Tribocatalytic Reaction Enabled by TiO2 Nanoparticle for MoDTC-Derived Tribofilm Formation at ta-C/Steel Contact

Abstract

:1. Introduction

2. Materials and Methods

3. Results

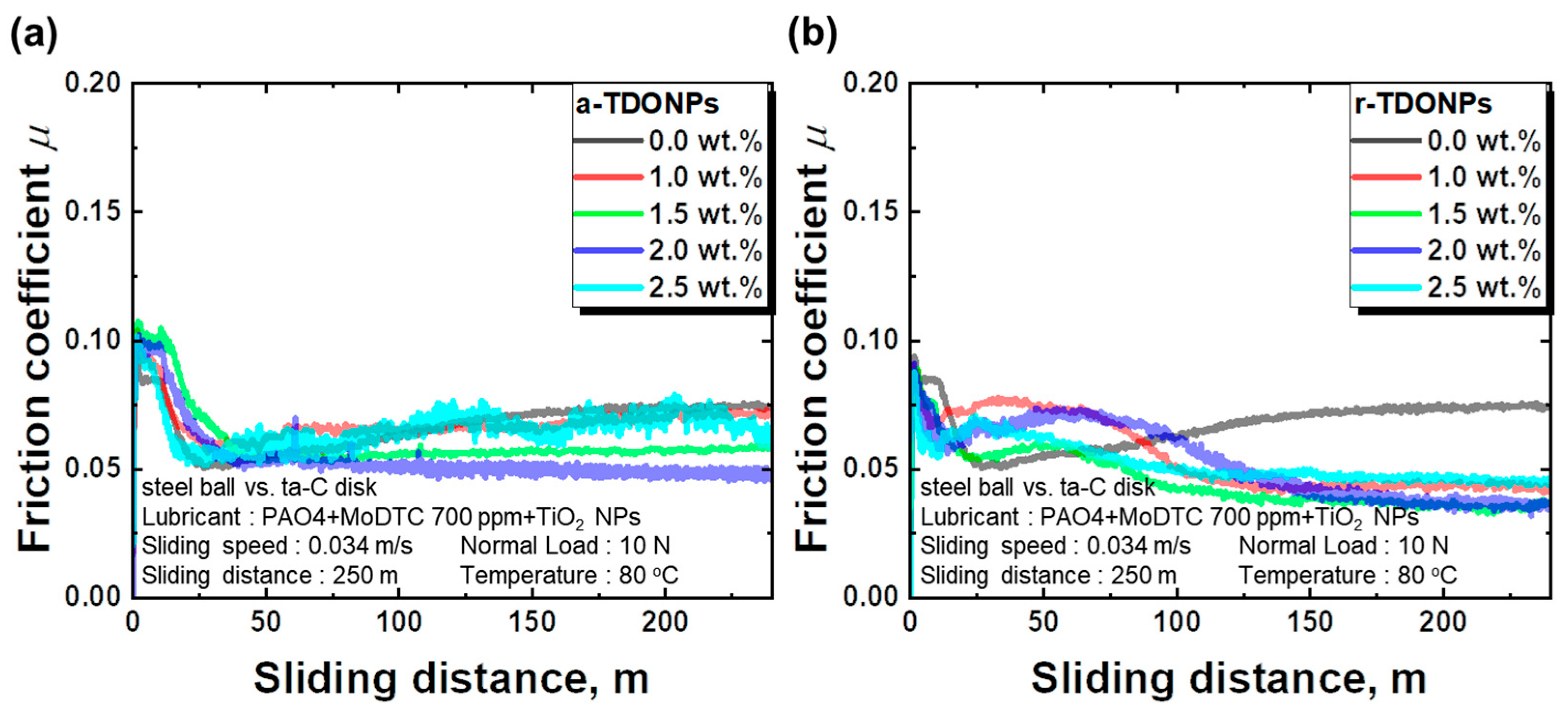

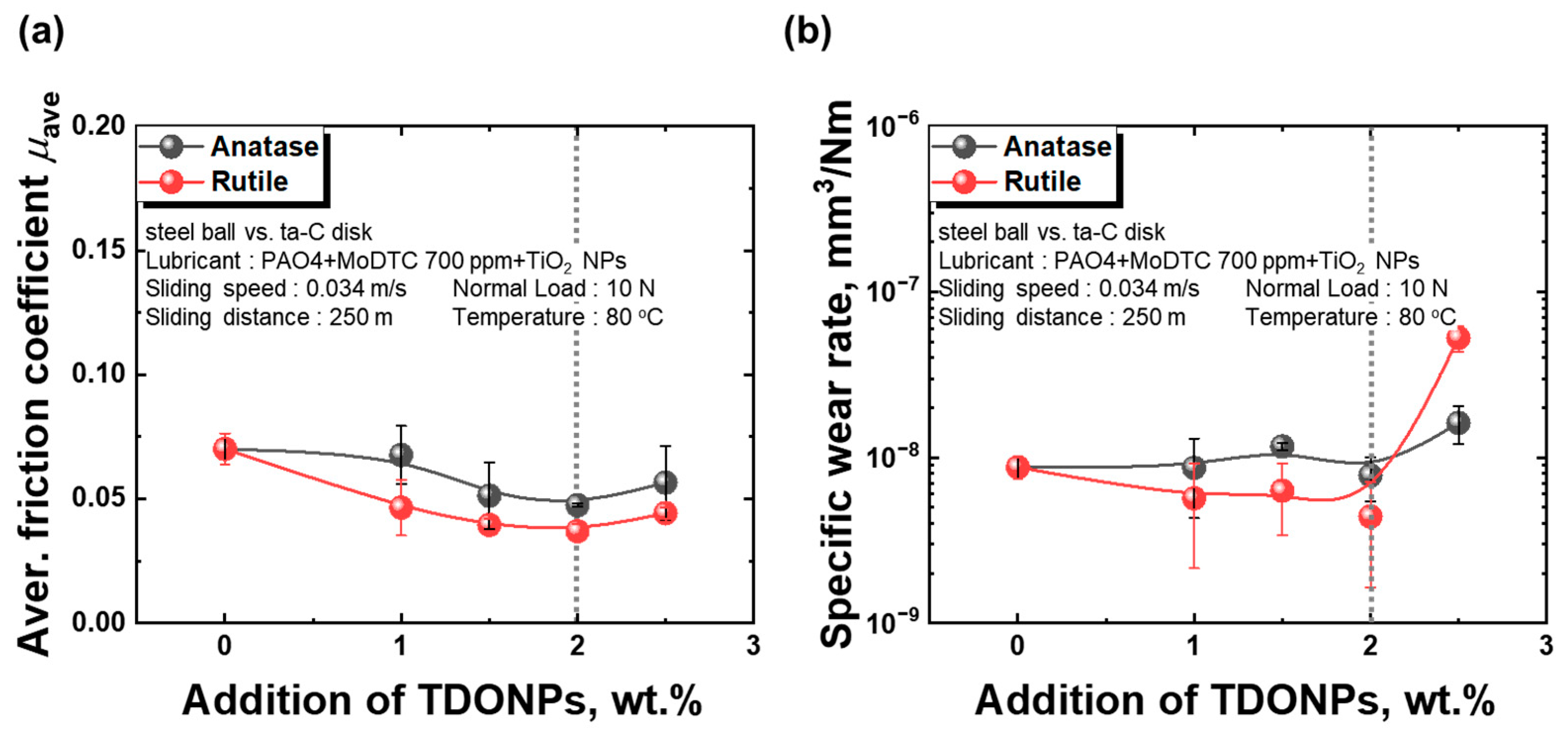

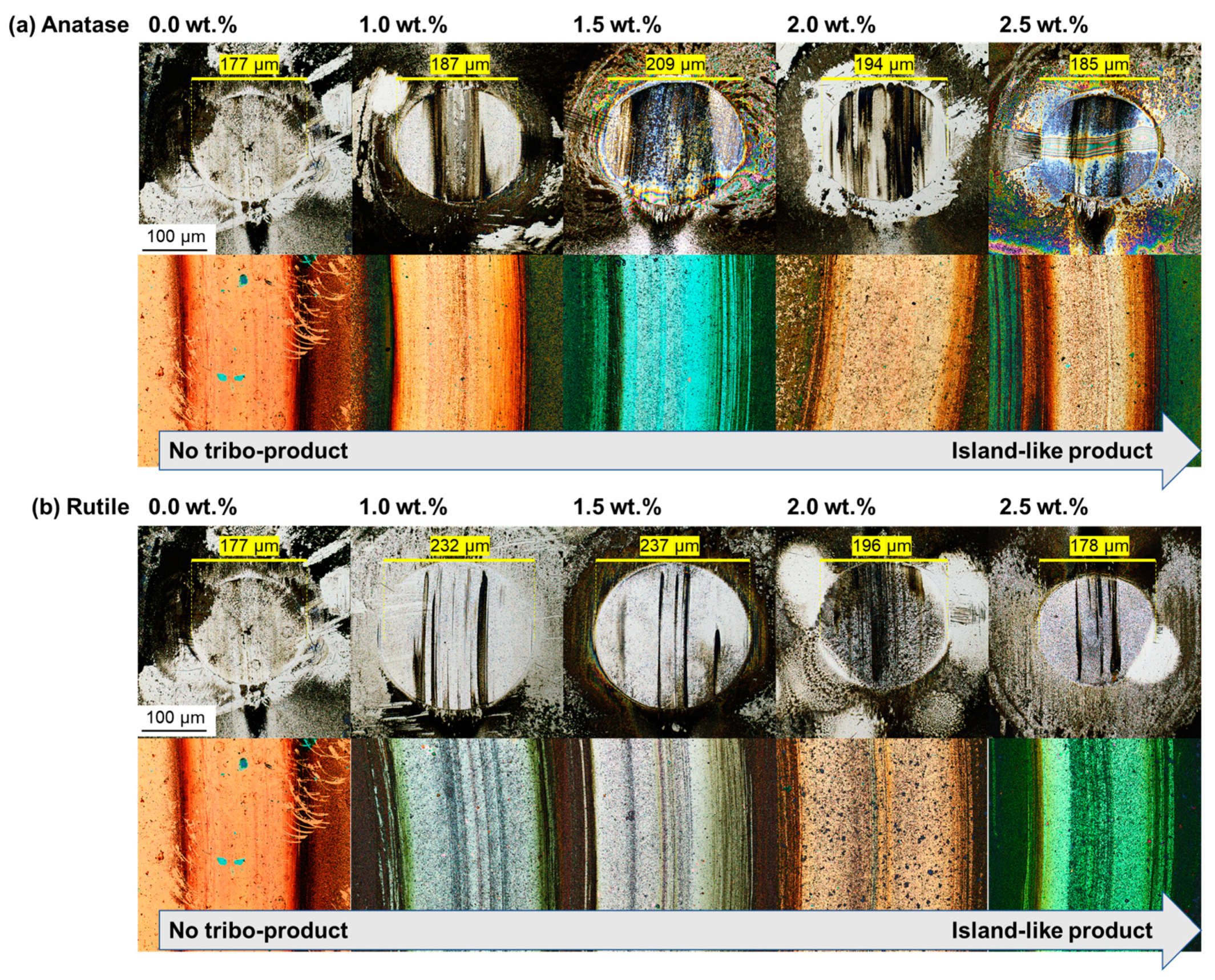

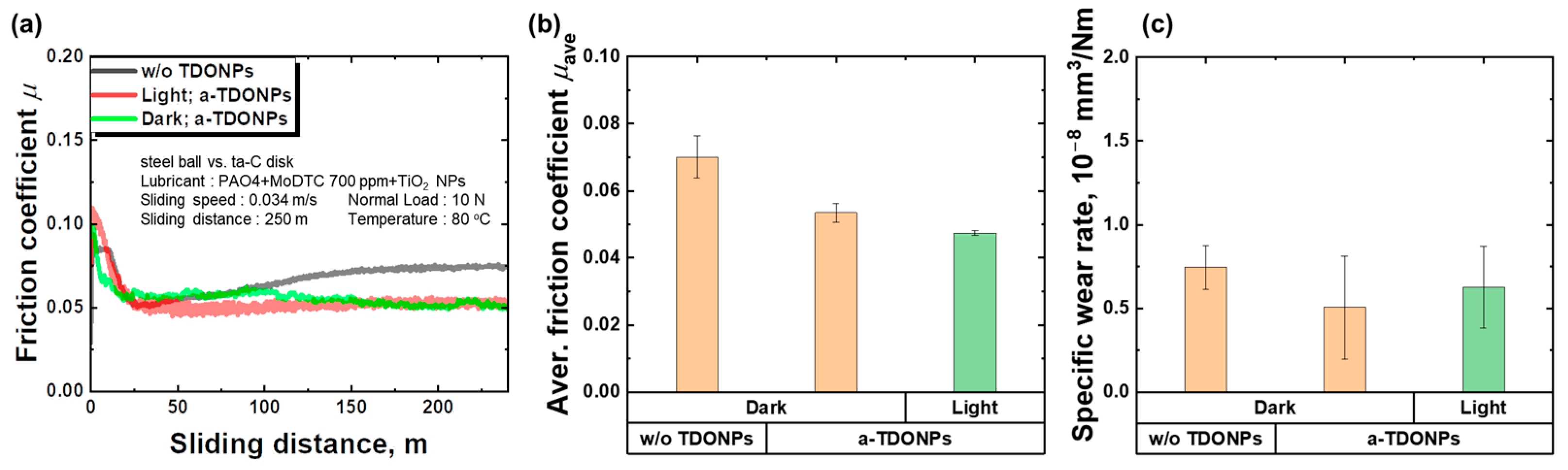

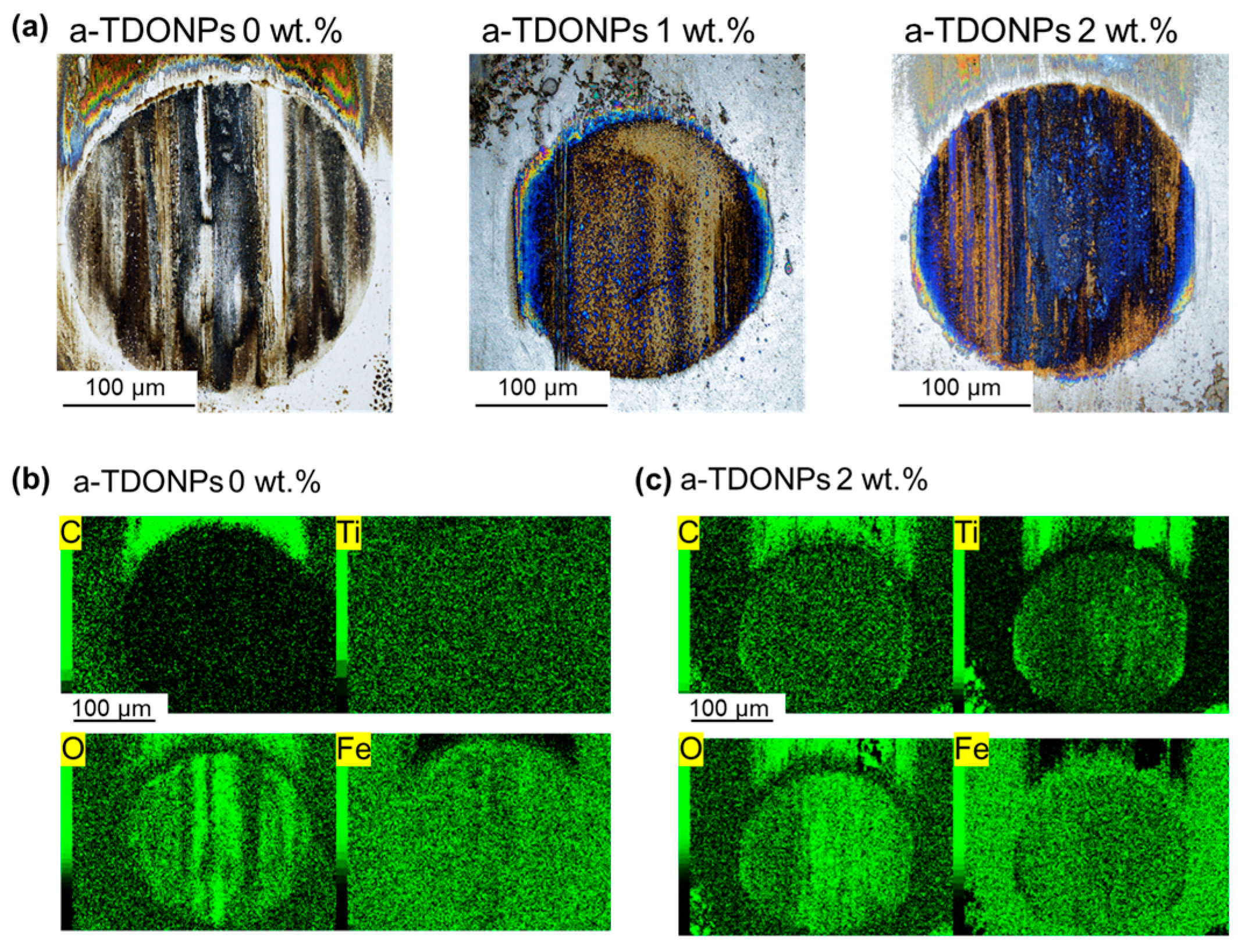

3.1. Friction Performance of TiO2 Nanoparticles with MoDTC Addition

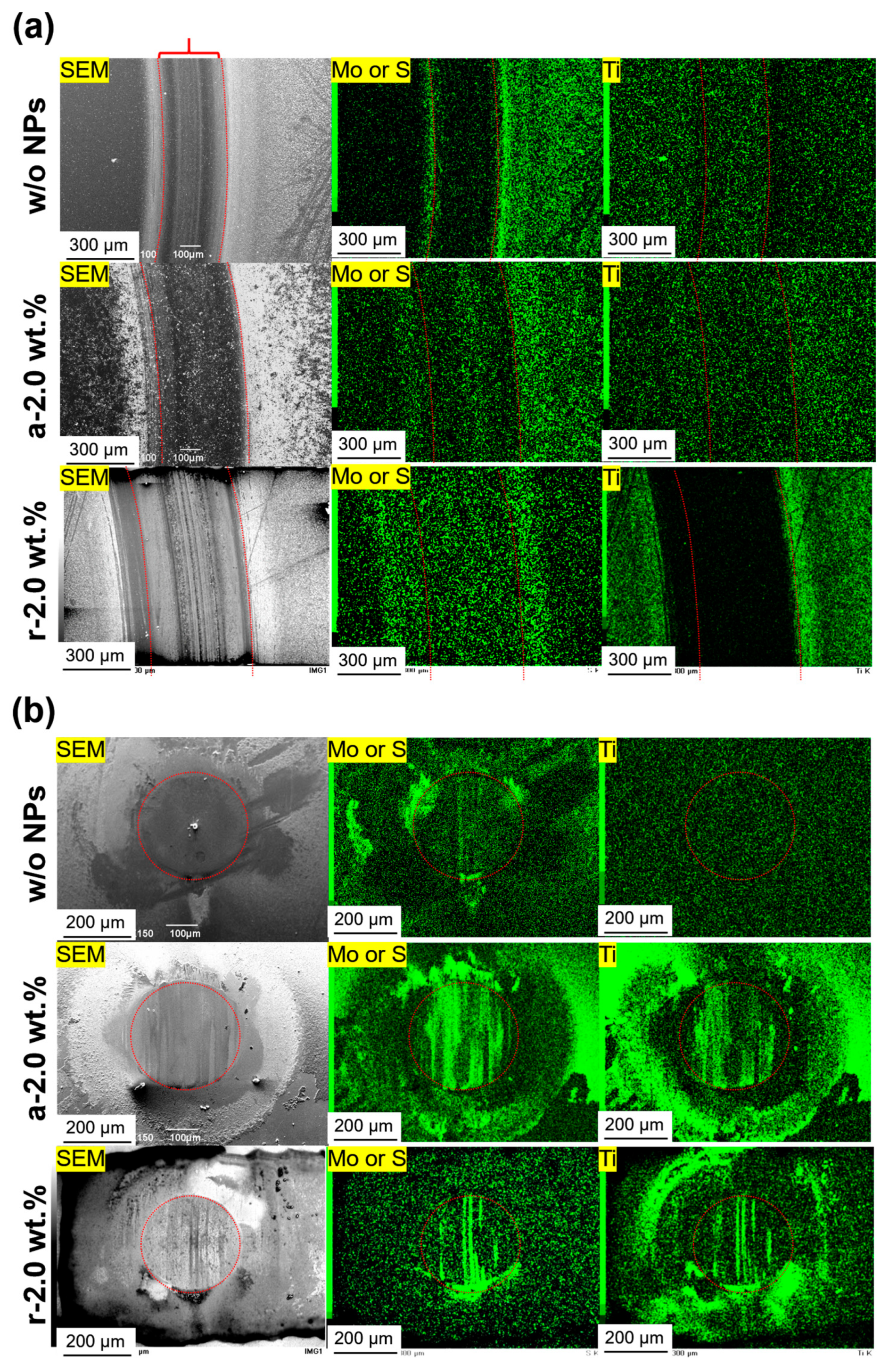

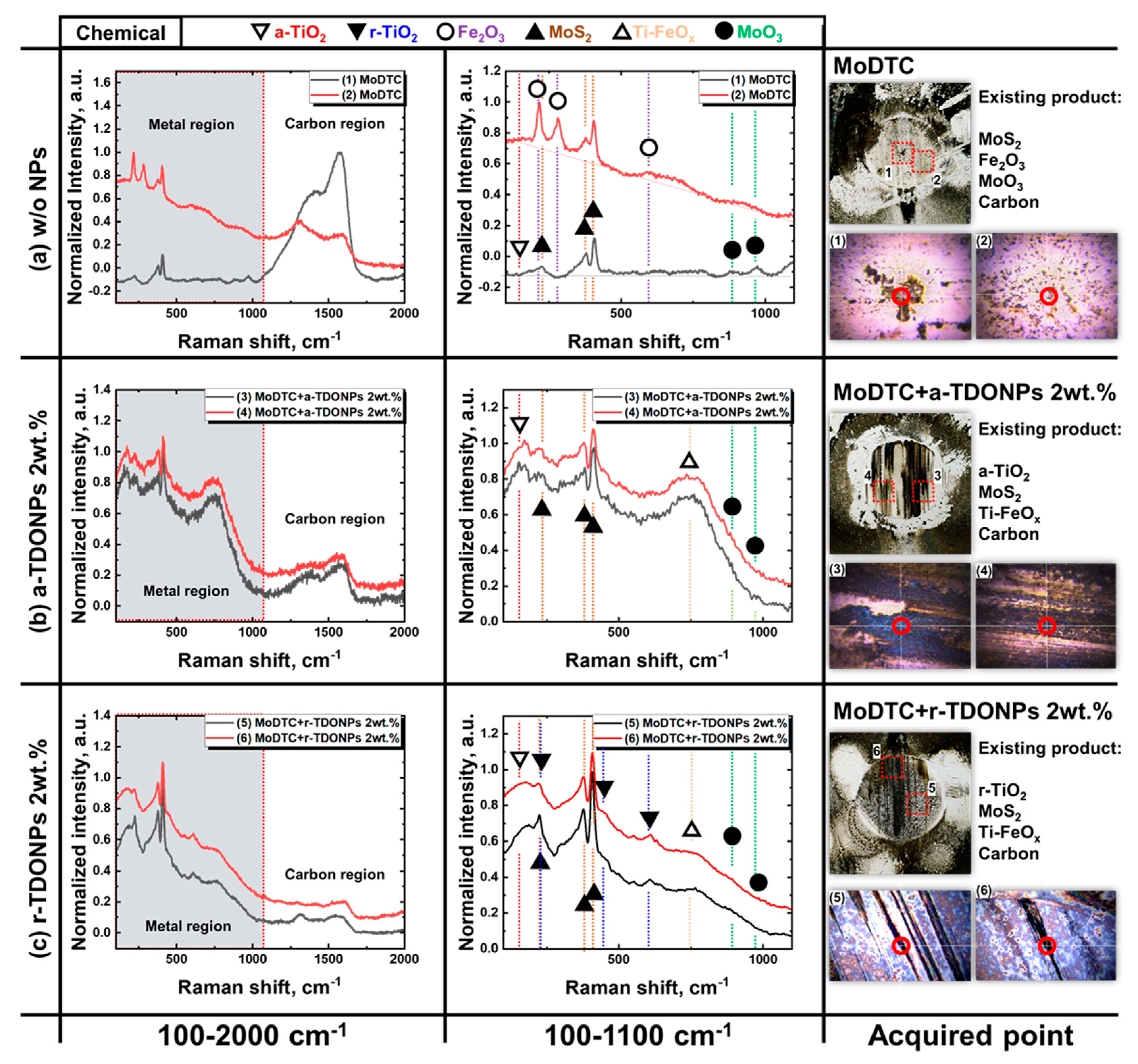

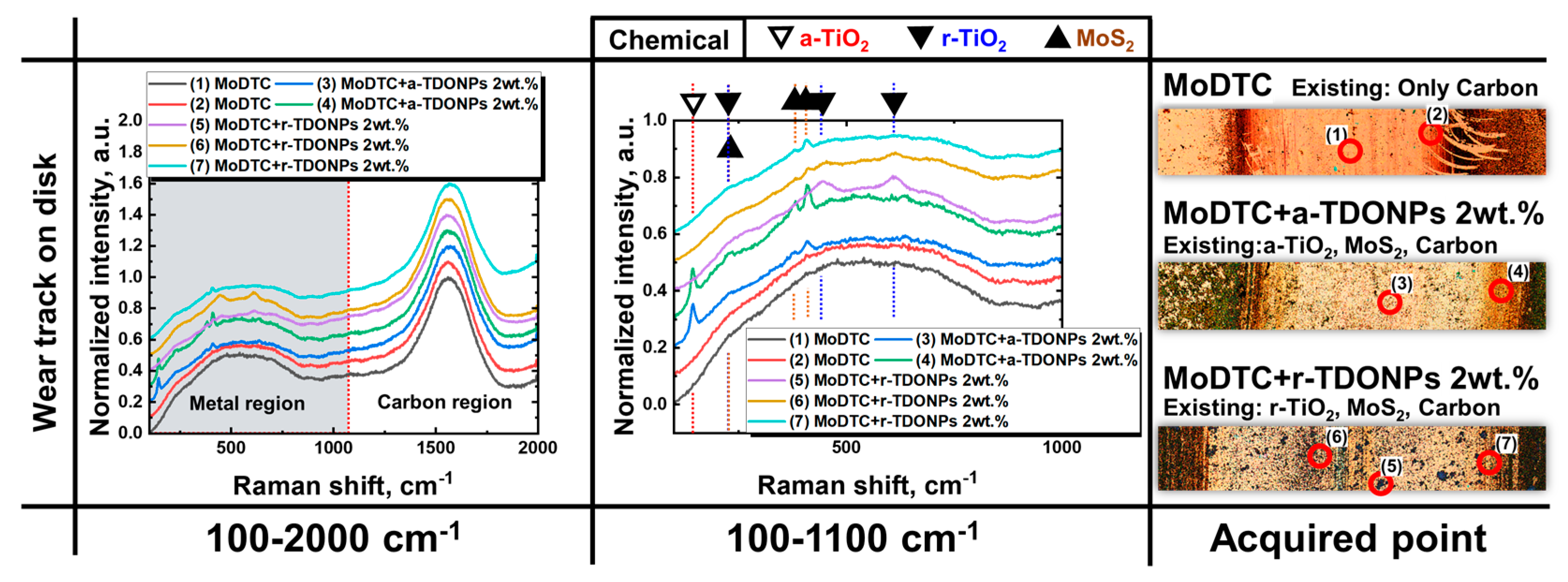

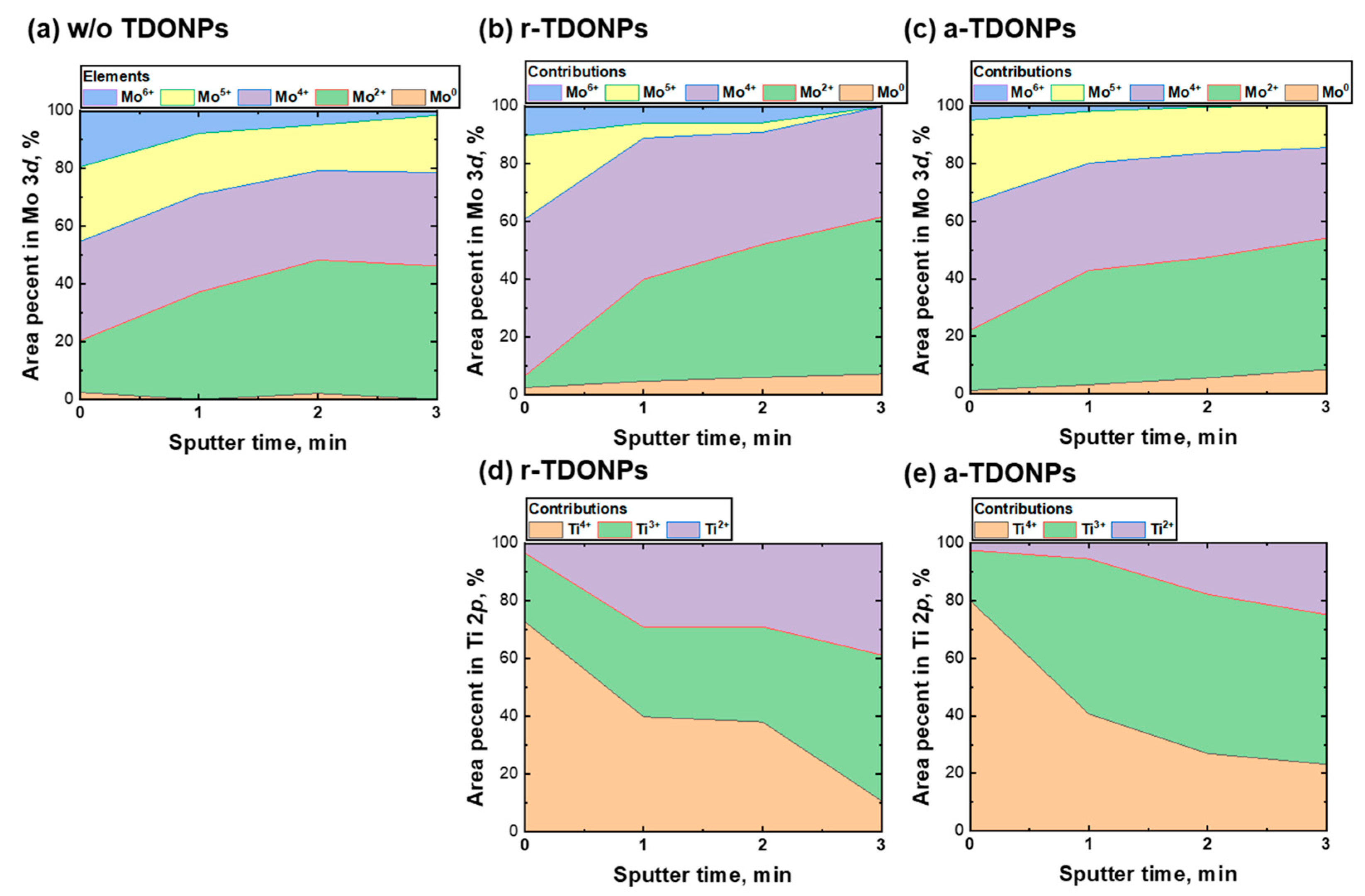

