Study on the Degradation Performance of AlGaN-Based Deep Ultraviolet LEDs under Thermal and Electrical Stress

Abstract

:1. Introduction

2. Experimental Details

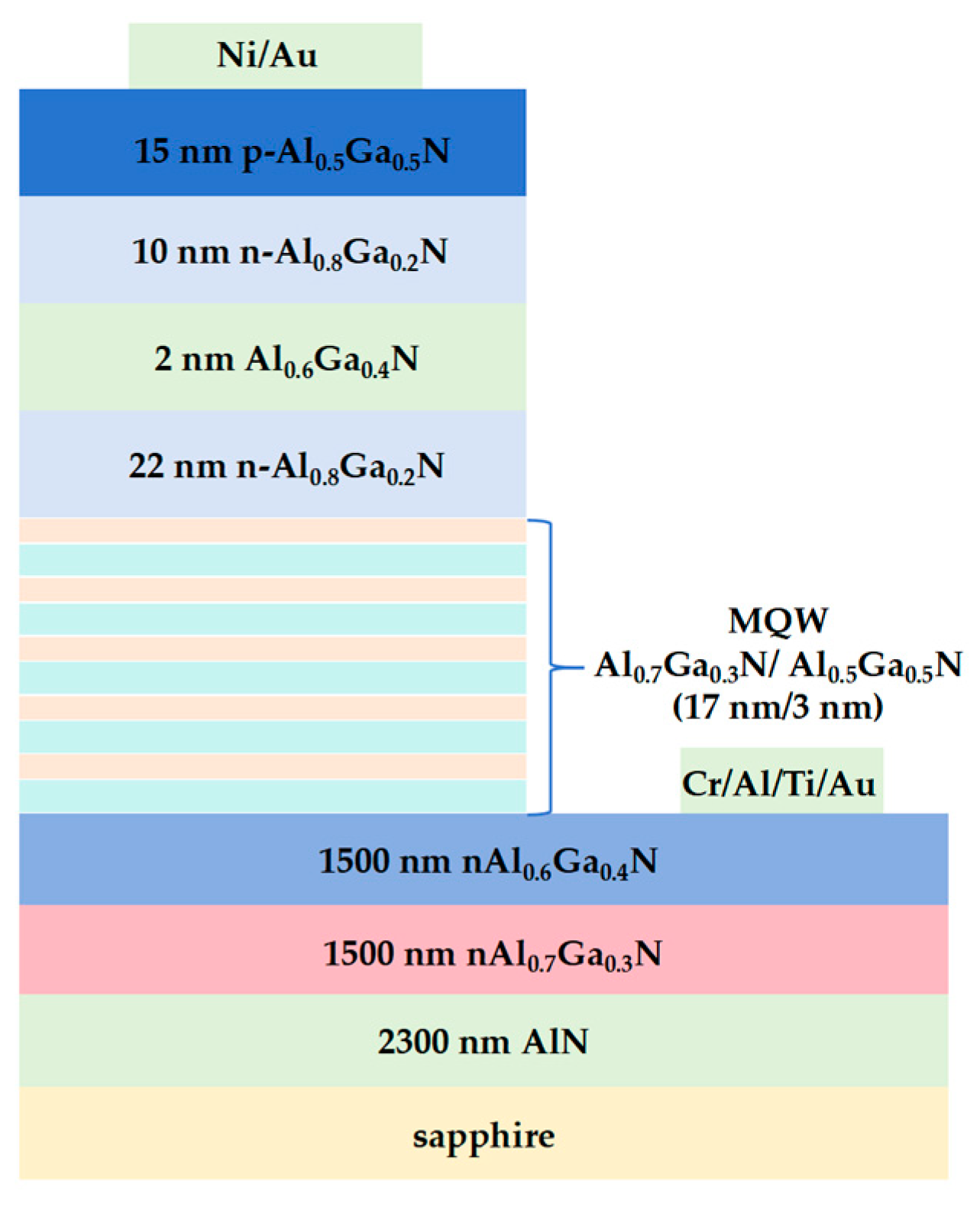

2.1. The Heterostructures of AlGaN-Based DUV LEDs

2.2. Sample Preparation and the Design of Aging Tests

