Upscaled Multilayer Dispersion Coating Application for Barrier Packaging: PLAX and bioORMOCER®

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Methods

2.3. Characterization

2.3.1. Coat Weight and Coating Thickness

2.3.2. Surface Roughness and Air Permeability Measurements

2.3.3. Imaging of Surface and Cross-Section

2.3.4. Moisture and Mineral Oil Barrier Measurements

2.3.5. Oxygen Barrier Measurement

2.3.6. Grease Barrier Measurement

2.3.7. Heat Sealability Test

3. Results and Discussion

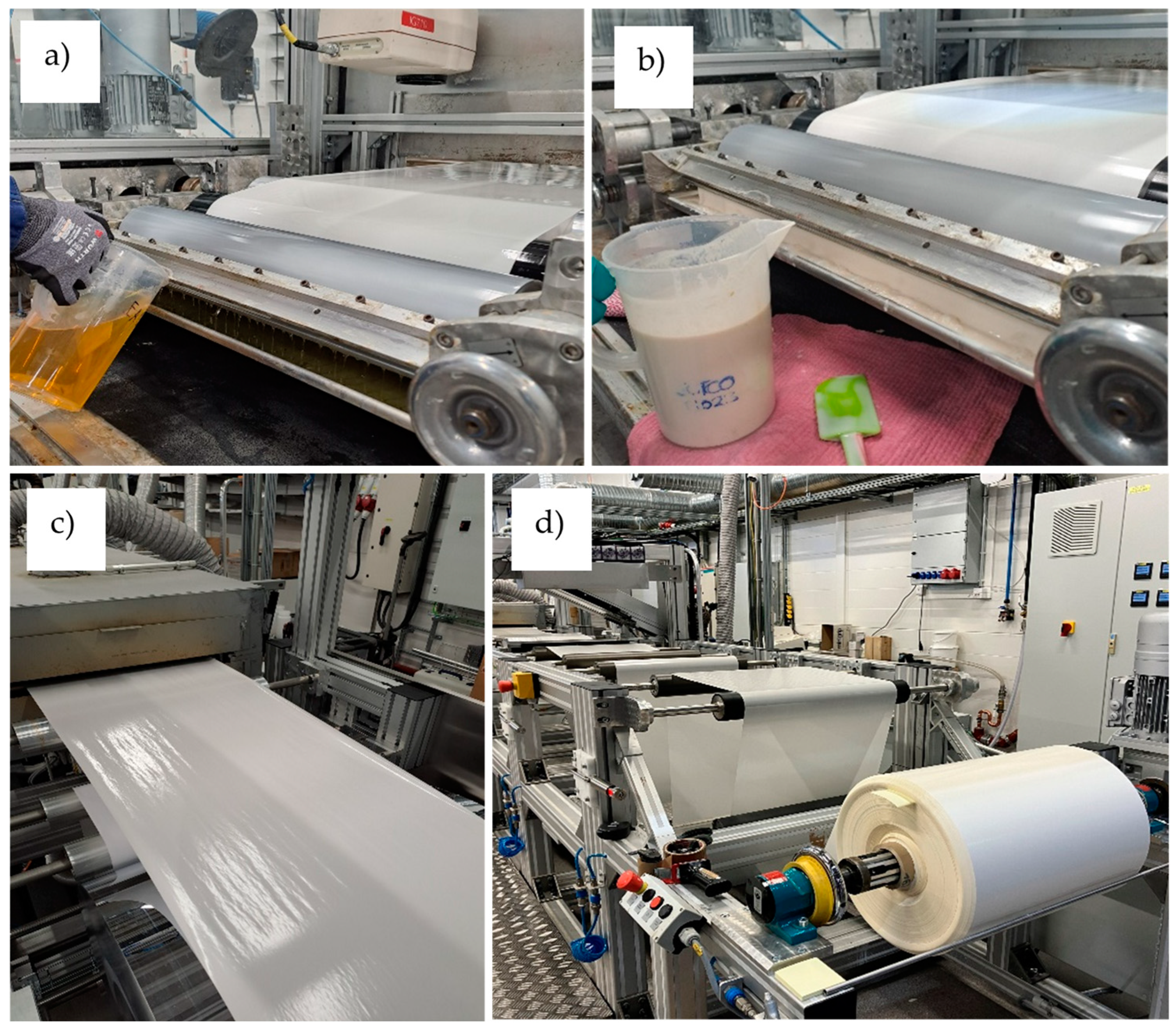

3.1. Coating Process

3.2. Coat Weights and Coating Thicknesses

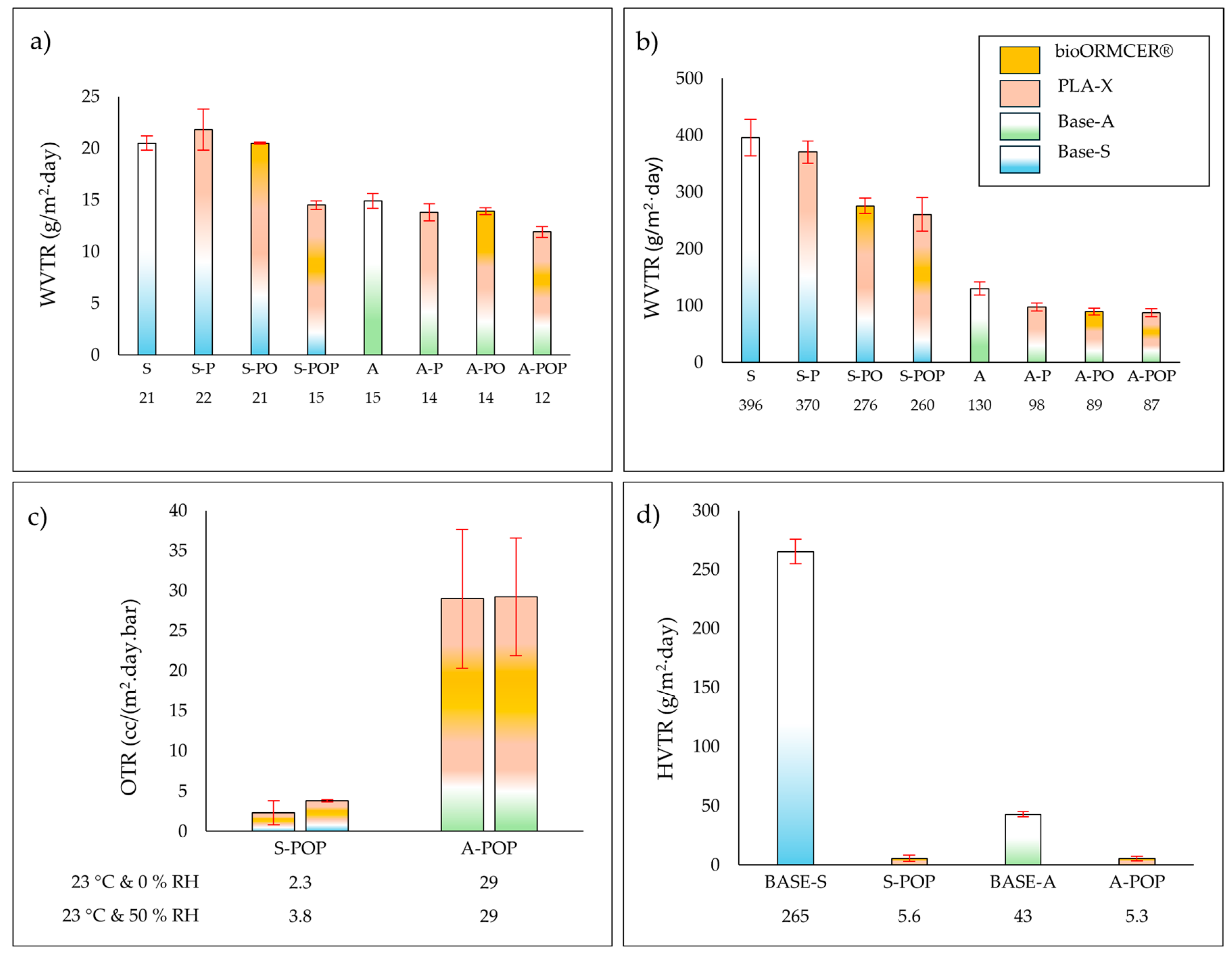

3.3. Barrier Properties

3.4. Heat Sealability

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Bayer, I.S. Biopolymers in multilayer films for long-lasting protective food packaging: A review. In Sustainable Food Packaging Technology; Wiley-VCH: Weinheim, Germany, 2021; pp. 395–426. [Google Scholar]

