Design and Preparation of a Novel Double-Modified Cement-Based Protective Coating Material and Its Improved Protection Performance Against Chloride Corrosion

Abstract

:1. Introduction

2. Materials and Methods

2.1. Coating Method and Preparation of Samples

2.1.1. Raw Materials

2.1.2. Mix Proportion Design and Preparation of Double-Modified Cement-Based Protective Coating Materials

2.1.3. Preparation of Electrochemical Corrosion Test Sample

2.1.4. Preparation of Electrochemical Corrosion Test Sample with Cement-Based Protective Coating

2.2. Test Performed on the Samples

2.2.1. SEM Analysis

2.2.2. XRD Analysis

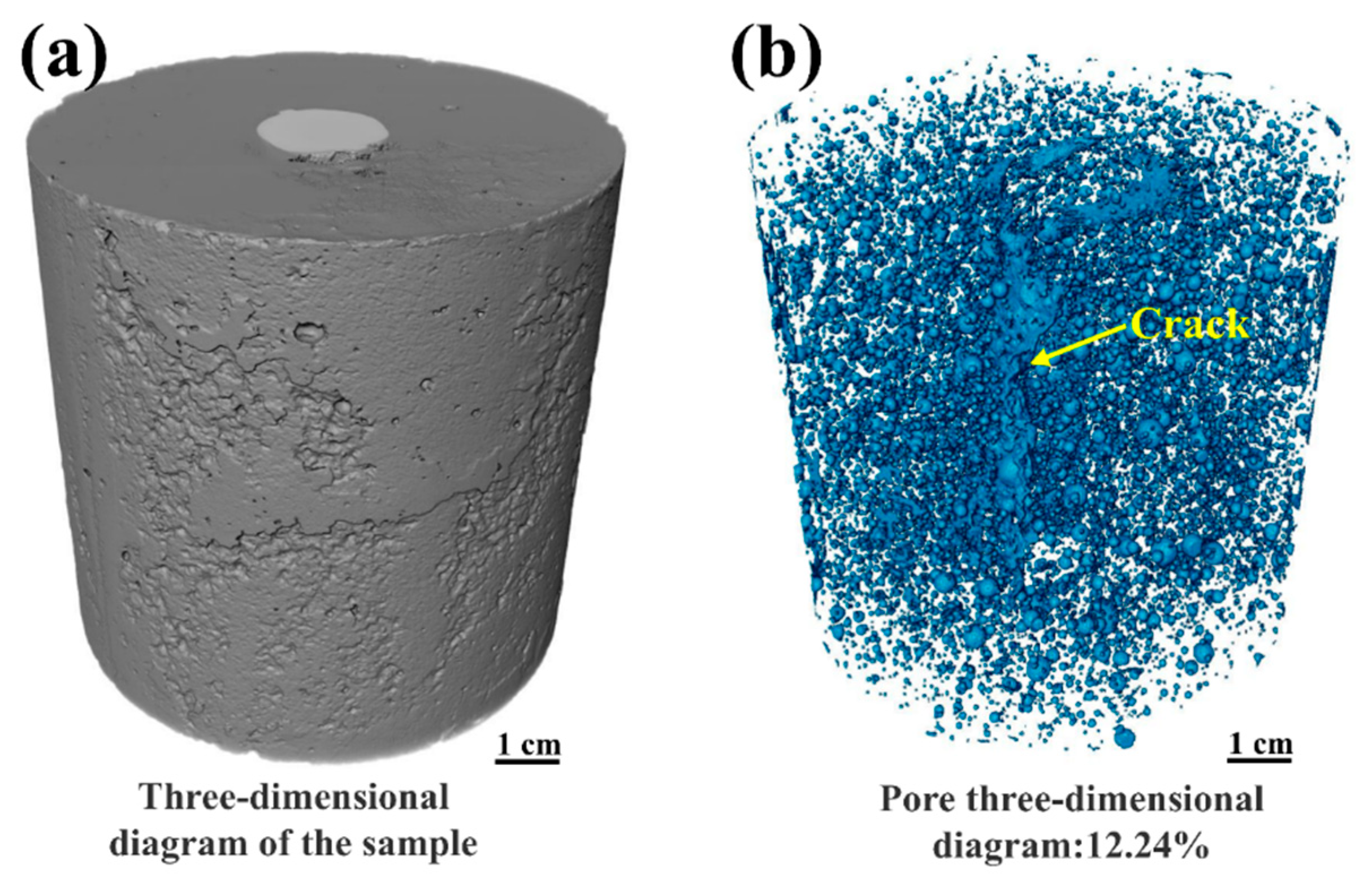

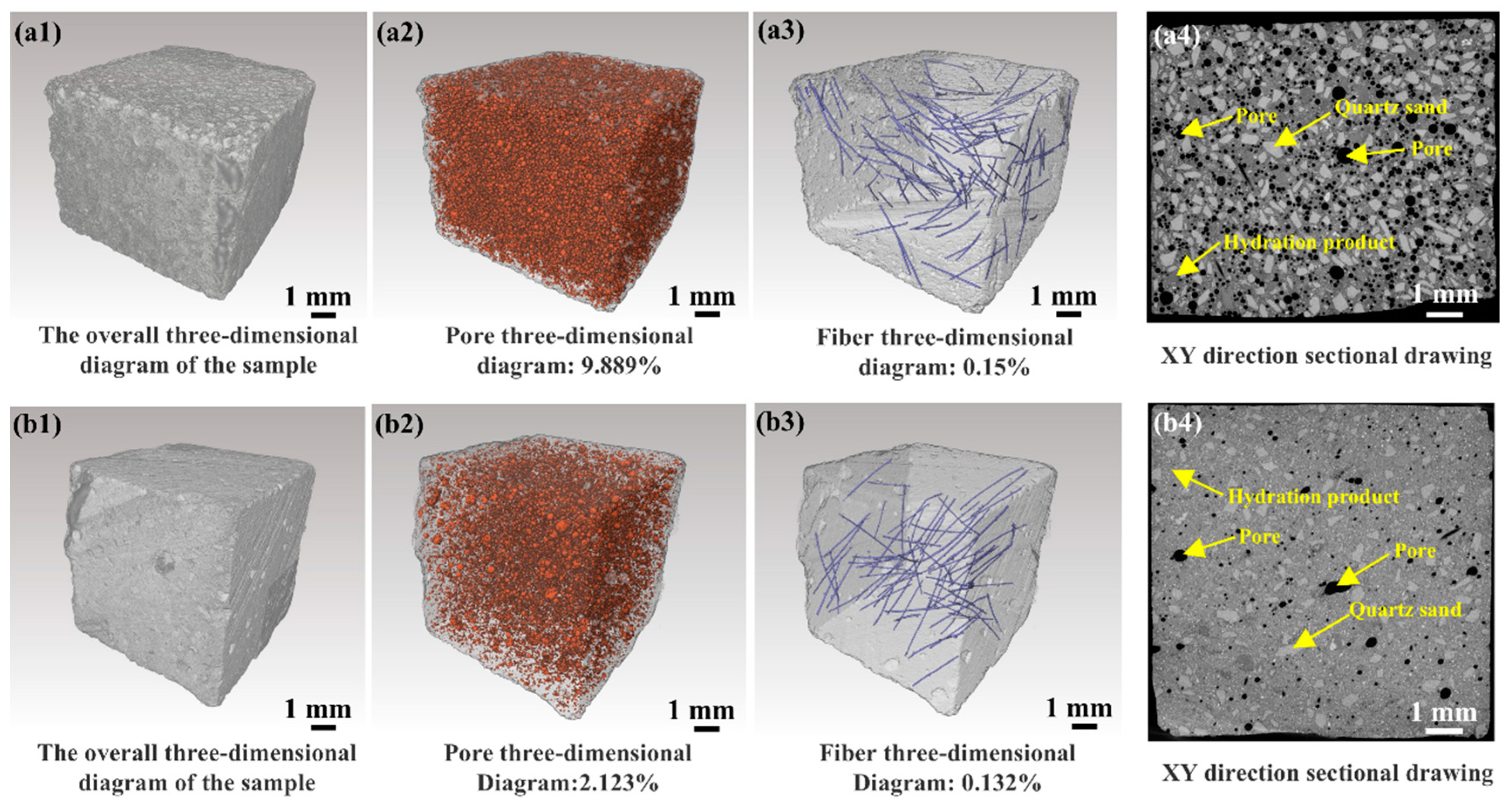

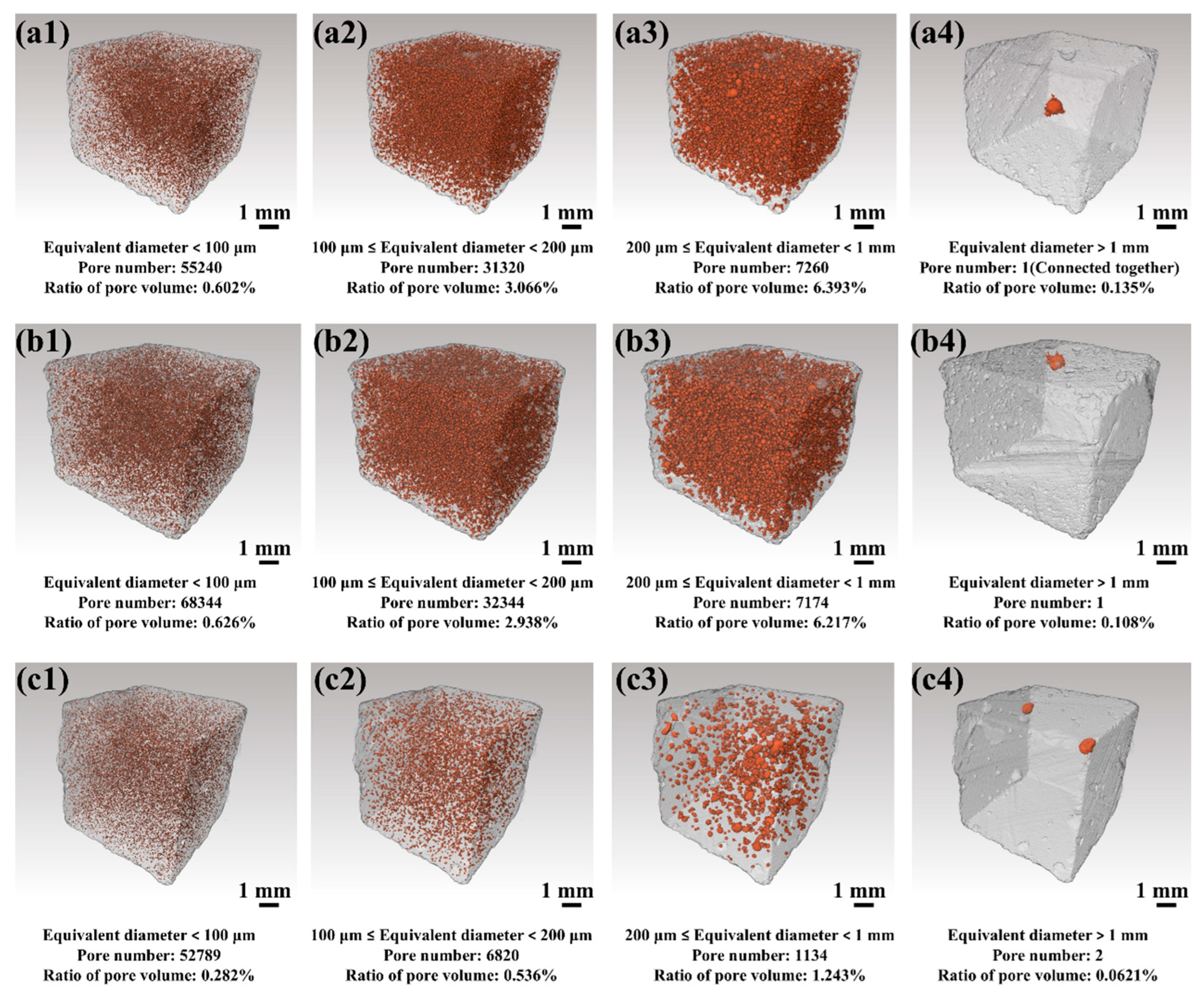

2.2.3. X-CT Analysis

2.2.4. Impermeability Test of Cement-Based Protective Coating Material

2.2.5. Electrochemical Test