3. Results and Discussion

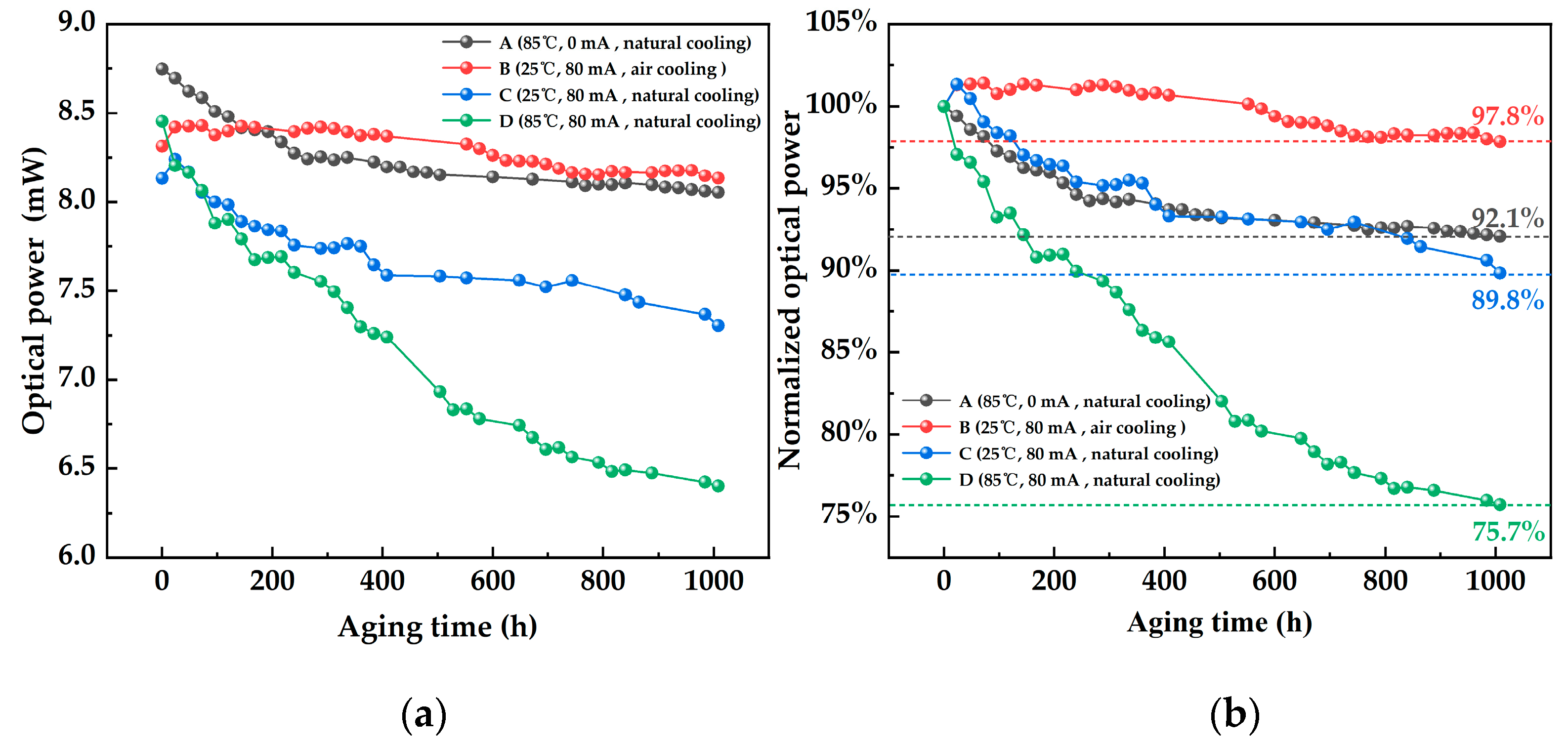

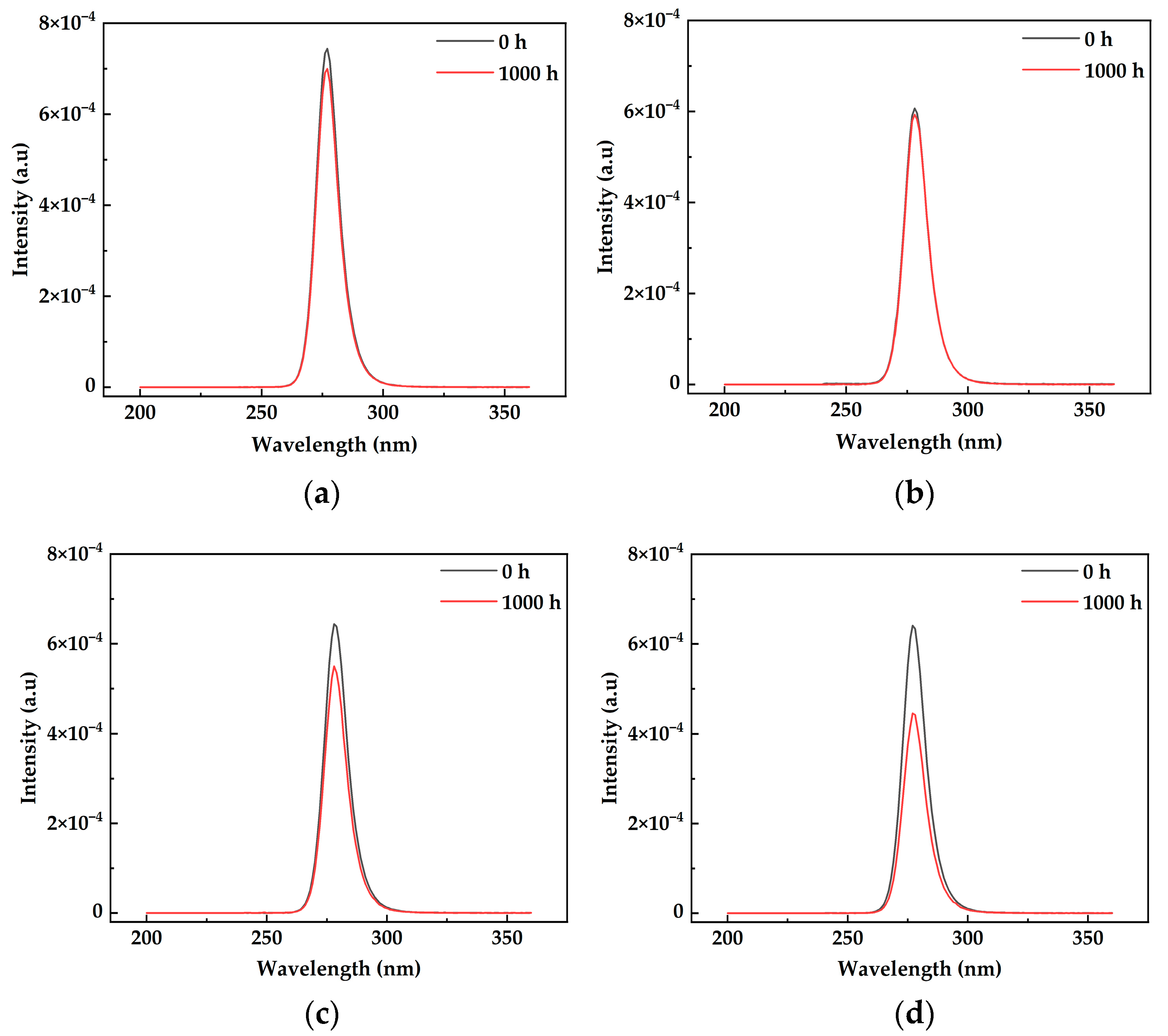

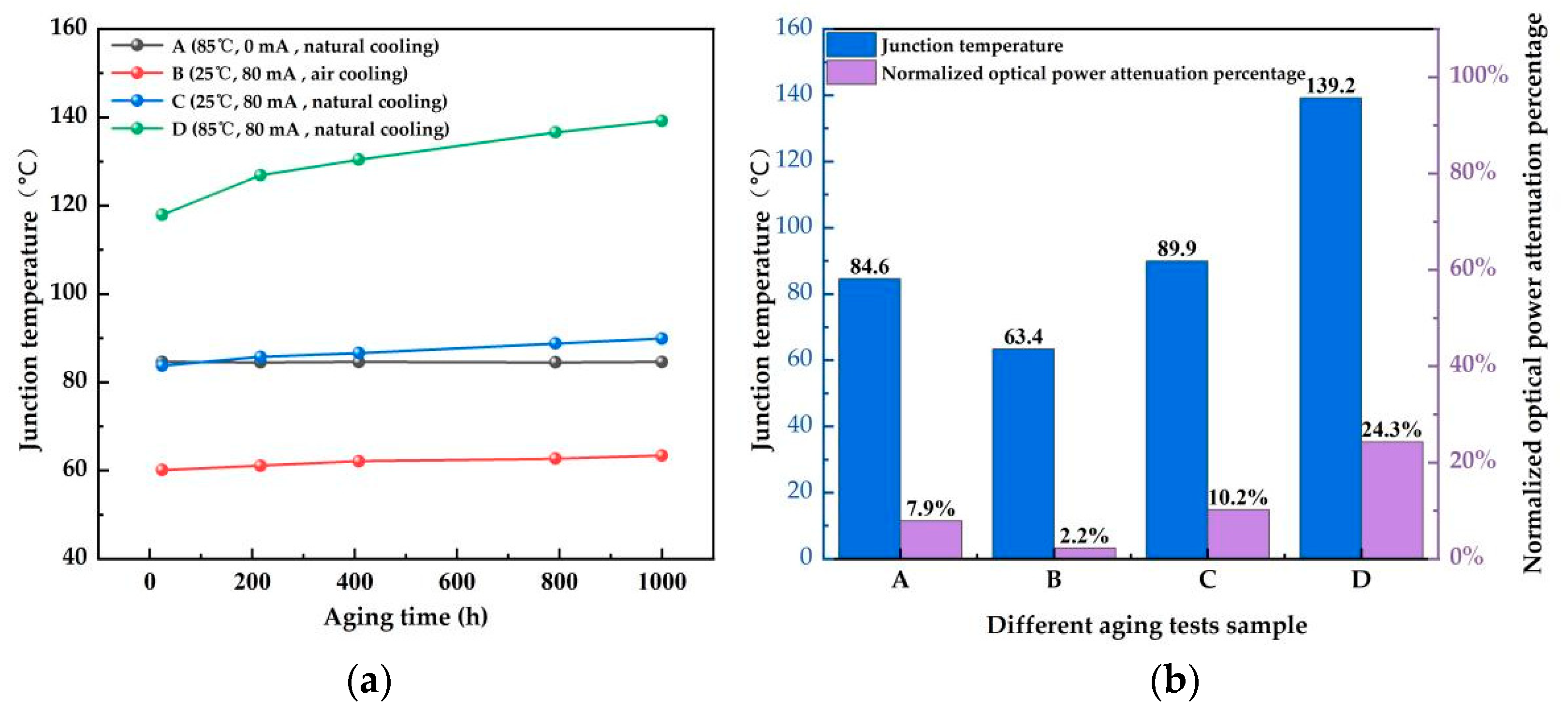

3.1. Optical Properties

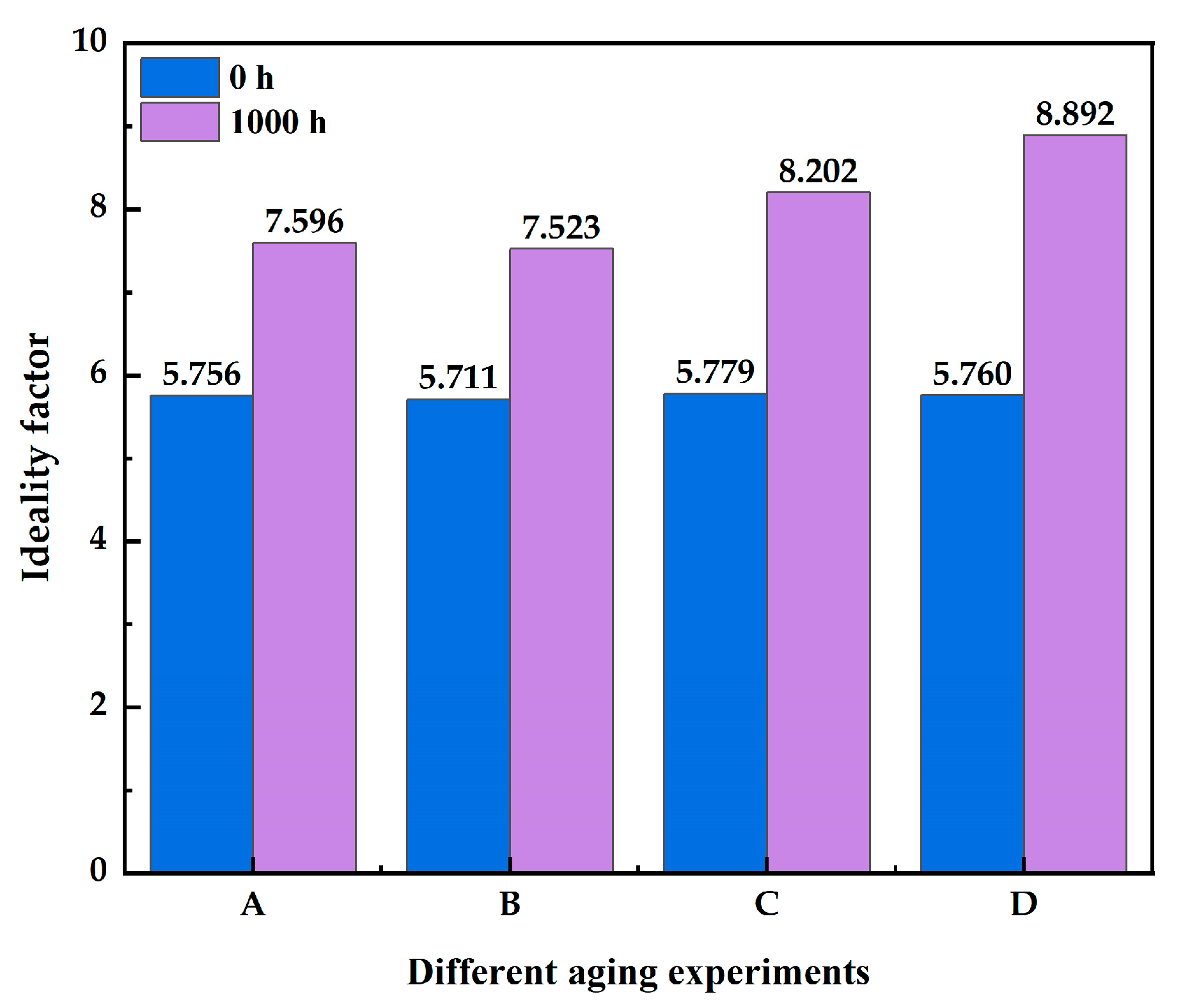

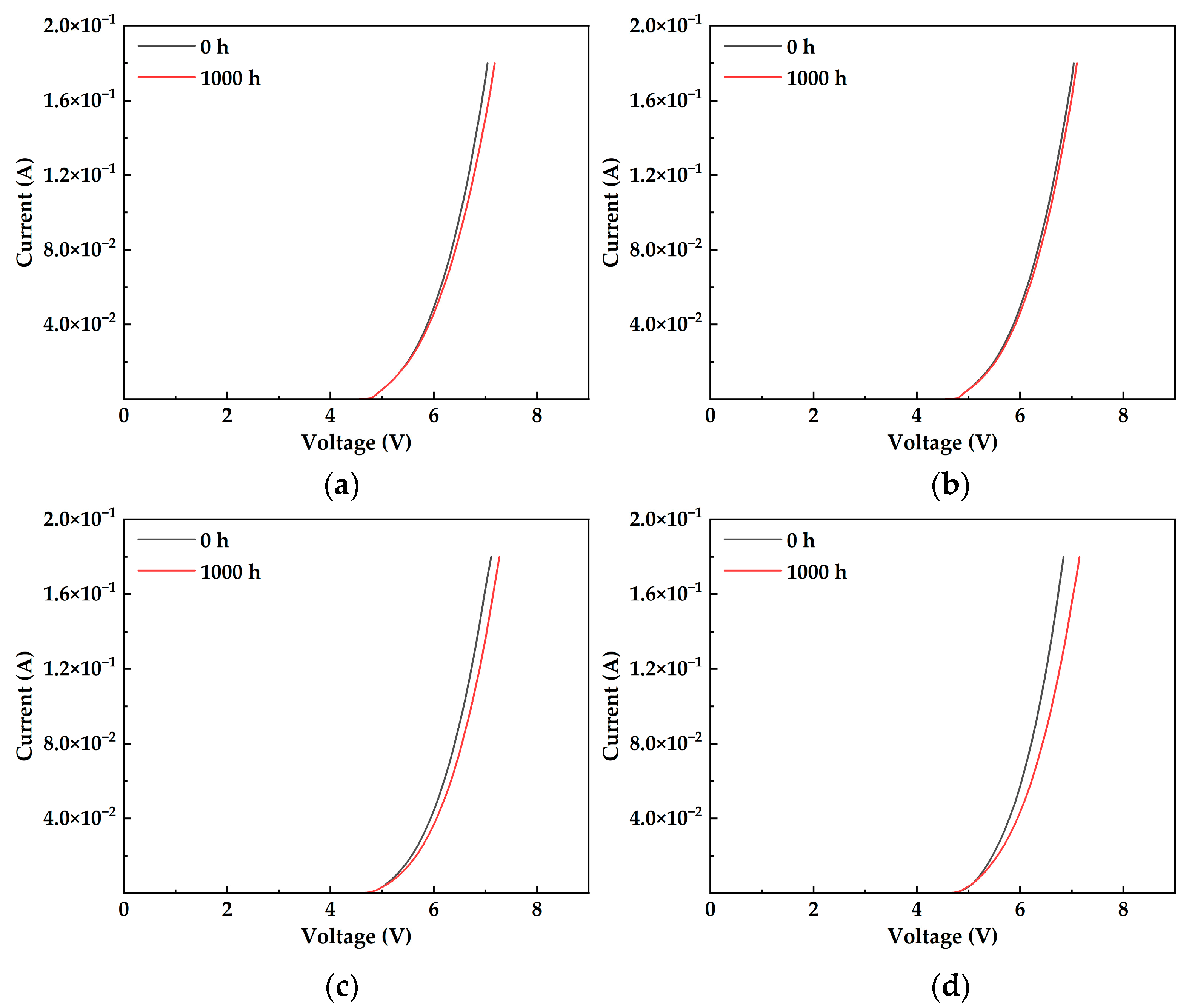

3.2. Electrical Properties

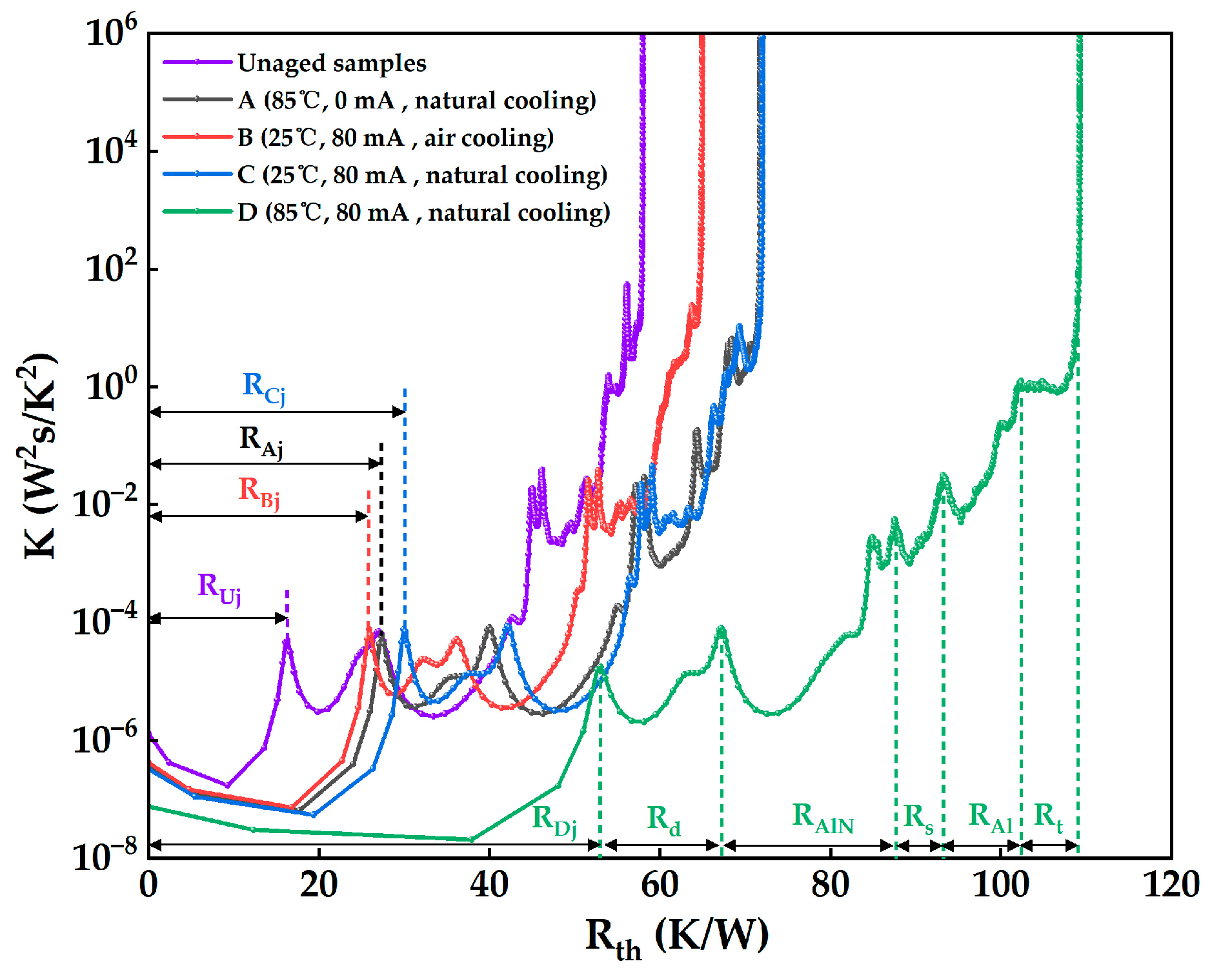

