Impact of Sewing Needle Coating on Needle Heating

Abstract

1. Introduction

- Cooling the needle with forced air/vortex;

- Lubrication of thread (wax/oils);

- Surface coating of needle.

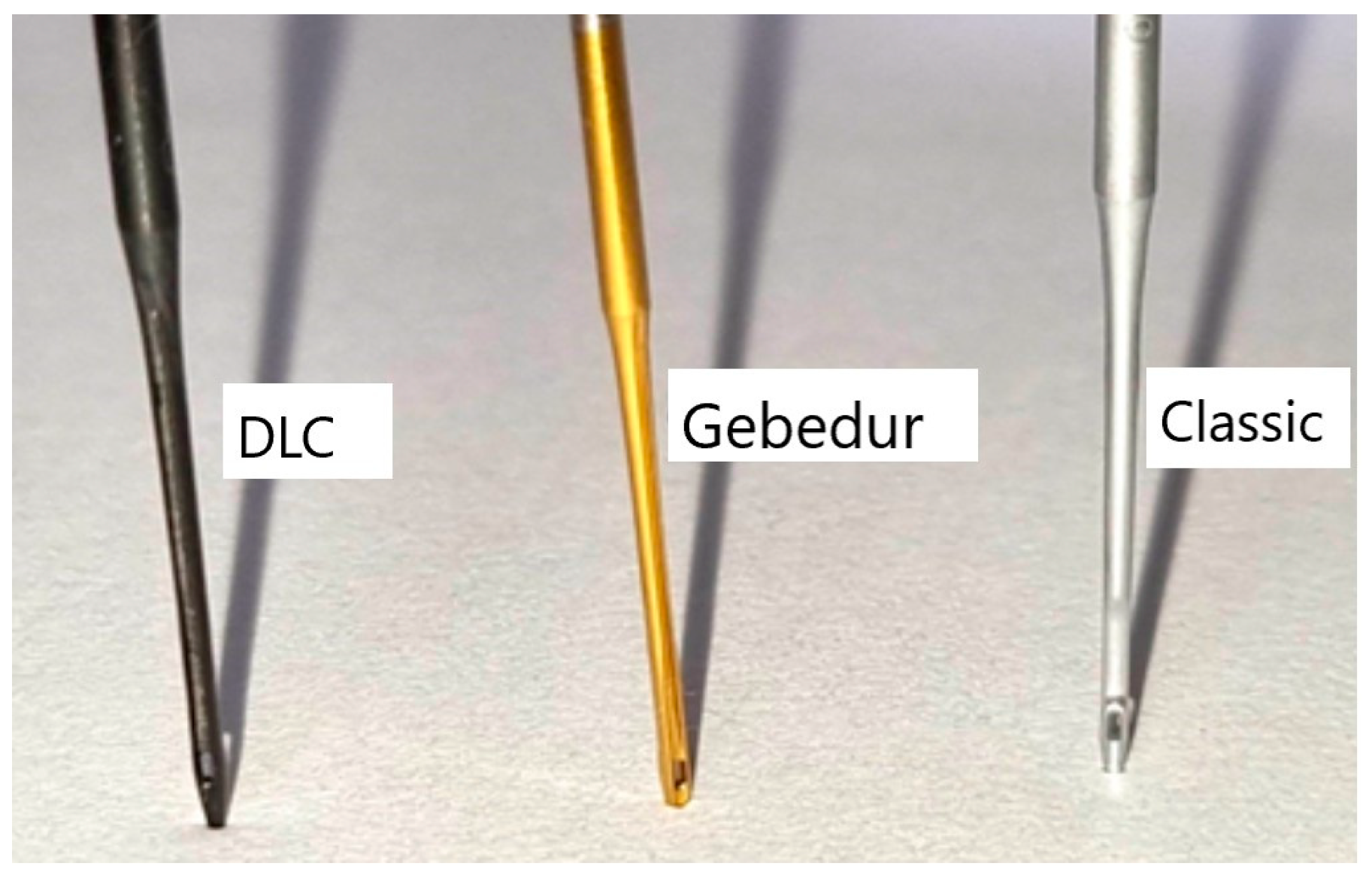

2. Experiments

- Atomic force microscopy (AFM)

