Energy Storage Performance of (Na0.5Bi0.5)TiO3 Relaxor Ferroelectric Film

Abstract

1. Introduction

2. Experimental

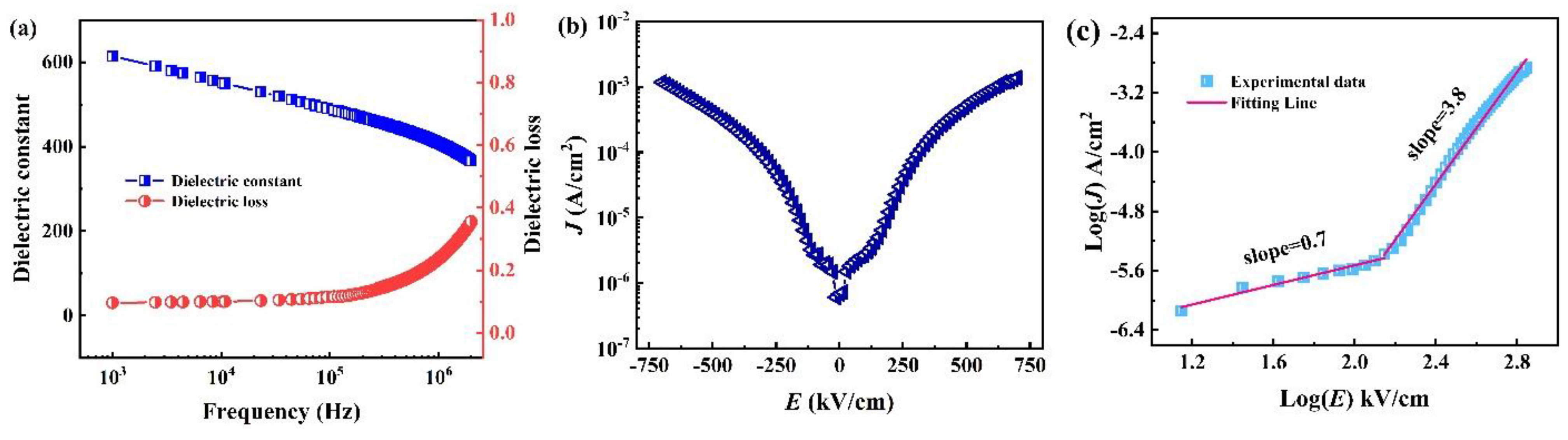

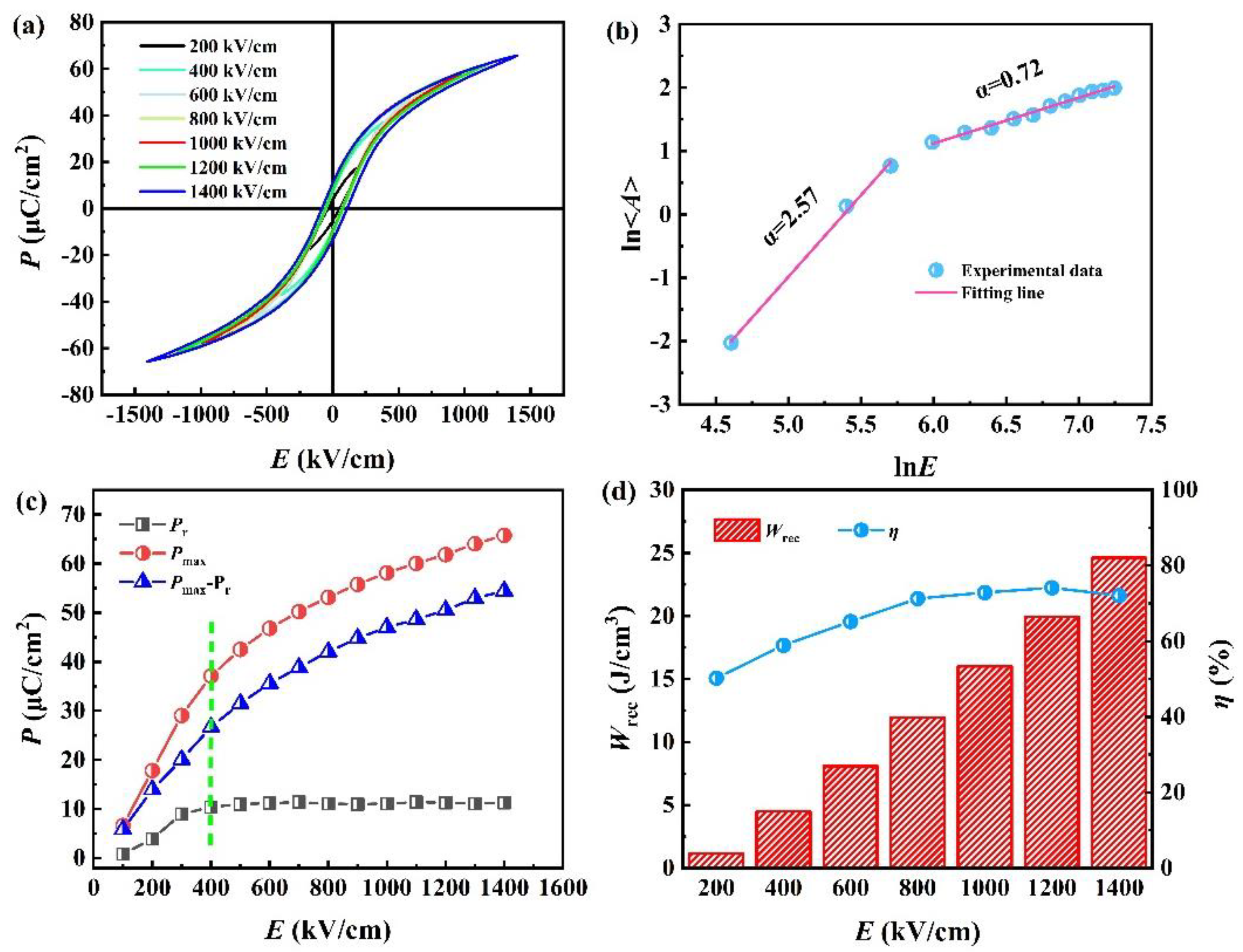

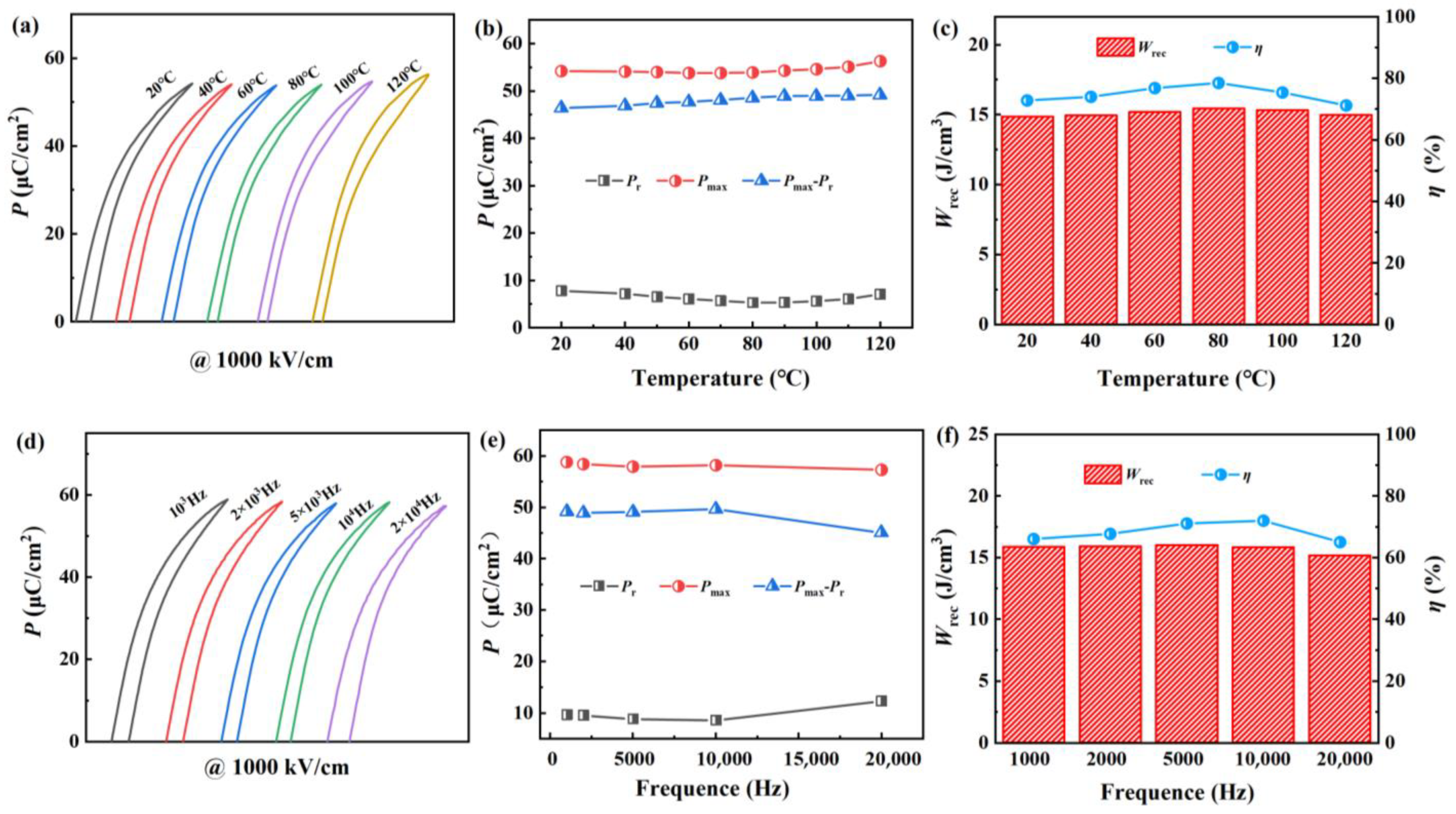

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Pan, H.; Lan, S.; Xu, S.Q.; Zhang, Q.H.; Yao, H.B.; Liu, Y.Q.; Meng, F.Q.; Guo, E.J.; Gu, L.; Yi, D.; et al. Ultrahigh energy storage in superparaelectric relaxor ferroelectrics. Science 2021, 374, 100–104. [Google Scholar] [CrossRef] [PubMed]