- Butler, T.I.; Morris, B.A. PE-based multilayer film structures. In Multilayer Flexible Packaging; Elsevier: Amsterdam, The Netherlands, 2016; pp. 281–310. [Google Scholar]

- Schmid, M. Whey protein-based coatings as sustainable barrier material in food packaging applications. In Proceedings of the 18th IAPRI World Packaging Conference, San Luis Obispo, CA, USA, 17–21 June 2012; pp. 279–286. [Google Scholar]

- Viacava, G.E.; Ansorena, M.R.; Marcovich, N.E. Multilayered films for food packaging. In Nanostructured Materials for Food Packaging Applications; Elsevier: Amsterdam, The Netherlands, 2024; pp. 447–475. [Google Scholar]

- Wagner, J.R., Jr. Multilayer Flexible Packaging; William Andrew: Napa, CA, USA, 2016. [Google Scholar]

- Bauer, A.-S.; Tacker, M.; Uysal-Unalan, I.; Cruz, R.M.; Varzakas, T.; Krauter, V. Recyclability and redesign challenges in multilayer flexible food packaging—A review. Foods 2021, 10, 2702. [Google Scholar] [CrossRef]

- de Mello Soares, C.T.; Ek, M.; Östmark, E.; Gällstedt, M.; Karlsson, S. Recycling of multi-material multilayer plastic packaging: Current trends and future scenarios. Resour. Conserv. Recycl. 2022, 176, 105905. [Google Scholar] [CrossRef]

- Seier, M.; Archodoulaki, V.-M.; Koch, T. The morphology and properties of recycled plastics made from multi-layered packages and the consequences for the circular economy. Resour. Conserv. Recycl. 2024, 202, 107388. [Google Scholar] [CrossRef]

- Diop, C.I.K.; Lavoie, J.-M.; Huneault, M.A. Separation and reuse of multilayer food packaging in cellulose reinforced polyethylene composites. Waste Biomass Valorization 2017, 8, 85–93. [Google Scholar] [CrossRef]

- Fávaro, S.; Freitas, A.; Ganzerli, T.; Pereira, A.; Cardozo, A.; Baron, O.; Muniz, E.; Girotto, E.; Radovanovic, E. PET and aluminum recycling from multilayer food packaging using supercritical ethanol. J. Supercrit. Fluids 2013, 75, 138–143. [Google Scholar] [CrossRef]

- Pal, S.K.; Prabhudesai, V.S.; Vinu, R. Catalytic upcycling of post-consumer multilayered plastic packaging wastes for the selective production of monoaromatic hydrocarbons. J. Environ. Manag. 2024, 351, 119630. [Google Scholar] [CrossRef] [PubMed]

- Pierri, E.; Egle, L.; Gaudillat, P.; Gallo, F.; Manfredi, S.; Saveyn, H. Technical Recommendations on Packaging Categories to Support the Design for Recycling Assessment of the Packaging and Packaging Waste Regulation Proposal; Publications Office of the European Union: Luxembourg, 2024. [Google Scholar]

- European Commission. Single-Use Plastics: New EU Rules to Reduce Marine Litter; European Commission: Brussels, Belgium, 2018. [Google Scholar]

- European Commission. European Green Deal: Putting an End to Wasteful Packaging, Boosting Reuse and Recycling; European Commission: Brussels, Belgium, 2022. [Google Scholar]

- Ali, A.; Bairagi, S.; Ganie, S.A.; Ahmed, S. Polysaccharides and proteins based bionanocomposites as smart packaging materials: From fabrication to food packaging applications a review. Int. J. Biol. Macromol. 2023, 252, 126534. [Google Scholar] [CrossRef] [PubMed]