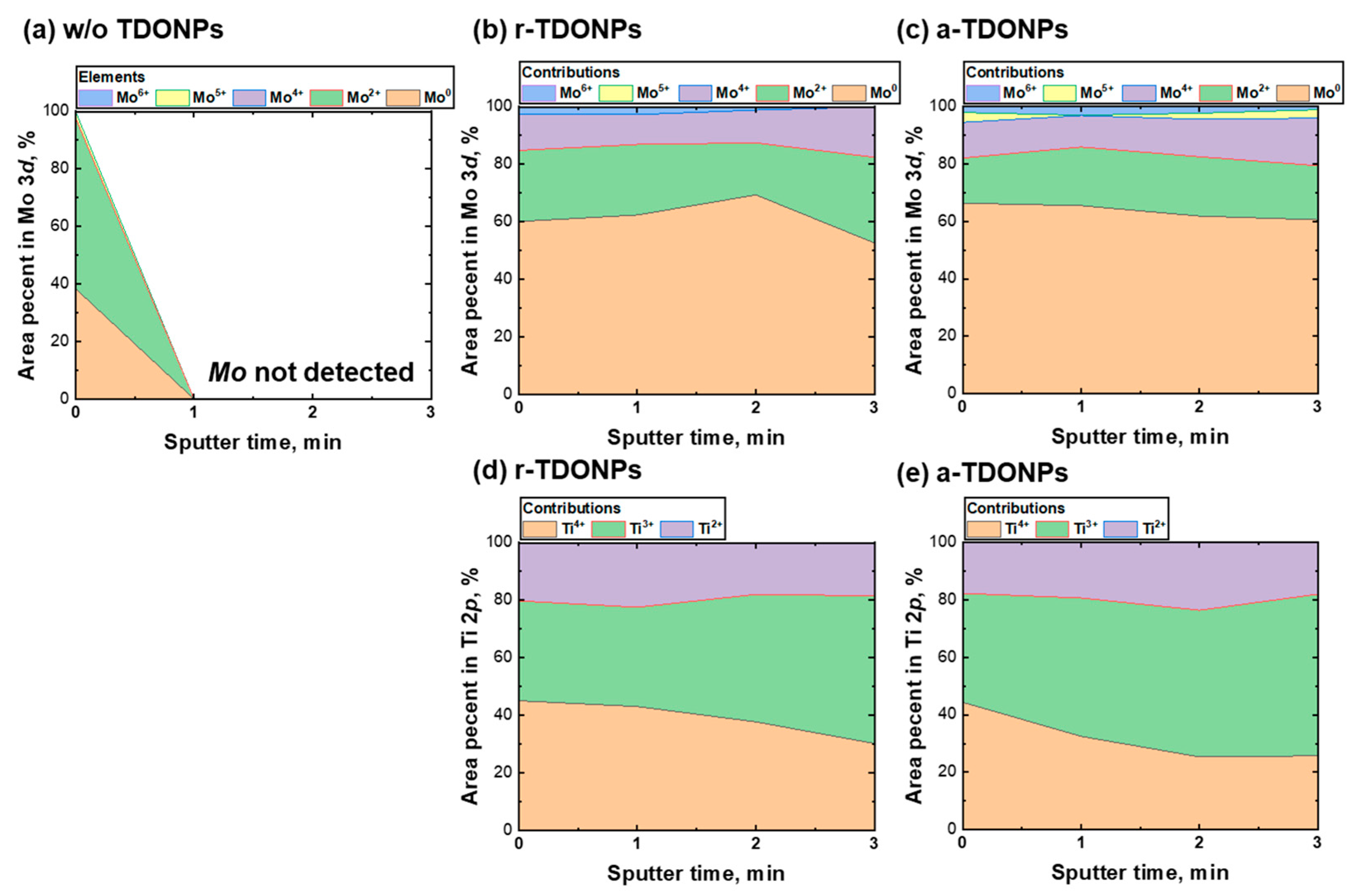

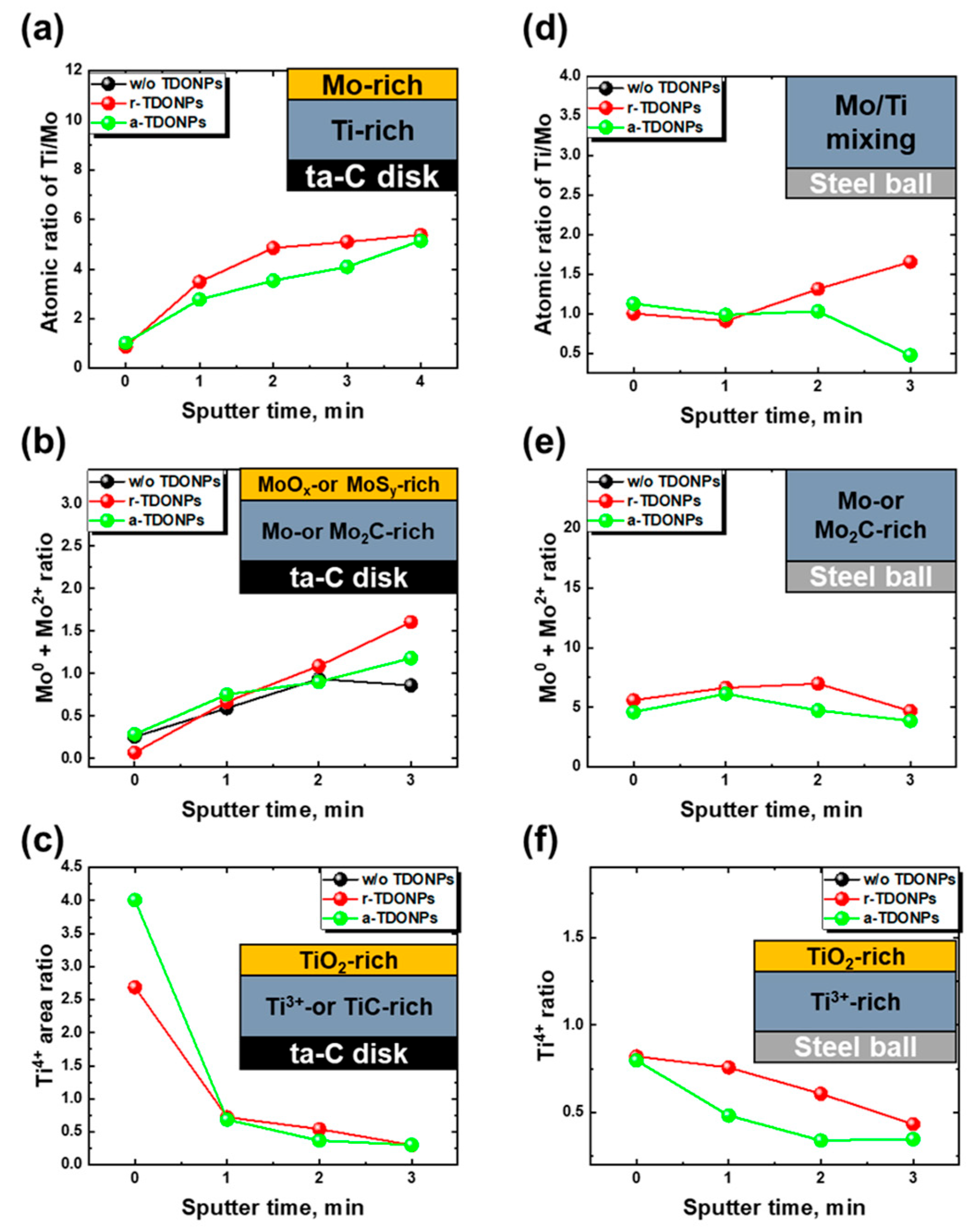

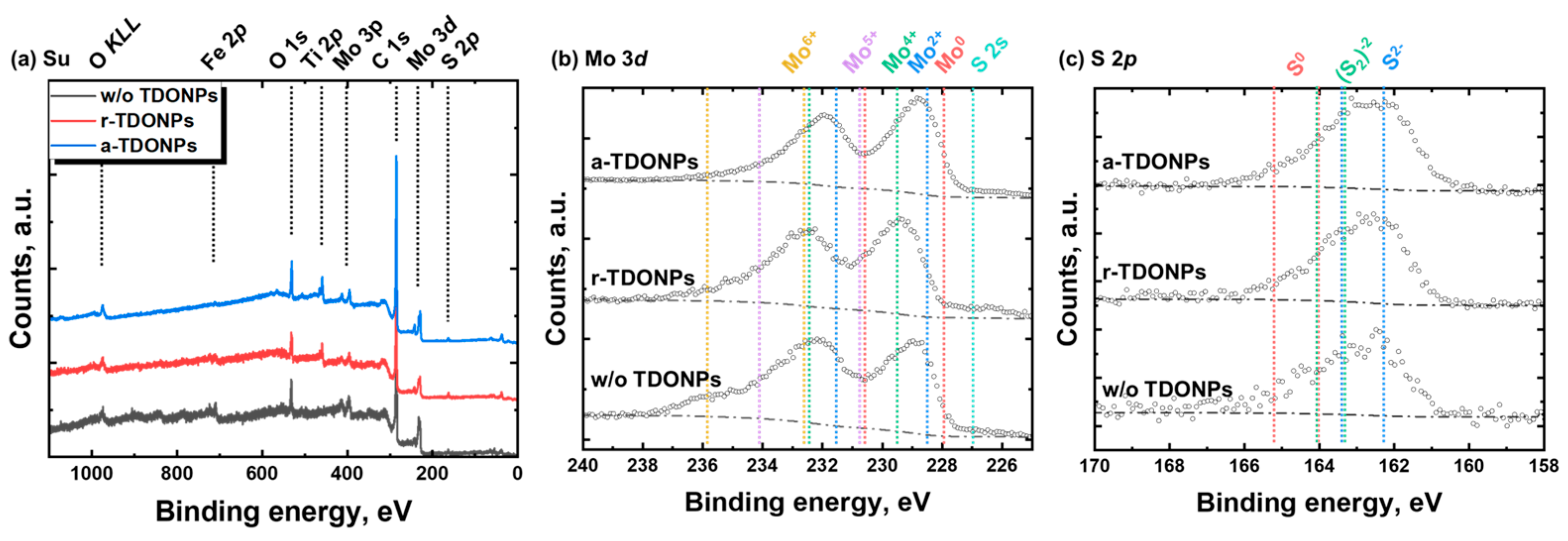

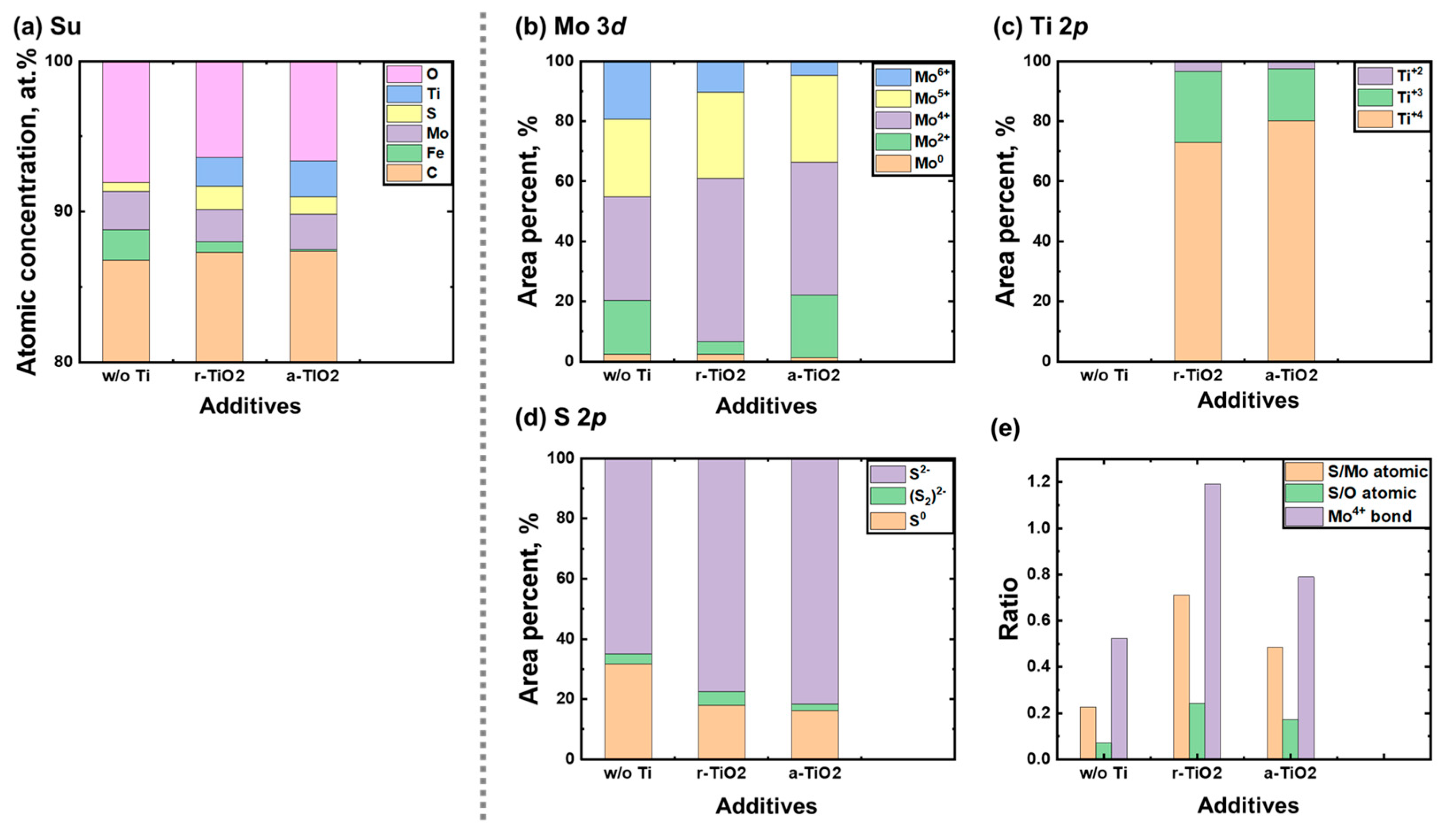

3.2. Chemical Structure of Tribofilm

3.3. Friction Performance of TiO2 Nanoparticles without Light

3.4. Friction Performance of TiO2 Nanoparticles without MoDTC Addition

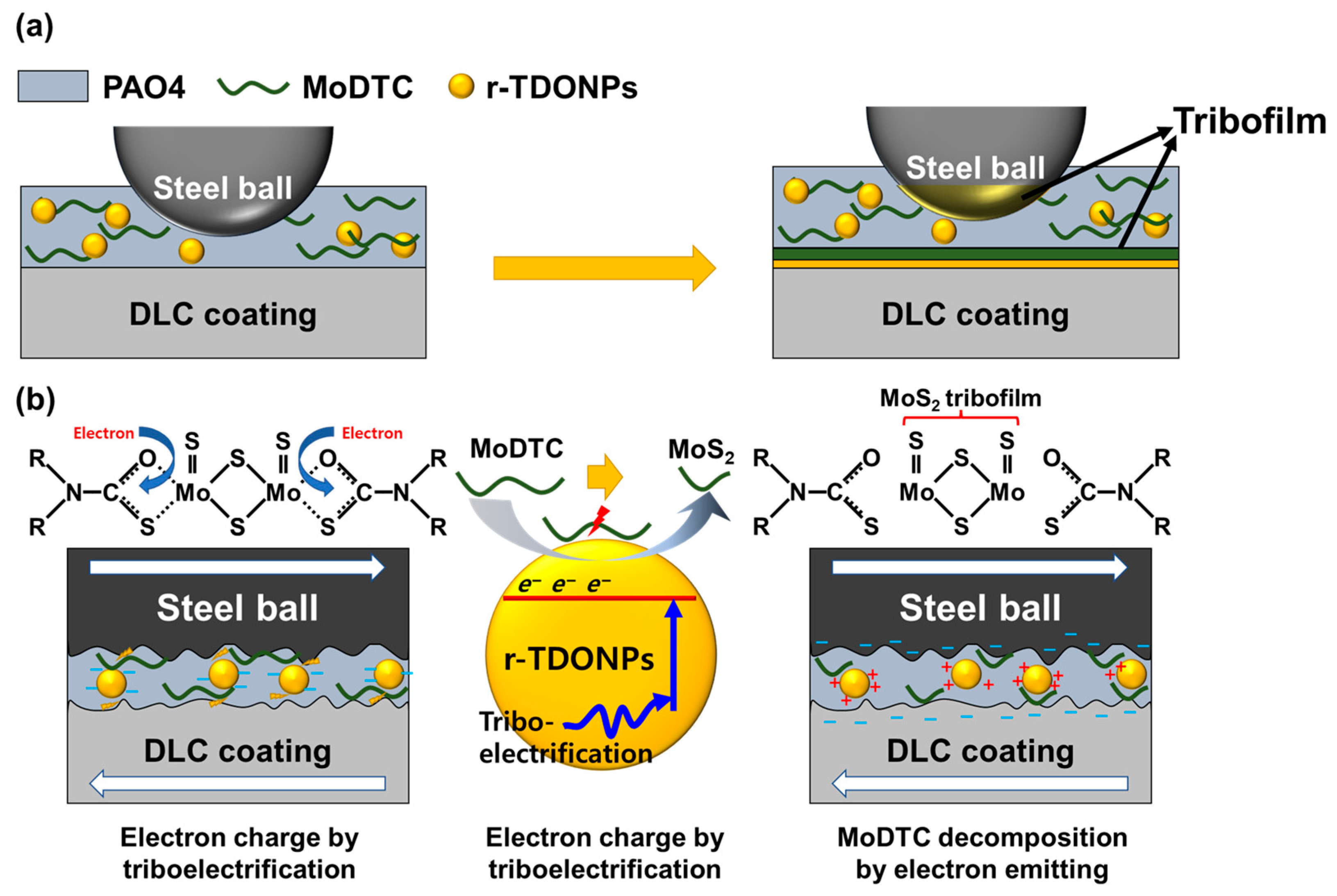

4. Discussion

5. Conclusions

- (1)

- TDONPs alone added to PAO4 lubricant without MoDTC did not improve the friction performance. On the other hand, TDONPs attached to the wear surface of DLC and steel activated the surface to attach carbon.

- (2)

