A Comparative Study of Machining Property in Inconel 718 Superalloy Grinding with Al2O3- and CBN/Fe-Based Spherical Magnetic Abrasives

Abstract

1. Introduction

2. Materials and Methods

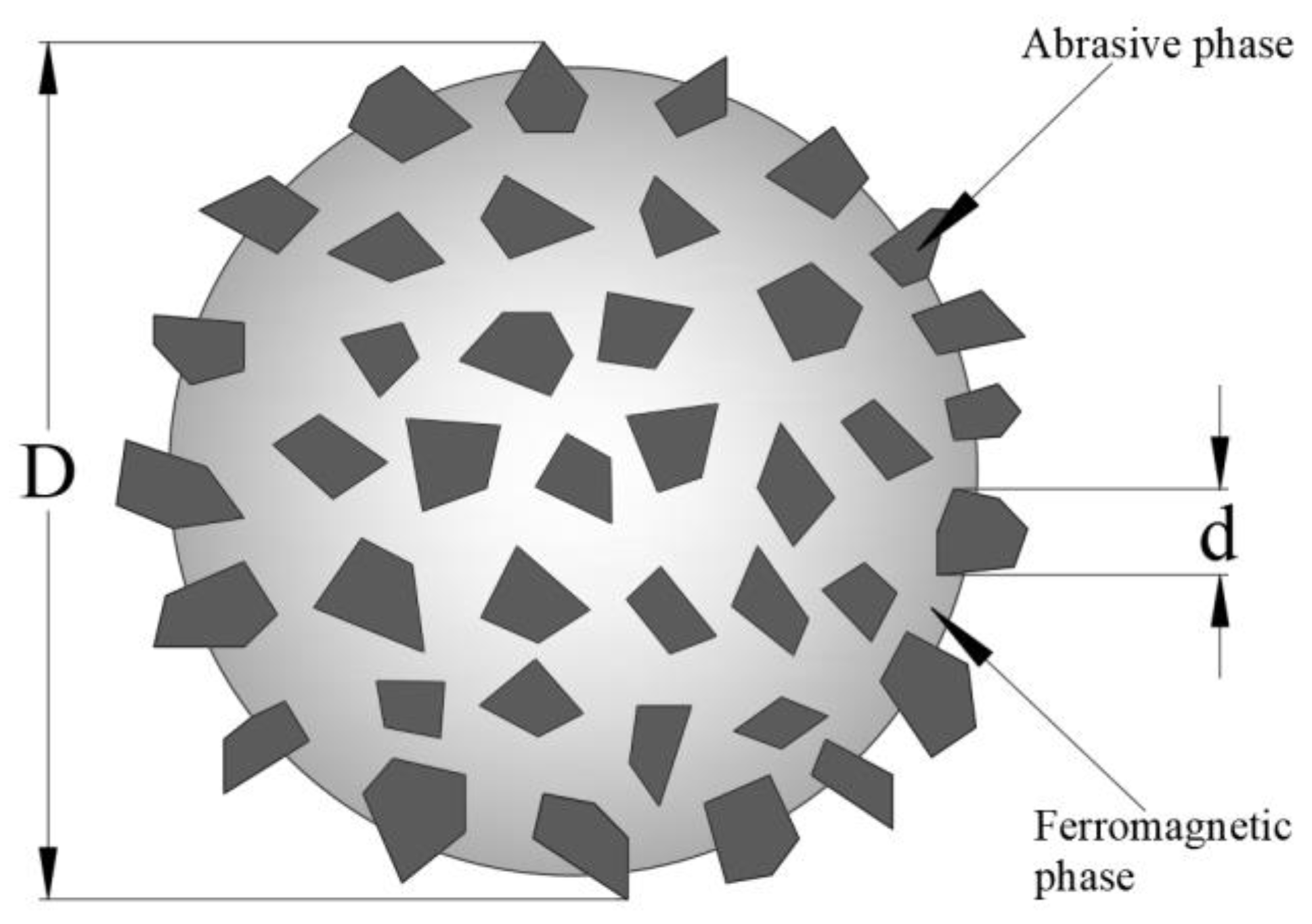

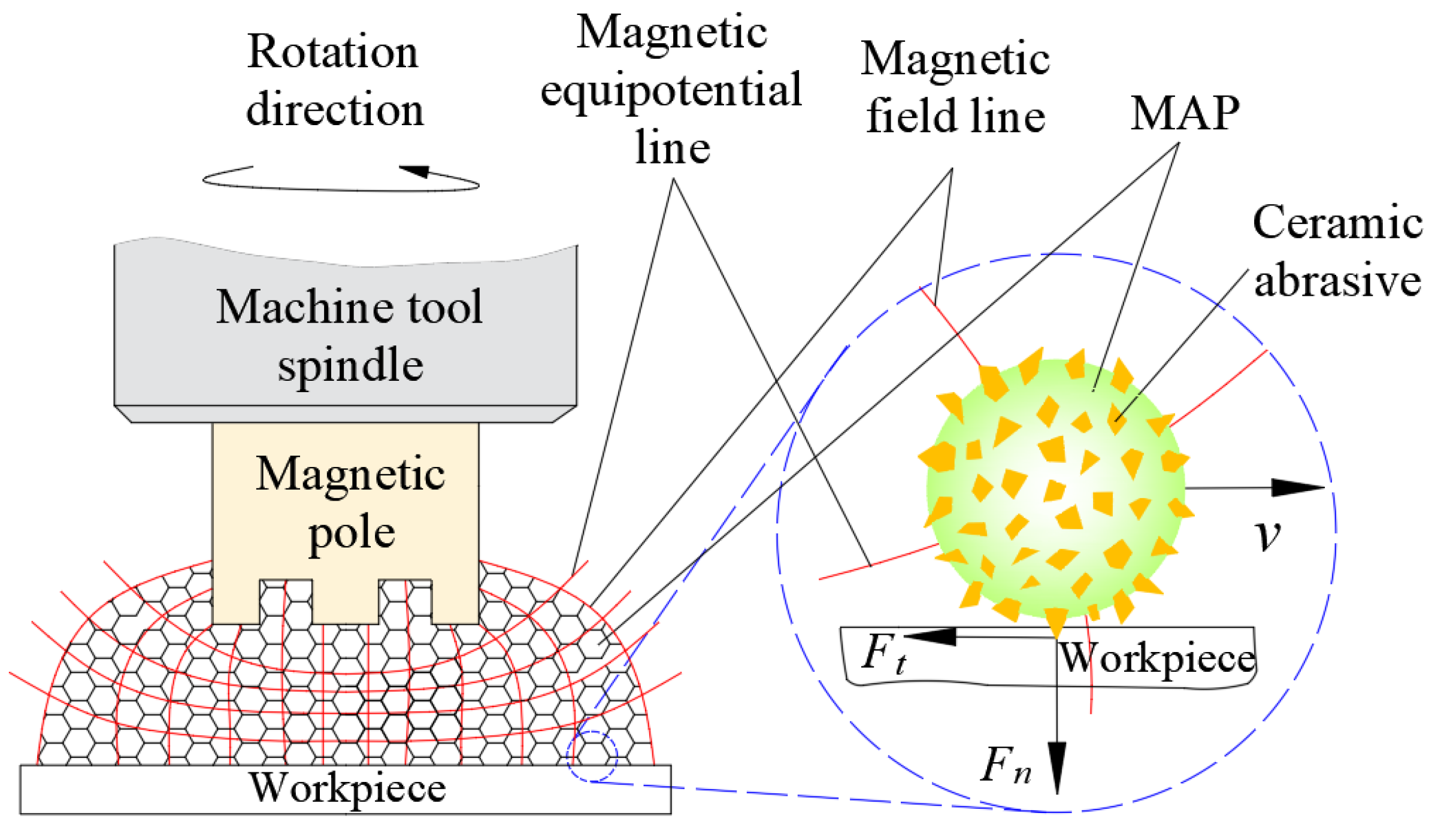

2.1. Experimental Principles

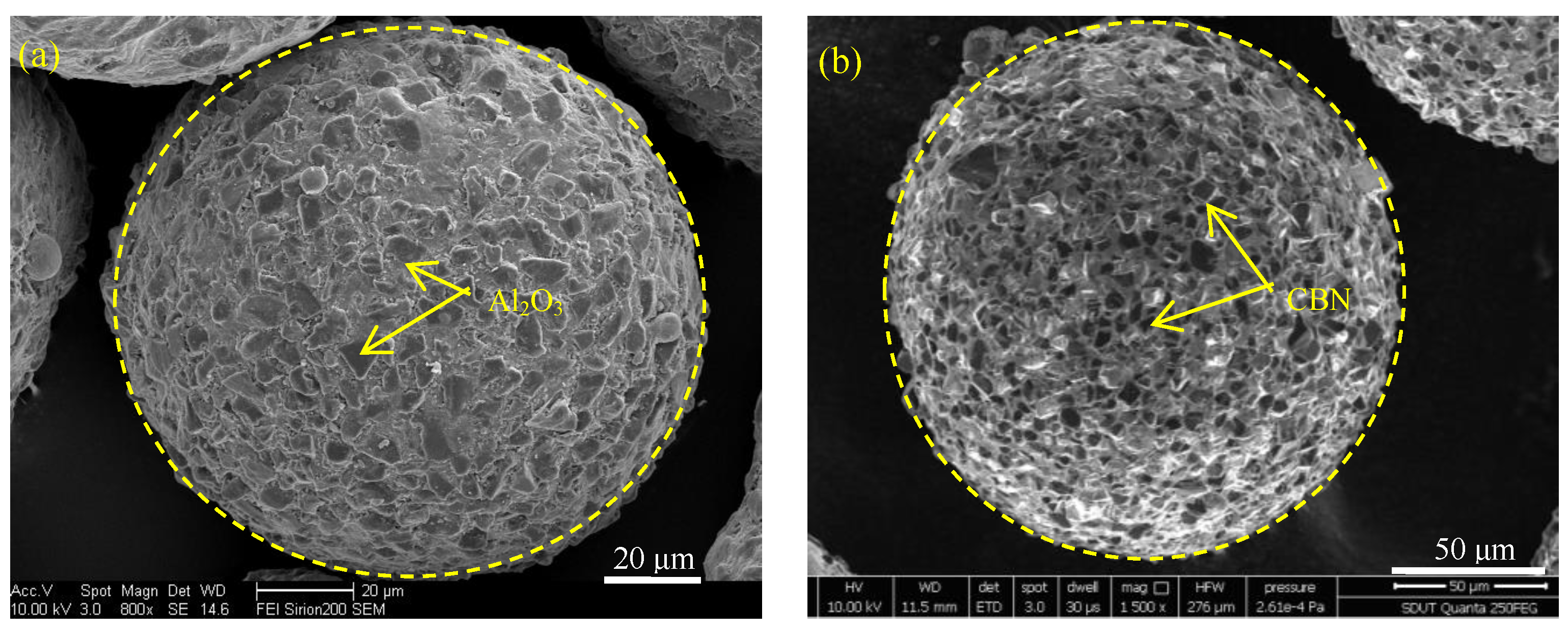

2.2. Experimental Materials

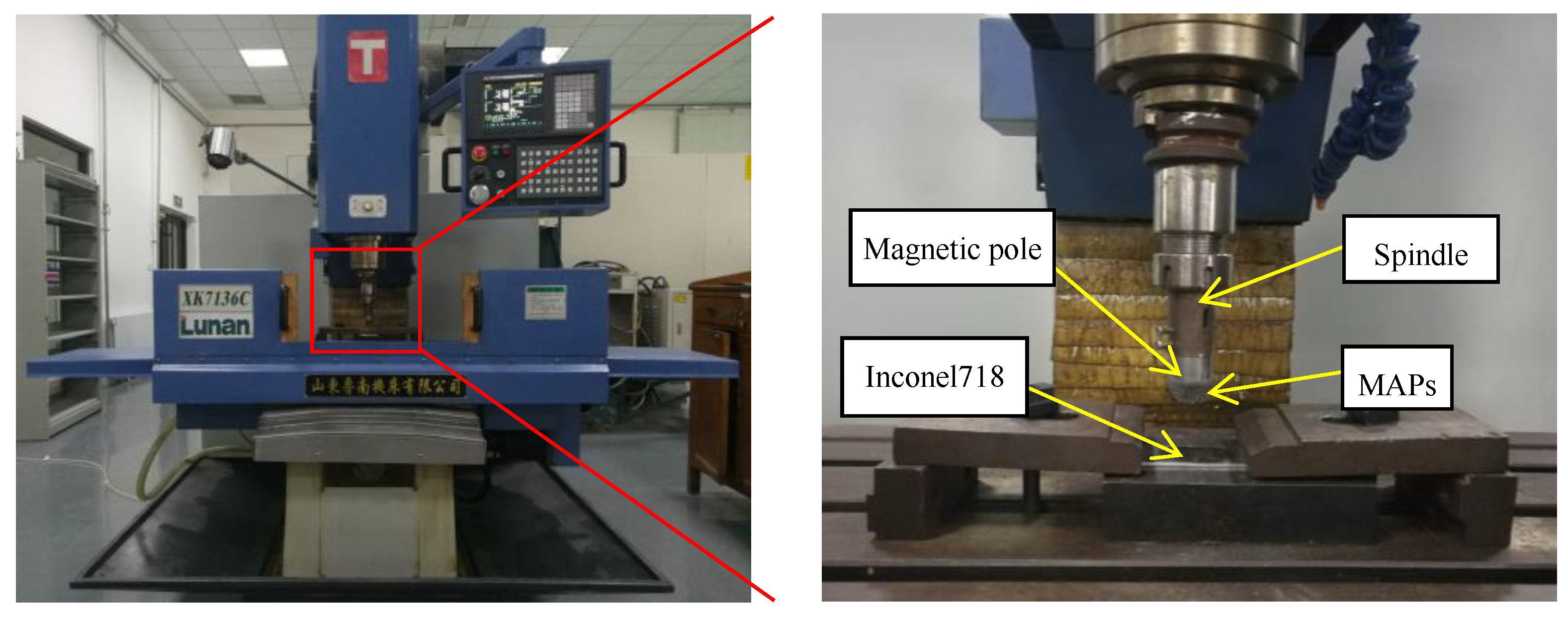

2.3. Experimental Setup and Conditions

3. Results and Discussion

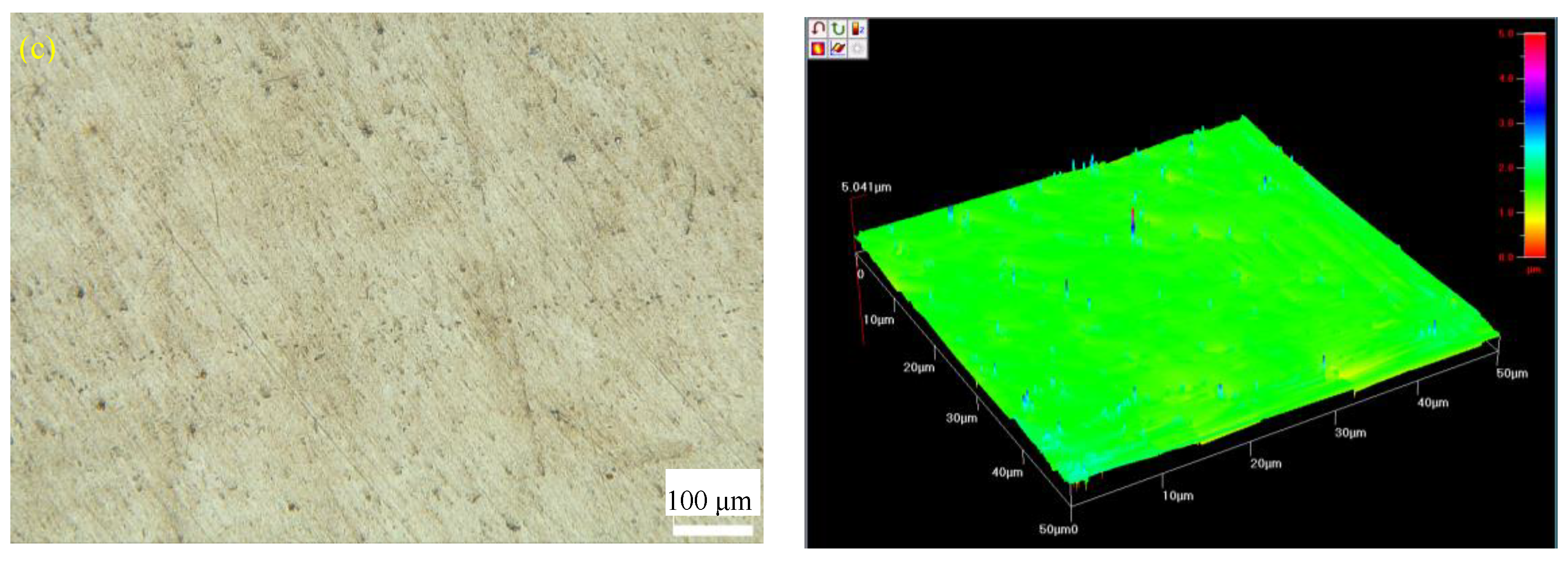