- Kim, J.; Saremi, S.; Acharya, M.; Velarde, G.; Parsonnet, E.; Donahue, P.; Qualls, A.; Garcia, D.; Martin, L.W. Ultrahigh capacitive energy density in ion-bombarded relaxor ferroelectric films. Science 2020, 369, 81–84. [Google Scholar] [CrossRef] [PubMed]

- Zhao, M.Y.; Wang, J.; Yuan, H.; Zheng, Z.H.; Zhao, L. Energy storage performance and phase transition under high electric field in Na/Ta co-doped AgNbO3 ceramics. J. Materiomics 2023, 9, 19–26. [Google Scholar] [CrossRef]

- Jain, A.; Wang, Y.G.; Shi, L.N. Recent developments in BaTiO3 based lead-free materials for energy storage applications. J. Alloys Compd. 2022, 928, 167066. [Google Scholar] [CrossRef]

- Ge, P.Z.; Liu, Z.G.; Huang, X.X.; Tang, X.G.; Tang, Z.H.; Li, S.F.; Liu, Q.X.; Jiang, Y.P.; Guo, X.B. Excellent energy storage properties realized in novel BaTiO3-based lead-free ceramics by regulating relaxation behavior. J. Materiomics 2023, 9, 910–919. [Google Scholar] [CrossRef]

- Zhang, Y.L.; Li, X.B.; Song, J.M.; Zhang, S.W.; Wang, J.; Dai, X.H.; Liu, B.T.; Dong, G.Y.; Zhao, L. AgNbO3 antiferroelectric film with high energy storage performance. J. Materiomics 2021, 7, 1294–1300. [Google Scholar] [CrossRef]

