The Evolution of Surfaces on Medium-Carbon Steel for Fatigue Life Estimations

Abstract

1. Introduction

2. Materials and Methods

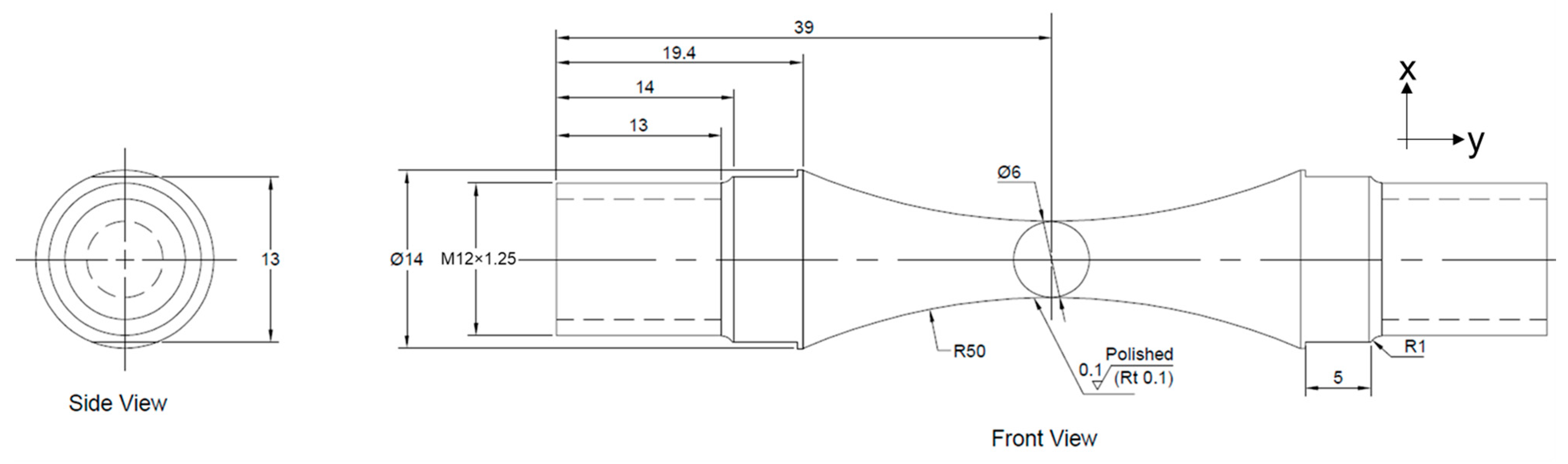

2.1. Material and Specimen Preparations

2.2. Fatigue Test Setups

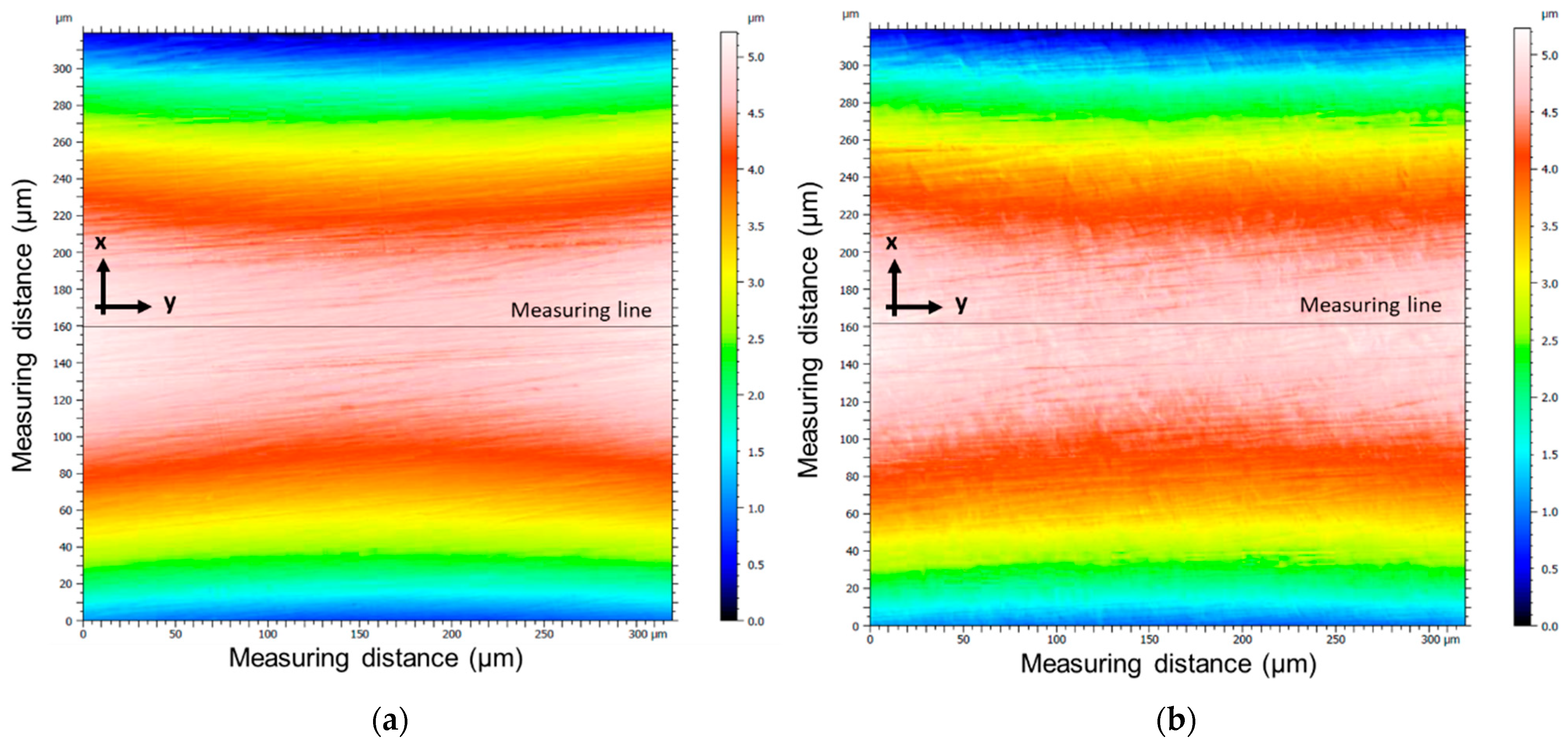

2.3. Surface Measurements

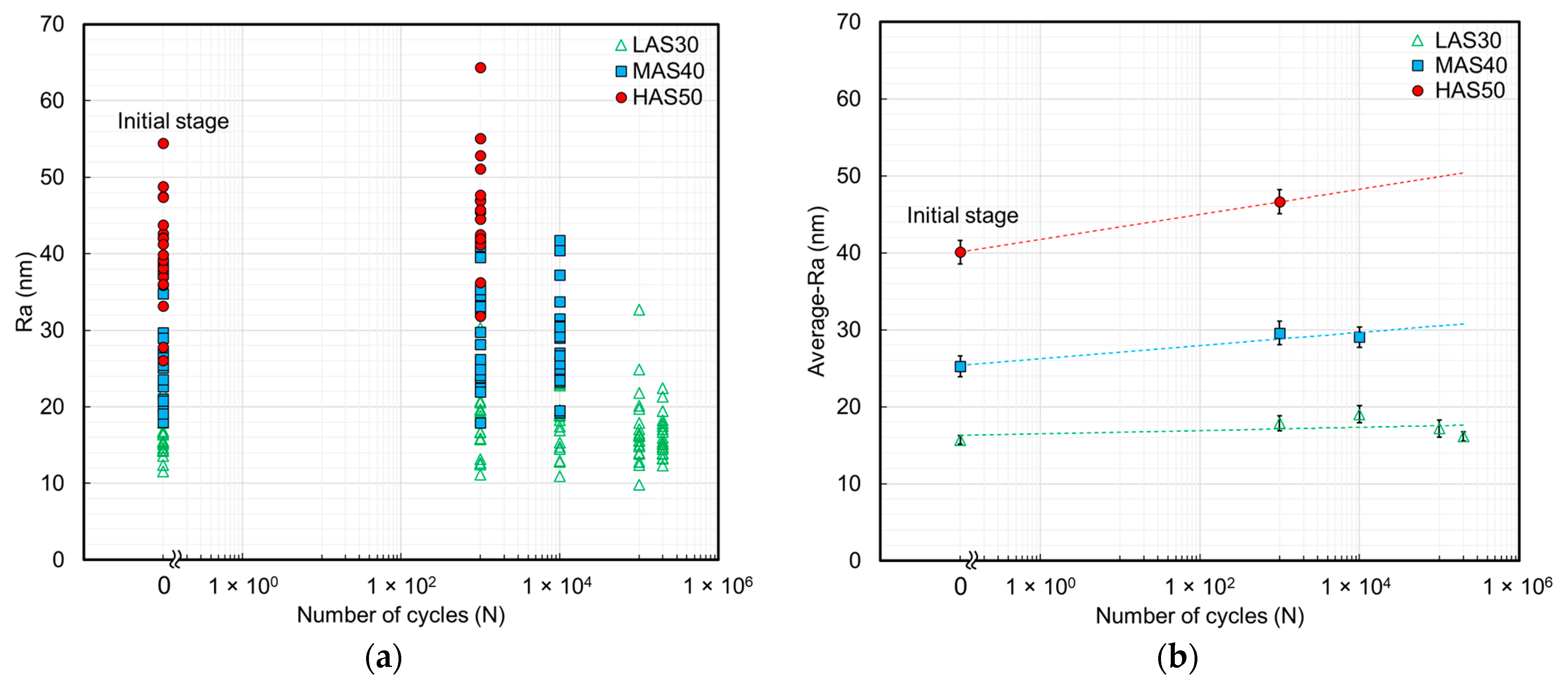

