Evaluation and Characterization of Ultrasonic Cutting of Monofilament Nylon

Abstract

1. Introduction

2. Monofilament Nylon Cutting

3. Cutting Force Analysis

4. Micromorphological Characteristics of Cut Nylon End Face

4.1. Monofilament Nylon Sample

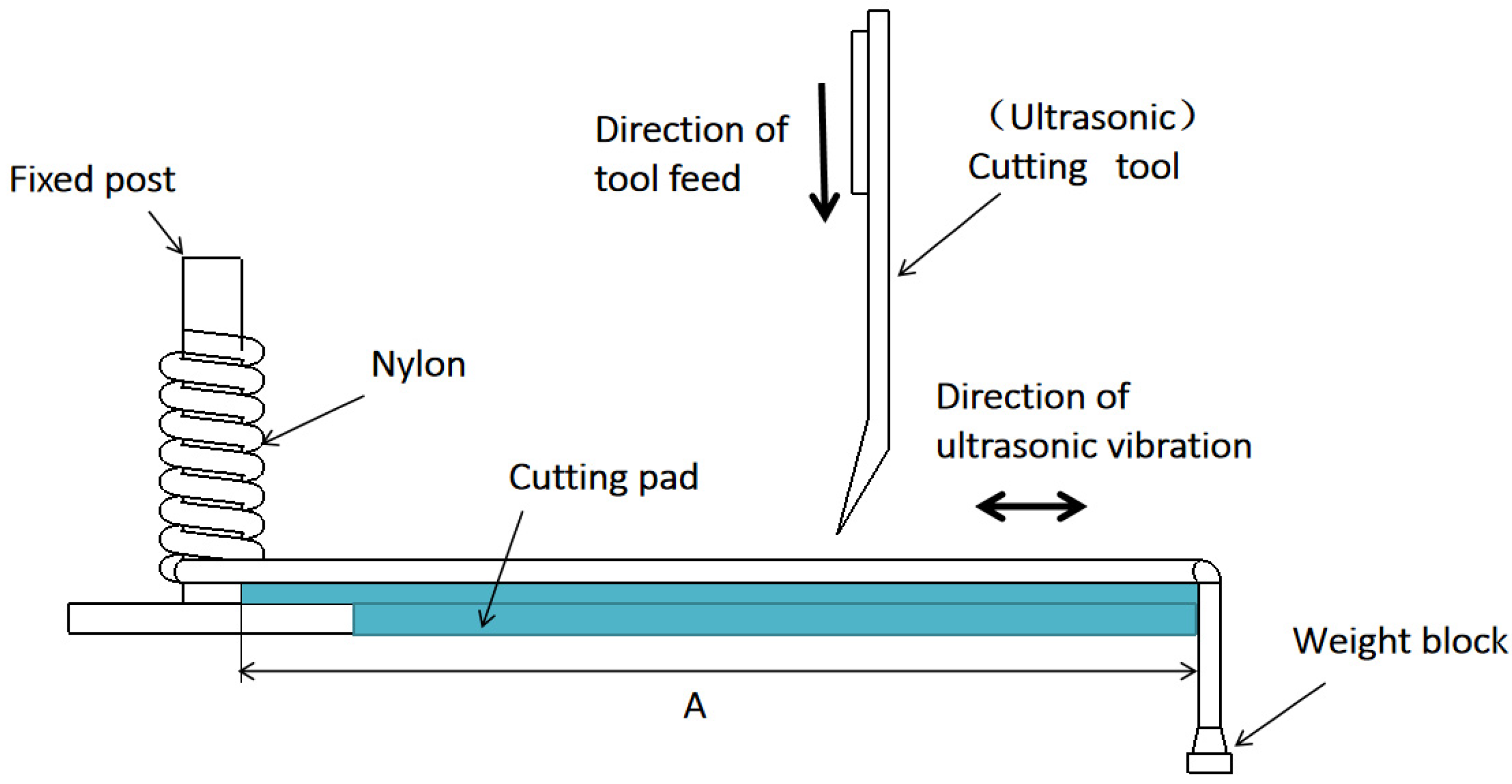

4.2. Cutting Test

4.3. Nylon Sample Morphology without Added Tension

4.4. Micromorphology of Nylon with Added Tension

- (1)