3. Results and Discussion

3.1. Analysis of SEM Microstructure Characteristics of Cement-Based Protective Coating Materials

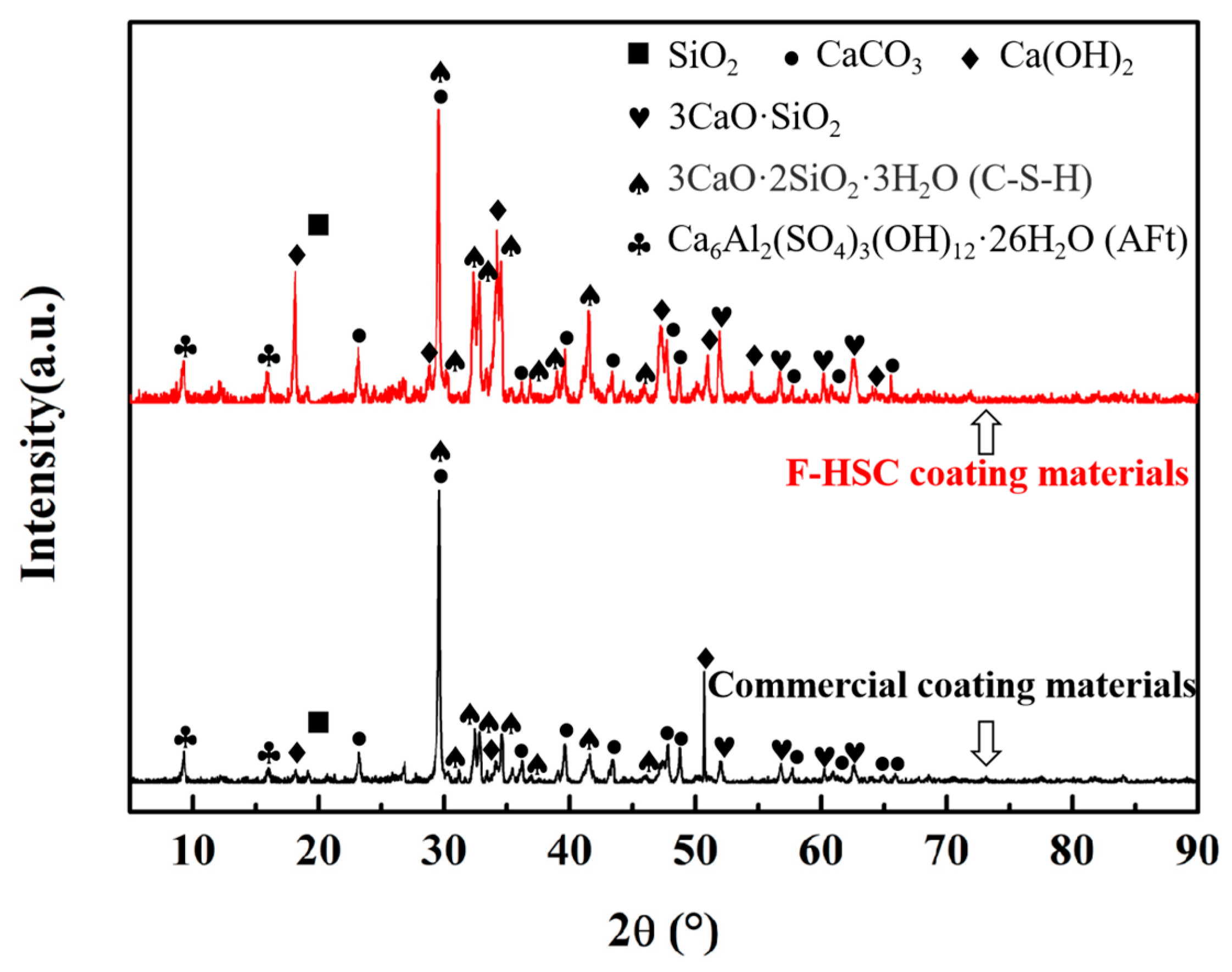

3.2. XRD Phase Analysis of Cement-Based Protective Coating Materials

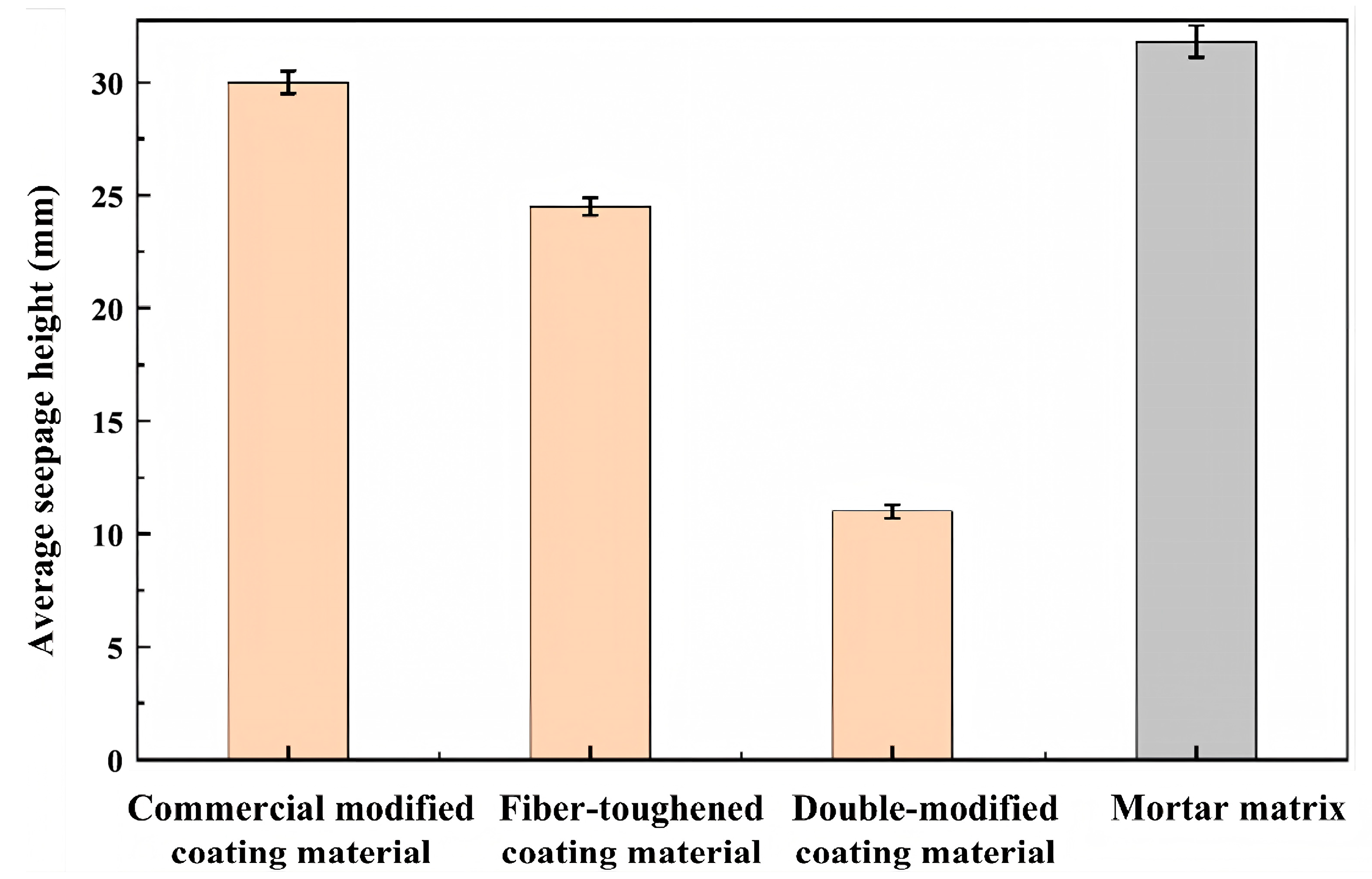