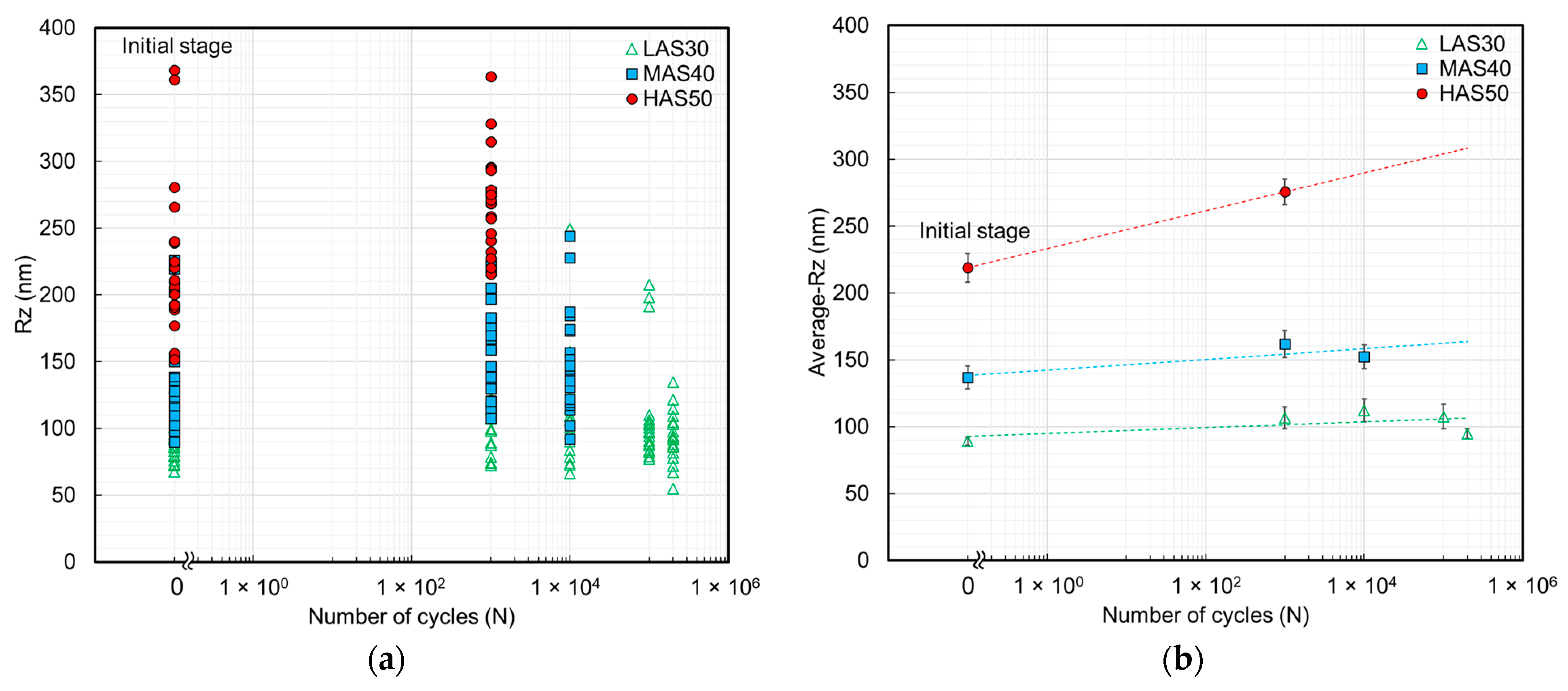

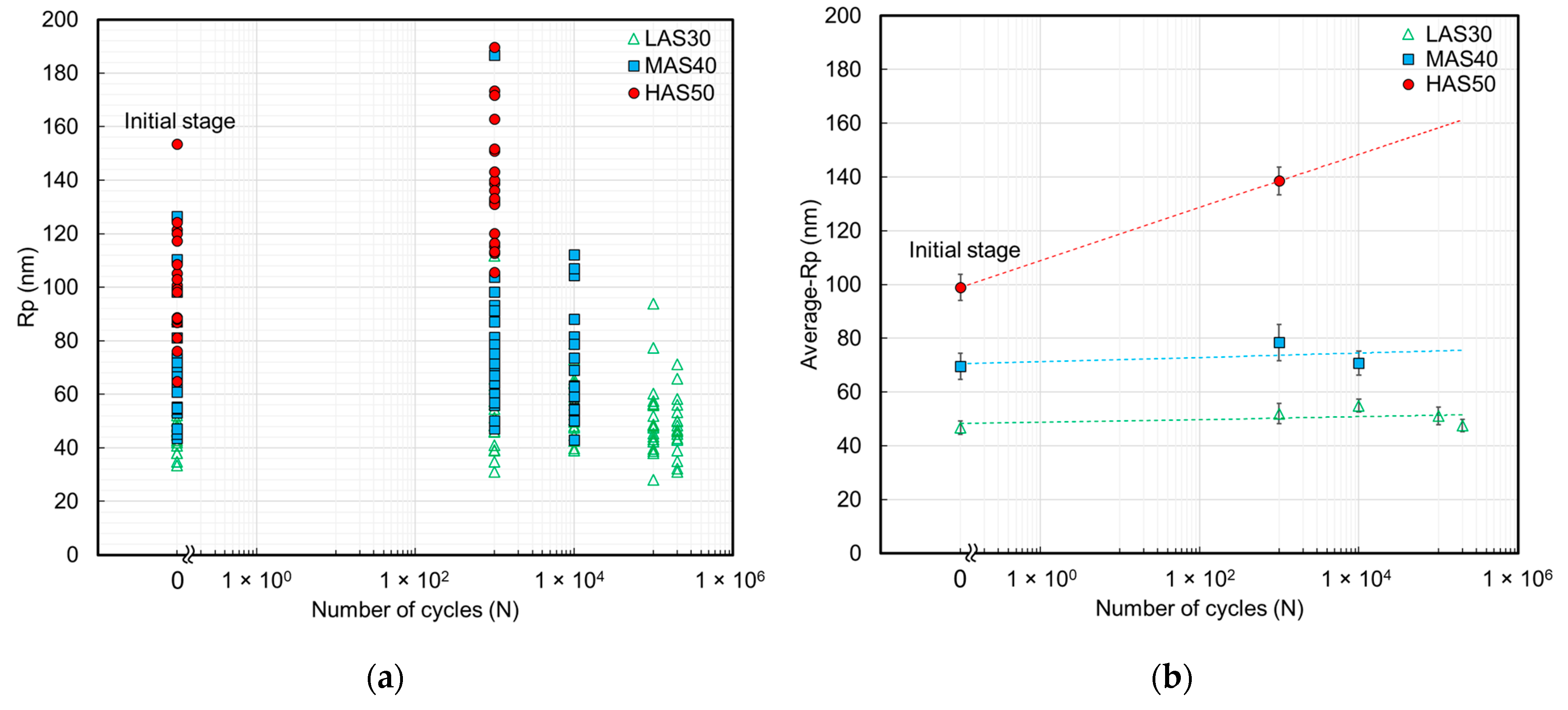

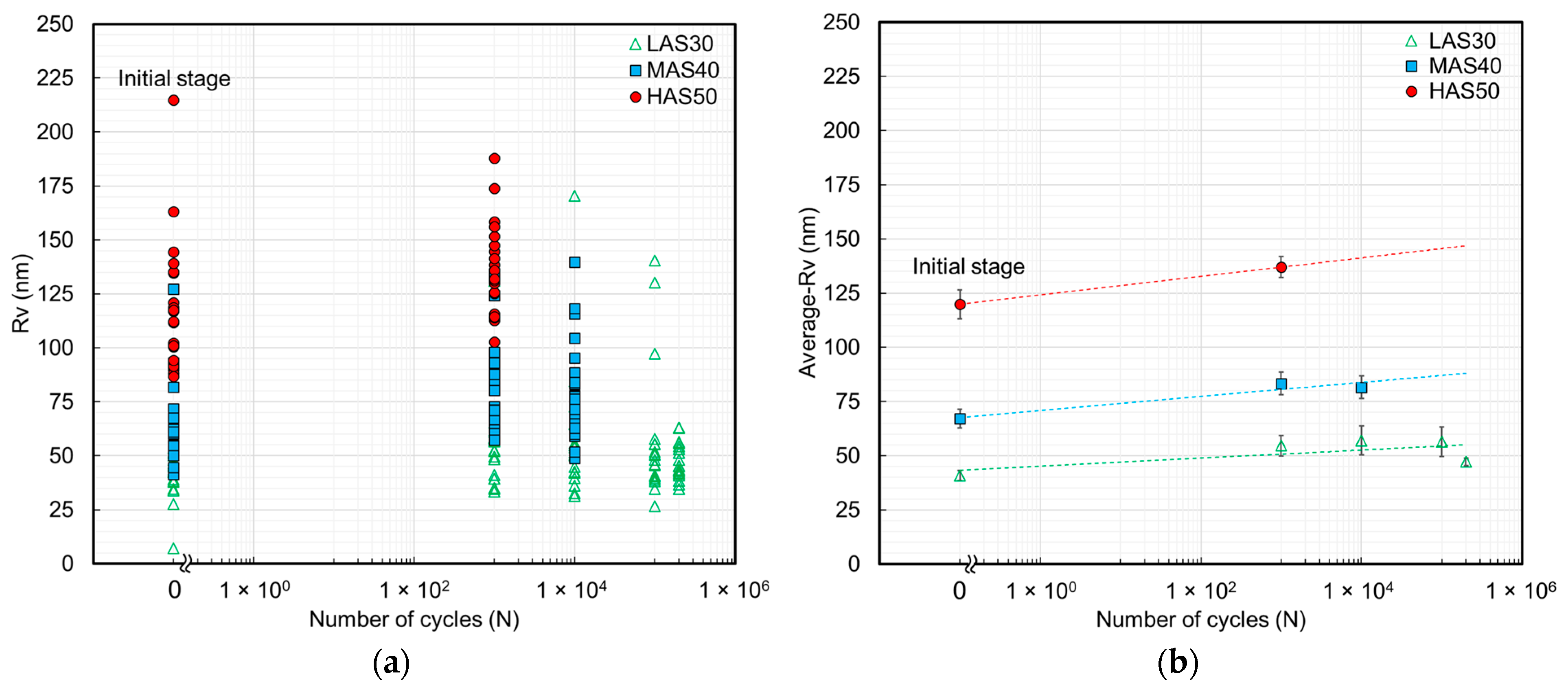

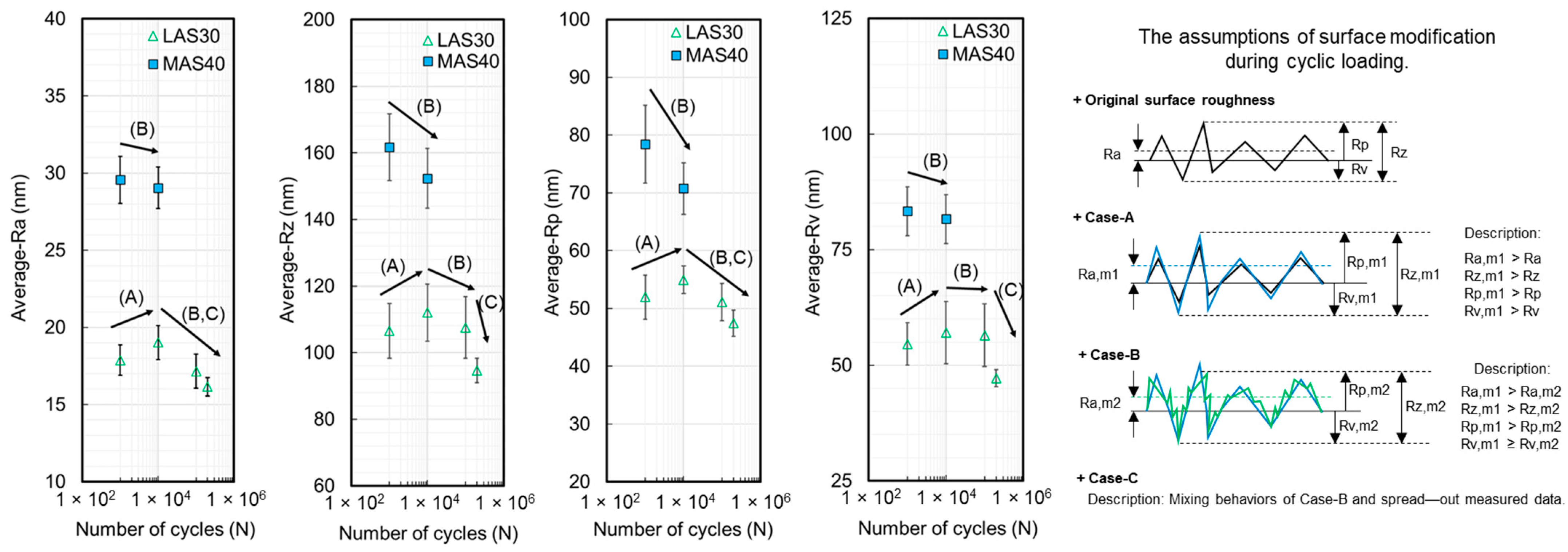

3. Results

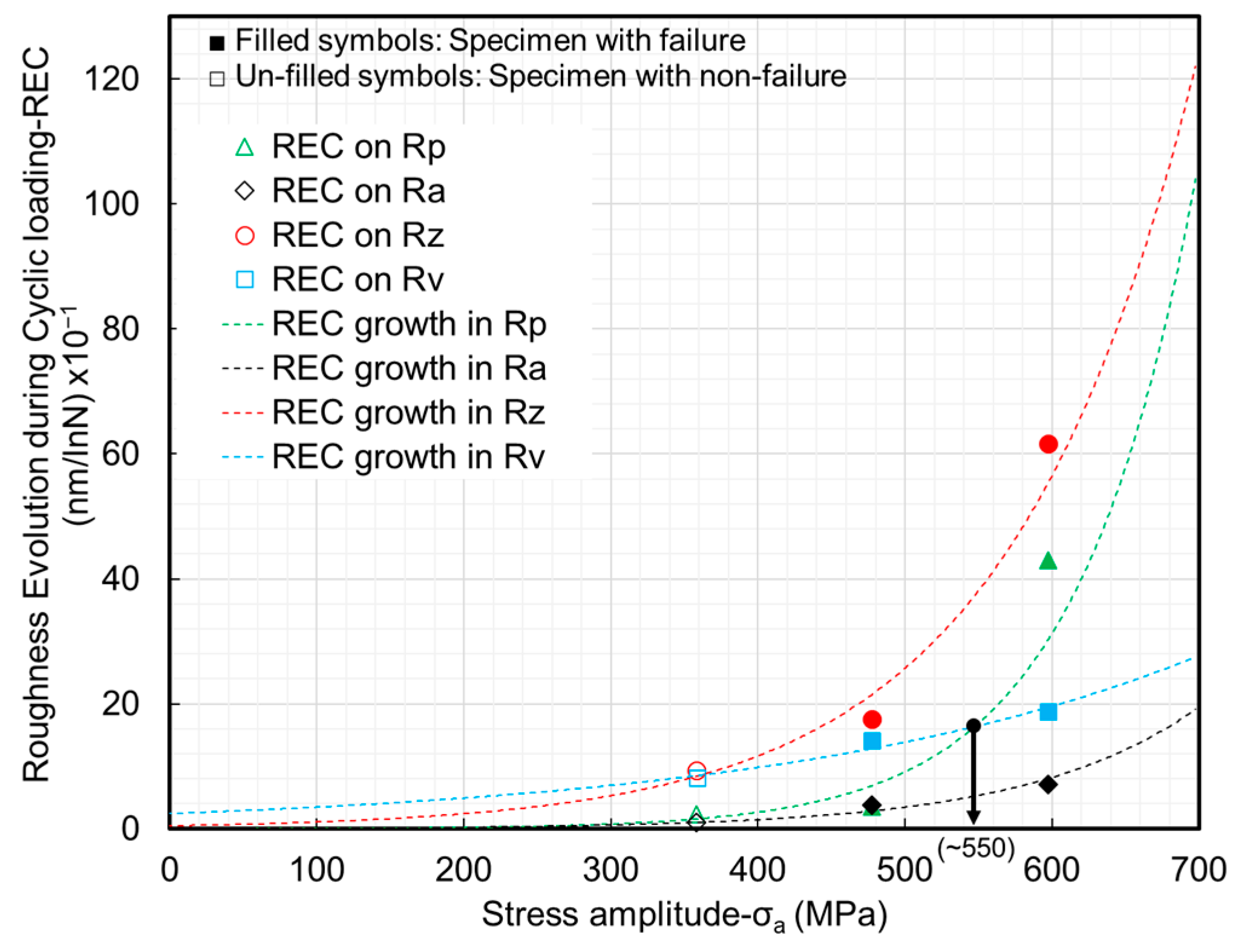

4. Discussion

5. Conclusions

- Using 40% (MAS40) and 50% (HAS50) of UTS as stress amplitudes, the specimens were tested until failure, which revealed significant changes in their Ra, Rz, Rp, and Rv values. However, for the LAS30 specimen (the run-out specimen), surface roughness development was observed even with a small amount of alteration.

- Regarding the HAS50 specimen, the RECs exhibited higher values than the specimens subjected to lower stress amplitudes.

- The surface roughness of the tested specimens was completely enhanced by increasing the stress amplitude, and the evidence to confirm its effect is the increase in inclinations (RECs).

- The PSBs were more readily generated by higher than lower stress amplitudes.

- The specimens with a finite fatigue life (MAS40 and HAS50) revealed significant surface development, which means that the local plastic strain completely formed on the surface grains.

- Although the LAS30 specimen was designated as having infinite fatigue life in this study, the roughness modification results confirmed that local plastic strain could have been generated, which can modify the specimen surfaces in the LCF regime.

