Effective Promotion of Micro Damping of GO Hybrid PU–PF Copolymer Grinding Wheels on Precision Machining

Abstract

:1. Introduction

2. Experimental

2.1. Materials

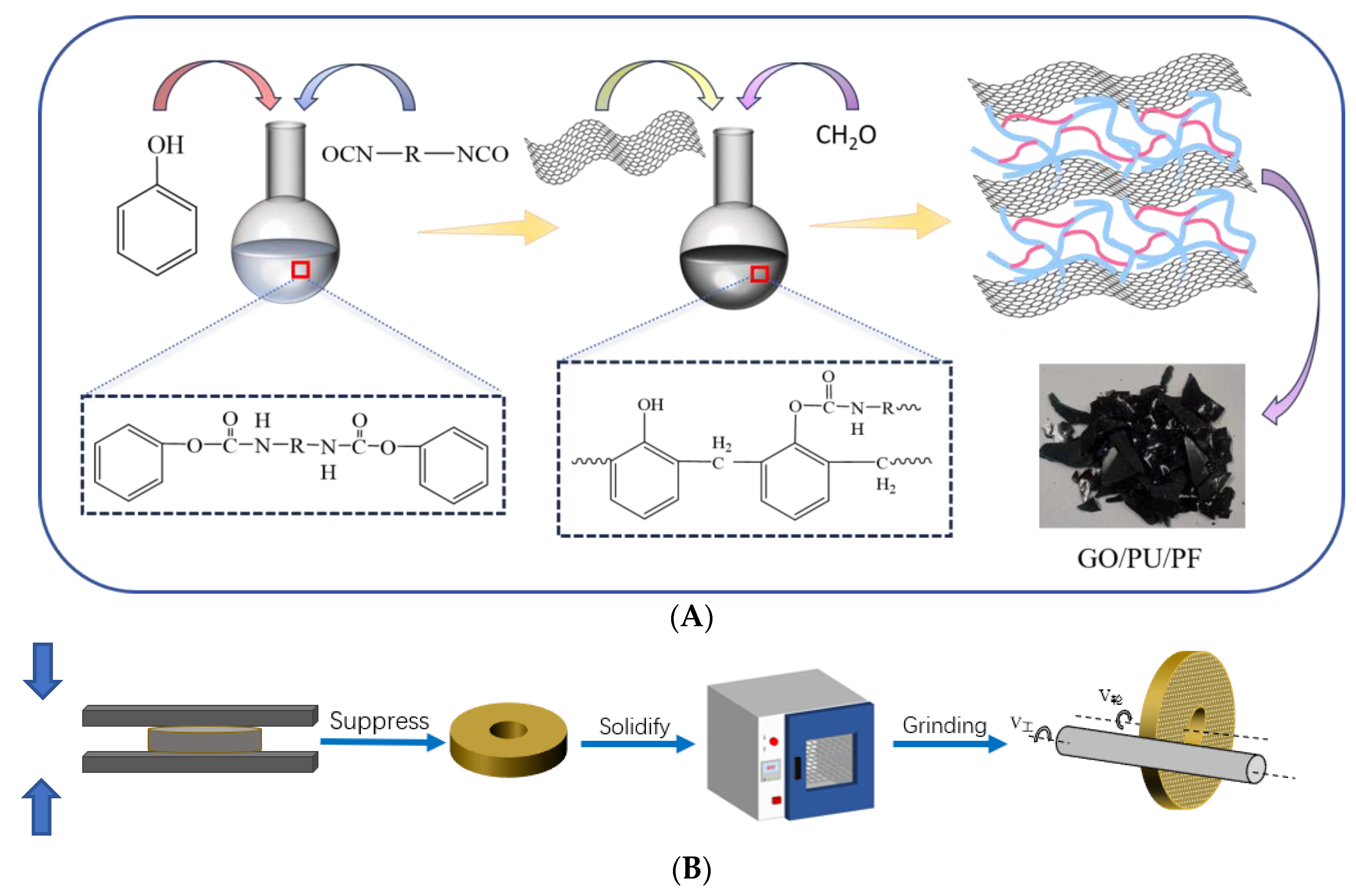

2.2. In Situ Synthesis of GO Hybrid PU–PF Copolymers

2.3. Testing Methods

3. Results and Discussion

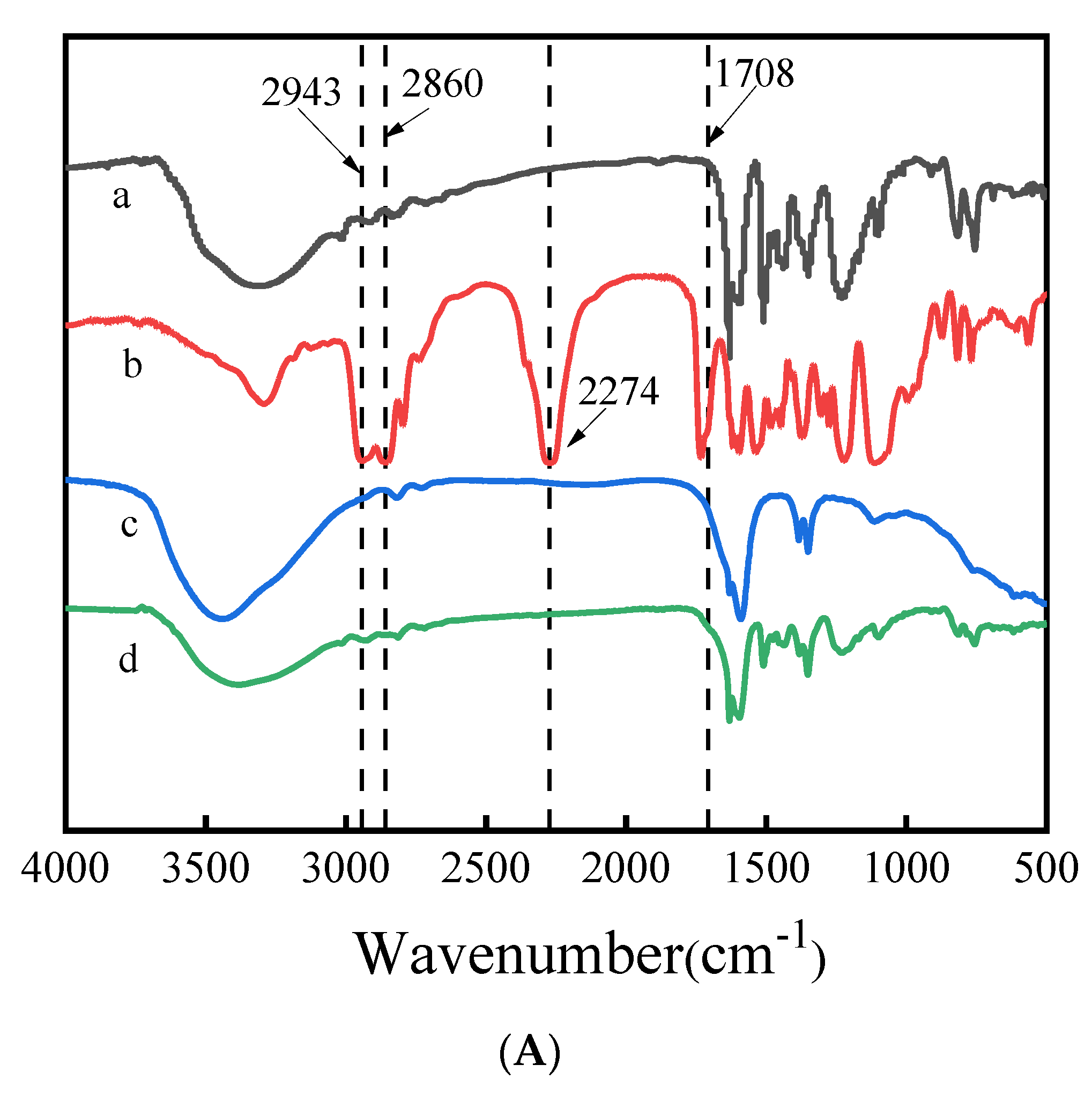

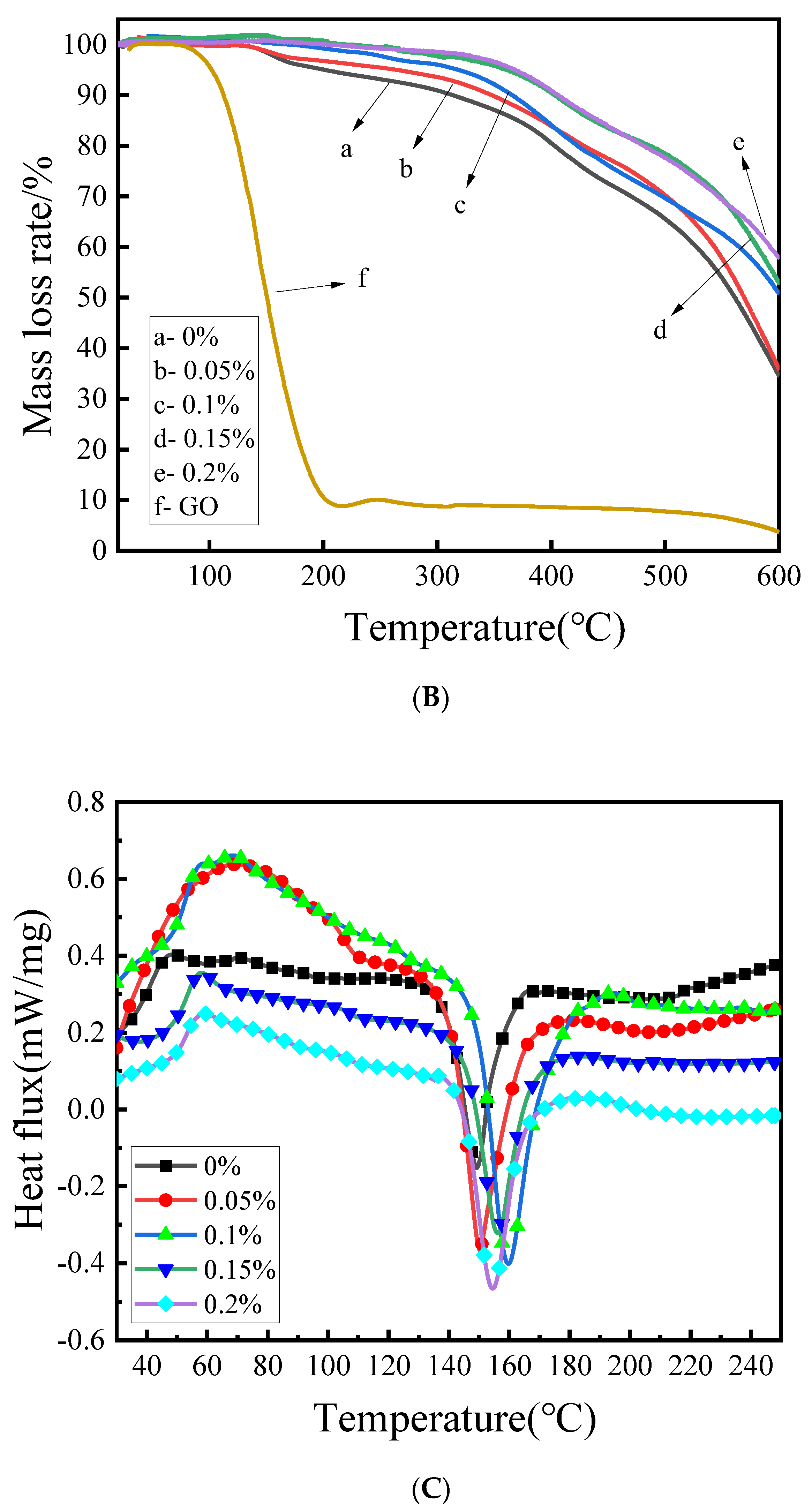

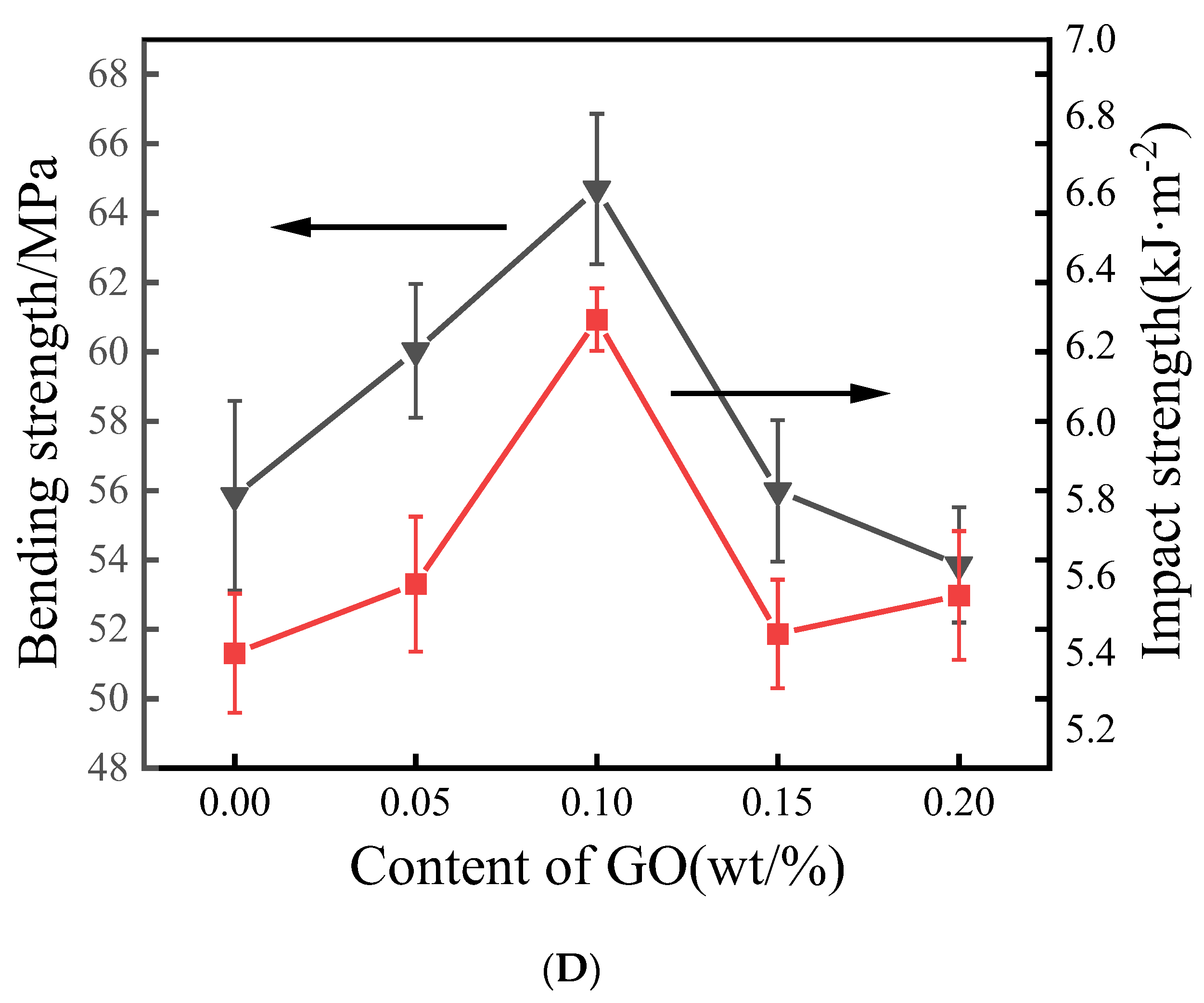

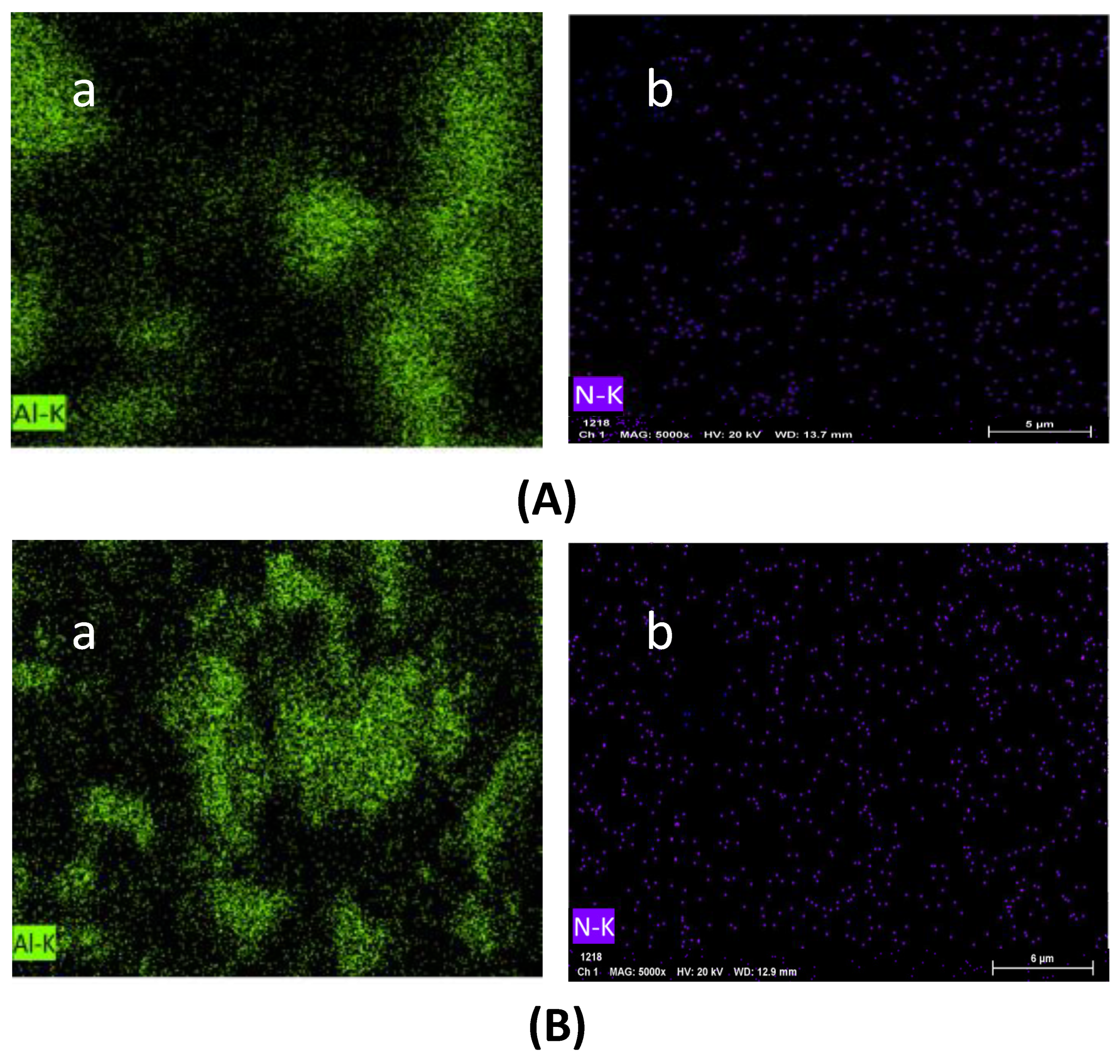

