The Effect of W, Cr, Mo Content on the Microstructure and Mechanical Properties of the Weld Interface of TiC Cermet and Low-Carbon Steel

Abstract

:1. Introduction

2. Materials and Methods

Materials

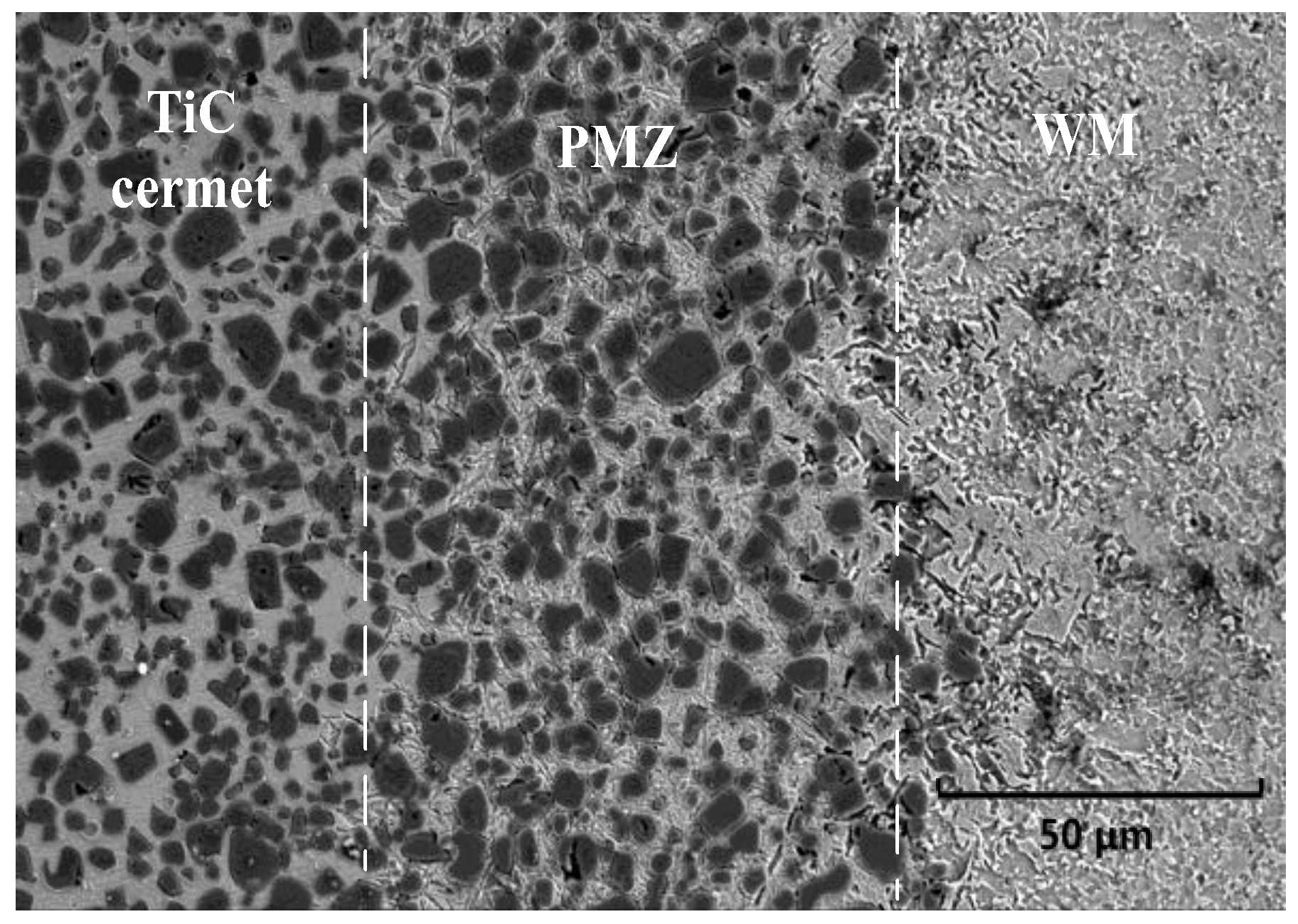

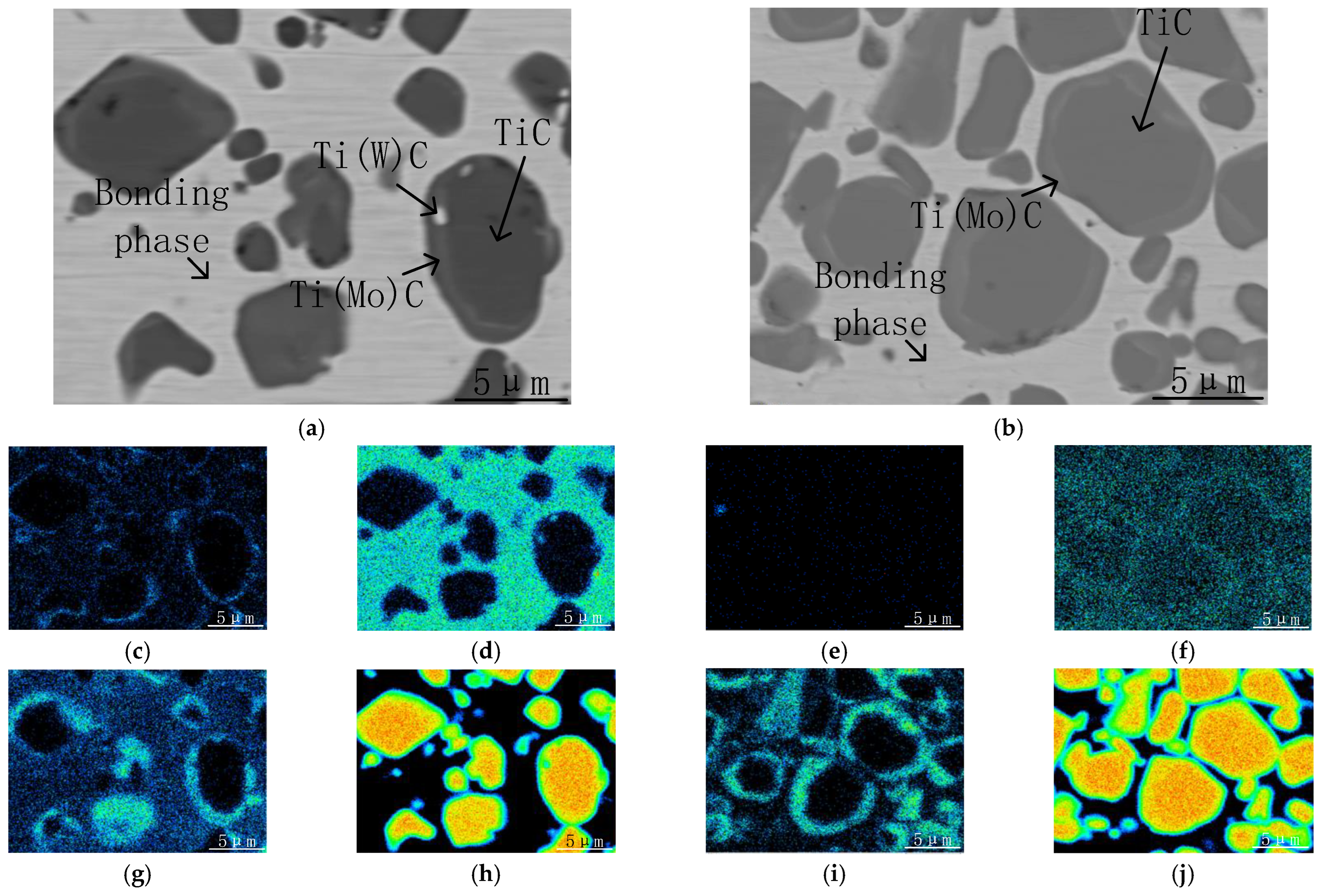

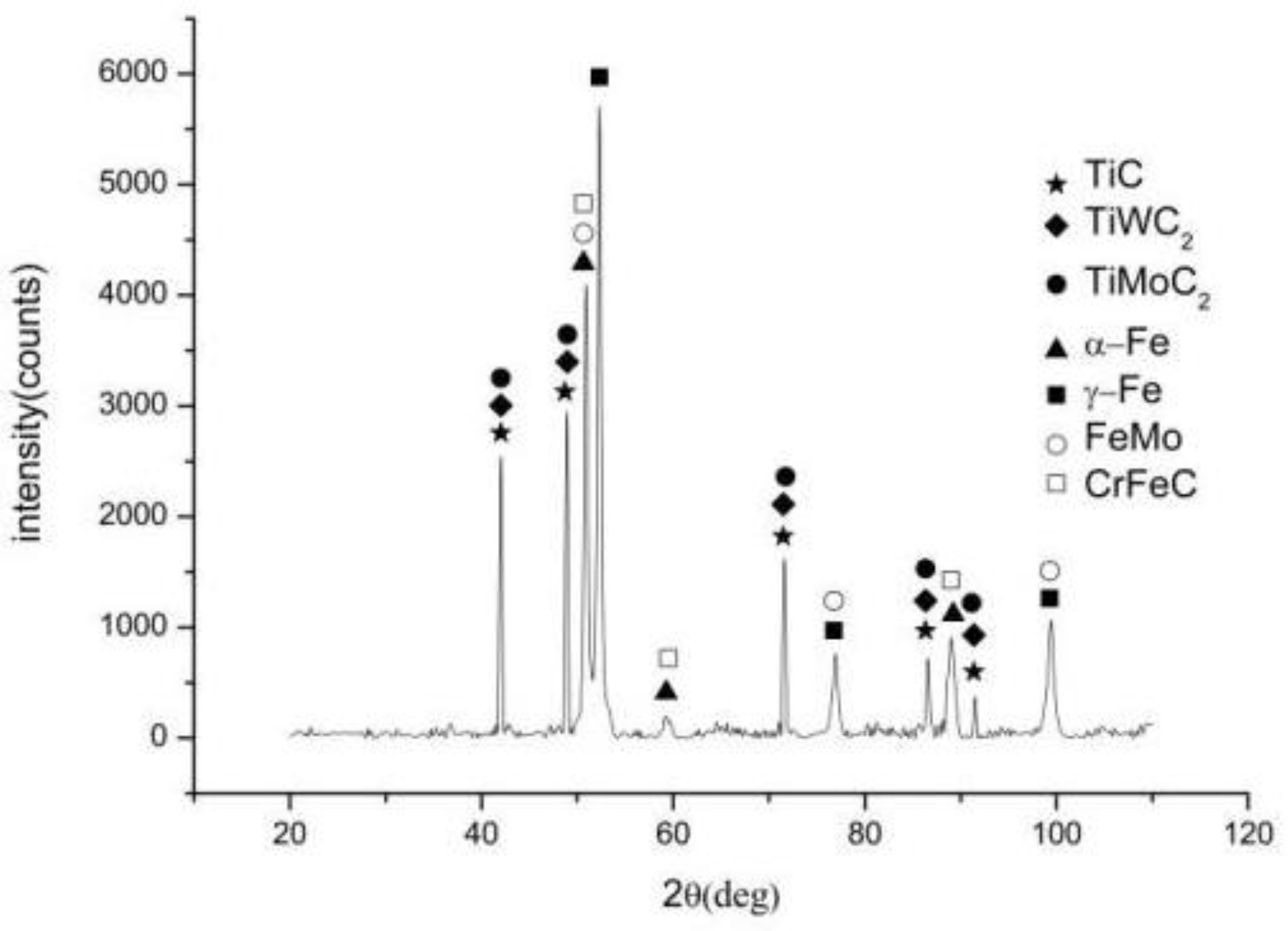

3. Results

