Effect of Partial Fibre Laser Processing on the Wear Resistance of NiCrMoFeCSiB Coatings

Abstract

1. Introduction

- Control and limitation of the hard phase content and the use of additional alloying elements (e.g., rare earth oxides) allow for obtaining a more ductile and fine structure of the coating metal [36];

- Optimisation of the laser processing parameters and the use of numerical modelling to predict crack formation [36];

- Using preheating of the substrate before the formation of the coating allows for reducing the temperature gradient and thermal stresses in the coating metal [33];

- Using post-thermal treatment of the formed coatings allows the creation of a uniform, fine and equiaxed structure of the coating metal [38].

2. Materials and Methods

3. Results

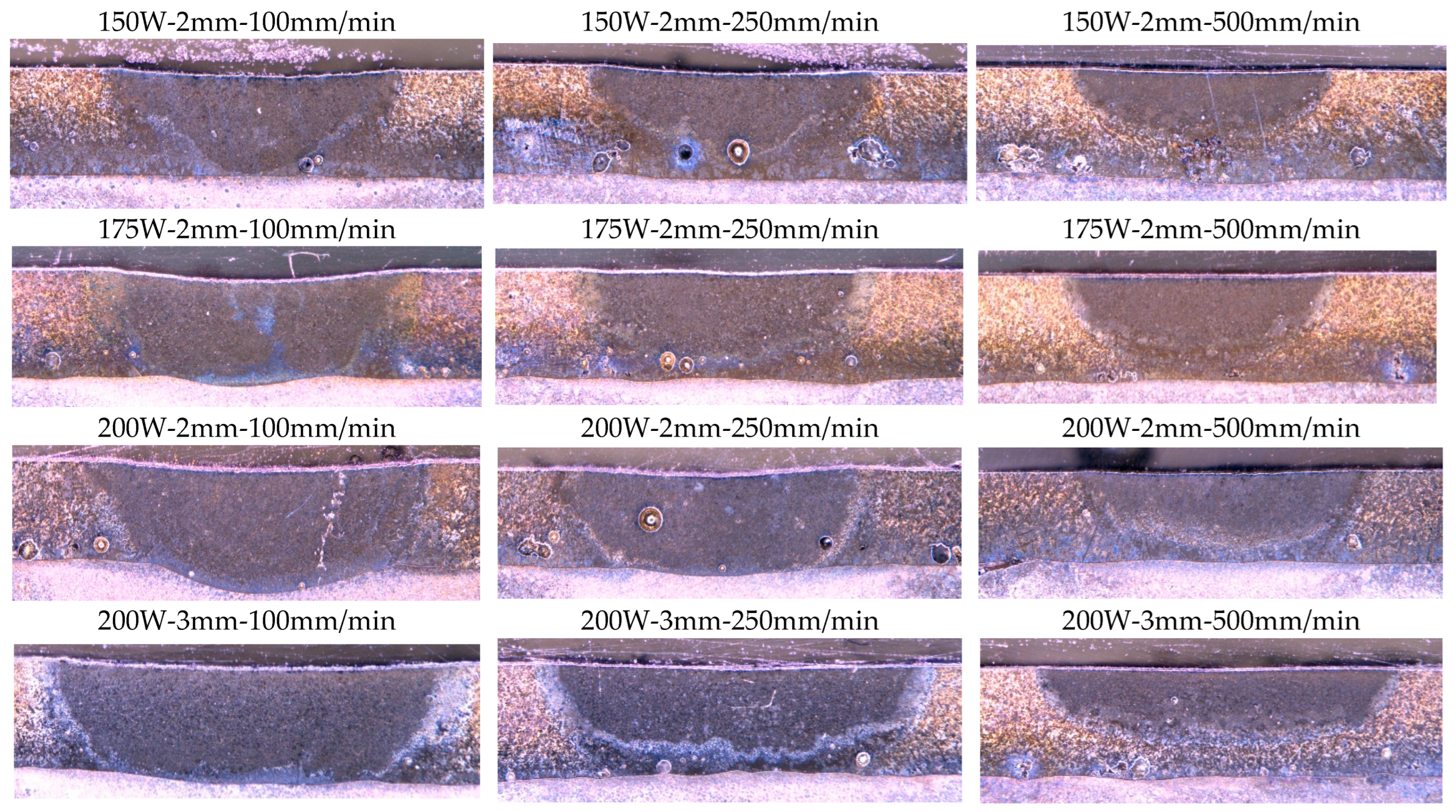

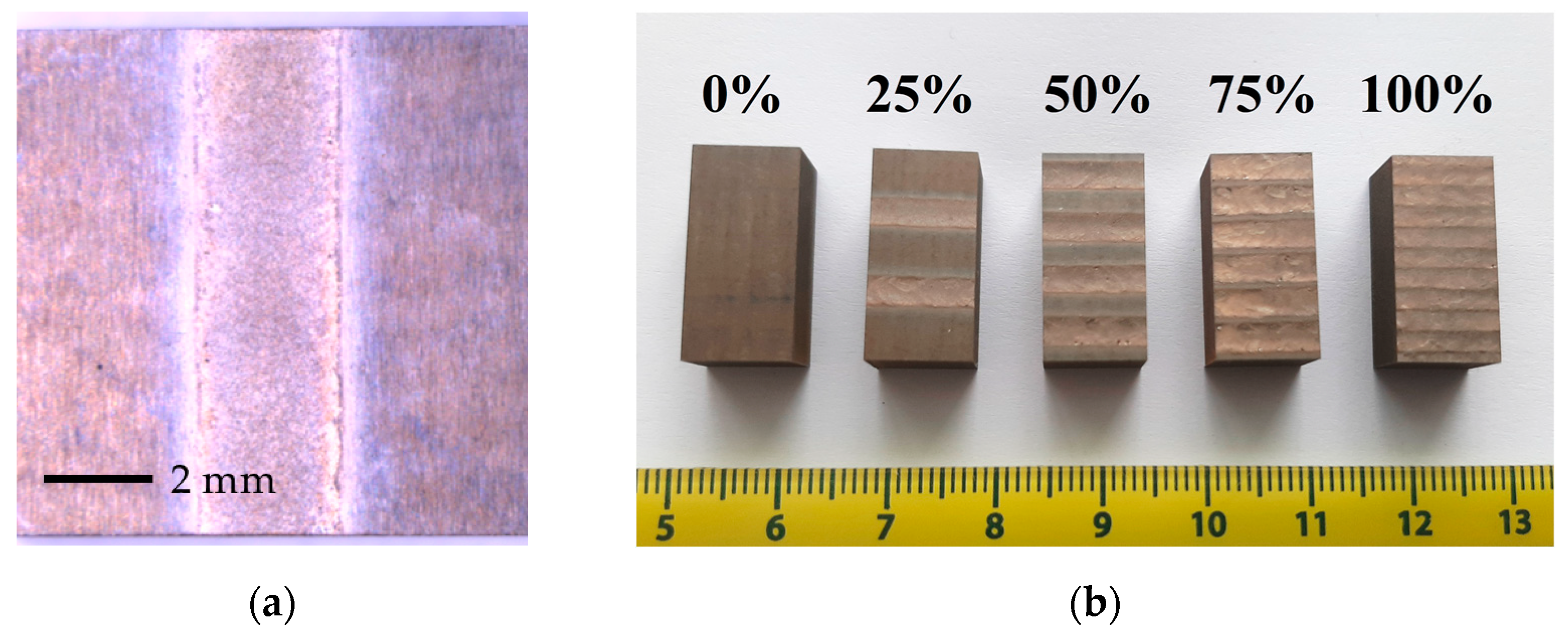

3.1. Characterisation of Coatings Obtained by Heating in Furnace and Laser Processing