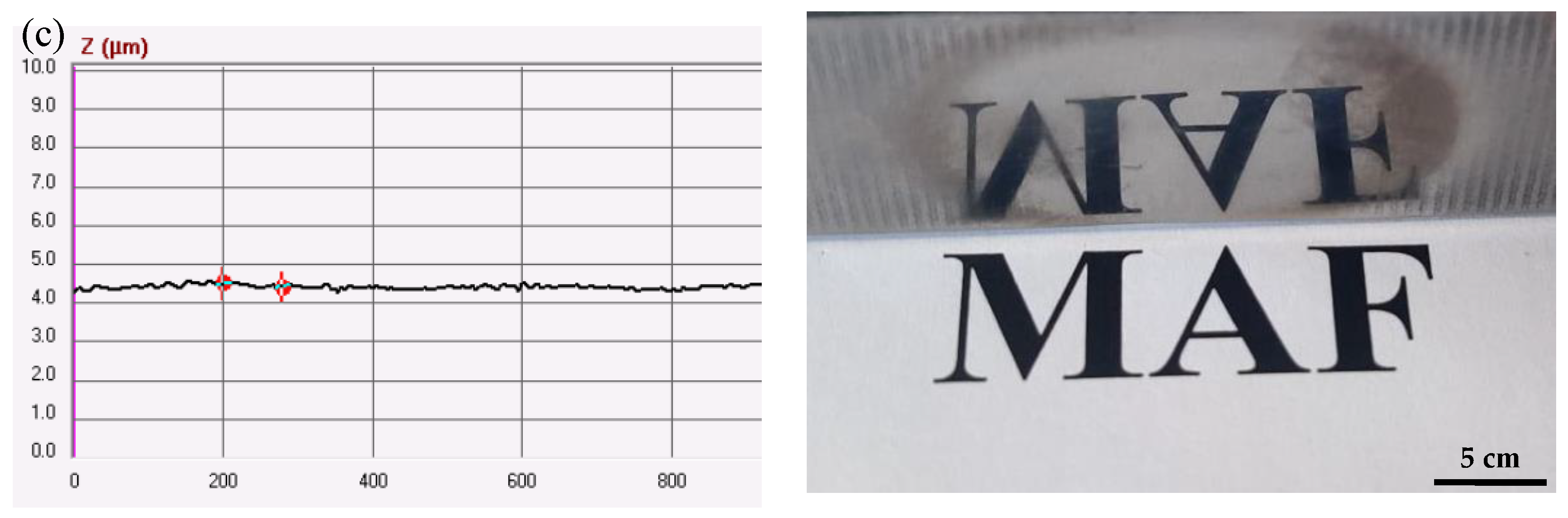

3.1. Surface Morphology Changes of Inconel 718 Superalloy

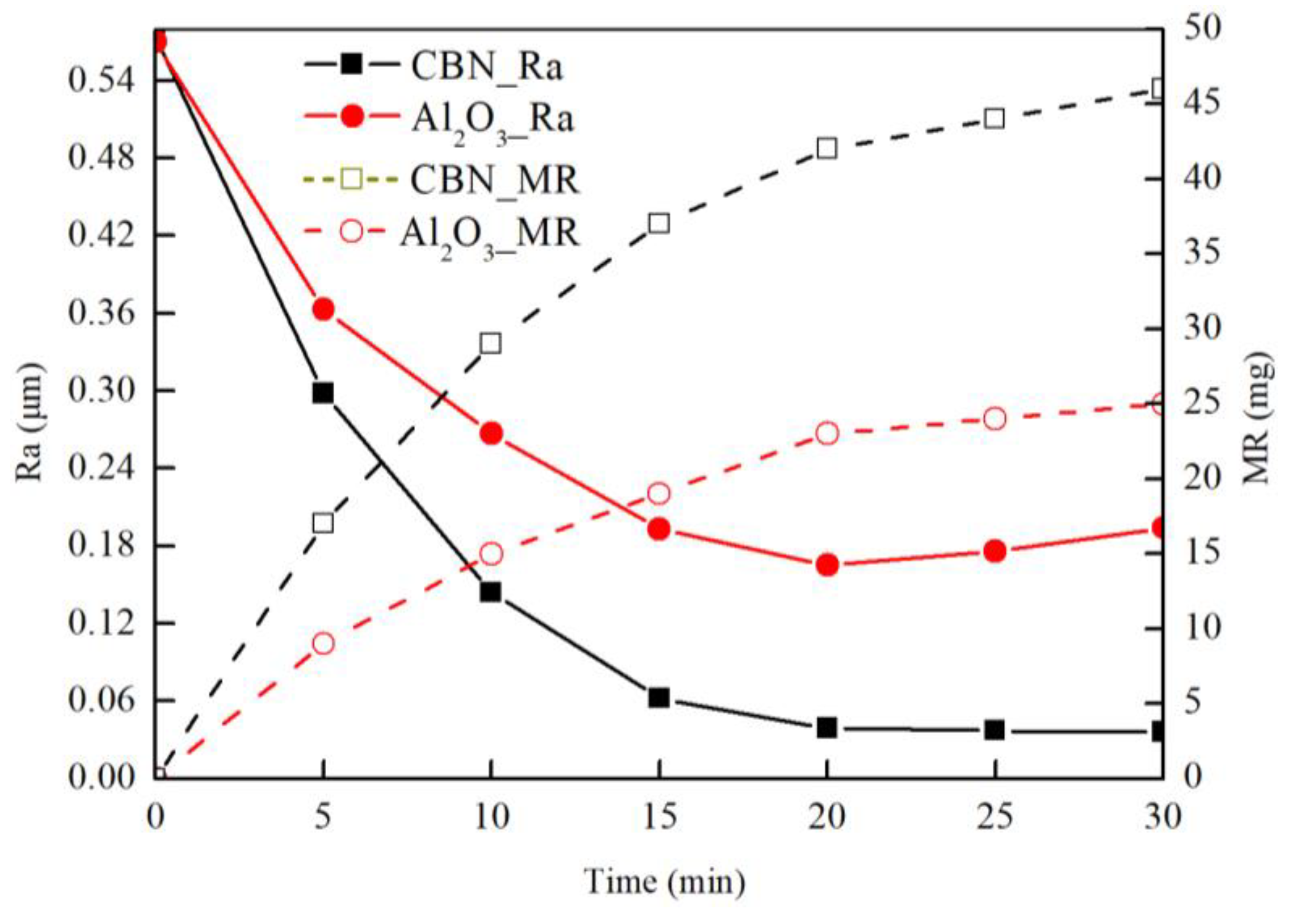

3.2. Changes in Surface Roughness and Material Removal of Inconel 718 Superalloy

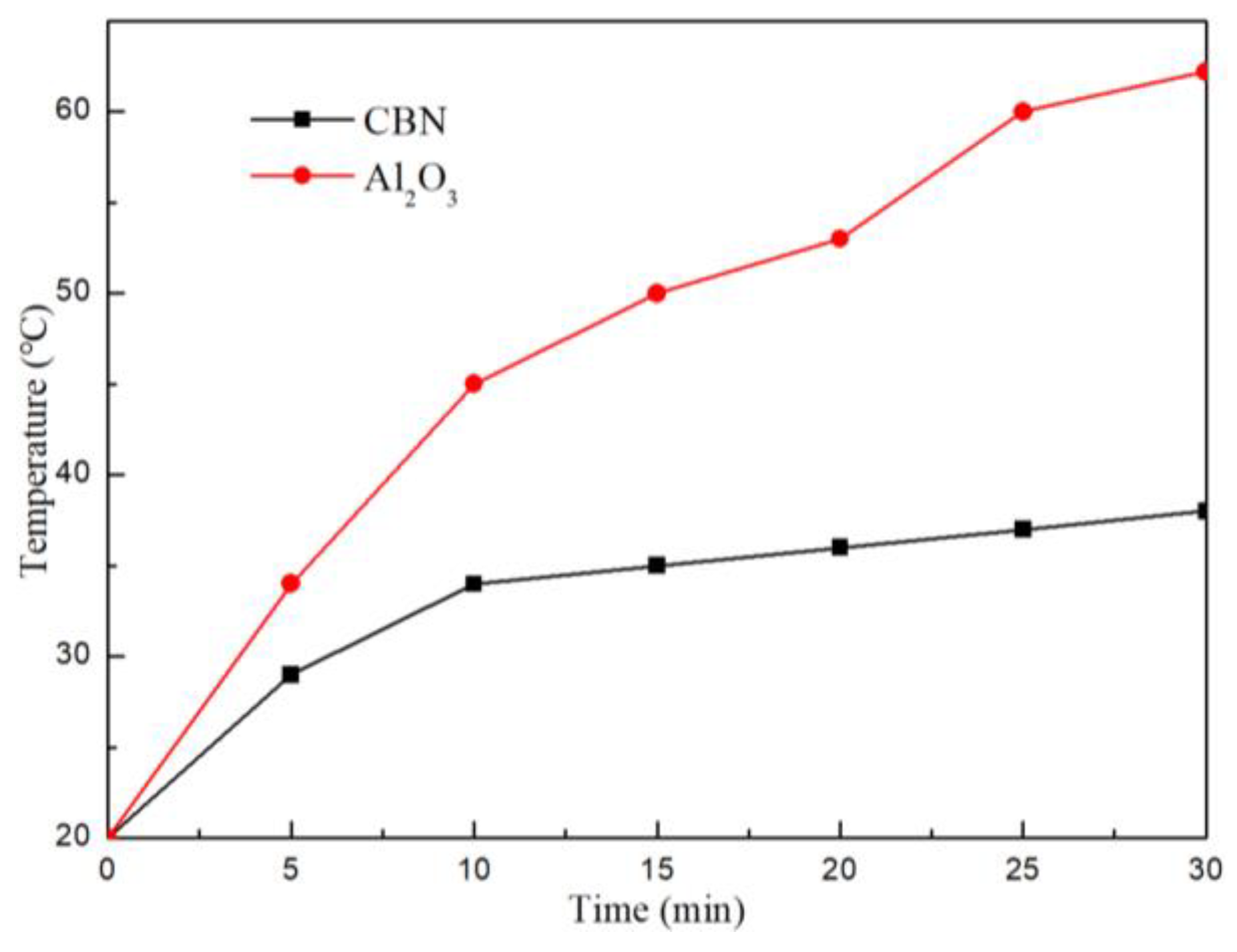

3.3. Surface Temperature Changes of Inconel 718 Superalloy

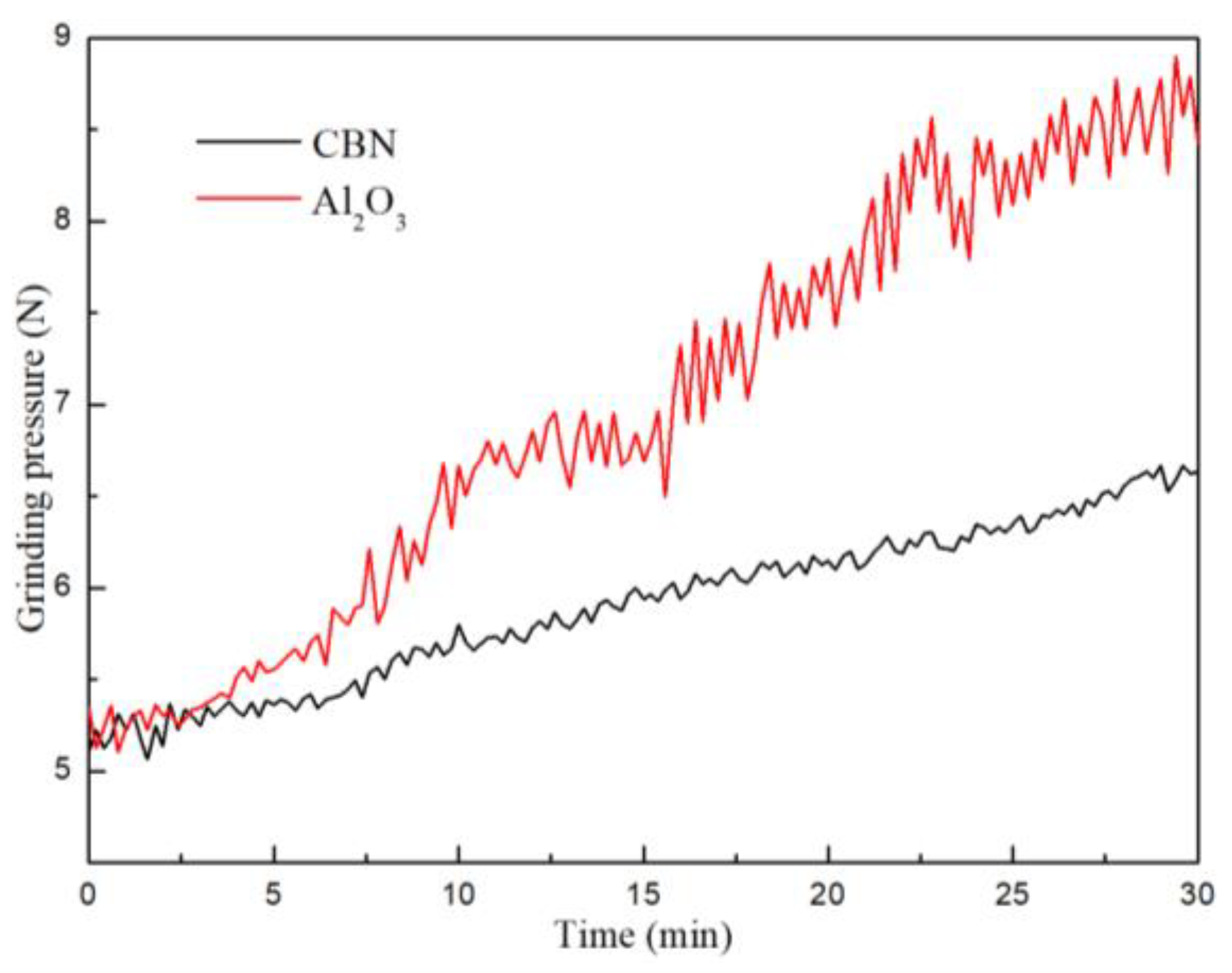

3.4. Surface Grinding Force Changes of Inconel 718 Superalloy

