A Review on Transparent Electrodes for Flexible Organic Solar Cells

Abstract

1. Introduction

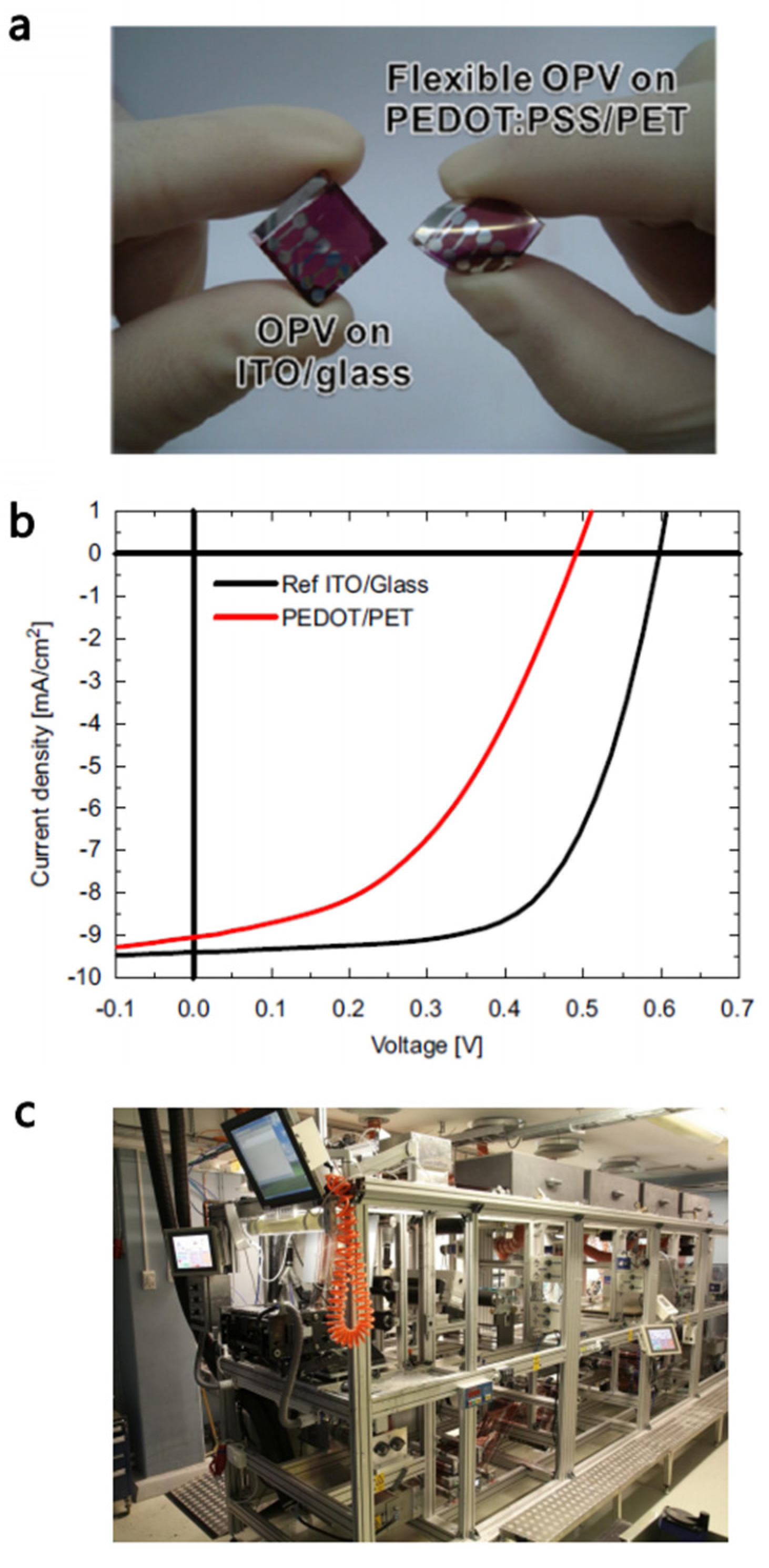

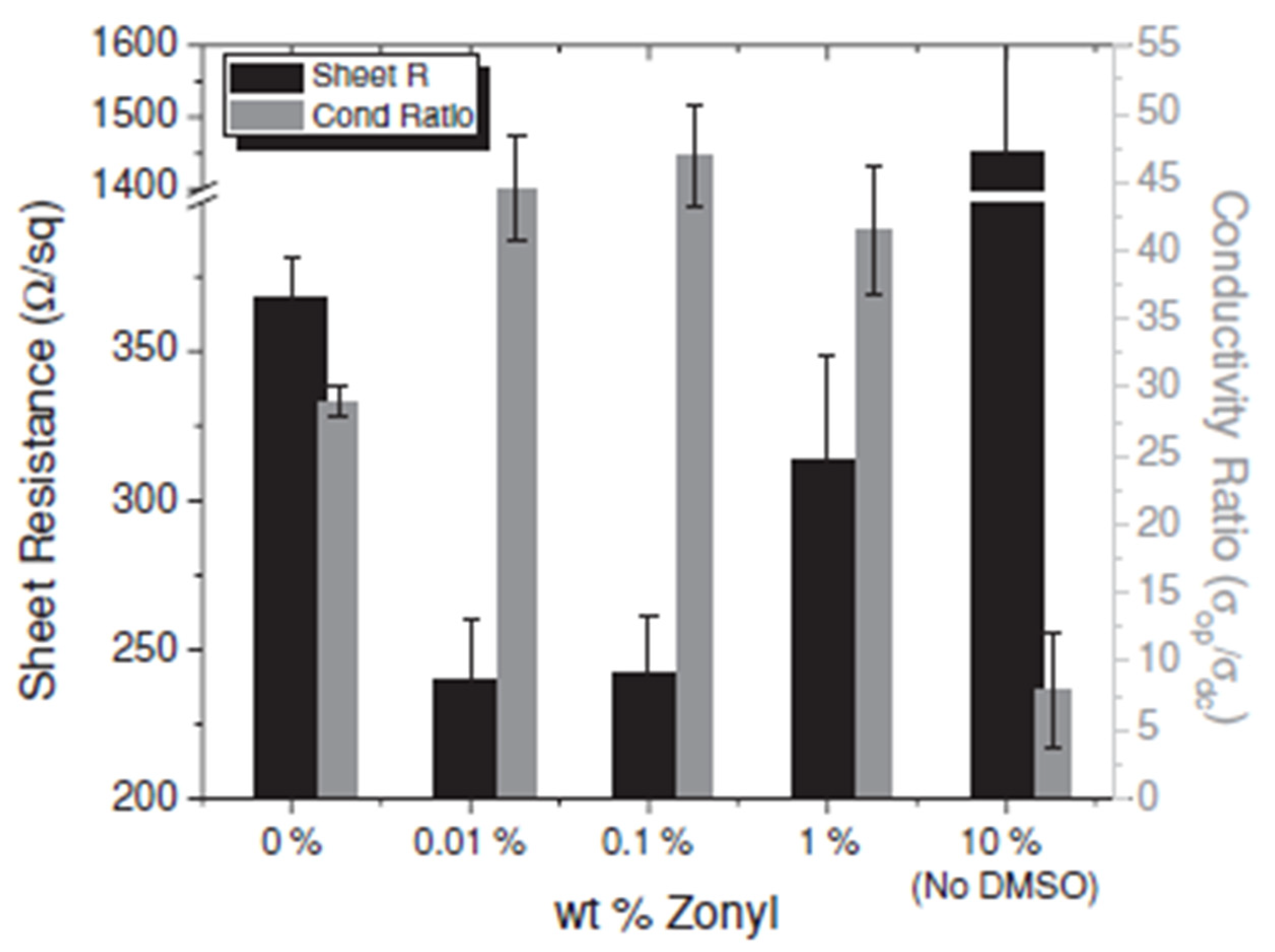

2. Conducting Polymer

3. Carbon Materials

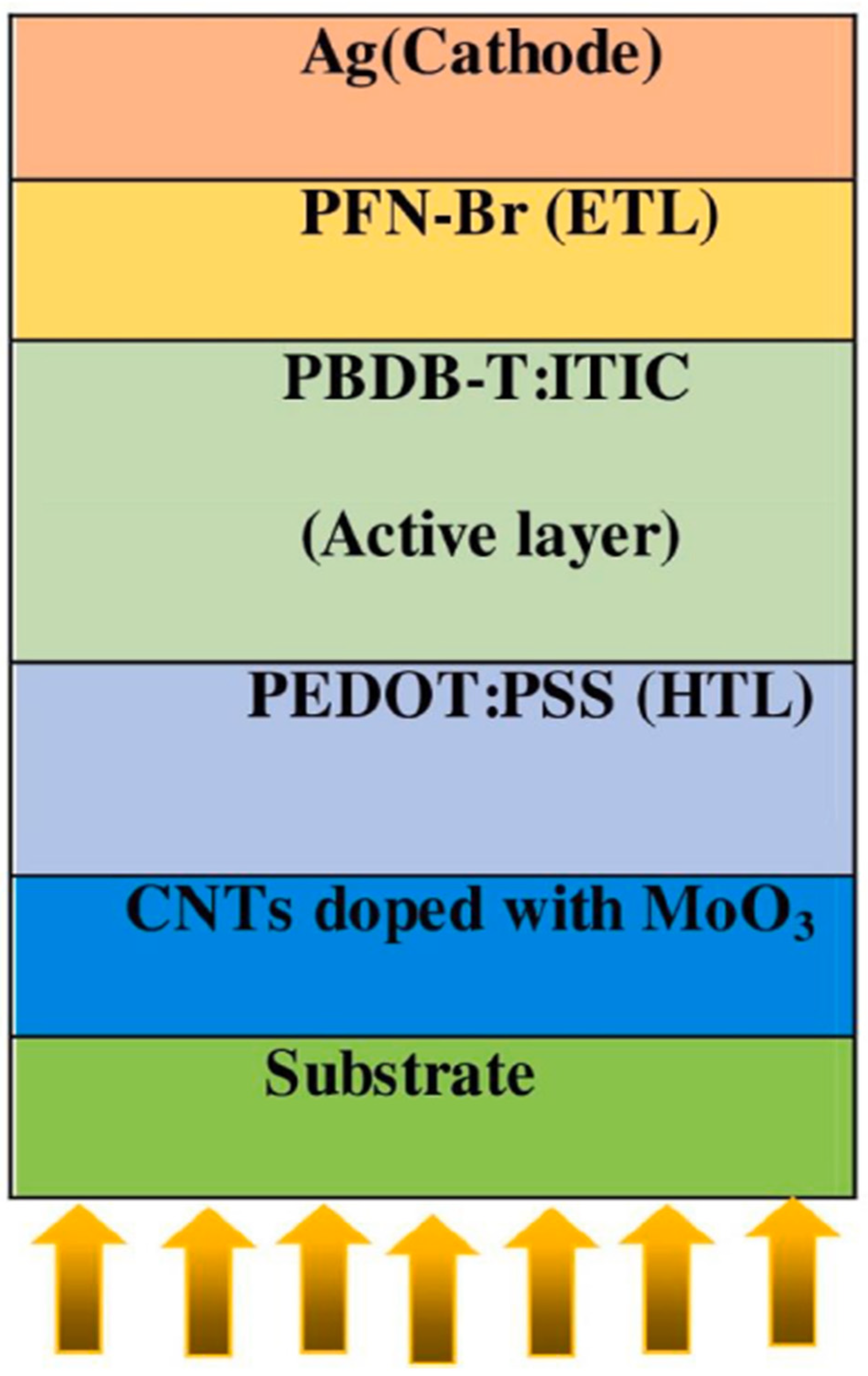

3.1. Carbon Nanotubes

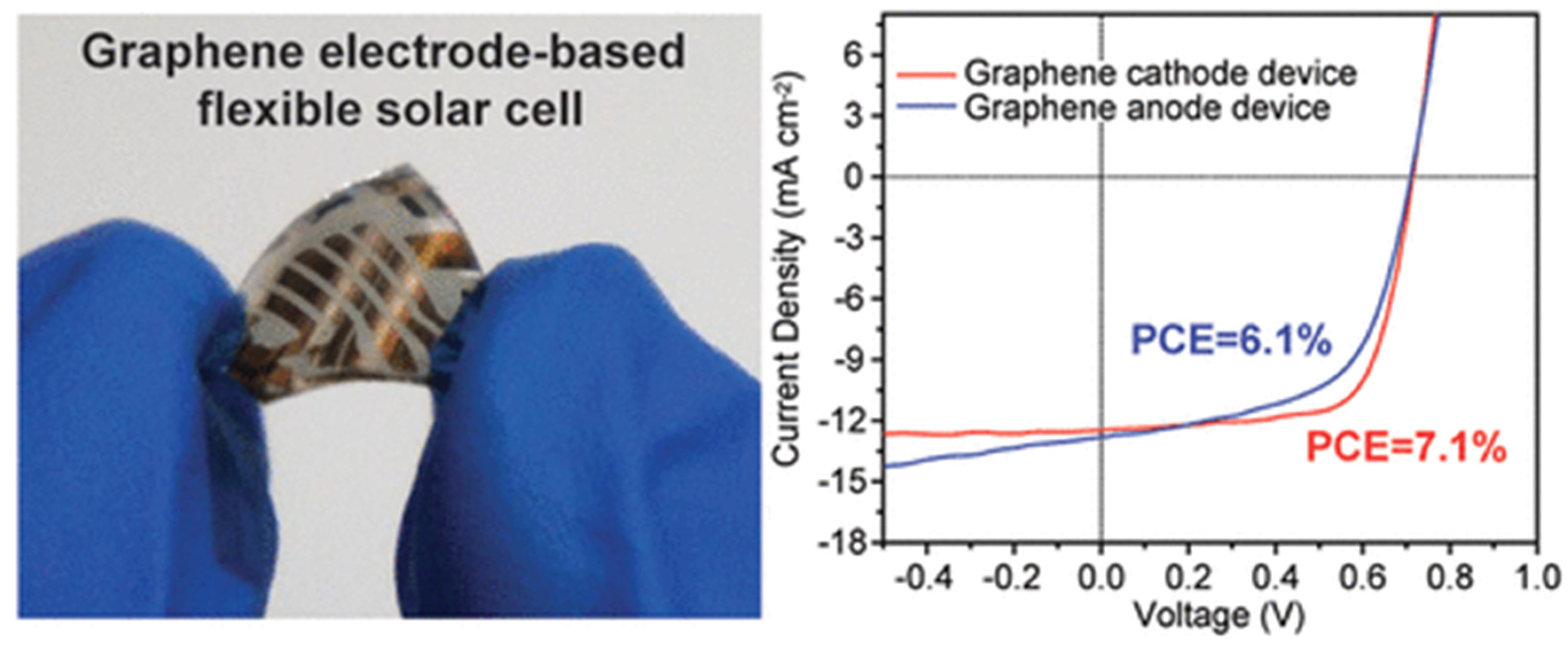

3.2. Graphene

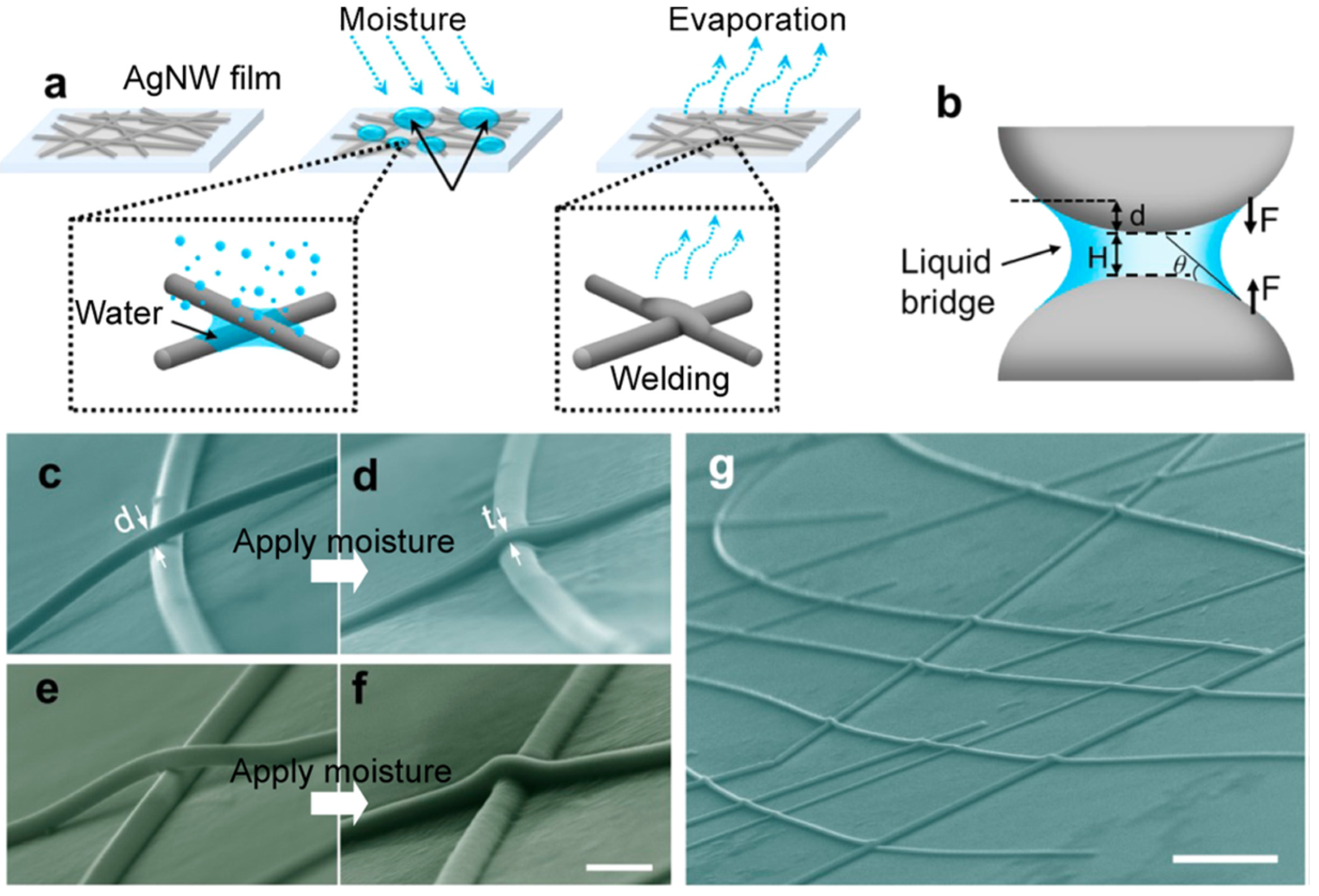

4. Metal Nanowires

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Lipomi, D.J.; Tee, B.C.; Vosgueritchian, M.; Bao, Z. Stretchable Organic Solar Cells. Adv. Mater. 