Surface Quality of High-Concentration SiC/Al Grinding with Electroassisted Biolubricant MQL

Abstract

1. Introduction

2. Experimental Scheme

2.1. Experimental Materials

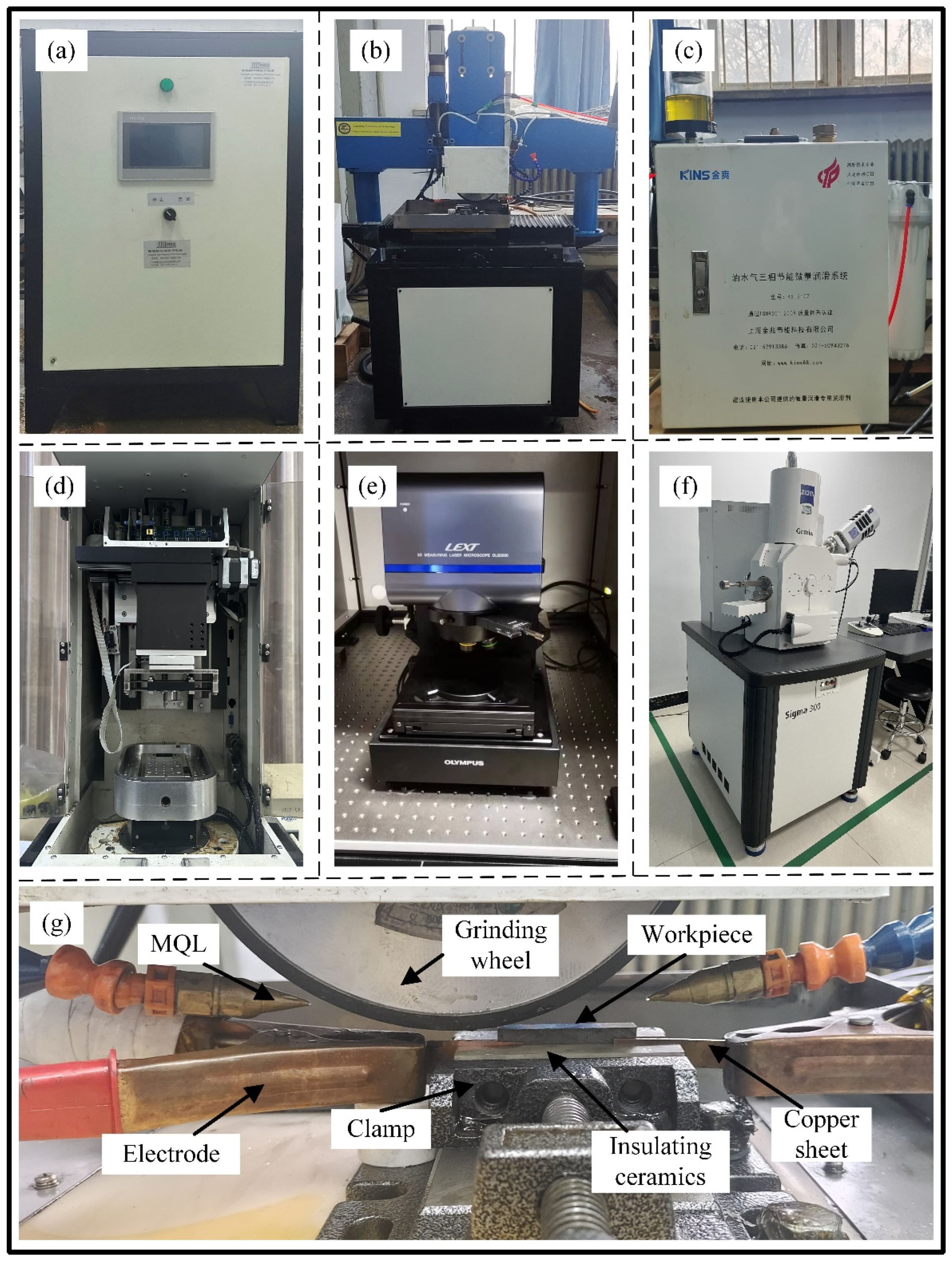

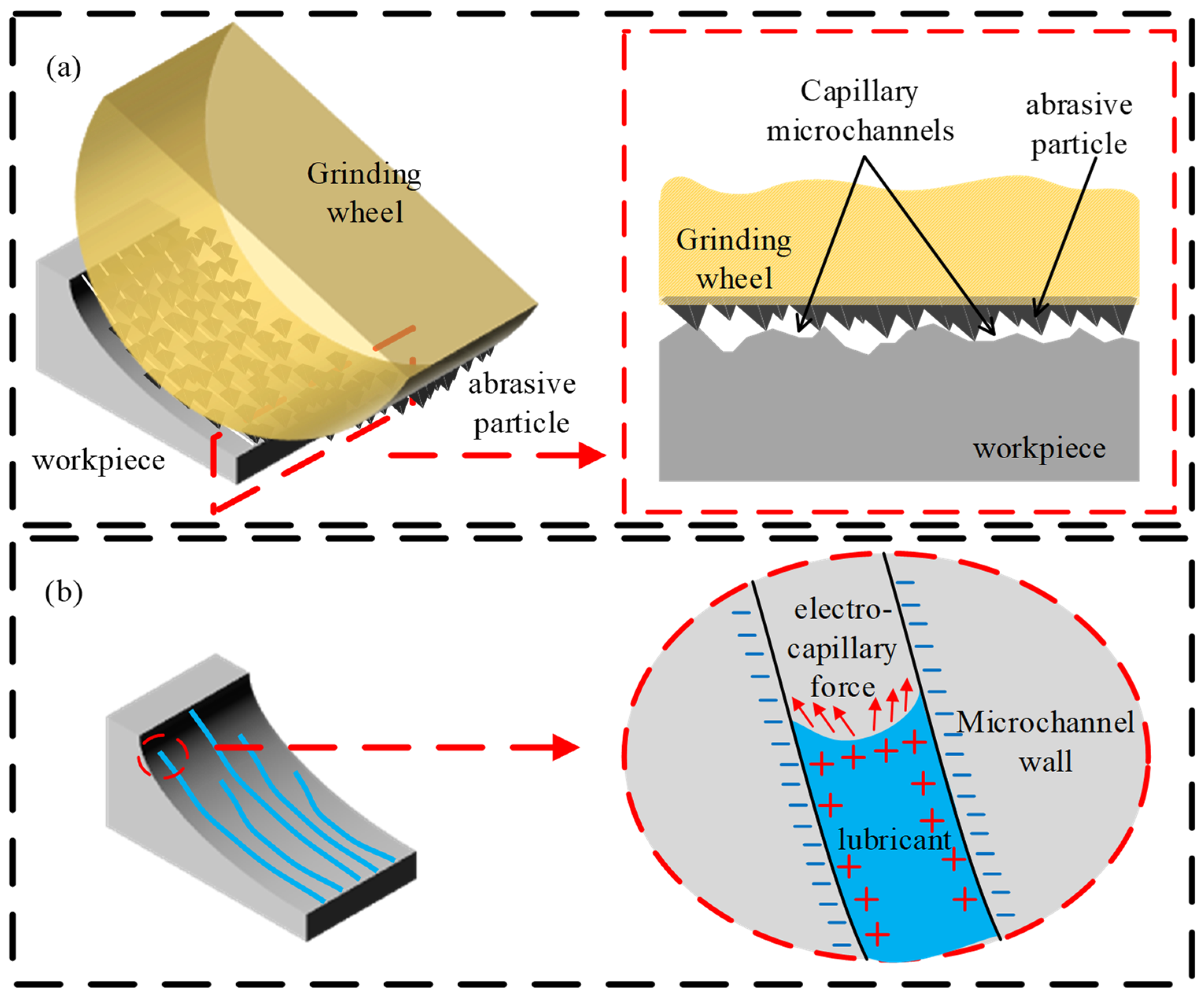

2.2. Experimental Device

3. Results and Discussion

3.1. Grinding

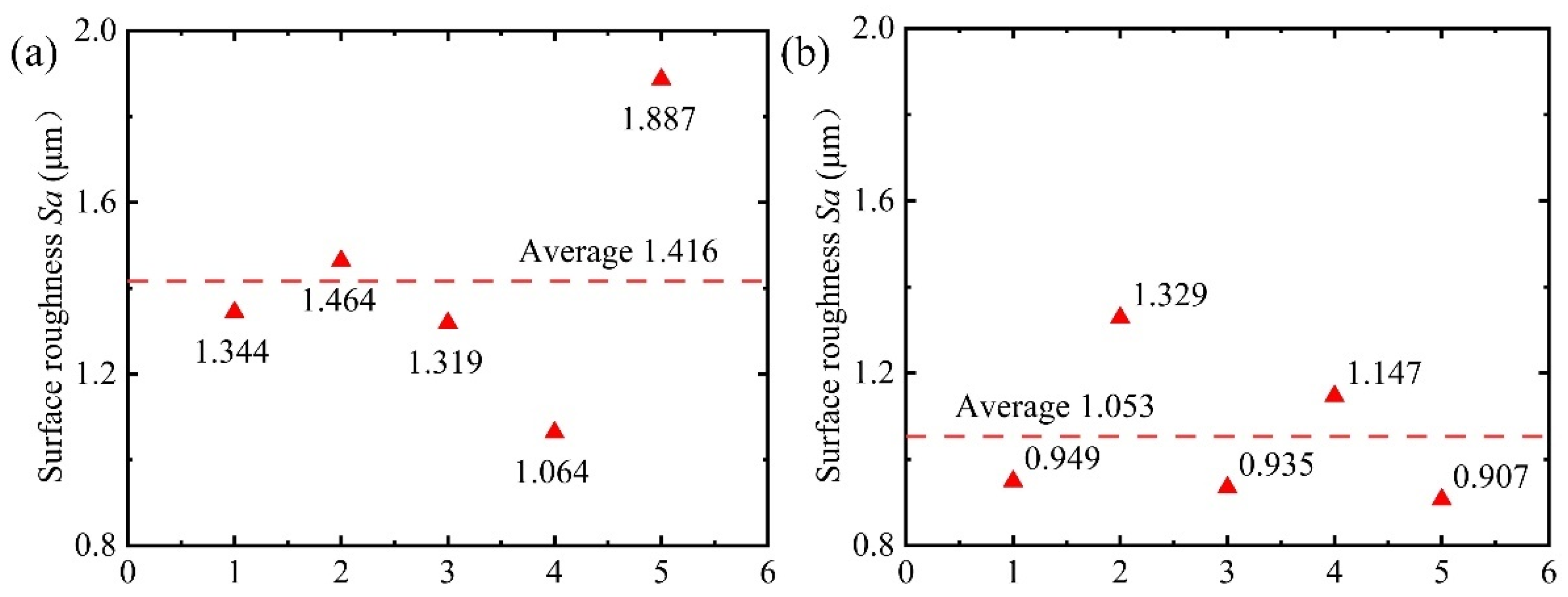