- Patil, A.S.; Nille, O.S.; Kolekar, G.B.; Sohn, D.; Gore, A.H. UV-shielding biopolymer@ nanocomposites for sustainable packaging applications. In Sustainable Packaging; Springer: Singapore, 2021; pp. 177–202. [Google Scholar]

- Perera, K.Y.; Jaiswal, A.K.; Jaiswal, S. Biopolymer-based sustainable food packaging materials: Challenges, solutions, and applications. Foods 2023, 12, 2422. [Google Scholar] [CrossRef]

- Rhim, J.-W.; Park, H.-M.; Ha, C.-S. Bio-nanocomposites for food packaging applications. Prog. Polym. Sci. 2013, 38, 1629–1652. [Google Scholar] [CrossRef]

- Soulestin, J.; Prashantha, K.; Lacrampe, M.; Krawczak, P. Bioplastics based nanocomposites for packaging applications. In Handbook of Bioplastics and Biocomposites Engineering Applications; John Wiley & Sons: Hoboken, NJ, USA, 2011; Volume 24, p. 77. [Google Scholar]

- Tabassum, Z.; Mohan, A.; Girdhar, M. A comprehensive review on chitosan based bionanocomposites: Enormous potential for biodegradable food packaging applications of future. AIP Conf. Proc. 2024, 2986, 030044. [Google Scholar]

- Lahti, J.; Tuominen, M. The effects of corona and flame treatment: Part 1. PE-LD coated packaging board. In Proceedings of the 11th TAPPI Europlace Conference, Athens, Greece, 14–16 May 2007. [Google Scholar]

- Ilyas, R.; Sapuan, S.; Kadier, A.; Kalil, M.S.; Ibrahim, R.; Atikah, M.; Nurazzi, N.M.; Nazrin, A.; Lee, C.; Norrrahim, M.N.F. Properties and characterization of PLA, PHA, and other types of biopolymer composites. In Advanced Processing, Properties, and Applications of Starch and Other Bio-Based Polymers; Elsevier: Amsterdam, The Netherlands, 2020; pp. 111–138. [Google Scholar]

- Lee, C.; Sapuan, S.; Ilyas, R.; Lee, S.; Khalina, A. Development and processing of PLA, PHA, and other biopolymers. In Advanced Processing, Properties, and Applications of Starch and Other Bio-Based Polymers; Elsevier: Amsterdam, The Netherlands, 2020; pp. 47–63. [Google Scholar]

- Kendel, F.; De Morton, P.; Kugge, C.; Vanderhoek, N.; Garnier, G. Effect of pre-coat and substrate porosity on conventional barrier coatings performance. In Proceedings of the 62nd Appita Annual Conference and Exhibition, Rotorua, New Zealand, 20–23 April 2008; Conference Technical Papers. pp. 229–232. [Google Scholar]

- Larsson, T.; Emilsson, P. Impact of Cupstock coated with multilayer WBBC’s process & product performance. In Proceedings of the TAPPICon LIVE 2021, Atlanta, GA, USA, 3–6 October 2021; pp. 122–134. [Google Scholar]

- Marinelli, A.; Diamanti, M.V.; Pedeferri, M.; Del Curto, B. Kaolin-filled styrene-butadiene-based dispersion coatings for paper-based packaging: Effect on water, moisture, and grease barrier properties. Coatings 2023, 13, 195. [Google Scholar] [CrossRef]

- Kunam, P.K.; Ramakanth, D.; Akhila, K.; Gaikwad, K.K. Bio-based materials for barrier coatings on paper packaging. Biomass Convers. Biorefinery 2024, 14, 12637–12652. [Google Scholar] [CrossRef] [PubMed]

- Sundar, N.; Kumar, A.; Pavithra, A.; Ghosh, S. Studies on semi-crystalline poly lactic acid (PLA) as a hydrophobic coating material on kraft paper for imparting barrier properties in coated abrasive applications. Prog. Org. Coat. 2020, 145, 105682. [Google Scholar]

