Nondestructive Evaluation of Aging Failure in Insulation Coatings by Ultrasonic Guided Wave Based on Signal Processing and Machine Learning

Abstract

:1. Introduction

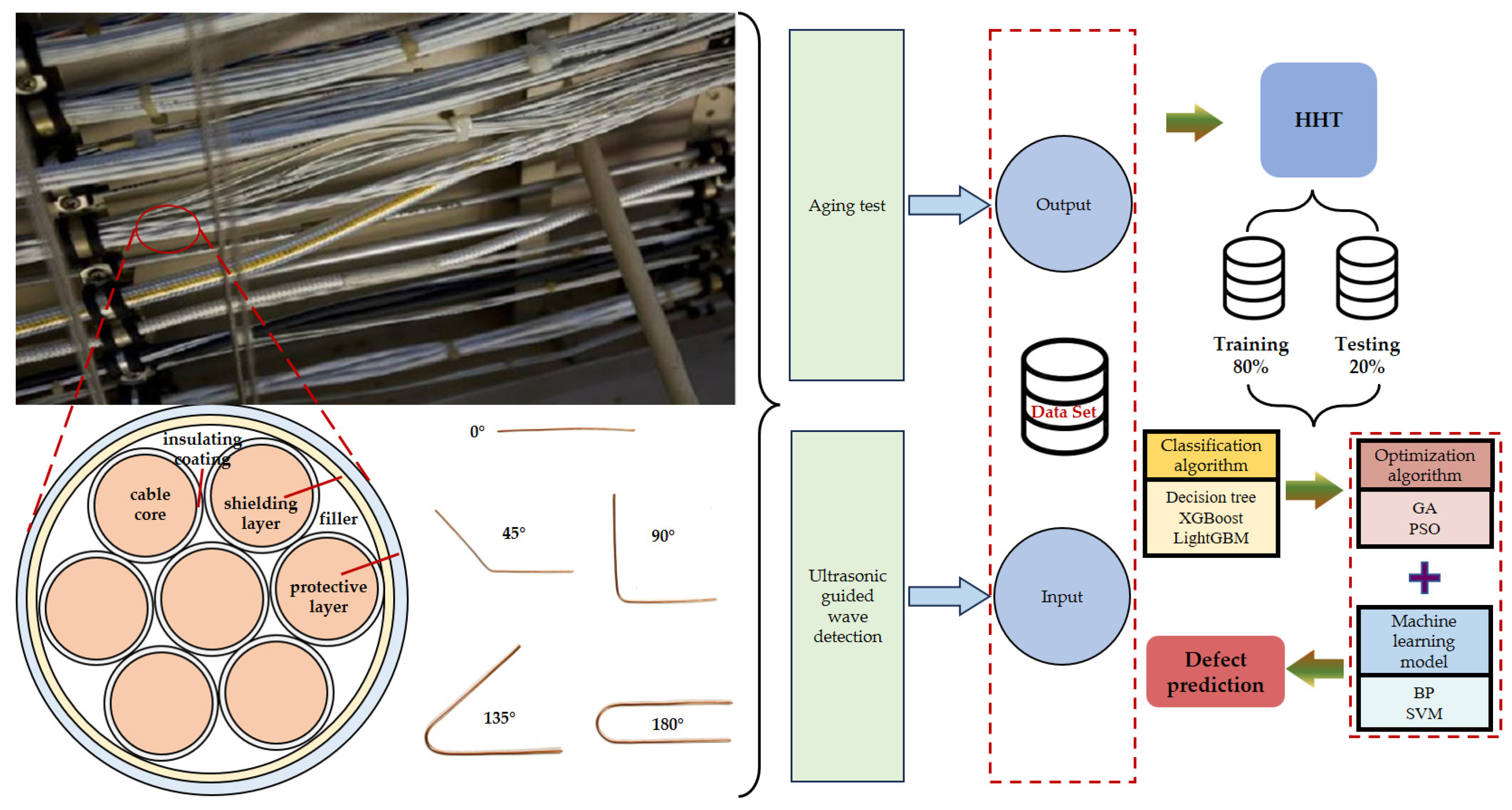

2. Materials and Methods

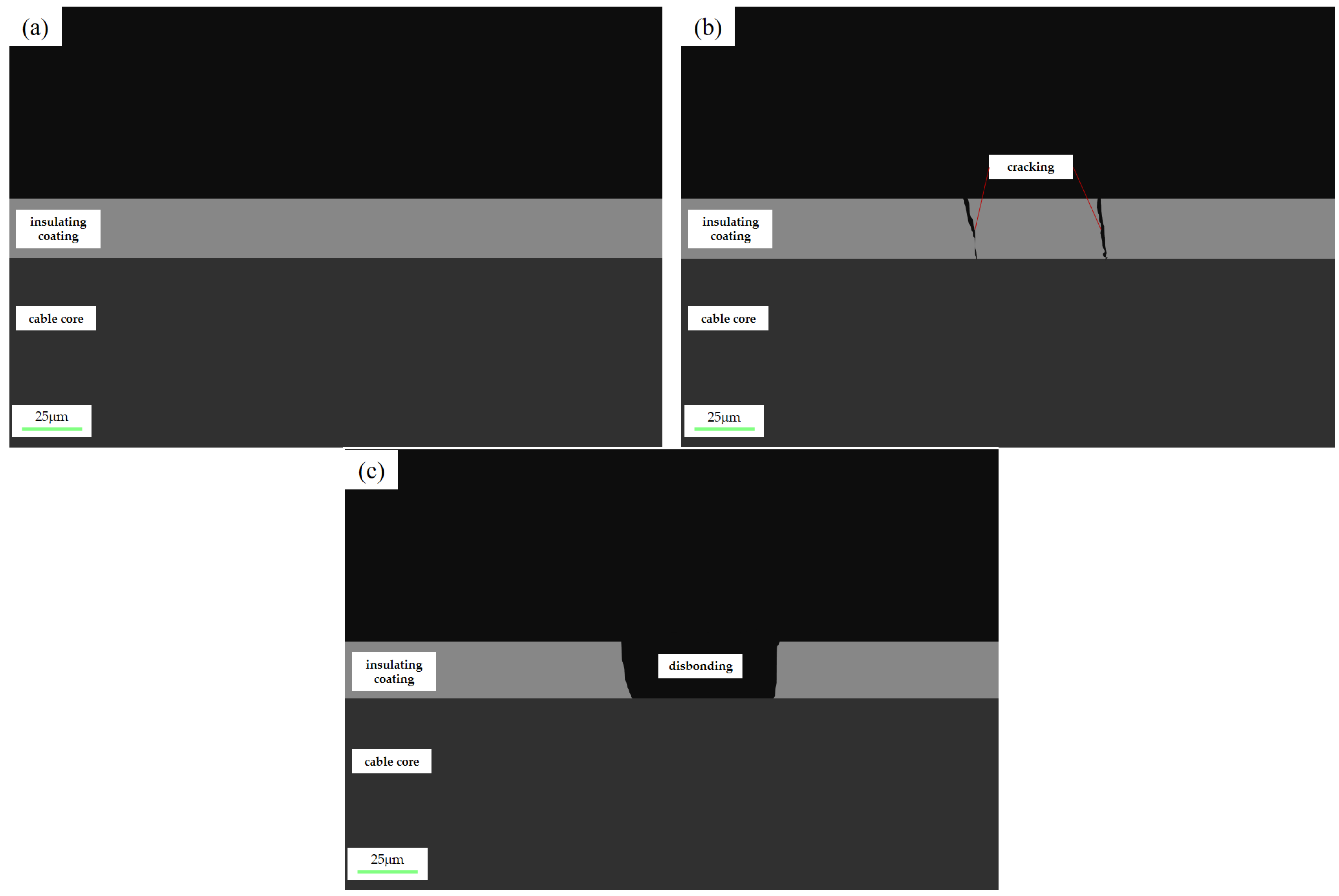

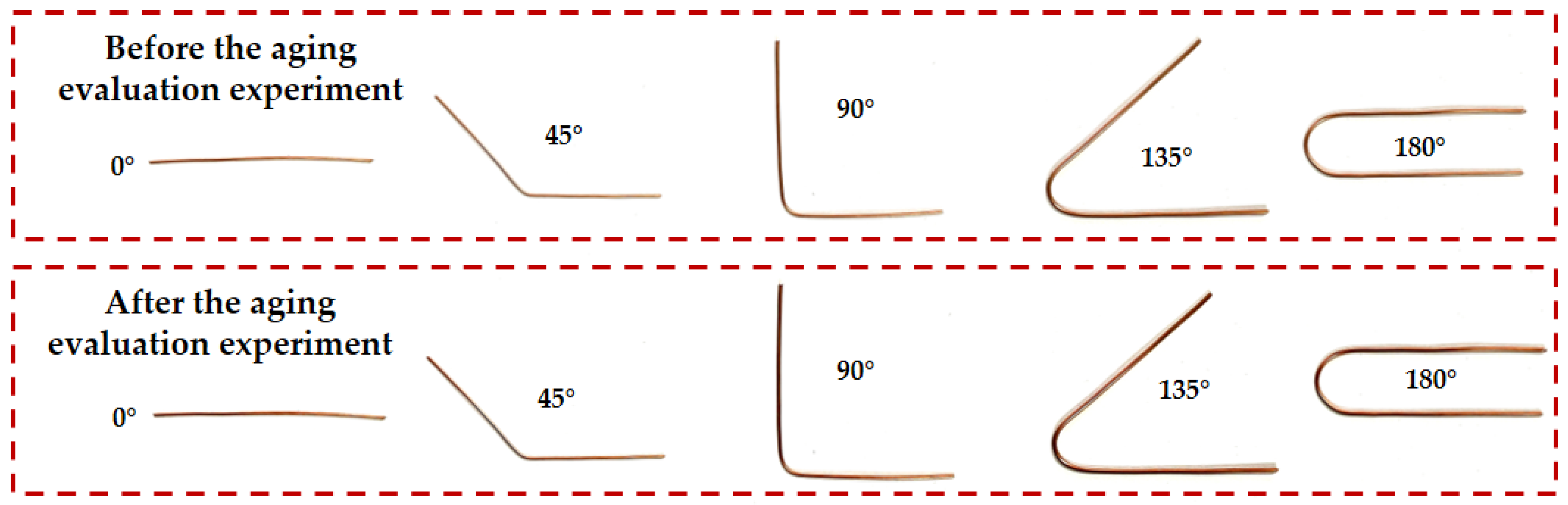

2.1. Specimen Preparation and Defect Detection

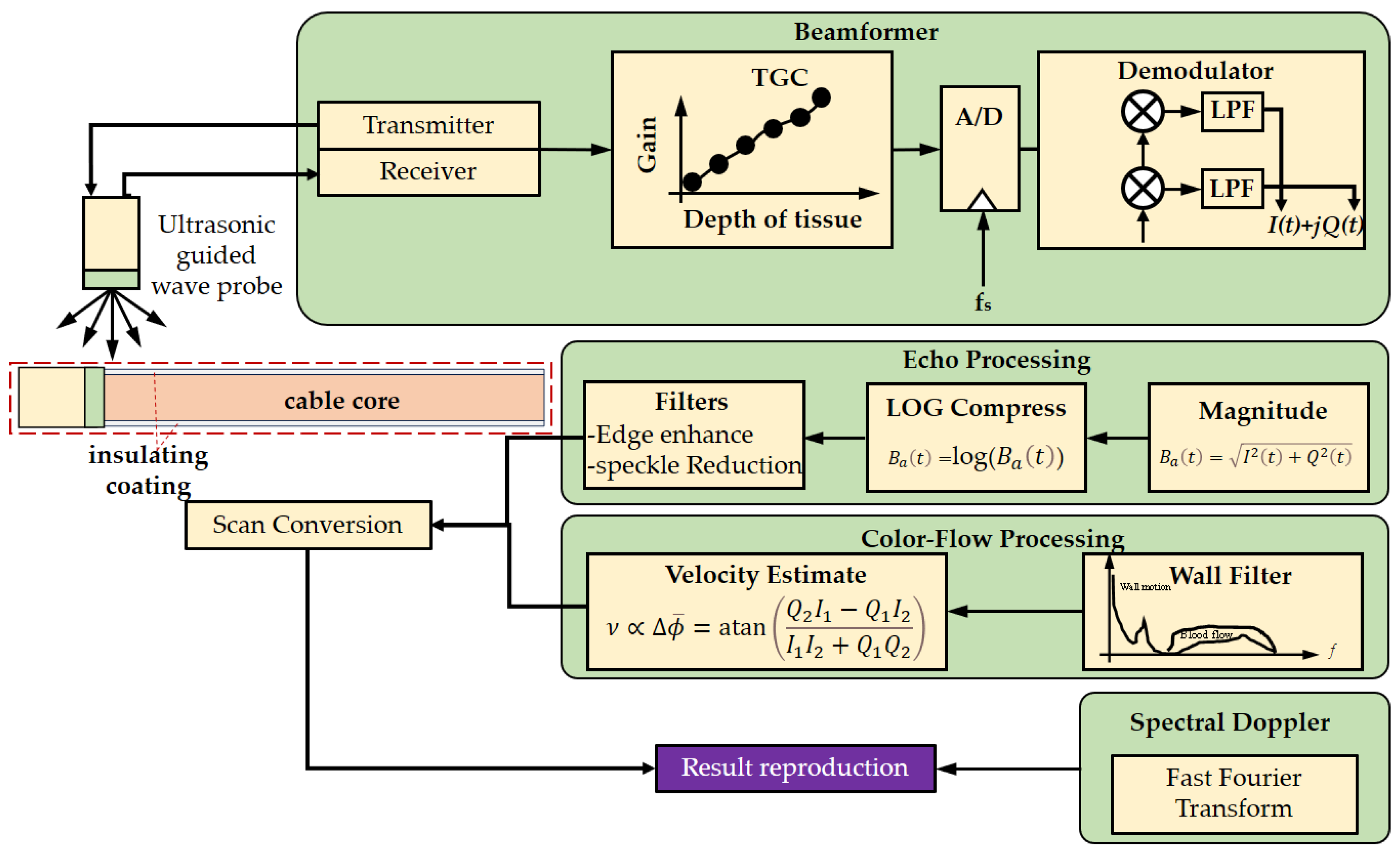

2.2. Data Processing

2.3. Machine Learning Model Building

3. Results and Discussion

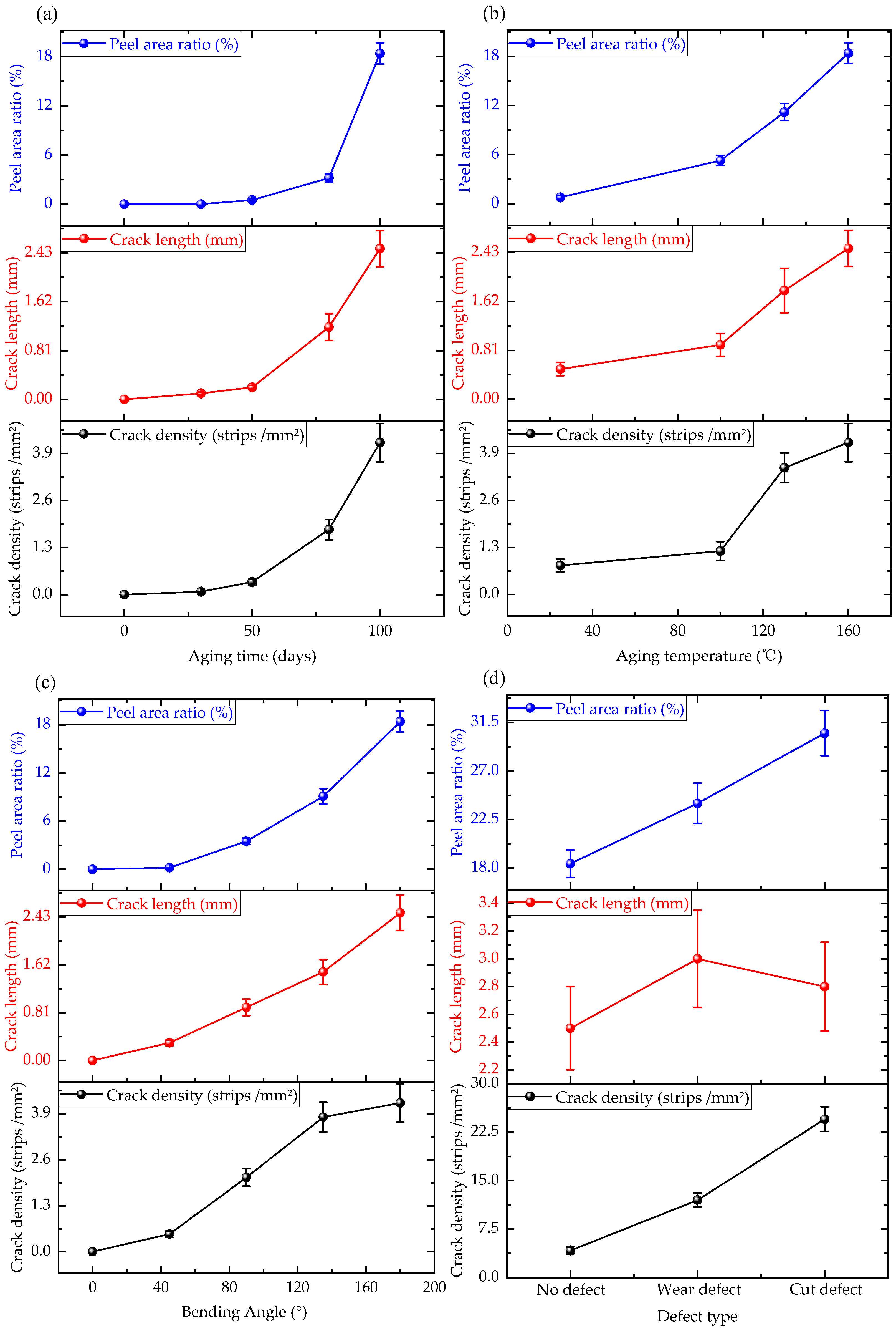

3.1. Effect of Different Aging Parameters on the Insulation Coating of Cable Cores

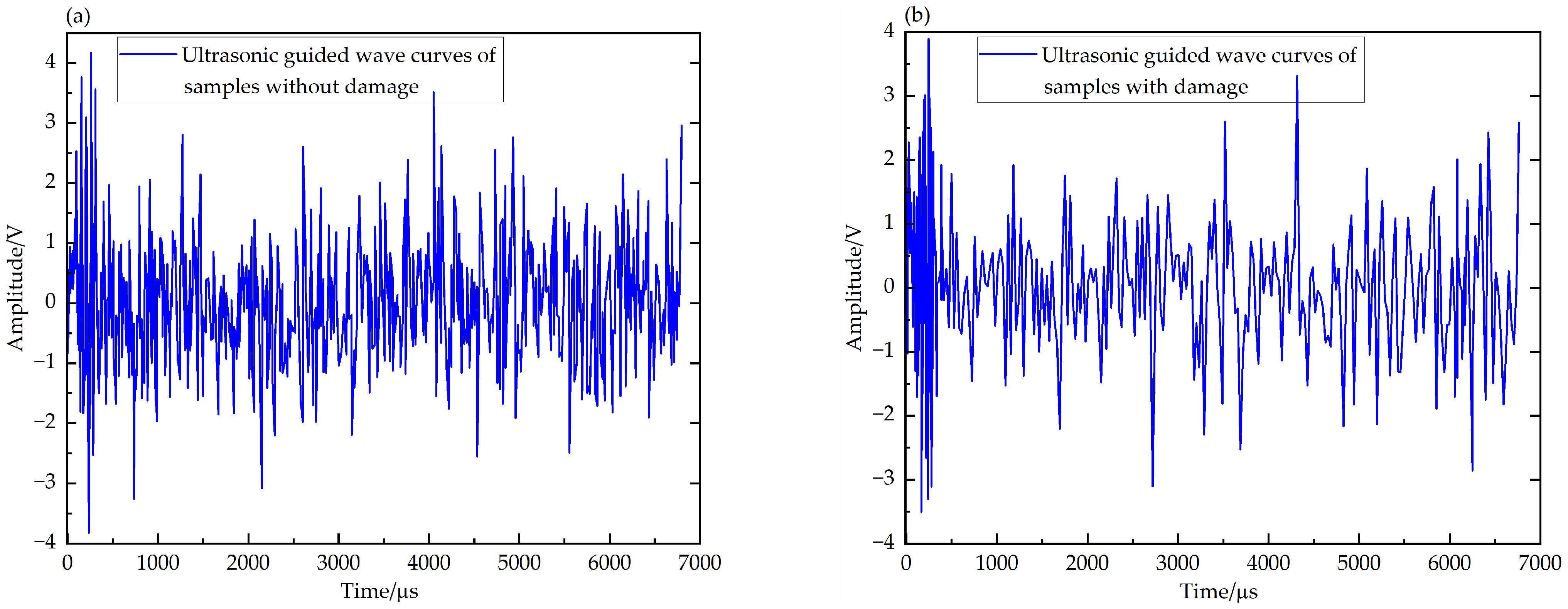

3.2. Ultrasonic Guided Wave Detection and Signal Processing Results

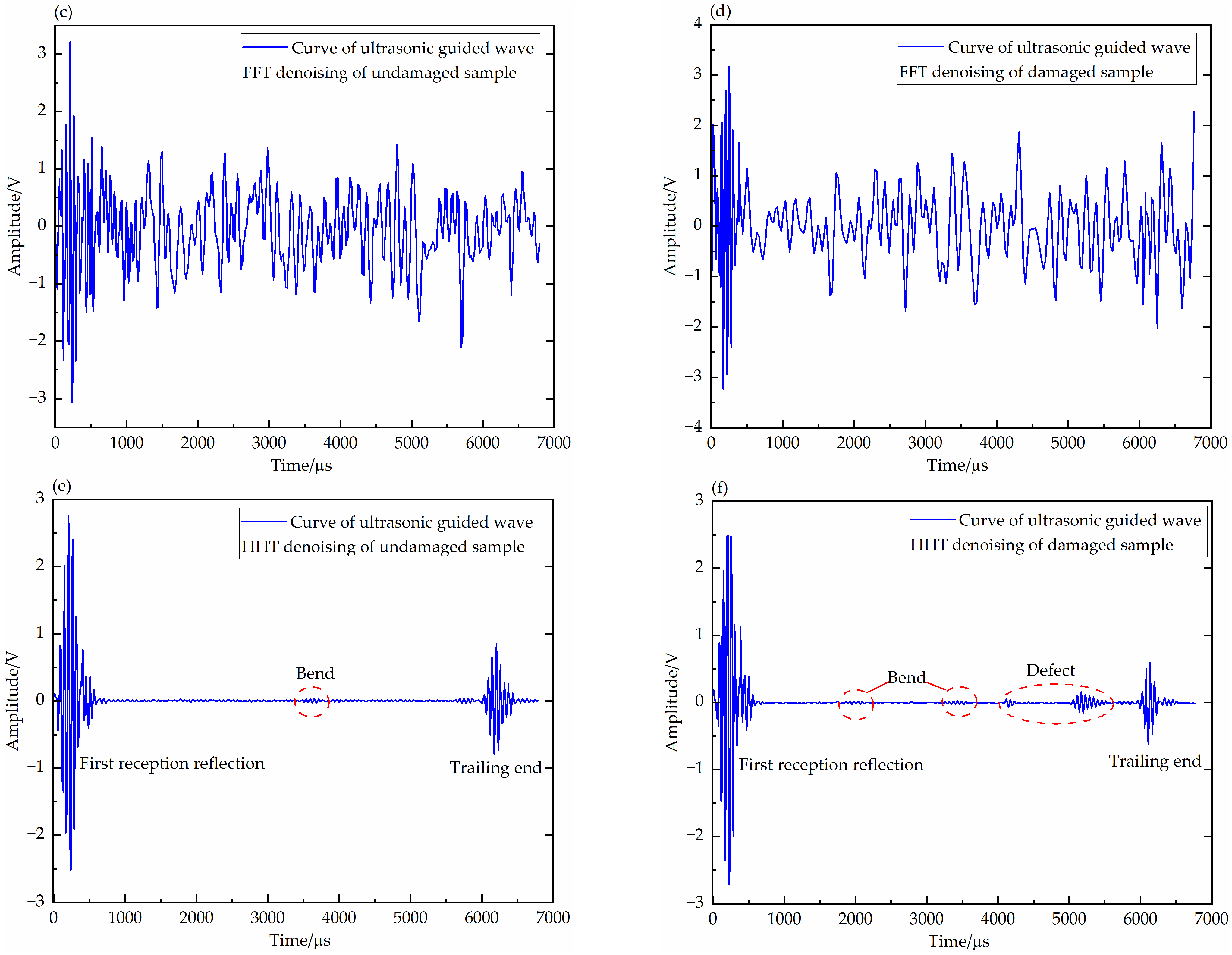

3.3. Machine Learning Modeling Results

4. Conclusions

