Characterization of Laser-Textured Surfaces of Parts of a Biodegradable Polymer

Abstract

1. Introduction

- -

- Poly(etheretherketone) (PEEK) has excellent mechanical properties (in some cases, even similar to cortical bone), high chemical resistance, and sterilization capacity. So far, the surface functionalization of PEEK by means of LST has been successfully achieved using laser wavelengths ranging from UV (355 nm) to middle infrared (MIR) (10.6 μm). PEEK was observed to respond very differently as a function of laser radiation. Laser radiation at 1064 nm burned the surface, while 532 nm laser radiation was able to ablate the material. Using this laser wavelength, grooves with a mean width of 100 μm were machined [30,31,32]. The 355 nm laser radiation only produced slight surface melting; however, this laser radiation was identified as the most suitable for biomedical purposes because it induced the formation of some polar groups. The main applications are in orthopedics (e.g., in joint replacement, cage implants, bone screws, and pins) [33,34,35].

- -

- Polypropylene (PP) has good biostability, good thermal stability, and appropriate mechanical properties. However, PP exhibits low surface energy, which hinders its systematic use in tissue replacement [36,37]. The effect of treatment under 1064, 532, and 355 nm laser wavelengths on the surface features of PP was evaluated [21]. A layer of carbon black was used to increase the original absorption features of this thermoplastic given its high transmittance for wavelengths ranging between 400 and 1600 nm [38]. The treated surfaces were characterized in terms of surface roughness (Ra), WCA, microhardness, and chemical composition. The LST of PP resulted in the melting of the surface, along with the adhesion of carbon particles to its surface. The final roughness (Ra) was found to be higher than 1 μm, which is considered the minimum required value to improve the bone/implant bonding degree [39]. To increase the wettability of polypropylene (PP), Murahara and Okoshi [40] utilized a different approach, irradiating the material with an ArF laser in the presence of tap water. This laser treatment significantly reduced the contact angle of the PP surface. The minimum contact angle achieved was 65° for the treated surfaces, compared to 93° for the untreated base material. This optimal wettability was observed at a laser fluence of 12.5 mJ/cm2 and a shot number of 10,000 [40].

- -

- Polyethylene (PE) is a synthetic thermoplastic polymer, bioinert, and non-biodegradable when in contact with body fluids. LST has been applied to this material given its inertness [41,42,43,44]. Okoshi and Inoue [42] studied the utilization of fs laser sources to ablate and modify the surface of PE samples. The LST of PE was performed with a fs Ti:sapphire laser source using 790 nm laser light, with second harmonics of 395 nm. Both wavelengths were found to successfully ablate PE surfaces [42,44]. The biological performance of PE laser-textured surfaces was evaluated after being subjected to Nd:YAG laser radiation (λ = 1064 nm) by Blanchemain et al. [43]. After laser irradiation, the surface roughness of PE was increased up to Ra = 0.2 μm [43]. Among the typical implant applications of this material, chin, cheek, and jaw reconstruction should be highlighted [41,42,43,44,45,46,47,48].

- -

- Polyimide (PI) was textured using different laser wavelengths (λ = 1064, 532, 355, and 266 nm) to avoid biofilm formation on indwelling medical devices. Several topographies were tested against Staphylococcus aureus adhesion [49].

2. Materials and Methods

2.1. Sample Preparation

2.2. Laser Surface Texturing (LST)

2.3. Microscopic Observation

2.4. Wettability Test

2.5. Wear Test

2.6. Degradation Test

- -

- Step I: Temperature decrease T↓ up to T = −5 °C, t = 1 h;

- -

- Step II: Aging: T = −5 °C, t = 3 h;

- -

- Step III: Temperature increase T↑ up to T = 50 °C, HD = 90%, t = 1 h;

- -

- Step IV: Aging, T = 50 °C, HD = 90%, t = 3 h.