- The REC of Rv (intrusions) indicated that the dominant behavior on the developed surfaces at stress amplitudes lower than 550 MPa was the formation of intrusions. But at higher stress levels, Rp (extrusions) served as the main surface development behavior.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Nomenclature

| coefficient of notch factor | |

| A, B, C, k, l, m | material constant values for round specimens with a notch |

| t | notch thickness |

| notch radius | |

| a | radius of the diameter of gauge length |

| kN | kilonewton |

| MPa | megapascal |

| nm | nanometer |

| µm | micrometer |

| Ri | considered roughness parameter |

| Ra | arithmetic mean deviation |

| Rz | maximum height |

| Rp | maximum profile peak height |

| Rv | maximum profile valley depth |

| Z(x) | ordinate value |

| L | roughness sampling length |

| ∂Ra/∂ln(N) | roughness/number of cycles rate |

| σmin | minimum stress |

| σmax | maximum stress |

| σa | stress amplitude |

| R | load ratio |

| f | fatigue test frequency |

| N | number of cycles |

| Nu | ultimate number of cycles |

| R2 | coefficient of determination |

| HV | Vickers hardness |

| UTS | ultimate tensile strength |

| LCF | low cycle fatigue |

| HCF | high cycle fatigue |

| VHCF | very high cycle fatigue |

| PSB | persistent slip band |

| PSM | persistent slip mark |

| REC | roughness evolution during cyclic loading |

| LAS30 | specimen with a stress amplitude of 30% of ultimate tensile strength |

| MAS40 | specimen with a stress amplitude of 40% of ultimate tensile strength |

| HAS50 | specimen with a stress amplitude of 50% of ultimate tensile strength |

| ASTM | American Society for Testing and Materials |

| DIN | Deutsches Institut für Normung e. V. |

| SAE | Society of Automotive Engineers |

| ISO | International Organization for Standardization |

References

- Bartošák, M.; Horváth, J.; Španiel, M. Isothermal low-cycle fatigue and fatigue-creep of a 42CrMo4 steel. Int. J. Fatigue 2020, 135, 105538. [Google Scholar] [CrossRef]

- Kreethi, R.; Sivateja, C.; Mondal, A.K.; Dutta, K. Ratcheting life prediction of quenched–tempered 42CrMo4 steel. J. Mater. Sci. 2019, 54, 11703–11712. [Google Scholar] [CrossRef]

- Görzen, D.; Ostermayer, P.; Lehner, P.; Blinn, B.; Eifler, D.; Beck, T. A New Approach to Estimate the Fatigue Limit of Steels Based on Conventional and Cyclic Indentation Testing. Metals 2022, 12, 1066. [Google Scholar] [CrossRef]

- Di Marzo, M.; Tomassi, A.; Placidi, L. A Methodology for Structural Damage Detection Adding Masses. Res. Nondestruct. Eval. 2024, 35, 172–196. [Google Scholar] [CrossRef]

- Qiu, B.; Lan, T.; Ji, X.; Lei, H.; Zhang, S. Optimizing fatigue life prediction of high strength bolts in bolted spherical joints. J. Constr. Steel Res. 2024, 217, 108635. [Google Scholar] [CrossRef]

- Xu, Y.; Li, X.; Zhang, Y.; Yang, J. Ultra-Low Cycle Fatigue Life Prediction Model—A Review. Metals 2023, 13, 1142. [Google Scholar] [CrossRef]

- Li, K.-S.; Yao, S.-L.; Cheng, L.-Y.; Wang, R.-Z.; Sun, L.; Gu, H.-H.; Wang, J.; Lu, T.-W.; Zhang, C.-C.; Zhang, X.-C.; et al. Creep-fatigue life prediction of notched structure after an advanced surface strengthening treatment in a nickel-based superalloy at 650 °C. Int. J. Plast. 2024, 173, 103861. [Google Scholar] [CrossRef]

- Gao, C.; Pang, J.; Hu, D.; Li, S.; Qi, K.; Wang, B.; Zhang, Y.; Nie, L.; Yang, M.; Zhang, Z. A new method for predicting the fatigue strength at various stress ratios based on damage of metallic materials. Fatigue Fract. Eng. Mat. Struct. 2024, 47, 2103–2126. [Google Scholar] [CrossRef]

- Cretegny, L.; Saxena, A. Evolution of surface deformation during fatigue of PH 13-8 Mo stainless steel using atomic force microscopy. Fatigue Fract. Eng. Mat. Struct. 2002, 25, 305–314. [Google Scholar] [CrossRef]

- Bjørheim, F.; Siriwardane, S.C.; Pavlou, D. A review of fatigue damage detection and measurement techniques. Int. J. Fatigue 2022, 154, 106556. [Google Scholar] [CrossRef]

- Gonchar, A.V.; Kurashkin, K.V.; Andreeva, O.V.; Anosov, M.S.; Klyushnikov, V.A. Fatigue life prediction of structural steel using acoustic birefringence and characteristics of persistent slip bands. Fatigue Fract. Eng. Mat. Struct. 2022, 45, 101–112. [Google Scholar] [CrossRef]

- Sharma, D.; Singh, I.V.; Kumar, J.; Ahmed, S. Microstructure based fatigue life prediction of polycrystalline materials using SFEM and CDM. Int. J. Fract. 2024, 247, 265–284. [Google Scholar] [CrossRef]

- Gao, H.; Zhan, J.; Yu, B.; Li, W.; Lin, Z.; Shang, H. Multi-scale characterization of fatigue crack tip deformation and propagation in QP steel. Mater. Charact. 2024, 210, 113822. [Google Scholar] [CrossRef]

- Mehdizadeh, M.; Haghshenas, A.; Khonsari, M.M. In-situ Technique for Fatigue Life Prediction of Metals Based on Temperature Evolution. Int. J. Mech. Sci. 2021, 192, 106113. [Google Scholar] [CrossRef]

- Fourel, L.; Noyel, J.-P.; Bossy, E.; Kleber, X.; Sainsot, P.; Ville, F. Towards a grain-scale modeling of crack initiation in rolling contact fatigue—Part 2: Persistent slip band modeling. Tribol. Int. 2021, 163, 107173. [Google Scholar] [CrossRef]