- Significant effects of aging parameters on coating life: Experiments show that aging time and temperature have nonlinear accelerating effects on coating damage, with 50 days as the critical inflection point for damage accumulation and 130 °C as the critical threshold for sudden change in performance. Mechanical stress concentration significantly accelerates coating failure at bending angles greater than 90°. Preset defects, especially cut defects, significantly enhance the crack density and peeling area through stress concentration, shortening the cable life to 40% of the defect-free group.

- Effectiveness of ultrasonic guided wave and HHT noise reduction: The study confirms that HHT noise reduction is superior to FFT in processing ultrasonic guided wave signals and can effectively extract the characteristic signals to realize in situ quantitative assessment of coating damage. The noise-reduced ultrasonic guided wave signal has higher sensitivity to bending and damage and is suitable for the early detection of micro-defects in cable coatings.

- Excellent prediction performance of the machine learning model: the LightGBM classification model exhibits the highest classification accuracy and AUC value (0.94), and the prediction model (LightGBM-PSO-SVM) constructed by combining the PSO-SVM regression algorithm reaches an accuracy of 94.05% on the training set and 88.36% on the test set, with an error close to 0, which is significantly better than that of the unclassified data constructed. Although the accuracy on the test set is still high, there is a certain gap compared to the training set, which may indicate that the model has an overfitting problem. In future studies, we