3.3. Thermal Properties

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Wu, C.-J.; Kuo, C.-Y.; Wang, C.-J.; Chang, W.-E.; Tsai, C.-L.; Lin, C.-F.; Han, J. Deep-UV Porous AlGaN Distributed Bragg Reflectors for Deep Ultraviolet Light-Emitting Diodes and Laser Diodes. ACS Appl. Nano Mater. 2020, 3, 399–402. [Google Scholar] [CrossRef]

- Kneissl, M.; Seong, T.-Y.; Han, J.; Amano, H. The Emergence and Prospects of Deep-Ultraviolet Light-Emitting Diode Technologies. Nat. Photon. 2019, 13, 233–244. [Google Scholar] [CrossRef]

- Mondal, R.K.; Chatterjee, V.; Pal, S. AlInGaN-Based Superlattice P-Region for Improvement of Performance of Deep UV LEDs. Opt. Mater. 2020, 104, 109846. [Google Scholar] [CrossRef]

- Lee, D.; Lee, J.W.; Jang, J.; Shin, I.-S.; Jin, L.; Park, J.H.; Kim, J.; Lee, J.; Noh, H.-S.; Kim, Y.-I.; et al. Improved Performance of AlGaN-Based Deep Ultraviolet Light-Emitting Diodes with Nano-Patterned AlN/Sapphire Substrates. Appl. Phys. Lett. 2017, 110, 191103. [Google Scholar] [CrossRef]

- Susilo, N.; Hagedorn, S.; Jaeger, D.; Miyake, H.; Zeimer, U.; Reich, C.; Neuschulz, B.; Sulmoni, L.; Guttmann, M.; Mehnke, F.; et al. AlGaN-Based Deep UV LEDs Grown on Sputtered and High Temperature Annealed AlN/Sapphire. Appl. Phys. Lett. 2018, 112, 041110. [Google Scholar] [CrossRef]

