Effect of Arc Current on the Microstructure of AlTiN-Coated Tools and Milling of 304 Stainless Steel

Abstract

:1. Introduction

2. Experiment

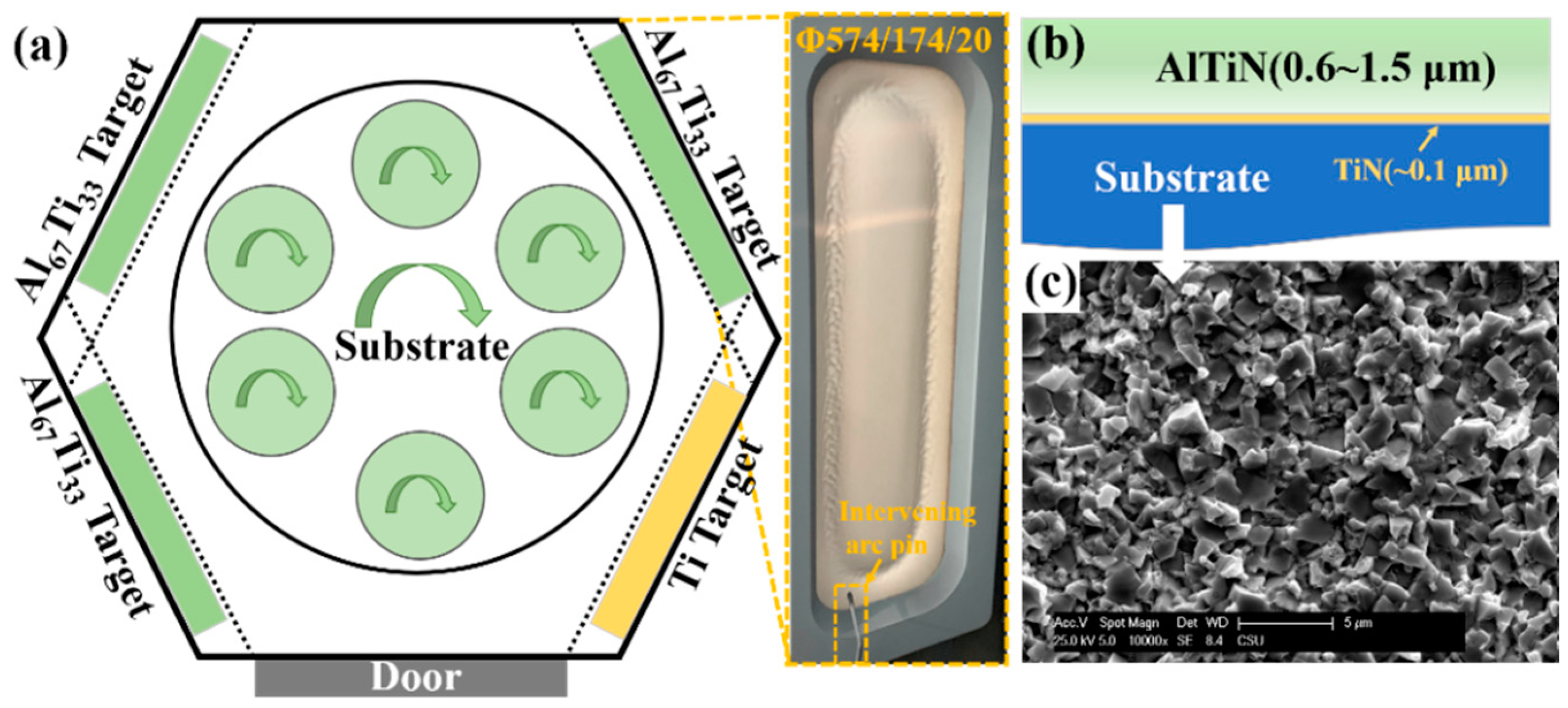

2.1. Coating Preparation

2.2. Microstructure Characterization

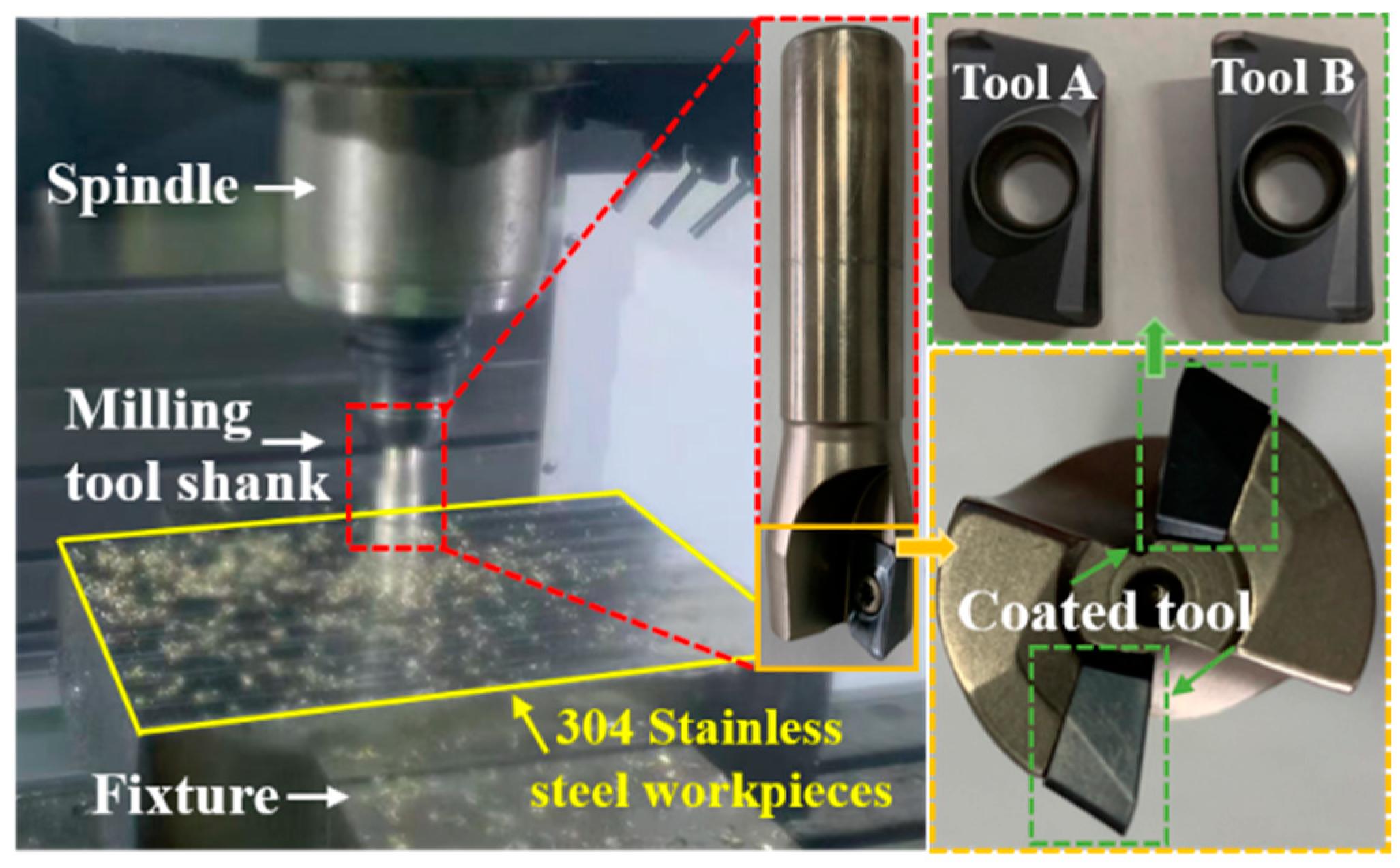

2.3. Mechanical Performance and Milling Cutter Testing

3. Results and Discussion

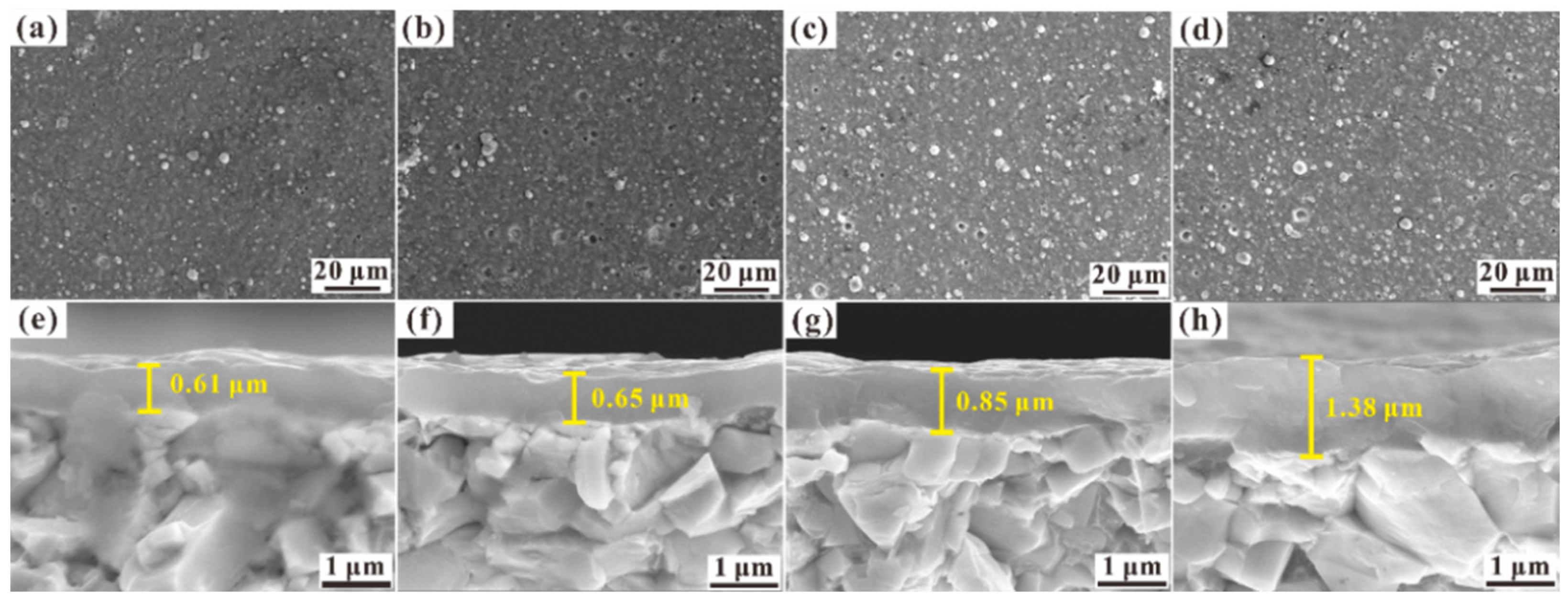

3.1. Effect of Arc Tatget on Microstructure

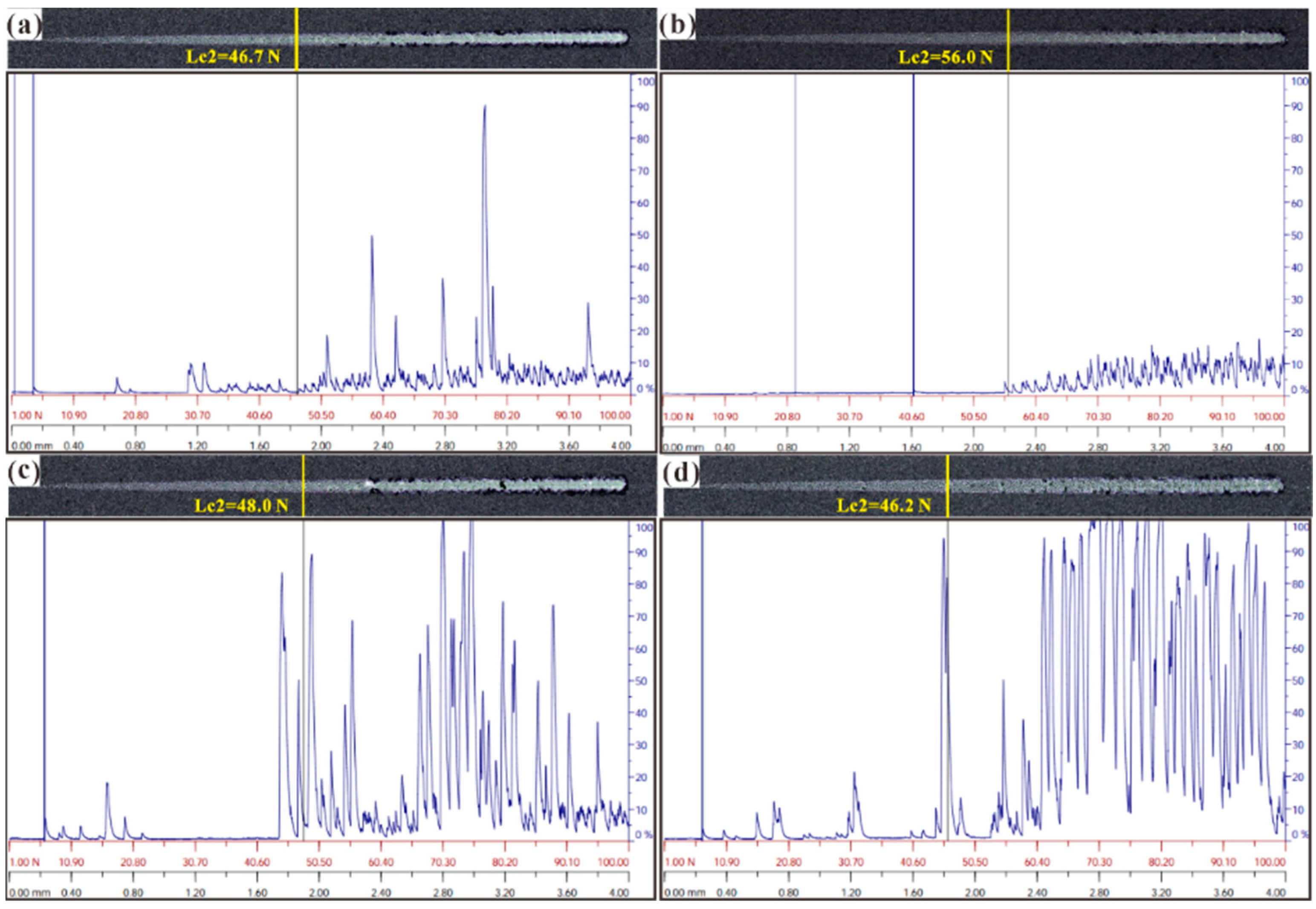

3.2. Mechanical Properties of Coatings

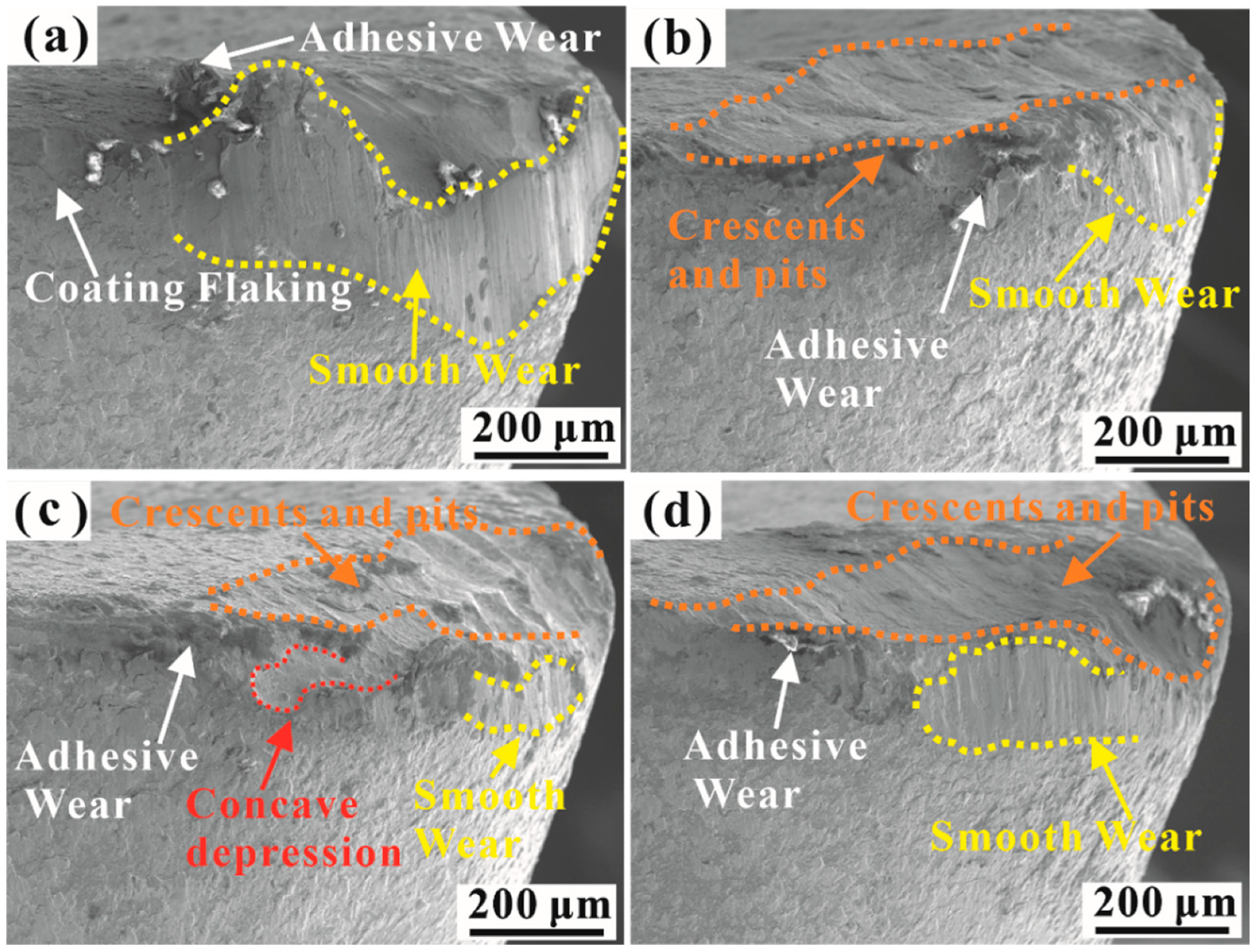