3.1. Fabrication of GO Hybrid PU–PF Copolymers

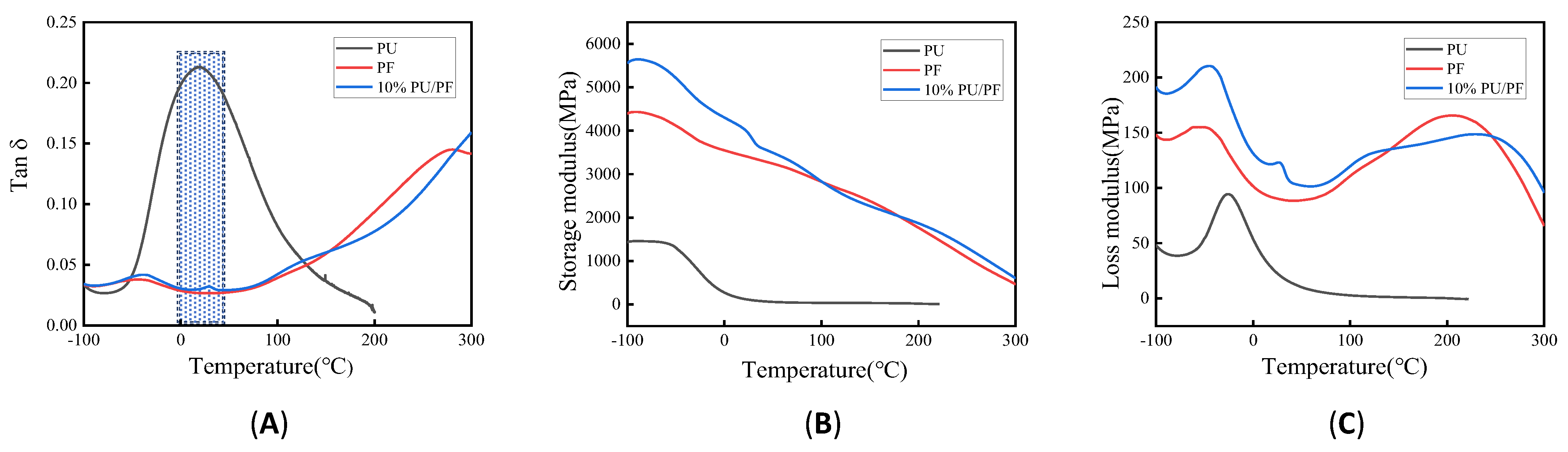

3.2. Damping Property

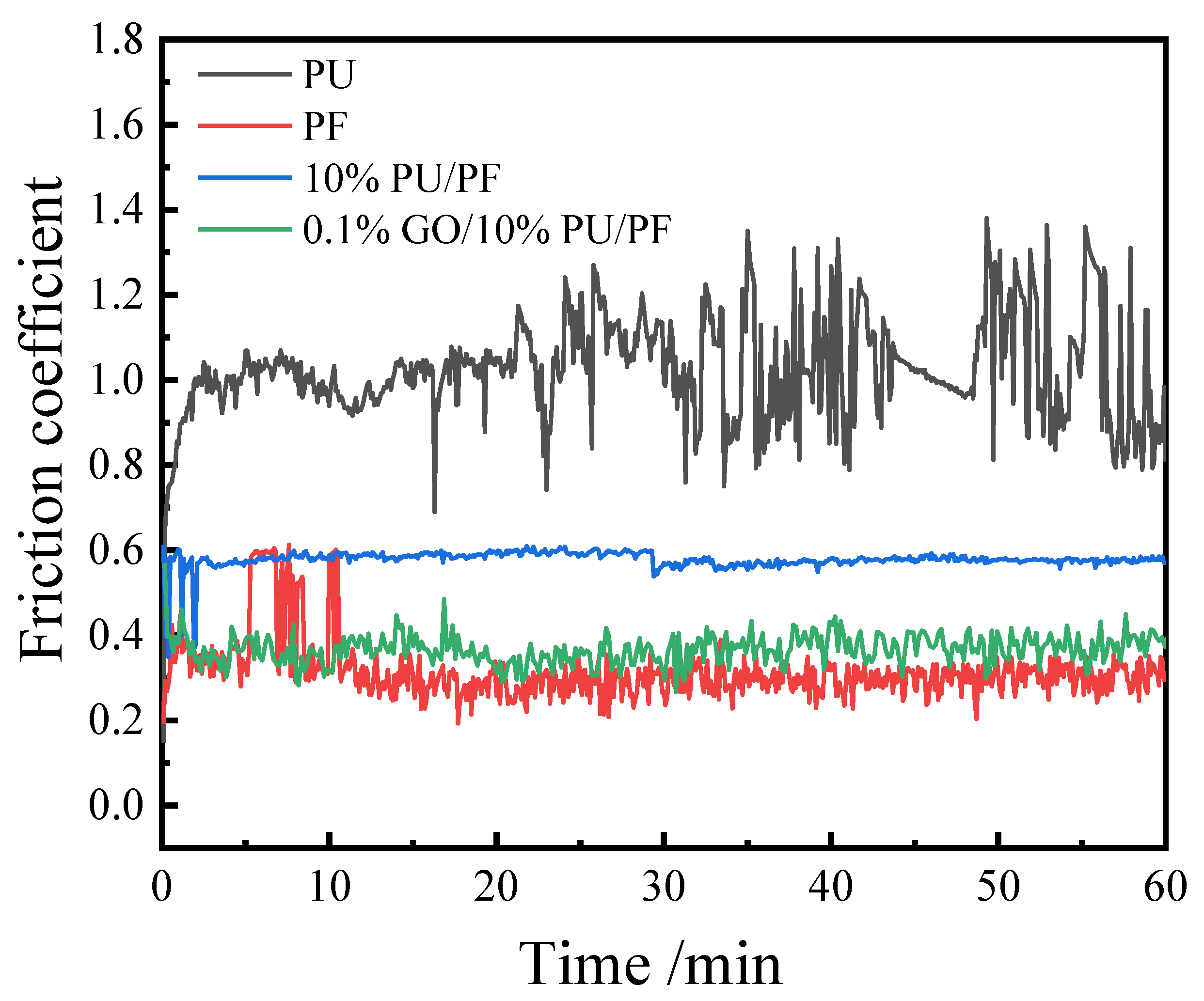

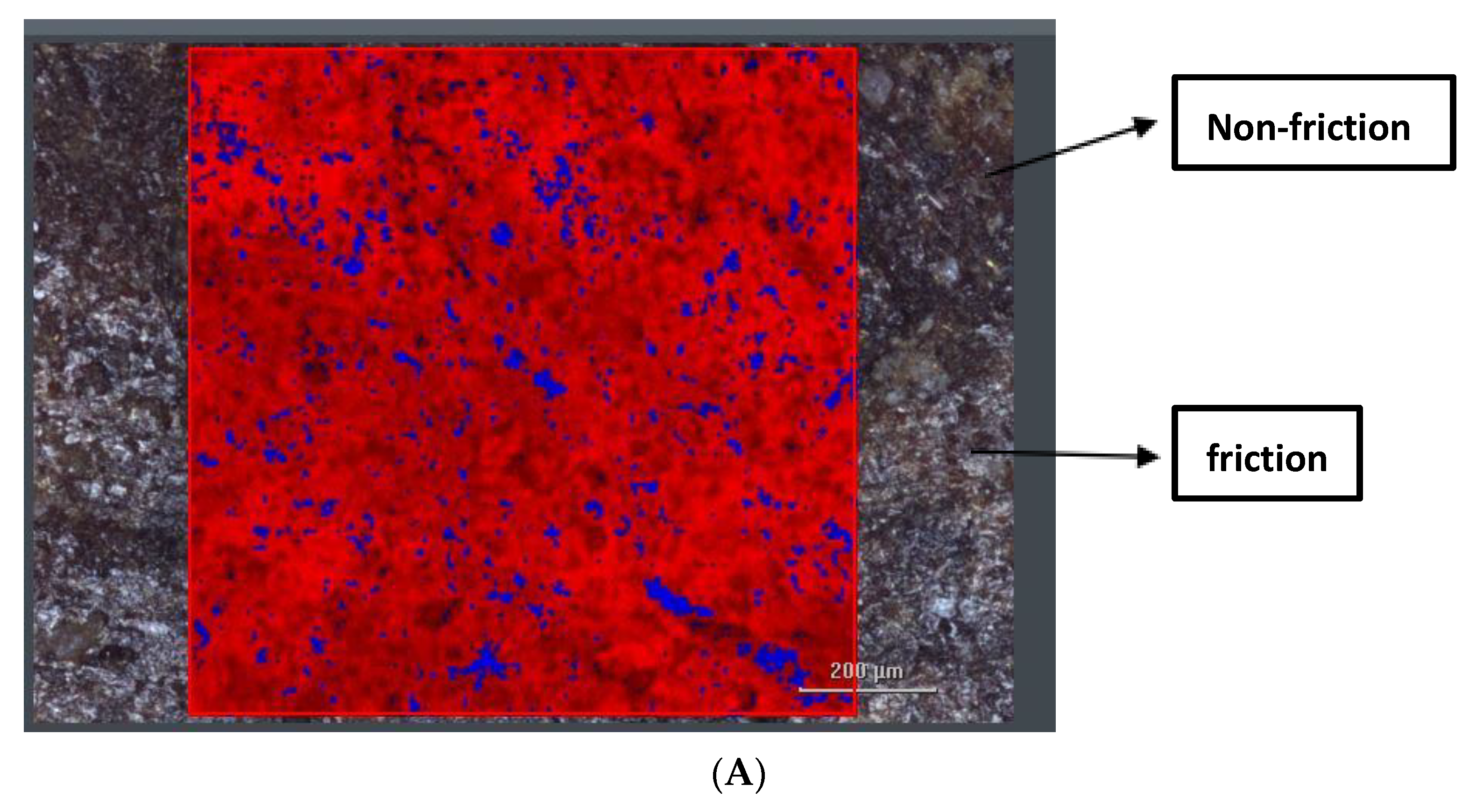

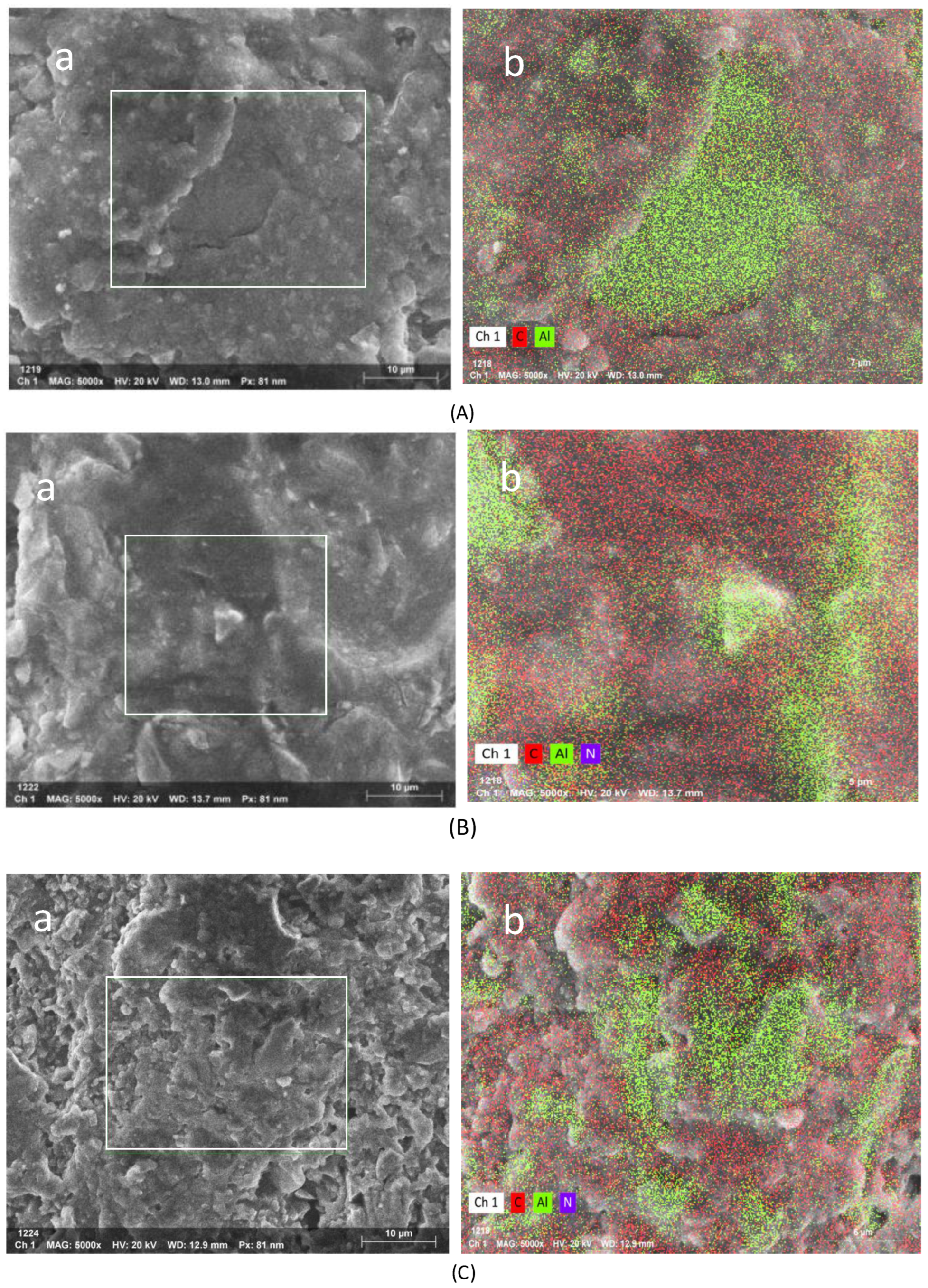

3.3. Tribological Character

3.4. Precision Machining

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Brinksmeier, E.; Mutlugünes, Y.; Ohmori, H. Ultra-precision grinding. CIRP Ann. 2010, 59, 652–671. [Google Scholar] [CrossRef]