2011, 23, 1771–1775. [Google Scholar] [CrossRef] [PubMed]

- Qin, J.; Lan, L.; Chen, S.; Huang, F.; Shi, H.; Chen, W.; Xia, H.; Sun, K.; Yang, C. Recent Progress in Flexible and Stretchable Organic Solar Cells. Adv. Funct. Mater. 2020, 30, 2002529. [Google Scholar] [CrossRef]

- Kaltenbrunner, M.; White, M.S.; Głowacki, E.D.; Sekitani, T.; Someya, T.; Sariciftci, N.S.; Bauer, S. Ultrathin and lightweight organic solar cells with high flexibility. Nat. Commun. 2012, 3, 770. [Google Scholar] [CrossRef] [PubMed]

- Fukuda, K.; Yu, K.; Someya, T. The Future of Flexible Organic Solar Cells. Adv. Energy Mater. 2020, 10, 2000765. [Google Scholar] [CrossRef]

- Ellmer, K. Past achievements and future challenges in the development of optically transparent electrodes. Nat. Photon. 2012, 6, 809–817. [Google Scholar] [CrossRef]

- Haris, M.; Ullah, Z.; Lee, S.; Ryu, D.H.; Ryu, S.U.; Kang, B.J.; Jeon, N.J.; Kim, B.J.; Park, T.; Shin, W.S.; et al. Amplifying High-Performance Organic Solar Cells Through Differencing Interactions of Solid Additive with Donor/Acceptor Materials Processed from Non-Halogenated Solvent. Adv. Energy Mater. 2024. Early View. [Google Scholar] [CrossRef]

- Dhal, B.C.; Hajra, S.; Priyadarshini, A.; Panda, S.; Vivekananthan, V.; Swain, J.; Swain, S.; Das, N.; Samantray, R.; Kim, H.J.; et al. Innovative Synthesis of Zeolitic Imidazolate Framework by a Stovetop Kitchen Pressure Cook Pot for Triboelectric Nanogenerator. Energy Technol. 2024, 12, 2400099. [Google Scholar] [CrossRef]