will focus on further optimizing the model structure, adjusting parameters, and increasing data diversity to reduce the risk of overfitting and improve the generalization ability of the model.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Singer, C.; Guernsey, C.M.; Gousy, J.; Cottingham, J.D.; Frerichs, J. Aircraft Electrical Power Systems and Nonlinear Dynamic Loads. SAE Int. J. Aerosp. 2012, 5, 447–454. [Google Scholar] [CrossRef]

- Muja, O.; Lamper, D. Automated Fault Isolation of Intermittent Wiring/Conductive Path Systems Inside Weapons Replaceable Assemblies. SAE Int. J. Aerosp. 2012, 5, 579–589. [Google Scholar] [CrossRef]

- Shi, X.; Zhang, L.; Jing, T.; Wang, L. Research on aircraft cable defects locating method based on time-frequency domain reflection. Procedia Eng. 2011, 17, 446–454. [Google Scholar]

- Xu, C.; Song, W.; Pan, Q.; Li, H.; Liu, S. Nondestructive testing residual stress using ultrasonic critical refracted longitudinal wave. Phys. Procedia 2015, 70, 594–598. [Google Scholar] [CrossRef]

- Dong, Z.; Jun, Z.R.; Ma, Y.Z.; An, X.N. The Present Development Situation of Air-Coupled Ultrasonic Non-Destructive Testing Technology. Adv. Mater. Res. 2012, 532, 178–182. [Google Scholar] [CrossRef]

- Chen, W.; Huang, S. Human Reliability Analysis for Visual Inspection in Aviation Maintenance by a Bayesian Network Approach. Transp. Res. Rec. 2014, 2449, 105–113. [Google Scholar] [CrossRef]

- Papa, U.; Ponte, S. Preliminary Design of an Unmanned Aircraft System for Aircraft General Visual Inspection. Electronics 2018, 7, 435. [Google Scholar] [CrossRef]

- Zhang, Z.W.; Chen, L.; Ren, B.F. Design of Insulation Resistance Test for Cables in Intelligent Munition. Key Eng. Mater. 2011, 474, 361–364. [Google Scholar] [CrossRef]

- Barnum, J.R.; Warne, L.K.; Jorgenson, R.E.; Schneider, L.X. Method and apparatus for electrical cable testing by pulse-arrested spark discharge. J. Technol. Educ. 2005, 12, 21–34. [Google Scholar]

- Schneider, L.; Howard, K.; Glover, S.; Lockner, T.; Dinallo, M. A new capability to detect and locate insulation defects in complex wiring systems. IEEE Electr. Insul. Mag. 2005, 21, 14–20. [Google Scholar] [CrossRef]

- Smith, P.; Furse, C.; Gunther, J. Analysis of spread spectrum time domain reflectometry for wire fault location. IEEE Sens. J. 2005, 5, 1469–1478. [Google Scholar] [CrossRef]

- Zhang, X.; Zhang, M.; Liu, D. Reconstruction of Faulty Cable Network Using Time- Domain Reflectometry. PIER 2013, 136, 457–478. [Google Scholar] [CrossRef]

