Approach to Heterogeneous Surface Roughness Evaluation for Surface Coating Preparation

Abstract

1. Introduction

2. Materials and Methods

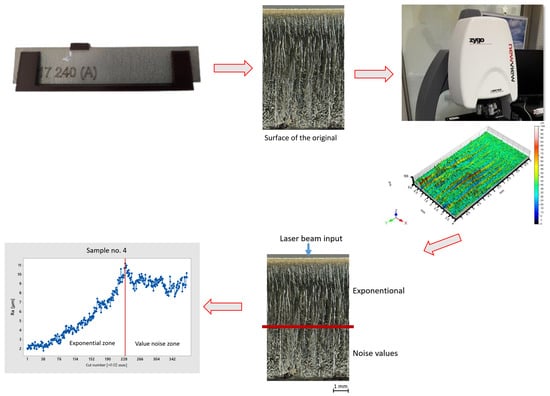

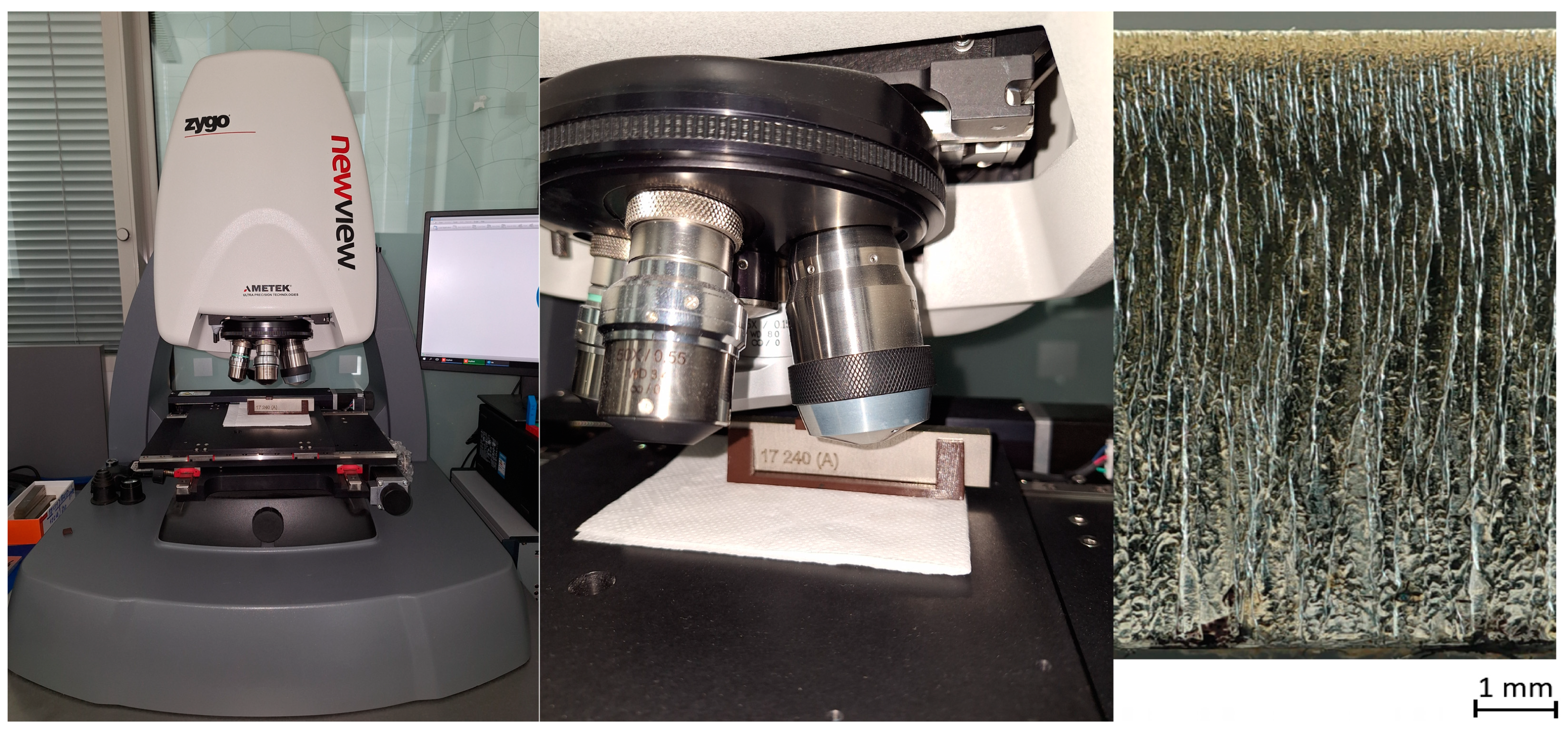

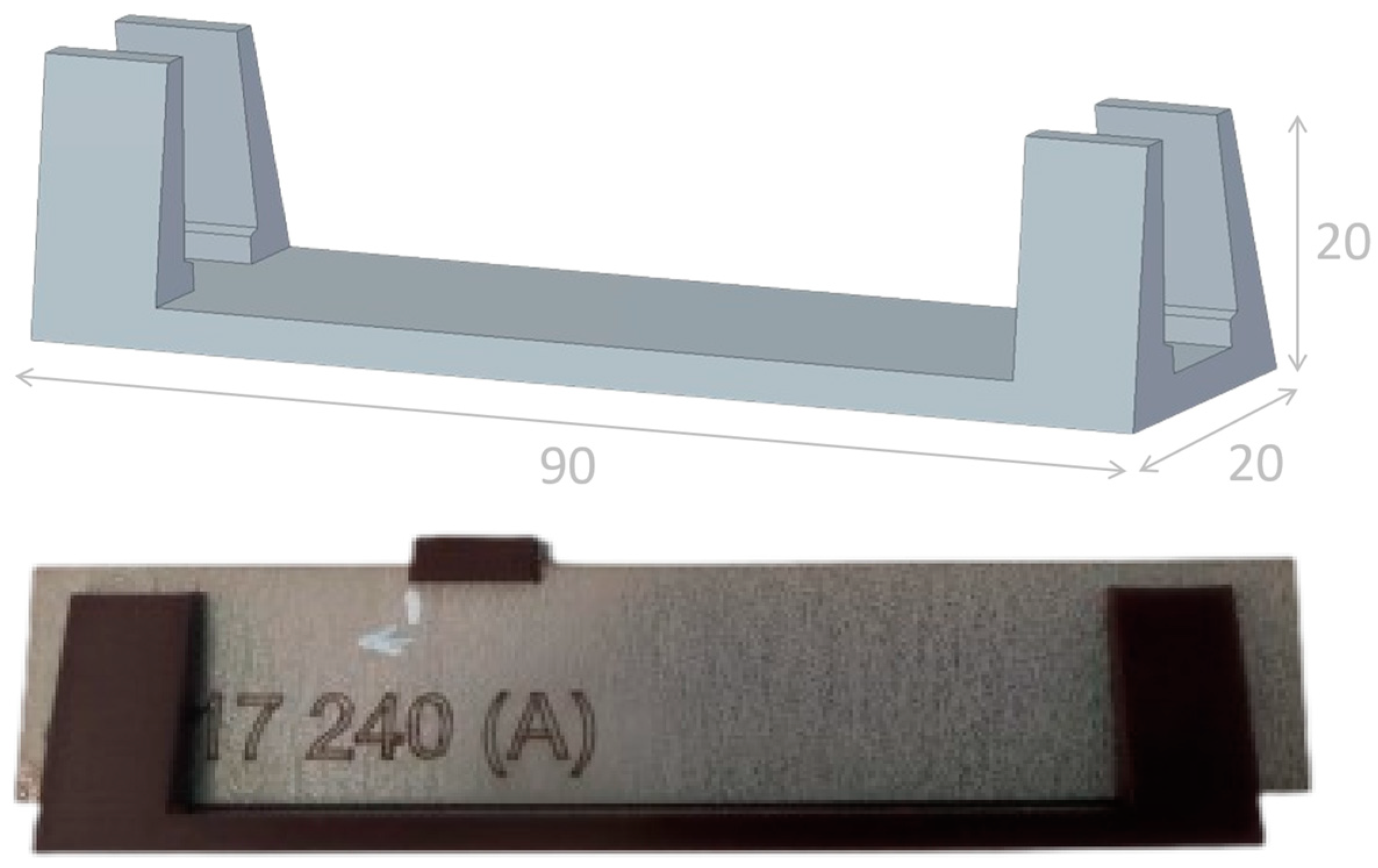

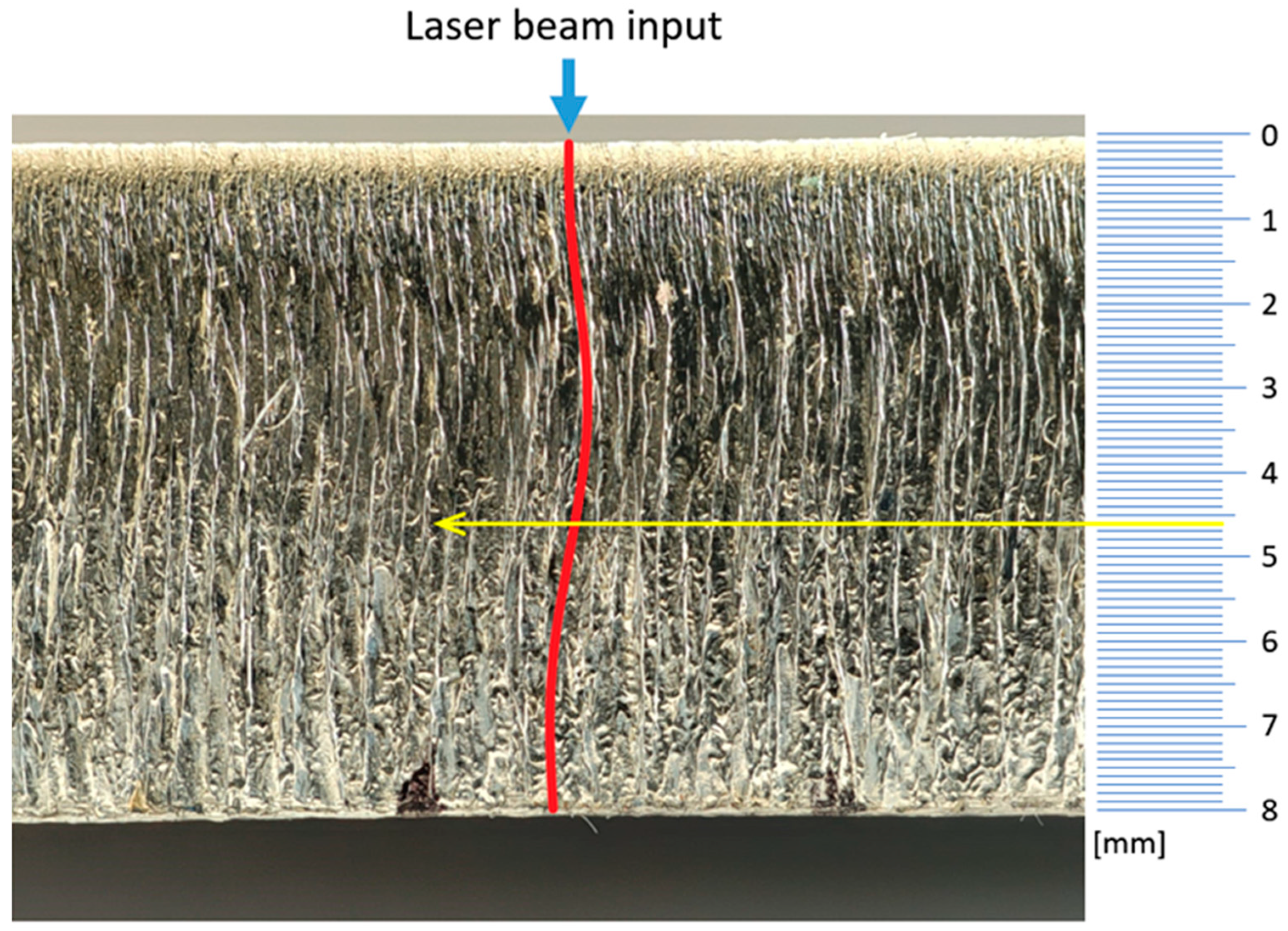

2.1. Sample Preparation for Measurement

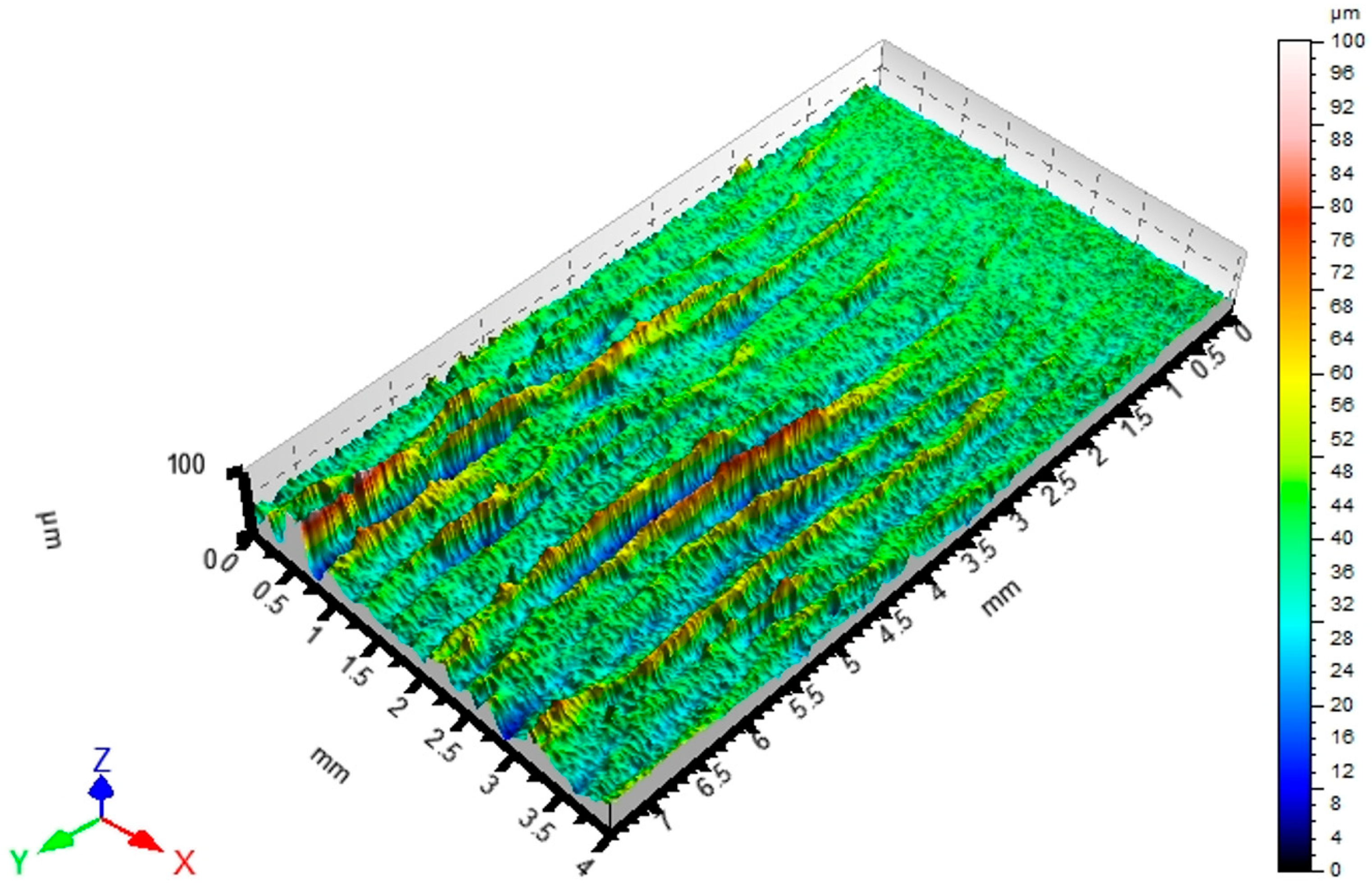