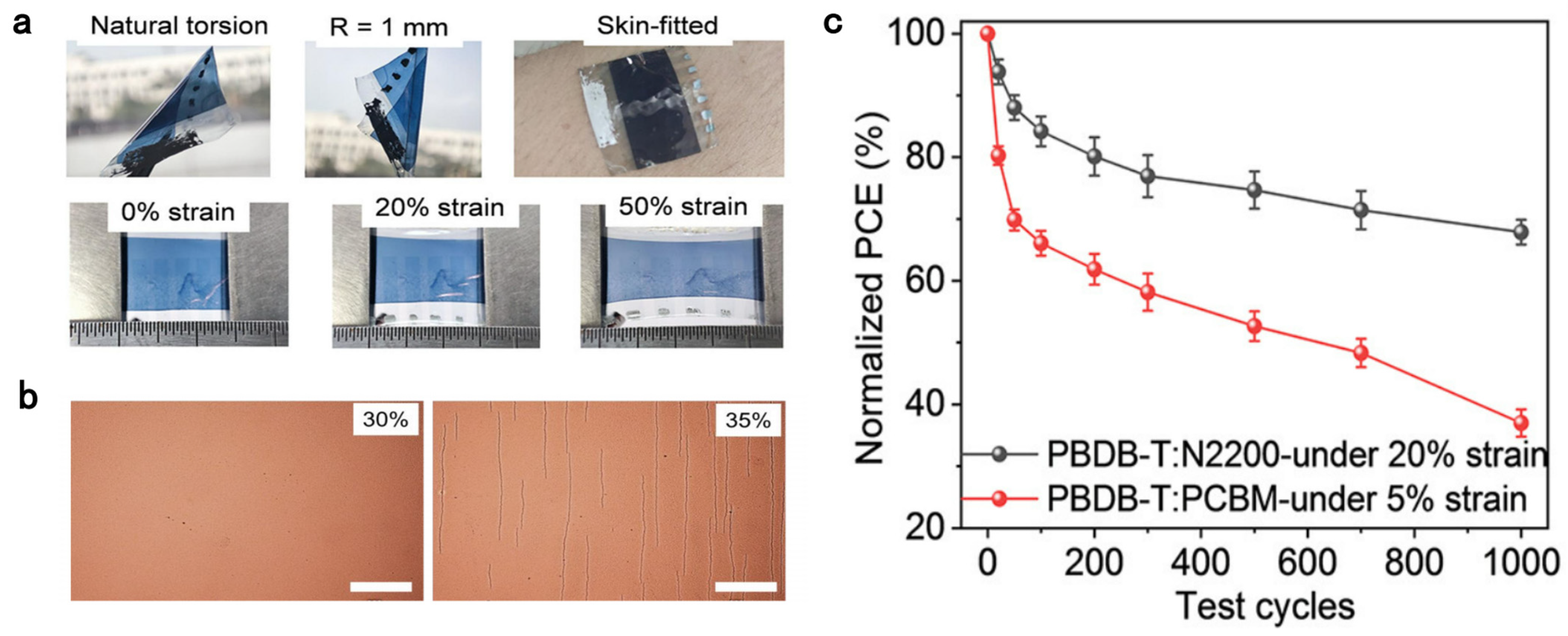

- Wang, Z.; Zhang, D.; Xu, M.; Liu, J.; He, J.; Yang, L.; Li, Z.; Gao, Y.; Chen, Y.; Gong, H.; et al. Revealing the Strain-Induced Morphological, Mechanical, and Photovoltaic Evolution of Self-Encapsulated and Semitransparent Intrinsically Stretchable Organic Solar Cells. ACS Mater. Lett. 2024, 6, 1811–1819. [Google Scholar] [CrossRef]

- Haris, M.; Ryu, D.H.; Ullah, Z.; Kang, B.J.; Jeon, N.J.; Lee, S.; Lee, H.K.; Lee, S.K.; Lee, J.C.; Kwon, H.W.; et al. Morphological modulation enabled by non-halogenated solvent-processed simple solid additives for high-efficiency organic solar cells. EcoMat 2024, 6, e12436. [Google Scholar] [CrossRef]

- Bayoumy, A.M.; Hessein, A.; Belal, M.A.; Ezzat, M.; Ibrahim, M.A.; Osman, A.; El-Moneim, A.A. Microdrop InkJet printed supercapacitors of graphene/graphene oxide ink for flexible electronics. J. Power Sources 2024, 617, 235145. [Google Scholar] [CrossRef]

- Arshad, F.; Haris, M.; Oh, E.S.; Ullah, Z.; Ryu, D.H.; Lee, S.; Lee, H.K.; Lee, S.K.; Kim, T.; Kwon, H.; et al. Hydrogen-Bonding Interactions Between Terpolymers Enable Excellent Device Efficiency and Operational Stability of Non-Halogenated Solvent-Processed Polymer Solar Cells. Adv. Funct. Mater. 2024. Early View. [Google Scholar] [CrossRef]

- Cao, W.; Li, J.; Chen, H.; Xue, J. Transparent electrodes for organic optoelectronic devices: A review. J. Photon. Energy 2014, 4, 040990. [Google Scholar] [CrossRef]

- Choi, K.-H.; Jeong, J.-A.; Kang, J.-W.; Kim, D.-G.; Kim, J.K.; Na, S.-I.; Kim, D.-Y.; Kim, S.-S.; Kim, H.-K. Characteristics of flexible indium tin oxide electrode grown by continuous roll-to-roll sputtering process for flexible organic solar cells. Sol. Energy Mater. Sol. Cells 2009, 93, 1248–1255. [Google Scholar] [CrossRef]

- Lin, H.; Hsu, W. Electrode patterning of ITO thin films by high repetition rate fiber laser. Appl. Surf. Sci. 2014, 308, 58–62. [Google Scholar] [CrossRef]