3.3. Impermeability Test of Cement-Based Protective Coating Materials

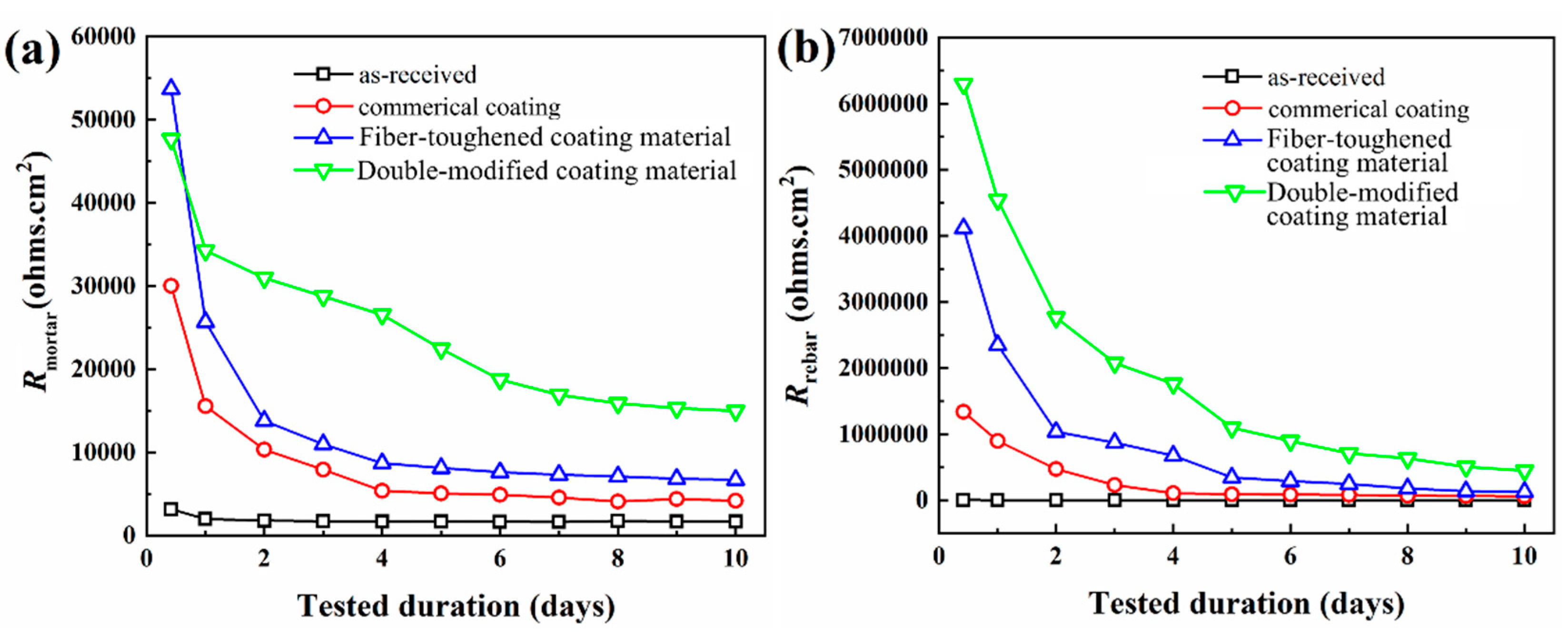

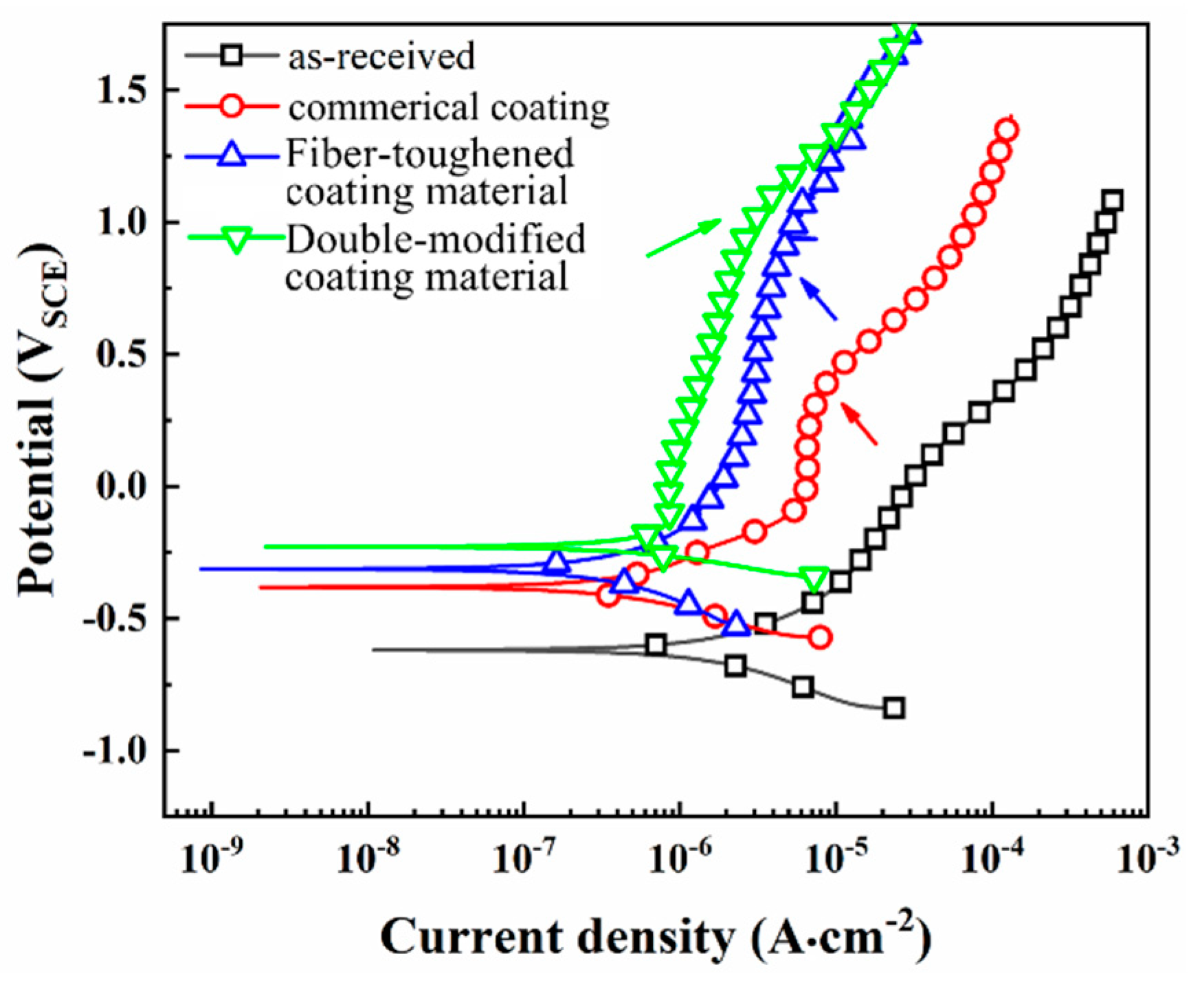

3.4. Evaluation of Corrosion Protection Performance of Cement-Based Coating Materials Based on Electrochemical Corrosion Test