2.2. Data Obtainment

3. Results

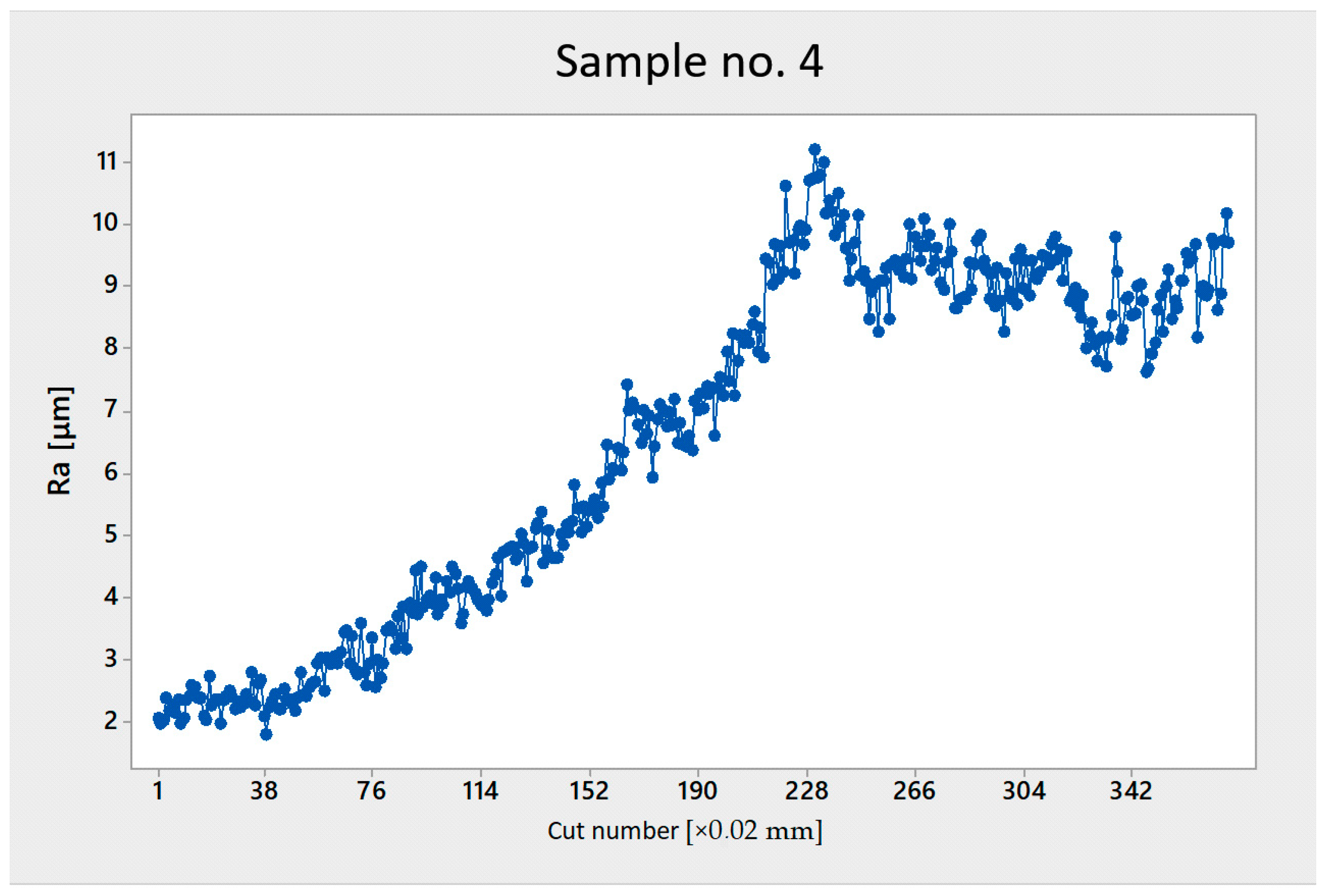

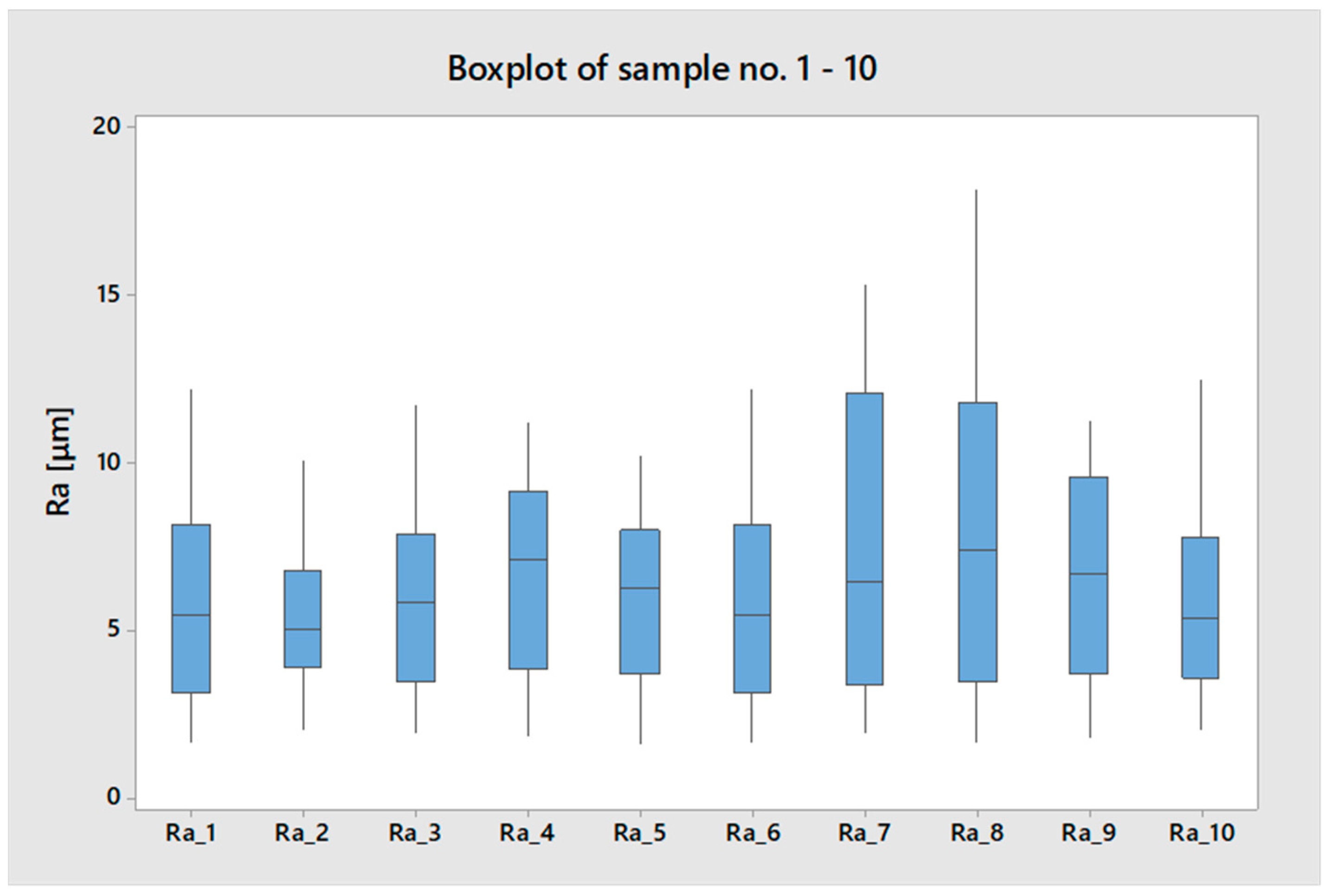

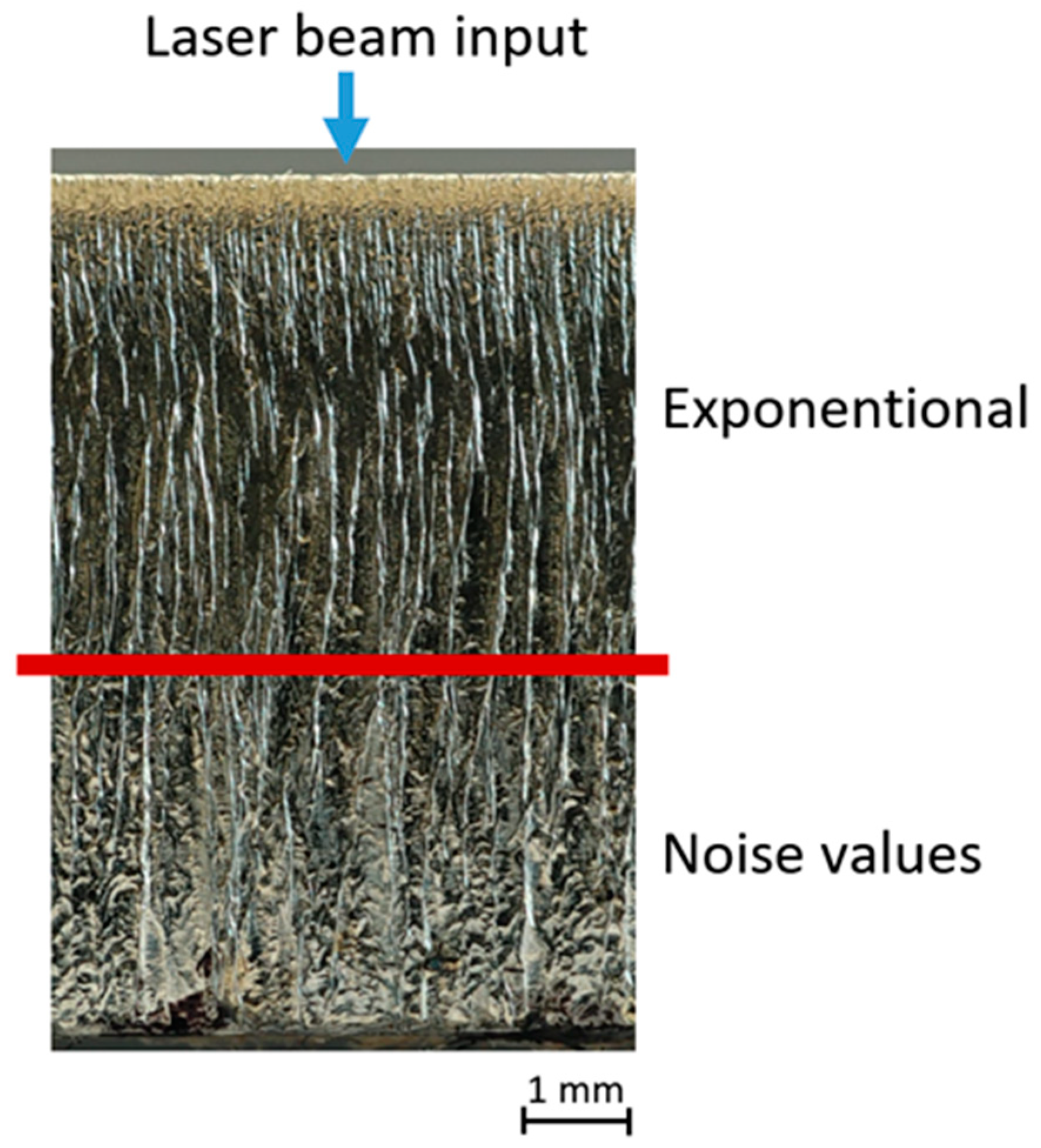

3.1. Exploratory Data Analysis (EDA)

3.2. Further Data Exploration

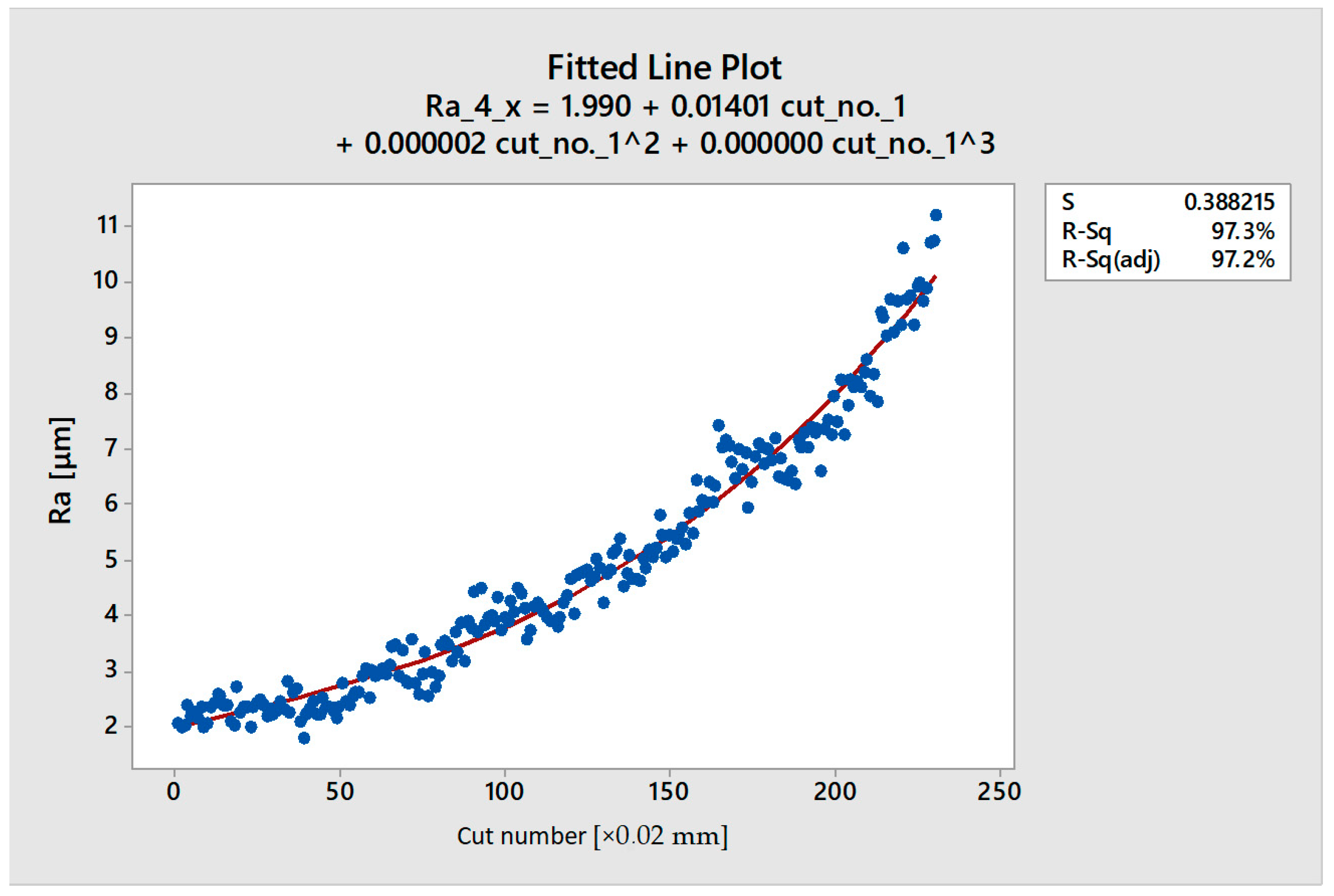

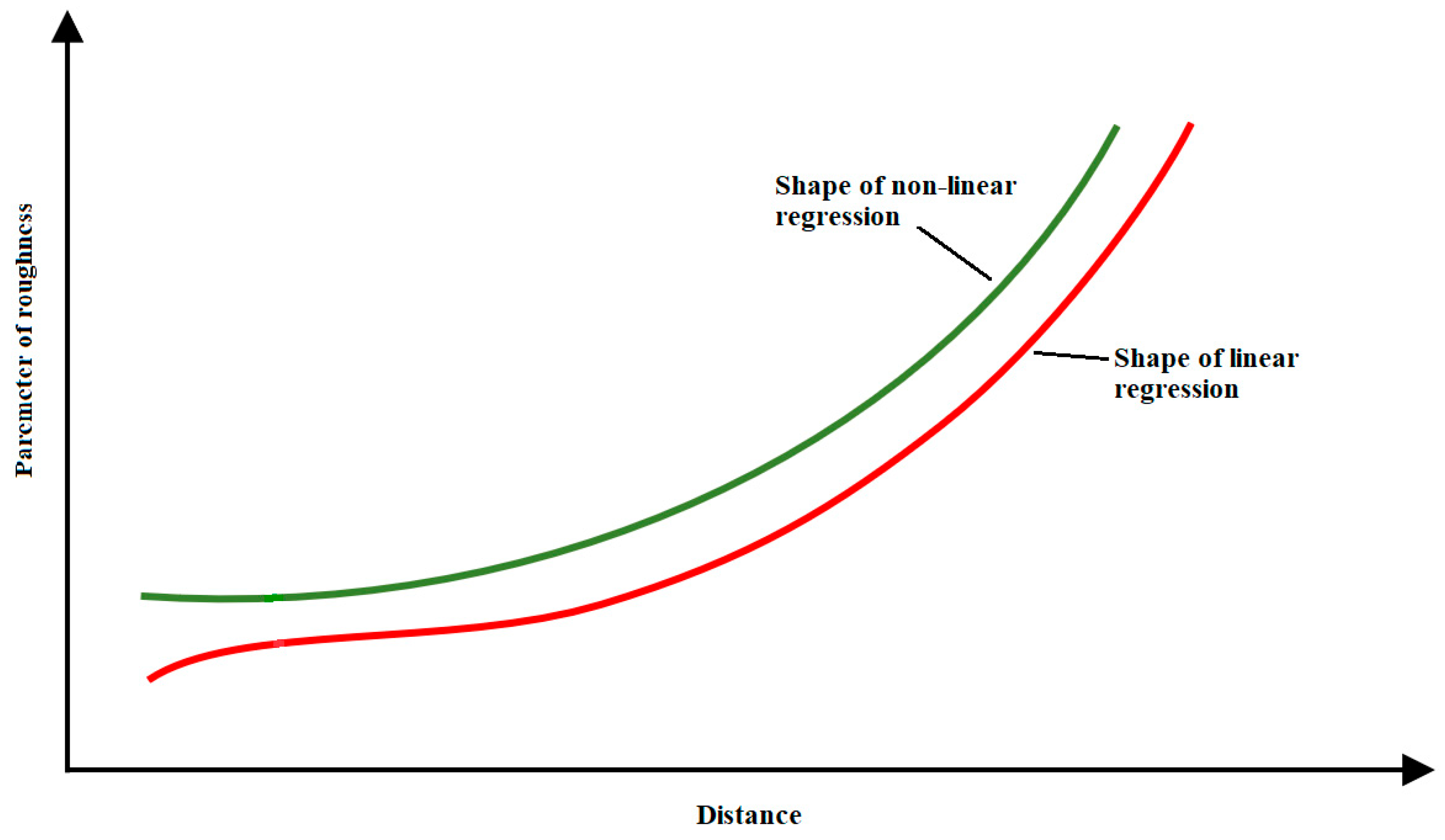

3.3. Linear Regression

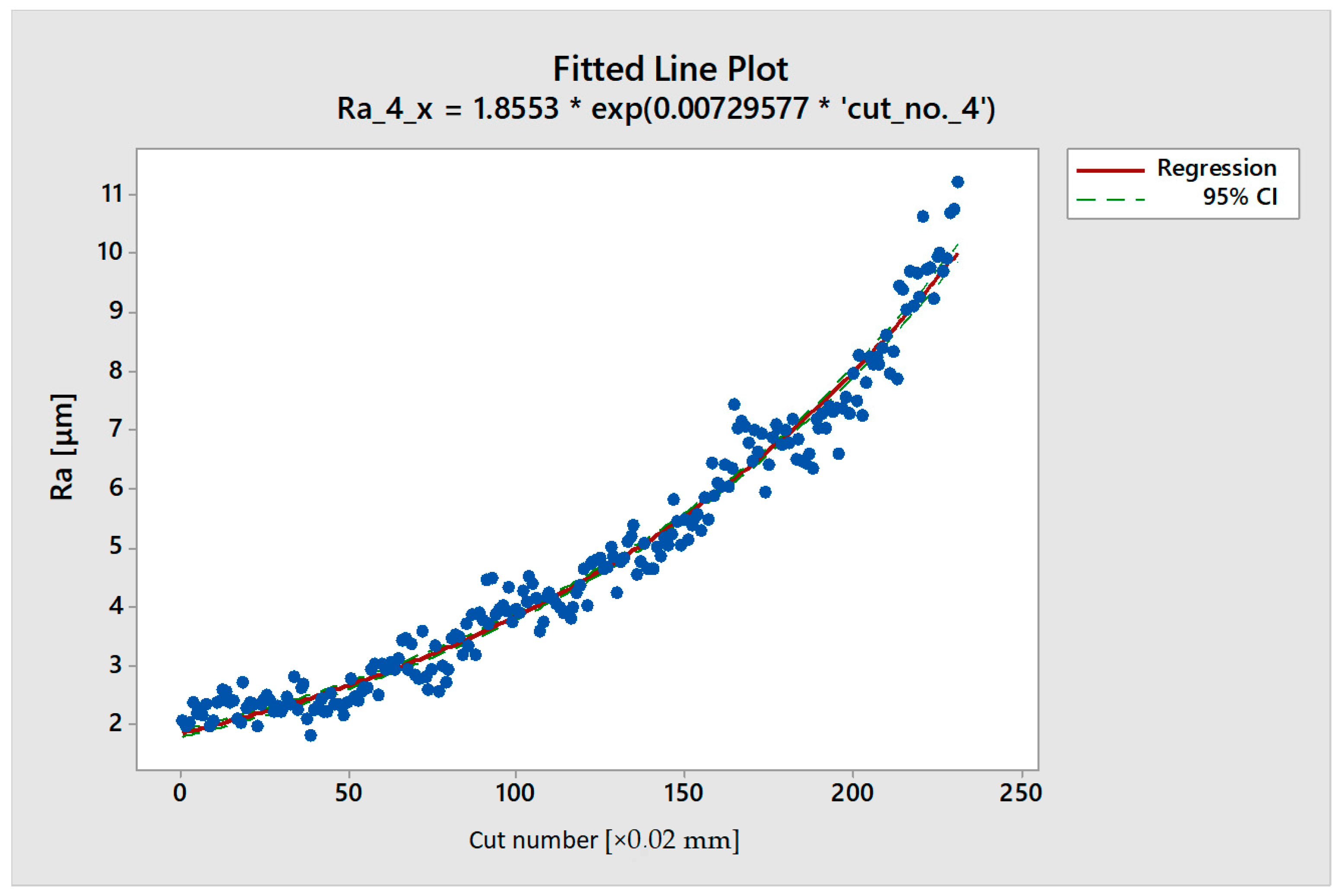

3.4. Non-Linear Regression

