Correlation between Surface Texture, Wettability and Mechanical Strength of Polylactic Acid Parts Fabricated by Fused Filament Fabrication

Abstract

:1. Introduction

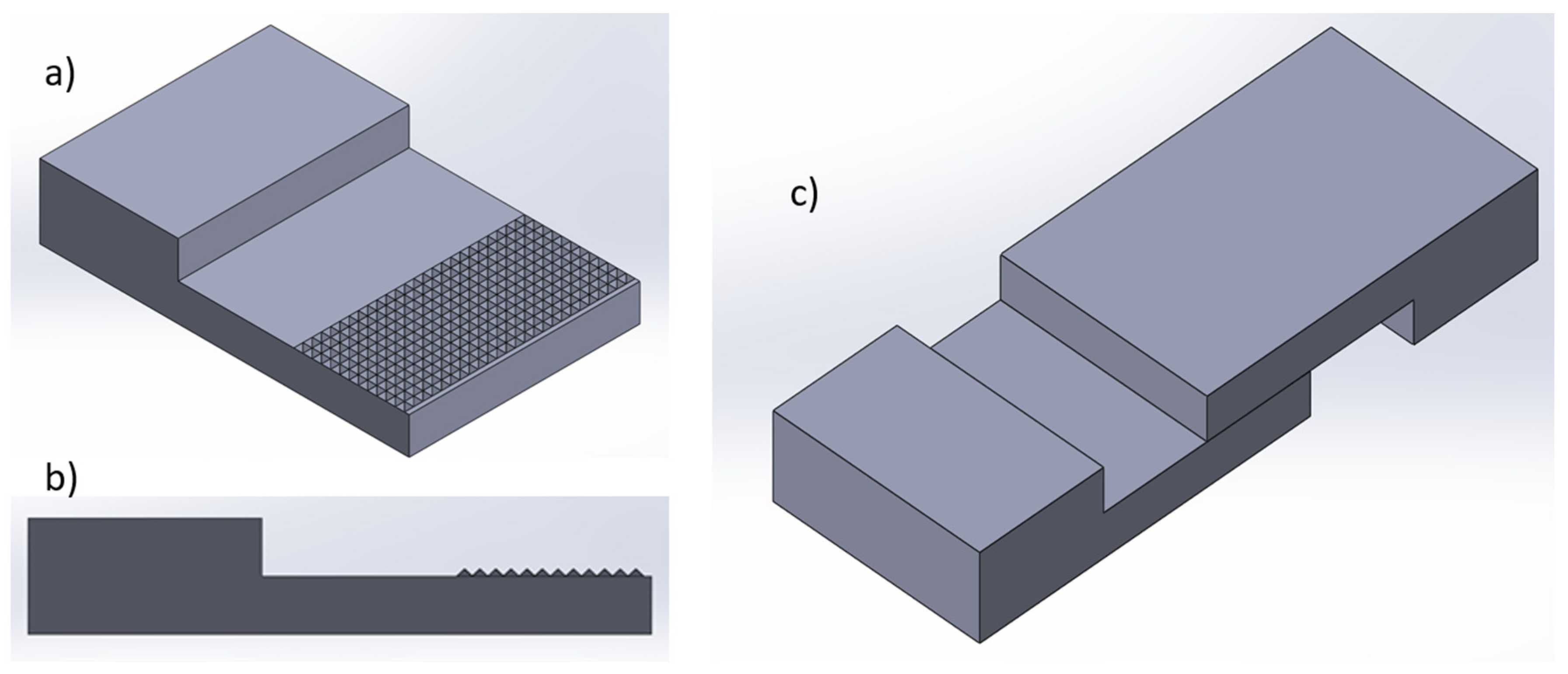

2. Materials and Methods

3. Results

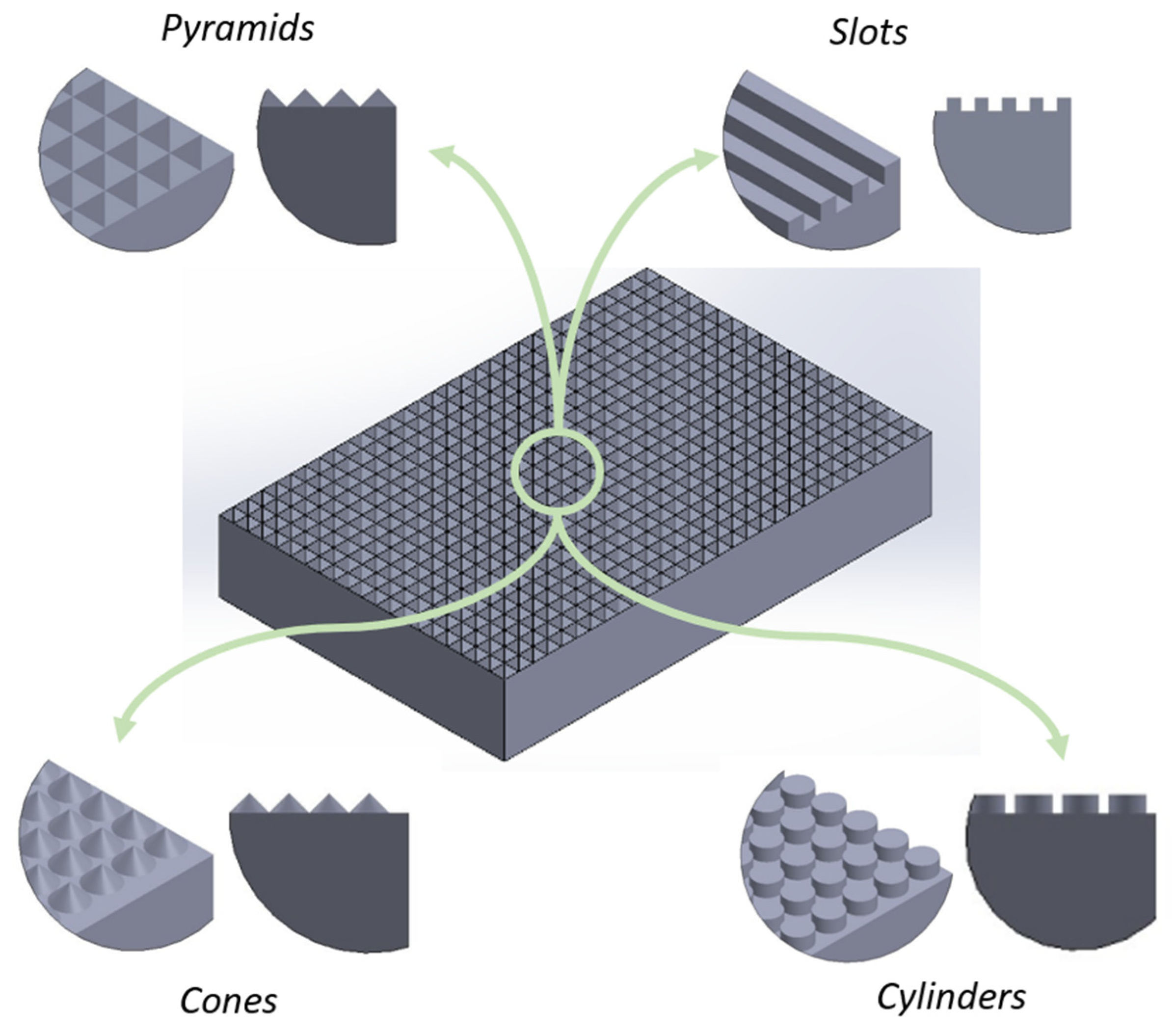

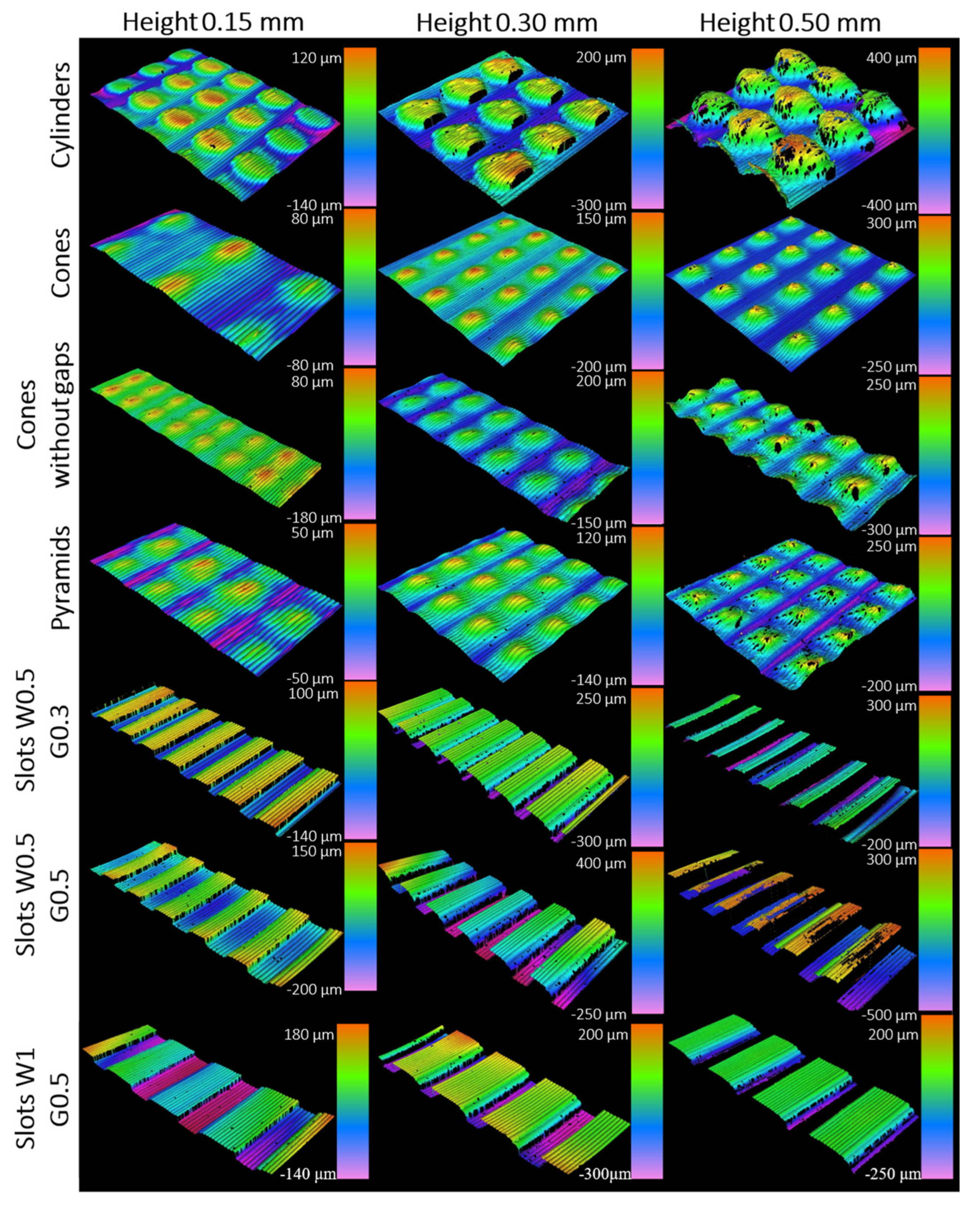

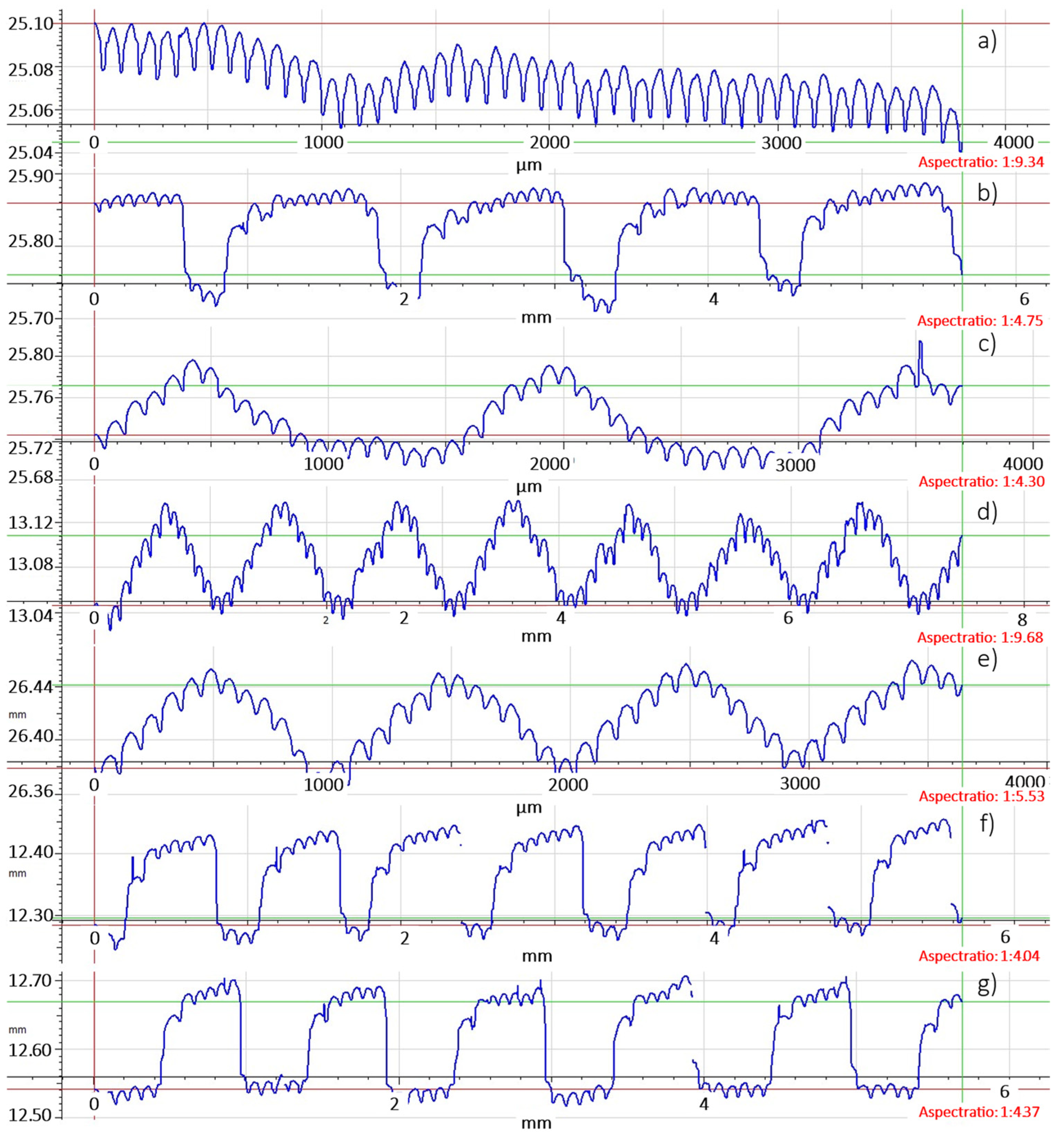

3.1. Geometric Texture Results

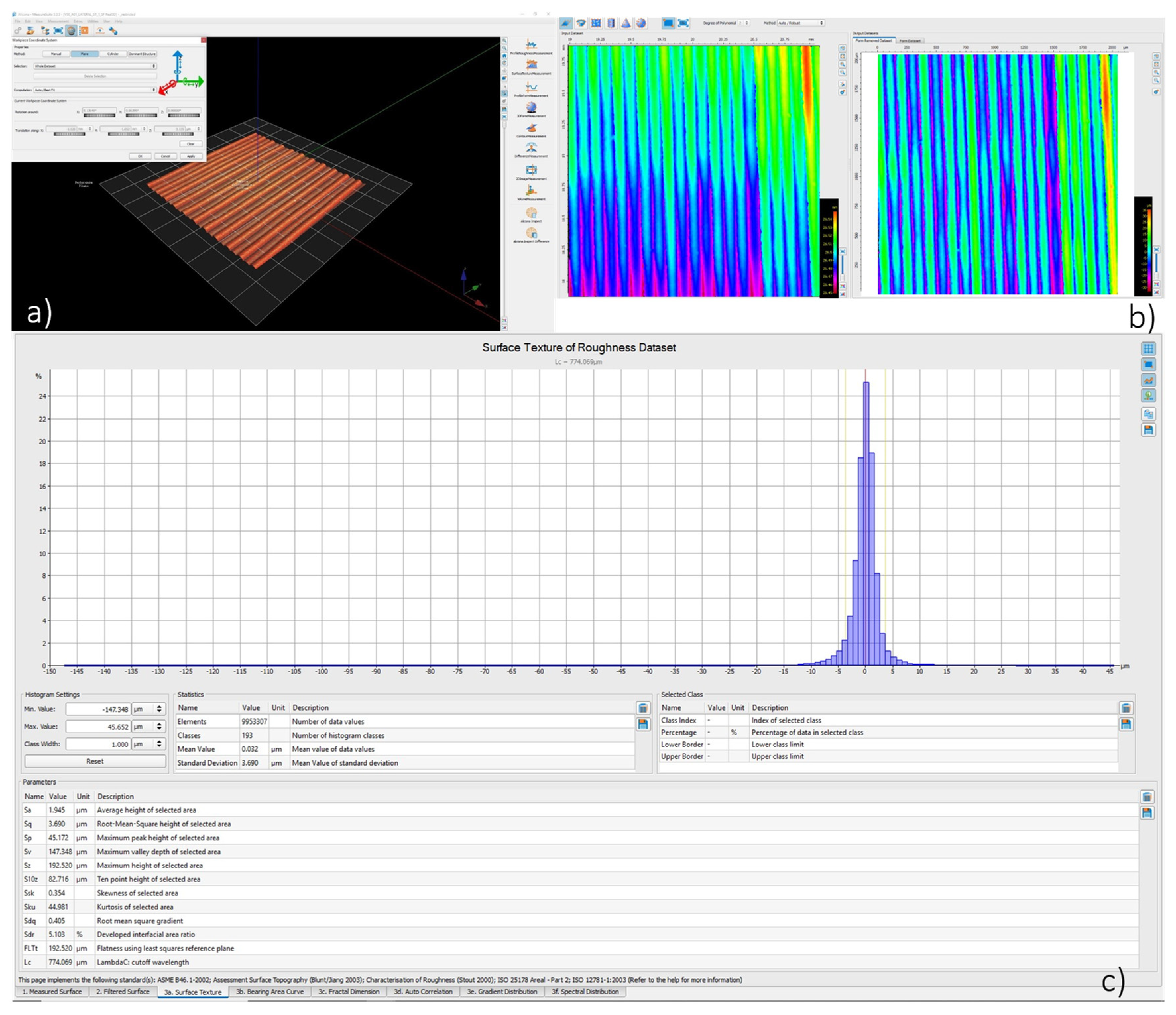

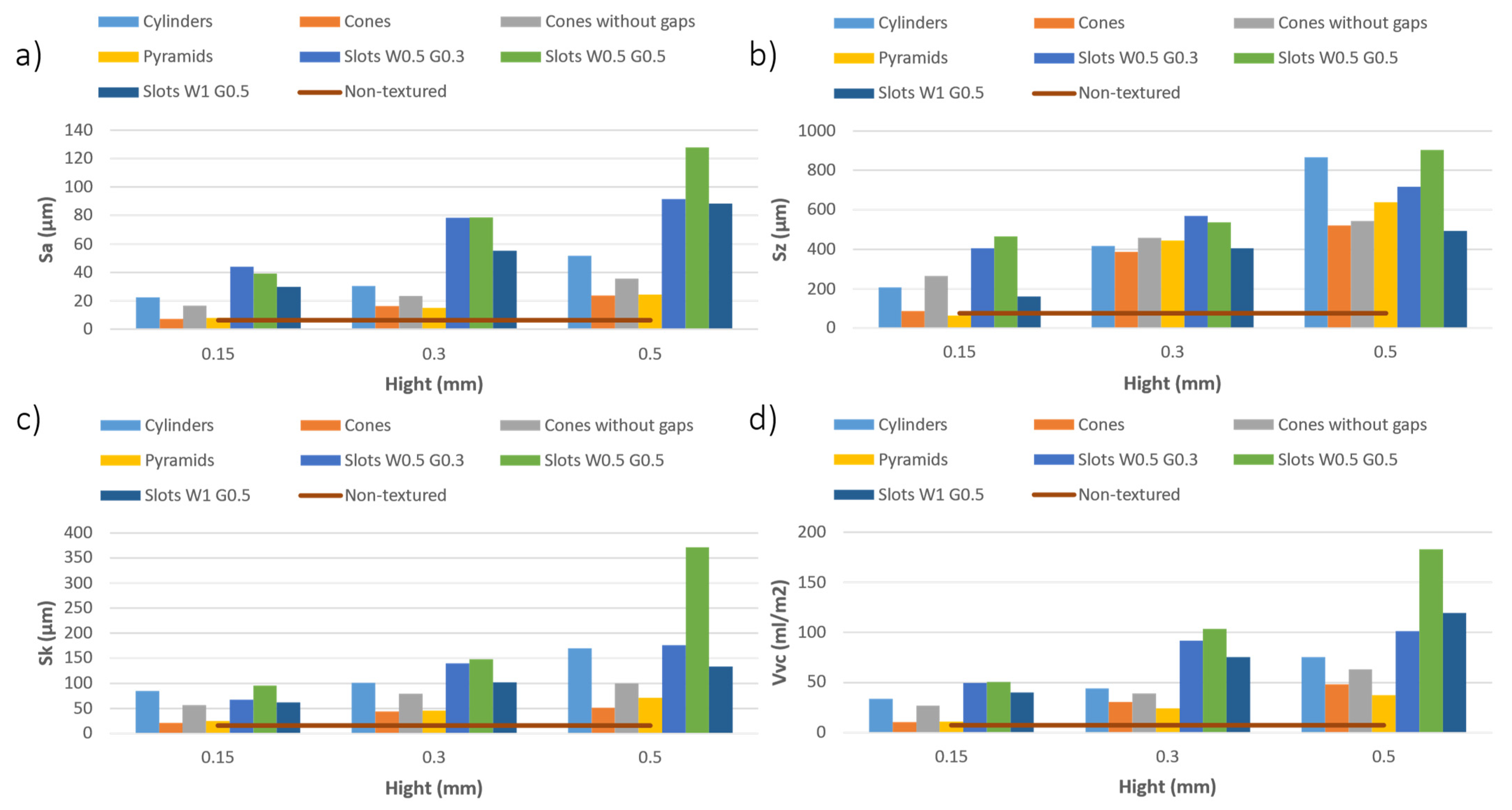

3.2. Surface Quality

3.3. Wettability Results

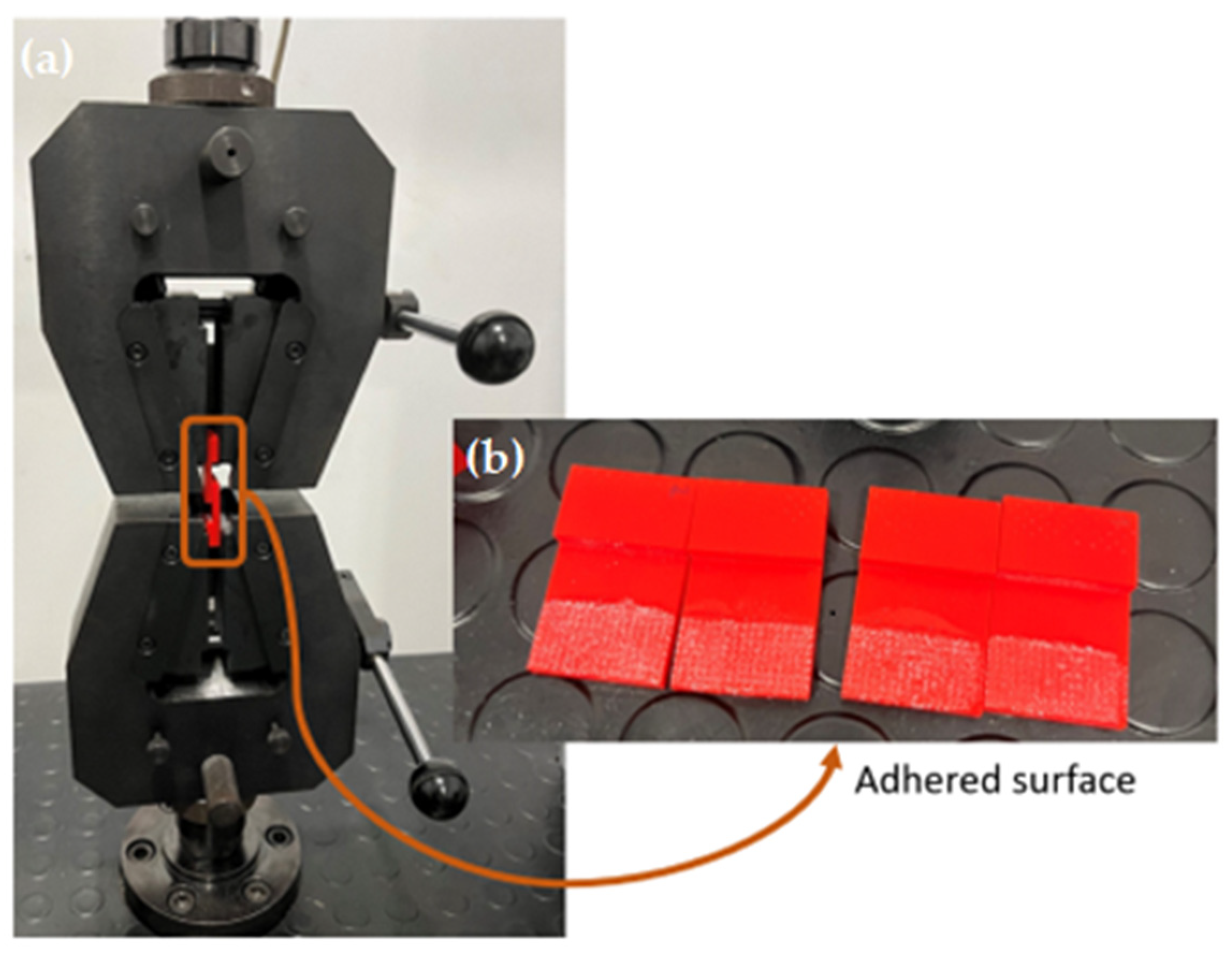

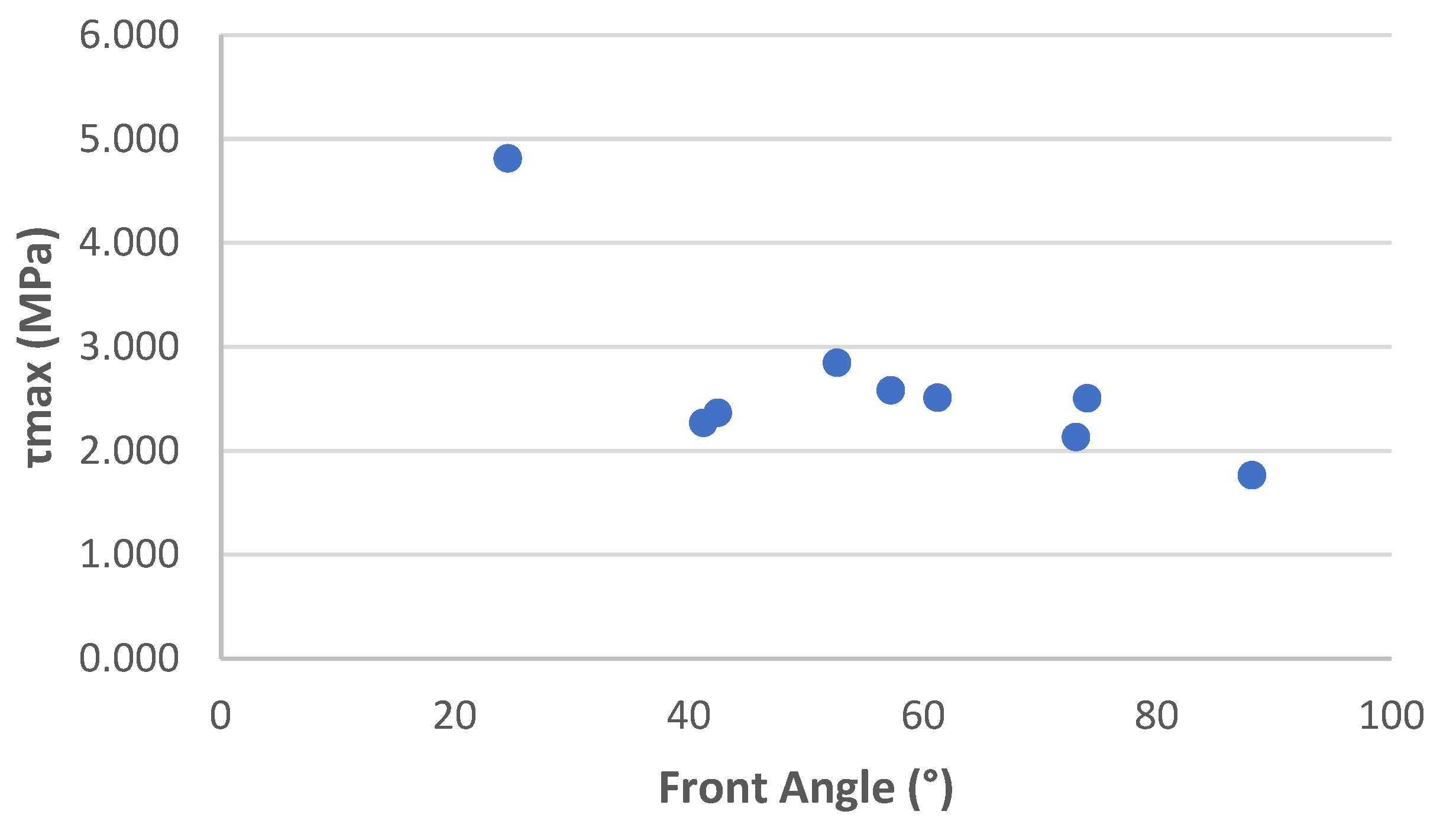