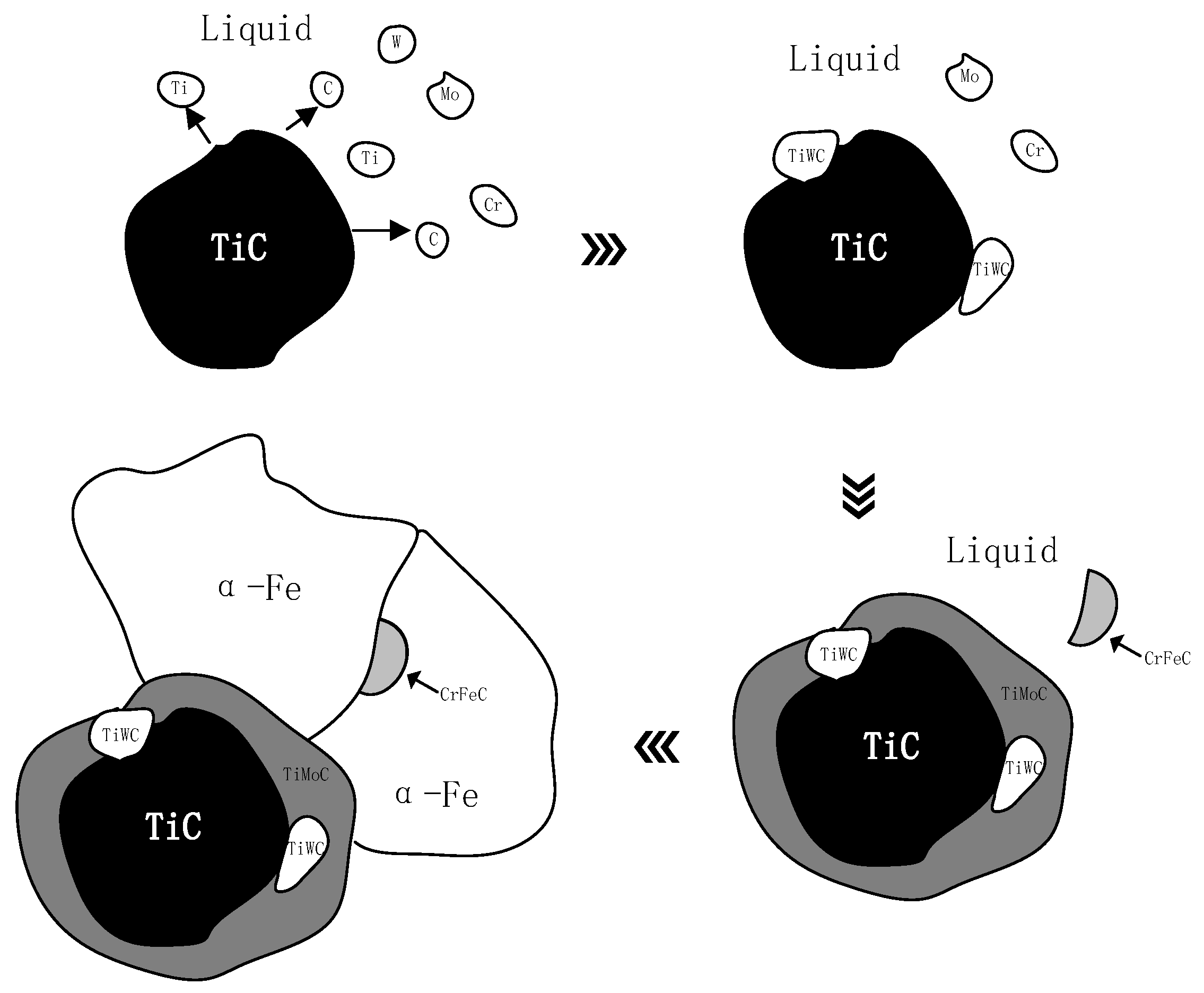

4. Discussion

- (1)

- An L34 orthogonal experiment was carried out to investigate the effects of W, Cr, and Mo on the microstructure and properties of the arc-welded interface of TiC cermet. The order of importance within the experimental range on the interface properties was perceived as Cr > W > Mo.