- Dispersion of the TDONPs in PAO4 oil containing MoDTC improved the lubrication performance by up to ~100%. When a-TDONPs were added at 1 wt.% and 2.5 wt.%, the effect of reducing friction was not significant. The optimal content of TDONPs was 2.0 wt.%, and when more than this was added, the friction and wear increased due to a rapid decrease in precipitation and dispersion performance.

- (3)

- The addition of TDONPs may have increased the formation or adhesion of MoS2 on the DLC and steel surfaces, thereby reducing friction.

- (4)

- The improved friction and wear characteristics of r-TDONPs were superior to those of a-TDONPs, and this difference in tribocatalytic properties is presumed to result from their triboelectric capabilities.

- (5)

- TDONPs have been tribologically useful additives due to their adhesive and catalytic action, but the technology to maintain their dispersion remains a problem to be solved.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Spikes, H. Friction Modifier Additives. Tribol. Lett. 2015, 60, 5. [Google Scholar] [CrossRef]

- Yamamoto, Y.; Gondo, S. Friction and Wear Characteristics of Molybdenum Dithiocarbamate and Molybdenum Dithiophosphate. Tribol. Trans. 1989, 32, 251–257. [Google Scholar] [CrossRef]

- Kassim, K.A.M.; Tokoroyama, T.; Murashima, M.; Umehara, N. The Wear Classification of MoDTC-Derived Particles on Silicon and Hydrogenated Diamond-like Carbon at Room Temperature. Tribol. Int. 2020, 147, 106176. [Google Scholar] [CrossRef]

- Kassim, K.A.M.; Tokoroyama, T.; Murashima, M.; Lee, W.Y.; Umehara, N.; Mustafa, M.M.B. Wear Acceleration of A-C:H Coatings by Molybdenum-Derived Particles: Mixing and Temperature Effects. Tribol. Int. 2021, 159, 106944. [Google Scholar] [CrossRef]

- Bin Mustafa, M.M.; Umehara, N.; Tokoroyama, T.; Murashima, M.; Shibata, A.; Utsumi, Y.; Moriguchi, H. Effect of Pillar and Mesh Structure of Tetrahedral Amorphous Carbon (TA-C) Coatings on the Wear Properties and Fracture Toughness of the Coating. Tribol. Online 2019, 14, 388–397. [Google Scholar] [CrossRef]

- Hashizume, N.; Murashima, M.; Umehara, N.; Tokoroyama, T.; Lee, W.-Y. In Situ Observation of the Formation of MoDTC-Derived Tribofilm on a Ta-C Coating Using Reflectance Spectroscopy and Its Effects on Friction. Tribol. Int. 2021, 162, 107128. [Google Scholar] [CrossRef]

- Miyake, S.; Saito, T.; Yasuda, Y.; Okamoto, Y.; Kano, M. Improvement of Boundary Lubrication Properties of Diamond-like Carbon (DLC) Films Due to Metal Addition. Tribol. Int. 2004, 37, 751–761. [Google Scholar] [CrossRef]