- Sibin, K.; Swain, N.; Chowdhury, P.; Dey, A.; Sridhara, N.; Shashikala, H.; Sharma, A.K.; Barshilia, H.C. Optical and electrical properties of ITO thin films sputtered on flexible FEP substrate as passive thermal control system for space applications. Sol. Energy Mater. Sol. Cells 2016, 145, 314–322. [Google Scholar] [CrossRef]

- Sakamoto, K.; Kuwae, H.; Kobayashi, N.; Nobori, A.; Shoji, S.; Mizuno, J. Highly flexible transparent electrodes based on mesh-patterned rigid indium tin oxide. Sci. Rep. 2018, 8, 2825. [Google Scholar] [CrossRef] [PubMed]

- Bender, M.; Seelig, W.; Daube, C.; Frankenberger, H.; Ocker, B.; Stollenwerk, J. Dependence of film composition and thicknesses on optical and electrical properties of ITO–metal–ITO multilayers. Thin Solid Films 1998, 326, 67–71. [Google Scholar] [CrossRef]

- Lewis, J.; Grego, S.; Chalamala, B.; Vick, E.; Temple, D. Highly flexible transparent electrodes for organic light-emitting diode-based displays. Appl. Phys. Lett. 2004, 85, 3450–3452. [Google Scholar] [CrossRef]

- Huang, W.; Jiang, Z.; Fukuda, K.; Jiao, X.; McNeill, C.R.; Yokota, T.; Someya, T. Efficient and Mechanically Robust Ultraflexible Organic Solar Cells Based on Mixed Acceptors. Joule 2019, 4, 128–141. [Google Scholar] [CrossRef]

- Wan, J.; Fan, X.; Li, Y.; Li, P.; Zhang, T.; Hui, K.N.; Huang, H.; Kang, K.; Qian, L. High-Efficiency Flexible Organic Photovoltaics and Thermoelectricities Based on Thionyl Chloride Treated PEDOT:PSS Electrodes. Front. Chem. 2021, 9, 807538. [Google Scholar] [CrossRef]

- Koo, D.; Jung, S.; Seo, J.; Jeong, G.; Choi, Y.; Lee, J.; Lee, S.M.; Cho, Y.; Jeong, M.; Lee, J.; et al. Flexible Organic Solar Cells Over 15% Efficiency with Polyimide-Integrated Graphene Electrodes. Joule 2020, 4, 1021–1034. [Google Scholar] [CrossRef]

- Chen, X.; Xu, G.; Zeng, G.; Gu, H.; Chen, H.; Xu, H.; Yao, H.; Li, Y.; Hou, J.; Li, Y. Realizing Ultrahigh Mechanical Flexibility and >15% Efficiency of Flexible Organic Solar Cells via a “Welding” Flexible Transparent Electrode. Adv. Mater. 2020, 32, e1908478. [Google Scholar] [CrossRef]

- Sharma, B.; Mathur, A.; Singh, I.K.; Singh, B. Performance optimization of non-fullerene acceptor organic solar cell by incorporating carbon nanotubes as flexible transparent electrode. Results Opt. 2022, 9, 100315. [Google Scholar] [CrossRef]

- Krantz, J.; Richter, M.; Spallek, S.; Spiecker, E.; Brabec, C.J. Solution-Processed Metallic Nanowire Electrodes as Indium Tin Oxide Replacement for Thin-Film Solar Cells. Adv. Funct. Mater. 2011, 21, 4784–4787. [Google Scholar] [CrossRef]

- Hecht, D.S.; Hu, L.; Irvin, G. Emerging Transparent Electrodes Based on Thin Films of Carbon Nanotubes, Graphene, and Metallic Nanostructures. Adv. Mater. 2011, 23, 1482–1513. [Google Scholar] [CrossRef] [PubMed]

- Sandström, A.; Dam, H.F.; Krebs, F.C.; Edman, L. Ambient fabrication of flexible and large-area organic light-emitting devices using slot-die coating. Nat. Commun. 2012, 3, 1002. [Google Scholar] [CrossRef]

- Liu, C.; Xiao, C.; Xie, C.; Li, W. Flexible organic solar cells: Materials, large-area fabrication techniques and potential applications. Nano Energy 2021, 89, 106399. [Google Scholar] [CrossRef]

- Gao, W.; Ota, H.; Kiriya, D.; Takei, K.; Javey, A. Flexible Electronics toward Wearable Sensing. Accounts Chem. Res. 2019, 52, 523–533. [Google Scholar] [CrossRef]

- Li, X.; Li, P.; Wu, Z.; Luo, D.; Yu, H.-Y.; Lu, Z.-H. Review and perspective of materials for flexible solar cells. Mater. Rep. Energy 2021, 1, 100001. [Google Scholar] [CrossRef]

- Lipomi, D.J.; Vosgueritchian, M.; Tee, B.C.K.; Hellstrom, S.L.; Lee, J.A.; Fox, C.H.; Bao, Z. Skin-like pressure and strain sensors based on transparent elastic films of carbon nanotubes. Nat. Nanotechnol. 2011, 6, 788–792. [Google Scholar] [CrossRef]

- Kim, Y.H.; Sachse, C.; Machala, M.L.; May, C.; Müller-Meskamp, L.; Leo, K. Highly Conductive PEDOT:PSS Electrode with Optimized Solvent and Thermal Post-Treatment for ITO-Free Organic Solar Cells. Adv. Funct. Mater. 2011, 21, 1076–1081. [Google Scholar] [CrossRef]