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Sebbe, N.P.V.; Fernandes, F.; Silva, F.J.G.; Pedroso, A.F.V.; Sales-Contini, R.C.M.; Barbosa, M.L.S.; Durão, L.M.; Magalhães, L.L. Wear Behavior of TiAlVN-Coated Tools in Milling Operations of INCONEL® 718. Coatings 2024, 14, 311. [Google Scholar] [CrossRef]

- Sharma, S.; Palaniappan, K.; Mishra, V.D. Mechanical Characterization of Near-Isotropic Inconel 718 Fabricated by Laser Powder-Bed Fusion. Metall. Mater. Trans. A 2023, 54, 270–285. [Google Scholar] [CrossRef]

- Du, J.; Cheng, W.; Sun, Y.; Ma, R.; Liu, H.; Song, X.; Yang, J.; Tan, C. The Effect of Precipitates on the Stress Rupture Properties of Laser Powder Bed Fusion Inconel 718 Alloy. Coatings 2023, 13, 2087. [Google Scholar] [CrossRef]

- Panteleenko, F.I.; Maksarov, V.V.; Petrishin, G.V. Fast Magnetic Abrasive Finishing with Diffusionally Alloyed Powder. Russ. Eng. Res. 2023, 43, 470–473. [Google Scholar]

- Mousa, S.M.; Hameed, A.S.; Ibrahim, A.F. Measurement from the residual stresses on magnetic abrasive finishing process by utilizing steel sheet 201. In Multiscale and