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Nazarpour, S. Introduction: What Are Coatings? In Thin Films and Coatings in Biology; Biological and Medical Physics, Biomedical Engineering; Springer: Dordrecht, The Netherlands, 2013; pp. 1–9. ISBN 978-94-007-2591-1. [Google Scholar]

- Pedroso, A.F.V.; Sousa, V.F.C.; Sebbe, N.P.V.; Silva, F.J.G.; Campilho, R.D.S.G.; Sales-Contini, R.C.M.; Jesus, A.M.P. A Comprehensive Review on the Conventional and Non-Conventional Machining and Tool-Wear Mechanisms of Inconel®. Metals 2023, 13, 585. [Google Scholar] [CrossRef]

- Xu, Y.; Jiang, Y.; Xie, J.; Xu, Q.; Fei, H.; Lu, Y.; Gong, J. Effect of Temperature, Vacuum Condition and Surface Roughness on Oxygen Boost Diffusion of Ti–6Al–4V Alloy. Coatings 2024, 14, 314. [Google Scholar] [CrossRef]

- Mičietová, A.; Neslušan, M.; Florková, Z.; Čilliková, M. Analysis of the Coating Delamination after Laser Beam Cutting. Manuf. Technol. 2023, 23, 670–675. [Google Scholar] [CrossRef]

- Bohdal, Ł.; Schmidtke, D. Effect of Fiber and CO2 Lasers Parameters on the Cut Surface Quality of Rvs 1.4301 Stainless Steel. J. Mech. Eng. Sci. 2022, 16, 8862–8872. [Google Scholar] [CrossRef]

- Wala, T.; Lis, K. Influence of Selected Diagnostic Parameters on the Quality of Awj Cutting Surface. Adv. Sci. Technol. Res. J. 2022, 16, 129–140. [Google Scholar] [CrossRef] [PubMed]

- Basmacı, G.; Kayacan, M.Y.; Ay, M.; Etyemez, A. Optimization of Cutting Forces and Surface Roughness via Anova and Grey Relational Analysis in Machining of In718. Open Chem. 2023, 21, 129–140. [Google Scholar] [CrossRef]

- Bautista, A.; Sáez-Maderuelo, A.; Monrrabal, G.; Ruiz-Lorenzo, M.L.; Perosanz, F.J.; Maffiotte, C.; Volpe, L.; Scenini, F.; Maurotto, A.; Halodová, P.; et al. Surface Characterization and Electrochemical Behavior of Aisi 316L Stainless Steel Machined with Green Supercritical CO2 Coolant. J. Mater. Eng. Perform. 2023, 21, 129–140. [Google Scholar] [CrossRef]