- Abdenour, C.; Eesaee, M.; Stuppa, C.; Chabot, B.; Barnabé, S.; Bley, J.; Tolnai, B.; Guy, N.; Nguyen-Tri, P. Water vapor and air barrier performance of sustainable paper coatings based on PLA and xanthan gum. Mater. Today Commun. 2023, 36, 106626. [Google Scholar] [CrossRef]

- Belletti, G.; Buoso, S.; Ricci, L.; Guillem-Ortiz, A.; Aragón-Gutiérrez, A.; Bortolini, O.; Bertoldo, M. Preparations of poly (lactic acid) dispersions in water for coating applications. Polymers 2021, 13, 2767. [Google Scholar] [CrossRef] [PubMed]

- Vähä-Nissi, M.; Laine, C.; Talja, R.; Mikkonen, H.; Hyvärinen, S.; Harlin, A. Aqueous dispersions from biodegradable/renewable polymers. In Proceedings of the TAPPI PLACE 2010 Conference, Albuquerque, NM, USA, 18–21 April 2010; pp. 18–21. [Google Scholar]

- Mehtiö, T.; Anghelescu-Hakala, A.; Hartman, J.; Kunnari, V.; Harlin, A. Crosslinkable poly(lactic acid)-based materials: Biomass-derived solution for barrier coatings. J. Appl. Polym. Sci. 2017, 134, 44326. [Google Scholar] [CrossRef]

- Li, C.; Jiang, T.; Wang, J.; Peng, S.; Wu, H.; Shen, J.; Guo, S.; Zhang, X.; Harkin-Jones, E. Enhancing the oxygen-barrier properties of polylactide by tailoring the arrangement of crystalline lamellae. ACS Sustain. Chem. Eng. 2018, 6, 6247–6255. [Google Scholar] [CrossRef]

- Koppolu, R.; Lahti, J.; Abitbol, T.; Swerin, A.; Kuusipalo, J.; Toivakka, M. Continuous processing of nanocellulose and polylactic acid into multilayer barrier coatings. ACS Appl. Mater. Interfaces 2019, 11, 11920–11927. [Google Scholar] [CrossRef] [PubMed]

- Koppolu, R.; Toivakka, M. High-throughput processing of nanocelluloses into biodegradable barrier coatings. In Proceedings of the 17th Fundamental Research Symposium, Cambridge, UK, 29 August–1 September 2022. [Google Scholar]

- Koppolu, R. High-Throughput Processing of Nanocelluloses into Barrier Coatings: A Focus on Nanocellulose Rheology and Multilayer Barrier Properties. 2024. Available online: https://www.doria.fi/bitstream/handle/10024/188696/koppolu_rajesh.pdf?sequence=1&isAllowed=y (accessed on 7 February 2025).

- Rocca-Smith, J.R.; Pasquarelli, R.; Lagorce-Tachon, A.; Rousseau, J.; Fontaine, S.; Aguié-Béghin, V.; Debeaufort, F.; Karbowiak, T. Toward sustainable PLA-based multilayer complexes with improved barrier properties. ACS Sustain. Chem. Eng. 2019, 7, 3759–3771. [Google Scholar] [CrossRef]

- Scarfato, P.; Di Maio, L.; Milana, M.R.; Giamberardini, S.; Denaro, M.; Incarnato, L. Performance properties, lactic acid specific migration and swelling by simulant of biodegradable poly (lactic acid)/nanoclay multilayer films for food packaging. Food Addit. Contam. Part A 2017, 34, 1730–1742. [Google Scholar] [CrossRef]

- Haas, K.-H.; Wolter, H. Synthesis, properties and applications of inorganic–organic copolymers (ORMOCER® s). Curr. Opin. Solid State Mater. Sci. 1999, 4, 571–580. [Google Scholar] [CrossRef]

- Amberg-Schwab, S.; Hoffmann, M.; Bader, H.; Gessler, M. Inorganic-organic polymers with barrier properties for water vapor, oxygen and flavors. J. Sol-Gel Sci. Technol. 1998, 13, 141–146. [Google Scholar] [CrossRef]

- Charton, C.; Schiller, N.; Fahland, M.; Holländer, A.; Wedel, A.; Noller, K. Development of high barrier films on flexible polymer substrates. Thin Solid Film. 2006, 502, 99–103. [Google Scholar] [CrossRef]