- Vengudusamy, B.; Green, J.H.; Lamb, G.D.; Spikes, H.A. Behaviour of MoDTC in DLC/DLC and DLC/Steel Contacts. Tribol. Int. 2012, 54, 68–76. [Google Scholar] [CrossRef]

- Bae, S.M.; Horibata, S.; Miyauchi, Y.; Choi, J. Tribochemical Investigation of Cr-Doped Diamond-like Carbon with a MoDTC-Containing Engine Oil under Boundary Lubricated Condition. Tribol. Int. 2023, 188, 108849. [Google Scholar] [CrossRef]

- Yu, H.; Fu, J.; Zhu, X.; Zhao, Z.; Sui, X.; Sun, S.; He, X.; Zhang, Y.; Ye, W. Tribocatalytic Degradation of Organic Pollutants Using Fe2O3 Nanoparticles. ACS Appl. Nano Mater. 2023, 6, 14364–14373. [Google Scholar] [CrossRef]

- Zhang, Q.; Jia, Y.; Wang, X.; Zhang, L.; Yuan, G.; Wu, Z. Efficient Tribocatalysis of Magnetically Recyclable Cobalt Ferrite Nanoparticles through Harvesting Friction Energy. Sep. Purif. Technol. 2023, 307, 122846. [Google Scholar] [CrossRef]

- Li, X.; Tong, W.; Shi, J.; Chen, Y.; Zhang, Y.; An, Q. Tribocatalysis Mechanisms: Electron Transfer and Transition. J. Mater. Chem. A 2023, 11, 4458–4472. [Google Scholar] [CrossRef]

- Fouts, J.A.; Shiller, P.J.; Mistry, K.K.; Evans, R.D.; Doll, G.L. Additive Effects on the Tribological Performance of WC/a-C:H and TiC/a-C:H Coatings in Boundary Lubrication. Wear 2017, 372, 104–115. [Google Scholar] [CrossRef]

- Miyake, S.; Shindo, T.; Suzuki, M. Nanomechanical and Boundary Lubrication Properties of Titanium Carbide and Diamond-like Carbon Nanoperiod Multilayer and Nanocomposite Films. Surf. Coat. Technol. 2013, 221, 124–132. [Google Scholar] [CrossRef]

- Kim, J.I.; Lee, W.Y.; Tokoroyama, T.; Umehara, N. Long-Term Low-Friction of Ti-Overcoated and-Doped DLCs: Robustly Developed Carbonous Transfer Layer with Titanium. Carbon N. Y. 2023, 204, 268–283. [Google Scholar] [CrossRef]

- Kim, J.-I.; Lee, W.-Y.; Tokoroyama, T.; Umehara, N. Superlubricity with Graphitization in Ti-Doped DLC/Steel Tribopair: Response on Humidity and Temperature. ACS Appl. Mater. Interfaces 2023, 15, 19715–19729. [Google Scholar] [CrossRef]

- Pauling, L.C. A Resonating-Valence-Bond Theory of Metals and Intermetallic Compounds. Proc. R. Soc. Lond. Ser. A Math. Phys. Sci. 1949, 196, 343–362. [Google Scholar] [CrossRef]

- Cui, X.; Li, P.; Lei, H.; Tu, C.; Wang, D.; Wang, Z.; Chen, W. Greatly Enhanced Tribocatalytic Degradation of Organic Pollutants by TiO2 Nanoparticles through Efficiently Harvesting Mechanical Energy. Sep. Purif. Technol. 2022, 289, 120814. [Google Scholar] [CrossRef]

- Bunriw, W.; Harnchana, V.; Chanthad, C.; Huynh, V.N. Natural Rubber-TiO2 Nanocomposite Film for Triboelectric Nanogenerator Application. Polymers 2021, 13, 2213. [Google Scholar] [CrossRef]

- Tokoroyama, T.; Tagami, Y.; Murashima, M.; Lee, W.Y.; Umehara, N.; Kousaka, H. Tribological Property of Ta-CNx:Ta Deposited via Ion Beam Assisted-Filtered Arc Deposition. Tribol. Int. 2022, 168, 107450. [Google Scholar] [CrossRef]

- Parvizian, F.; Ansari, F.; Bandehali, S. Oleic Acid-Functionalized TiO2 Nanoparticles for Fabrication of PES-Based Nanofiltration Membranes. Chem. Eng. Res. Des. 2020, 156, 433–441. [Google Scholar] [CrossRef]

- Dobrenizki, L.; Tremmel, S.; Wartzack, S.; Hoffmann, D.C.; Brögelmann, T.; Bobzin, K.; Bagcivan, N.; Musayev, Y.; Hosenfeldt, T. Efficiency Improvement in Automobile Bucket Tappet/Camshaft Contacts by DLC Coatings—Influence of Engine Oil, Temperature and Camshaft Speed. Surf. Coat. Technol. 2016, 308, 360–373. [Google Scholar] [CrossRef]

- Challagulla, S.; Tarafder, K.; Ganesan, R.; Roy, S. Structure Sensitive Photocatalytic Reduction of Nitroarenes over TiO2. Sci. Rep. 2017, 7, 8783. [Google Scholar] [CrossRef]

- Lu, J.; Tsai, C.J. Hydrothermal Phase Transformation of Hematite to Magnetite. Nanoscale Res. Lett. 2014, 9, 230. [Google Scholar] [CrossRef]

- Khaemba, D.N.; Neville, A.; Morina, A. A Methodology for Raman Characterisation of MoDTC Tribofilms and Its Application in Investigating the Influence of Surface Chemistry on Friction Performance of MoDTC Lubricants. Tribol. Lett. 2015, 59, 38. [Google Scholar] [CrossRef]

- Imperial, A.; Pe-Piper, G.; Piper, D.J.W.; Grey, I.E. Identifying Pseudorutile and Kleberite Using Raman Spectroscopy. Minerals 2022, 12, 1210. [Google Scholar] [CrossRef]

- Wang, A.; Kuebler, K.E.; Jolliff, B.L.; Haskin, L.A. Raman Spectroscopy of Fe-Ti-Cr-Oxides, Case Study: Martian Meteorite EETA79001. Am. Mineral. 2004, 89, 665–680. [Google Scholar] [CrossRef]

- Ajito, K.; Nagahara, L.A.; Tryk, D.A.; Hashimoto, K.; Fujishima, A. Study of the Photochromic Properties of Amorphous MoO3 Films Using Raman Microscopy. J. Phys. Chem. 1995, 99, 16383–16388. [Google Scholar] [CrossRef]

- Biesinger, M.C.; Lau, L.W.M.; Gerson, A.R.; Smart, R.S.C. Resolving Surface Chemical States in XPS Analysis of First Row Transition Metals, Oxides and Hydroxides: Sc, Ti, V, Cu and Zn. Appl. Surf. Sci. 2010, 257, 887–898. [Google Scholar] [CrossRef]

- Lindberg, B.J.; Hamrin, K.; Johansson, G.; Gelius, U.; Fahlman, A.; Nordling, C.; Siegbahn, K. Molecular Spectroscopy by Means of Esca. Phys. Scr. 1970, 1, 286–298. [Google Scholar] [CrossRef]

- Benoist, L.; Gonbeau, D.; Pfister-Guillouzo, G.; Schmidt, E.; Meunier, G.; Levasseur, A. X-ray Photoelectron Spectroscopy Characterization of Amorphous Molybdenum Oxysulfide Thin Films. Thin Solid Films 1995, 258, 110–114. [Google Scholar] [CrossRef]

- Licklederer, M.; Cha, G.; Hahn, R.; Schmuki, P. Ordered Nanotubular Titanium Disulfide (TiS2) Structures: Synthesis and Use as Counter Electrodes in Dye Sensitized Solar Cells (DSSCs). J. Electrochem. Soc. 2019, 166, H3009–H3013. [Google Scholar] [CrossRef]

- Halim, J.; Cook, K.M.; Eklund, P.; Rosen, J.; Barsoum, M.W. XPS of Cold Pressed Multilayered and Freestanding Delaminated 2D Thin Films of Mo2TiC2Tz and Mo2Ti2C3Tz (MXenes). Appl. Surf. Sci. 2019, 494, 1138–1147. [Google Scholar] [CrossRef]

- Ignaszak, A.; Song, C.; Zhu, W.; Zhang, J.; Bauer, A.; Baker, R.; Neburchilov, V.; Ye, S.; Campbell, S. Titanium Carbide and Its Core-Shelled Derivative TiC@TiO2 as Catalyst Supports for Proton Exchange Membrane Fuel Cells. Electrochim. Acta 2012, 69, 397–405. [Google Scholar] [CrossRef]

- Ohara, K.; Hanyuda, K.; Kawamura, Y.; Omura, K.; Kameda, I.; Umehara, N.; Kousaka, H. Analysis of Wear Track on DLC Coatings after Sliding with MoDTC-Containing Lubricants. Tribol. Online 2017, 12, 110–116. [Google Scholar] [CrossRef]