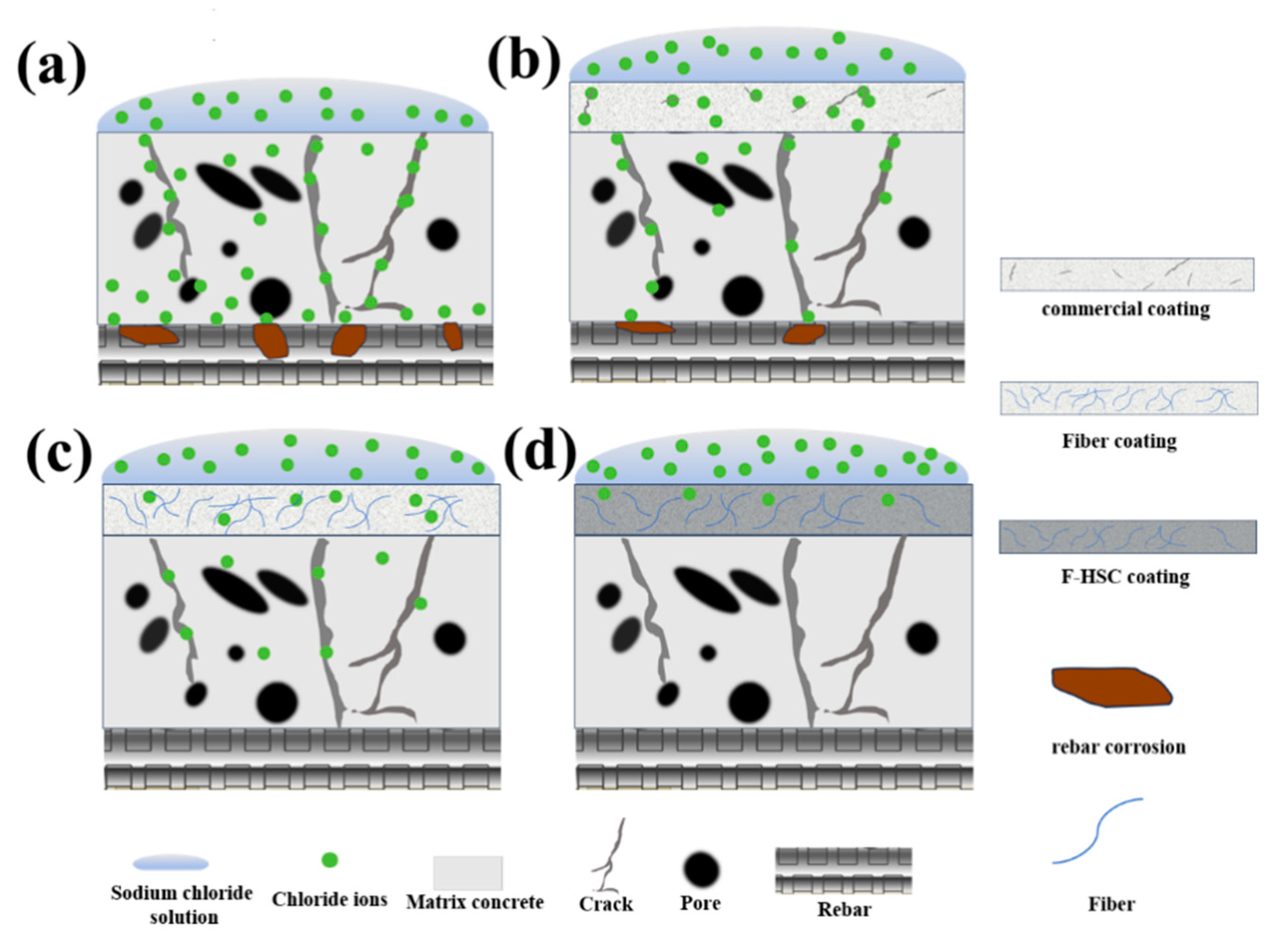

3.5. Discussion on Chlorine Salt Corrosion Protection Mechanism of Double-Modified Cement-Based Protective Coating Materials

4. Conclusions

- (1)

- The X-CT scanning analysis shows that the microstructure of the double-modified cement-based protective coating material is denser and the porosity is lower. The porosity is greatly reduced from 10.196% of the commercial cement-based protective coating material to 2.123%. The reduction in porosity can effectively improve the impermeability of the protective coating material, making its impermeability about 2.8 times higher than that of the untreated mortar.

- (2)

- The corrosion current density of the mortar rebar sample treated with the double modified coating is 8.60 × 10−7 A·cm−2, which is about 86% lower than that of the untreated sample (6.11 × 10−6 A·cm−2), which significantly reduces the corrosion rate. This indicates that the double modified cement-based protective coating can more effectively prevent chloride ion penetration, thereby delaying the occurrence of rebar corrosion.

- (3)

- The introduction of fiber effectively inhibits the formation and propagation of microcracks in cement-based protective coating materials through bridging effect, and significantly improves the toughness of coating materials. At the same time, the enhancement of the substrate realizes the optimal regulation of the cement hydration products of the cement-based protective coating material, which makes the pore structure of the coating material more density. Therefore, the double-modified cement-based protective coating material has excellent resistance to chloride ion penetration, which can provide long-term protection for RCSs in chloride erosion environment.

- (4)

- Regarding the large-scale application of the new coating materials, especially in some special application scenarios, where coating materials face external loads, even impact or erosion effects, the strength and adhesion of coatings are key properties. The potential lack of coating strength and adhesion can lead to the failure of protection, and further design and regulation are needed for optimization.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Djenaoucine, L.; Argiz, C.; Picazo, Á.; Moragues, A.; Gálvez, J.C. The corrosion-inhibitory influence of graphene oxide on steel reinforcement embedded in concrete exposed to a 3.5M NaCl solution. Cem. Concr. Compos. 2025, 155, 105835. [Google Scholar] [CrossRef]

- Yu, B.; Liu, J.B.; Chen, Z. Probabilistic evaluation method for corrosion risk of steel reinforcement based on concrete resistivity. Constr. Build. Mater. 2017, 138, 101–113. [Google Scholar] [CrossRef]

- Kenny, A.; Katz, A. Steel-concrete interface influence on chloride threshold for corrosion–Empirical reinforcement to theory. Constr. Build. Mater. 2020, 244, 118376. [Google Scholar] [CrossRef]

- Liu, Q.; Easterbrook, D.; Yang, J.; Li, L. A three-phase, multi-component ionic transport model for simulation of chloride penetration in concrete. Eng. Struct. 2015, 86, 122–133. [Google Scholar] [CrossRef]

- Yang, J.; Ye, X.; Jiang, C.; Yang, W. Effect of NaCl solution and simulated concrete pore solution environment on the efficiency of rebar energized corrosion. Materials 2022, 15, 7040. [Google Scholar]

- Heede DV, P.; Keersmaecker, D.M.; Elia, A.; Adriaens, A.; Belie, N. Service life and global warming potential of chloride exposed concrete with high volumes of fly ash. Cem. Concr. Compos. 2017, 80, 210–223. [Google Scholar] [CrossRef]

- Liu, W.L.; Wang, Q.Y.; Hao, J.; Zou, G.; Zhang, P.; Wang, G.; Ai, Z.; Chen, H.; Ma, H.; Song, D. Corrosion resistance and corrosion interface characteristics of Cr-alloyed rebar based on accelerated corrosion testing with impressed current. J. Mater. Res. Technol. 2023, 22, 2996–3009. [Google Scholar] [CrossRef]

- Yang, H.; Liu, K.; Zhang, M.; Sun, S.; Li, T. Bond performance of marine concrete with nano-particles to rebars under the action of both Cl− erosion and freeze-thaw cycles. J. Build. Eng. 2024, 95, 110105. [Google Scholar] [CrossRef]

- Sammaljärvi, J.; Li, X.; Gaboreau, S.; Betelu, S.; Donnard, J.; Sardini, P.; Siitari-Kauppi, M.; Henocq, P. Autoradiographic imaging of the spatial distribution of Cl-36 in concrete. Constr. Build. Mater. 2024, 456, 139279. [Google Scholar] [CrossRef]

- Zhang, M.; Cui, J.; Liu, K.; Sun, S. Study on the durability deterioration law of marine concrete with nano-particles under the coupled effects of freeze-thaw cycles, flexural fatigue load and Cl− erosion. J. Build. Eng. 2024, 87, 109039. [Google Scholar] [CrossRef]