- Hsiao, Y.-S.; Chen, C.-P.; Chao, C.-H.; Whang, W.-T. All-solution-processed inverted polymer solar cells on granular surface-nickelized polyimide. Org. Electron. 2009, 10, 551–561. [Google Scholar] [CrossRef]

- Peng, B.; Guo, X.; Cui, C.; Zou, Y.; Pan, C.; Li, Y. Performance improvement of polymer solar cells by using a solvent-treated poly(3,4-ethylenedioxythiophene):poly(styrenesulfonate) buffer layer. Appl. Phys. Lett. 2011, 98, 243308. [Google Scholar] [CrossRef]

- Kayser, L.V.; Lipomi, D.J. Stretchable Conductive Polymers and Composites Based on PEDOT and PEDOT:PSS. Adv. Mater. 2019, 31, e1806133. [Google Scholar] [CrossRef] [PubMed]

- Zhang, W.; Zhao, B.; He, Z.; Zhao, X.; Wang, H.; Yang, S.; Wu, H.; Cao, Y. High-efficiency ITO-free polymer solar cells using highly conductive PEDOT:PSS/surfactant bilayer transparent anodes. Energy Environ. Sci. 2013, 6, 1956–1964. [Google Scholar] [CrossRef]

- Hau, S.K.; Yip, H.-L.; Zou, J.; Jen, A.K.-Y. Indium tin oxide-free semi-transparent inverted polymer solar cells using conducting polymer as both bottom and top electrodes. Org. Electron. 2009, 10, 1401–1407. [Google Scholar] [CrossRef]

- Zhang, F.; Johansson, M.; Andersson, M.R.; Hummelen, J.C.; Inganäs, O. Polymer Photovoltaic Cells with Conducting Polymer Anodes. Adv. Mater. 2002, 14, 662–665. [Google Scholar] [CrossRef]

- Kim, Y.Y.; Yang, T.Y.; Suhonen, R.; Valimaki, M.; Maaninen, T.; Kemppainen, A.; Jeon, N.J.; Seo, J. Gravure-Printed Flexible Perovskite Solar Cells: Toward Roll-to-Roll Manufacturing. Adv. Sci. 2019, 6, 1802094. [Google Scholar] [CrossRef] [PubMed]

- Cho, C.K.; Hwang, W.J.; Eun, K.; Choa, S.H.; Na, S.I.; Kim, H.K. Mechanical flexibility of transparent PEDOT:PSS electrodes prepared by gravure printing for flexible organic solar cells. Sol. Energy Mater. Sol. Cells 2011, 95, 3269–3275. [Google Scholar] [CrossRef]

- Na, S.; Kim, S.; Jo, J.; Kim, D. Efficient and Flexible ITO-Free Organic Solar Cells Using Highly Conductive Polymer Anodes. Adv. Mater. 2008, 20, 4061–4067. [Google Scholar] [CrossRef]

- Vosgueritchian, M.; Lipomi, D.J.; Bao, Z. Highly Conductive and Transparent PEDOT:PSS Films with a Fluorosurfactant for Stretchable and Flexible Transparent Electrodes. Adv. Funct. Mater. 2011, 22, 421–428. [Google Scholar] [CrossRef]

- Lupu, D.; Grüneis, A.; Ayala, P.; Rümmeli, M.H.; Pichler, T.; Li, Z.; Xu, Y.; Misan, I.; Dervishi, E.; Biris, A.S. High-Quality Double-Walled Carbon Nanotubes Grown by a Cold-Walled Radio Frequency Chemical Vapor Deposition Process. Chem. Mater. 2008, 20, 3466–3472. [Google Scholar] [CrossRef]

- Baughman, R.H.; Zakhidov, A.A.; de Heer, W.A. Carbon nanotubes—The route toward applications. Science 2002, 297, 787–792. [Google Scholar] [CrossRef] [PubMed]

- Fu, X.; Xu, L.; Li, J.; Sun, X.; Peng, H. Flexible solar cells based on carbon nanomaterials. Carbon 2018, 139, 1063–1073. [Google Scholar] [CrossRef]

- Zhang, Z.; Wei, L.; Qin, X.; Li, Y. Carbon nanomaterials for photovoltaic process. Nano Energy 2015, 15, 490–522. [Google Scholar] [CrossRef]

- De Arco, L.G.; Zhang, Y.; Schlenker, C.W.; Ryu, K.; Thompson, M.E.; Zhou, C. Continuous, Highly Flexible, and Transparent Graphene Films by Chemical Vapor Deposition for Organic Photovoltaics. ACS Nano 2015, 4, 2865–2873. [Google Scholar] [CrossRef] [PubMed]

- Eda, G.; Fanchini, G.; Chhowalla, M. Large-area ultrathin films of reduced graphene oxide as a transparent and flexible electronic material. Nat. Nanotechnol. 2008, 3, 270–274. [Google Scholar] [CrossRef] [PubMed]

- Shin, D.H.; Seo, S.W.; Kim, J.M.; Lee, H.S.; Choi, S.-H. Graphene transparent conductive electrodes doped with graphene quantum dots-mixed silver nanowires for highly-flexible organic solar cells. J. Alloys Compd. 2018, 744, 1–6. [Google Scholar] [CrossRef]

- Bae, S.; Kim, H.; Lee, Y.; Xu, X.; Park, J.-S.; Zheng, Y.; Balakrishnan, J.; Lei, T.; Kim, H.R.; Song, Y.I.; et al. Roll-to-roll production of 30-inch graphene films for transparent electrodes. Nat. Nanotechnol. 2010, 5, 574–578. [Google Scholar] [CrossRef]