2.7. DSC Analysis

2.8. Topography

3. Results and Discussion

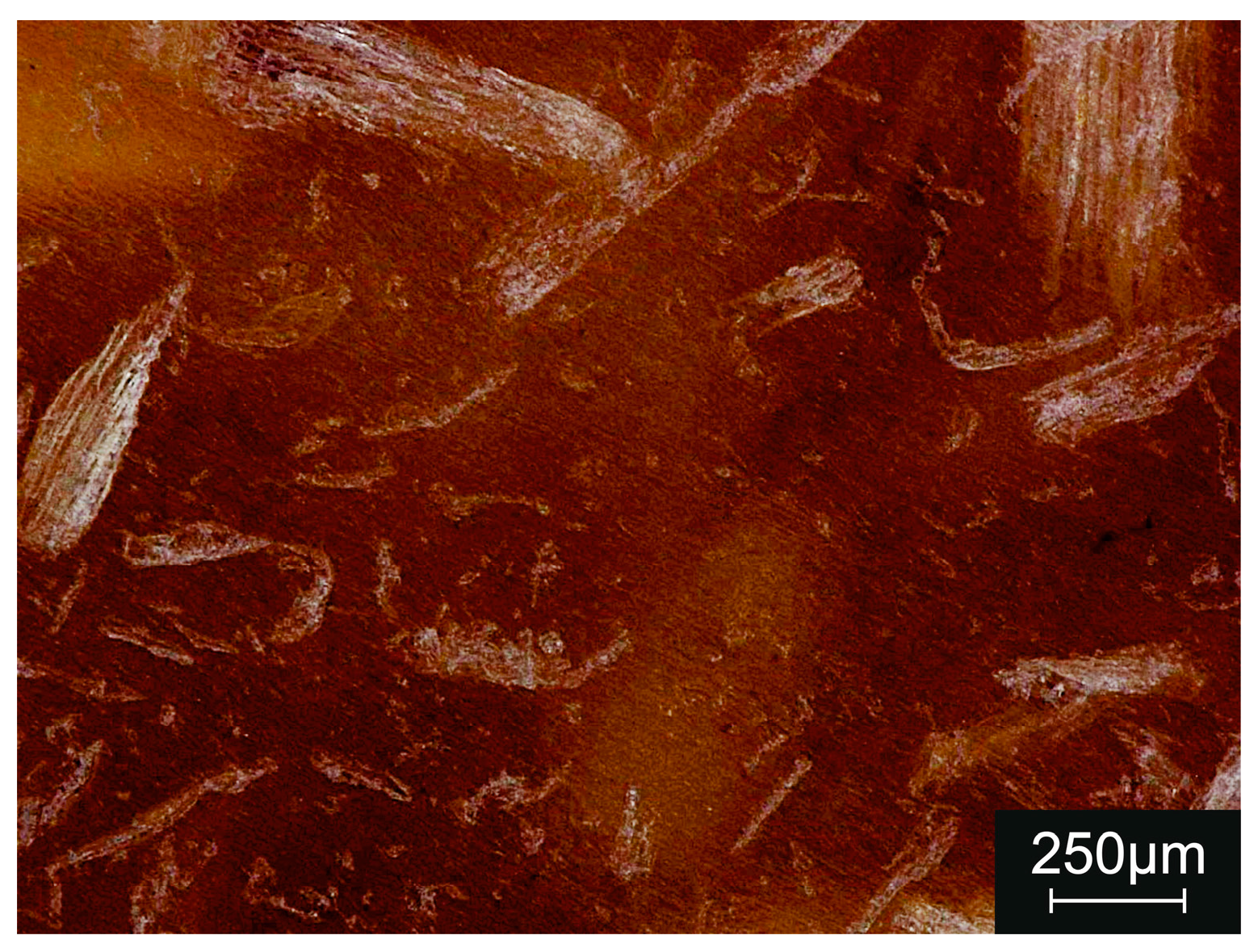

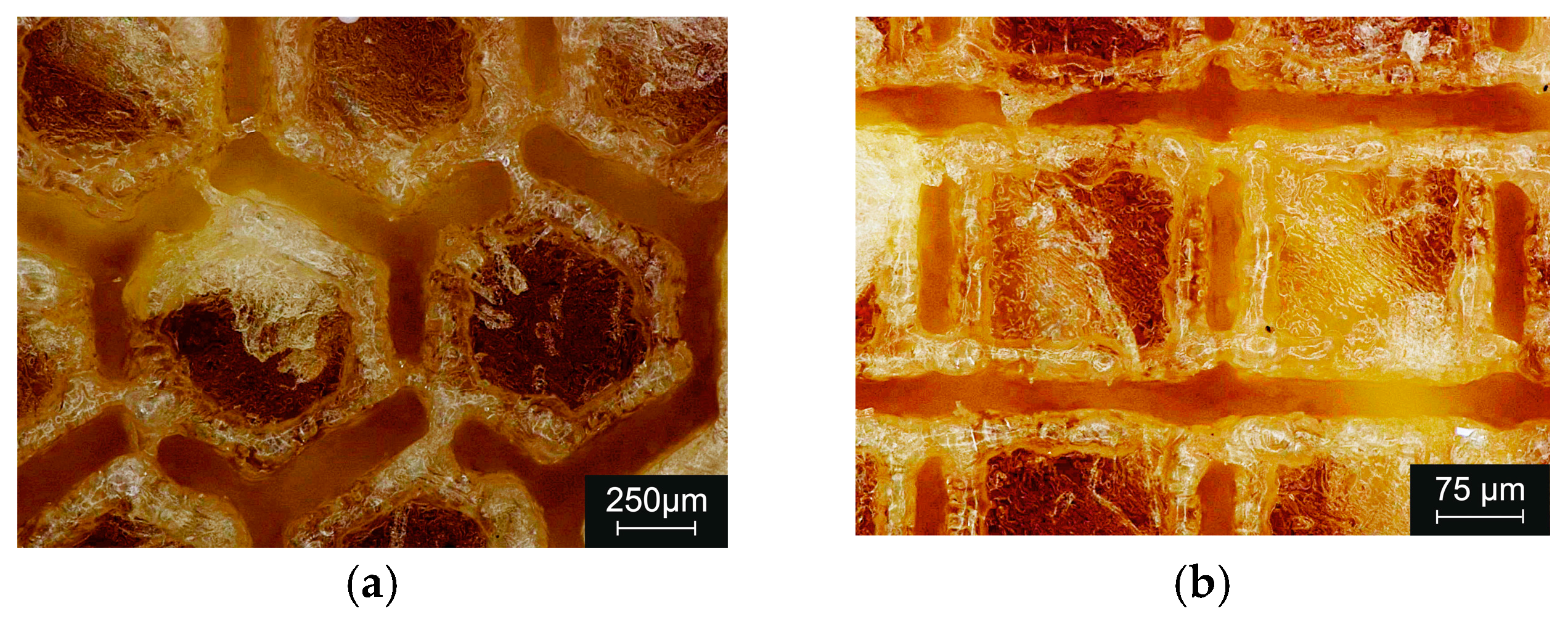

3.1. Microscopic Observation

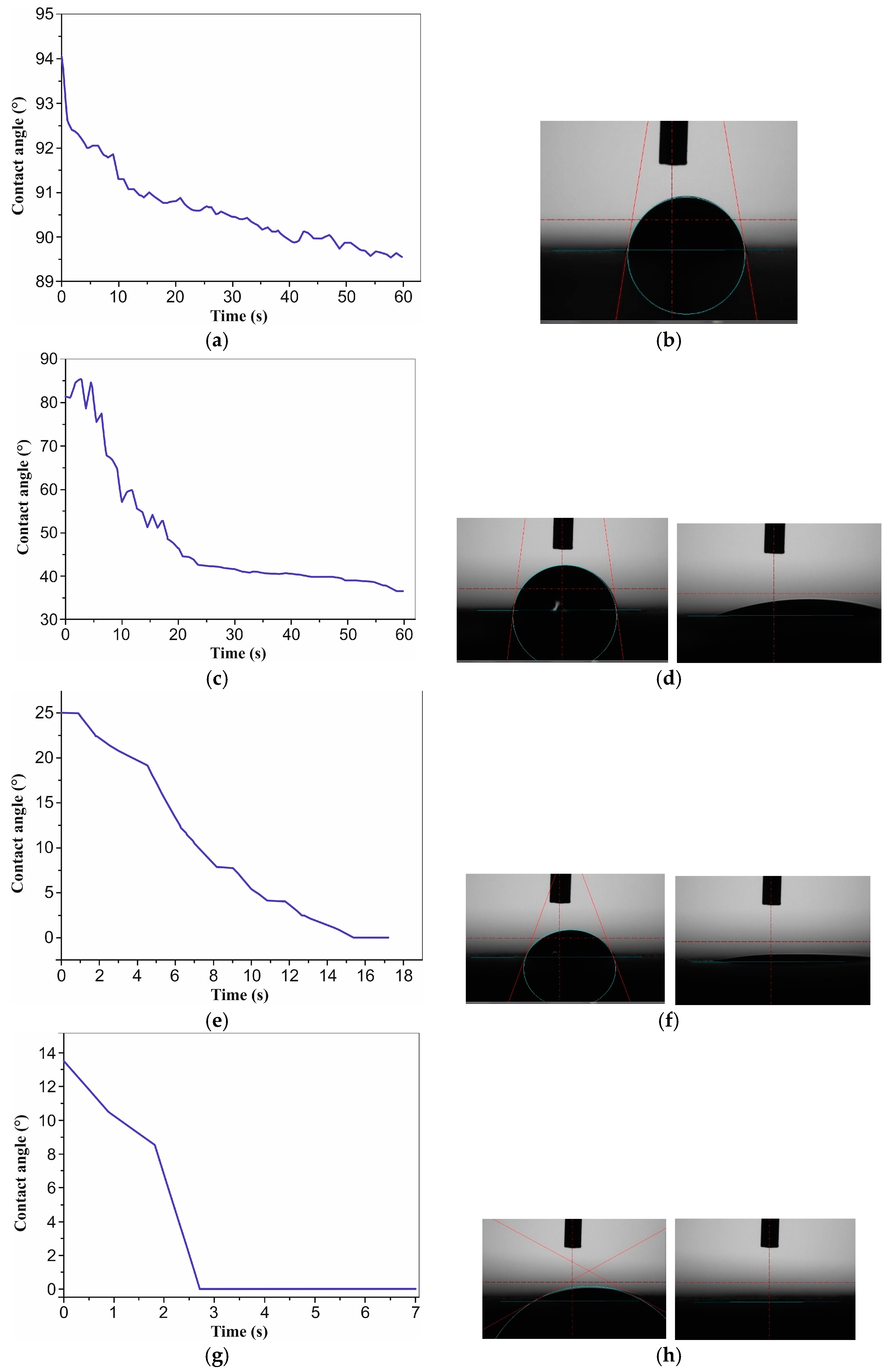

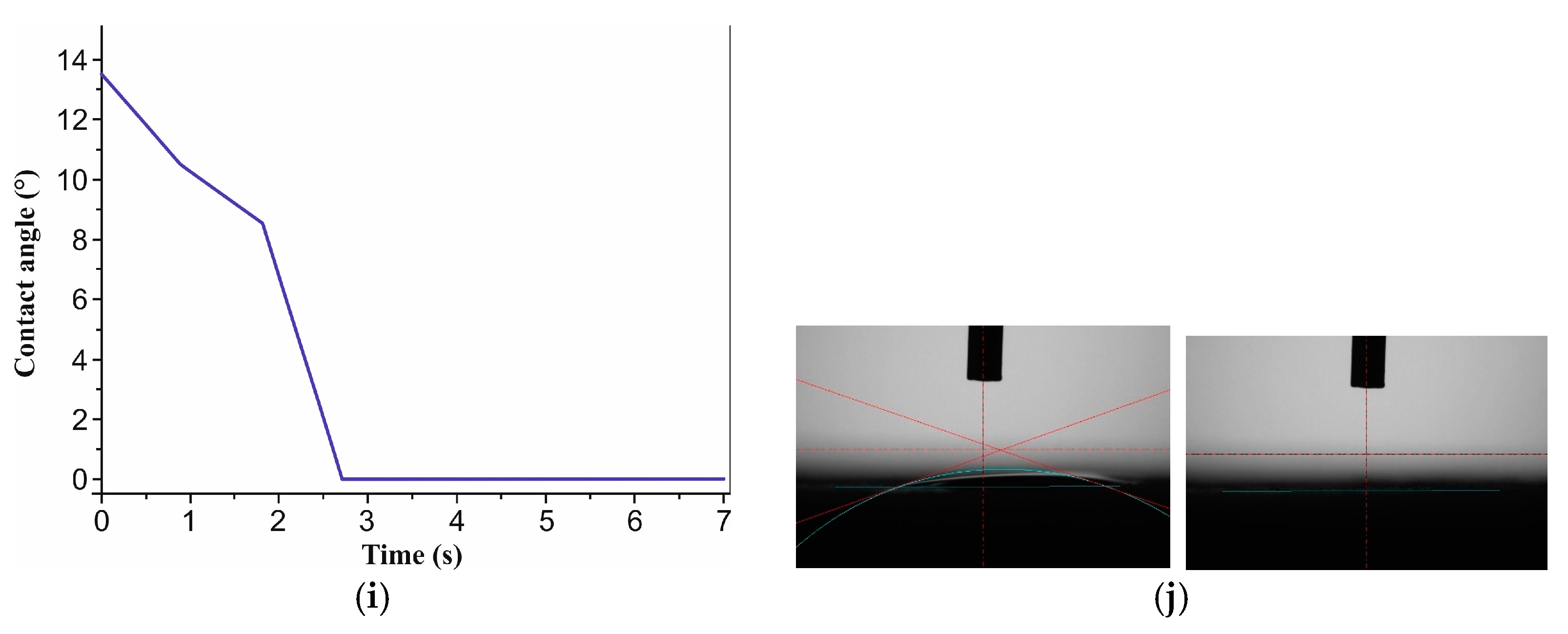

3.2. Wettability Test

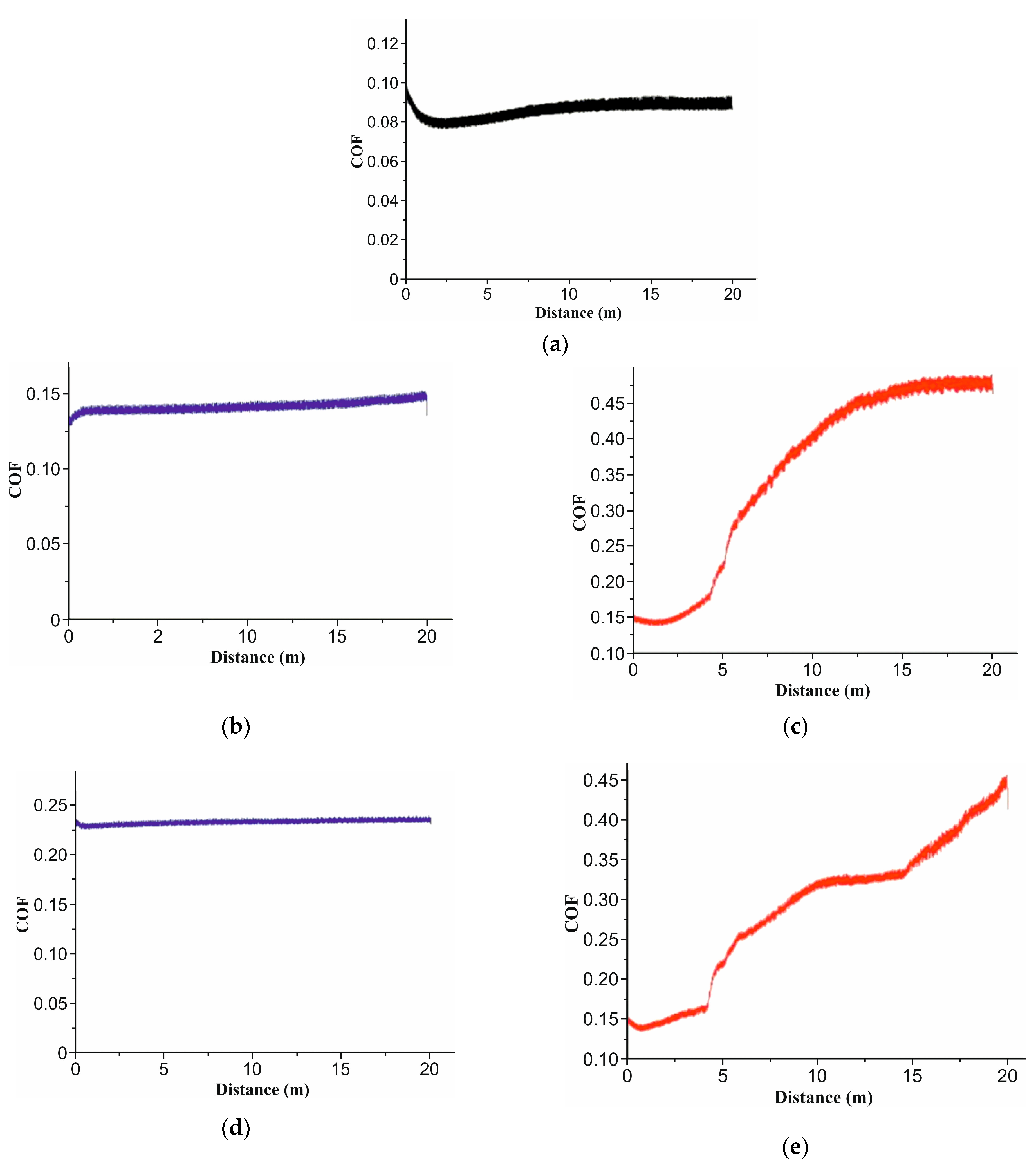