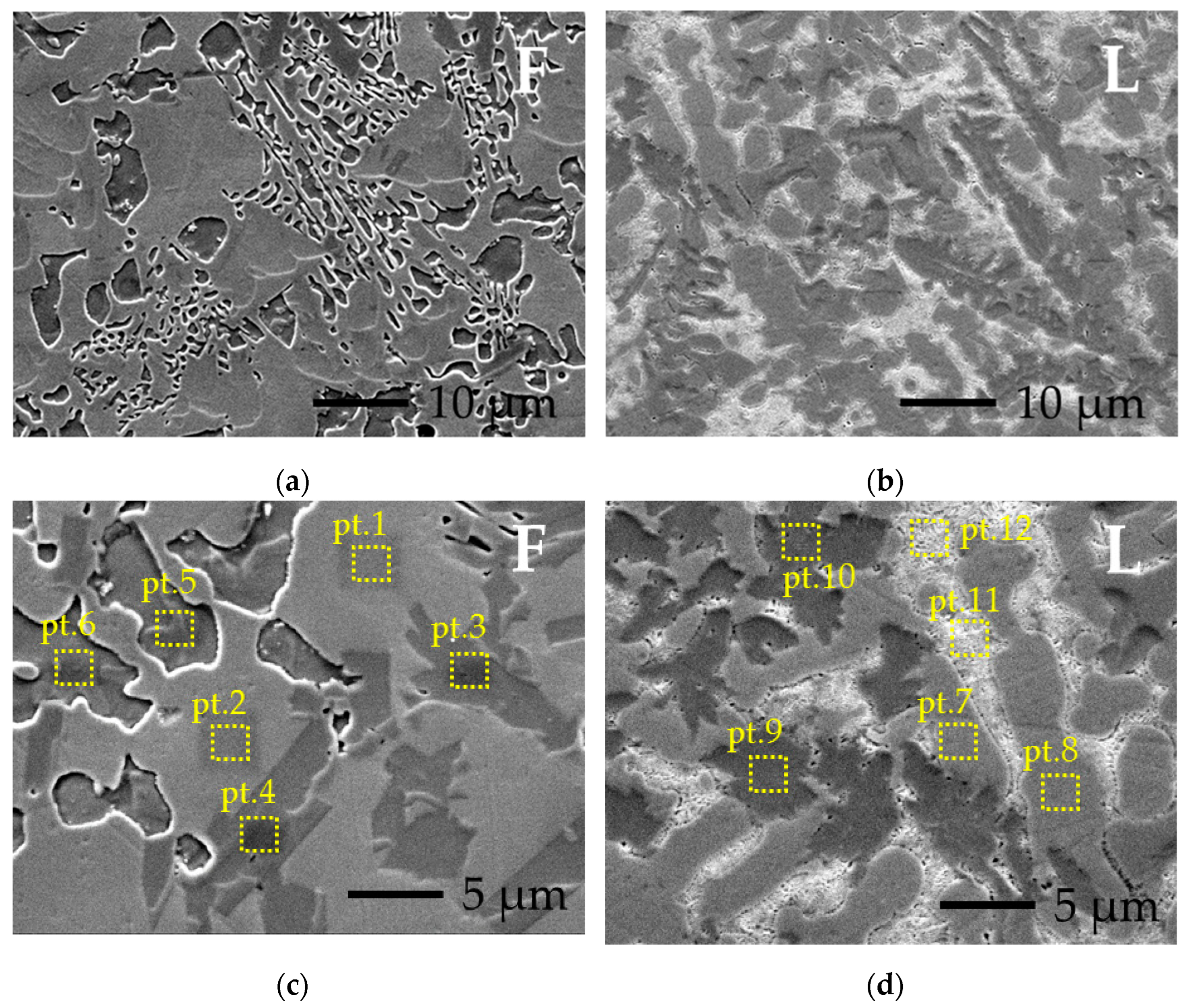

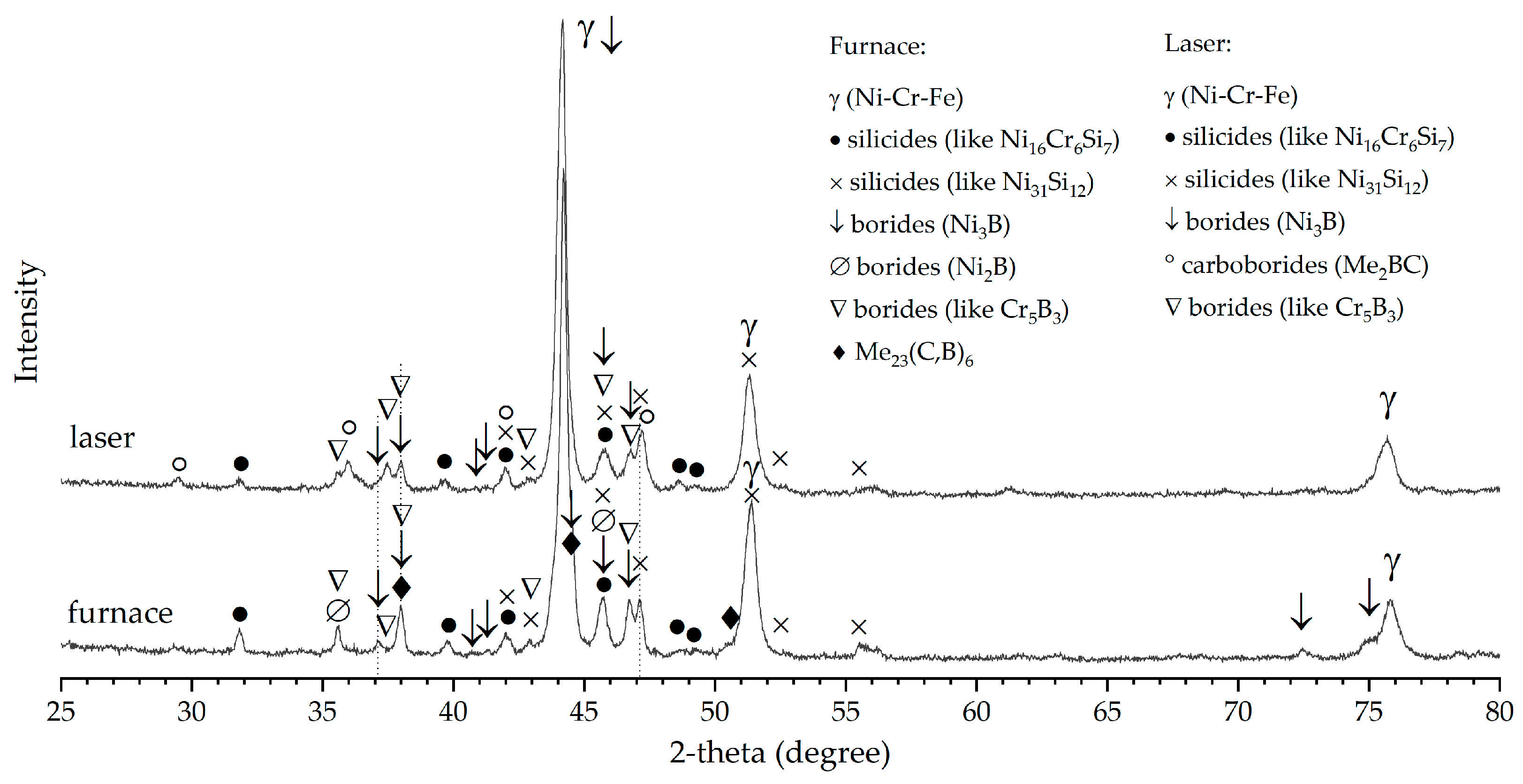

3.1.1. Coatings Microstructure and Phase Composition

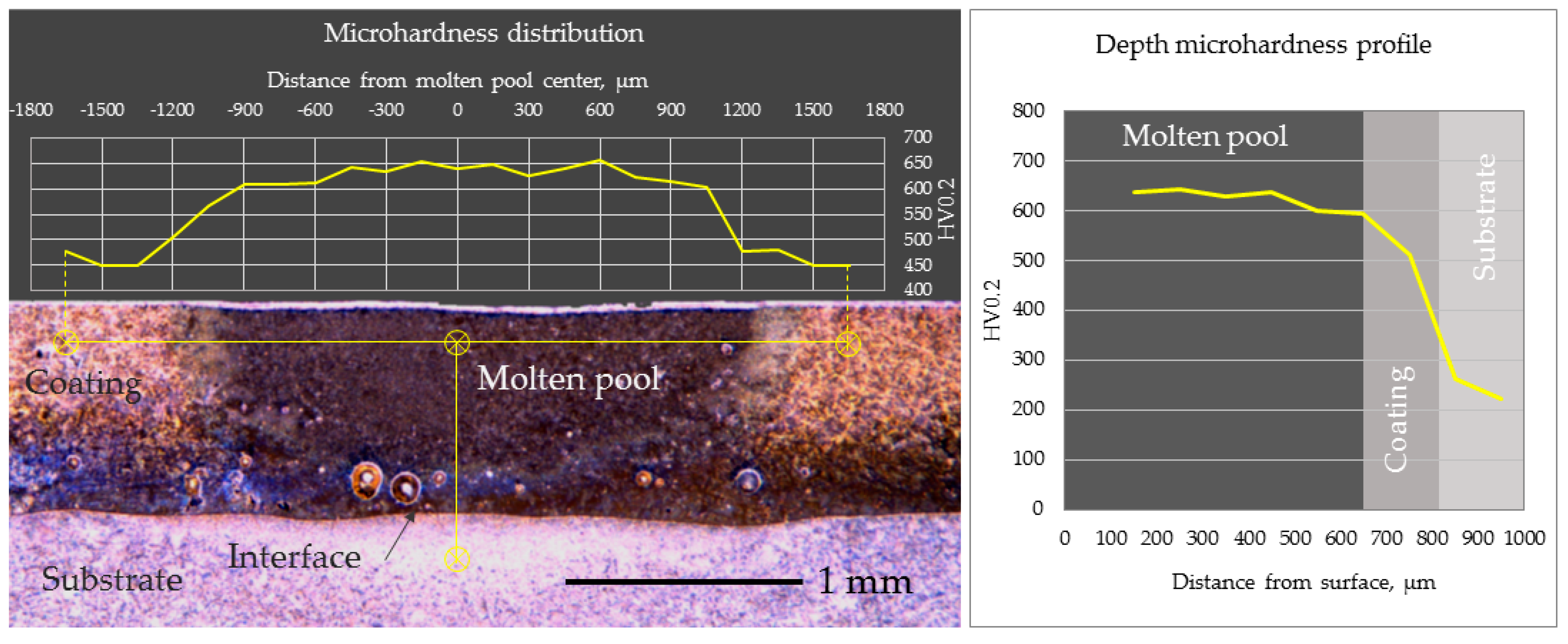

3.1.2. Microhardness and Tribology of Coatings

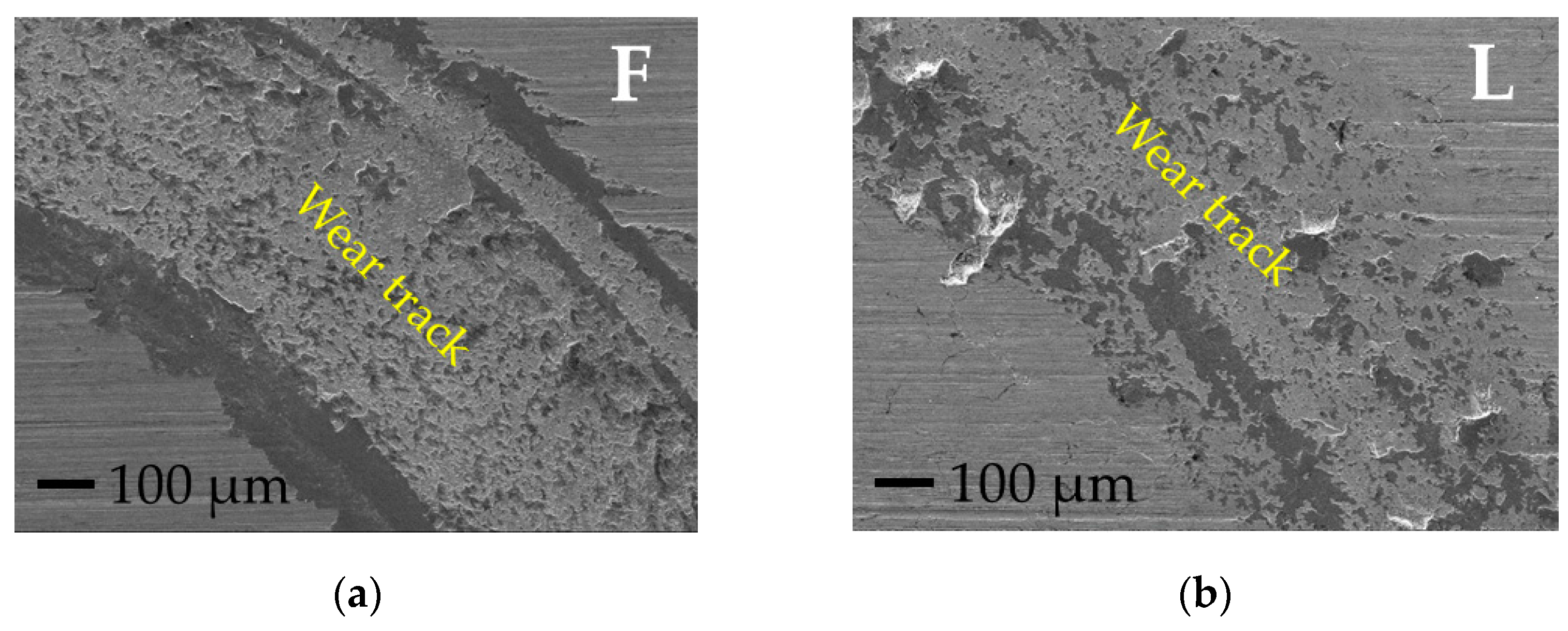

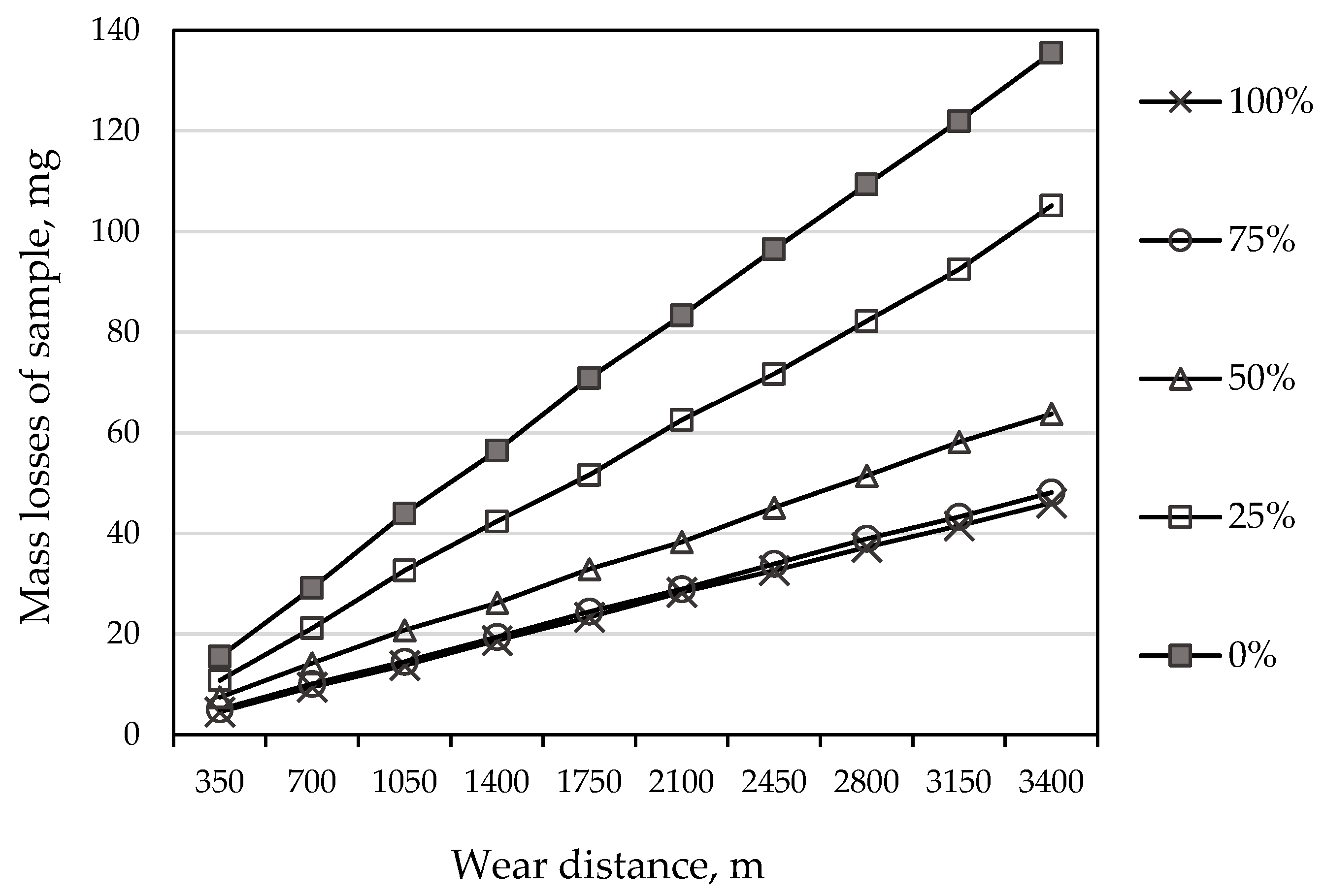

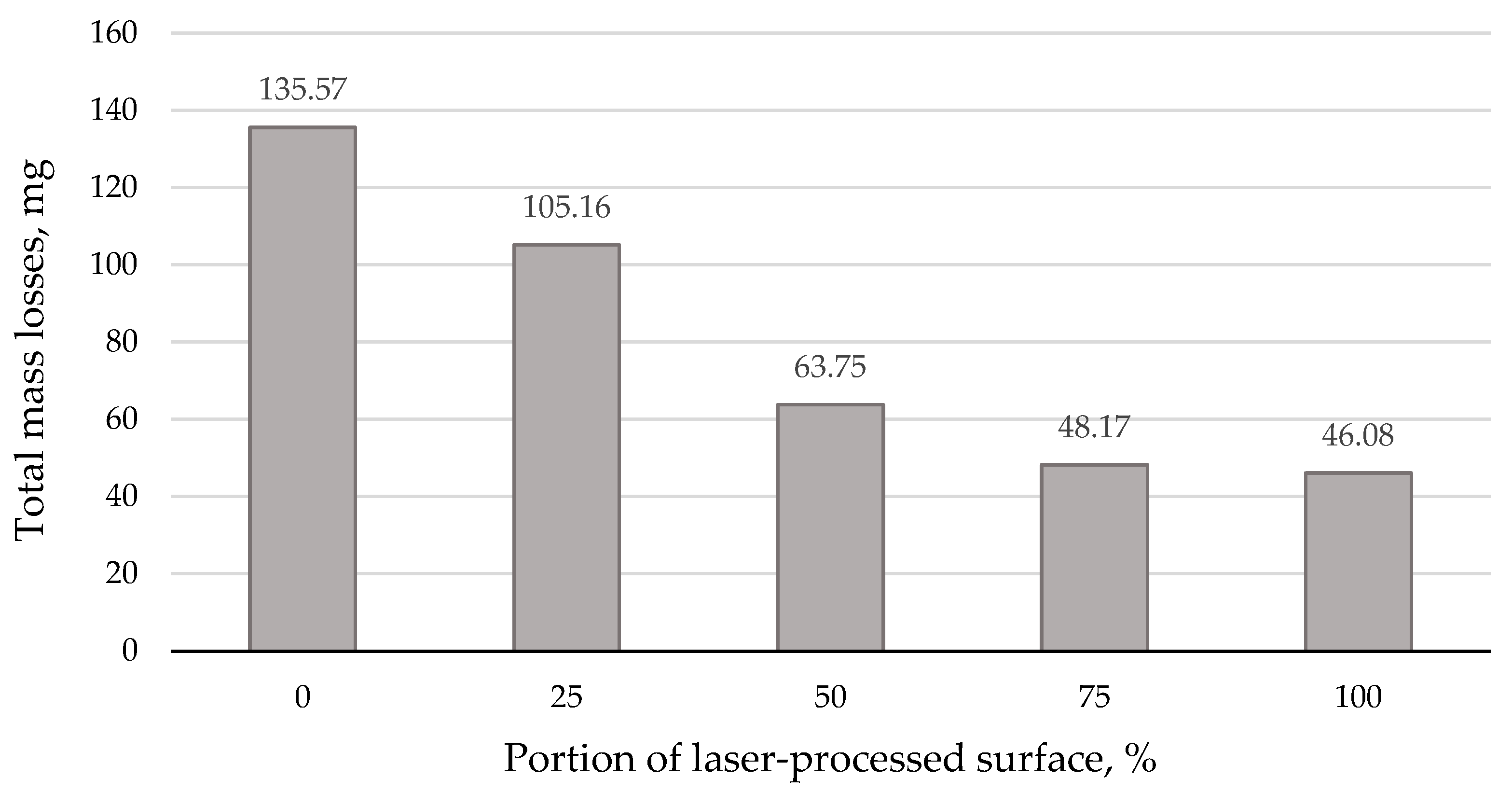

3.2. Wear Resistance Study of Coatings

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| XRD | X-ray diffraction |

| EDS | Energy dispersive spectrometry |

| WR | Wear resistance |

References

- Ang, A.S.M.; Berndt, C.C. A review of testing methods for thermal spray coatings. Int. Mater. Rev. 2014, 59, 179–223. [Google Scholar] [CrossRef]

- Kandeva, M.; Penyashki, T.; Kostadinov, G.; Nikolova, M.; Grozdanova, T. Wear resistance of multi-component composite coatings applied by concentrating energy flows. Proc. Eng. Sci. 2019, 1, 197–207. [Google Scholar] [CrossRef]