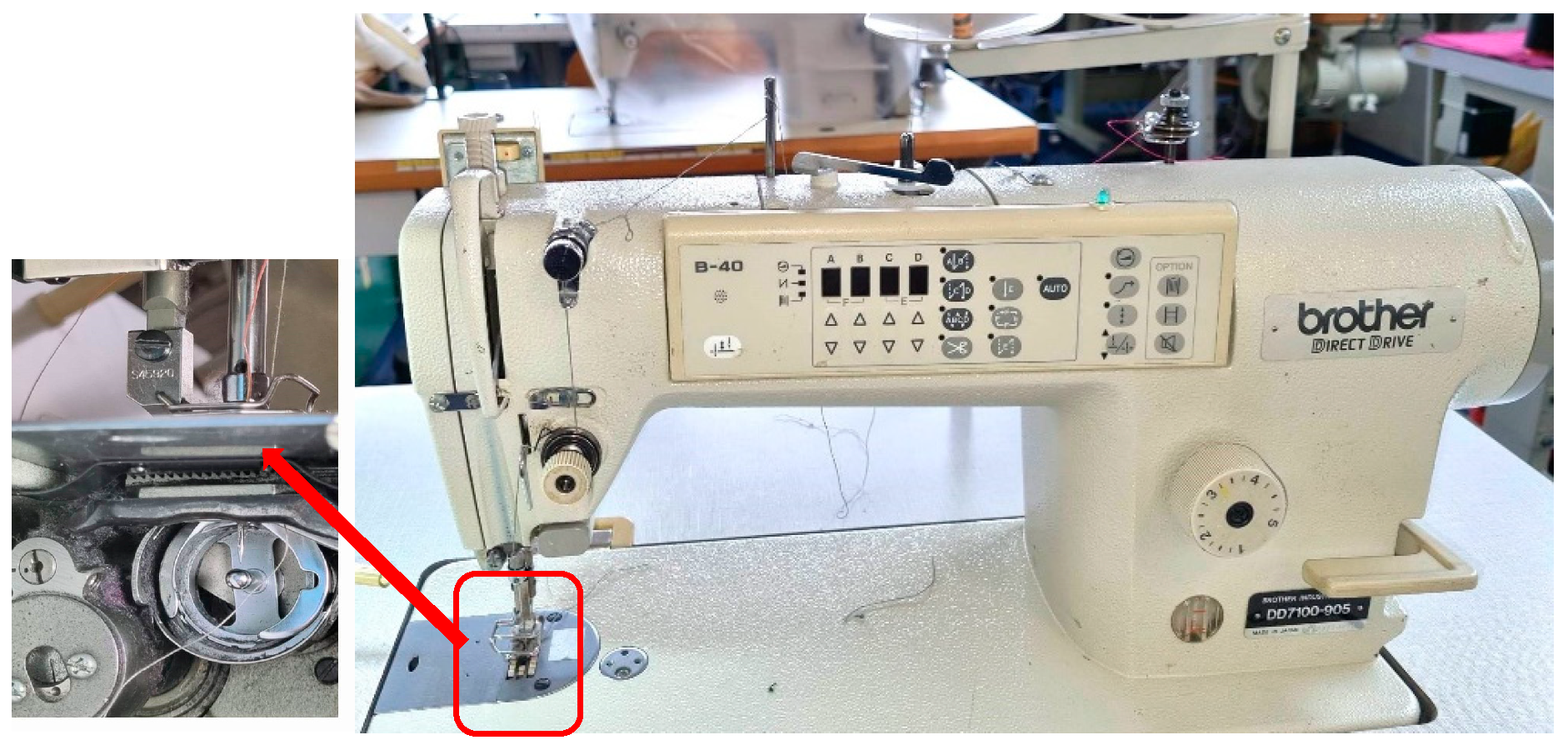

2.1. Needle Temperature Measurement

2.2. Tensile Properties Measurement

3. Results and Discussion

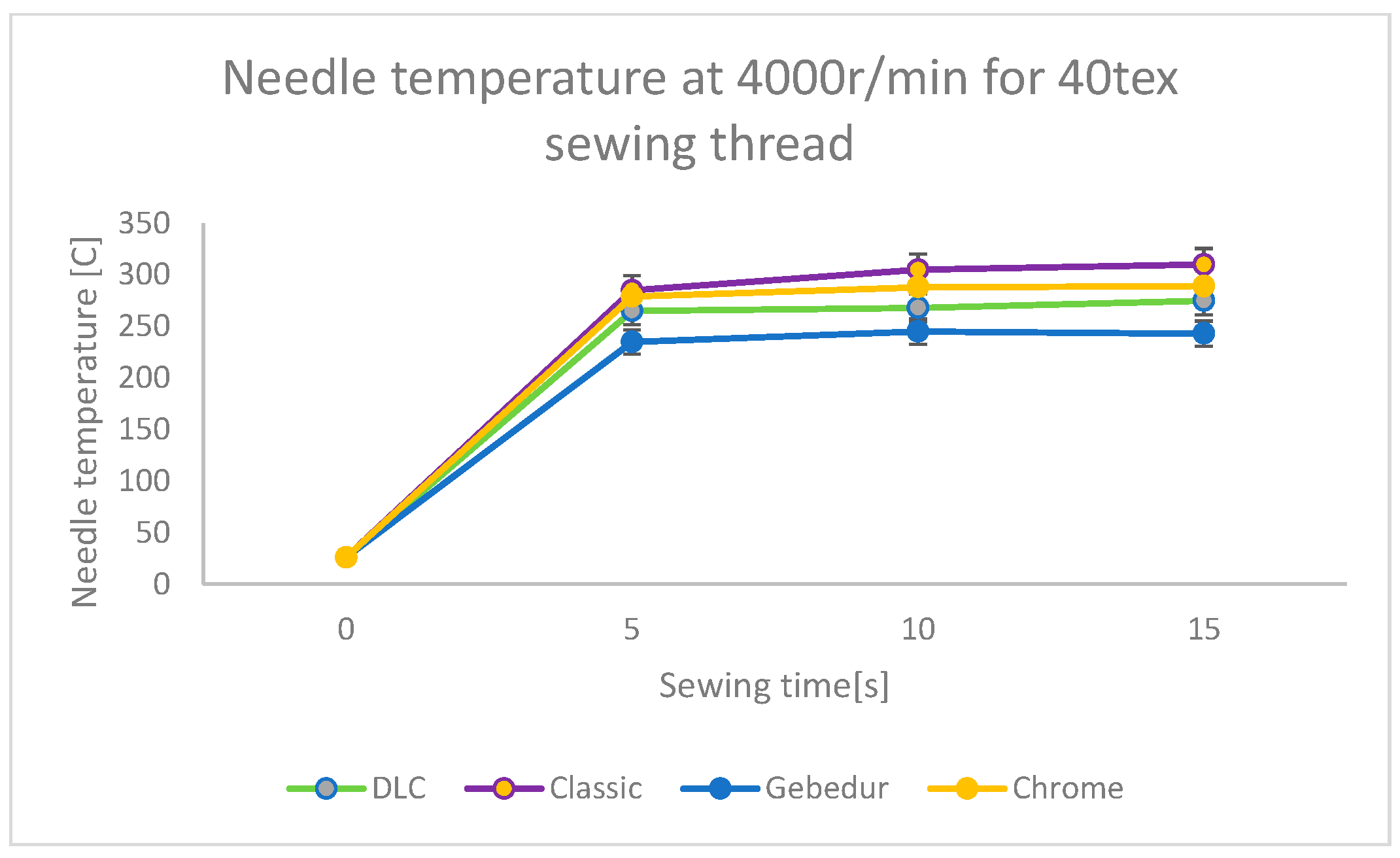