Multidisciplinary Modeling, Experiments and Design; Springer: Berlin/Heidelberg, Germany, 2024. [Google Scholar] [CrossRef]

- Maraboina, R.; Pasam, V.K. Enhancing Surface Integrity of Selective Laser Melted Al-Si Alloys through Ultrasonic Assisted Magnetic Abrasive Finishing utilizing SiC Abrasives. Silicon 2024, 16, 1183–1196. [Google Scholar] [CrossRef]

- Zhou, Z.; Sun, X.; Yang, Y.; Fu, Y. A Study on Using Magnetic Abrasive Finishing with a 6-Axis Robot to Polish the Internal Surface Finishing of Curved Tubes. Coatings 2023, 13, 1179. [Google Scholar] [CrossRef]

- Zhang, X.; Zhao, X.; Cheng, B. Finishing mechanism modelling on magnetic abrasive finishing behaviours with core-shell magnetic abrasive particles. Int. J. Adv. Manuf. Technol. 2023, 129, 573–585. [Google Scholar] [CrossRef]

- Kumar, Y.; Singh, H. Development of Novel Low-Cost Sintered Magnetic Abrasive for Surface Finishing. In Advances in Micro and Nano Manufacturing and Surface Engineering; Bhattacharyya, B., Mathew, J., Saravanakumar, N., Rajeshkumar, G., Eds.; Lecture Notes in Mechanical Engineering; Springer: Singapore, 2022. [Google Scholar] [CrossRef]

- Zhang, W. Dynamic Accumulation Mechanism of Magnetic Abrasive Particles on the Saw Wire Surface. Trans. Electr. Electron. Mater. 2022, 23, 535–543. [Google Scholar] [CrossRef]

- Wang, Z.; Ding, Y.; Wang, P. Research of dry tribochemical mechanical polishing SiC with an innovation abrasive-catalytic abrasive cluster. Int. J. Adv. Manuf. Technol. 2024, 131, 2365–2376. [Google Scholar] [CrossRef]