- Goto, M.; Yakushiji, T.; Kim, S.; Yamamoto, T.; Han, S.Z. Formation process of fatigue slip bands with unique configurations of ultrafine-grained high-purity Cu fabricated by severe plastic deformation. J. Alloys Compd. 2022, 899, 163263. [Google Scholar] [CrossRef]

- Meng, F.; Ferrié, E.; Déprés, C.; Fivel, M. 3D discrete dislocation dynamic investigations of persistent slip band formation in FCC metals under cyclical deformation. Int. J. Fatigue 2021, 149, 106234. [Google Scholar] [CrossRef]

- Polák, J. Role of Persistent Slip Bands and Persistent Slip Markings in Fatigue Crack Initiation in Polycrystals. Crystals 2023, 13, 220. [Google Scholar] [CrossRef]

- Zhang, P.; Zhang, L.; Baxevanakis, K.P.; Lu, S.; Zhao, L.G.; Bullough, C. Discrete crystal plasticity modelling of slip-controlled cyclic deformation and short crack growth under low cycle fatigue. Int. J. Fatigue 2021, 145, 106095. [Google Scholar] [CrossRef]

- Polák, J.; Mazánová, V.; Heczko, M.; Petráš, R.; Kuběna, I.; Casalena, L.; Man, J. The role of extrusions and intrusions in fatigue crack initiation. Eng. Fract. Mech. 2017, 185, 46–60. [Google Scholar] [CrossRef]

- Essmann, U.; Gösele, U.; Mughrabi, H. A model of extrusions and intrusions in fatigued metals I. Point-Defect. Prod. Growth Extrus. Philos. Mag. A 1981, 44, 405–426. [Google Scholar]

- Polák, J.; Jadlovský, D.; Kruml, T. Extrusions and intrusions in the cyclic plastic zone of the growing fatigue crack in polycrystalline copper. Int. J. Fatigue 2024, 179, 108063. [Google Scholar] [CrossRef]

- Polák, J.; Babinský, T.; Vražina, T.; Kruml, T. The Role of Extrusions and Intrusions in the Initiation and Intergranular Growth of Fatigue Cracks. Adv. Eng. Mater. 2024, 2400313. [Google Scholar] [CrossRef]

- Schaefer, F.; Geyer, S.; Motz, C. How Hydrogen Affects the Formation and Evolution of Persistent Slip Bands in High-Purity α-Iron. Adv. Eng. Mater. 2023, 25, 2201932. [Google Scholar] [CrossRef]

- Polák, J. Atomic force microscopy and high resolution scanning electron microscopy evidence concerning fatigue crack nucleation. The Abstracts of ATEM International Conference on Advanced Technology in Experimental Mechanics Asian Conference on Experimental Mechanics; The Japan Society of Mechanical Engineers: Tokyo, Japan, 2003. [Google Scholar]

- Lacerda, J.C.d.; Martins, G.D.; Signoretti, V.T.; Teixeira, R. Evolution of the surface roughness of a low carbon steel subjected to fatigue. Int. J. Fatigue 2017, 102, 143–148. [Google Scholar] [CrossRef]

- Man, J.; Obrtlík, K.; Polák, J. Study of surface relief evolution in fatigued 316L austenitic stainless steel by AFM. Mater. Sci. Eng. A 2003, 351, 123–132. [Google Scholar] [CrossRef]

- Phung, N.L.; Favier, V.; Ranc, N.; Valès, F.; Mughrabi, H. Very high cycle fatigue of copper: Evolution, morphology and locations of surface slip markings. Int. J. Fatigue 2014, 63, 68–77. [Google Scholar] [CrossRef]

- DIN 50150; DIN Deutsches Institut für Normung e. V. Testing of metallic materials: Conversion of hardness values. Beuth Verlag GmbH: Berlin, Germany, 2000.

- ASTM E466; Standard Practice for Conducting Force Controlled Constant Amplitude Axial Fatigue Tests of Metallic Materials. ASTM International: West Conshohocken, PA, USA, 2015.

- Haibach, E. Betriebsfestigkeit: Verfahren und Daten zur Bauteilberechnung; korrigierte und ergänzte Auflage; Springer: Berlin/Heidelberg, Germany, 2006; ISBN 9783540293644. [Google Scholar]

- DIN EN ISO 4287; DIN Deutsches Institut für Normung e. V. Geometrical Product Specifications (GPS)—Surface Texture: Profile Method—Terms. Beuth Verlag GmbH: Berlin, Germany, 2010.

- Polák, J.; Man, J.; Kruml, T. The sources of cyclic slip irreversibility. Acta Mater. 2024, 267, 119709. [Google Scholar] [CrossRef]

- Mughrabi, H. Microstructural mechanisms of cyclic deformation, fatigue crack initiation and early crack growth. Philos. Trans. A Math. Phys. Eng. Sci. 2015, 373, 20140132. [Google Scholar] [CrossRef]

- Murakami, Y. Effect of surface roughness on fatigue strength. In Metal Fatigue; Elsevier: Amsterdam, The Netherlands, 2019; pp. 407–430. ISBN 9780128138762. [Google Scholar] [CrossRef]

- Murakami, Y.; Nomoto, T.; Ueda, T. Factors influencing the mechanism of superlong fatigue failure in steels. Fatigue Fract. Eng. Mat. Struct. 1999, 22, 581–590. [Google Scholar] [CrossRef]

- Mughrabi, H. On ‘multi-stage’ fatigue life diagrams and the relevant life-controlling mechanisms in ultrahigh-cycle fatigue. Fatigue Fract. Eng. Mat. Struct. 2002, 25, 755–764. [Google Scholar] [CrossRef]