3.3. Wear Test

3.4. Degradation Test

3.5. DSC Analysis

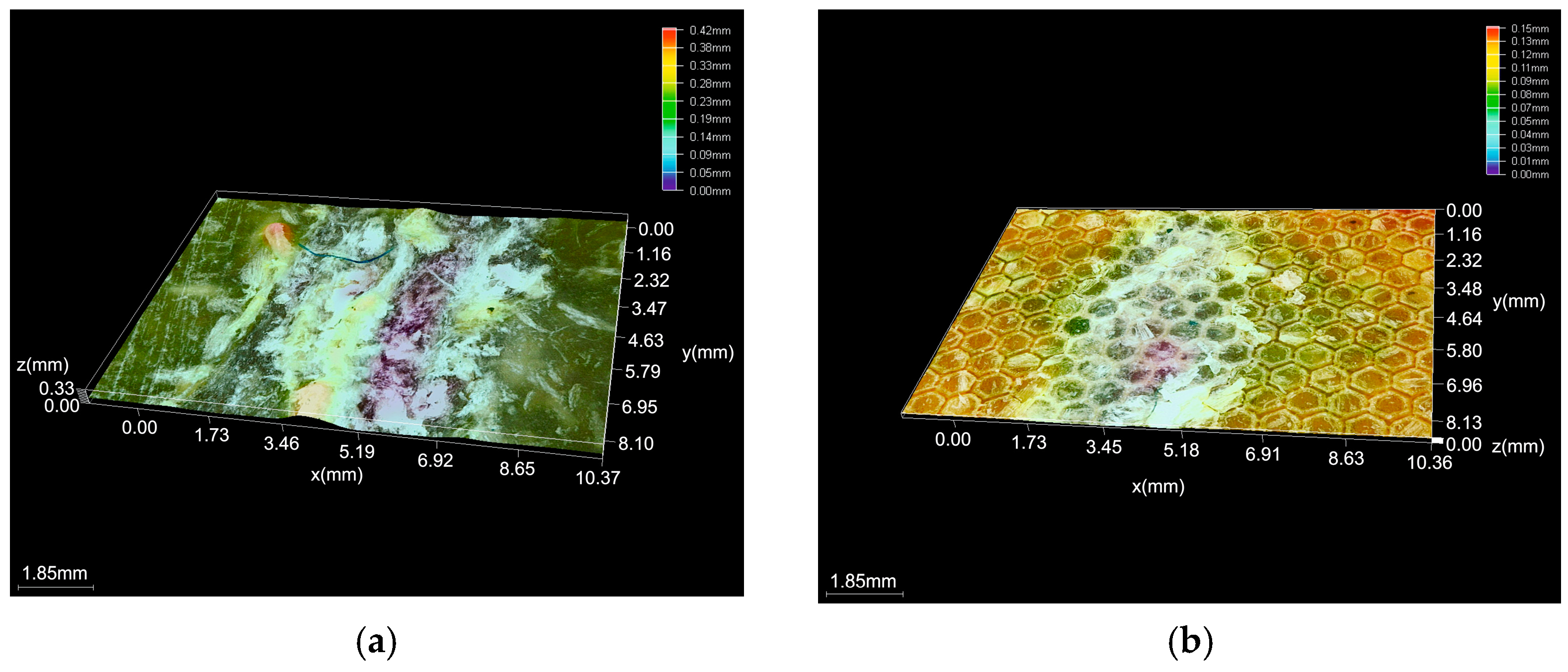

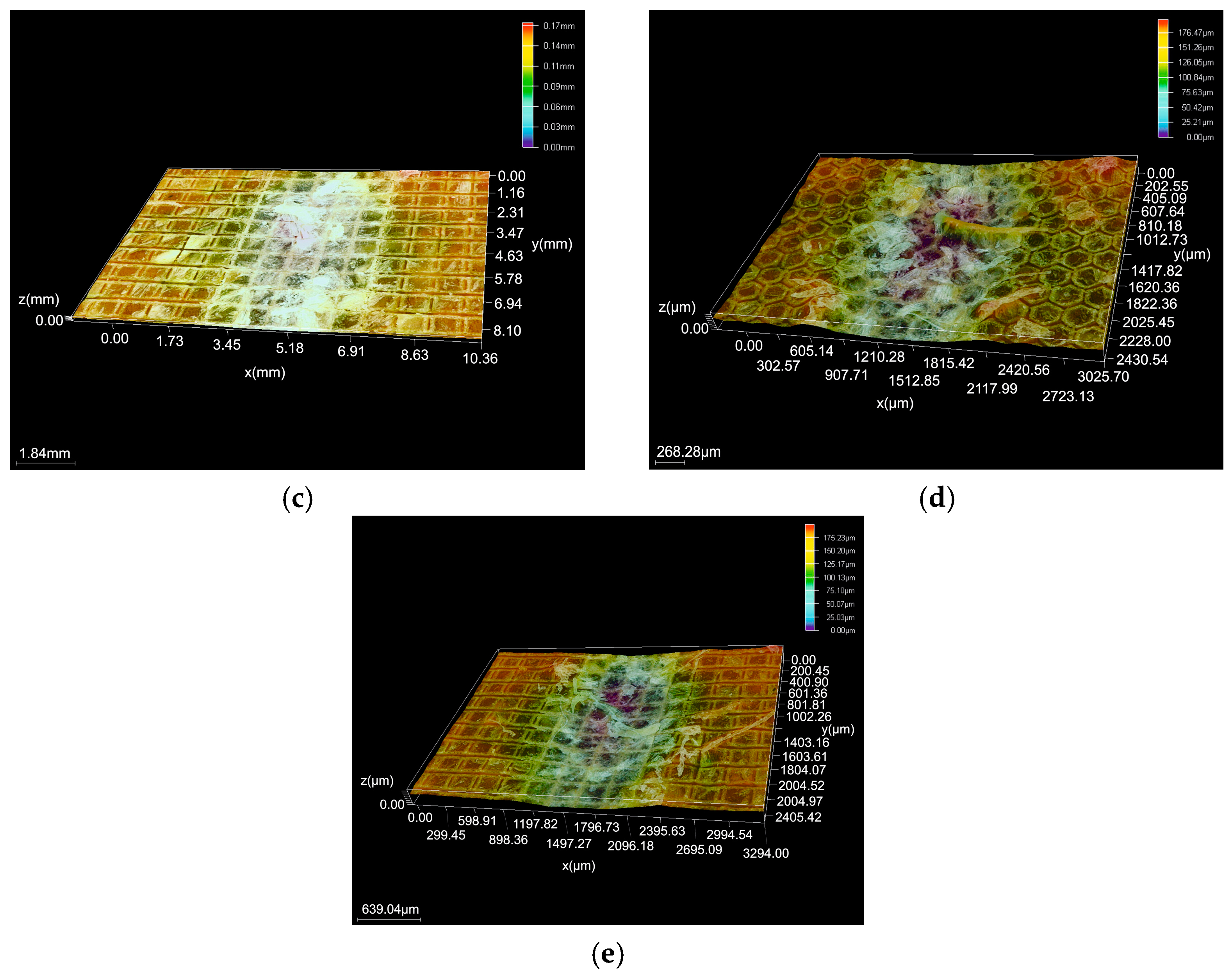

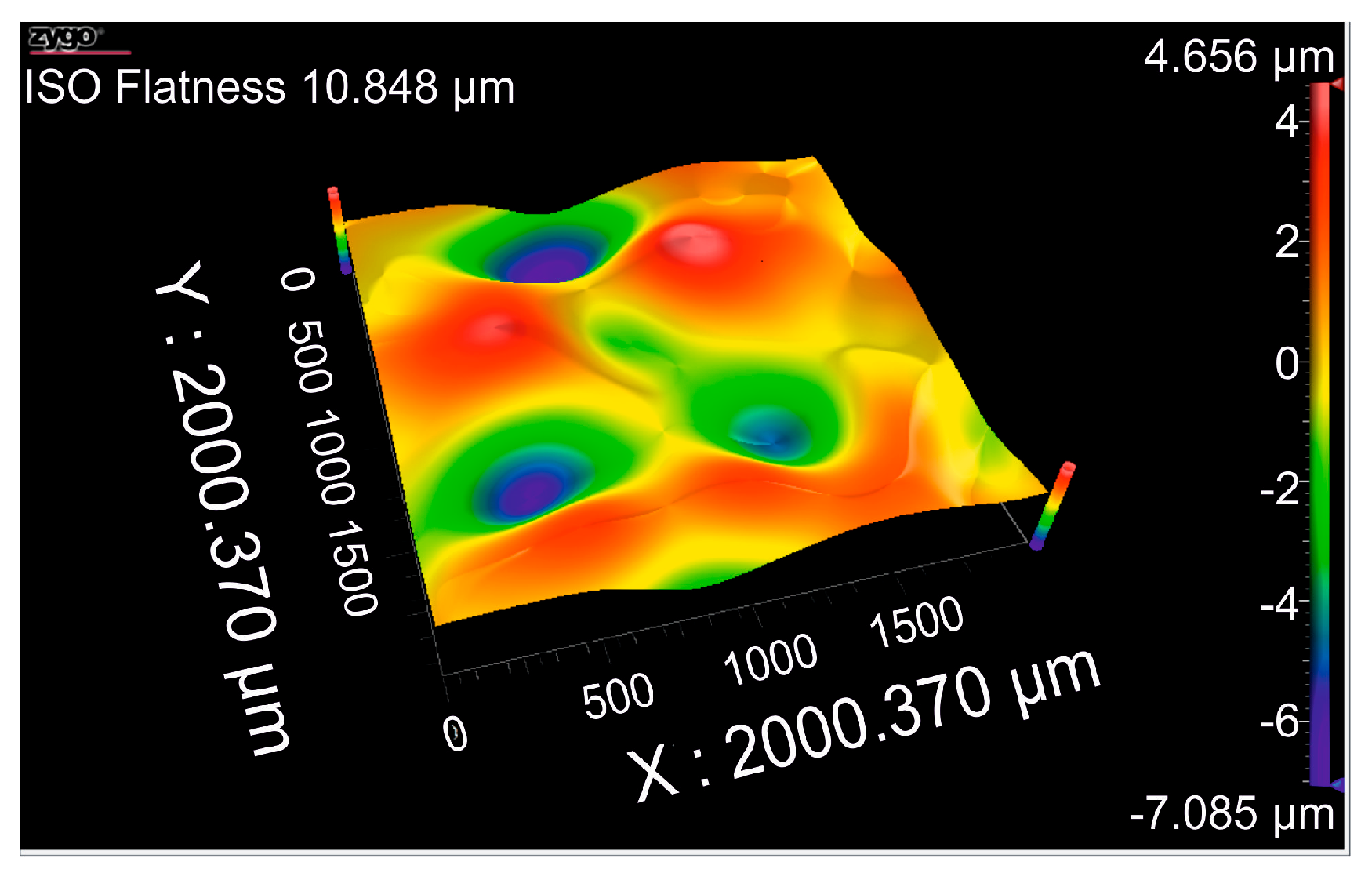

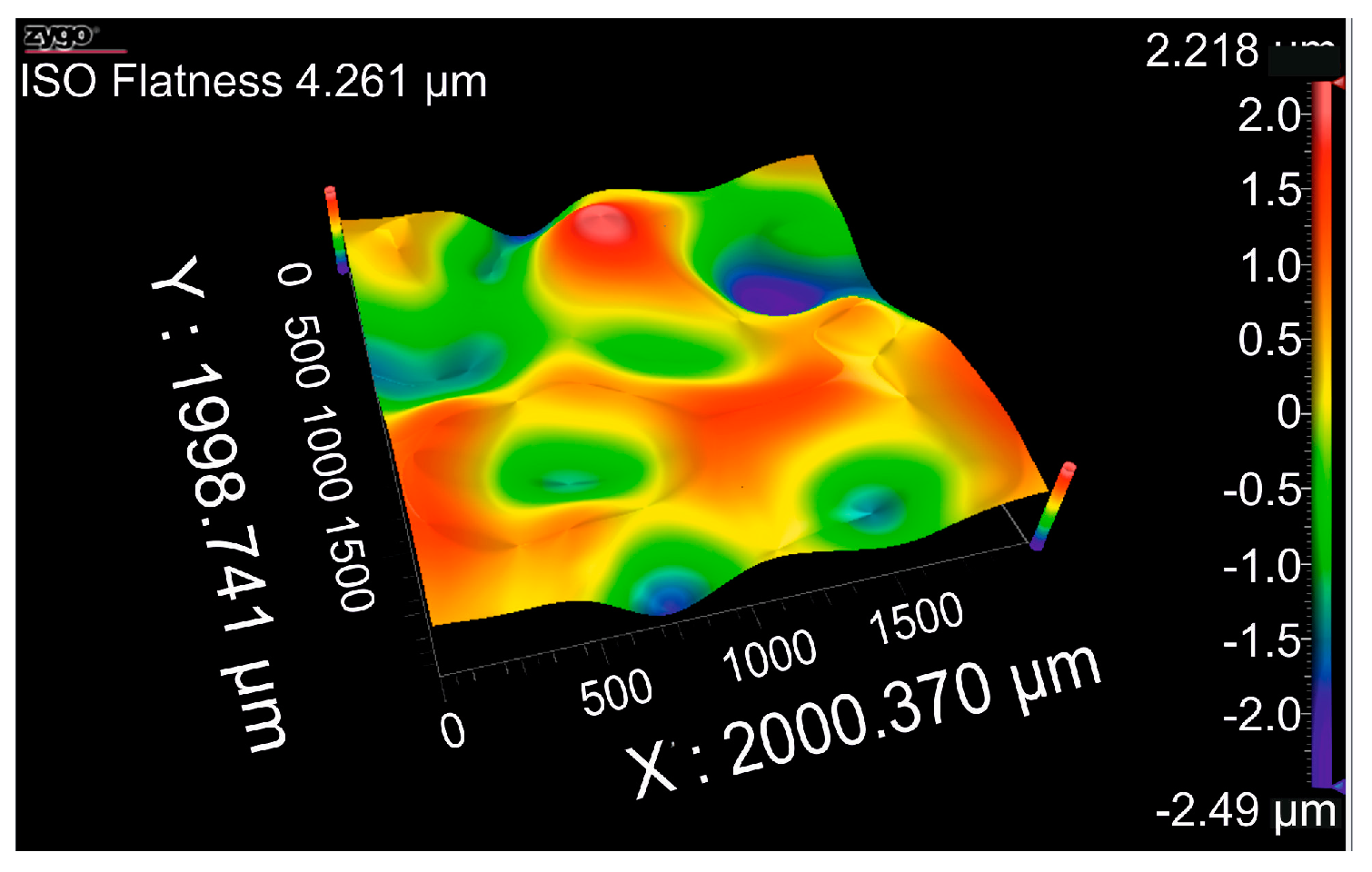

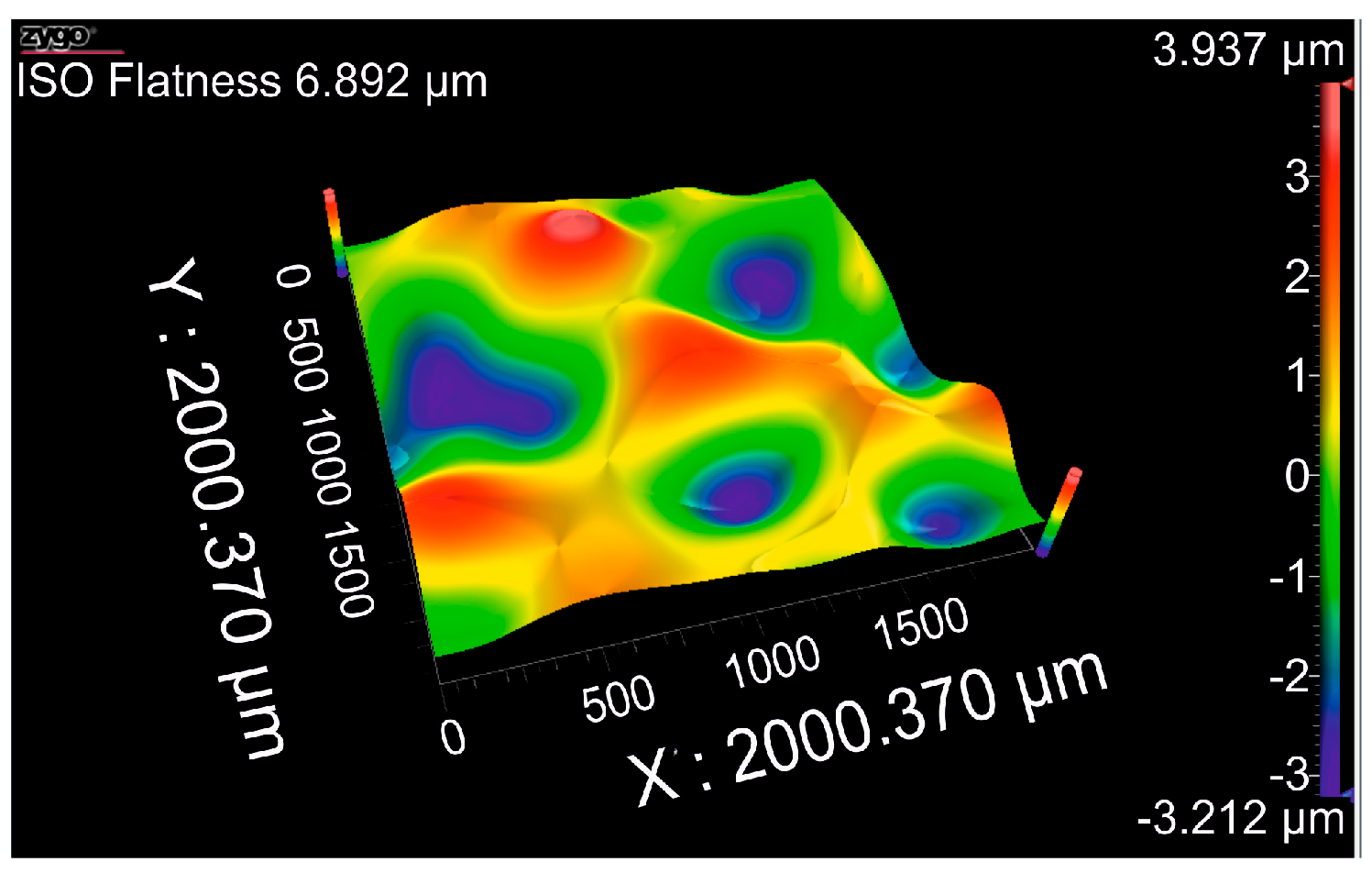

3.6. Topography