- Nylon end face morphological characteristics

- (2)

- Nylon edge morphological characteristics

5. Conclusions

- (1)

- Conventional cutting is performed through a one-dimensional feed movement. Ultrasonic cutting involves small movements in a two-dimensional plane for a tool to complete the cutting of monofilament nylon samples and obtain high-quality cutting end faces, making it a feasible and convenient processing method.

- (2)

- Ultrasonic cutting can overcome curling deformation caused by the extrusion of the tool. In addition, the edge shows no fracture or collapse, and the end face maintains a good shape without obvious deformation.

- (3)

- Moreover, ultrasonic cutting can eliminate the dependence of the cutting quality on the position relationship between the cutter and nylon under appropriate tension. For a given tension, increasing the feed speed of the cutter can improve the cutting quality, with the increase in the ratio of the end face topography being 1.7 times compared with conventional cutting.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Prakash, N.; Vuppala, G.K.; Maddineni, A.B.P.R.; Narra, G.; Bhimavarapu, C.R.; Chandran, P.; Sathyamurthy, R. Investigation on structural analysis of a regenerative shock absorber using nylon material. Mater. Today Proc. 2021, 46, 363–368. [Google Scholar] [CrossRef]

- Agarwal, J.; Sahoo, S.; Mohanty, S.; Nayak, S.K. Progress of novel techniques for lightweight automobile applications through innovative eco-friendly composite materials: A review. J. Thermoplast. Compos. Mater. 2020, 33, 978–1013. [Google Scholar] [CrossRef]

- Lee, Y.M.; You, J.; Kim, M.; Kim, T.A.; Lee, S.-S.; Bang, J.; Park, J.H. Highly improved interfacial affinity in carbon fiber-reinforced polymer composites via oxygen and nitrogen plasma-assisted mechanochemistry. Compos. Part B Eng. 2019, 165, 725–732. [Google Scholar] [CrossRef]

- Yu, Y.; Hua, P.H.; Li, Q.D.; Ling, G.P. Relationship between incision morphology of nylon wire and sharpness of rotary shaver. Phys. Chem. Test. Phys. 2015, 51, 874–879. [Google Scholar] [CrossRef]

- Jagtap, T.; Mandave, H. Experimental Investigation and Optimization of Cutting Parameters on Surface Roughness and Material Removal Rate in Turning of Nylon 6 Polymer. Mater. Sci. Eng. 2016, 4, 236–246. [Google Scholar]

- Nguyen, H.C.; Nagasawa, S. Experimental and Numerical Investigation of Cutting Characteristics of PA6/PE Nylon Film Subjected to Wedge Indentation Process. Mater. Sci. Forum 2020, 1009, 129–134. [Google Scholar] [CrossRef]

- Park, Y.H.; Go, J.S.; Chae, B.G.; Lee, S.H.; Oh, H.U. Functional Verification of Nylon Wire Cutting-Type Holding & Release Mechanism for 6U CubeSat’s Solar Panel. J. Korean Soc. Aeronaut. Space Sci. 2018, 46, 867–875. [Google Scholar] [CrossRef]

- Suksawat, B. Experimental Investigations of Cutting Conditions Influence on Main Cutting Force and Surface Roughness Based on Chip Form Types in Cast Nylon Turning. Appl. Mech. Mater. 2011, 110–116, 3563–3569. [Google Scholar] [CrossRef]

- Tangwarodomnukun, V.; Khamwiset, K.; Qi, H. Investigation into laser machining of carbon fiber reinforced plastic in a flowing water layer. Int. J. Adv. Manuf. Technol. 2019, 104, 3629–3645. [Google Scholar] [CrossRef]