- Liu, G.J.; Shen, F.M.; Zhang, Y.S.; Liu, C.; Yang, L.; Chang, H. Reactive molecular dynamics study on carbon steel corrosion induced by chloride: Effects of applied potential and temperature. Constr. Build. Mater. 2024, 411, 134250. [Google Scholar] [CrossRef]

- Qiao, Y.; Sun, W.; Jiang, J. Damage process of concrete subjected to coupling fatigue load and freeze/thaw cycles. Constr. Build. Mater. 2015, 93, 806–811. [Google Scholar] [CrossRef]

- Wang, Y.; Xiao, W.X.; Ma, K.; Dai, H.; Wang, D.; Wang, J. Revealing anti-corrosion behavior of Mg alloy concrete formwork coated with release agents in Cl−-containing Portland cement paste. Constr. Build. Mater. 2023, 406, 133413. [Google Scholar] [CrossRef]

- Zou, G.N.; Wang, Q.Y.; Wang, G.W. Revealing excellent passivation performance of a novel Cr-alloyed steel rebar in carbonized concrete environment. J. Mater. Res. Technol. 2023, 23, 1848–1861. [Google Scholar] [CrossRef]

- Shohide, M.A. Fabrication and application of an innovative low cost-efficient polymer nano-composite as concrete protective coating. Int. J. Adhes. Adhes. 2024, 128, 103542. [Google Scholar] [CrossRef]

- Leung, Y.K.C.; Zhu, H.; Kim, J.; Woo, S.C.R. Use of polymer/organoclay nanocomposite surface treatment as water/ion barrier for concrete. J. Mater. Civ. Eng. 2008, 20, 484–492. [Google Scholar] [CrossRef]

- Liu, Y.Q.; Shi, J.J. Design of a smart protective coating with molybdate-loaded halloysite nanotubes towards corrosion protection in reinforced concrete. Cem. Concr. Compos. 2024, 147, 105419. [Google Scholar] [CrossRef]

- Diamanti, M.; Brenna, A.; Bolzoni, F.; Berra, M.; Pastore, T.; Ormellese, M. Effect of polymer modified cementitious coatings on water and chloride permeability in concrete. Constr. Build. Mater. 2013, 49, 720–728. [Google Scholar] [CrossRef]

- Sergi, G.; Seneviratne GM, A.; Maleki, T.M. Control of reinforcement corrosion by surface treatment of concrete. Proc. Inst. Civ. Eng.-Struct. Build. 2000, 140, 85–100. [Google Scholar] [CrossRef]

- María AG, A.; Ruby GD, M. Alkali-activated protective coatings for reinforced concrete exposed to chlorides. Constr. Build. Mater. 2021, 268, 121098. [Google Scholar]

- Cao, S.; Erol, Y.; Yin, Z.Y.; Xue, A.; Song, W.; Sun, L. CT scanning of internal crack mechanism and strength behavior of cement-fiber-tailings matrix composites. Cem. Concr. Compos. 2020, 116, 103865. [Google Scholar] [CrossRef]

- Wang, H.; Cai, X.; Peng, X.; Wang, H.; Wang, P. Study on soil corrosion resistance reinforced with reactive powder concrete in chloride environment. Coatings 2023, 13, 1134. [Google Scholar] [CrossRef]

- Cao, J.; Zou, Z.Y.; Zeng, P.H. Mechanical properties of fly ash concrete after the coupling effects of sustained load and sulphate erosion. Constr. Build. Mater. 2025, 460, 139866. [Google Scholar] [CrossRef]

- Hemalatha, T.; Ramaswamy, A. A review on fly ash characteristics–Towards promoting high volume utilization in developing sustainable concrete. J. Clean. Prod. 2017, 147, 546–559. [Google Scholar] [CrossRef]

- Chen, G.F.; Gao, J.M.; Liu, C.; Li, S.; Zhao, Y.; Wu, H.; Guo, Z.; Luo, X.; Liu, Q.; Chen, X. Effect of waste clay brick powder and slag on mechanical properties and durability of concrete. Powder Technol. 2025, 453, 20623. [Google Scholar] [CrossRef]

- Ghosh, A.; Ransinchung, G.; Kumar, P.; Zaw, H.H.C. Effect of particle size and proportion of RAP aggregates on the strength durability and microstructure of ambient cured geopolymer concrete mixes. Constr. Build. Mater. 2024, 455, 139164. [Google Scholar] [CrossRef]

- Gao, Y.; Liu, G.; Han, X.; Gao, Q.; Ren, J. Research on the design method of mix proportion of ceramsite lightweight aggregate concrete. Constr. Build. Mater. 2024, 433, 136665. [Google Scholar] [CrossRef]

- Patel, V.J.; Desai, D.S.; Sinha, K.V. Two pack polyurethane coatings from isophthalic acid and biomaterial based polyester polyol. Int. J. Polym. Mater. Polym. Biomater. 2003, 52, 1075–1085. [Google Scholar] [CrossRef]

- Wang, M.; Wang, R.; Yao, H.; Farhan, S.; Zheng, S.; Wang, Z.; Du, C.; Jiang, H. Research on the mechanism of polymer latex modified cement. Constr. Build. Mater. 2016, 111, 710–718. [Google Scholar] [CrossRef]

- Wang, R.; Wang, P.; Li, X. Physical and mechanical properties of styrene–butadiene rubber emulsion modified cement mortars. Cem. Concr. Res. 2004, 35, 900–906. [Google Scholar] [CrossRef]

- Yang, Z.; Shi, X.; Creighton, T.A.; Peterson, M.M. Effect of styrene-butadiene rubber latex onthe chloride permeability and microstructure of Portland cement mortar. Constr. Build. Mater. 2009, 23, 2283–2290. [Google Scholar] [CrossRef]

- Luo, S.; Li, W.; Wang, D. Study on bending performance of 3D printed PVA fiber reinforced cement-based material. Constr. Build. Mater. 2024, 433, 136637. [Google Scholar] [CrossRef]