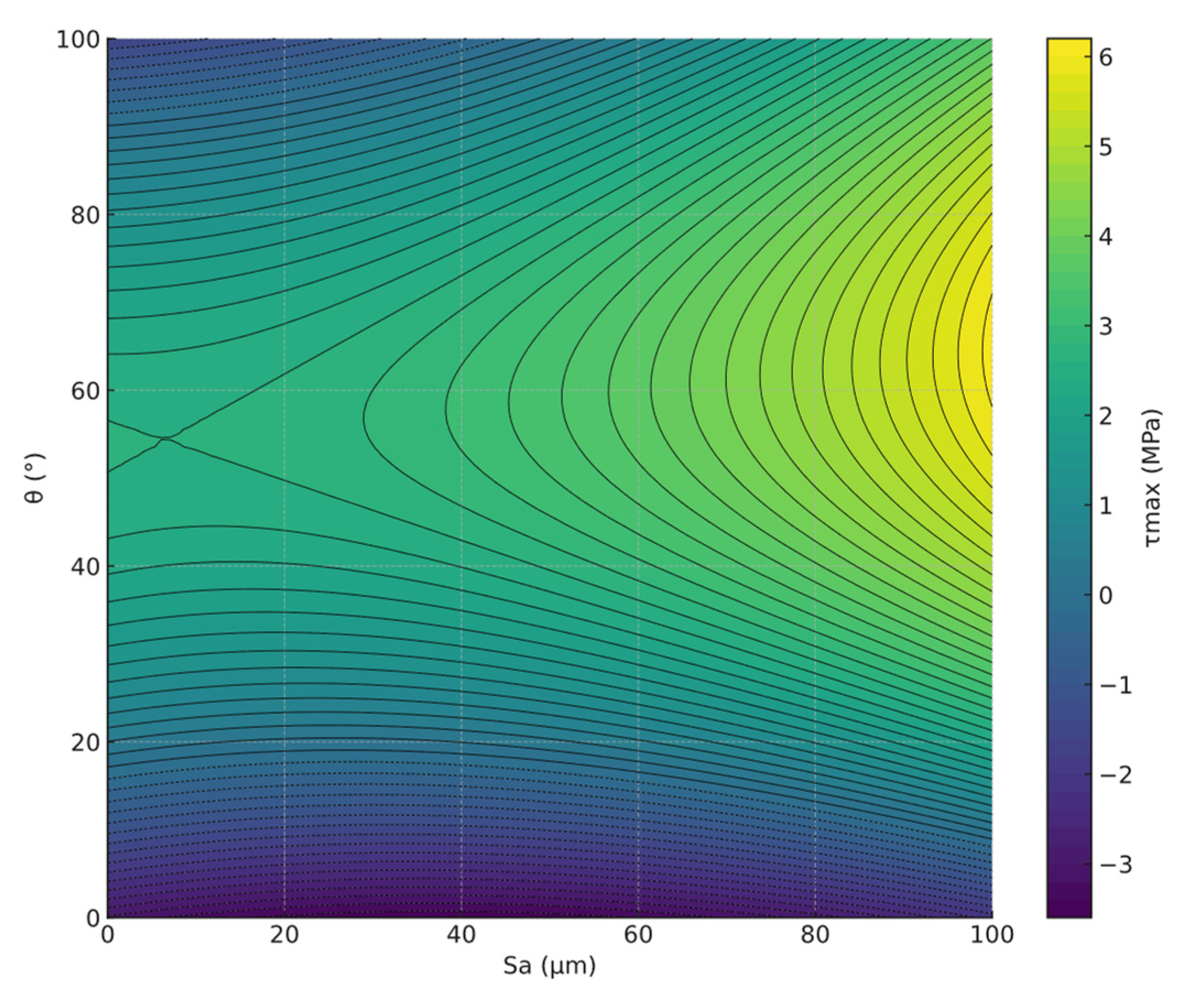

3.4. Shear Stress Results

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| FFF | Fused filament fabrication |

| PLA | Polylactic acid |

| ABS | Acrylonitrile butadiene styrene |

| Sa | Average height of selected area |

| Sz | Maximum height of selected area |

| Sk | Core roughness depth, height of the core material |

| Vvc | Core void volume of the surface |

| H | Height |

| G | Gap |

| W | Width |

| τmax | Maximum shear stress at bond |

References

- Singh, S.; Singh, G.; Prakash, C.; Ramakrishna, S. Current Status and Future Directions of Fused Filament Fabrication. J. Manuf. Process. 2020, 55, 288–306. [Google Scholar] [CrossRef]