- Gupta, G.; Tyagi, R.K.; Rajput, S.K.; Maan, R.; Jacob, S.; Verma, S. Review on Thermal Spray Coating Methods and Property of Different Types of Metal-Based Coatings. In Advances in Engineering Materials; Springer: Singapore, 2021; pp. 427–439. [Google Scholar] [CrossRef]

- Mohit, V.; Qasim, M.; Paras, K. Effect of rare earth elements on coatings developed by thermal spraying processes (TSP)—A brief review. Mater. Today Proc. 2021, 44, 4053–4058. [Google Scholar] [CrossRef]

- Lakkannavar, V.; Yogesha, K.B.; Prasad, C.D.; Phanden, R.K.; Srinivasa, G.; Prasad, S.C. Thermal spray coatings on high-temperature oxidation and corrosion applications—A comprehensive review. Results Surf. Interfaces 2024, 16, 100250. [Google Scholar] [CrossRef]

- Soundararajan, R.; Kaviyarasan, K.; Sathishkumar, A.; Sivasankaran, S. Evaluating the metallurgical and corrosion characteristics of HVOF-sprayed Ni and Ni-TiB2 coatings on duplex stainless steel. Ceram. Int. 2025, 21, 7636–7650. [Google Scholar] [CrossRef]

- Salman, S.; Köse, R.; Urtekin, L.; Findik, F. An investigation of different ceramic coating thermal properties. Mater. Des. 2006, 27, 585–590. [Google Scholar] [CrossRef]

- Łatka, L.; Pawłowski, L.; Winnicki, M.; Sokołowski, P.; Małachowska, A.; Kozerski, S. Review of Functionally Graded Thermal Sprayed Coatings. Appl. Sci. 2020, 10, 5153. [Google Scholar] [CrossRef]

- Zhou, J.; Zhao, G.; Li, J.; Chen, J.; Zhang, S.; Wang, J.W.; Wang, S.; Xue, Y. Electroplating of non-fluorinated superhydrophobic Ni/WC/WS2 composite coatings with high abrasive resistance. Appl. Surf. Sci. 2019, 487, 1329–1340. [Google Scholar] [CrossRef]

- Zhang, C.; Zhang, L.; Wang, Y.; Li, S.; Li, J.; Xie, Z. Microstructural evolution and dissolution mechanisms of hard WC particles reinforced nickel based composite coatings fabricated by plasma transferred arc welding. J. Alloys Compd. 2025, 1019, 179293. [Google Scholar] [CrossRef]