3.1. Sewing Needle Temperature

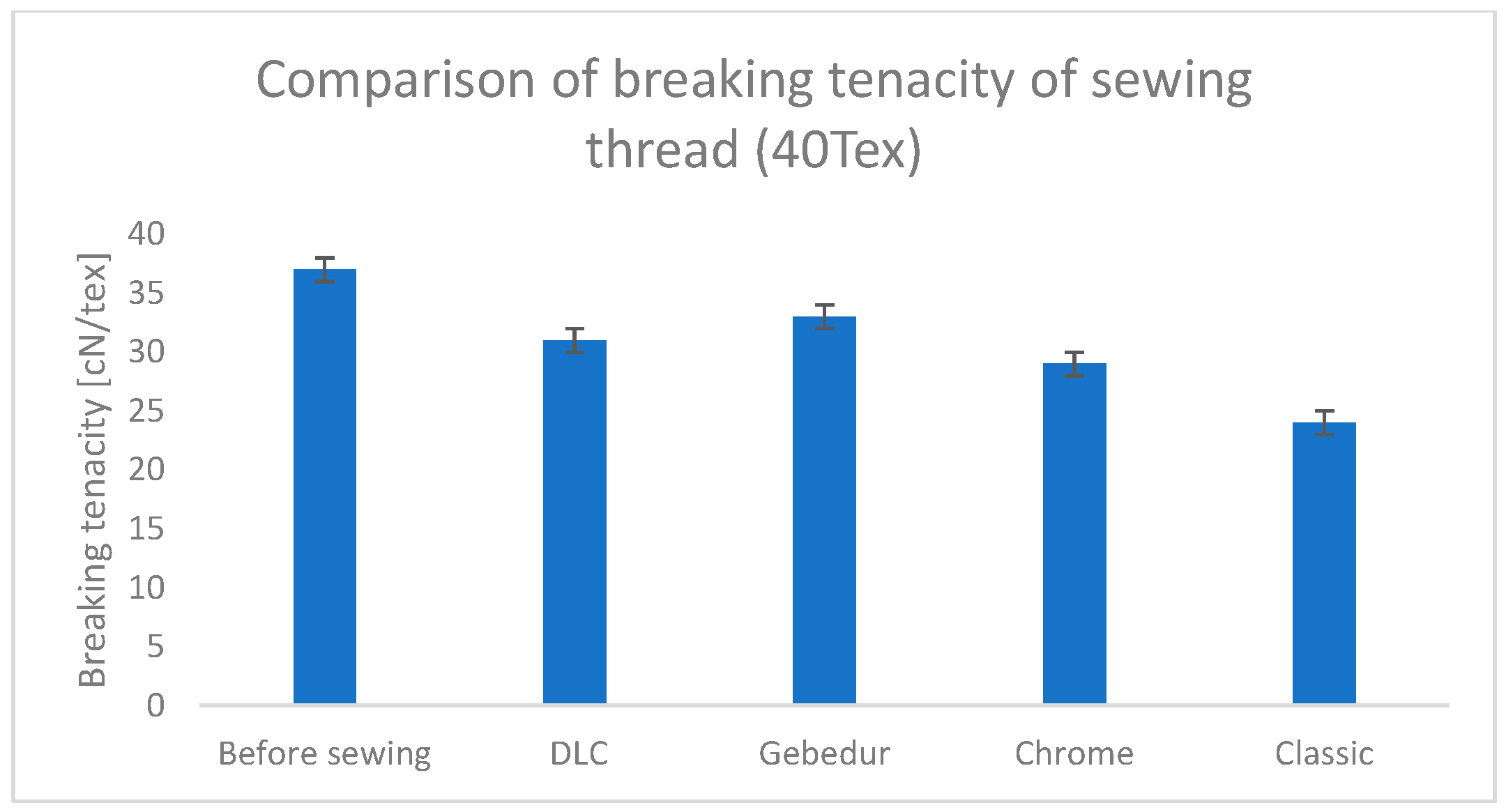

3.2. Comparison of Wear Test Until Breakage of Thread

3.3. Surface Properties of Needles

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Godley, A. Selling the sewing machine around the world: Singer’s international marketing strategies, 1850–1920. Enterp. Soc. 2006, 7, 266–314. [Google Scholar] [CrossRef]