- Mazzei Capote, G.A.; Rudolph, N.M.; Osswald, P.V.; Osswald, T.A. Failure Surface Development for ABS Fused Filament Fabrication Parts. Addit. Manuf. 2019, 28, 169–175. [Google Scholar] [CrossRef]

- Abel, J.; Scheithauer, U.; Janics, T.; Hampel, S.; Cano, S.; Müller-Köhn, A.; Günther, A.; Kukla, C.; Moritz, T. Fused Filament Fabrication (FFF) of Metal-Ceramic Components. J. Vis. Exp. 2019, 143, e57693. [Google Scholar] [CrossRef]

- Gao, X.; Qi, S.; Kuang, X.; Su, Y.; Li, J.; Wang, D. Fused Filament Fabrication of Polymer Materials: A Review of Interlayer Bond. Addit. Manuf. 2021, 37, 101658. [Google Scholar] [CrossRef]

- Guerra Silva, R.; Torres, M.J.; Zahr Viñuela, J.; Zamora, A.G. Manufacturing and Characterization of 3D Miniature Polymer Lattice Structures Using Fused Filament Fabrication. Polymers 2021, 13, 635. [Google Scholar] [CrossRef] [PubMed]

- Fico, D.; Rizzo, D.; Casciaro, R.; Esposito Corcione, C. A Review of Polymer-Based Materials for Fused Filament Fabrication (FFF): Focus on Sustainability and Recycled Materials. Polymers 2022, 14, 465. [Google Scholar] [CrossRef] [PubMed]