- Zavareha, M.A.; Sarhan, A.A.; Zavarehc, P.A.; Razakd, B.A.; Kakooei, S. Fundamentals and Applications of Thermal Spray Coating. Can. J. Basic. Appl. Sci. 2017, 5, 178–191. [Google Scholar]

- Paraschiv, A.; Matache, G.; Puscasu, C.; Grigorescu, M. A correlation between fracture toughness and cohesion strength of molybdenum thermal sprayed coatings. MATEC Web Conf. 2017, 145, 02007. [Google Scholar] [CrossRef]

- Doe, J.; Roe, R. Laser treatment of thermal sprayed coatings: A review. J. Mater. Process Technol. 2019, 271, 1–13. [Google Scholar] [CrossRef]

- Xia, Y.; Chen, H.; Liang, X.; Lei, J. Circular oscillating laser melting deposition of nickel-based superalloy reinforced by WC: Microstructure, wear resistance and electrochemical properties. J. Manuf. Process. 2021, 68, 1694–1704. [Google Scholar] [CrossRef]

- Erfanmanesh, M.; Abdollah-Pour, H.; Mohammadian-Semnani, H.; Razavi, R.S. Kinetics and oxidation behavior of laser clad WC-Co and Ni/WC-Co coatings. Ceram. Int. 2018, 44, 12805–12814. [Google Scholar] [CrossRef]

- Kumar, M.; Mitra, R. Effect of substrate temperature and annealing on structure, stress and properties of reactively co-sputtered Ni-TiN nanocomposite thin films. Thin Solid Films 2017, 624, 70–82. [Google Scholar] [CrossRef]

- Salim, M.S.; Sabri, N.; Ibrahim, T.K.; Noaman, N.M.; Akram, I.N.; Latif, I.H. Effect of laser processing parameters on the efficiency of material: A review in industrial application field. Int. J. Eng. Technol. 2019, 8, 509–516. [Google Scholar] [CrossRef]

- Li, B.; Fan, L.; Bai, J.; He, J.; Su, J.; Wang, S.; Deng, C.; Liu, S.; Zhang, Z. Study on Porosity of Thermal-Sprayed Commercially Pure Aluminum Coating. Materials 2023, 16, 6612. [Google Scholar] [CrossRef]