- Wang, X.; Li, W.; Chen, L.; Bao, X. Distributed Mode Coupling Measurement Along Tapered Single-Mode Fibers with Optical Frequency-Domain Reflectometry. J. Lightwave Technol. 2012, 30, 1499–1508. [Google Scholar] [CrossRef]

- Ding, Z.; Yao, X.S.; Liu, T.; Du, Y.; Liu, K.; Han, Q.; Meng, Z.; Chen, H. Long-range vibration sensor based on correlation analysis of optical frequency-domain reflectometry signals. Opt. Express 2012, 20, 28319. [Google Scholar] [CrossRef]

- Das, S.; Santoso, S.; Gaikwad, A.; Patel, M. Impedance-based fault location in transmission networks: Theory and application. IEEE Access 2014, 2, 537–557. [Google Scholar] [CrossRef]

- Rosiek, M.; Martowicz, A.; Uhl, T. Electromechanical impedance based SHM system for aviation applications. Key Eng. Mater. 2012, 518, 127–136. [Google Scholar] [CrossRef]

- Zhang, J.; Zhang, Y.; Guan, Y. Analysis of time-domain reflectometry combined with wavelet transform for fault detection in aircraft shielded cables. IEEE Sens. J. 2016, 16, 4579–4586. [Google Scholar] [CrossRef]

- Zhao, W.; Song, Y.H.; Chen, W.R. Improved GPS travelling wave fault locator for power cables by using wavelet analysis. Int. J. Electr. Power Energy Syst. 2001, 23, 403–411. [Google Scholar] [CrossRef]

- Souza, R.E.; Gomes, R.M.; Lima, G.S.; Silveira, F.H.; De Conti, A.; Visacro, S. Analysis of the impulse breakdown behavior of covered cables used in compact distribution lines. Electr. Power Syst. Res. 2018, 159, 24–30. [Google Scholar] [CrossRef]

- Chet, L.; Furse, C. Noise-domain reflectometry for locating wiring faults. IEEE Trans. Electromagn. Compat. 2005, 47, 97–104. [Google Scholar]

- Shangguan, M.; Wang, C.; Xia, H.; Shentu, G.; Dou, X.; Zhang, Q.; Pan, J.W. Brillouin optical time domain reflectometry for fast detection of dynamic strain incorporating double-edge technique. Opt. Commun. 2017, 398, 95–100. [Google Scholar] [CrossRef]

- Sidhu, T.S.; Xu, Z. Detection of incipient faults in distribution underground cables. IEEE Trans. Power Deliv. 2010, 25, 1363–1371. [Google Scholar] [CrossRef]

- Leinov, E.; Lowe, M.J.S.; Cawley, P. Investigation of guided wave propagation and attenuation in pipe buried in sand. J. Sound Vib. 2015, 36, 96–114. [Google Scholar] [CrossRef]

- Guan, R.; Lu, Y.; Duan, W.; Wang, X. Guided waves for damage identification in pipeline structures: A review. Struct. Control Health Monit. 2017, 24, e2007. [Google Scholar] [CrossRef]

- Narendar, S.; Gopalakrishnan, S. Nonlocal continuum mechanics based ultrasonic flexural wave dispersion characteristics of a monolayer graphene embedded in polymer matrix. Compos. Part B Eng. 2012, 43, 3096–3103. [Google Scholar] [CrossRef]

- Ghorbanpour, A.A.; Kolahchi, R.; Mortazavi, S.A. Nonlocal piezoelasticity based wave propagation of bonded double-piezoelectric nanobeam-systems. Int. J. Mech. Mater. Des. 2014, 10, 179–191. [Google Scholar] [CrossRef]

- Ma, L.H.; Ke, L.L.; Wang, Y.Z.; Wang, Y.S. Wave propagation analysis of piezoelectric nanoplates based on the nonlocal theory. Int. J. Struct. Stab. Dyn. 2018, 18, 1850060. [Google Scholar] [CrossRef]

- Chen, W.Q.; Wu, B.; Zhang, C.L.; Zhang, C. On wave propagation in anisotropic elastic cylinders at nanoscale: Surface elasticity and its effect. Acta Mech. 2014, 225, 2743–2760. [Google Scholar] [CrossRef]

- Wu, Y.; Feng, J. Development and application of artificial neural network. Wirel. Pers. Commun. 2018, 102, 1645–1656. [Google Scholar] [CrossRef]

- Xu, Z.; Yin, C.; Wu, Y.; Liu, H.; Zhou, H.; Xu, S.; Xu, J.; Ye, D. Terahertz Nondestructive Measurement of Heat Radiation Performance of Thermal Barrier Coatings Based on Hybrid Artificial Neural Network. Coatings 2024, 14, 647. [Google Scholar] [CrossRef]

- Abiodun, O.I.; Jantan, A.; Omolara, A.E.; Dada, K.V.; Mohamed, N.A.; Arshad, H. State-of-the-art in artificial neural network applications: A survey. Heliyon 2018, 4, e00938. [Google Scholar] [CrossRef] [PubMed]