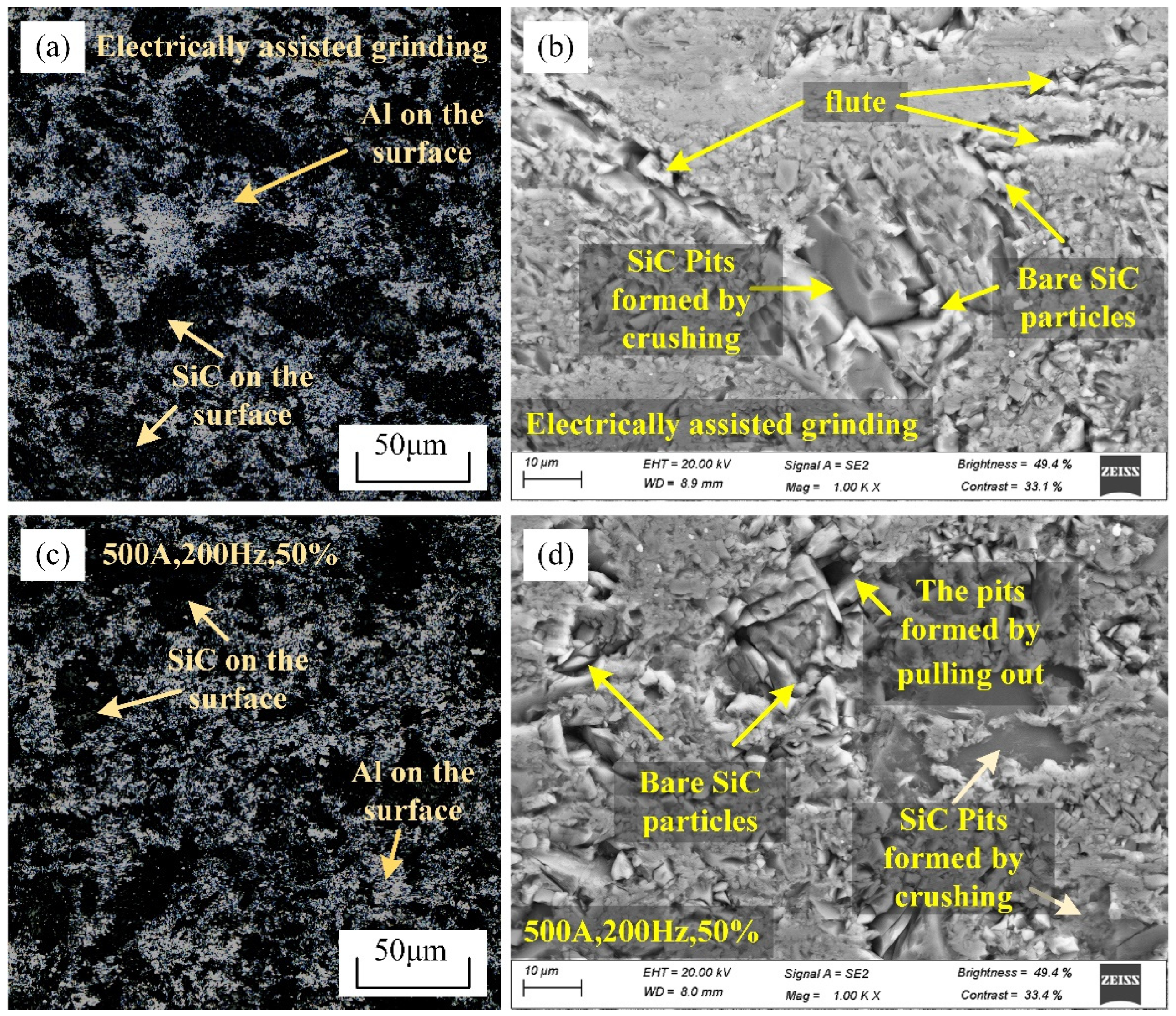

3.1.1. Comparative Experiment

3.1.2. Effect of Pulse Current on Grinding Surface

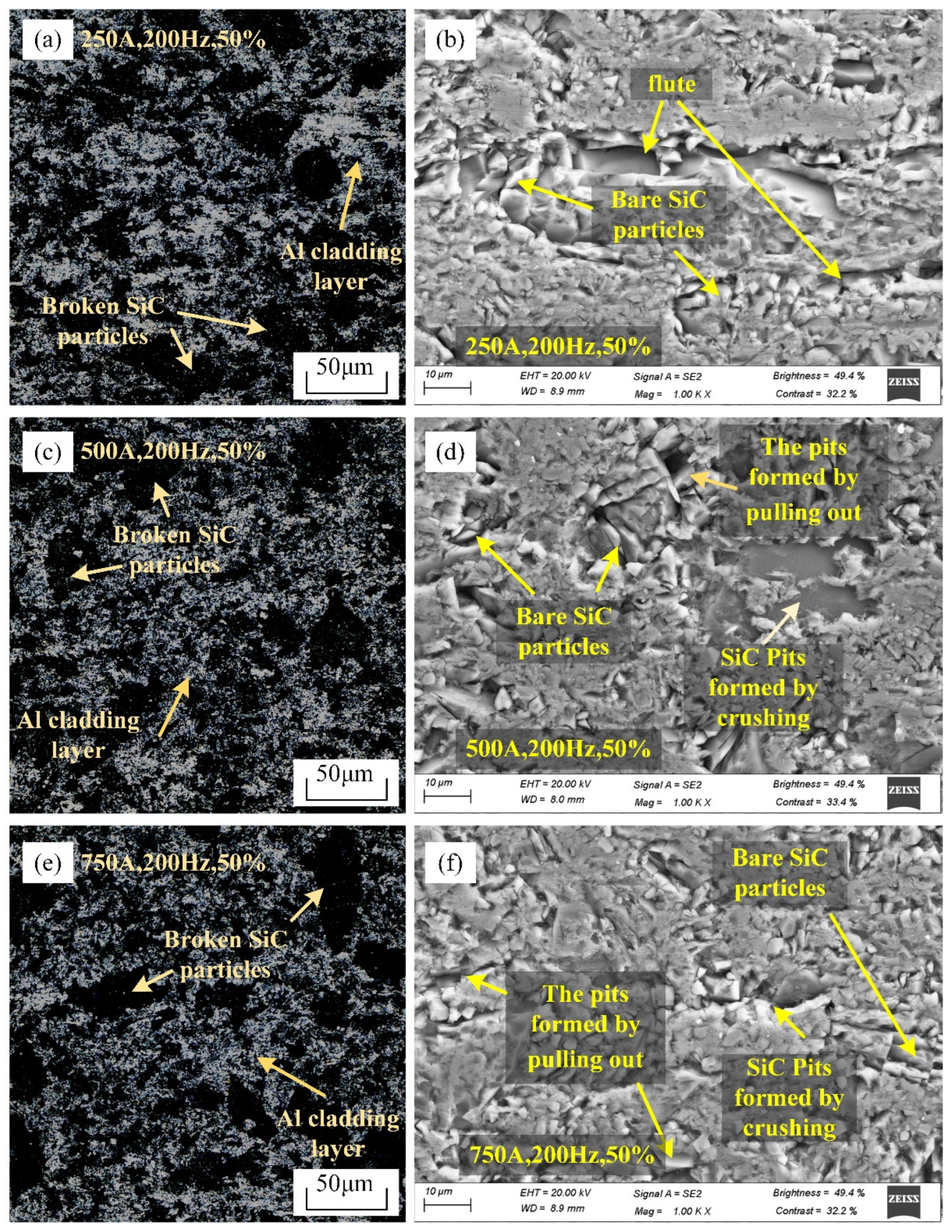

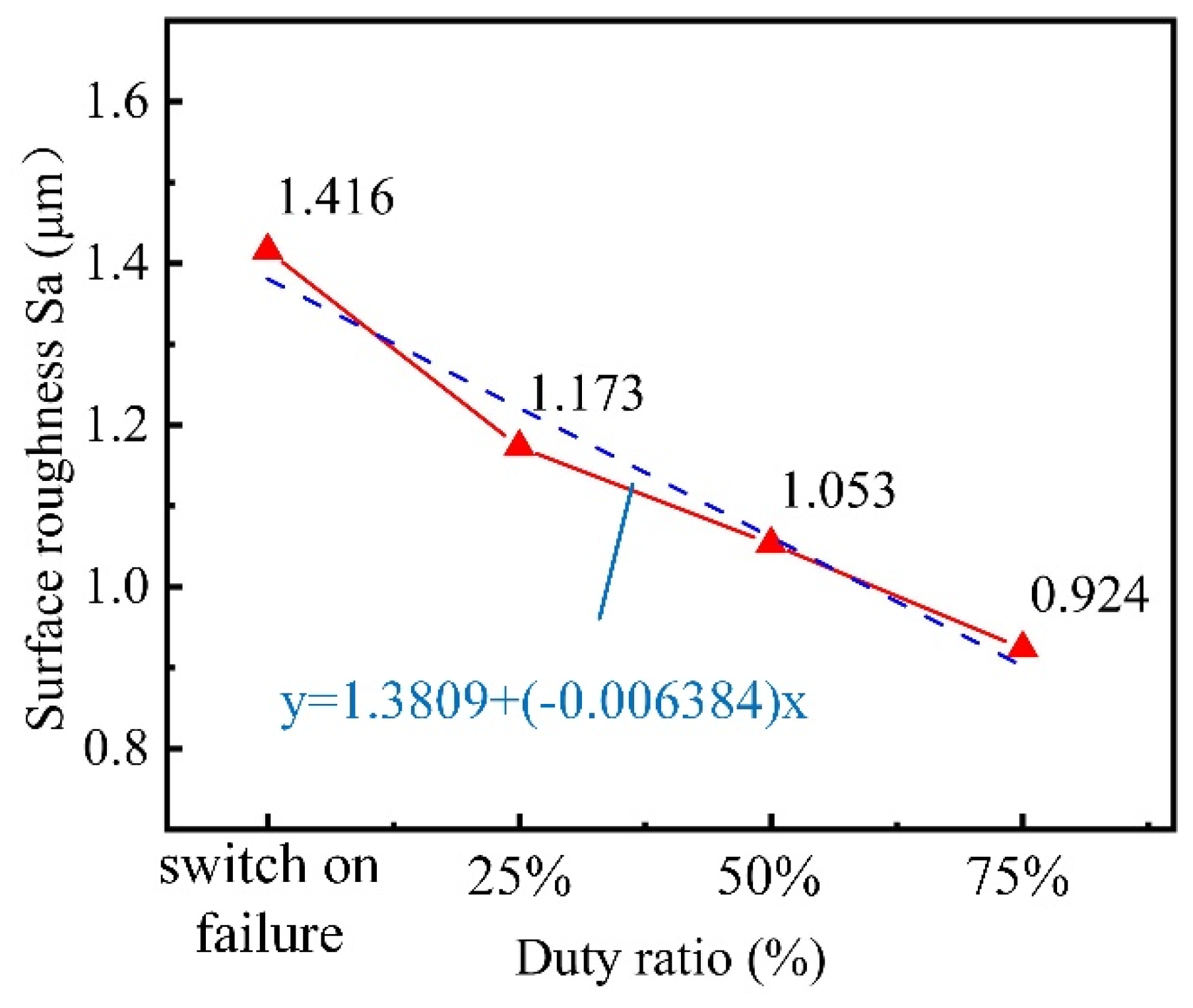

3.1.3. Effect of Duty Ratio on Grinding Surface

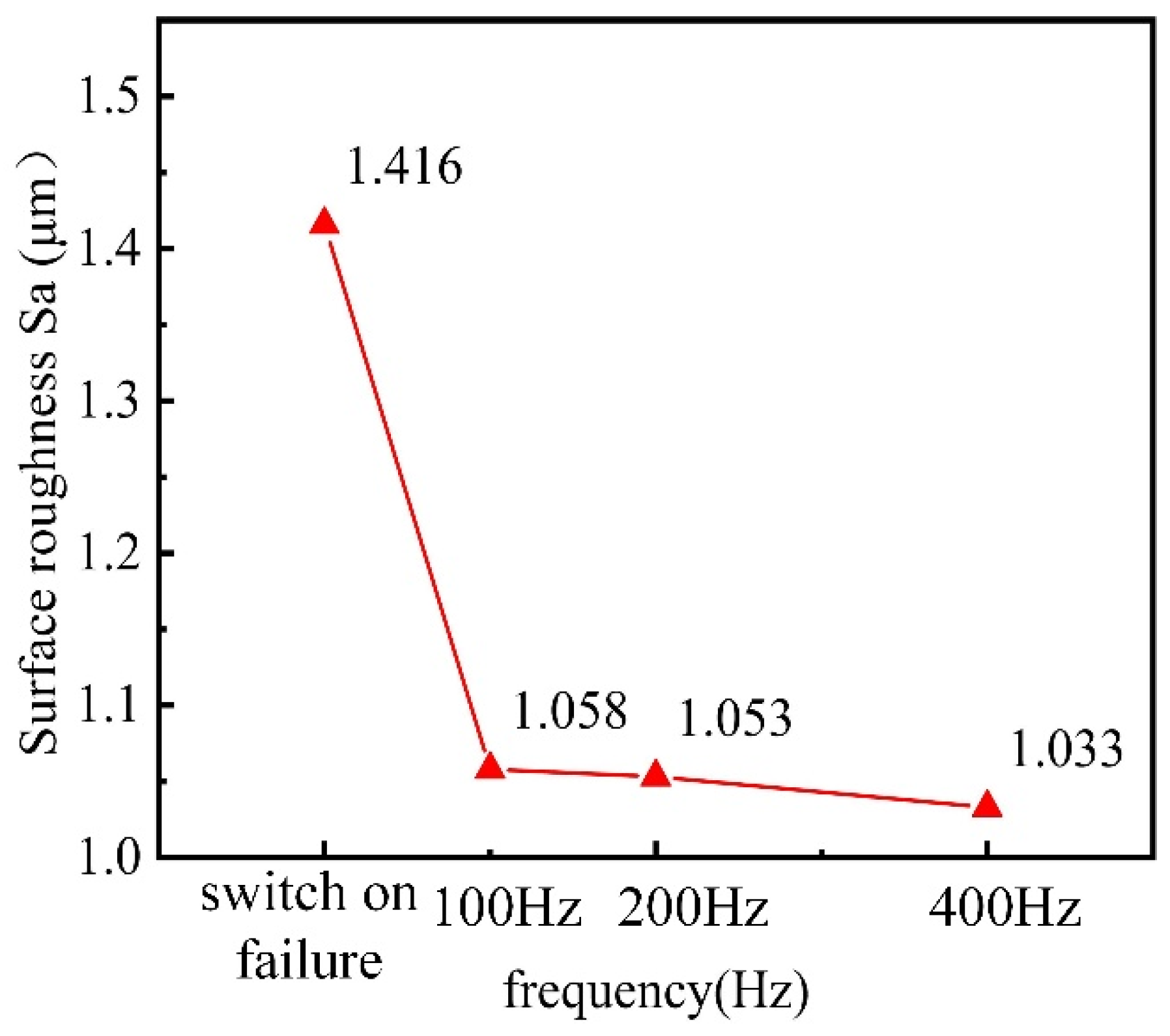

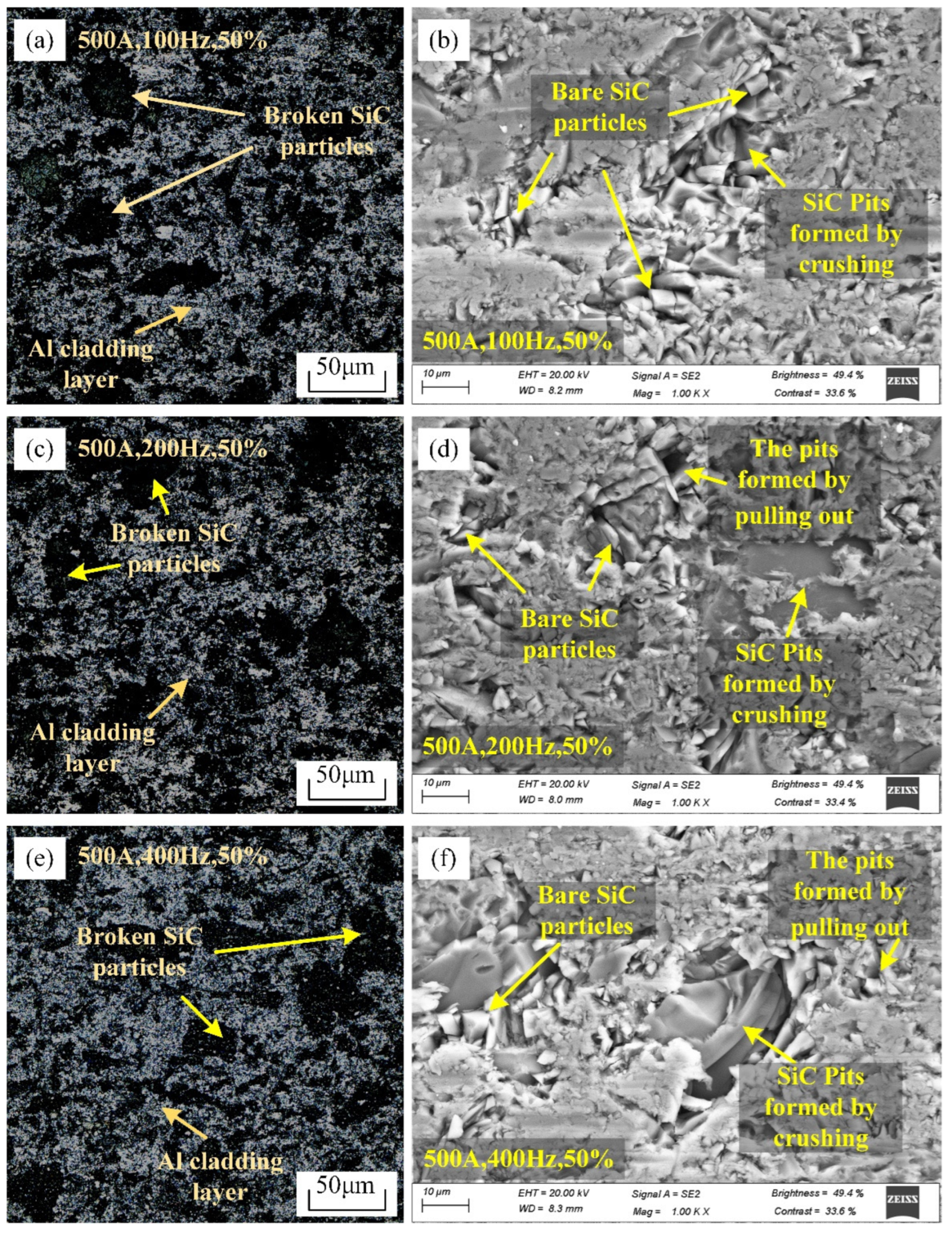

3.1.4. Influence of Frequency on Grinding Surface