3.3. Milling Performance of Coated Tools

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- He, Q.; Paiva, J.M.; Kohlscheen, J.; Beake, B.D.; Veldhuis, S.C. An integrative approach to coating/carbide substrate design of CVD and PVD coated cutting tools during the machining of austenitic stainless steel. Ceram. Int. 2020, 46, 5149–5158. [Google Scholar] [CrossRef]

- Junaidh, A.P.; Yuvaraj, G.; Peter, J.; Bhuvaneshwari, V.; Kanagasabapathi; Karthik, K. Influence of Process Parameters on the Machining Characteristics of Austensite Stainless Steel (AISI 304). Mater. Today Proc. 2018, 5, 13321–13333. [Google Scholar] [CrossRef]

- He, Q.; Jin, Z.J.; Jiang, G.N.; Shi, Y. The investigation on electrochemical denatured layer of 304 stainless steel. Mater. Manuf. Process. 2018, 33, 1661–1666. [Google Scholar] [CrossRef]

- Varghese, V.; Akhil, K.; Ramesh, M.R.; Chakradhar, D. Investigation on the performance of AlCrN and AlTiN coated cemented carbide inserts during end milling of maraging steel under dry, wet and cryogenic environments. J. Manuf. Process. 2019, 43, 136–144. [Google Scholar] [CrossRef]