- Lee, E.S.; Baek, S.Y. A study on optimum grinding factors for aspheric convex surface micro-lens using design of experiments. Int. J. Mach. Tool. Manuf. 2007, 47, 509–520. [Google Scholar] [CrossRef]

- Yan, Y.; Zhang, Z.; Liu, J. Study on the algorithm of three-dimensional surface residual material height of nano-ZrO2 ceramics under ultra-precision grinding. Micromachines 2021, 12, 1363. [Google Scholar] [CrossRef] [PubMed]

- Xu, J.; He, Q.; Zhang, X. Euler’s equation grinding track. microgrinding mechanism, and process research of space optical crystal materials. Int. J. Adv. Manuf. Technol. 2023, 128, 5209–5221. [Google Scholar] [CrossRef]

- Jahnel, K.; Michels, R.; Wilhelm, D.P. Investigation of surface integrity induced by ultra-precision grinding and scratching of glassy carbon. Micromachines 2023, 14, 2240. [Google Scholar] [CrossRef]

- Wang, S.; Zhao, Q.; Wu, T. An investigation of monitoring the damage mechanism in ultra-precision grinding of monocrystalline silicon based on AE signals processing. J. Manuf. Process. 2022, 81, 945–961. [Google Scholar] [CrossRef]

- Kakinuma, Y.; Konuma, Y.; Fukuta, M. Ultra-precision grinding of optical glass lenses with La-doped CeO2 slurry. CIRP Ann. 2019, 68, 345–348. [Google Scholar] [CrossRef]

- Jiang, C.; Li, H.; Mai, Y. Material removal monitoring in precision cylindrical plunge grinding using acoustic emission signal. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2014, 228, 715–722. [Google Scholar] [CrossRef]

- Sun, Z.; Guan, C.; Dai, Y. Ultra-precision time-controlled grinding for flat mechanical parts with weak stiffness. J. Manuf. Process. 2023, 99, 105–120. [Google Scholar] [CrossRef]

- Monier, A.; Guo, B.; Zhao, Q. Effects of the grinding conditions on geometry of microstructured surfaces fabricated via designed precision grinding. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2023, 237, 573–587. [Google Scholar] [CrossRef]