- Iotti, M.; Fabbri, P.; Messori, M.; Pilati, F.; Fava, P. Organic–inorganic hybrid coatings for the modification of barrier properties of poly (lactic acid) films for food packaging applications. J. Polym. Environ. 2009, 17, 10–19. [Google Scholar] [CrossRef]

- Solberg, A.; Zehner, J.; Somorowsky, F.; Rose, K.; Korpela, A.; Syverud, K. Material properties and water resistance of inorganic–organic polymer coated cellulose paper and nanopaper. Cellulose 2023, 30, 1205–1223. [Google Scholar] [CrossRef]

- Emmert, K.; Amberg-Schwab, S.; Braca, F.; Bazzichi, A.; Cecchi, A.; Somorowsky, F. bioORMOCER®—Compostable Functional Barrier Coatings for Food Packaging. Polymers 2021, 13, 1257. [Google Scholar] [CrossRef] [PubMed]

- Luo, Y.; Lin, Z.; Guo, G. Biodegradation assessment of poly (lactic acid) filled with functionalized titania nanoparticles (PLA/TiO2) under compost conditions. Nanoscale Res. Lett. 2019, 14, 56. [Google Scholar] [CrossRef]

- Miettinen, P.; Auvinen, S.; Kuusipalo, J.; Haakana, S. Validity of traditional barrier-testing methods to predict the achievable benefits of the new generation water based barrier coatings for packaging materials. In Proceedings of the PTS Coating Symposium, Munich, Germany, 16–17 September 2015; pp. 328–342. [Google Scholar]

- Kugge, C.; Johnson, B. Improved barrier properties of double dispersion coated liner. Prog. Org. Coat. 2008, 62, 430–435. [Google Scholar] [CrossRef]

- Lamminmäki, T.; Kettle, J.; Puukko, P.; Ridgway, C.; Gane, P. Short timescale inkjet ink component diffusion: An active part of the absorption mechanism into inkjet coatings. J. Colloid Interface Sci. 2012, 365, 222–235. [Google Scholar] [CrossRef]

- Schuster, J.; Cichos, F.; Von Borzcyskowski, C. Diffusion in ultrathin liquid films. Eur. Polym. J. 2004, 40, 993–999. [Google Scholar] [CrossRef]

- Chen, C.; Wang, L.; Es-haghi, S.S.; Tajvidi, M.; Wang, J.; Gardner, D.J. Biodegradable and recyclable bio-based laminated films of poly (lactic acid) and cellulose nanocrystals for food barrier packaging. Food Packag. Shelf Life 2024, 42, 101244. [Google Scholar] [CrossRef]

- Chinga-Carrasco, G.; Syverud, K. On the structure and oxygen transmission rate of biodegradable cellulose nanobarriers. Nanoscale Res. Lett. 2012, 7, 192. [Google Scholar] [CrossRef] [PubMed]

- Seong, J.-W.; Kim, S.-M.; Choi, D.; Yoon, K. Transparent oxygen impermeable AlOx thin films on polycarbonate deposited by reactive ion beam sputtering. Appl. Surf. Sci. 2005, 249, 60–64. [Google Scholar] [CrossRef]

- Struller, C.; Kelly, P.; Copeland, N.; Tobin, V.; Assender, H.; Holliday, C.; Read, S. Aluminium Oxide Barrier Layers and their Conversion for Packaging Applications. In Proceedings of the 58th Annual Technical Conference Proceedings, Society of Vacuum Coaters, Santa Clara, CA, USA, 25–30 April 2015; pp. 518–523. [Google Scholar]

- Koivula, H.M.; Jalkanen, L.; Saukkonen, E.; Ovaska, S.-S.; Lahti, J.; Christophliemk, H.; Mikkonen, K.S. Machine-coated starch-based dispersion coatings prevent mineral oil migration from paperboard. Prog. Org. Coat. 2016, 99, 173–181. [Google Scholar] [CrossRef]

- Gaudreault, R.; Brochu, C.; Sandrock, R.; Deglmann, P.; Seyffer, H.; Tétreault, A. Overview of practical and theoretical aspects of mineral oil contaminants in mill process and paperboard. In Proceedings of the 15th Fundamental Research Symposium, Cambridge, UK, 9–13 September 2013. [Google Scholar]