- De Feo, M.; Minfray, C.; De Barros Bouchet, M.I.; Thiebaut, B.; Le Mogne, T.; Vacher, B.; Martin, J.M. Ageing Impact on Tribological Properties of MoDTC-Containing Base Oil. Tribol. Int. 2015, 92, 126–135. [Google Scholar] [CrossRef]

- Onodera, T.; Miura, R.; Suzuki, A.; Tsuboi, H.; Hatakeyama, N.; Endou, A.; Takaba, H.; Kubo, M.; Miyamoto, A. Development of a Quantum Chemical Molecular Dynamics Tribochemical Simulator and Its Application to Tribochemical Reaction Dynamics of Lubricant Additives. Model. Simul. Mater. Sci. Eng. 2010, 18, 034009. [Google Scholar] [CrossRef]

- Deshpande, P.; Minfray, C.; Dassenoy, F.; Thiebaut, B.; Le Mogne, T.; Vacher, B.; Jarnias, F. Tribological Behaviour of TiO2 Atmospheric Plasma Spray (APS) Coating under Mixed and Boundary Lubrication Conditions in Presence of Oil Containing MoDTC. Tribol. Int. 2018, 118, 273–286. [Google Scholar] [CrossRef]

- Deshpande, P.; Minfray, C.; Dassenoy, F.; Le Mogne, T.; Jose, D.; Cobian, M.; Thiebaut, B. Tribocatalytic Behaviour of a TiO2 Atmospheric Plasma Spray (APS) Coating in the Presence of the Friction Modifier MoDTC: A Parametric Study. RSC Adv. 2018, 8, 15056–15068. [Google Scholar] [CrossRef]

- Galhenage, R.P.; Yan, H.; Rawal, T.B.; Le, D.; Brandt, A.J.; Maddumapatabandi, T.D.; Nguyen, N.; Rahman, T.S.; Chen, D.A. MoS2 Nanoclusters Grown on TiO2: Evidence for New Adsorption Sites at Edges and Sulfur Vacancies. J. Phys. Chem. C 2019, 123, 7185–7201. [Google Scholar] [CrossRef]

- Waqas, M.; Zahid, R.; Bhutta, M.U.; Khan, Z.A.; Saeed, A. A Review of Friction Performance of Lubricants with Nano Additives. Materials 2021, 14, 6310. [Google Scholar] [CrossRef]

- Kim, J.; Lee, W.Y.; Tokoroyama, T.; Murashima, M.; Umehara, N. Friction Characteristics of Amorphous Carbon Coating against Various 3d-Transition Metals. Tribol. Int. 2022, 174, 107690. [Google Scholar] [CrossRef]

- Gao, Y.; Sun, R.; Zhang, Z.; Xue, Q. Tribological Properties of Oleic Acid—Modified TiO2 Nanoparticle in Water. Mater. Sci. Eng. A 2000, 286, 149–151. [Google Scholar] [CrossRef]

- Gao, Y.; Chen, G.; Oli, Y.; Zhang, Z.; Xue, Q. Study on Tribological Properties of Oleic Acid-Modified TiO2 Nanoparticle in Water. Wear 2002, 252, 454–458. [Google Scholar] [CrossRef]

- Grossiord, C.; Varlot, K.; Martin, J.M.; Le Mogne, T.; Esnouf, C.; Inoue, K. MoS2 Single Sheet Lubrication by Molybdenum Dithiocarbamate. Tribol. Int. 1998, 31, 737–743. [Google Scholar] [CrossRef]

- Luttrell, T.; Halpegamage, S.; Tao, J.; Kramer, A.; Sutter, E.; Batzill, M. Why Is Anatase a Better Photocatalyst than Rutile?—Model Studies on Epitaxial TiO2 Films. Sci. Rep. 2015, 4, 4043. [Google Scholar] [CrossRef]

- Kajdas, C.; Hiratsuka, K. Tribochemistry, Tribocatalysis, and the Negative-Ion-Radical Action Mechanism. Proc. Inst. Mech. Eng. Part J J. Eng. Tribol. 2009, 223, 827–848. [Google Scholar] [CrossRef]

- Hiratsuka, K.; Kajdas, C.; Yoshida, M. Tribo-Catalysis in the Synthesis Reaction of Carbon Dioxide. Tribol. Trans. 2004, 47, 86–93. [Google Scholar] [CrossRef]

- Hiratsuka, K.; Kajdas, C. Mechanochemistry as a Key to Understand the Mechanisms of Boundary Lubrication, Mechanolysis and Gas Evolution during Friction. Proc. Inst. Mech. Eng. Part J J. Eng. Tribol. 2013, 227, 1191–1203. [Google Scholar] [CrossRef]

- Kajdas, C. Importance of Mechanochemistry and Tribochemistry for Tribology. Tribol. Schmier. 2013, 60, 45–50. [Google Scholar]

- Khaemba, D.N.; Neville, A.; Morina, A. New Insights on the Decomposition Mechanism of Molybdenum DialkyldiThioCarbamate (MoDTC): A Raman Spectroscopic Study. RSC Adv. 2016, 6, 38637–38646. [Google Scholar] [CrossRef]

- Koike, R.; Suzuki, A.; Kurihara, K.; Adachi, K. Formation of Low Friction Interface under Sliding Contact between Bearing Steels in MoDTC Oil. Toraibarojisuto/J. Jpn. Soc. Tribol. 2019, 64, 250–258. [Google Scholar]

- Koike, R.; Suzuki, A.; Kurihara, K.; Adachi, K. Formation of Nano Interface by Sliding between Hard Coatings and Metals in MoDTC Contained Oil. Tribol. Online 2022, 17, 1–8. [Google Scholar] [CrossRef]

- Fan, F.R.; Xie, S.; Wang, G.W.; Tian, Z.Q. Tribocatalysis: Challenges and Perspectives. Sci. China Chem. 2021, 64, 1609–1613. [Google Scholar] [CrossRef]

- Shin, E.C.; Ko, J.H.; Lyeo, H.K.; Kim, Y.H. Derivation of a Governing Rule in Triboelectric Charging and Series from Thermoelectricity. Phys. Rev. Res. 2022, 4, 023131. [Google Scholar] [CrossRef]

| Element | Contribution | Binding Energy, eV | Assigned Species | G/L Ratio | Ref. |

|---|---|---|---|---|---|

| S 2p3/2 | S0 | 164.0 ± 0.2 | S-S/CS2 | 2:8 | [30] |

| (S2)2− | 163.4 ± 0.2 | MoOySx/MoS3 | [31] | ||

| S2− in Mo-S | 162.4 ± 0.2 | MoS2 | [31] | ||

| Ti 2p3/2 | Ti4+ | 458.7 ± 0.3 | TiO2 | 7:3 | [32,33] |

| Ti3+ | 456.5 ± 0.3 | TiO2-x | [32] | ||

| Ti2+ | 455.1 ± 0.3 | TiC/TiO | [33,34] | ||

| Mo 3d5/2 | Mo6+ | 232.6 ± 0.3 | MoO3/MoS3 | 2:8 | [33,35] |

| Mo5+ | 231.0 ± 0.3 | MoOx/MoSx/MoOySx | [33,36] | ||

| Mo4+ | 229.4 ± 0.3 | MoS2/MoO2 | [35] | ||

| Mo2+ | 228.6 ± 0.3 | Mo2C/MoO | [33,35] | ||

| Mo0 | 227.8 ± 0.3 | Mo-metal | [35] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Matsukawa, D.; Park, J.-H.; Lee, W.-Y.; Tokoroyama, T.; Kim, J.-I.; Ichino, R.; Umehara, N. Tribocatalytic Reaction Enabled by TiO2 Nanoparticle for MoDTC-Derived Tribofilm Formation at ta-C/Steel Contact. Coatings 2024, 14, 773. https://doi.org/10.3390/coatings14060773

Matsukawa D, Park J-H, Lee W-Y, Tokoroyama T, Kim J-I, Ichino R, Umehara N. Tribocatalytic Reaction Enabled by TiO2 Nanoparticle for MoDTC-Derived Tribofilm Formation at ta-C/Steel Contact. Coatings. 2024; 14(6):773. https://doi.org/10.3390/coatings14060773

Chicago/Turabian StyleMatsukawa, Daiki, Jae-Hyeok Park, Woo-Young Lee, Takayuki Tokoroyama, Jae-Il Kim, Ryoichi Ichino, and Noritsugu Umehara. 2024. "Tribocatalytic Reaction Enabled by TiO2 Nanoparticle for MoDTC-Derived Tribofilm Formation at ta-C/Steel Contact" Coatings 14, no. 6: 773. https://doi.org/10.3390/coatings14060773

APA StyleMatsukawa, D., Park, J. -H., Lee, W. -Y., Tokoroyama, T., Kim, J. -I., Ichino, R., & Umehara, N. (2024). Tribocatalytic Reaction Enabled by TiO2 Nanoparticle for MoDTC-Derived Tribofilm Formation at ta-C/Steel Contact. Coatings, 14(6), 773. https://doi.org/10.3390/coatings14060773