- Xiao, G.; Huang, Y. Adaptive belt precision grinding for the weak rigidity deformation of blisk leading and trailing edge. Adv. Mech. Eng. 2017, 9, 1687814017731705. [Google Scholar] [CrossRef]

- Cai, R.; Wan, N.; Mo, R. Prediction of un-uniform grinding wheel wear based on instantaneous engagement of multi-axis grinding. Int. J. Adv. Manuf. Technol. 2022, 119, 3407–3425. [Google Scholar] [CrossRef]

- Brecher, C.; Baumler, S.; Brockmann, B. Avoiding chatter by means of active damping systems for machine tools. J. Mach. Eng. 2013, 13, 117–128. [Google Scholar]

- Bianchi, G.; Cagna, S.; Cau, N. Analysis of vibration damping in machine tools. Procedia CIRP 2014, 21, 367–372. [Google Scholar] [CrossRef]

- Ghorbani, S.; Polushin, N.I. Effect of composite material on damping capacity improvement of cutting tool in machining operation using taguchi approach. Eng. Technol. Int. 2015, 9, 1339–1349. [Google Scholar]

- Devin, L.N.; Osadchii, A.A. Improving performance of CBN cutting tools by increasing their damping properties. J. Superhard Mater. 2012, 34, 328–335. [Google Scholar] [CrossRef]

- Sexton, J.S.; Howes, T.D.; Stone, B.J. The use of increased wheel flexibility to improve chatter performance in grinding. Proc. Inst. Mech. Eng. 1982, 196, 291–300. [Google Scholar] [CrossRef]

- Shen, R.; Qian, X.; Zhou, J. Characteristics of passive vibration control for exponential non-viscous damping system: Vibration isolator and absorber. J. Vib. Control. 2023, 29, 5078–5089. [Google Scholar] [CrossRef]

- Zhu, L.; Hao, J.; Lu, L. Research on influence of damping on the vibration noise of transformer. IEEE Access 2022, 10, 92128–92136. [Google Scholar] [CrossRef]

- Shum, K.M. Tuned vibration absorbers with nonlinear viscous damping for damped structures under random load. J. Sound. Vib. 2015, 346, 70–80. [Google Scholar] [CrossRef]

- Chen, S.; Yang, Z.; Ying, M. Parallel load-bearing and damping system design and test for satellite vibration suppression. Appl. Sci. 2020, 10, 1548. [Google Scholar] [CrossRef]

- Luo, H.; Guo, S.; Yu, C. Vibration suppression analysis and experimental test of additional constrained damping layer in space science experiment cabinet. Compos. Adv. Mater. 2021, 30, 2633366X20978659. [Google Scholar] [CrossRef]

- Gou, Z.; Li, B.; Fei, J. Frictional characteristics and vibration behavior of silicone rubber powders modified resin-based friction materials. J. Appl. Polym. Sci. 2024, 141, e55344. [Google Scholar] [CrossRef]

- Babkina, N.; Antonenko, O.; Kosyanchuk, L. Effect of polyurethane material design on damping ability. Polym. Adv. Technol. 2023, 34, 3426–3437. [Google Scholar] [CrossRef]

- Sain, T.; Yeom, B.; Waas, A.M. Effect of soft segment and clay volume fraction on rate dependent damping of polyurethane and polyurethane-clay nanocomposites. J. Reinf. Plast. Comp. 2014, 33, 2129–2135. [Google Scholar] [CrossRef]

- Khanouki, M.A.; Ohadi, A. Improved acoustic damping in polyurethane foams bythe inclusion of silicon dioxide nanoparticles. Adv. Polym. Technol. 2018, 37, 2799–2810. [Google Scholar] [CrossRef]

- Li, L.; Tian, B.; Li, L. Preparation and characterization of silicone oil modified polyurethane damping materials. J. Appl. Polym. Sci. 2019, 136, 47579. [Google Scholar] [CrossRef]

- Chen, S.; Wang, Q.; Wang, T. Preparation, tensile, damping and thermal properties of polyurethanes based on various structural polymer polyols: Effects of composition and isocyanate index. Polym. Res. 2012, 19, 9994. [Google Scholar] [CrossRef]

- Shi, M.; Zheng, J.; Huang, Z. Synthesis of polyurethane prepolymers and damping property of polyurethane/epoxy composites. Adv. Sci. Lett. 2014, 4, 740–744. [Google Scholar] [CrossRef]

- Su, Y.; Li, T.; Liu, Y. Mechanical and damping properties of graphene-modified polyurethane-epoxy composites for structures. Polym-Korea 2021, 45, 483–490. Available online: https://10.7317/pk.2022.45.4.483 (accessed on 26 July 2021). [CrossRef]

- Zhang, C.; Chen, Y.; Li, H. Facile fabrication of polyurethane/epoxy IPNs filled graphene aerogel with improved damping, thermal and mechanical properties. RSC Adv. 2018, 8, 27390–27399. [Google Scholar] [CrossRef]

- Feng, Q.; Shen, M.; Zhu, J. Realization of polyurethane/epoxy interpenetrating polymer networks with a broad high-damping temperature range using β-cyclodextrins as chain extenders. Mater. Des. 2021, 212, 110208. [Google Scholar] [CrossRef]

- Yu, W.; Zhang, D.; Du, M. Role of graded length side chains up to 18 carbons in length on the damping behavior of polyurethane/epoxy interpenetrating polymer networks. Eur. Polym. J. 2013, 49, 1731–1741. [Google Scholar] [CrossRef]

- Chen, S.; Wang, Q.; Pei, X. Dynamic mechanical properties of castor oil-based polyurethane/epoxy graft interpenetrating polymer network composites. J. Appl. Polym. Sci. 2010, 118, 1144–1151. [Google Scholar] [CrossRef]

- Chen, S.; Wang, T.; Wang, Q. Studies on tribological, damping and thermal properties of polyurethane/polystyrene interpenetrating polymer networks. J. Polym. Mater. 2016, 33, 503–512. [Google Scholar]

- Wang, Q.; Chen, S.; Wang, T. Damping, thermal, and mechanical properties of polyurethane based on poly(tetramethylene glycol)/epoxy interpenetrating polymer networks: Effects of composition and isocyanate index. Appl. Phys. A-Mater. 2011, 104, 375–382. [Google Scholar] [CrossRef]