- Merabtene, M.; Tanninen, P.; Varis, J.; Leminen, V. Heat sealing evaluation and runnability issues of flexible paper materials in a vertical form fill seal packaging machine. BioResources 2022, 17, 223. [Google Scholar] [CrossRef]

- Merabtene, M.; Tanninen, P.; Wolf, J.; Kayatz, F.; Hauptmann, M.; Saukkonen, E.; Pesonen, A.; Laukala, T.; Varis, J.; Leminen, V. Heat-sealing and microscopic evaluation of paper-based coated materials using various seal bar geometries in vertical form fill seal machine. Packag. Technol. Sci. 2023, 36, 667–679. [Google Scholar] [CrossRef]

- Willberg-Keyriläinen, P.; Ropponen, J.; Alakomi, H.L.; Vartiainen, J. Cellulose fatty acid ester coated papers for stand-up pouch applications. J. Appl. Polym. Sci. 2018, 135, 46936. [Google Scholar] [CrossRef]

| Base Paper | 1st Layer | 2nd Layer | 3rd Layer | Abbreviation |

|---|---|---|---|---|

| Solide Lucent | PLAX | - | - | S-P |

| Solide Lucent | PLAX | bioORMOCER® | - | S-PO |

| Solide Lucent | PLAX | bioORMOCER® | PLAX | S-POP |

| Asendo | PLAX | - | - | A-P |

| Asendo | PLAX | bioORMOCER® | - | A-PO |

| Asendo | PLAX | bioORMOCER® | PLAX | A-POP |

| Sample | WVTR g/(m2∙Day) | OTR cc/(m2∙Day) |

|---|---|---|

| S-POP | 15 | 3.8 |

| A-POP | 12 | 29 |

| CNF | 220 | 4.8 |

| Chitosan | 1800 | 200 |

| LDPE | 16 | 25,000 |

| PET | 149 | 110 |

| PP | 60 | 11,000 |

| EVOH | 750 | 4.5 |

| Metallised PET | 0.35 | 1 |

| Sample | KIT Value | Max. Sealing Strength (N/25 mm) | Sample | KIT Value | Max. Sealing Strength (N/25 mm) |

|---|---|---|---|---|---|

| BASE-S | 1 | - | BASE-A | 12 | - |

| S-P | 12 | - | A-P | 12 | - |

| S-PO | 12 | - | A-PO | 12 | - |

| S-POP | 12 | 4.1 | A-POP | 12 | 7.5 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Nissinen, E.; Anghelescu-Hakala, A.; Hämäläinen, R.; Kivinen, P.; Somorowsky, F.; Avellan, J.; Koppolu, R. Upscaled Multilayer Dispersion Coating Application for Barrier Packaging: PLAX and bioORMOCER®. Coatings 2025, 15, 214. https://doi.org/10.3390/coatings15020214

Nissinen E, Anghelescu-Hakala A, Hämäläinen R, Kivinen P, Somorowsky F, Avellan J, Koppolu R. Upscaled Multilayer Dispersion Coating Application for Barrier Packaging: PLAX and bioORMOCER®. Coatings. 2025; 15(2):214. https://doi.org/10.3390/coatings15020214

Chicago/Turabian StyleNissinen, Eetu, Adina Anghelescu-Hakala, Roosa Hämäläinen, Pauliina Kivinen, Ferdinand Somorowsky, Jani Avellan, and Rajesh Koppolu. 2025. "Upscaled Multilayer Dispersion Coating Application for Barrier Packaging: PLAX and bioORMOCER®" Coatings 15, no. 2: 214. https://doi.org/10.3390/coatings15020214

APA StyleNissinen, E., Anghelescu-Hakala, A., Hämäläinen, R., Kivinen, P., Somorowsky, F., Avellan, J., & Koppolu, R. (2025). Upscaled Multilayer Dispersion Coating Application for Barrier Packaging: PLAX and bioORMOCER®. Coatings, 15(2), 214. https://doi.org/10.3390/coatings15020214