- Chmielewski, T.; Hudycz, M.; Krajewski, A.; Sałaciński, T.; Skowrońska, B.; Świercz, R.; Volpe, L.; Scenini, F.; Maurotto, A.; Halodová, P.; et al. Structure Investigation of Titanium Metallization Coating Deposited onto Aln Ceramics Substrate by Means of Friction Surfacing Process. Coatings 2019, 9, 129–140. [Google Scholar] [CrossRef]

- Patel, P.; Nakum, B.; Abhishek, K.; Rakesh Kumar, V. Machining Performance Optimization during Plasma Arc Cutting of Aisi D2 Steel: Application of Fis, Nonlinear Regression and Jaya Optimization Algorithm. J. Braz. Soc. Mech. Sci. Eng. 2018, 40, 240. [Google Scholar] [CrossRef]

- Anghel, C.; Gupta, K.; Jen, T.C. Analysis and Optimization of Surface Quality of Stainless Steel Miniature Gears Manufactured by CO2 Laser Cutting. Optik 2020, 203, 164049. [Google Scholar] [CrossRef]

- Kechagias, J.D.; Ninikas, K.; Petousis, M.; Vidakis, N. Laser Cutting of 3D Printed Acrylonitrile Butadiene Styrene Plates for Dimensional and Surface Roughness Optimization. Int. J. Adv. Manuf. Technol. 2022, 119, 2301–2315. [Google Scholar] [CrossRef]

- Kechagias, J.D.; Tsiolikas, A.; Petousis, M.; Ninikas, K.; Vidakis, N.; Tzounis, L. A Robust Methodology for Optimizing the Topology and the Learning Parameters of an Ann For Accurate Predictions of Laser-Cut Edges Surface Roughness. Simul. Model. Pract. Theory 2022, 114, 102414. [Google Scholar] [CrossRef]

- Biermann, D.; Steiner, M.; Krebs, E. Investigation of Different Hard Coatings for Micromilling of Austenitic Stainless Steel. Procedia CIRP 2013, 7, 246–251. [Google Scholar] [CrossRef]

- ISO 21920-2:2021; Specifications, Geometrical Product. “Surface Texture: Profile—Part 2: Terms, Definitions and Surface Texture Parameters”. International Organization for Standardization: Geneva, Switzerland, 2021. Available online: https://www.iso.org/standard/72226.html (accessed on 10 March 2024).

- Marek, M.; Novák, M.; Šramhauser, K. The Impact of Changes in Infeed Rate on Surface Integrity after Chrome Plate Grinding by Microcrystalline Corundum. Manuf. Technol. 2019, 19, 461–468. [Google Scholar] [CrossRef]

- Timárová, Ľ.; Breznická, A.; Kopiláková, B. Application of the Method of Planned Experiment for the Evaluation of the Surface Roughness Parameter Ra. Manuf. Technol. 2023, 23, 348–353. [Google Scholar] [CrossRef]

- Allen, T.T.; Sui, Z.; Akbari, K.; Silva, F.J.G.; Campilho, R.D.S.G.; Sales-Contini, R.C.M.; Jesus, A.M.P. Exploratory Text Data Analysis for Quality Hypothesis Generation. Qual. Eng. 2018, 30, 701–712. [Google Scholar] [CrossRef]

| N | 376 |

|---|---|

| Mean | 7.343 [μm] |

| Se Mean | 0.220 [μm] |

| St. Dev. [σ] | 4.263 [μm] |

| Minimum | 1.943 [μm] |

| Q1 | 3.368 [μm] |

| Median | 6.457 [μm] |

| Q3 | 12.052 [μm] |

| Maximum | 15.264 [μm] |

| R-Sq(adj) [%] | ||

|---|---|---|

| Quadratic | Cubic | |

| Ra_1 | 95.4 | 97.7 |

| Ra_2 | 81.6 | 90.6 |

| Ra_3 | 84.2 | 87.5 |

| Ra_4 | 97.1 | 97.2 |

| Ra_5 | 89.9 | 90.3 |

| Ra_6 | 95.4 | 97.7 |

| Ra_7 | 97.1 | 97.9 |

| Ra_8 | 97.8 | 98.0 |

| Ra_9 | 96.6 | 96.9 |

| Ra_10 | 93.8 | 96.5 |

| Exponential Reg. Model | |||

|---|---|---|---|

| MSE | S | Iterations | |

| Ra_1 | 0.38 | 0.61 | 23 |

| Ra_2 | 0.74 | 0.86 | 18 |

| Ra_3 | 0.87 | 0.94 | 19 |

| Ra_4 | 0.15 | 0.39 | 17 |

| Ra_5 | 0.39 | 0.62 | 21 |

| Ra_6 | 0.38 | 0.61 | 23 |

| Ra_7 | 0.26 | 0.52 | 19 |

| Ra_8 | 0.31 | 0.56 | 22 |

| Ra_9 | 0.21 | 0.56 | 21 |

| Ra_10 | 0.54 | 0.73 | 20 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Vrbová, H.; Kubišová, M.; Pata, V.; Knedlová, J.; Javořík, J.; Bočáková, B. Approach to Heterogeneous Surface Roughness Evaluation for Surface Coating Preparation. Coatings 2024, 14, 471. https://doi.org/10.3390/coatings14040471

Vrbová H, Kubišová M, Pata V, Knedlová J, Javořík J, Bočáková B. Approach to Heterogeneous Surface Roughness Evaluation for Surface Coating Preparation. Coatings. 2024; 14(4):471. https://doi.org/10.3390/coatings14040471

Chicago/Turabian StyleVrbová, Hana, Milena Kubišová, Vladimír Pata, Jana Knedlová, Jakub Javořík, and Barbora Bočáková. 2024. "Approach to Heterogeneous Surface Roughness Evaluation for Surface Coating Preparation" Coatings 14, no. 4: 471. https://doi.org/10.3390/coatings14040471

APA StyleVrbová, H., Kubišová, M., Pata, V., Knedlová, J., Javořík, J., & Bočáková, B. (2024). Approach to Heterogeneous Surface Roughness Evaluation for Surface Coating Preparation. Coatings, 14(4), 471. https://doi.org/10.3390/coatings14040471