- (2)

- During the welding process, W and Mo alloy elements formed a ‘core-rim’ structure around the TiC particles, inhibiting the dissolution, while Cr formed dispersed carbides within the bonding phase. The combined effects of these elements enhanced the shear strength of the arc-welded interface of TiC cermet. The optimal alloy proportions for welding TiC cermet were determined to be W 1.0 wt.%, Cr 0.5 wt.%, and Mo 2.0 wt.%.

- (3)

- The shear strength of the welded interface increased by 83% compared to non-strengthened conditions, significantly enhancing the bonding strength of the arc-welded interface of TiC cermet.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Kalita, V.I.; Radyuk, A.A.; Komlev, D.I.; Mikhailova, A.B.; Alpatov, A.V.; Chueva, T.R.; Gamurar, N.V.; Titov, D.D. TiC–Cr3C2–WC–TiB2–SiC-Based Cermets. Inorg. Mater. Appl. Res. 2020, 11, 1199–1213. [Google Scholar] [CrossRef]

- SAlgodi, J.; Murray, J.W.; Brown, P.D.; Clare, A.T. Wear performance of TiC/Fe cermet electrical discharge coatings. Wear 2018, 402–403, 109–123. [Google Scholar] [CrossRef]

- Sribalaji, M.; Mukherjee, B.; Bakshi, S.R.; Arunkumar, P.; Babu, K.S.; Keshri, A.K. In-situ formed graphene nanoribbon induced toughening and thermal shock resistance of spark plasma sintered carbon nanotube reinforced titanium carbide composite. Compos. B Eng. 2017, 123, 227–240. [Google Scholar] [CrossRef]

- Xue, J.X.; Liu, J.X.; Zhang, G.J.; Zhang, H.B.; Liu, T.; Zhou, X.S.; Peng, S.M. Improvement in mechanical/physical properties of TiC625 ceramics sintered at 1500 °C for inert matrix fuels. Scr. Mater. 2016, 114, 5–8. [Google Scholar] [CrossRef]

- Namini, A.S.; Ahmadi, Z.; Babapoor, A.; Shokouhimehr, M.; Asl, M.S. Microstructure and thermomechanical characteristics of spark plasma sintered TiC ceramics doped with nano-sized WC. Ceram. Int. 2019, 45, 2153–2160. [Google Scholar] [CrossRef]

- Babapoor, A.; Asl, M.S.; Ahmadi, Z.; Namini, A.S. Effects of spark plasma sintering temperature on densification, hardness and thermal conductivity of titanium carbide. Ceram. Int. 2018, 44, 14541–14546. [Google Scholar] [CrossRef]

- Maurya, H.S.; Kollo, L.; Tarraste, M.; Juhani, K.; Sergejev, F.; Prashanth, K.G. Selective Laser Melting of TiC-Based Cermet: HIP Studies. Trans. Indian Inst. Met. 2023, 76, 565–570. [Google Scholar] [CrossRef]

- Maurya, H.S.; Kollo, L.; Juhani, K.; Sergejev, F.; Prashanth, K.G. Effect of preheating and cooling of the powder bed by laser pulse shaping on the microstructure of the TiC based cermets. Ceram. Int. 2022, 48, 20612–20618. [Google Scholar] [CrossRef]

- Wei, W.; Huang, Z.; Zhang, H.; Guan, S. Effect of the Welding Thermal Cycle on the Microstructure and Mechanical Properties of TiC Cermet HAZ Using the Gleeble Simulator. Coatings 2023, 13, 476. [Google Scholar] [CrossRef]