- Khandelwal, M.; Marto, A.; Fatemi, S.A.; Ghoroqi, M.; Armaghani, D.J.; Singh, T.N.; Tabrizi, O. Implementing an ANN model optimized by genetic algorithm for estimating cohesion of limestone samples. Eng. Comput. 2018, 34, 307–317. [Google Scholar] [CrossRef]

- McCall, J. Genetic algorithms for modelling and optimisation. J. Comput. Appl. Math. 2005, 184, 205–222. [Google Scholar] [CrossRef]

- Marini, F.; Walczak, B. Particle swarm optimization (PSO). A tutorial. Chemometr. Intell. Lab. Syst. 2015, 149, 153–165. [Google Scholar] [CrossRef]

- Ding, S.; Su, C.; Yu, J. An optimizing BP neural network algorithm based on genetic algorithm. Artif. Intell. Rev. 2011, 36, 153–162. [Google Scholar] [CrossRef]

- Noble, W.S. What is a support vector machine? Nat. Biotechnol. 2006, 24, 1565–1567. [Google Scholar] [CrossRef] [PubMed]

- Akram, N.A.; Isa, D.; Rajkumar, R.; Lee, L.H. Active incremental Support Vector Machine for oil and gas pipeline defects prediction system using long range ultrasonic transducers. Ultrasonics 2014, 54, 1534–1544. [Google Scholar] [CrossRef]

- Oberst, U. The fast Fourier transform. SICON 2007, 46, 496–540. [Google Scholar] [CrossRef]

- Qin, S.R.; Zhong, Y.M. A new envelope algorithm of Hilbert–Huang transform. Mech. Syst. Signal Process. 2006, 20, 1941–1952. [Google Scholar] [CrossRef]

- Song, Y.Y.; Ying, L.U. Decision tree methods: Applications for classification and prediction. Shanghai Arch. Psychiatry 2015, 27, 130. [Google Scholar]

- Li, J.; An, X.; Li, Q.; Wang, C.; Yu, H.; Zhou, X.; Geng, Y.A. Application of XGBoost algorithm in the optimization of pollutant concentration. Atmos. Res. 2022, 276, 106238. [Google Scholar] [CrossRef]

- GuolinKe, Q.M.; Finley, T.; Wang, T.; Chen, W.; Ma, W.; Ye, Q.; Liu, T.Y. Lightgbm: A highly efficient gradient boosting decision tree. Adv. Neural Inf. Process. Syst. 2017, 30, 52. [Google Scholar]

- Delor-Jestin, F.; Drouin, D.; Cheval, P.Y.; Lacoste, J. Thermal and photochemical ageing of epoxy resin–Influence of curing agents. Polym. Degrad. Stab. 2006, 91, 1247–1255. [Google Scholar] [CrossRef]

| Aging Time/Day | Aging Temperature/°C | Bending Angle/° | Preset Defects |

|---|---|---|---|

| 0, 10, 20, 30, 40, 50, 60, 70, 80, 90, 100 | Room temperature, 100, 130, 160 | 0, 45, 90, 135, 180 | No defects, abrasions, cuts |

| Model | Optimization Algorithms | RMSE | R2adj | Training Time/s |

|---|---|---|---|---|

| BP | None | 0.25 | 0.82 | 310 |

| GA | 0.06 | 0.98 | 520 | |

| SVM | None | 0.20 | 0.89 | 290 |

| PSO | 0.03 | 0.99 | 480 |

| Model | Optimization Algorithms | RMSE | R2adj | Training Time/s |

|---|---|---|---|---|

| BP | None | 0.42 | 0.65 | 420 |

| GA | 0.24 | 0.83 | 670 | |

| SVM | None | 0.32 | 0.73 | 390 |

| PSO | 0.21 | 0.87 | 580 |

| Model | Optimization Algorithms | RMSE | R2adj |

|---|---|---|---|

| BP | None | 0.28 | 0.81 |

| GA | 0.19 | 0.90 | |

| SVM | None | 0.22 | 0.87 |

| PSO | 0.15 | 0.94 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Qiu, M.; Ge, X. Nondestructive Evaluation of Aging Failure in Insulation Coatings by Ultrasonic Guided Wave Based on Signal Processing and Machine Learning. Coatings 2025, 15, 347. https://doi.org/10.3390/coatings15030347

Qiu M, Ge X. Nondestructive Evaluation of Aging Failure in Insulation Coatings by Ultrasonic Guided Wave Based on Signal Processing and Machine Learning. Coatings. 2025; 15(3):347. https://doi.org/10.3390/coatings15030347

Chicago/Turabian StyleQiu, Mengmeng, and Xin Ge. 2025. "Nondestructive Evaluation of Aging Failure in Insulation Coatings by Ultrasonic Guided Wave Based on Signal Processing and Machine Learning" Coatings 15, no. 3: 347. https://doi.org/10.3390/coatings15030347

APA StyleQiu, M., & Ge, X. (2025). Nondestructive Evaluation of Aging Failure in Insulation Coatings by Ultrasonic Guided Wave Based on Signal Processing and Machine Learning. Coatings, 15(3), 347. https://doi.org/10.3390/coatings15030347