- Santhanakumar, M.; Adalarasan, R.; Siddharth, S.; Velayudham, A. An investigation on surface finish and flank wear in hard machining of solution treated and aged 18% Ni maraging steel. J. Braz. Soc. Mech. Sci. Eng. 2017, 39, 2071–2084. [Google Scholar] [CrossRef]

- de Paiva, J.M.F.; Torres, R.D.; Amorim, F.L.; Covelli, D.; Tauhiduzzaman, M.; Veldhuis, S.; Dosbaeva, G.; Fox-Rabinovich, G. Frictional and wear performance of hard coatings during machining of superduplex stainless steel. Int. J. Adv. Manuf. Technol. 2017, 92, 423–432. [Google Scholar] [CrossRef]

- Ren, Z.K.; Fan, W.W.; Hou, J.; Wang, T. A Numerical Study of Slip System Evolution in Ultra-Thin Stainless Steel Foil. Materials 2019, 12, 1819. [Google Scholar] [CrossRef] [PubMed]

- Radziejewska, J.; Psiuk, R.; Moscicki, T. Characterization and Wear Response of Magnetron Sputtered W-B and W-Ti-B Coatings on WC-Co Tools. Coatings 2020, 10, 1231. [Google Scholar] [CrossRef]

- Garcia, J.; Cipres, V.C.; Blomqvist, A.; Kaplan, B. Cemented carbide microstructures: A review. Int. J. Refract. Met. Hard Mater. 2019, 80, 40–68. [Google Scholar] [CrossRef]