- Wei, W.; Huang, Z.; Zhang, H.; Guan, S. The Influence of Different Alloyed Welding Materials on the Microstructure and Mechanical Properties of Welded Interface in TiC Cermet MIG Welding Bonds. Mater. Lett. 2024, 361, 135641. [Google Scholar] [CrossRef]

- Lee, J.H.; Park, H.K. Microstructural evolution and mechanical properties of TiC-Mo2C-WC-Ni multi-component powder by high energy ball milling. J. Ceram. Process. Res. 2021, 22, 590–596. [Google Scholar]

- Chen, R.; Chen, L.; Wang, L.; Liang, C. Alloying effects of Zr, Nb, Ta, and W on thermodynamic and mechanical properties of TiC based on first-principles calculation. Nucl. Mater. Energy 2024, 38, 101604. [Google Scholar] [CrossRef]

- Lin, T.; Guo, Y.; Wang, Z.; Shao, H.; Lu, H.; Li, F.; He, X. Effects of chromium and carbon content on microstructure and properties of TiC-steel composites. Int. J. Refract. Met. Hard Mater. 2018, 72, 228–235. [Google Scholar] [CrossRef]

- GB/T 223.54.2022; Iron, Steel and Alloy—Determination of Nickel Content—Flame Atomic Absorption Spectrometric Method. Standards Press of China: Beijing, China, 2022.

- GB/T 40388-2021; Test Method for Shear Strength of C/C Composites. Standards Press of China: Beijing, China, 2022.

- ASTM E1269-11; Standard Test Method for Determining Specific Heat Capacity by Differential Scanning Calorimetry. ASTM: West Conshohocken, PA, USA, 2018.

- Jõeleht, M.; Pirso, J.; Juhani, K.; Viljus, M.; Traksmaa, R. The influence of high energy milling and sintering parameters on reactive sintered (Ti, Mo)C–Ni cermets. J. Alloys Compd. 2015, 636, 381–386. [Google Scholar] [CrossRef]

- Li, Y.; Liu, N.; Zhang, X.; Rong, C. Effect of Mo addition on the microstructure and mechanical properties of ultra-fine grade TiC-TiN-WC-Mo2C-Co cermets. Int. J. Refract. Metals Hard Mater. 2008, 26, 190–196. [Google Scholar] [CrossRef]

- Zhai, W.; Zhu, Z.; Zhou, W.; Nai, S.M.L.; Wei, J. Selective laser melting of dispersed TiC particles strengthened 316L stainless steel. Compos. Part B Eng. 2020, 199, 108291. [Google Scholar] [CrossRef]

- Guan, Y.; Huang, Q.; Peng, Y.; Liu, X.; Kong, Y.; Mao, H. Phase-field simulation of core-rim structure at the early sintering stage in TiC-WC-Ni cermet. Calphad 2024, 84, 102660. [Google Scholar] [CrossRef]

- Xiong, H.; Wu, Y.; Li, Z.; Gan, X.; Zhou, K.; Chai, L. Comparison of Ti(C, N)-based cermets by vacuum and gas-pressure sintering: Microstructure and mechanical properties. Ceram. Int. 2018, 44, 805–881. [Google Scholar] [CrossRef]

- Jin, C.; Plucknett, K.P. Microstructure instability in TiC-316L stainless steel cermets. Int. J. Refract. Met. Hard Mater. 2016, 58, 74–83. [Google Scholar] [CrossRef]