- Škamat, J.; Černašėjus, O.; Zhetessova, G.; Nikonova, T.; Zharkevich, O.M.; Višniakov, N. Effect of laser processing parameters on microstructure, hardness and tribology of NiCrCoFeCBSi/WC coatings. Materials 2021, 14, 6034. [Google Scholar] [CrossRef]

- Garcia-Alonso, D.; Serres, N.; Demian, C.; Costil, S.; Langlade, C.; Coddet, C. Pre-/During-/Post-Laser Processes to Enhance the Adhesion and Mechanical Properties of Thermal-Sprayed Coatings with a Reduced Environmental Impact. J. Therm. Spray Technol. 2011, 20, 719–735. [Google Scholar] [CrossRef]

- Garcia, A.; Fernandez, R. Phase transformation in laser-treated thermal spray coatings. J. Therm. Spray. Technol. 2016, 25, 987–995. [Google Scholar]

- Zhao, Q.; Li, M. Optimization of laser parameters for post-treatment of thermal spray coatings. Opt. Laser Technol. 2022, 150, 107–115. [Google Scholar] [CrossRef]

- Zhang, B.; Li, Y.; Bai, Q. Defect Formation Mechanisms in Selective Laser Melting: A Review. Chin. J. Mech. Eng. 2017, 30, 515–527. [Google Scholar] [CrossRef]

- Qiu, C.; Panwisawas, C.; Ward, M.; Basoalto, H.; Brooks, J.; Attallah, M.M. On the role of melt flow into the surface structure and porosity development during selective laser melting. Acta Mater. 2015, 96, 72–79. [Google Scholar] [CrossRef]

- Fomin, V.M.; Golyshev, A.A.; Malikov, A.G.; Filippov, A.A.; Shikalov, V.S.; Yadrenkin, M.A.; Orishich, A.M. Experimental Investigation of the Effect of Laser Treatment on the Resistance of a Cermet Coating to a High-Speed Impact. J. Eng. Phys. Thermophys. 2022, 95, 1773–1779. [Google Scholar] [CrossRef]

- Gisario, A.; Puopolo, M.; Venettacci, S.; Veniali, F. Improvement of thermally sprayed WC–Co/NiCr coatings by surface laser processing. Int. J. Ref. Met. Hard Mater. 2015, 52, 123–130. [Google Scholar] [CrossRef]

- Liu, H.; Wang, R.; Gao, Q.; Chen, P.; Hao, J.; Yang, H.; Liu, X. Evolution in microstructure and tribological behavior of laser cladded MoxNbTiZr high-entropy refractory alloy coatings with varying Mo content. Mater. Charact. 2023, 206, 113449. [Google Scholar] [CrossRef]

- Hulka, I.; Uțu, I.D.; Avram, D.; Dan, M.L.; Pascu, A.; Stanciu, E.M.; Roată, I.C. Influence of the Laser Cladding Parameters on the Morphology, Wear and Corrosion Resistance of WC-Co/NiCrBSi Composite Coatings. Mater. 2021, 14, 5583. [Google Scholar] [CrossRef] [PubMed]

- Farahmand, P.; Liu, S.; Zhang, Z.; Kovacevic, R. Laser cladding assisted by induction heating of Ni–WC composite enhanced bynano-WC and La2O3. Ceram. Int. 2014, 40, 15421–15438. [Google Scholar] [CrossRef]

- Tewolde, M.; Zhang, T.; Lee, H.; Sampath, S.; Hwang, D.; Longtin, J. Laser Processing of Multilayered Thermal Spray Coatings: Optimal Processing Parameters. J. Therm. Spray. Technol. 2017, 26, 1994–2004. [Google Scholar] [CrossRef]

- Surzhenkov, A.; Kulu, P.; Tarbe, R.; Mikli, V.; Sarjas, H.; Latokartano, J. Wear resistance of laser remelted thermally sprayed coatings. Est. J. Eng. 2009, 15, 318–328. [Google Scholar] [CrossRef]

- Lisiecki, A. Development of Laser Welding and Surface Treatment of Metals. Materials 2022, 15, 1765. [Google Scholar] [CrossRef]

- Černašėjus, O.; Škamat, J.; Čepukė, Ž.; Zhetessova, G.; Nikonova, T.; Zharkevich, O.; Višniakov, N.; Berg, A. Oscillating Laser Post-Processing of NiCrCoFeCBSi/WC Thermally Sprayed Coatings. Materials 2022, 15, 8041. [Google Scholar]

- Horník, P.; Šebestová, H.; Novotný, J.; Mrňa, L. Laser beam oscillation strategy for weld geometry variation. J. Manuf. Process. 2022, 84, 216–222. [Google Scholar] [CrossRef]

- Deng, R.; Li, H.; Chunjiang, Z.; Ouyang, C.; Wei, R.; Wang, R.; Bai, Q.; Liu, Y. Study on the Effect of Laser Remelting Energy Density on the Microstructure and Wear Resistance of Fe-Based Alloy Coatings Fabricated by Laser Cladding. J. Therm. Spray. Technol. 2024, 33, 1455–1471. [Google Scholar] [CrossRef]

- Li, M.; Huang, K.; Yi, X. Crack Formation Mechanisms and Control Methods of Laser Cladding Coatings: A Review. Coatings 2023, 13, 1117. [Google Scholar] [CrossRef]

- Arulvel, S.; Dsilva, W.R.D.; Akshat, J.; Jayakrishna, K.; Mridul, S. Laser processing techniques for surface property enhancement: Focus on material advancement. Surf. Interfaces 2023, 42, 103293. [Google Scholar] [CrossRef]

- Li, G.L.; Li, J.; Luo, X. Effects of high temperature treatment on microstructure and mechanical properties of laser-clad NiCrBSi/WC coatings on titanium alloy substrate. Mater. Char 2014, 98, 83–92. [Google Scholar] [CrossRef]