- Liu, X.Z.; Xiang, K.; Guo, Y.C.; Ye, Q.; Zhang, J.; Pei, X.; Wang, X. Experimental study on impact toughness of multi-combination hybrid fiber-reinforced magnesium phosphate cement-based materials. J. Build. Eng. 2023, 78, 107564. [Google Scholar] [CrossRef]

- Feng, S.; Xiao, H.; Geng, J. Bond strength between concrete substrate and repair mortar: Effect of fibre stiffness and substrate surface roughness. Cem. Concr. Compos. 2020, 114, 103746. [Google Scholar] [CrossRef]

- GB/T 50082-2009; Standard for Test Method of Long-Term Performance and Durability of Ordinary Concrete. Construction Industry Press: Beijing, China, 2009. (In Chinese)

- Shafiei, S.; Mohammadi, Y. Effect of AR-glass fibers and natural micronized zeolite on mechanical and permeability properties of concrete exposed to normal, sodium chloride, and magnesium sulfate environments. Constr. Build. Mater. 2024, 457, 139288. [Google Scholar] [CrossRef]

- Liu, C.; Mao, F.; Wang, J.; Li, B. Combined effect of chloride and sulfate ions on the corrosion behavior of Q355B steel in simulated concrete pore solution. Mater. Today Commun. 2024, 40, 109703. [Google Scholar] [CrossRef]

- Jin, M.; Li, W.W.; Wang, X.X.; Tang, J.; Teng, L.; Ma, Y.; Zeng, H. Investigating the dual influence of freezing-thawing cycles and chloride ion penetration on GGBS-AEA concrete deterioration. J. Build. Eng. 2023, 78, 107759. [Google Scholar] [CrossRef]

- Long, Z.; Long, G.; Tang, Z.; Shangguan, M.; Gao, G.; Yi, M.; He, Z.; Zhang, Y. Effects of aggregates and fibers on the strength and permeability of concrete exposed to low vacuum environment. J. Build. Eng. 2024, 97, 110902. [Google Scholar] [CrossRef]

- Kampai, C.; Chindasiriphan, P.; Jongvivatsakul, P.; Mao, P.; Tangchirapat, W. Durability properties of high-strength concrete with high-volume bottom ash as a substitute for cement and fine aggregate. Constr. Build. Mater. 2024, 457, 139401. [Google Scholar] [CrossRef]

| Chemical Composition | CaO | SiO2 | Al2O3 | CO2 | Fe2O3 | SO3 | Na2O | K2O |

|---|---|---|---|---|---|---|---|---|

| Content (wt.%) | 52.79 | 19.34 | 10.06 | 5.08 | 4.77 | 3.86 | 2.29 | 1.01 |

| Chemical Composition | CaO | SiO2 | Al2O3 | CO2 | Fe2O3 | SO3 | K2O |

|---|---|---|---|---|---|---|---|

| Content (wt.%) | 59.90 | 16.47 | 5.21 | 6.68 | 5.06 | 4.57 | 1.01 |

| Water–Cement Ratio | Water/kg | Commercial Coating Material/kg | P·II 52.5R Portland Cement/kg | Polypropylene Fiber/kg | |

|---|---|---|---|---|---|

| Commercial coating material | 0.25 | 0.2 | 0.8 | 0 | 0 |

| Fiber-toughened coating material | 0.25 | 0.2 | 0.8 | 0 | 0.003 |

| Double-modified coating material | 0.25 | 0.2 | 0.56 | 0.24 | 0.003 |

| Raw Materials | P·O 42.5 Cement | Standard Sand | Water |

|---|---|---|---|

| Content (kg/m3) | 700 | 1259 | 280 |

| Samples | Ecorr (VSCE) | icorr (A·cm−2) | Epit (VSCE) |

|---|---|---|---|

| as-received | −0.620 | 6.11 × 10−6 | / |

| Commercial coating | −0.382 | 4.06 × 10−6 | 0.35 |

| Fiber-toughened coating | −0.313 | 1.32 × 10−6 | 0.81 |

| Double-modified coating | −0.229 | 8.60 × 10−7 | 0.82 |

| <100 μm | 100 μm~200 μm | 200 μm~1 mm | >1 mm | |

|---|---|---|---|---|

| Commercial coating material (%) | 0.602 | 3.066 | 6.393 | 0.135 |

| Fiber-toughened coating material (%) | 0.626 | 2.938 | 6.217 | 0.108 |

| Double-modified coating material (%) | 0.282 | 0.536 | 1.243 | 0.0621 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hua, Q.; Wu, C.; Zhu, Y.; Wang, J.; Zhou, Z.; Wang, X.; Wang, G.; Zhang, S.; Song, D. Design and Preparation of a Novel Double-Modified Cement-Based Protective Coating Material and Its Improved Protection Performance Against Chloride Corrosion. Coatings 2025, 15, 277. https://doi.org/10.3390/coatings15030277

Hua Q, Wu C, Zhu Y, Wang J, Zhou Z, Wang X, Wang G, Zhang S, Song D. Design and Preparation of a Novel Double-Modified Cement-Based Protective Coating Material and Its Improved Protection Performance Against Chloride Corrosion. Coatings. 2025; 15(3):277. https://doi.org/10.3390/coatings15030277

Chicago/Turabian StyleHua, Quan, Changyun Wu, Yangshun Zhu, Juhang Wang, Zhou Zhou, Xing Wang, Guowei Wang, Shuguang Zhang, and Dan Song. 2025. "Design and Preparation of a Novel Double-Modified Cement-Based Protective Coating Material and Its Improved Protection Performance Against Chloride Corrosion" Coatings 15, no. 3: 277. https://doi.org/10.3390/coatings15030277

APA StyleHua, Q., Wu, C., Zhu, Y., Wang, J., Zhou, Z., Wang, X., Wang, G., Zhang, S., & Song, D. (2025). Design and Preparation of a Novel Double-Modified Cement-Based Protective Coating Material and Its Improved Protection Performance Against Chloride Corrosion. Coatings, 15(3), 277. https://doi.org/10.3390/coatings15030277