| C | Ni | Mn | TiC | Mo | Fe | Shear Strength (MPa) | |

|---|---|---|---|---|---|---|---|

| ZDZC60 | 0.53 | 1.78 | 6.21 | 39.50 | 1.31 | etc. | 469 |

| LCS | 0.051 | - | 0.78 | - | etc. | 430 |

| W | Cr | Mo | |

|---|---|---|---|

| 1# | 0.5 | 0.5 | 1.0 |

| 2# | 0.5 | 1.0 | 1.5 |

| 3# | 0.5 | 1.5 | 2.0 |

| 4# | 0.5 | 2.0 | 2.5 |

| 5# | 1.0 | 0.5 | 1.5 |

| 6# | 1.0 | 1.0 | 1.0 |

| 7# | 1.0 | 1.5 | 2.5 |

| 8# | 1.0 | 2.0 | 2.0 |

| 9# | 1.5 | 0.5 | 2.0 |

| 10# | 1.5 | 1.0 | 2.5 |

| 11# | 1.5 | 1.5 | 1.0 |

| 12# | 1.5 | 2.0 | 1.5 |

| 13# | 2.0 | 0.5 | 2.5 |

| 14# | 2.0 | 1.0 | 2.0 |

| 15# | 2.0 | 1.5 | 1.5 |

| 16# | 2.0 | 2.0 | 1.0 |

| W | Cr | Mo | Shear Strength (MPa) | |

|---|---|---|---|---|

| 1# | 0.5 | 0.5 | 1.0 | 746 |

| 2# | 0.5 | 1.0 | 1.5 | 712 |

| 3# | 0.5 | 1.5 | 2.0 | 698 |

| 4# | 0.5 | 2.0 | 2.5 | 765 |

| 5# | 1.0 | 0.5 | 1.5 | 752 |

| 6# | 1.0 | 1.0 | 1.0 | 711 |

| 7# | 1.0 | 1.5 | 2.5 | 773 |

| 8# | 1.0 | 2.0 | 2.0 | 767 |

| 9# | 1.5 | 0.5 | 2.0 | 782 |

| 10# | 1.5 | 1.0 | 2.5 | 646 |

| 11# | 1.5 | 1.5 | 1.0 | 761 |

| 12# | 1.5 | 2.0 | 1.5 | 747 |

| 13# | 2.0 | 0.5 | 2.5 | 751 |

| 14# | 2.0 | 1.0 | 2.0 | 727 |

| 15# | 2.0 | 1.5 | 1.5 | 755 |

| 16# | 2.0 | 2.0 | 1.0 | 714 |

| mean value 1 | 730.25 | 757.75 | 733.00 | |

| mean value 2 | 750.75 | 699.00 | 741.50 | |

| mean value 3 | 734.00 | 746.75 | 743.50 | |

| mean value 4 | 736.75 | 748.25 | 733.75 | |

| MAX | 750.75 | 757.75 | 743.50 | |

| MIN | 730.25 | 699.00 | 733.00 | |

| range | 20.50 | 58.75 | 10.50 |

| C | W | Mn | Cr | Mo | Fe | |

|---|---|---|---|---|---|---|

| LCS | 0.051 | 0.95 | 0.78 | 0.55 | 1.94 | etc. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wei, W.; Huang, Z.; Zhang, H.; Guan, S. The Effect of W, Cr, Mo Content on the Microstructure and Mechanical Properties of the Weld Interface of TiC Cermet and Low-Carbon Steel. Coatings 2024, 14, 558. https://doi.org/10.3390/coatings14050558

Wei W, Huang Z, Zhang H, Guan S. The Effect of W, Cr, Mo Content on the Microstructure and Mechanical Properties of the Weld Interface of TiC Cermet and Low-Carbon Steel. Coatings. 2024; 14(5):558. https://doi.org/10.3390/coatings14050558

Chicago/Turabian StyleWei, Wei, Zhiquan Huang, Haiyan Zhang, and Shaokang Guan. 2024. "The Effect of W, Cr, Mo Content on the Microstructure and Mechanical Properties of the Weld Interface of TiC Cermet and Low-Carbon Steel" Coatings 14, no. 5: 558. https://doi.org/10.3390/coatings14050558

APA StyleWei, W., Huang, Z., Zhang, H., & Guan, S. (2024). The Effect of W, Cr, Mo Content on the Microstructure and Mechanical Properties of the Weld Interface of TiC Cermet and Low-Carbon Steel. Coatings, 14(5), 558. https://doi.org/10.3390/coatings14050558