- Midha, V.K.; Gupta, V.; Mukhopadhyay, A. Impact of Positive Thread Feeding for High-Speed Industrial Lockstitch Sewing Machines: Part II Response with Cotton and Spun Polyester Needle Threads. J. Inst. Eng. (India) Ser. E 2019, 100, 147–153. [Google Scholar] [CrossRef]

- Midha, V.K.; Suresh Kumar, S. Effect of seam angle on seam puckering in lightweight woven fabrics. J. Text. Inst. 2015, 106, 395–401. [Google Scholar] [CrossRef]

- Tiber, B.; Yilmaz, N. Investigation of the Effects of Elastic Sewing Thread on Seam Performance Properties of Stretch Denim Fabrics. Text. Appar. 2022, 32, 47–56. [Google Scholar] [CrossRef]

- Jucienė, M.; Vobolis, J. Influence of fabric external friction force and certain parameters of a sewing machine upon stitch length. PES 2004, 1, 100. [Google Scholar]

- Yıldız, E.Z.; Pamuk, O. The parameters affecting seam quality: A comprehensive review. Res. J. Text. Appar. 2021, 25, 309–329. [Google Scholar] [CrossRef]

- Ali, N.; Rehan, A.M.; Ahmed, Z.; Memon, H.; Hussain, A. Effect of different types of seam, stitch class and stitch density on seam performance. J. Appl. Emerg. Sci. 2016, 5, 32–43. [Google Scholar]

- İlleez, A.A.; Dalbaşı, E.S.; Kayseri, G.Ö. Improving of sewability properties of various knitted fabrics with the softeners. Procedia-Soc. Behav. Sci. 2015, 195, 2786–2795. [Google Scholar] [CrossRef]

- Bansal, P.; Sikka, M.; Choudhary, A.K. Optimization of parameters for needle cut index using TOPSIS method. Indian J. Fibre Text. Res. (IJFTR) 2021, 46, 319–324. [Google Scholar]

- Ork, N.; Mutlu, M.M.; Yildiz, E.Z.; Pamuk, O. Sewability properties of garment leathers tanned with various tanning materials. Ann. Univ. Oradea Fascicle Text. Leatherwork 2016, 17, 197–202. [Google Scholar]

- Bharani, M.; Shiyamaladevi, P.S.S.; Mahendra Gowda, R.V. Characterization of seam strength and seam slippage on cotton fabric with woven structures and finish. Res. J. Eng. Sci. 2012, 2278, 9472. [Google Scholar]

- Hayes, S.; Mcloughlin, J. The sewing of textiles. In Joining Textiles; Woodhead Publishing: Sawston, UK, 2013; pp. 62–122. [Google Scholar]

- De Jong, H.G. Yarn-to-yarn friction in relation to some properties of fiber materials. Text. Res. J. 1993, 63, 14–18. [Google Scholar] [CrossRef]

- Mazari, A.; Havelka, A.; Wiener, J.; Zbigniew, R. A study on DLC-coated industrial lockstitch sewing needle. Ind. Textila 2015, 66, 43–47. [Google Scholar]

- Vobolis, J.; Juciene, M.; Punys, J.; Vaitkevicius, V. Influence of selected machine and material parameters on the stitch length and its irregularity. Fibres Text. East. Eur. 2003, 11, 50–55. [Google Scholar]

- Rudolf, A.; Grešak, J. Influence of sewing speed on the changes of mechanical properties of differently twisted and lubricated threads during the process of sewing. Tekstil časopis za tekstilnu i odjevnu tehnologiju 2007, 56, 278–285. [Google Scholar]

- Rudolf, A.; Geršak, J. The effect of drawing on PET filament sewing thread performance properties. Text. Res. J. 2012, 82, 148–160. [Google Scholar] [CrossRef]

- Khanna, S. Interactions of sewing variables: Effect on the tensile properties of sewing threads during sewing process. J. Text. Appar. Technol. Manag. 2015, 9, 1–13. [Google Scholar]

- Prevorsek, D.C.; Lyons, W.J. Effect of Temperature and Draw Ratio on Force-Extension Properties of Twisted Fibers1. Text. Res. J. 1965, 35, 581–587. [Google Scholar] [CrossRef]