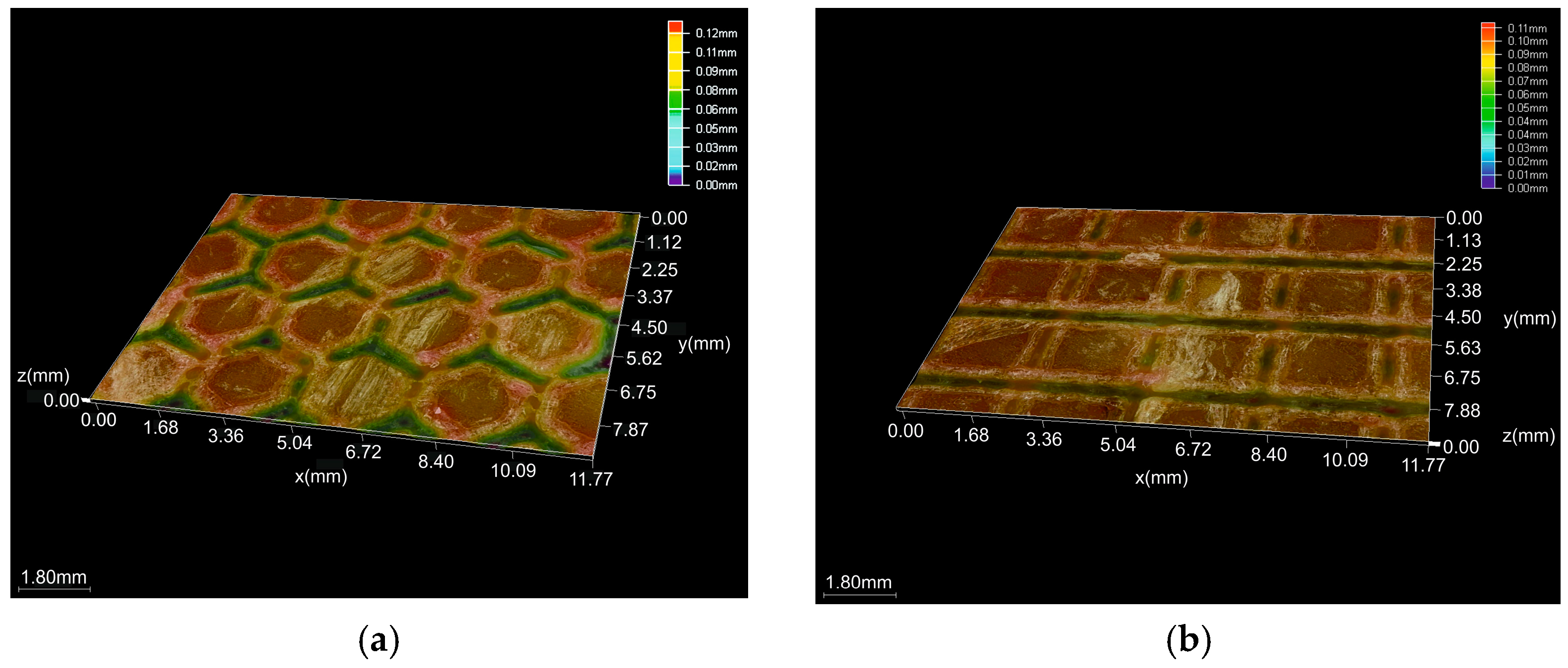

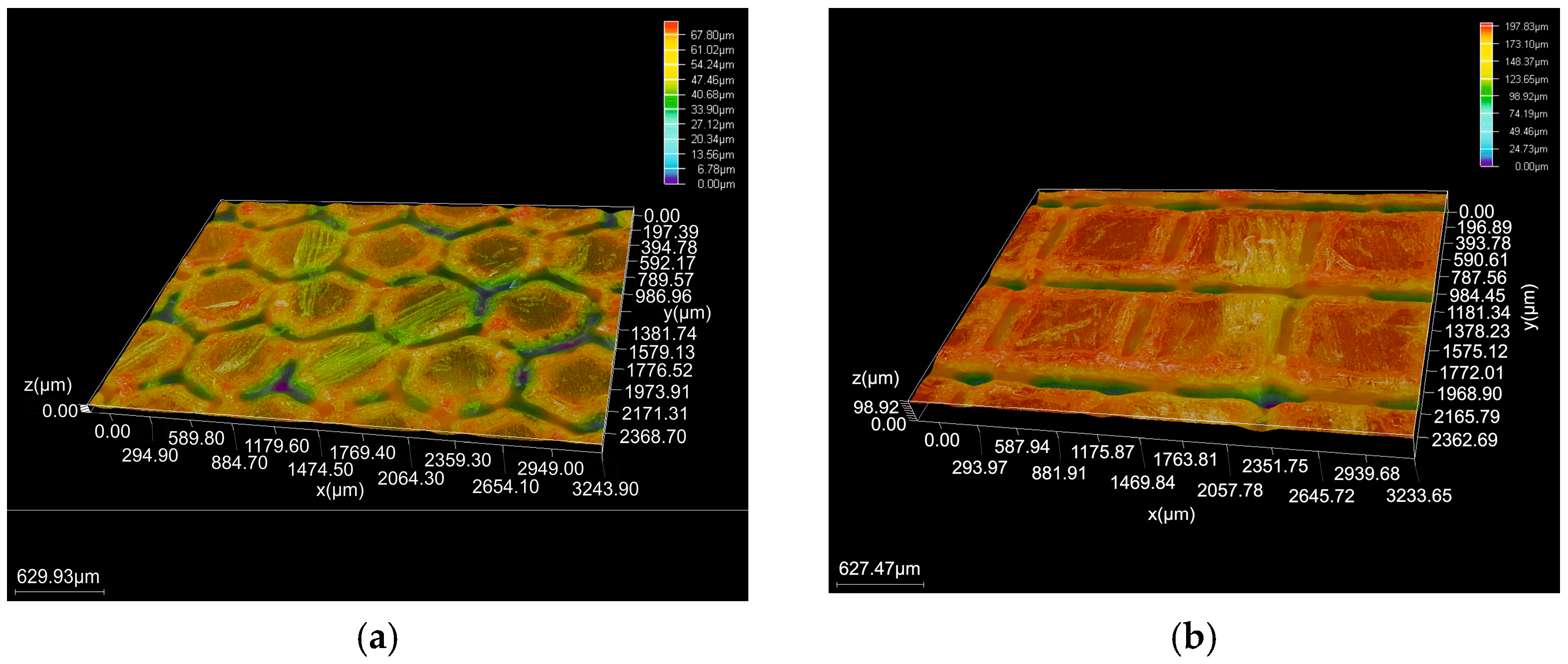

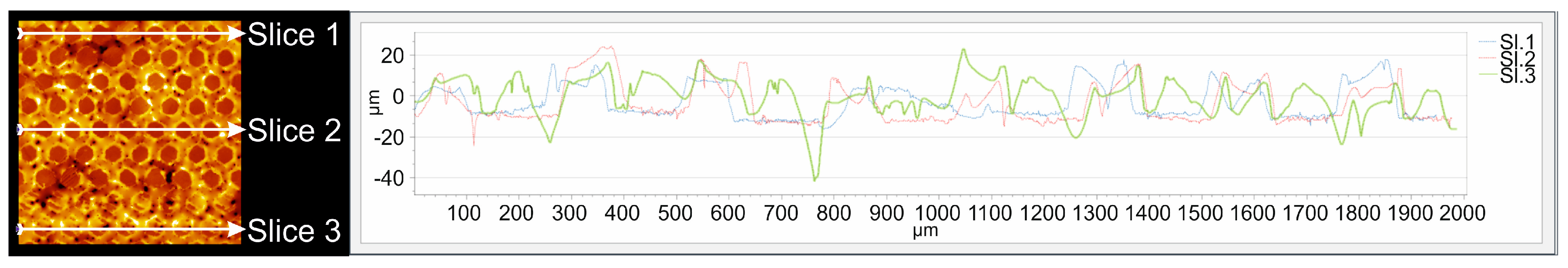

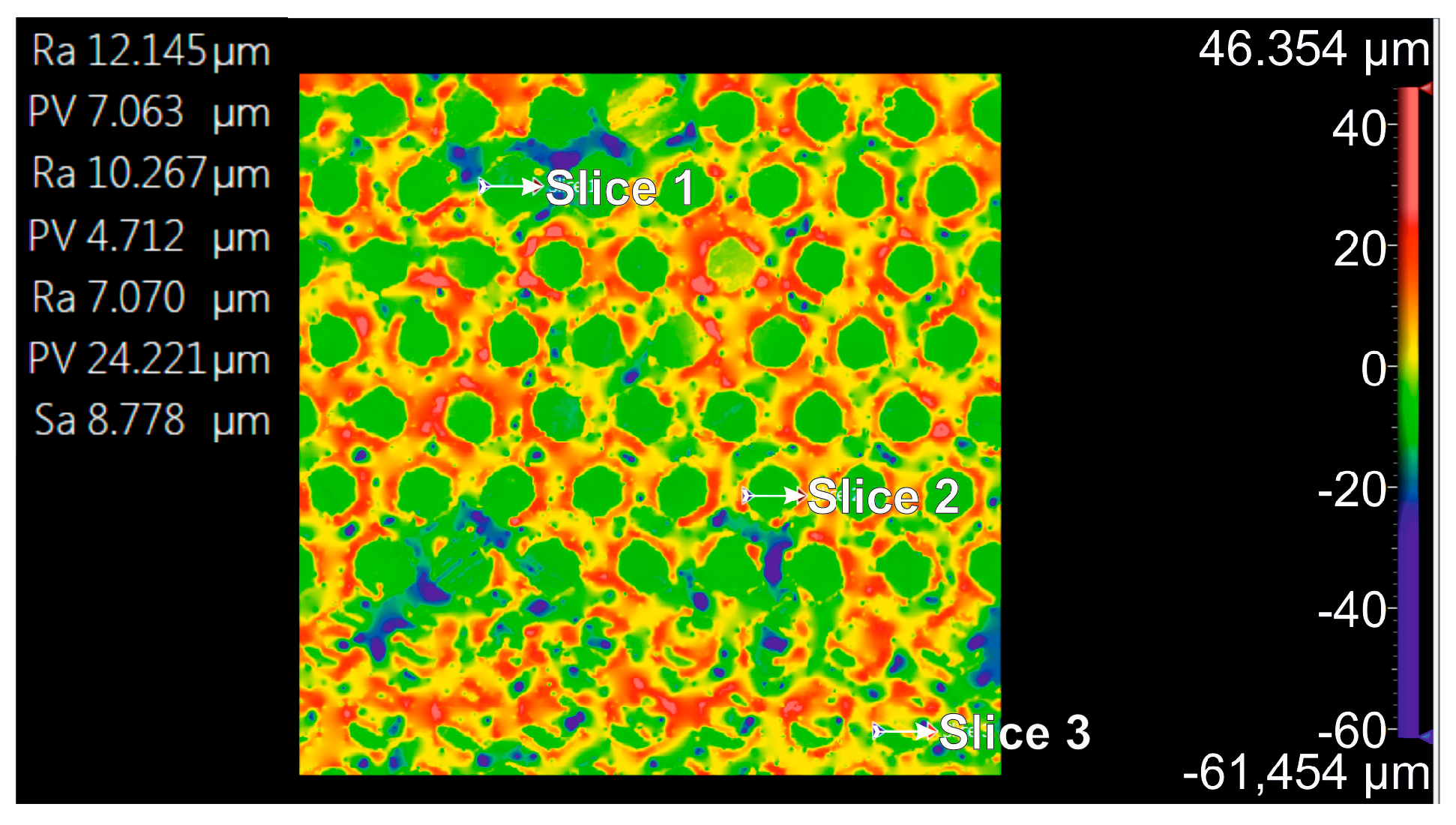

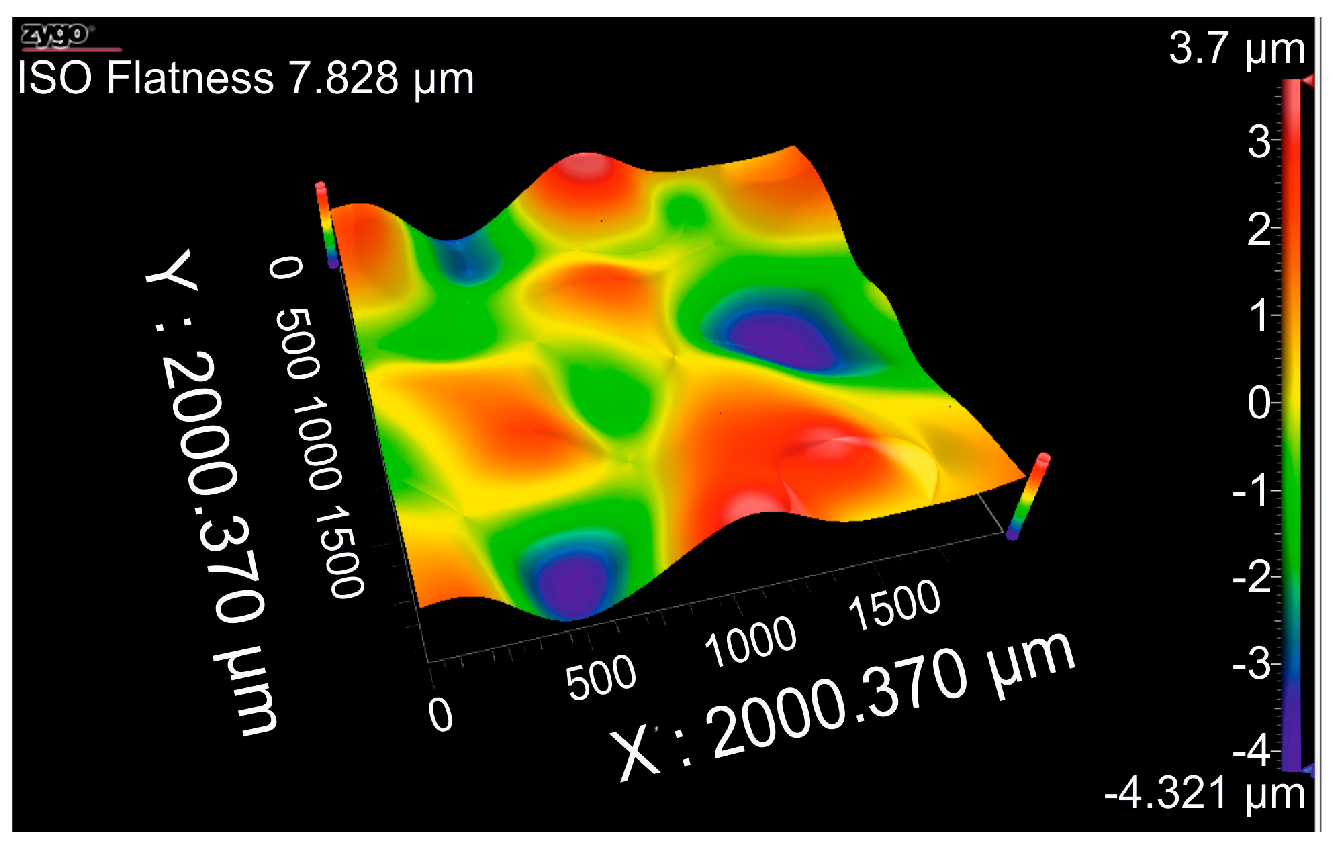

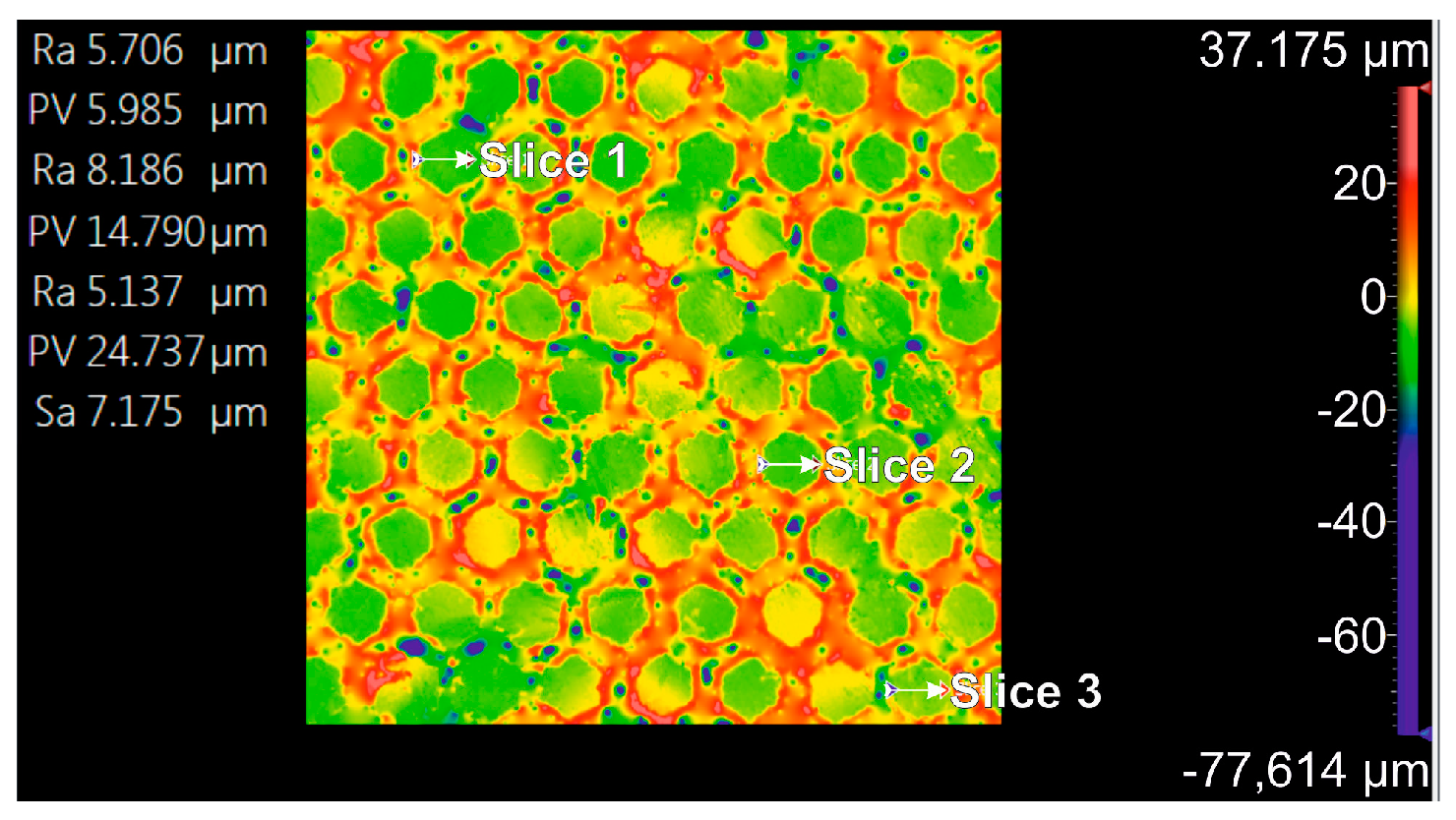

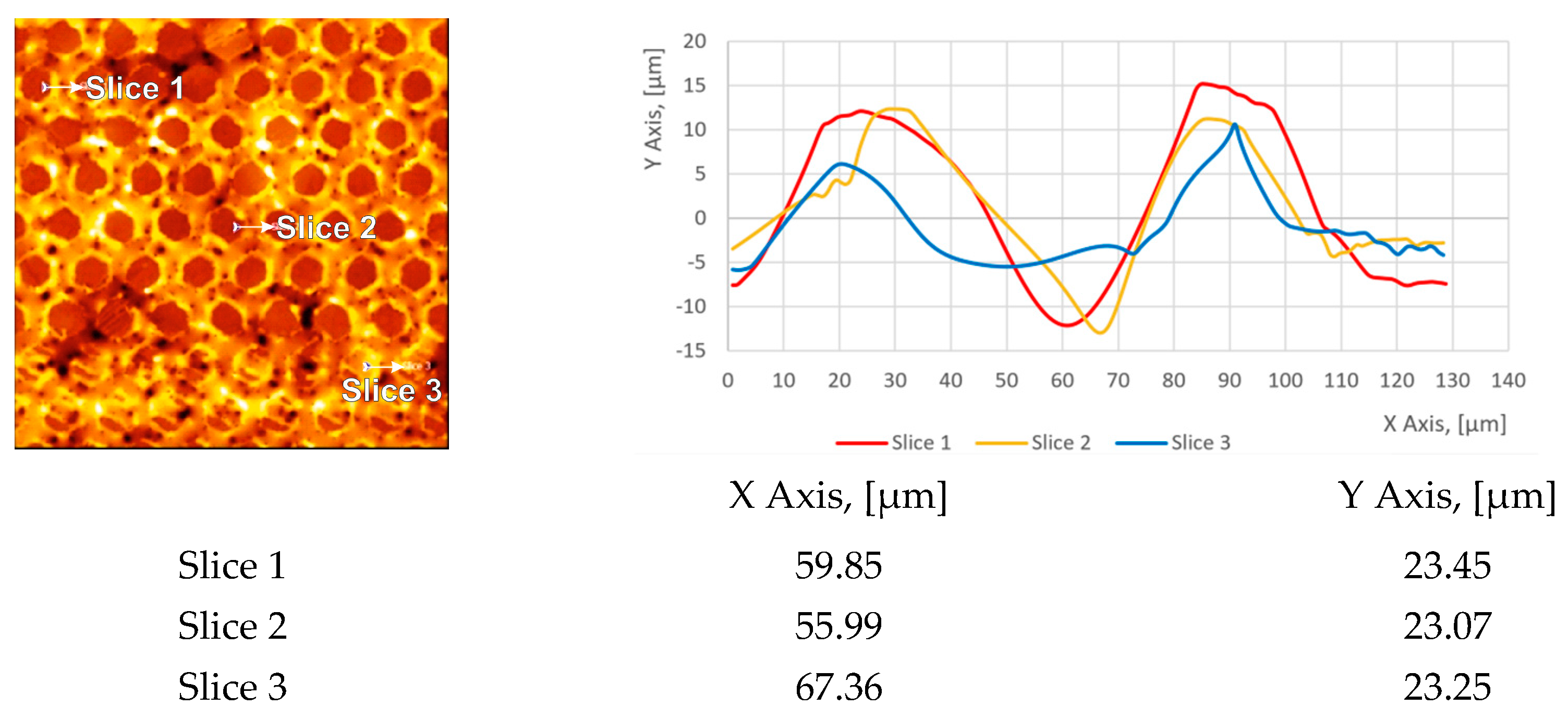