- Vijande, R.; Cuetos, J.M.; Cortizo, J.L.; Rodriguez, E.; Noriega, A. Desgaste Lubri-cado de Recubrimientos NiCrBSi Refundidos Parcialmente con Laser/Lubricated wear of NiCrBSi coatings partially remelted with laser. Rev. Metal. 2009, 45, 114–123. [Google Scholar] [CrossRef][Green Version]

- Lumley, R.; Morton, A.; Polmear, I. 9—Nanoengineering of metallic materials. In Nanostructure Control of Materials; Hannink, R.H.J., Hill, A.J., Eds.; Woodhead Publishing: Sawston, UK, 2006; pp. 219–250. [Google Scholar] [CrossRef]

- Liu, L.; Zhang, J.; Ai, C. Nickel-Based Superalloys. In Encyclopedia of Materials: Metals and Alloys; Caballero, F.G., Ed.; Elsevier: Amsterdam, The Netherlands, 2022; pp. 294–304. [Google Scholar] [CrossRef]

- Zhao, B.; Wang, L.; Tao, Q.; Zhu, P. The structure and multifunctionality of high-boron transition metal borides. J. Phys. Condens. Matter 2023, 35, 36758243. [Google Scholar] [CrossRef]

- Cahill, J.T.; Graeve, O.A. Hexaborides: A review of structure, synthesis and processing. J. Mater. Res. Technol. 2019, 8, 6321–6335. [Google Scholar] [CrossRef]

| Point | Ni | Cr | Mo | Fe | Cu | Si | 1 B | 1 C | The Phase Estimated |

|---|---|---|---|---|---|---|---|---|---|

| Furnace-treated coating | |||||||||

| pt. 1 | 81.19 | 5.66 | 0.32 | 6.26 | 3.39 | 3.16 | - | - | Ni-base solid solution |

| pt. 2 | 81.49 | 5.54 | - | 6.29 | 3.41 | 3.18 | - | - | |

| pt. 3 | 1.65 | 60.16 | 11.12 | - | - | - | 19.40 | 7.67 | Borides/ Borocarbides |

| pt. 4 | 0.37 | 63.80 | 9.96 | - | - | - | 20.40 | 5.48 | |

| pt. 5 | 83.86 | 9.72 | 0.56 | 4.06 | 1.79 | - | + | + | Eutectic |

| pt. 6 | 90.29 | 7.37 | 0.55 | 1.51 | 0.28 | - | + | + | |

| Laser-processed coating | |||||||||

| pt. 7 | 67.06 | 10.54 | 1.99 | 15.23 | 3.31 | 1.88 | - | - | Ni-base solid solution |

| pt. 8 | 69.10 | 9.07 | 1.13 | 15.56 | 3.03 | 2.11 | - | - | |

| pt. 9 | 2.81 | 48.51 | 14.24 | 6.68 | 0.21 | 0.09 | 20.91 | 6.54 | Borides/ Borocarbides |

| pt. 10 | 2.88 | 48.33 | 15.62 | 6.08 | 0.30 | 0.11 | 19.51 | 7.19 | |

| pt. 11 | 76.34 | 5.97 | 0.98 | 10.49 | 2.81 | 3.40 | + | + | Eutectic |

| pt. 12 | 78.59 | 4.58 | - | 10.50 | 2.83 | 3.51 | + | + | |

| Sample | Sample Mass Loss, mg | Counter-Body Mass Loss, mg | Coefficient of Friction (30–300 m) | Wear Resistance, m/µg |

|---|---|---|---|---|

| Furnace | 0.533 ± 0.050 | 0.040 ± 0.006 | 0.550 ± 0.052 | 0.563 |

| Laser | 0.267 ± 0.060 | 0.100 ± 0.008 | 0.380 ± 0.026 | 1.124 |

| Parameter | Portion of Laser-Processed Surface | ||||

|---|---|---|---|---|---|

| 0% | 25% | 50% | 75% | 100% | |

| Total mass loss ML, mg | 135.57 | 105.16 | 63.75 | 48.17 | 46.08 |

| Wear distance D, m | 3400 | 3400 | 3400 | 3400 | 3400 |

| Wear resistance WR = D/ML, m/mg | 25.079 | 32.332 | 53.333 | 70.583 | 73.785 |

| Expected wear resistance WRexp, m/mg | - | 37.256 | 49.432 | 61.608 | - |

| Difference, m/mg (WR − WRexp) | - | −4.924 | +3.901 | +8.975 | - |

| Difference, % 100 × (WR − WRex)/WRex | - | −13.2 | +7.9 | +14.6 | - |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Černašėjus, O.; Škamat, J.; Gierz, Ł.; Zharkevich, O.; Berg, A. Effect of Partial Fibre Laser Processing on the Wear Resistance of NiCrMoFeCSiB Coatings. Coatings 2025, 15, 323. https://doi.org/10.3390/coatings15030323

Černašėjus O, Škamat J, Gierz Ł, Zharkevich O, Berg A. Effect of Partial Fibre Laser Processing on the Wear Resistance of NiCrMoFeCSiB Coatings. Coatings. 2025; 15(3):323. https://doi.org/10.3390/coatings15030323

Chicago/Turabian StyleČernašėjus, Olegas, Jelena Škamat, Łukasz Gierz, Olga Zharkevich, and Alexandra Berg. 2025. "Effect of Partial Fibre Laser Processing on the Wear Resistance of NiCrMoFeCSiB Coatings" Coatings 15, no. 3: 323. https://doi.org/10.3390/coatings15030323

APA StyleČernašėjus, O., Škamat, J., Gierz, Ł., Zharkevich, O., & Berg, A. (2025). Effect of Partial Fibre Laser Processing on the Wear Resistance of NiCrMoFeCSiB Coatings. Coatings, 15(3), 323. https://doi.org/10.3390/coatings15030323