- Molino Alvarez, E.; Quintana González, S.A.; Lopez Taborda, L.L.; Niebles Nuñez, E.E. Experimental Study of Adhesive Joints with Mechanical Interlocking of Acrylonitrile Butadiene Styrene (ABS) Parts Fabricated for Fused Filament (FFF). Rapid Prototyp. J. 2023, 29, 1984–2000. [Google Scholar] [CrossRef]

- Frascio, M.; Mandolfino, C.; Moroni, F.; Jilich, M.; Lagazzo, A.; Pizzorni, M.; Bergonzi, L.; Morano, C.; Alfano, M.; Avalle, M. Appraisal of Surface Preparation in Adhesive Bonding of Additive Manufactured Substrates. Int. J. Adhes. Adhes. 2021, 106, 102802. [Google Scholar] [CrossRef]

- Mashayekhi, F.; Bardon, J.; Westermann, S.; Addiego, F. Adhesion Optimization between Incompatible Polymers through Interfacial Engineering. Polymers 2021, 13, 4273. [Google Scholar] [CrossRef]

- Nagam, V.B.; Narayanan, V. Effect of Process Parameters on Mechanical Properties and Wettability of Polylactic Acid by Fused Filament Fabrication Process. Int. J. Mater. Res. 2023, 114, 1088–1100. [Google Scholar] [CrossRef]

- Lee, K.-M.; Park, H.; Kim, J.; Chun, D.-M. Fabrication of a Superhydrophobic Surface Using a Fused Deposition Modeling (FDM) 3D Printer with Poly Lactic Acid (PLA) Filament and Dip Coating with Silica Nanoparticles. Appl. Surf. Sci. 2019, 467–468, 979–991. [Google Scholar] [CrossRef]