- Qiao, X.S.; Sheng, A.H.; Wu, D.; Zhang, F.D.; Chen, B.; Niang, P.F.; Wang, J.J.; Chao, X.L.; Yang, Z.P. A novel multifunctional ceramic with photoluminescence and outstanding energy storage properties. Chem. Eng. J. 2021, 408, 127368. [Google Scholar] [CrossRef]

- Zhou, X.F.; Qi, H.; Yan, Z.N.; Xue, G.L.; Luo, H.; Zhang, D. Superior thermal stability of high energy density and power density in domain-engineered Bi0.5Na0.5TiO3–NaTaO3 relaxor ferroelectrics. ACS Appl. Mater. Interfaces 2019, 11, 43107–43115. [Google Scholar] [CrossRef]

- Zhao, Y.; Hao, X.H.; Li, M.L. Dielectric properties and energy-storage performance of (Na0.5Bi0.5)TiO3 thick films. J. Alloys Compd. 2014, 601, 112–115. [Google Scholar] [CrossRef]

- Wang, F.; Zhu, C.; Zhao, S.F. Good energy storage properties of Na0.5Bi0.5TiO3 thin films. J. Alloys Compd. 2021, 869, 159366. [Google Scholar] [CrossRef]

- Han, H.J.; Zhang, Q.H.; Li, W.; Liu, Y.Q.; Guo, J.S.; Wang, Y.; Li, Q.; Gu, L.; Nan, C.W.; Ma, J. Interfacial oxygen octahedral coupling-driven robust ferroelectricity in epitaxial Na0.5Bi0.5TiO3 thin films. Research 2023, 6, 0191. [Google Scholar] [CrossRef] [PubMed]

- An, Z.X.; Yao, Y.; Wang, J.; Zhu, L.F.; Zhao, L. Energy storage performance and piezoelectric response of silver niobate antiferroelectric thin film. Ceram. Int. 2024, 50, 12427–12433. [Google Scholar] [CrossRef]

- Sui, H.T.; Yang, C.H.; Wang, G.; Feng, C. Dielectric tunability of highly (l00)-oriented Fe-doped Na0.5Bi0.5TiO3 thin film. Ceram. Int. 2014, 40, 12989–12992. [Google Scholar] [CrossRef]

- Saxena, A.; Sharma, P.; Saxena, A.; Verma, V.; Saxena, R.S. Effect of La doping on dielectric properties of BiFe0.95Mn0.05O3 multiferroics. Ceram. Int. 2014, 40, 15065–15072. [Google Scholar] [CrossRef]

- Cheng, M.; Tan, G.Q.; Xue, X.; Xia, A.; Ren, H.J. Preparation of Nd-doped BiFeO3 films and their electrical properties. Phys. Rev. B Condens. 2012, 407, 3360–3363. [Google Scholar] [CrossRef]

- Wang, S.Y.; Cheng, B.L.; Wang, C.; Dai, S.Y.; Lu, H.B.; Zhou, Y.L.; Chen, Z.H.; Yang, G.Z. Reduction of leakage current by Co doping in Pt/Ba0.5Sr0.5TiO3/Nb–SrTiO3 capacitor. Appl. Phys. Lett. 2004, 84, 4116–4118. [Google Scholar] [CrossRef]

- YQi, J.; Lu, C.J.; Zhang, Q.F.; Wang, L.H.; Chen, F.; Cheng, C.S.; Liu, B.T. Improved ferroelectric and leakage properties in sol–gel derived BiFeO3/Bi3.15Nd0.85Ti3O12 bi-layers deposited on Pt/Ti/SiO2/Si. J. Phys. D Appl. Phys. 2008, 41, 065407. [Google Scholar] [CrossRef]

- Song, J.M.; Gao, J.; Zhang, S.W.; Luo, L.H.; Dai, X.H.; Zhao, L.; Liu, B.T. Structure and electrical properties of Na0.5Bi0.5TiO3 epitaxial films with (110) orientation. Crystals 2019, 9, 558. [Google Scholar] [CrossRef]