3.6.1. Topographic Analysis of Biodegradable Polymer with Hexagonal Texture

3.6.2. Comparative Analysis Between Two Processing Models: 4x_H/6x_H

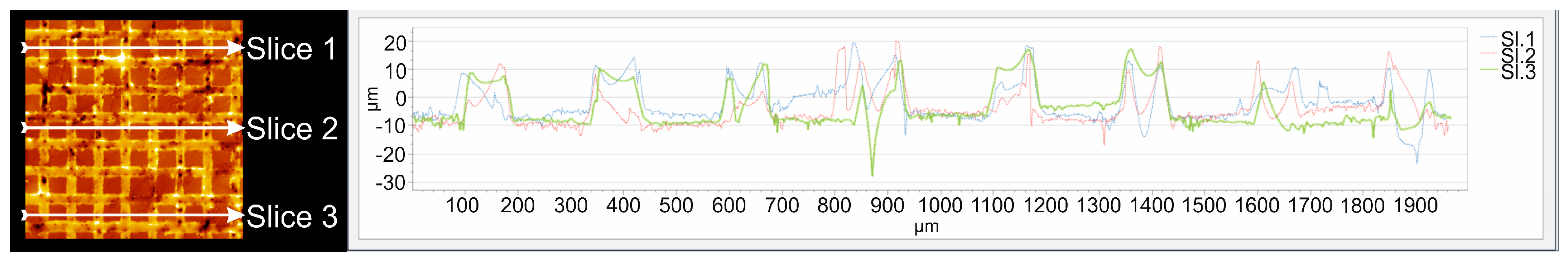

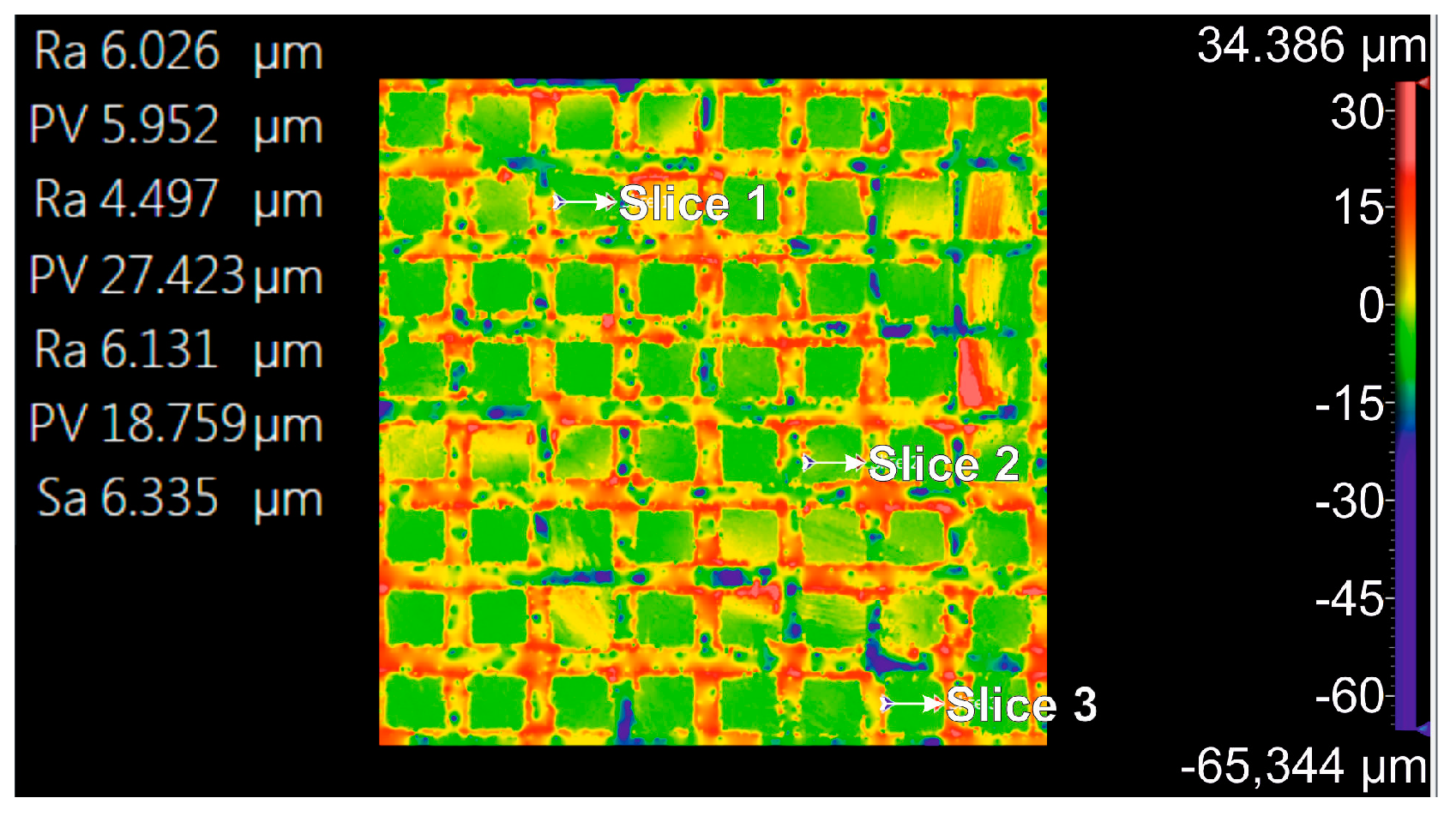

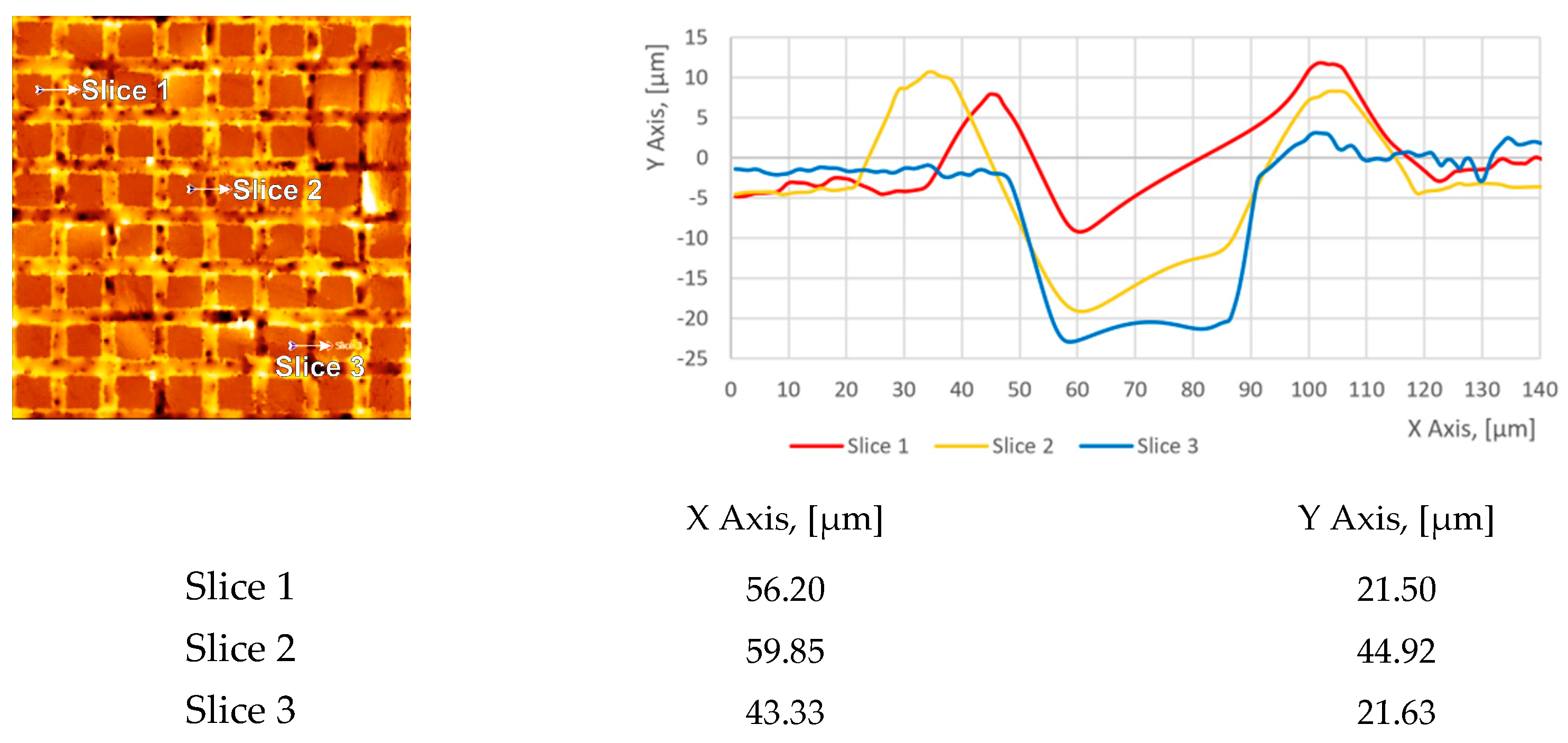

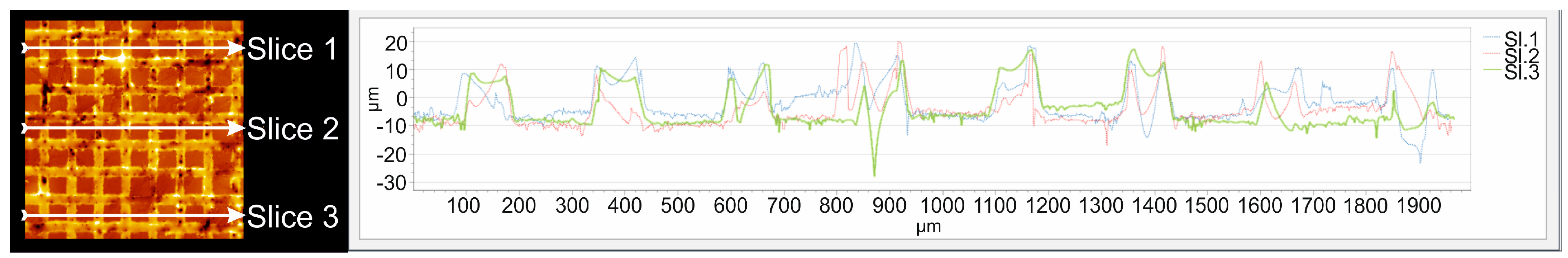

3.6.3. Topographic Analysis of Arbofill Fichte Material with a Square Texture

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Li, D.; Chen, X.; Guo, C.; Tao, J.; Tian, C.; Deng, Y.; Zhang, W. Micro surface texturing of alumina ceramic with nanosecond laser. Procedia Eng. 2017, 174, 370–376. [Google Scholar] [CrossRef]