3.2. Friction and Wear Experiment

4. Conclusions

- (I)

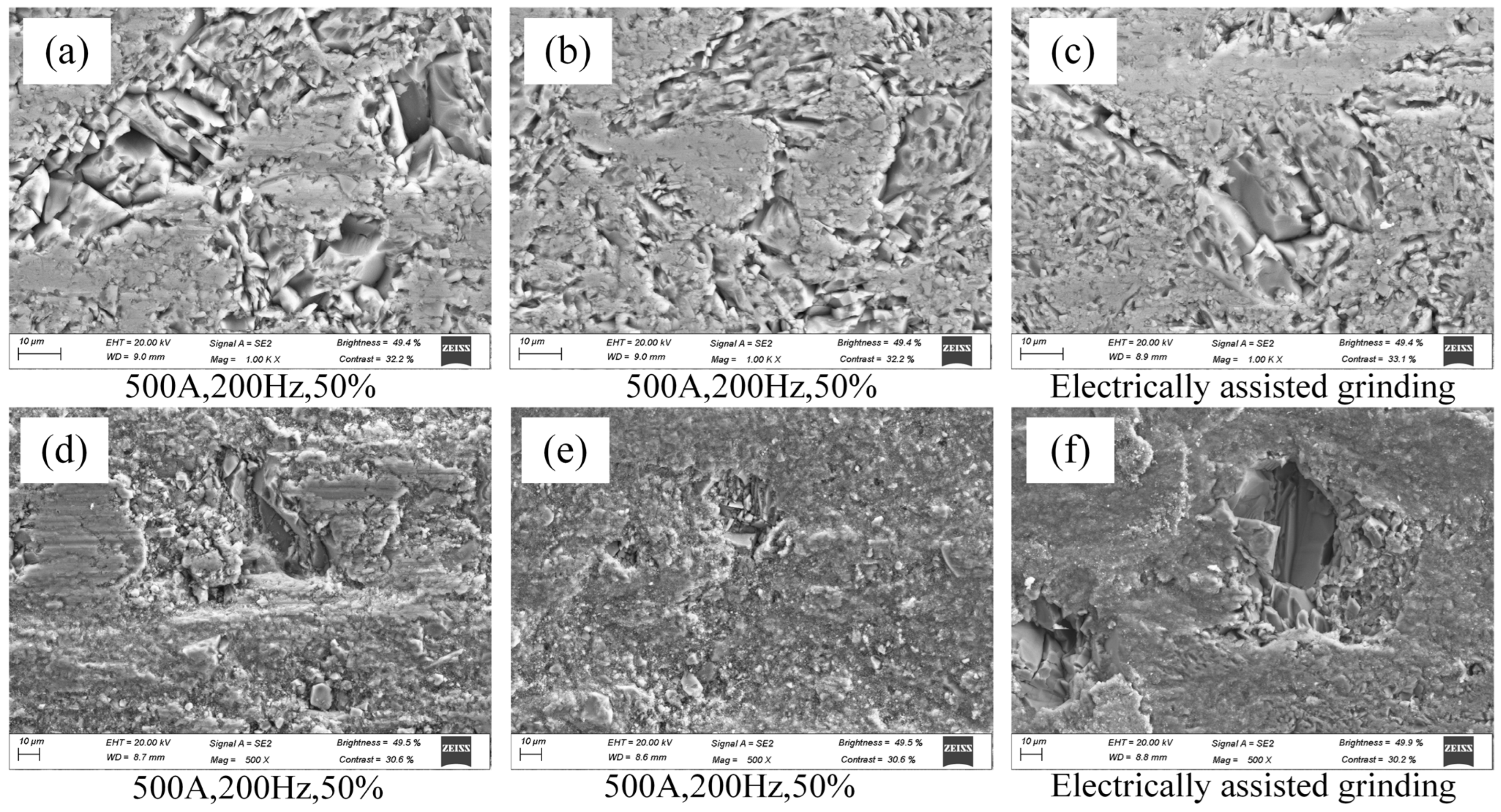

- The application of a pulse current significantly reduces the surface roughness and improves the surface morphology of the workpiece compared to conventional grinding. Under the operating conditions of 500 A, 200 Hz, and a 50% duty ratio, the average surface roughness value Ra is 1.053 μm, which is 25.6% lower than the average surface roughness value Ra of 1.416 μm obtained from conventional grinding.

- (II)

- Increasing the pulse current and duty ratio leads to a significant reduction in surface roughness. Increasing the pulse current from 250 A to 750 A results in a decrease in surface roughness from 1.166 to 0.863, a reduction of 26%. Similarly, increasing the duty ratio from 25% to 75% leads to a decrease in surface roughness from 1.173 to 0.924, a reduction of 21.3%. However, the frequency has no significant influence on the surface roughness. Increasing the frequency from 100 Hz to 400 Hz only leads to a slight reduction in surface roughness from 1.058 to 1.033, a decrease of only 2.4%.