- Zhou, S.; Liao, Z.; Sun, K.; Zhang, Z.; Qian, Y.; Liu, P.; Du, P.; Jiang, J.; Lv, Z.; Qi, S. High-Power AlGaN-Based Ultrathin Tunneling Junction Deep Ultraviolet Light-Emitting Diodes. Laser Photon. Rev. 2023, 18, 2300464. [Google Scholar] [CrossRef]

- Ruschel, J.; Glaab, J.; Susilo, N.; Hagedorn, S.; Walde, S.; Ziffer, E.; Cho, H.K.; Ploch, N.L.; Wernicke, T.; Weyers, M.; et al. Reliability of UVC LEDs Fabricated on AlN/Sapphire Templates with Different Threading Dislocation Densities. Appl. Phys. Lett. 2020, 117, 241104. [Google Scholar] [CrossRef]

- Moseley, M.; Allerman, A.; Crawford, M.; Wierer, J.J.; Smith, M.; Biedermann, L. Electrical Current Leakage and Open-Core Threading Dislocations in AlGaN-Based Deep Ultraviolet Light-Emitting Diodes. J. Appl. Phys. 2014, 116, 053104. [Google Scholar] [CrossRef]

- Ma, Z.H. Reliability and Failure Mechanisms of Nitride Optoelectronic Devices for Optical Communications. Ph.D. Thesis, Chinese Academy of Sciences, Beijing, China, 2020. [Google Scholar]

- Wang, Y. Degradation Mechanisms of the Nitride-Based Ultraviolet LEDs under Electrical, Thermal and Radiation Fields. Ph.D. Thesis, Xidian University, Xi’an, China, 2020. [Google Scholar]

- Dalapati, P.; Yamamoto, K.; Egawa, T.; Miyoshi, M. Current-Induced Degradation Process in (In)AlGaN-Based Deep-UV Light-Emitting Diode Fabricated on AlN/Sapphire Template. Opt. Mater. 2020, 109, 110352. [Google Scholar] [CrossRef]

- Wang, Y.-Z.; Zheng, X.-F.; Zhu, J.-D.; Xu, L.-L.; Xu, S.-R.; Liang, R.-L.; Dai, J.-N.; Li, P.-X.; Zhou, X.-W.; Mao, W.; et al. Degradation in AlGaN-Based UV-C LEDs under Constant Current Stress: A Study on Defect Behaviors. Appl. Phys. Lett. 2020, 116, 203501. [Google Scholar] [CrossRef]

- Su, M.; Zhu, X.; Guo, Q.; Chen, Z.; Deng, S.; Wang, Y.; Deng, J.; Sun, W. Characterization and simulation of 280 nm UV-LED degradation. AIP Adv. 2021, 11, 035315. [Google Scholar] [CrossRef]

- Ma, Z.; Cao, H.; Lin, S.; Li, X.; Zhao, L. Degradation and failure mechanism of AlGaN-based UVC-LEDs. Solid-State Electron. 2019, 156, 92–96. [Google Scholar] [CrossRef]

- Shen, C.-H.; Yang, R.-L.; Gong, H.-L.; Zhu, L.-H.; Gao, Y.-L.; Chen, G.-L.; Chen, Z.; Lu, Y.-J. Optical power degradation mechanisms in 271 nm AlGaN-based deep ultraviolet light-emitting diodes. Opt. Express 2023, 31, 20265–20273. [Google Scholar] [CrossRef] [PubMed]

- Fu, J.; Zhao, L.; Cao, H.; Sun, X.; Sun, B.; Wang, J.; Li, J. Degradation and Corresponding Failure Mechanism for GaN-Based LEDs. AIP Adv. 2016, 6, 055219. [Google Scholar] [CrossRef]

- Monti, D.; Meneghini, M.; De Santi, C.; Meneghesso, G.; Zanoni, E.; Glaab, J.; Rass, J.; Einfeldt, S.; Mehnke, F.; Enslin, J.; et al. Defect-Related Degradation of AlGaN-Based UV-B LEDs. IEEE Trans. Electron. Devices 2017, 64, 200–205. [Google Scholar] [CrossRef]

- Pinos, A.; Marcinkevičius, S.; Shur, M.S. High Current-Induced Degradation of AlGaN Ultraviolet Light Emitting Diodes. J. Appl. Phys. 2011, 109, 103108. [Google Scholar] [CrossRef]

- Moseley, M.W.; Allerman, A.A.; Crawford, M.H.; Wierer, J.J.; Smith, M.L.; Armstrong, A.M. Detection and Modeling of Leakage Current in AlGaN-Based Deep Ultraviolet Light-Emitting Diodes. J. Appl. Phys. 2015, 117, 095301. [Google Scholar] [CrossRef]

- Cao, X.; Sandvik, P.; LeBoeuf, S.; Arthur, S. Defect Generation in InGaN/GaN Light-Emitting Diodes under Forward and Reverse Electrical Stresses. Microelectron. Reliab. 2003, 43, 1987–1991. [Google Scholar] [CrossRef]