- Mazari, A. Study in Needle Heating. Ph.D. Thesis, Department of Clothing Technical University of Liberec, Liberec, Czechia, 2015. [Google Scholar]

- Gurada, A.; Yukseltan, E.; Kaplangiray, B.M.; Kanik, M. The effects of various lubricants on the friction properties of sewing threads. Text. Res. J. 2008, 83, 1273–1282. [Google Scholar] [CrossRef]

- Mazari, A.; Bal, K.; Havelka, A. Prediction of needle heating in an industrial sewing machine. Text. Res. J. 2016, 86, 302–310. [Google Scholar] [CrossRef]

- Lee, K.R.; Eun, K.Y.; Kim, I.; Kim, J. Design of W buffer layer for adhesion improvement of DLC films on tool steels. Thin Solid Film. 2000, 377, 261–268. [Google Scholar] [CrossRef]

- Li, K.Y.; Zhou, Z.F.; Chan, C.Y.; Bello, I.; Lee, C.S.; Lee, S.T. Mechanical and tribological properties of diamond-like carbon films prepared on steel by ECR-CVD process. Diam. Relat. Mater. 2001, 10, 1855–1861. [Google Scholar] [CrossRef]

- Cruz, R.; Rao, J.; Rose, T.; Lawson, K.; Nicholls, J.R. DLC—Ceramic multilayers for automotive applications, Diamond Relat. Materials 2006, 15, 2055–2060. [Google Scholar]

- Delfín, F.A.; Brühl, S.P.; Forsich, C.; Heim, D. Carbon based DLC films: Influence of the processing parameters on the structure and properties. Matéria 2018, 23. [Google Scholar] [CrossRef]

| Thread Type | Company Name/Product Name | Fineness [Tex] | Twist (t/m) | Twist Direction (ply/Single) | Coefficient of Friction µ |

|---|---|---|---|---|---|

| Polyester–polyester core spun | AMANN/Saba C-80 | 40 (20 × 2) | 660 (±12) | Z/S | 0.20 (±0.015) |

| Fabric Type | Weave | Weight | Ends/cm | Picks/cm | Fabric Thickness |

|---|---|---|---|---|---|

| 100%cotton Denim | 2/1 Twill | 257 g/m2 | 25 | 20 | 0.035 cm |

| - | Needle Without Coating | Chrome-Coated Needles (Groz Beckert) | Titanium Nitride-Coated Needle (Gebedur™, Groz Beckert) | DLC-Coated Needle |

|---|---|---|---|---|

| Frictional coefficient | 0.32 (±0.03) | 0.21 (±0.04) | 0.14 (±0.02) | 0.19 (±0.04) |

| Peak-to-valley roughness Rt | 3.95 µm | 3.86 µm | 3.59 µm | 3.72 µm |

| - | Classic Needle | Chrome-Coated Needle | Gebedur™ Needle | DLC-Coated Needle |

|---|---|---|---|---|

| Average roughness Ra | 113 nm | 98.6 nm | 21.2 nm | 48.3 nm |

| RMS roughness Rq | 137 nm | 78.3 nm | 28.5 nm | 57.6 nm |

| Peak-to-valley roughness Rt | 683 nm | 560 nm | 211 nm | 380 nm |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mazari, A.; Buyuk Mazari, F. Impact of Sewing Needle Coating on Needle Heating. Coatings 2025, 15, 485. https://doi.org/10.3390/coatings15040485

Mazari A, Buyuk Mazari F. Impact of Sewing Needle Coating on Needle Heating. Coatings. 2025; 15(4):485. https://doi.org/10.3390/coatings15040485

Chicago/Turabian StyleMazari, Adnan, and Funda Buyuk Mazari. 2025. "Impact of Sewing Needle Coating on Needle Heating" Coatings 15, no. 4: 485. https://doi.org/10.3390/coatings15040485

APA StyleMazari, A., & Buyuk Mazari, F. (2025). Impact of Sewing Needle Coating on Needle Heating. Coatings, 15(4), 485. https://doi.org/10.3390/coatings15040485