- Beard, W.; Lancaster, R.; Barnard, N.; Jones, T.; Adams, J. The influence of surface finish and build orientation on the low cycle fatigue behaviour of laser powder bed fused stainless steel 316L. Mater. Sci. Eng. A 2023, 864, 144593. [Google Scholar] [CrossRef]

- Bui, T.P.; Miyashita, Y.; Mutoh, Y.; Morikage, Y.; Tagawa, T.; Handa, T.; Otsuka, Y. Fatigue crack deflection and branching behavior of low carbon steel under mechanically large grain condition. Int. J. Fatigue 2021, 148, 106217. [Google Scholar] [CrossRef]

| Material | Chemical Compositions (wt.%) | Mechanical Properties | |||||

|---|---|---|---|---|---|---|---|

| C | Si | Mn | Cr | Fe | Hardness (HV10) | UTS (MPa) | |

| 42CrMo4 | 0.38–0.45 | 0.17–0.35 | 0.50–0.80 | 0.90–1.20 | Bal. | 372 ± 5.4 | 1195 * |

| Specimen-ID (σa) | Number of Cycles | Ra (nm) | Rz (nm) | Rp (nm) | Rv (nm) | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Min. | Max. | Mean | Min. | Max. | Mean | Min. | Max. | Mean | Min. | Max. | Mean | ||

| LAS30 (358.5 MPa) | Initial stage | 11.54 | 21.85 | 15.69 | 67.45 | 130.50 | 89.10 | 33.49 | 88.11 | 46.79 | 7.12 | 53.61 | 40.80 |

| 1 × 103 | 11.13 | 30.35 | 17.87 | 66.24 | 242.70 | 106.56 | 31.00 | 111.70 | 51.97 | 33.35 | 131.00 | 54.59 | |

| 1 × 104 | 10.96 | 30.34 | 19.02 | 72.45 | 249.50 | 112.01 | 38.98 | 78.93 | 54.96 | 31.41 | 170.50 | 57.05 | |

| 1 × 105 | 9.81 | 32.66 | 17.16 | 54.73 | 207.60 | 107.57 | 28.03 | 93.93 | 51.08 | 26.71 | 140.50 | 56.49 | |

| 2 × 105 | 12.31 | 22.43 | 16.15 | 66.93 | 134.30 | 94.64 | 31.05 | 71.21 | 47.47 | 34.61 | 63.21 | 47.17 | |

| MAS40 (478.0 MPa) | Initial stage | 18.00 | 38.62 | 25.24 | 89.89 | 225.70 | 136.66 | 43.54 | 126.40 | 69.56 | 41.43 | 127.30 | 67.10 |

| 1 × 103 | 17.94 | 41.59 | 29.56 | 107.50 | 277.10 | 161.72 | 47.08 | 186.70 | 78.40 | 57.42 | 134.40 | 83.31 | |

| 1 × 104 | 19.23 | 41.78 | 29.04 | 91.96 | 244.10 | 152.36 | 43.01 | 112.20 | 70.74 | 48.95 | 139.60 | 81.62 | |

| HAS50 (597.5 MPa) | Initial stage | 26.06 | 54.45 | 40.08 | 151.60 | 368.50 | 218.81 | 64.80 | 153.60 | 98.99 | 86.77 | 214.90 | 119.84 |

| 1 × 103 | 31.88 | 64.33 | 46.62 | 215.40 | 363.60 | 275.54 | 105.50 | 189.80 | 138.53 | 102.70 | 187.90 | 137.01 | |

| Specimen ID | LAS30 | MAS40 | HAS50 | |

|---|---|---|---|---|

| Stress Amplitude (MPa)-σa | 358.5 | 478.0 | 597.5 | |

| Failed at | Run-Out | 24,240 N | 2078 N | |

| Slope (REC)-∂Ra/∂ln(N) | Ra | +0.900 × 10−1 | +3.700 × 10−1 | +7.099 × 10−1 |

| Rz | +9.346 × 10−1 | +17.514 × 10−1 | +61.594 × 10−1 | |

| Rp | +2.261 × 10−1 | +3.474 × 10−1 | +42.933 × 10−1 | |

| Rv | +8.15 × 10−1 | +14.04 × 10−1 | +18.63 × 10−1 | |

| Description | Ra | Rz | Rp | Rv |

|---|---|---|---|---|

| Equation | ln(REC) = 0.009 (σ) + ln(0.046) | ln(REC) = 0.007(σ) + ln(0.666) | ln(REC) = 0.012(σ) + ln(0.019) | ln(REC) = 0.004(σ) + ln(2.461) |

| Reliability (R2) | 95.66% (0.9566) | 93.66% (0.9366) | 85.68% (0.8568) | 96.80% (0.968) |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Seensattayawong, P.; Kerscher, E. The Evolution of Surfaces on Medium-Carbon Steel for Fatigue Life Estimations. Coatings 2024, 14, 1077. https://doi.org/10.3390/coatings14081077

Seensattayawong P, Kerscher E. The Evolution of Surfaces on Medium-Carbon Steel for Fatigue Life Estimations. Coatings. 2024; 14(8):1077. https://doi.org/10.3390/coatings14081077

Chicago/Turabian StyleSeensattayawong, Phanuphak, and Eberhard Kerscher. 2024. "The Evolution of Surfaces on Medium-Carbon Steel for Fatigue Life Estimations" Coatings 14, no. 8: 1077. https://doi.org/10.3390/coatings14081077

APA StyleSeensattayawong, P., & Kerscher, E. (2024). The Evolution of Surfaces on Medium-Carbon Steel for Fatigue Life Estimations. Coatings, 14(8), 1077. https://doi.org/10.3390/coatings14081077