- Shimada, K.; Hirai, T.; Mizutani, M.; Kuriyagawa, T. Unidirectional Wetting Surfaces Fabricated by Ultrasonic-Assisted Cutting. Int. J. Autom. Technol. 2019, 13, 191–198. [Google Scholar] [CrossRef]

- Edachery, V.; Shashank, R.; Kailas, S.V. Influence of Surface Texture Directionality and Roughness on Wettability, Sliding Angle, Contact Angle Hysteresis, and Lubricant Entrapment Capability. Tribol. Int. 2021, 158, 106932. [Google Scholar] [CrossRef]

- Sung, J.; Lee, H.M.; Yoon, G.H.; Bae, S.; So, H. One-Step Fabrication of Superhydrophobic Surfaces with Wettability Gradient Using Three-Dimensional Printing. Int. J. Precis. Eng. Manuf.-Green Technol. 2023, 10, 85–96. [Google Scholar] [CrossRef]

- Sagbas, B.; Durakbasa, N.M. Profile and Areal Surface Characterization of Additive Manufacturing Polymer and Metal Parts. In Proceedings of the 12th International Conference on Measurement and Quality Control-Cyber Physical Issue: IMEKO TC 14 2019, Belgrade, Serbia, 4–7 June 2019; Springer: Berlin/Heidelberg, Germany, 2019; pp. 240–246. [Google Scholar]

- Gao, H.; Ma, B.; Singh, R.P.; Yang, H. Areal Surface Roughness of AZ31B Magnesium Alloy Processed by Dry Face Turning: An Experimental Framework Combined with Regression Analysis. Materials 2020, 13, 2303. [Google Scholar] [CrossRef] [PubMed]

- Duo, Y.; Jinyuan, T.; Fujia, X.; Wei, Z. Surface Roughness Characterization and Inversion of Ultrasonic Grinding Parameters Based on Support Vector Machine. J. Tribol. 2022, 144, 094501–094507. [Google Scholar] [CrossRef]

- Maros, Z.; Felhő, C.; Vass, Z.; Maros, M.B. Application of 2D-3D Surface Geometrical Features in Tribological Analysis of Ceramics and Ceramic Layers. Mater. Sci. Forum 2015, 812, 435–440. [Google Scholar] [CrossRef]

- Sedlaček, M.; Gregorčič, P.; Podgornik, B. Use of the Roughness Parameters Ssk and Sku to Control Friction—A Method for Designing Surface Texturing. Tribol. Trans. 2017, 60, 260–266. [Google Scholar] [CrossRef]

- Souza, A.M.; Ferreira, R.; Barragán, G.; Nuñez, J.G.; Mariani, F.E.; da Silva, E.J.; Coelho, R.T. Effects of Laser Polishing on Surface Characteristics and Wettability of Directed Energy-Deposited 316L Stainless Steel. J. Mater. Eng. Perform. 2021, 30, 6752–6765. [Google Scholar] [CrossRef]

- Feng, Z.; Zhao, H.; Tan, C.; Zhu, B.; Xia, F.; Wang, Q.; Chen, B.; Song, X. Effect of Laser Texturing on the Surface Characteristics and Bonding Property of 30CrMnSiA Steel Adhesive Joints. J. Manuf. Process. 2019, 47, 219–228. [Google Scholar] [CrossRef]

- Dwivedi, S.; Dixit, A.R.; Das, A.K.; Srivastava, A.K. Time-Dependent Wetting Behavior of the Micro-Textured Stainless Steel 316L Using the Mechanical Indentation Method. Proc. Inst. Mech. Eng. Part E J. Process. Mech. Eng. 2023, 144, 094501–094507. [Google Scholar] [CrossRef]

- Tofil, S.; Kurp, P.; Manikandan, M. Surface Laser Micropatterning of Polyethylene (PE) to Increase the Shearing Strength of Adhesive Joints. Lubricants 2023, 11, 368. [Google Scholar] [CrossRef]

- Abd El Wahab, S.; El-Sharkawy, Z. Effect of Different Surface Treatments on Cone Beam Computed Tomography Image and Push Out Bond Strength of Conventional and Reinforced Fiber Posts. Al-Azhar Dent. J. Girls 2017, 4, 79–94. [Google Scholar] [CrossRef]

- Yu, H.; Ju, J.; Yang, T.; Wang, C.; Zhang, T.; Peng, P.; Feng, T.; Ding, C.; Kang, M.; Wang, J. Experimental and Finite Element Simulation Studies of the Bio-Tribological Behavior of L-PBF Ti-6Al-4V Alloys with Various Surface Roughness. Tribol. Int. 2024, 194, 109514. [Google Scholar] [CrossRef]

- Chen, L.; Liu, Z.; Wang, X.; Wang, Q.; Liang, X. Effects of Surface Roughness Parameters on Tribological Performance for Micro-Textured Eutectic Aluminum–Silicon Alloy. J. Tribol. 2020, 142, 021702. [Google Scholar] [CrossRef]

- Molnár, V.; Sztankovics, I. Analysis of Roughness Parameters Determining Tribological Properties in Hard Turned Surfaces. Hung. J. Ind. Chem. 2021, 49, 77–84. [Google Scholar] [CrossRef]

- Perez, F.; Bissonnette, B.; Courard, L.; Morency, M. Correlation between the Roughness of the Substrate Surface and the Debonding Risk. In Concrete Repair, Rehabilitation and Retrofitting II; CRC Press: Boca Raton, FL, USA, 2008; pp. 347–348. [Google Scholar]

- van Dam, J.P.B.; Abrahami, S.T.; Yilmaz, A.; Gonzalez-Garcia, Y.; Terryn, H.; Mol, J.M.C. Effect of Surface Roughness and Chemistry on the Adhesion and Durability of a Steel-Epoxy Adhesive Interface. Int. J. Adhes. Adhes. 2020, 96, 102450. [Google Scholar] [CrossRef]

- Tan, A.W.-Y.; Sun, W.; Bhowmik, A.; Lek, J.Y.; Song, X.; Zhai, W.; Zheng, H.; Li, F.; Marinescu, I.; Dong, Z.; et al. Effect of Substrate Surface Roughness on Microstructure and Mechanical Properties of Cold-Sprayed Ti6Al4V Coatings on Ti6Al4V Substrates. J. Therm. Spray Technol. 2019, 28, 1959–1973. [Google Scholar] [CrossRef]