- Xing, Y.; Deng, J.; Feng, X.; Yu, S. Effect of laser surface texturing on Si3N4/TiC ceramic sliding against steel under dry friction. Mater. Des. (1980–2015) 2013, 52, 34–45. [Google Scholar] [CrossRef]

- Šugár, P.; Šugárová, J.; Frnčík, M. Laser surface texturing of tool steel: Textured surfaces quality evaluation. Open Eng. 2016, 6, 90–97. [Google Scholar] [CrossRef]

- Tripathi, K.; Gyawali, G.; Joshi, B.; Amanov, A.; Wohn, S. Improved tribological behavior of grey cast Iron Under low and high viscous lubricants by laser surface texturing. Mater. Perform. Charact. 2017, 6, 24–41. [Google Scholar] [CrossRef]

- Riveiro, A.; Maçon, A.L.; del Val, J.; Comesaña, R.; Pou, J. Laser surface texturing of polymers for biomedical applications. Front. Phys. 2018, 6, 16. [Google Scholar] [CrossRef]

- Ezhilmaran, V.; Vasa, N.J.; Vijayaraghavan, L. Investigation on generation of laser assisted dimples on piston ring surface and influence of dimple parameters on friction. Surf. Coat. Technol. 2018, 335, 314–326. [Google Scholar] [CrossRef]

- Liang, L.; Yuan, J.; Li, X.; Yang, F.; Jiang, L. Wear behavior of the micro-grooved texture on WC-Ni3Al cermet prepared by laser surface texturing. Int. J. Refract. Met. Hard Mater. 2018, 72, 211–222. [Google Scholar] [CrossRef]

- Shivakoti, I.; Kibria, G.; Cep, R.; Pradhan, B.B.; Sharma, A. Laser Surface Texturing for Biomedical Applications: A Review. Coatings 2021, 11, 124. [Google Scholar] [CrossRef]

- Environmental Silicate Nano-Biocomposites; Averous, L., Pollet, E., Eds.; Springer: London, UK, 2012; ISBN 978-1-4471-4108-2. [Google Scholar]

- Handbook of Biodegradable Polymers; Bastioli, C., Ed.; Rapra Technology: Shrewsbury, UK, 2005; ISBN 978-1-8473-5044-2. [Google Scholar]

- Nutton, V. Ancient Medicine, 2nd ed.; Routledge: London, UK, 2012; ISBN 9780415520942. [Google Scholar]

- Vroman, I.; Tighzert, L. Biodegradable Polymers. Materials 2009, 2, 307–344. [Google Scholar] [CrossRef]

- Improving Biopolymers for Packaging Applications Using Surface-Tailored Cellulose Nanocrystals. Available online: https://research.fs.usda.gov/fpl/news/highlights/improving-biopolymers-packaging-applications-using-surface-tailored-cellulose (accessed on 15 January 2025).

- Milani, P.; França, D.; Balieiro, A.G.; Faez, R. Polymers and its applications in agriculture. Polímeros 2017, 27, 256–266. [Google Scholar] [CrossRef]

- Singh, D.; Thomas, D. Advances in medical polymer technology towards the panacea of complex 3D tissue and organ manufacture. Am. J. Surg. 2019, 217, 807–808. [Google Scholar] [CrossRef] [PubMed]

- Lendlein, A.; Sisson, A. (Eds.) Handbook of Biodegradable Polymers: Isolation, Synthesis, Characterization and Applications; Wiley-VCH Verlag GmbH Co. KGaA: Weinheim, Germany, 2011. [Google Scholar] [CrossRef]

- Tian, H.; Tang, Z.; Zhuang, X.; Chen, X.; Jing, X. Biodegradable synthetic polymers: Preparation, functionalization and biomedical application. Prog. Polym. Sci. 2012, 37, 237–280. [Google Scholar] [CrossRef]

- Biomaterials Principles and Applications; Park, J.B., Bronzino, J.D., Eds.; CRC Press: Boca Raton, FL, USA, 2002; ISBN 0-8493-1491-7. [Google Scholar]

- White, N.; Eder, K.; Byrnes, J.; Cairney, J.M.; McCarroll, I.E. Laser ablation sample preparation for atom probe tomography and transmission electron microscopy. Ultramicroscopy 2020, 220, 113161. [Google Scholar] [CrossRef] [PubMed]

- Tomanik, M.; Kobielarz, M.; Filipiak, J.; Szymonowicz, M.; Rusak, A.; Mroczkowska, K.; Antończak, A.; Pezowicz, C. Laser Texturing as a Way of Influencing the Micromechanical and Biological Properties of the Poly (L-Lactide) Surface. Materials 2020, 13, 3786. [Google Scholar] [CrossRef]

- Riveiro, A.; Soto, R.; Del Val, J.; Comesaña, R.; Boutinguiza, M.; Quintero, F.; Lusquiños, F.; Pou, J. Texturing of polypropylene (PP) with nanosecond lasers. Appl. Surf. Sci. 2016, 374, 379–386. [Google Scholar] [CrossRef]

- Mirzadeh, H.; Katbab, A.A.; Burford, R.P. CO2-laser graft copolymerization of HEMA and NVP onto ethylene-propylene rubber (EPR) as biomaterial-(III). Radiat. Phys. Chem. 1995, 46, 859–862. [Google Scholar] [CrossRef]

- Dinca, V.; Alloncle, P.; Delaporte, P.; Ion, V.; Rusen, L.; Filipescu, M.; Mustaciosu, C.; Luculescu, C.; Dinescu, M. Excimer laser texturing of natural composite polymer surfaces for studying cell-to-substrate specific response. Appl. Surf. Sci. 2015, 352, 82–90. [Google Scholar] [CrossRef]

- Koufaki, N.; Ranella, A.; Aifantis, K.E.; Barberoglou, M.; Psycharakis, S.; Fotakis, C.; Stratakis, E. Controlling cell adhesion via replication of laser micro/nano-textured surfaces on polymers. Biofabrication 2011, 3, 045004. [Google Scholar] [CrossRef]

- Yeong, W.Y.; Yu, H.; Lim, K.P.; Ng, K.L.; Boey, Y.C.; Subbu, V.S.; Tan, L.P. Multiscale topological guidance for cell alignment via direct laser writing on biodegradable polymer. Tissue Eng. Part C Methods 2010, 16, 1011–1021. [Google Scholar] [CrossRef] [PubMed]

- Waugh, D.; Lawrence, J. Laser surface processing of polymers for biomedical applications. In Laser-Assisted Fabrication of Materials; Springer: Berlin/Heidelberg, Germany, 2013; pp. 275–318. [Google Scholar]

- Jagur-Grodzinski, J. Polymers for tissue engineering, medical devices, and regenerative medicine. Concise general review of recent studies. Polym. Adv. Technol. 2006, 17, 395–418. [Google Scholar] [CrossRef]

- Kohane, D.S.; Langer, R. Polymeric biomaterials in tissue engineering. Pediatr. Res. 2008, 63, 487–491. [Google Scholar] [CrossRef] [PubMed]

- Teo, A.J.T.; Mishra, A.; Park, I.; Kim, Y.J.; Park, W.T.; Yoon, Y.J. Polymeric biomaterials for medical implants and devices. ACS Biomater. Sci. Eng. 2016, 2, 454–472. [Google Scholar] [CrossRef] [PubMed]

- Abu Bakar, M.S.; Cheng, M.H.W.; Tang, S.M.; Yu, S.C.; Liao, K.; Tan, C.T.; Khor, K.A.; Cheang, P. Tensile properties, tension–tension fatigue and biological response of polyetheretherketone–hydroxyapatite composites for load-bearing orthopedic implants. Biomaterials 2003, 24, 2245–2250. [Google Scholar] [CrossRef] [PubMed]

- Godara, A.; Raabe, D.; Green, S. The influence of sterilization processes on the micromechanical properties of carbon fiber-reinforced PEEK composites for bone implant applications. Acta Biomater. 2007, 3, 209–220. [Google Scholar] [CrossRef]

- Riveiro, A.; Soto, R.; Comesaña, R.; Boutinguiza, M.; del Val, J.; Quintero, F.; Lusquiños, F.; Pou, J. Laser surface modification of PEEK. Appl. Surf. Sci. 2012, 258, 9437–9442. [Google Scholar] [CrossRef]

- Zheng, Y.; Xiong, C.; Wang, Z.; Li, X.; Zhang, L. A combination of CO2 laser and plasma surface modification of poly(etheretherketone) to enhance osteoblast response. Appl. Surf. Sci. 2015, 344, 79–88. [Google Scholar] [CrossRef]

- Wilson, A.; Jones, I.; Salamat-Zadeh, F.; Watts, J.F. Laser surface modification of poly(etheretherketone) to enhance surface free energy, wettability and adhesion. Int. J. Adhes. Adhes. 2015, 62, 69–77. [Google Scholar] [CrossRef]

- Lorusso, A.; Nassisi, V.; Paladini, F.; Torrisi, L.; Visco, A.M.; Campo, N. Comparison of the laser effects induced on ultra-high-molecular-weight polyethylene. Radiat. Eff. Defects Solids 2008, 163, 435–440. [Google Scholar] [CrossRef]

- Riveiro, A.; Soto, R.; del Val, J.; Comesaña, R.; Boutinguiza, M.; Quintero, F.; Lusquiños, F.; Pou, J. Laser surface modification of ultra-high-molecular-weight polyethylene (UHMWPE) for biomedical applications. Appl. Surf. Sci. 2014, 302, 236–242. [Google Scholar] [CrossRef]

- Himma, N.F.; Anisah, S.; Prasetya, N.; Wenten, I.G. Advances in preparation, modification, and application of polypropylene membrane. J. Polym. Eng. 2016, 36, 329–362. [Google Scholar] [CrossRef]

- Wissemborski, R.; Klein, R. Welding and marking of plastics with lasers. Laser Tech. J. 2010, 7, 19–22. [Google Scholar] [CrossRef]

- Stanford, C.M. Surface modifications of dental implants. Aust. Dent. J. 2008, 53, S26–S33. [Google Scholar] [CrossRef]

- Murahara, M.; Okoshi, M. Photochemical surface modification of polypropylene for adhesion enhancement by using an excimer laser. J. Adhes. Sci. Technol. 1995, 9, 1593–1599. [Google Scholar] [CrossRef]

- Deshpande, S.; Munoli, A. Long-term results of high-density porous polyethylene implants in facial skeletal augmentation: An Indian perspective. Indian J. Plast. Surg. 2010, 43, 34–39. [Google Scholar] [CrossRef]

- Okoshi, M.; Inoue, N. Microfabrication of polyethylene using femtosecond Ti:sapphire laser and nanosecond ArF laser. Jpn. J. Appl. Phys. 2003, 42, 5642. [Google Scholar] [CrossRef]

- Blanchemain, N.; Chai, F.; Bacquet, M.; Gengembre, L.; Traisnel, M.; Setti, Y.; Hildebrand, H.F. Improvement of biological response of YAG laser irradiated polyethylene. J. Mater. Chem. 2007, 17, 4041–4049. [Google Scholar] [CrossRef]

- Okoshi, M.; Inoue, N. Laser ablation of polymers using 395 nm and 790 nm femtosecond lasers. Appl. Phys. Mater. Sci. Process 2004, 79, 841–844. [Google Scholar] [CrossRef]

- Ahad, I.U.; Budner, B.; Korczyc, B.; Fiedorowicz, H.; Bartnik, A.; Kostecki, J.; Burdyńska, S.; Brabazon, D. Polycarbonate polymer surface modification by extreme ultraviolet (EUV) radiation. Acta Phys. Pol. A 2014, 125, 924–928. [Google Scholar] [CrossRef]