- (III)

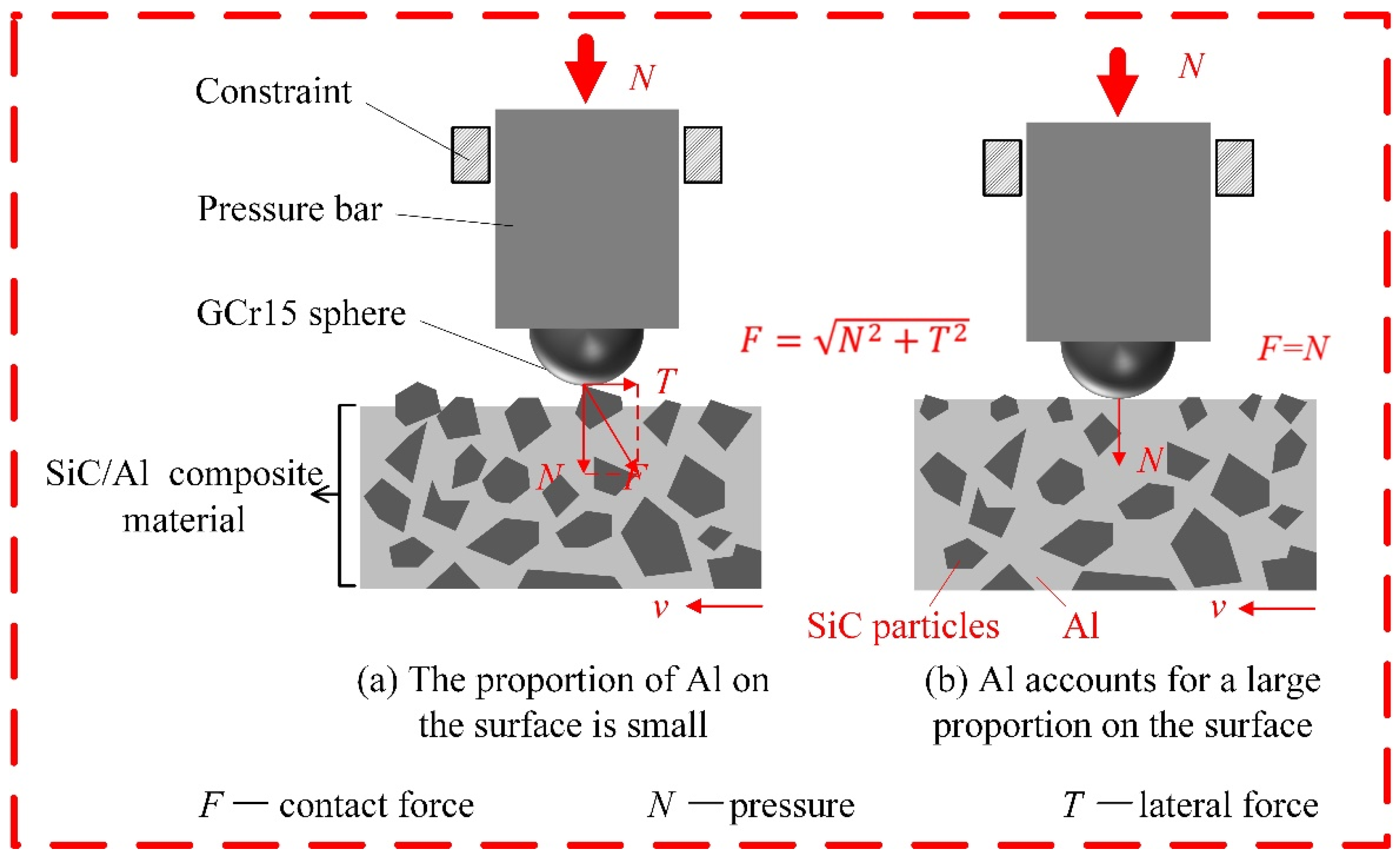

- The workpiece surface obtained from electric-assisted grinding exhibits higher wear resistance compared to that obtained with conventional grinding. The refinement of the SiC particles on the machined surface and the web-like overall structure formed by the flocculent Al under the influence of the pulse current reduce the contact force during the friction–wear process, resulting in a decrease in the friction coefficient. This is evident from the significant reduction in the initial rise rate of the friction coefficient during the early stage of friction–wear and the corresponding decrease in the friction coefficient observed in the later stage of friction–wear.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Liu, J.; Cheng, K.; Ding, H.; Chen, S. An analytical model for force prediction in micromilling silicon carbide particle–reinforced aluminum matrix composites. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2020, 234, 1273–1282. [Google Scholar] [CrossRef]

- Xu, W.; Yiquan, L.; Jinkai, X.; Yu, H.; Liu, Q.; Liang, W. Comparison and research on simulation models of aluminum-based silicon carbide micro-cutting. Int. J. Adv. Manuf. Technol. 2020, 109, 589–605. [Google Scholar] [CrossRef]

- Reddy, P.S.; Kesavan, R.; Vijaya Ramnath, B. Investigation of mechanical properties of aluminium 6061-silicon carbide, boron carbide metal matrix composite. Silicon 2018, 10, 495–502. [Google Scholar] [CrossRef]

- Acharya, S.; Gupta, R.K.; Ghosh, J.; Bysakh, S.; Ghosh, K.; Mondal, D.; Mukhopadhyay, A. High strain rate dynamic compressive behaviour of Al6061-T6 alloys. Mater. Charact. 2017, 127, 185–197. [Google Scholar] [CrossRef]

- Qu, S.; Wei, C.; Yang, Y.; Yao, P.; Chu, D.; Gong, Y.; Zhao, D.; Zhang, X. Grinding mechanism and surface quality evaluation strategy of single crystal 4H-SiC. Tribol. Int. 2024, 194, 109515. [Google Scholar] [CrossRef]

- Qu, S.; Yao, P.; Gong, Y.; Chu, D.; Yang, Y.; Li, C.; Wang, Z.; Zhang, X.; Hou, Y. Environmentally friendly grinding of C/SiCs using carbon nanofluid minimum quantity lubrication technology. J. Clean. Prod. 2022, 366, 132898. [Google Scholar] [CrossRef]

- Duan, Z.; Wang, S.; Wang, Z.; Li, C.; Li, Y.; Song, J.; Liu, J.; Liu, X. Tool wear mechanisms in cold plasma and nano-lubricant multi-energy field coupled micro-milling of Al-Li alloy. Tribol. Int. 2024, 192, 109337. [Google Scholar] [CrossRef]

- Aurich, J.C.; Zimmermann, M.; Schindler, S.; Steinmann, P. Turning of aluminum metal matrix composites: Influence of the reinforcement and the cutting condition on the surface layer of the workpiece. Adv. Manuf. 2016, 4, 225–236. [Google Scholar] [CrossRef]