- Mei, H.J.; Geng, D.S.; Wang, R.; Cheng, L.X.; Ding, J.C.; Luo, Q.S.; Zhang, T.F.; Wang, Q.M. Effect of Cu doping on the microstructure and mechanical properties of AlTiVN-Cu nanocomposite coatings. Surf. Coat. Technol. 2020, 402, 126490. [Google Scholar] [CrossRef]

- Wu, L.Y.; Qiu, L.C.; Du, Y.; Zeng, F.F.; Lu, Q.; Tan, Z.P.; Yin, L.; Chen, L.Y.; Zhu, J.F. Structure and Mechanical Properties of PVD and CVD TiAlSiN Coatings Deposited on Cemented Carbide. Crystals 2021, 11, 598. [Google Scholar] [CrossRef]

- Chen, Y.; Zhang, L.; Zhong, Z.; Wang, S. Effect of Substrates Characteristics on Tribological Behaviors of AlTiN-Based Coated WC–Co Cemented Carbides. Coatings 2022, 12, 1517. [Google Scholar] [CrossRef]

- Cipres, V.C.; Dalibon, E.L.; Garcia, J.; Escalada, L.; Roa, J.J.; Jimenez-Pique, E.; Soldera, F.; Bruhl, S.P.; Simison, S.; Llanes, L.; et al. Contact fatigue behaviour of CVD coated cemented carbides in dry and wet conditions. Wear 2022, 492–493, 204215. [Google Scholar] [CrossRef]

- Xiao, B.J.; Zhang, T.F.; Guo, Z.; Li, Z.; Fan, B.; Chen, G.X.; Xiong, Z.H.; Wang, Q.M. Mechanical, oxidation, and cutting properties of AlCrN/AlTiSiN nano-multilayer coatings. Surf. Coat. Technol. 2022, 433, 128094. [Google Scholar] [CrossRef]

- Yousaf, M.I.; Abudouwufu, T.; Yang, B.; Tolstoguzov, A.; Fu, D.J. Influence of Bilayer Thickness on Mechanical and Tribological Properties of (Ti-Al)N/MoN Nanostructured Hard Coatings Deposited by Cathodic Arc Ion Plating. Coatings 2023, 13, 1654. [Google Scholar] [CrossRef]

- Tian, C.X.; Xiang, Y.X.; Zou, C.W.; Yu, Y.J.; Abudouwufu, T.; Yang, B.; Fu, D.J. Mechanical and Tribological Properties of CrWN/MoN Nano-Multilayer Coatings Deposited by Cathodic Arc Ion Plating. Coatings 2024, 14, 367. [Google Scholar] [CrossRef]

- Xian, G.; Xiong, J.; Fan, H.Y.; Guo, Z.X.; Xian, L.J.; Sun, L.; Zhao, H.B. Effect of substrate pretreatments on the structure and properties of AlTiN coatings deposited on TiCN-based cermets. Thin Solid Film. 2023, 770, 139769. [Google Scholar] [CrossRef]

- Li, L.; Xian, L.J.; Xian, G.; Fan, H.Y.; Zhao, H.B. Excellent corrosion resistance and good wear resistance of amorphous AlTiO coating prepared by arc ion plating. Mater. Lett. 2024, 358, 135817. [Google Scholar] [CrossRef]

- Xu, J.P.; Xu, M.Z.; Wang, J.J.; Wang, H.W.; Gong, C.Z.; Yang, C.; Wang, C.Y.; Zhang, X.C.; Ma, T.H.; Zhao, J.X. Discharge characterization and technological application of an arc ion plating with a hollow cathode vacuum arc. J. Adhes. Sci. Technol. 2023, 37, 649–662. [Google Scholar] [CrossRef]

- He, Q.; DePaiva, J.M.; Kohlscheen, J.; Beake, B.D.; Veldhuis, S.C. Study of wear performance and tribological characterization of AlTiN PVD coatings with different Al/Ti ratios during ultra-high speed turning of stainless steel 304. Int. J. Refract. Met. Hard Mater. 2021, 96, 105570. [Google Scholar] [CrossRef]

- He, Q.X.; DePaiva, J.M.; Kohlscheen, J.; Veldhuis, S.C. Analysis of the performance of PVD AlTiN coating with five different Al/Ti ratios during the high-speed turning of stainless steel 304 under dry and wet cooling conditions. Wear 2022, 492–493, 2024213. [Google Scholar] [CrossRef]