- Mosavat, M.; Rahimi, A. Numerical-experimental study on polishing of silicon wafer using magnetic abrasive finishing process. Wear 2019, 424–425, 143–150. [Google Scholar] [CrossRef]

- Guo, J.; Feng, W.; Jia, H. Finishing of rectangular microfeatures by localized vibration-assisted magnetic abrasive polishing method. J. Manuf. Process. 2020, 49, 204–213. [Google Scholar] [CrossRef]

- Heng, L.; Kim, J.; Tu, J. Fabrication of precision meso-scale diameter ZrO2 ceramic bars using new magnetic pole designs in ultra-precision magnetic abrasive finishing. Ceram. Int. 2020, 46, 17335–17346. [Google Scholar] [CrossRef]

- Babbar, A.; Prakash, C.; Singh, S. Application of hybrid nature-inspired algorithm: Single and bi-objective constrained optimization of magnetic abrasive finishing process parameters. J. Mater. Res. Technol. 2020, 9, 7961–7974. [Google Scholar] [CrossRef]

- Tan, Y.; Ni, Y.; Xu, W. Key technologies and development trends of the soft abrasive flow finishing method. J. Zhejiang Univ. Sci. A 2023, 24, 1043–1064. [Google Scholar] [CrossRef]

- Wang, Z.; Yang, Y.; Wang, S. The Effect of Hydrogen Peroxide on Composite Lapping of Titanium Alloy (TC4) by Free Abrasive Assisted Fixed Abrasive. J. Inst. Eng. India Ser. E 2023, 104, 171–183. [Google Scholar] [CrossRef]

- Li, W.; Li, J.; Cheng, B. Achieving in-situ alloy-hardening core-shell structured carbonyl iron powders for magnetic abrasive finishing. Mater. Des. 2021, 212, 110198. [Google Scholar] [CrossRef]

- Jiang, L.; Chang, T.; Zhang, G. Influence of process conditions on preparation of CBN/Fe-based spherical magnetic abrasive via gas atomization. Ceram. Int. 2021, 47, 31367–31374. [Google Scholar] [CrossRef]

- Jiang, L.; Chang, T.; Zhang, G. Formation mechanism of ceramic/metal composite spherical magnetic abrasive prepared via gas-solid atomization. J. Alloys Compd. 2022, 923, 166400. [Google Scholar] [CrossRef]

- Jiang, L.; Zhang, G.; Du, J. Processing performance of Al2O3/Fe-based composite spherical magnetic abrasive particles. J. Magn. Magn. Mater. 2021, 528, 167811. [Google Scholar] [CrossRef]

| Material | Al2O3 | CBN |

|---|---|---|

| Density/g·cm−3 | 3.5 | 3.48 |

| Nup hardness/N·mm−2 | 21,000~24,000 | 45,000~48,000 |

| Bending strength/N·mm−2 | 80~90 | 300 |

| Compressive strength/N·mm−2 | 3000 | 7200 |

| Coefficient of thermal expansion/10−6·K−1 | 8.5 | 2.5~2.6 |

| Thermal diffusivity/m2·s−1 | 0.36 | 4.03 |

| Melting point/°C | 2050 | 2220 |

| Processing Parameter | Value |

|---|---|

| Workpiece | Inconel 718 superalloy (60 × 30 × 2 mm) |

| MAPs | Al2O3- and CBN/Fe-based spherical MAPs |

| Amount of MAPs | 2 g |

| Spindle speed | 1200 r/min |

| Feed rate | 15 mm/min |

| Working gap | 2 mm |

| Processing time | 30 min |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jiang, L.; Zhang, G.; Zhang, H.; Xia, Y.; Xiang, J. A Comparative Study of Machining Property in Inconel 718 Superalloy Grinding with Al2O3- and CBN/Fe-Based Spherical Magnetic Abrasives. Coatings 2024, 14, 686. https://doi.org/10.3390/coatings14060686

Jiang L, Zhang G, Zhang H, Xia Y, Xiang J. A Comparative Study of Machining Property in Inconel 718 Superalloy Grinding with Al2O3- and CBN/Fe-Based Spherical Magnetic Abrasives. Coatings. 2024; 14(6):686. https://doi.org/10.3390/coatings14060686

Chicago/Turabian StyleJiang, Linzhi, Guixiang Zhang, Haozhe Zhang, Yandan Xia, and Jinli Xiang. 2024. "A Comparative Study of Machining Property in Inconel 718 Superalloy Grinding with Al2O3- and CBN/Fe-Based Spherical Magnetic Abrasives" Coatings 14, no. 6: 686. https://doi.org/10.3390/coatings14060686

APA StyleJiang, L., Zhang, G., Zhang, H., Xia, Y., & Xiang, J. (2024). A Comparative Study of Machining Property in Inconel 718 Superalloy Grinding with Al2O3- and CBN/Fe-Based Spherical Magnetic Abrasives. Coatings, 14(6), 686. https://doi.org/10.3390/coatings14060686