- Shaheen-Mualim, M.; Kovel, G.; Atrash, F.; Ben-Bashat-Bergman, L.; Gleizer, A.; Ma, L.; Sherman, D. From macro fracture energy to micro bond breaking mechanisms–Shorter is tougher. Eng. Fract. Mech. 2023, 289, 109447. [Google Scholar] [CrossRef]

- Steinert, L.A. Geometrical Anisotropy of Magnetic Materials in Wave Guides and Cavities. J. Appl. Phys. 1959, 30, 1109. [Google Scholar] [CrossRef]

- Yang, L.; Zhang, H.; Liu, G. Performance analysis of wide magnesium alloy foil rolled by multi-pass electric plastic rolling. Met. Mater. Int. 2023, 29, 2783–2794. [Google Scholar] [CrossRef]

- Song, Y.; Wu, Y.; Lu, J.; Mei, M.; Xie, L.; Hao, C. Promoting Dynamic Recrystallization of Al-Zn-Mg-Cu Alloy via Electroshock Treatment. Metals 2023, 13, 944. [Google Scholar] [CrossRef]

- Wang, P.; Wu, W.; Cui, F.; Yang, X.; Pan, A. Investigation of thermal and mechanical effects during electrically-assisted compression of CoCrFeNiW0.5 high entropy alloy. Mater. Charact. 2023, 202, 112981. [Google Scholar] [CrossRef]

- Liu, Y.; Meng, B.; Wan, M. Deformation characteristics and performance evolution of superalloy capillary drawn by electrically assisted microforming. Int. J. Mech. Sci. 2023, 240, 107912. [Google Scholar] [CrossRef]

- Yang, Z.; Bao, J.; Ding, C.; Son, S.; Ning, Z.; Xu, J.; Shan, D.; Guo, B.; Kim, H. Electroplasticity in the Al0.6CoCrFeNiMn high entropy alloy subjected to electrically-assisted uniaxial tension. J. Mater. Sci. Technol. 2023, 148, 209–221. [Google Scholar] [CrossRef]

- Xue, L.; Liao, C.; Wu, M.; Li, Q.; Hu, Z.; Yang, Y.; Liu, J. Improvement of mechanical properties and corrosion resistance of SLM-AlSi10Mg alloy by an eco-friendly electric pulse treatment. J. Clean. Prod. 2024, 439, 140864. [Google Scholar] [CrossRef]

- Li, Y.; Zhang, X. Suppression of hydrogen embrittlement of gear steel 20CrMnTiH with pulsed electric current. Int. J. Hydrogen Energy 2023, 48, 21920–21931. [Google Scholar] [CrossRef]

- Li, H.; Su, L.; Wang, L.; Jinag, Y.; Long, J.; Lin, G.; Xiao, Z.; Jia, Y.; Li, Z. Rapidly induced homogenization and microstructure control of Cu–15Ni–8Sn alloy by electropulsing treatment. Mater. Sci. Eng. A 2024, 890, 145932. [Google Scholar] [CrossRef]

- Gu, S.; Liu, C.; Toku, Y.; Kimura, Y.; Yoon, S.; Li, S.; Cui, Y.; Ju, Y. Ultrahigh deformability of Ti-6Al-4V assisted by high-density pulsed electric current treatment. J. Alloys Compd. 2024, 973, 172892. [Google Scholar] [CrossRef]

- Liu, J.; Jia, D.; Fu, Y.; Kong, X.; Lv, Z.; Zeng, E.; Gao, Q. Electroplasticity effects: From mechanism to application. Int. J. Adv. Manuf. Technol. 2024, 131, 3267–3286. [Google Scholar] [CrossRef]

- Goldman, P.; Motowidlo, L.; Galligan, J. The absence of an electric plastic effect in lead at 4.2K. Scr. Metall. 1981, 15, 353–356. [Google Scholar] [CrossRef]

- Magargee, J.; Morestin, F.; Cao, J. Characterization of flow stress for commercially pure titanium subjected to electrically assisted deformation. J. Eng. Mater. Technol. 2013, 135, 041003. [Google Scholar] [CrossRef]

- Xu, Z.; Jiang, T.; Huang, J.; Peng, L.; Lai, X.; Fu, M. Electroplasticity in electrically-assisted forming: Process phenomena, performances and modelling. Int. J. Mach. Tools Manuf. 2022, 175, 103871. [Google Scholar] [CrossRef]

- Liu, X.; Lan, S.; Ni, J. Experimental study of electro-plastic effect on advanced high strength steels. Mater. Sci. Eng. A 2013, 582, 211–218. [Google Scholar] [CrossRef]

- Krokhin, A.A.; Gumen, L.N.; Galligan, J.M. Tilt effect in the electron drag of dislocations in metals. Philos. Mag. A 1998, 77, 497–506. [Google Scholar] [CrossRef]

- Li, M.; Shen, Y.; Luo, K.; An, Q.; Gao, P.; Xiao, P.; Zou, Y. Harnessing dislocation motion using an electric field. Nat. Mater. 2023, 22, 958–963. [Google Scholar] [CrossRef]

- Ruszkiewicz, B.J.; Grimm, T.; Ragai, I.; Laine, M.; John, R. A review of electrically-assisted manufacturing with emphasis on modeling and understanding of the electroplastic effect. J. Manuf. Sci. Eng. 2017, 139, 110801. [Google Scholar] [CrossRef]

- Zhou, C.; Zhan, L.; Li, H.; Liu, C.; Xu, Y.; Ma, B.; Yang, Y.; Huang, M. Dislocation reconfiguration during creep deformation of an Al-Cu-Li alloy via electropulsing. J. Mater. Sci. Technol. 2022, 130, 27–34. [Google Scholar] [CrossRef]

- Xiang, S.; Zhang, X. Dislocation structure evolution under electroplastic effect. Mater. Sci. Eng. A 2019, 761, 138026. [Google Scholar] [CrossRef]

- Hansen, N. Cold deformation microstructures. Mater. Sci. Technol. 1990, 6, 1039–1047. [Google Scholar] [CrossRef]

- Guo, L.; Yang, H.; Zhan, M. Research on plastic deformation behaviour in cold ring rolling by FEM numerical simulation. Model. Simul. Mater. Sci. Eng. 2005, 13, 1029. [Google Scholar] [CrossRef]

- Wang, B.; Liu, Z.; Cai, Y.; Luo, X.; Ma, H.; Song, Q.; Xiang, Z. Advancements in material removal mechanism and surface integrity of high speed metal cutting: A review. Int. J. Mach. Tools Manuf. 2021, 166, 103744. [Google Scholar] [CrossRef]

- Hameed, S.; Gonzalez Rojas, H.A.; Sánchez Egea, A.J.; Alberro, A.N. Electroplastic cutting influence on power consumption during drilling process. Int. J. Adv. Manuf. Technol. 2016, 87, 1835–1841. [Google Scholar] [CrossRef]

- Baranov, S.A.; Staschenko, V.I.; Sukhov, A.V.; Troitskiy, O.A.; Tyapkin, A.V. Electroplastic metal cutting. Russ. Electr. Eng. 2011, 82, 477–479. [Google Scholar] [CrossRef]