- He, Q.; DePaiva, J.M.; Kohlscheen, J.; Veldhuis, S.C. A study of mechanical and tribological properties as well as wear performance of a multifunctional bilayer AlTiN PVD coating during the ultra-high-speed turning of 304 austenitic stainless steel. Surf. Coat. Technol. 2021, 423, 127577. [Google Scholar] [CrossRef]

- Cai, F.; Chen, M.H.; Li, M.X.; Zhang, S.H. Influence of negative bias voltage on microstructure and property of Al-Ti-N films deposited by multi-arc ion plating. Ceram. Int. 2017, 43, 3774–3783. [Google Scholar] [CrossRef]

- Tang, Y.; Ma, B.; Liu, B.; Yuan, W.; Yu, B.H.; Lu, L.S. Influences of Sedimentation Time and Target Current Ratio on Wear Resistance of a Magnetron Sputtered TiAlN Coating. Rare Met. Mater. Eng. 2016, 45, 3057–3061. [Google Scholar]

- Yan, Y.; Luo, Z.; Liu, K.; Zhang, C.; Wang, M.; Wang, X. Effect of Cryogenic Treatment on the Microstructure and Wear Resistance of 17Cr2Ni2MoVNb Carburizing Gear Steel. Coatings 2022, 12, 281. [Google Scholar] [CrossRef]

- Yang, J.; Heogh, W.; Ju, H.; Kang, S.; Jang, T.-S.; Jung, H.-D.; Jahazi, M.; Han, S.C.; Park, S.J.; Kim, H.S.; et al. Functionally graded structure of a nitride-strengthened Mg2Si-based hybrid composite. J. Magnes. Alloys 2024, 12, 1239–1256. [Google Scholar] [CrossRef]

- Li, J.; Tan, C.; Luo, X.; Xie, Z.; Zhong, X.; Wang, J.; Song, H. Preparation and toughness optimization of (AlCrSiN/TiN)20/Ti multilayer multiscale bionic tool coatings. Appl. Surf. Sci. 2023, 634, 157585. [Google Scholar] [CrossRef]

- Mei, H.J.; Yan, K.; Wang, R.; Peng, W.C.; Huang, K.J.; Shi, J.J.; Zhang, D.D.; Gong, W.P.; Ren, F.Z.; Wang, Q.M. Microstructure and mechanical properties of nanomultilayered AlTiN/Cu coatings prepared by a hybrid system of AIP and PDCMS. Ceram. Int. 2023, 49, 226–235. [Google Scholar] [CrossRef]

- Xiao, B.-J.; Chen, Y.; Dai, W.; Kwork, K.-Y.; Zhang, T.-F.; Wang, Q.-M.; Wang, C.-Y.; Kim, K.H. Microstructure, mechanical properties and cutting performance of AlTiN coatings prepared via arc ion plating using the arc splitting technique. Surf. Coat. Technol. 2017, 311, 98–103. [Google Scholar] [CrossRef]

- Zhang, S.; Wu, W.; Chen, W.; Yang, S. Structural optimisation and synthesis of multilayers and nanocomposite AlCrTiSiN coatings for excellent machinability. Surf. Coat. Technol. 2015, 277, 23–29. [Google Scholar] [CrossRef]

- Kulkarni, A.P.; Sargade, V.G. Characterization and Performance of AlTiN, AlTiCrN, TiN/TiAlN PVD Coated Carbide Tools While Turning SS 304. Mater. Manuf. Process. 2015, 30, 748–755. [Google Scholar] [CrossRef]

- Gao, Z.; Li, Z.; Wen, G.; Wu, J.; Li, Y.; Zhao, Y.; Jin, M. Investigation of the tribological mechanisms of TiN-ZrO2-B4C ternary ceramic-reinforced copper-metal matrix composites. Tribol. Int. 2024, 196, 109705. [Google Scholar] [CrossRef]

- Zhao, J.; Liu, Z.; Ren, X.; Wang, B.; Cai, Y.; Song, Q.; Wan, Y. Coating-thickness-dependent physical properties and cutting temperature for cutting Inconel 718 with TiAlN coated tools. J. Adv. Res. 2022, 38, 191–199. [Google Scholar] [CrossRef]