- Viville, P.; Beauvois, S.; Lambin, G.; Lazzaroni, R.; Brédas, J.L.; Kolev, K.; Laude, L. Excimer laser-induced surface modifications of biocompatible polymer blends. Appl. Surf. Sci. 1996, 96, 558–562. [Google Scholar] [CrossRef]

- Ahad, I.U.; Butruk, B.; Ayele, M.; Budner, B.; Bartnik, A.; Fiedorowicz, H.; Ciach, T.; Brabazon, D. Extreme ultraviolet (EUV) surface modification of polytetrafluoroethylene (PTFE) for control of biocompatibility. Nucl. Instrum. Methods Phys. Res. Sect. B Beam Interact Mater. At. 2015, 364, 98–107. [Google Scholar] [CrossRef]

- Waugh, D.G.; Lawrence, J.; Morgan, D.J.; Thomas, C.L. Interaction of CO2 laser-modified nylon with osteoblast cells in relation to wettability. Mater. Sci. Eng. C 2009, 29, 2514–2524. [Google Scholar] [CrossRef][Green Version]

- Günther, D.; Scharnweber, D.; Hess, R.; Wolf-Brandstetter, C.; Grosse Holthaus, M.; Lasagni, A.F. High precision patterning of biomaterials using the direct laser interference patterning technology. In Laser Surface Modification of Biomaterials; Vilar, R., Ed.; Woodhead Publishing: Cambridge, MA, USA, 2016. [Google Scholar] [CrossRef]

- Yasaka, K.; Koseki, Y.; Yoshinaka, K.; Miyake, K. Effects of Surface Texture on Soft-Materials for Medical Applications. Tribol. Online 2016, 11, 288–297. [Google Scholar] [CrossRef]

- Ikeuchi, K.; Takii, T.; Norikane, H.; Tomita, N.; Ohsumi, T.; Uyama, Y.; Ikada, Y. Water Lubrication of Polyurethane Grafted with Dimethylacrylamide for Medical Use. Wear 1993, 161, 179–185. [Google Scholar] [CrossRef]

- Evangelista, I.; Wencel, D.; Beguin, S.; Zhang, N.; Gilchrist, M.D. Influence of Surface Texturing on the Dry Tribological Properties of Polymers in Medical Devices. Polymers 2023, 15, 2858. [Google Scholar] [CrossRef] [PubMed]

- Affatato, S.; Brando, D. Introduction to wear phenomena of orthopaedic implants. In Wear of Orthopaedic Implants and Artificial Joints; Woodhead Publishing: Sawston, UK, 2013; pp. 3–26. [Google Scholar]

- Ching, H.A.; Choudhury, D.; Nine, M.J.; Abu Osman, N.A. Effects of surface coating on reducing friction and wear of orthopaedic implants. Sci. Technol. Adv. Mater. 2014, 15, 014402. [Google Scholar] [CrossRef]

- Howard, J.J. Balancing innovation and medical device regulation: The case of modern metal-on-metal hip replacements. Med. Devices 2016, 9, 267–275. [Google Scholar] [CrossRef] [PubMed]

- Bialas, O.; Lis, M.; Wozniak, A.; Adamiak, M. Laser Superficial Fusion of Gold Nanoparticles with PEEK Polymer for Cardiovascular Application. Materials 2021, 14, 971. [Google Scholar] [CrossRef] [PubMed]

- Available online: https://www.tecnaro.de/en/arboblend-arbofill-arboform/verarbeitung/ (accessed on 12 September 2022).

- Mazurchevici, S.-N.; Vaideanu, D.; Rapp, D.; Varganici, C.-D.; Cărăușu, C.; Boca, M.; Nedelcu, D. Dynamic mechanical analysis and thermal expansion of lignin-based biopolymers. Polymers 2021, 13, 2953. [Google Scholar] [CrossRef] [PubMed]

- Nedelcu, D. Investigation on microstructure and mechanical properties of samples obtained by injection from Arbofill. Compos. Part B Eng. 2013, 47, 126–129. [Google Scholar] [CrossRef]

- Nedelcu, D.; Ciofu, C.; Lohan, N.M. Microindentation and differential scanning calorimetry of “liquid wood”. Compos. Part B Eng. 2013, 55, 11–15. [Google Scholar] [CrossRef]

- Mazurchevici, S.; Quadrini, F.; Nedelcu, D. The liquid wood heat flow and material properties as a function of temperature. Mater. Res. Express 2018, 5, 035303. [Google Scholar] [CrossRef]

- Mazurchevici, S.N.; Bialas, O.; Mindru, T.D.; Adamiak, M.; Nedelcu, D. Characterization of Arboblend V2 Nature Textured Surfaces Obtained by Injection Molding. Polymers 2023, 15, 406. [Google Scholar] [CrossRef] [PubMed]

- Nedelcu, D.; Plavanescu, S.; Puiu, E. Impact resistance of “liquid wood”. Adv. Mater. Res. 2014, 1036, 13–17. [Google Scholar] [CrossRef]

- Broitman, E.; Nedelcu, D.; Mazurchevici, S.; Glenat, H.; Grillo, S. Tribological and nanomechanical behavior of liquid wood. J. Tribol. 2019, 141, 022001. [Google Scholar] [CrossRef]

- PN-EN 600068-14 Standard. Available online: https://magazin.asro.ro/ro/standard/179836 (accessed on 10 January 2025).

- Woźniak, A.; Bialas, O.; Adamiak, M.; Hadzima, B.; Szewczenko, J. The influence of laser texturing on the tribological behavior of titanium alloy Ti6Al4V in medical applications. Arch. Civ. Mech. Eng. 2024, 24, 1–19. [Google Scholar] [CrossRef]

- Costescu, E.P.; Vaideanu, D.; Simona, B.E.; Agop, M. Thermal and electrical behaviours of the arbofill, “liquid wood”. Int. J. Mod. Manuf. Technol. 2017, 9, 79–83. [Google Scholar]

| Software | Cimita Laser Micromachining Software Suite for Laser, Motion, and Vision |

| Laser | Diode-pumped solid state |

| Cut speed | 1 [mm/s] |

| Cut passes | 4 and 6 passes |

| Wavelength | 355 [nm] |

| Pulse width | 6 [ps] |

| Biodegradable Biopolymer | Biodegradable Biopolymer 4 Texturing Passes | Biodegradable Biopolymer 6 Texturing Passes | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| No. of Sample | Contact Angle (°) | Texturing Type | No. of Samples | Contact Angle (°) | Texturing Type | No. of Sample | Contact Angle (°) | |||||

| Max. | Min. | Average | Max. | Min. | Average | |||||||

| 1 | 89 | Hexagon | 1 | 94 | 18 | 41 | 38 ± 2 | Hexagon | 1 | 40 | 0 (22 s) | - |

| 2 | 84 | 2 | 89 | 17 | 35 | 2 | 20 | 0 (9 s) | - | |||

| 3 | 90 | 3 | 72 | 20 | 37 | 3 | 35 | 0 (15 s) | - | |||

| Average | 87 ± 3 | Square | 1 | 24 | 0 (15 s) | - | Square | 1 | 14 | 0 (2 s) | - | |

| 2 | 16 | 0 (20 s) | - | 2 | 18 | 0 (2 s) | - | |||||

| 3 | 18 | 0 (15 s) | - | 3 | 15 | 0 (1 s) | - | |||||

| Biodegradable Biopolymer—COF 0.10 Initial State | COF | |

|---|---|---|

| 4 texturing passes | Hexagon | 0.20 |

| Square | 0.51 | |

| 6 texturing passes | Hexagon | 0.26 |

| Square | 0.49 | |

| Material | Weight (g) | Difference | ||

|---|---|---|---|---|

| Before Degradation | After Degradation | |||

| Biodegradable polymer | 4 texturing passes | 30.123 | 30.159 | +0.036 |

| 6 texturing passes | 31.697 | 31.736 | +0.039 | |

| Sample | Ts [°C] | T50 [°C] | Tf [°C] | ΔH/m [kJ/kg] |

|---|---|---|---|---|

| Base material | 148.7 | 151.0 | 159.2 | −38.27 |

| 4x/hexagonal | 149.8 | 153.0 | 161.8 | −37.4 |

| 4x/square | 148.8 | 152.2 | 164.3 | −33.35 |

| 6x/hexagonal | 132.2 | 154.4 | 165.7 | −51.25 |

| 6x/square | 137.8 | 151.8 | 163.8 | −52.28 |

| No. | Reference Line | Rz (µm) | Rq (µm) |

|---|---|---|---|

| 1 | Slice 1 | 34.28 | 8.67 |

| 2 | Slice 2 | 46.68 | 10.22 |

| 3 | Slice 3 | 64.88 | 9.24 |

| 4 | Mean | 48.61 | 9.38 |

| 5 | Standard deviation | 15.38 | 0.78 |

| 6 | Range | 30.59 | 1.58 |

| 7 | 3 Sigma | 46.16 | 2.35 |

| No. | Reference Line | Rz (µm) | Rq (µm) |

|---|---|---|---|

| 1 | Slice 1 | 77.68 | 9.961 |

| 2 | Slice 2 | 40.40 | 6.887 |

| 3 | Slice 3 | 89.40 | 8.478 |

| 4 | Mean | 69.16 | 8.352 |

| 5 | Standard deviation | 25.58 | 1.406 |

| 6 | Range | 49.00 | 2.804 |

| 7 | 3 Sigma | 76.75 | 4.219 |

| No. | Reference Line | Rz (µm) | Rq (µm) |

|---|---|---|---|

| 1 | Slice 1 | 39.75 | 5.784 |

| 2 | Slice 2 | 52.97 | 7.334 |

| 3 | Slice 3 | 41.54 | 6.130 |

| 4 | Mean | 44.75 | 6.416 |

| 5 | Standard deviation | 7.17 | 0.814 |

| 6 | Range | 13.22 | 1.550 |

| 7 | 3 Sigma | 21.52 | 2.441 |

| No. | Reference Line | Rz (µm) | Rq (µm) |

|---|---|---|---|

| 1 | Slice 1 | 42.88 | 6.953 |

| 2 | Slice 2 | 37.04 | 7.446 |

| 3 | Slice 3 | 45.54 | 8.074 |

| 4 | Mean | 41.82 | 7.491 |

| 5 | Standard deviation | 4.34 | 0.562 |

| 6 | Range | 8.49 | 1.121 |

| 7 | 3 Sigma | 13.03 | 1.686 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rusu, P.-D.; Bialas, O.; Wozniak, A.; Adamiak, M.; Appiah, A.; Tampu, C.; Mazurchevici, S.-N.; Kyratsis, P.; Tzotzis, A.; Nedelcu, A.; et al. Characterization of Laser-Textured Surfaces of Parts of a Biodegradable Polymer. Coatings 2025, 15, 246. https://doi.org/10.3390/coatings15020246

Rusu P-D, Bialas O, Wozniak A, Adamiak M, Appiah A, Tampu C, Mazurchevici S-N, Kyratsis P, Tzotzis A, Nedelcu A, et al. Characterization of Laser-Textured Surfaces of Parts of a Biodegradable Polymer. Coatings. 2025; 15(2):246. https://doi.org/10.3390/coatings15020246

Chicago/Turabian StyleRusu (Ostahie), Petronela-Daniela, Oktawian Bialas, Anna Wozniak, Marcin Adamiak, Augustine Appiah, Catalin Tampu, Simona-Nicoleta Mazurchevici, Panagiotis Kyratsis, Anastasios Tzotzis, Alexandra Nedelcu, and et al. 2025. "Characterization of Laser-Textured Surfaces of Parts of a Biodegradable Polymer" Coatings 15, no. 2: 246. https://doi.org/10.3390/coatings15020246

APA StyleRusu, P.-D., Bialas, O., Wozniak, A., Adamiak, M., Appiah, A., Tampu, C., Mazurchevici, S.-N., Kyratsis, P., Tzotzis, A., Nedelcu, A., Mindru, T.-D., & Nedelcu, D. (2025). Characterization of Laser-Textured Surfaces of Parts of a Biodegradable Polymer. Coatings, 15(2), 246. https://doi.org/10.3390/coatings15020246