- Egea, A.J.S.; Rojas, H.A.G.; Montaña, C.A.M.; Echeverri, V.K. Effect of electroplastic cutting on the manufacturing process and surface properties. J. Mater. Process. Technol. 2015, 222, 327–334. [Google Scholar] [CrossRef]

- Guan, H.; Zhong, Y.; Zou, W.; Sun, P.; Zhai, J.; Qu, S. Research on the Electric-Pulse-Assisted Turning Behavior of TC27 Alloy. Metals 2023, 13, 702. [Google Scholar] [CrossRef]

- Ruszkiewicz, B.J.; Gendreau, E.; Niaki, F.A.; Akhavan, F.; Laine, M. Electroplastic drilling of low-and high-strength steels. J. Manuf. Sci. Eng. 2018, 140, 061017. [Google Scholar] [CrossRef]

- Liu, T.J.C. Joule heating behaviors around through crack emanating from circular hole under electric load. Eng. Fract. Mech. 2014, 123, 2–20. [Google Scholar] [CrossRef]

- Kumar, A.; Paul, S.K. Healing of fatigue crack in steel with the application of pulsed electric current. Materialia 2020, 14, 100906. [Google Scholar] [CrossRef]

- Tvergaard, V.; Hutchinson, J.W. Microcracking in ceramics induced by thermal expansion or elastic anisotropy. J. Am. Ceram. Soc. 1988, 71, 157–166. [Google Scholar] [CrossRef]

- Calka, A.; Wexler, D. Mechanical milling assisted by electrical discharge. Nature 2002, 419, 147–151. [Google Scholar] [CrossRef]

- Kishore, K.; Sinha, M.K.; Singh, A.; Gupta, M.K.; Korkmaz, M.E. A comprehensive review on the grinding process: Advancements, applications and challenges. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2022, 236, 10923–10952. [Google Scholar] [CrossRef]

- Oliveira, J.F.G.; Silva, E.J.; Guo, C.; Hashimoto, F. Industrial challenges in grinding. CIRP Ann. 2009, 58, 663–680. [Google Scholar] [CrossRef]

- Huang, H.; Liu, Y.C. Experimental investigations of machining characteristics and removal mechanisms of advanced ceramics in high speed deep grinding. Int. J. Mach. Tools Manuf. 2003, 43, 811–823. [Google Scholar] [CrossRef]

- Guo, C.; Shi, Z.; Attia, H.; McIntosh, D. Power and wheel wear for grinding nickel alloy with plated CBN wheels. CIRP Ann. 2007, 56, 343–346. [Google Scholar] [CrossRef]

- Cetin, M.H.; Ozcelik, B.; Kuram, E.; Demirbas, E. Evaluation of vegetable based cutting fluids with extreme pressure and cutting parameters in turning of AISI 304L by Taguchi method. J. Clean. Prod. 2011, 19, 2049–2056. [Google Scholar] [CrossRef]

- Lawal, S.A.; Choudhury, I.A.; Nukman, Y. A critical assessment of lubrication techniques in machining processes: A case for minimum quantity lubrication using vegetable oil-based lubricant. J. Clean. Prod. 2013, 41, 210–221. [Google Scholar] [CrossRef]

- Asadauskas, S.; Perez, J.H.; Duda, J.L. Lubrication properties of castor oil–potential basestock for biodegradable lubricants. Tribol. Lubr. Technol. 1997, 53, 35. [Google Scholar]

- Xiao, A.; Huang, C.; Liu, H.S.; Cui, X.; Wang, S. Deformation mechanism of 5052 aluminum alloy using electrically assisted electromagnetic forming. Met. Mater. Int. 2022, 28, 2483–2497. [Google Scholar] [CrossRef]

- Jia, D. The Formation Mechanism and Grinding Performance Evaluation of Charged Micro Droplets Atom Ization on Grinding Wheel Workpiece Interface; Qingdao University of Technology: Qingdao, China, 2021. [Google Scholar]

- Mohseni, K.; Dolatabadi, A. Electrowetting Droplet Actuation in Micro Scale Devices. In Proceedings of the 43rd AIAA Aerospace Sciences Meeting and Exhibit, Reno, NV, USA, 10–13 January 2005; p. 677. [Google Scholar]

- Lee, J.; Kim, C.J. Surface-tension-driven microactuation based on continuous electrowetting. J. Microelectromechanical Syst. 2000, 9, 171–180. [Google Scholar]

- Zhao, L.; Chen, G.; Liu, J.; Wei, H.; Huang, J. Effect of pulse current parameters on electroplastically assisted dry cutting performance of W93NiFe alloy. Int. J. Adv. Manuf. Technol. 2024, 131, 2123–2131. [Google Scholar] [CrossRef]

| Material | Component | Density (g/cm3) | Thermal Expansion Coefficient (10−6/K) | Thermal Conductivity W/(m·K) |

|---|---|---|---|---|

| SiC/Al | Al + 70%SiC | 2.9–3.3 | 6.5–9.5 | 180–240 |

| Fluid | Kinematic Viscosity @40 °C (mm2/s) | Open Cup Flash Point (°C) | Pour Point (°C) | Density @20 °C (g/cm3) |

|---|---|---|---|---|

| KS-1040 synthetic grease | 68 | 198 | −15 | 0.835 |

| Serial Number | Pulse Current Size (A) | Frequency (Hz) | Duty Ratio (%) |

|---|---|---|---|

| Control group | 0 | 0 | 0 |

| 1 | 250 | 200 | 50 |

| 500 | 200 | 50 | |

| 750 | 200 | 50 | |

| 2 | 500 | 200 | 25 |

| 500 | 200 | 50 | |

| 500 | 200 | 75 | |

| 3 | 500 | 100 | 50 |

| 500 | 200 | 50 | |

| 500 | 400 | 50 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, W.; Jia, D.; Yang, M.; Gao, Q.; Gao, T.; Duan, Z.; Qu, D. Surface Quality of High-Concentration SiC/Al Grinding with Electroassisted Biolubricant MQL. Coatings 2024, 14, 804. https://doi.org/10.3390/coatings14070804

Zhang W, Jia D, Yang M, Gao Q, Gao T, Duan Z, Qu D. Surface Quality of High-Concentration SiC/Al Grinding with Electroassisted Biolubricant MQL. Coatings. 2024; 14(7):804. https://doi.org/10.3390/coatings14070804

Chicago/Turabian StyleZhang, Weidong, Dongzhou Jia, Min Yang, Qi Gao, Teng Gao, Zhenjing Duan, and Da Qu. 2024. "Surface Quality of High-Concentration SiC/Al Grinding with Electroassisted Biolubricant MQL" Coatings 14, no. 7: 804. https://doi.org/10.3390/coatings14070804

APA StyleZhang, W., Jia, D., Yang, M., Gao, Q., Gao, T., Duan, Z., & Qu, D. (2024). Surface Quality of High-Concentration SiC/Al Grinding with Electroassisted Biolubricant MQL. Coatings, 14(7), 804. https://doi.org/10.3390/coatings14070804