- Ozkan, D.; Panjan, P.; Gok, M.S.; Karaoglanli, A.C. Investigation of machining parameters that affects surface roughness and cutting forces in milling of CFRPs with TiAlN and TiN coated carbide cutting tools. Mater. Res. Express 2019, 6, 095616. [Google Scholar] [CrossRef]

- Liu, Y.; Geng, D.; Shao, Z.; Zhou, Z.; Jiang, X.; Zhang, D. A study on strengthening and machining integrated ultrasonic peening drilling of Ti-6Al-4V. Mater. Des. 2021, 212, 110238. [Google Scholar] [CrossRef]

- Xiuxiu, H.U.; Xiaoping, Y.U.; Baohua, W.U.; Shengyou, X. Research on Ultrasonic Cutting Mechanism of Nomex Honeycomb Composites Based on Fracture Mechanics. J. Mech. Eng. 2015, 51, 205–212. [Google Scholar] [CrossRef]

- Xun, Z.; Zhigang, D.; Yidan, W.; Zengdi, X.; Hongxia, S.; Renke, K. Charization of Surface Microscopic of Nomex Honeycomb after Ultrasonic Assisted Cutting. J. Mech. Eng. 2017, 53, 90–99. [Google Scholar] [CrossRef]

- Sun, J.; Dong, Z.; Wang, Y.; Liu, J.; Qin, Y.; Kang, R. Experimental Study on Ultrasonic Cutting of Aluminum Honeycombs. J. Mech. Eng. 2017, 53, 128–135. [Google Scholar] [CrossRef]

- Shu, J.; Liao, W.; Zheng, K.; Hussein Youssef, A.M.F. Surface morphology on carbon fiber composites by rotary ultrasonic milling. Mach. Sci. Technol. 2021, 25, 721–737. [Google Scholar] [CrossRef]

| Material | Diameter (mm) | Tensile Strength (MPa) | Density (g/cm3) | Elastic Modulus |

|---|---|---|---|---|

| Nylon | 0.46 | 943.5 | 1.13 | 0.28 |

| Cutting Method | Group | Tension (N) | Cutting Speed (mm/s) |

|---|---|---|---|

| General cutting | 1 | 17.15 | 3.125 |

| 6.25 | |||

| 12.5 | |||

| 25 | |||

| 2 | 12.25 | 12.5 | |

| 14.7 | |||

| 17.15 | |||

| Ultrasonic cutting | 1 | 17.15 | 3.125 |

| 6.25 | |||

| 12.5 | |||

| 25 | |||

| 2 | 12.25 | 12.5 | |

| 14.7 | |||

| 17.15 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, H.; Shen, Z.; Cao, Z.; Hou, D.; Jiang, T.; Ye, X. Evaluation and Characterization of Ultrasonic Cutting of Monofilament Nylon. Coatings 2024, 14, 462. https://doi.org/10.3390/coatings14040462

Zhang H, Shen Z, Cao Z, Hou D, Jiang T, Ye X. Evaluation and Characterization of Ultrasonic Cutting of Monofilament Nylon. Coatings. 2024; 14(4):462. https://doi.org/10.3390/coatings14040462

Chicago/Turabian StyleZhang, Hainan, Zhihuang Shen, Zhonghe Cao, Dapan Hou, Tao Jiang, and Xianzhen Ye. 2024. "Evaluation and Characterization of Ultrasonic Cutting of Monofilament Nylon" Coatings 14, no. 4: 462. https://doi.org/10.3390/coatings14040462

APA StyleZhang, H., Shen, Z., Cao, Z., Hou, D., Jiang, T., & Ye, X. (2024). Evaluation and Characterization of Ultrasonic Cutting of Monofilament Nylon. Coatings, 14(4), 462. https://doi.org/10.3390/coatings14040462