- Wang, J.; Wu, Y.; Cao, Y.; Li, G.; Liao, Y. Influence of Surface Roughness on Contact Angle Hysteresis and Spreading Work. Colloid Polym. Sci. 2020, 298, 1107–1112. [Google Scholar] [CrossRef]

- Nosonovsky, M.; Bhushan, B. Multiscale Effects and Capillary Interactions in Functional Biomimetic Surfaces for Energy Conversion and Green Engineering. Philos. Trans. R. Soc. A Math. Phys. Eng. Sci. 2009, 367, 1511–1539. [Google Scholar] [CrossRef] [PubMed]

- Lafuma, A.; Quéré, D. Superhydrophobic States. Nat. Mater. 2003, 2, 457–460. [Google Scholar] [CrossRef] [PubMed]

- AlRatrout, A.; Blunt, M.J.; Bijeljic, B. Wettability in Complex Porous Materials, the Mixed-Wet State, and Its Relationship to Surface Roughness. Proc. Natl. Acad. Sci. USA 2018, 115, 8901–8906. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Y.; Wang, X.; Li, H.; Wang, B. Adhesive Behavior of Micro/Nano-Textured Surfaces. Appl. Surf. Sci. 2015, 329, 174–183. [Google Scholar] [CrossRef]

- Liao, L.; Huang, C.; Sawa, T. Effect of Adhesive Thickness, Adhesive Type and Scarf Angle on the Mechanical Properties of Scarf Adhesive Joints. Int. J. Solids Struct. 2013, 50, 4333–4340. [Google Scholar] [CrossRef]

- Zhang, Y.; Li, G.; Liu, C.; Yuan, F.; Han, F.; Ali, M.; Guo, W.; Gu, H. The Effect of Three-Dimensional Loading and Texture on Deformation Mechanism of Zircaloy-4 Alloy: Using Space Schmid Factor Model. Mater. Sci. Eng. A 2019, 761, 137992. [Google Scholar] [CrossRef]

- Tan, N.; Xing, Z.; Wang, X.; Wang, H.; Jin, G.; Xu, B. Effects of Texturing Patterns on the Adhesion Strength of Atmosphere Plasma Sprayed Coatings. J. Mater. Res. 2017, 32, 1682–1692. [Google Scholar] [CrossRef]

- Yan, Z.-M.; You, M.; Yi, X.-S.; Zheng, X.-L.; Li, Z. A Numerical Study of Parallel Slot in Adherend on the Stress Distribution in Adhesively Bonded Aluminum Single Lap Joint. Int. J. Adhes. Adhes. 2007, 27, 687–695. [Google Scholar] [CrossRef]

- Miazio, Ł. The Influence of Layer Height on the Tensile Strength of Specimens Printed in the FDM Technology. Tech. Sci. 2021, 24, 51–56. [Google Scholar] [CrossRef]

- Sedlaček, M.; Podgornik, B.; Ramalho, A.; Česnik, D. Influence of Geometry and the Sequence of Surface Texturing Process on Tribological Properties. Tribol. Int. 2017, 115, 268–273. [Google Scholar] [CrossRef]

- Bañon, F.; Martin, S.; Vazquez-Martinez, J.M.; Salguero, J.; Trujillo, F.J. Predictive Models Based on RSM and ANN for Roughness and Wettability Achieved by Laser Texturing of S275 Carbon Steel Alloy. Opt. Laser Technol. 2024, 168, 109963. [Google Scholar] [CrossRef]

| Geometry | Width (W) (mm) | Height (mm) | Gaps (G) (mm) |

|---|---|---|---|

| Non-textured | - | - | - |

| Pyramids | 1.0 (per side) | 0.15 0.30 0.50 | 0.0 |

| Cylinders | 1.0 (diameter) | 0.15 0.30 0.50 | 0.25 |

| Cones | 1.0 (diameter) | 0.15 0.30 0.50 | 0.0 0.50 |

| Slots | 0.5 (width) | 0.15 0.30 0.50 | 0.30 |

| Slots | 0.5 (width) | 0.15 0.30 0.50 | 0.50 |

| Slots | 1.0 (width) | 0.15 0.30 0.50 | 0.50 |

| Layer thickness | 0.08 mm |

| Speed deposition | 60 mm/s |

| Temperature | 200 °C |

| Infill density | 15% |

| Infill pattern | Giroid |

| Number of surface layers | 9 |

| Geometry | Base Size (mm) | Height (mm) | Gaps (mm) |

|---|---|---|---|

| Pyramids | 1 (per side) | 0.15 0.50 | 0.00 |

| Cylinders | 1 (diameter) | 0.15 0.50 | 0.25 |

| Cones | 1 (diameter) | 0.15 0.50 | 0.50 |

| Slots | 0.5 (width) | 0.15 0.50 | 0.50 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bañón-García, F.; Bermudo Gamboa, C.; López-Fernández, J.A.; Trujillo-Vilches, F.J.; Martín-Béjar, S. Correlation between Surface Texture, Wettability and Mechanical Strength of Polylactic Acid Parts Fabricated by Fused Filament Fabrication. Coatings 2024, 14, 1033. https://doi.org/10.3390/coatings14081033

Bañón-García F, Bermudo Gamboa C, López-Fernández JA, Trujillo-Vilches FJ, Martín-Béjar S. Correlation between Surface Texture, Wettability and Mechanical Strength of Polylactic Acid Parts Fabricated by Fused Filament Fabrication. Coatings. 2024; 14(8):1033. https://doi.org/10.3390/coatings14081033

Chicago/Turabian StyleBañón-García, Fermín, Carolina Bermudo Gamboa, José Andrés López-Fernández, Francisco Javier Trujillo-Vilches, and Sergio Martín-Béjar. 2024. "Correlation between Surface Texture, Wettability and Mechanical Strength of Polylactic Acid Parts Fabricated by Fused Filament Fabrication" Coatings 14, no. 8: 1033. https://doi.org/10.3390/coatings14081033

APA StyleBañón-García, F., Bermudo Gamboa, C., López-Fernández, J. A., Trujillo-Vilches, F. J., & Martín-Béjar, S. (2024). Correlation between Surface Texture, Wettability and Mechanical Strength of Polylactic Acid Parts Fabricated by Fused Filament Fabrication. Coatings, 14(8), 1033. https://doi.org/10.3390/coatings14081033