- Bouzakis, K.D.; Batsiolas, M.; Sagris, D.; Michailidis, N.; Pappa, M.; Pavlidou, E. Diffusion and oxidation phenomena at elevated temperatures in the contact area between hardened steel and various PVD coatings. Surf. Coat. Technol. 2011, 205, S115–S118. [Google Scholar] [CrossRef]

- Bouzakis, A.; Skordaris, G.; Bouzakis, E.; Bouzakis, K.-D.; Tsakalidis, D. Wear Evolution on PVD Coated Cutting Tool Flank and Rake Explained Considering Stress, Strain and Strain-Rate Dependent Material Properties. Coatings 2023, 13, 1982. [Google Scholar] [CrossRef]

- Liu, J.; Zhu, S.-S.; Deng, X.; Liu, J.-Y.; Wang, Z.-P.; Qu, Z. Cutting Performance and Wear Behavior of AlTiN- and TiAlSiN-Coated Carbide Tools During Dry Milling of Ti-6Al-4V. Acta Metall. Sin. 2020, 33, 459–470. [Google Scholar] [CrossRef]

- An, Q.; Wang, C.; Xu, J.; Liu, P.; Chen, M. Experimental investigation on hard milling of high strength steel using PVD-AlTiN coated cemented carbide tool. Int. J. Refract. Met. Hard Mater. 2014, 43, 94–101. [Google Scholar] [CrossRef]

- Chim, Y.C.; Ding, X.Z.; Zeng, X.T.; Zhang, S. Oxidation resistance of TiN, CrN, TiAlN and CrAlN coatings deposited by lateral rotating cathode arc. Thin Solid Film. 2009, 517, 4845–4849. [Google Scholar] [CrossRef]

| Parameters | TiN Layer | AlTiN Layer |

|---|---|---|

| Rotation of the substrate holder, rpm | 3 | 3 |

| Nitrogen flow, sccm | 200 | 200 |

| Deposition temperature, °C | 550 | 550 |

| Arc current, A | 120 | 120, 140, 160, 180 |

| Bias voltage, -V | 800 | 60 |

| Deposition time, min | 5 | 210 |

| Types of Tools | Uncoated; AlTiN-Coated Milling Inserts Deposited by Four Different Arc Currents |

|---|---|

| Work materials | 304 stainless steel |

| Spindle revolution, rpm | 1500 |

| Cutting speed, m/min | 120 |

| Feed rate, mm/r | 0.09 0.5 Surface milling, dry |

| Cutting depth, mm | |

| Milling style |

| Arc Current(A) | Chemical Composition (at%) | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| C | N | O | Al | Si | Ti | Cr | Mn | Fe | Ni | W | |

| 120 | 58.43 | 3.05 | 18.42 | 0.54 | 0.22 | 0.19 | 3.91 | 0.37 | 11.78 | 1.07 | 2.02 |

| 140 | 57.33 | - | 9.54 | 0.39 | 0.44 | 0.01 | 7.13 | 0.95 | 21.73 | 2.29 | 0.20 |

| 160 | 42.37 | - | 9.85 | 0.60 | 0.48 | 0.14 | 10.0 | 1.20 | 30.71 | 2.90 | 1.72 |

| 180 | 34.50 | - | 19.93 | 0.35 | 0.50 | 0.04 | 10.0 | 1.52 | 28.15 | 2.76 | 2.20 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zou, S.; Luo, Z.; Li, Y.; Yuan, L.; Tang, Y.; Zhou, J.; Li, H. Effect of Arc Current on the Microstructure of AlTiN-Coated Tools and Milling of 304 Stainless Steel. Coatings 2024, 14, 704. https://doi.org/10.3390/coatings14060704

Zou S, Luo Z, Li Y, Yuan L, Tang Y, Zhou J, Li H. Effect of Arc Current on the Microstructure of AlTiN-Coated Tools and Milling of 304 Stainless Steel. Coatings. 2024; 14(6):704. https://doi.org/10.3390/coatings14060704

Chicago/Turabian StyleZou, Simin, Zixiang Luo, Yingxin Li, Liang Yuan, Yu Tang, Jialin Zhou, and Huizhong Li. 2024. "Effect of Arc Current on the Microstructure of AlTiN-Coated Tools and Milling of 304 Stainless Steel" Coatings 14, no. 6: 704. https://doi.org/10.3390/coatings14060704