- Qin, C.; Jin, Z.; Bai, X. Compatibility of polyurethane/(vinyl ester resin)(ethyl acrylate) interpenetrating polymer network. Polym. J. 2007, 1365–1372. [Google Scholar] [CrossRef]

- Statharas, E.C.; Yao, K.; Rahimabady, M. Polyurethane/poly(vinylidene fluoride)/MWCNT composite foam for broadband airborne sound absorption. J. Appl. Polym. Sci. 2019, 136, 47868. [Google Scholar] [CrossRef]

- Xu, X.; Huang, S.; Guan, J. Grinding performance and self–lubrication mechanism of phenolic resin-bonded grinding wheel filled with inclusion complex of β-cyclodextrin and dialkyl pentasulfide. J. Mater. Process Technol. 2015, 221, 163–171. [Google Scholar] [CrossRef]

- Bashandeh, K.; Lan, P.; Meyer, J.L. Tribological performance of graphene and PTFE solid lubricants for polymer coatings at elevated temperatures. Tribol. Lett. 2019, 67, 99. [Google Scholar] [CrossRef]

- Aliyu, I.K.; Mohammed, A.S.; Al-Qutub, A. Tribological performance of ultra high molecular weight polyethylene nanocomposites reinforced with graphene nanoplatelets. Polym. Compos. 2019, 40, E1301–E1311. [Google Scholar] [CrossRef]

- Aliyu, I.K.; Mohammed, A.S.; Al-Qutub, A. Tribological performance of UHMWPE/GNPs nanocomposite coatings for solid lubrication in bearing applications. Tribol. Lett. 2018, 66, 144. [Google Scholar] [CrossRef]

- Ma, C.; Shan, Y.; Wang, N. High-damping polyurethane-based composites modified with amino-functionalized graphene. High. Perform. Polym. 2023, 35, 795–811. [Google Scholar] [CrossRef]

- Xia, S.; Liu, Y.; Pei, F. Identical steady tribological performance of graphene-oxide-strengthened polyurethane/epoxy interpenetrating polymer networks derived from graphene nanosheet. Polymer 2015, 64, 62–68. [Google Scholar] [CrossRef]

- Yue, R.; Liu, Y.; Xia, S. Raman imaging evidence for mechanical/tribological quasi-steady state in GO strengthening polyurethane/epoxy interpenetrating polymer network. Macromol. Res. 2022, 30, 477–485. [Google Scholar] [CrossRef]

- Zhang, H.Y.; Xia, S.L.; Liu, C. In-situ closed synthesis of phenolic resin from PPU and its damping properties. Comp. Sci. Eng. 2024, 1–9. Available online: http://kns.cnki.net/kcms/detail/10.1683.TU.20240227.1807.006.html (accessed on 23 November 2023). [CrossRef]

- GB/T 528-1998; Rubber, Vulcanized or Thermoplastic—Determination of Tensile Stress-Strain Properties [Including MODIFICATION 1]. Ministry of Chemical Industry of the People Republic of China: Beijing, China, 1998.

| Weight-Loss Rate | GO wt% | ||||

|---|---|---|---|---|---|

| 0 | 0.05 | 0.1 | 0.15 | 0.2 | |

| 20% | 405 | 428 | 424 | 486 | 482 |

| 50% | 528 | 543 | 565 | 580 | 595 |

| GO Content | 0 wt% | 0.05 wt% | 0.1 wt% | 0.15 wt% | 0.2 wt% |

|---|---|---|---|---|---|

| Curing temperatures | 148 °C | 150 °C | 159 °C | 155 °C | 154 °C |

| Resin Type | PU | PF | 10%PU–PF | 0.05%GO + 10%PU–PF | 0.1%GO + 10%PU–PF | 0.15%GO + 10%PU–PF | 0.2%GO + 10%PU–PF |

|---|---|---|---|---|---|---|---|

| COFs | 1.03 | 0.3 | 0.58 | 0.42 | 0.37 | 0.4 | 0.39 |

| Resin Type | PU | PF | 10%PU–PF | 0.05%GO + 10%PU–PF | 0.1%GO + 10%PU–PF | 0.15%GO + 10%PU–PF | 0.2%GO + 10%PU–PF |

|---|---|---|---|---|---|---|---|

| Specific wear rate (10−4 mm3/Nm) | 53.44 | 3.13 | 4.38 | 2.77 | 1.16 | 1.7 | 1.89 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xia, S.; Zhang, H.; Xu, J.; Liu, Y.; Liu, C.; Guo, S.; Song, X.; Peng, J.; Jia, Y.; Li, J. Effective Promotion of Micro Damping of GO Hybrid PU–PF Copolymer Grinding Wheels on Precision Machining. Coatings 2024, 14, 632. https://doi.org/10.3390/coatings14050632

Xia S, Zhang H, Xu J, Liu Y, Liu C, Guo S, Song X, Peng J, Jia Y, Li J. Effective Promotion of Micro Damping of GO Hybrid PU–PF Copolymer Grinding Wheels on Precision Machining. Coatings. 2024; 14(5):632. https://doi.org/10.3390/coatings14050632

Chicago/Turabian StyleXia, Shaoling, Hongying Zhang, Jixian Xu, Yingliang Liu, Cong Liu, Shengdong Guo, Xudong Song, Jin Peng, Yu Jia, and Jialu Li. 2024. "Effective Promotion of Micro Damping of GO Hybrid PU–PF Copolymer Grinding Wheels on Precision Machining" Coatings 14, no. 5: 632. https://doi.org/10.3390/coatings14050632

APA StyleXia, S., Zhang, H., Xu, J., Liu, Y., Liu, C., Guo, S., Song, X., Peng, J., Jia, Y., & Li, J. (2024). Effective Promotion of Micro Damping of GO Hybrid PU–PF Copolymer Grinding Wheels on Precision Machining. Coatings, 14(5), 632. https://doi.org/10.3390/coatings14050632