigation on tribological performance of micro-dimples textured surface under hydrodynamic lubrication. Int. J. Mech. Sci. 2019, 163, 105095. [Google Scholar] [CrossRef]

- Janssen, A.; Pinedo, B.; Igartua, A. Study on friction and wear reducing surface micro-structures for a positive displacement pump handling highly abrasive shale oil. Tribol. Int. 2017, 107, 1–9. [Google Scholar] [CrossRef]

- Zhang, J.H.; Chen, Y.; Xu, B. Effect of surface texture on wear reduction of the tilting cylinder and the valve plate for a high-speed electro-hydrostatic actuator pump. Wear 2018, 414–415, 68–78. [Google Scholar] [CrossRef]

| Element | Content/% |

|---|---|

| C | ≤0.03 |

| Mn | ≤1.20 |

| Si | ≤0.8 |

| S | ≤0.02 |

| P | ≤0.035 |

| Cr | 24.0–26.0 |

| Ni | 6.0–8.0 |

| Mo | 3.0–5.0 |

| Cu | ≤0.5 |

| N | 0.24–0.32 |

| Fe | Bal. |

| Density/(g/cm3) | Elasticity Modulus /GPa | Brinell Hardness /HB | Elongation /% | Thermal Conductance/(W·m−1·k−1) | Coefficient of Thermal Expansion/(10−6·°C−1) | Tensile Strength/MPa | Yield Strength/MPa |

|---|---|---|---|---|---|---|---|

| 8.03 | 200 | 310 | 20 | 15 | 13 | 795 | 550 |

| Density/(g/cm3) | Water Absorption (24 h)/% | Rockwell Hardness/HRR | Heat Distortion Temperature/°C | Coefficient of Thermal Expansion/(10−6·°C−1) | Tensile Strength/MPa | Bending Strength/MPa | Compressive Strength/MPa |

|---|---|---|---|---|---|---|---|

| 1.4 | 0.06 | 107 | 315 | 1.5 | 220 | 298 | 240 |

| The Upper Sample | The Lower Sample | Abbreviation |

|---|---|---|

| SAF2507 | CF/PEEK | S-CP |

| SAF2507 | Low-surface-energy CF/PEEK | S-LCP |

| Low-surface-energy SAF2507 | CF/PEEK | LS-CP |

| Low-surface-energy SAF2507 | Low-surface-energy CF/PEEK | LS-LCP |

| The Upper Sample | The Lower Sample | Abbreviation |

|---|---|---|

| Cylindrical textured surface | Smooth surface | CT-S |

| Square cylindrical textured surface | Smooth surface | ST-S |

| Smooth surface | Cylindrical textured surface | S-CT |

| Smooth surface | Square cylindrical textured surface | S-ST |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liang, Y.; Zhang, Z.; Liu, X.; Shen, M.; Wang, W.; Xing, H.; Wang, C.; Gao, D. Experimental Study on Tribological Properties of Coated Surface and Textured Surface under Seawater Lubrication Conditions. Coatings 2024, 14, 415. https://doi.org/10.3390/coatings14040415

Liang Y, Zhang Z, Liu X, Shen M, Wang W, Xing H, Wang C, Gao D. Experimental Study on Tribological Properties of Coated Surface and Textured Surface under Seawater Lubrication Conditions. Coatings. 2024; 14(4):415. https://doi.org/10.3390/coatings14040415

Chicago/Turabian StyleLiang, Yingna, Zhepeng Zhang, Xiaohui Liu, Miaomiao Shen, Wei Wang, Hao Xing, Cunyuan Wang, and Dianrong Gao. 2024. "Experimental Study on Tribological Properties of Coated Surface and Textured Surface under Seawater Lubrication Conditions" Coatings 14, no. 4: 415. https://doi.org/10.3390/coatings14040415