- Kwon, S.-J.; Han, T.-H.; Ko, T.Y.; Li, N.; Kim, Y.; Kim, D.J.; Bae, S.-H.; Yang, Y.; Hong, B.H.; Kim, K.S.; et al. Extremely stable graphene electrodes doped with macromolecular acid. Nat. Commun. 2018, 9, 1–9. [Google Scholar] [CrossRef]

- Song, Y.; Chang, S.; Gradecak, S.; Kong, J. Visibly-Transparent Organic Solar Cells on Flexible Substrates with All-Graphene Electrodes. Adv. Energy Mater. 2016, 6, 1600847. [Google Scholar] [CrossRef]

- Park, H.; Chang, S.; Zhou, X.; Kong, J.; Palacios, T.; Gradečak, S. Flexible Graphene Electrode-Based Organic Photovoltaics with Record-High Efficiency. Nano Lett. 2014, 14, 5148–5154. [Google Scholar] [CrossRef] [PubMed]

- Rathmell, A.R.; Wiley, B.J. The Synthesis and Coating of Long, Thin Copper Nanowires to Make Flexible, Transparent Conducting Films on Plastic Substrates. Adv. Mater. 2011, 23, 4798–4803. [Google Scholar] [CrossRef]

- Sánchez-Iglesias, A.; Rivas-Murias, B.; Grzelczak, M.; Pérez-Juste, J.; Liz-Marzán, L.M.; Rivadulla, F.; Correa-Duarte, M.A. Highly Transparent and Conductive Films of Densely Aligned Ultrathin Au Nanowire Monolayers. Nano Lett. 2012, 12, 6066–6070. [Google Scholar] [CrossRef] [PubMed]

- Sannicolo, T.; Lagrange, M.; Cabos, A.; Celle, C.; Simonato, J.; Bellet, D. Metallic Nanowire-Based Transparent Electrodes for Next Generation Flexible Devices: A Review. Small 2016, 12, 6052–6075. [Google Scholar] [CrossRef]

- Zhang, D.; Wang, R.; Wen, M.; Weng, D.; Cui, X.; Sun, J.; Li, H.; Lu, Y. Synthesis of Ultralong Copper Nanowires for High-Performance Transparent Electrodes. J. Am. Chem. Soc. 2012, 134, 14283–14286. [Google Scholar] [CrossRef]

- Tokuno, T.; Nogi, M.; Karakawa, M.; Jiu, J.; Nge, T.T.; Aso, Y.; Suganuma, K. Fabrication of silver nanowire transparent electrodes at room temperature. Nano Res. 2011, 4, 1215–1222. [Google Scholar] [CrossRef]

- Sun, Y.; Chang, M.; Meng, L.; Wan, X.; Gao, H.; Zhang, Y.; Zhao, K.; Sun, Z.; Li, C.; Liu, S.; et al. Flexible organic photovoltaics based on water-processed silver nanowire electrodes. Nat. Electron. 2019, 2, 513–520. [Google Scholar] [CrossRef]

- Liu, Y.; Zhang, J.; Gao, H.; Wang, Y.; Liu, Q.; Huang, S.; Guo, C.F.; Ren, Z. Capillary-Force-Induced Cold Welding in Silver-Nanowire-Based Flexible Transparent Electrodes. Nano Lett. 2017, 17, 1090–1096. [Google Scholar] [CrossRef]

- Yin, Z.; Chen, S.; Guan, Y.; Ran, Q.; Zhang, Q.; Yan, X.; Jin, R.; Yu, H.; Li, L.; Yu, J. Copper Nanowire Dispersion through an Electrostatic Dispersion Mechanism for High-Performance Flexible Transparent Conducting Films and Optoelectronic Devices. ACS Appl. Mater. Interfaces 2019, 11, 5264–5275. [Google Scholar] [CrossRef]

| Electrode | Active Layer | PCE | Year |

|---|---|---|---|

| ITO | P3HT:PCBM | 3.3% | 2008 |

| ITO | PTB7-TH:IEIC | 2.26% | 2016 |

| Su-8/ITO | PBDTTT-OFT:IEICO-4F:PC71BM | 13% | 2020 |

| PEDOT:PSS | P3HT:PCBM | 2.8% | 2008 |

| SOCl2-treated PEDOT:PSS | PM6:Y6 | 13.69% | 2022 |

| ITO and graphene | PM6:Y6 | 15.2% | 2020 |

| CNTs(MoO3) | PBDB-T:ITIC | 27.57% | 2022 |

| AgNWs(Al/AZO) | PBDB-T-2F:Y6 | 15.21% | 2020 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, Y.; Sha, M.; Huang, S. A Review on Transparent Electrodes for Flexible Organic Solar Cells. Coatings 2024, 14, 1031. https://doi.org/10.3390/coatings14081031

Li Y, Sha M, Huang S. A Review on Transparent Electrodes for Flexible Organic Solar Cells. Coatings. 2024; 14(8):1031. https://doi.org/10.3390/coatings14081031

Chicago/Turabian StyleLi, Yiyun, Mengzhen Sha, and Shufen Huang. 2024. "A Review on Transparent Electrodes for Flexible Organic Solar Cells" Coatings 14, no. 8: 1031. https://doi.org/10.3390/coatings14081031

APA StyleLi, Y., Sha, M., & Huang, S. (2024). A Review on Transparent Electrodes for Flexible Organic Solar Cells. Coatings, 14(8), 1031. https://doi.org/10.3390/coatings14081031