- Tian, Y.; Geng, J.; She, L.N.; Lu, T.; Yang, Y.X.; Wu, Z.G.; Xue, X.; Li, C.C.; Wei, X.Y.; Xu, Z.; et al. High hysteresis-free dielectric tunability in silver niobate-based ceramics. Ceram. Int. 2024, 50, 14773–14781. [Google Scholar] [CrossRef]

- Narayanan, M.; Tong, S.; Ma, B.; Liu, S.S.; Balachandran, U. Modified Johnson model for ferroelectric lead lanthanum zirconate titanate at very high fields and below Curie temperature. Appl. Phys. Lett. 2012, 100, 022907. [Google Scholar] [CrossRef]

- Xie, A.; Fu, J.; Zuo, R.Z.; Li, X.W.J.T.Y.; Fu, Z.Q.; Yin, Y.W.; Li, X.G.; Zhang, S.J. Supercritical relaxor nanograined ferroelectrics for ultrahigh-energy-storage capacitors. Adv. Mater. 2024, 34, 2204356. [Google Scholar] [CrossRef] [PubMed]

- Yu, G.; Dong, X.L.; Wang, G.S.; Cao, F.; Chen, X.F.; Nie, H.C. Three-stage evolution of dynamic hysteresis scaling behavior in 63PbTiO3−37BiScO3 bulk ceramics. J. Appl. Phys. 2017, 107, 106102. [Google Scholar] [CrossRef]

- Yimnirun, R.; Wongmaneerung, R.; Wongsaenmai, S.; Ngamjarurojana, A.; Ananta, S.; Laosiritaworn, Y. Dynamic hysteresis and scaling behavior of hard lead zirconate titanate bulk ceramics. Appl. Phys. Lett. 2007, 90, 112908. [Google Scholar] [CrossRef]

- Shi, J.P.; Chen, X.L.; Li, X.; Sun, J.; Sun, C.C.; Pang, F.H.; Zhou, H.F. Realizing ultrahigh recoverable energy density and superior charge–discharge performance in NaNbO3-based lead-free ceramics via a local random field strategy. J. Mater. Chem. C 2020, 8, 3784–3794. [Google Scholar] [CrossRef]

- Venkidu, L.; Ruth, D.E.J.; Babu, M.V.G.; Rubavathi, P.E.; Dhayanithi, D.; Giridharan, N.V.; Sundarakannan, B. Suppression of intermediate antiferroelectric phase in sub-micron grain size Na0.5Bi0.5TiO3 ceramics. J. Mater. Sci.-Mater. Electron. 2022, 33, 25006–25024. [Google Scholar] [CrossRef]

- Jain, A.; Wang, Y.G.; Guo, H.; Wang, N. Grain size engineered Ba0.9Sr0.1Ti0.9Hf0.1O3-Na0.5Bi0.5TiO3 relaxor ceramics with improved energy storage performance. J. Am. Ceram. Soc. 2020, 103, 6308–6318. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, X.; Yao, Y.; Wang, X.; Zhao, L.; San, X. Energy Storage Performance of (Na0.5Bi0.5)TiO3 Relaxor Ferroelectric Film. Coatings 2024, 14, 801. https://doi.org/10.3390/coatings14070801

Liu X, Yao Y, Wang X, Zhao L, San X. Energy Storage Performance of (Na0.5Bi0.5)TiO3 Relaxor Ferroelectric Film. Coatings. 2024; 14(7):801. https://doi.org/10.3390/coatings14070801

Chicago/Turabian StyleLiu, Xuxia, Yao Yao, Xiaofei Wang, Lei Zhao, and Xingyuan San. 2024. "Energy Storage Performance of (Na0.5Bi0.5)TiO3 Relaxor Ferroelectric Film" Coatings 14, no. 7: 801. https://doi.org/10.3390/coatings14070801

APA StyleLiu, X., Yao, Y., Wang, X., Zhao, L., & San, X. (2024). Energy Storage Performance of (Na0.5Bi0.5)TiO3 Relaxor Ferroelectric Film. Coatings, 14(7), 801. https://doi.org/10.3390/coatings14070801