- Glaab, J.; Ploch, C.; Kelz, R.; Stölmacker, C.; Lapeyrade, M.; Ploch, N.L.; Rass, J.; Kolbe, T.; Einfeldt, S.; Mehnke, F.; et al. Temperature Induced Degradation of InAlGaN Multiple-Quantum Well UV-B LEDs. MRS Proc. 2015, 1792, mrss15-2102646. [Google Scholar] [CrossRef]

- Jung, E.; Lee, J.K.; Kim, M.S.; Kim, H. Leakage Current Analysis of GaN-Based Light-Emitting Diodes Using a Parasitic Diode Model. IEEE Trans. Electron. Devices 2015, 62, 3322–3325. [Google Scholar] [CrossRef]

- Ruschel, J.; Glaab, J.; Beidoun, B.; Ploch, N.L.; Rass, J.; Kolbe, T.; Knauer, A.; Weyers, M.; Einfeldt, S.; Kneissl, M. Current-Induced Degradation and Lifetime Prediction of 310 nm Ultraviolet Light-Emitting Diodes. Photon. Res. 2019, 7, B36–B40. [Google Scholar] [CrossRef]

- Masui, H. Diode ideality factor in modern light-emitting diodes. Semicond. Sci. Technol. 2011, 26, 075011. [Google Scholar] [CrossRef]

- Monti, D.; Meneghini, M.; De Santi, C.; Meneghesso, G.; Zanoni, E. Degradation of UV-A LEDs: Physical Origin and Dependence on Stress Conditions. IEEE Trans. Device Mater. Reliab. 2016, 16, 213–219. [Google Scholar] [CrossRef]

- Mandurrino, M.; Verzellesi, G.; Goano, M.; Vallone, M.; Bertazzi, F.; Ghione, G.; Meneghini, M.; Meneghesso, G.; Zanoni, E. Physics-based modeling and experimental implications of trap-assisted tunneling in InGaN/GaN light-emitting diodes. Phys. Status Solidi (A) Appl. Mater. Sci. 2015, 212, 947–953. [Google Scholar] [CrossRef]

- Liu, D. Research on Thermal Characteristies and Reliabilty of the Key Interface Structure of LED. Ph.D. Thesis, Jiangsu University, Zhenjiang, China, 2015. [Google Scholar]

- Liu, D.; Ru, Z.; Liu, F.; Zhang, C.; Huang, J. Research on test method of thermal resistance and junction temperature for LED modules. In Proceedings of the 2016 17th International Conference on Thermal, Mechanical and Multi-Physics Simulation and Experiments in Microelectronics and Microsystems (EuroSimE), Montpellier, France, 17–20 April 2016. [Google Scholar] [CrossRef]

| Aging Test | Aging Temperature (°C) | Aging Current (mA) | Cooling Method |

|---|---|---|---|

| Samples A | 85 | 0 | Natural cooling |

| Samples B | 25 | 80 | Air-cooling |

| Samples C | 25 | 80 | Natural cooling |

| Samples D | 85 | 80 | Natural cooling |

| Aging Test | Leakage Current at −2 V Bias (A) | Leakage Current at 2 V Bias (A) | ||

|---|---|---|---|---|

| 0 h | 1000 h | 0 h | 1000 h | |

| Sample A | −1.35 × 10−10 | −1.073 × 10−10 | 4.57 × 10−10 | 8.095 × 10−10 |

| Sample B | −9.095 × 10−11 | −4.638 × 10−10 | 6.585 × 10−10 | 6.712 × 10−10 |

| Sample C | −5.275 × 10−11 | −3.838 × 10−10 | 5.166 × 10−10 | 1.457 × 10−9 |

| Sample D | −4.183 × 10−11 | −7.452 × 10−9 | 3.693 × 10−10 | 5.939 × 10−8 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gong, M.; Sun, X.; Lei, C.; Liang, T.; Li, F.; Xie, Y.; Li, J.; Liu, N. Study on the Degradation Performance of AlGaN-Based Deep Ultraviolet LEDs under Thermal and Electrical Stress. Coatings 2024, 14, 904. https://doi.org/10.3390/coatings14070904

Gong M, Sun X, Lei C, Liang T, Li F, Xie Y, Li J, Liu N. Study on the Degradation Performance of AlGaN-Based Deep Ultraviolet LEDs under Thermal and Electrical Stress. Coatings. 2024; 14(7):904. https://doi.org/10.3390/coatings14070904

Chicago/Turabian StyleGong, Mingfeng, Xuejiao Sun, Cheng Lei, Ting Liang, Fengchao Li, Yu Xie, Jinmin Li, and Naixin Liu. 2024. "Study on the Degradation Performance of AlGaN-Based Deep Ultraviolet LEDs under Thermal and Electrical Stress" Coatings 14, no. 7: 904. https://doi.org/10.3390/coatings14070904