Abstract

Ultra-high-molecular-weight polyethylene (UHMWPE) fabric is widely used in many fields due to its excellent properties such as high modulus, high strength, and impact resistance. However, its high flammability prevents its application in high-temperature environments. Therefore, it is important to develop multifunctional UHMWPE fabric to meet its different requirements in firefighting, military, and other scenarios. Here, we have prepared a durable flame-retardant superhydrophobic UHMWPE fabric by a simple coating method. A polyurethane solution mixed with decabromodiphenylethane and antimony trioxide is scraped on the surface of the fabric to form a coating, which endows the fabric with flame retardancy. The sprayed fluorinated hydrophobic agent provides superhydrophobic properties to the fabric. It is worth mentioning that plasma pretreatment greatly improves the adhesion properties of the coating by stimulating the active groups on the surface of the fabric. Tests have shown that the adhesion between the coating and the surface of the plasma-treated UHMWPE fabric has been greatly improved. The limiting oxygen index value of the coating UHMWPE fabric has increased by 90%, and it immediately extinguishes after leaving the flame, demonstrating excellent flame retardancy. The contact angle between its surface and water reaches 156°, exhibiting excellent superhydrophobicity and self-cleaning properties. This study provides a simple, convenient, and effective method for the development of multifunctional UHMWPE fabric, greatly expanding its application scenarios and providing ideas for future development.

1. Introduction

Ultra-high-molecular-weight polyethylene (UHMWPE) fiber has been widely used in industrial building materials, civil production, bulletproof and stab-proof, aerospace, and even new energy materials [1,2,3,4,5] due to its high breaking strength and modulus, excellent impact resistance, chemical resistance, and other properties [6,7,8,9,10]. However, UHMWPE also faces challenges due to poor heat resistance. The melting point of UHMWPE is as low as 140 °C [11], and the thermal aging rate of UHMWPE fiber under tensile conditions is fast [12]. Therefore, the operating temperature of the UHMWPE is generally between 80 and 100 °C, and the limiting oxygen index (LOI) is only 17% [13]. This means that the UHMWPE, due to its melting point, cannot be used at high temperatures. Also, its flammability is high. Therefore, it is crucial to endow UHMWPE fabric with flame retardant properties for practical applications.

Surface modification [14,15] has become a commonly used flame retardant modification method due to its advantages of simple process and better applicability. Commonly used surface modification methods mainly include coating [16], dipping [17,18], sol–gel method [19], layer-by-layer self-assembly method [20], and the chemical modification method [21]. However, as a new type of high-performance fabric, UHMWPE fabric has received limited research on direct surface modification. At present, most of the research on flame retardant modification of UHMWPE focuses on the flame retardant treatment of fibers and their plastic products such as plates [22,23], while research on the direct surface flame retardant treatment of its fabrics is not common. Among the flame retardant modification methods of UHMWPE fiber and plastic products, blending modification is the most frequently used. For example, Wang et al. [24] successfully prepared UHMWPE flame-retardant composites by mixing polydopamine-modified expandable graphite (EG@PDA) with UHMWPE and hot pressing with the blending method. The final results show that compared with UHMWPE, the limiting oxygen index of UHMWPE/(APP/EG@PDA) is increased by 66.9%, the V-0 rating is reached in the UL-94 test, the ignition time is significantly increased, the peak heat release rate is reduced by 59.5%, and the total heat release is reduced by 13.1%. Shen et al. [25] prepared a composite by mixing a certain amount of UHMWPE, magnesium hydroxide (MH), and phenoxycyclophosphazene (HPCTP) at 170 °C, which showed significantly enhanced flame retardant ability, increased the limiting oxygen index (LOI) to 25.1%, and delayed the ignition time by 75 s.

Recently, the combination of superhydrophobicity with flame retardancy has allowed materials to remain relatively stable under different harsh conditions [26,27,28], such as in chemical production, where many pieces of equipment and pipelines need to cope with both liquid leakage [29,30] and fire risks [31,32]. Superhydrophobic and flame-retardant coated pipes prevent the adhesion and corrosion of liquids on the surface of the pipes and prevent the pipes from becoming conduits for the spread of fire in the event of a fire. Similarly, superhydrophobic and flame-retardant coated fabrics can be used as protective clothing materials. It can provide better safety protection for workers in the chemical, power, and other industries to reduce the risk of chemical leakage and electrical fire. In addition, the superhydrophobic superposition can also form a protective layer, which can not only largely reduce the loss of flame-retardant components, but also reduce the need for washing textiles to a certain extent, thereby protecting the washability of the fabric [33,34]. He et al. [35] used fluorinated polymers to enhance the flame retardancy of coatings. A superhydrophobic flame-retardant coating fabric with excellent durability was prepared by modifying PDMS with fluorinating agents (1H, 1H, 2H, 2H-perfluorodecyltrimethoxysilane) and depositing a composite coating composed of fluorinated PDMS, silicone rubber combustibles, and ammonium polyphosphate on PET fabric. Huang et al. [36] immersed the cotton fabric in branched poly(ethylenimine) (BPEI) and ammonium polyphosphate (APP) water dispersions, as well as polydimethylsiloxane (PDMS)/cellulose nanocrystals (CNC)-SiO2 toluene dispersions modified with 1H, 1H, 2H, 2H-perfluorooctyltriethoxysilane (FOTS), to obtain highly efficient flame-retardant and superhydrophobic cotton fabric with good abrasion resistance. However, the surface of UHMWPE fibers has a low content of polar functional groups and low reactivity, resulting in a smooth surface and poor adhesion when made into fabric [7,37]. Therefore, how to solve the problem of insufficient adhesion performance on the surface of UHMWPE fabric and apply a coating on it remains a challenge.

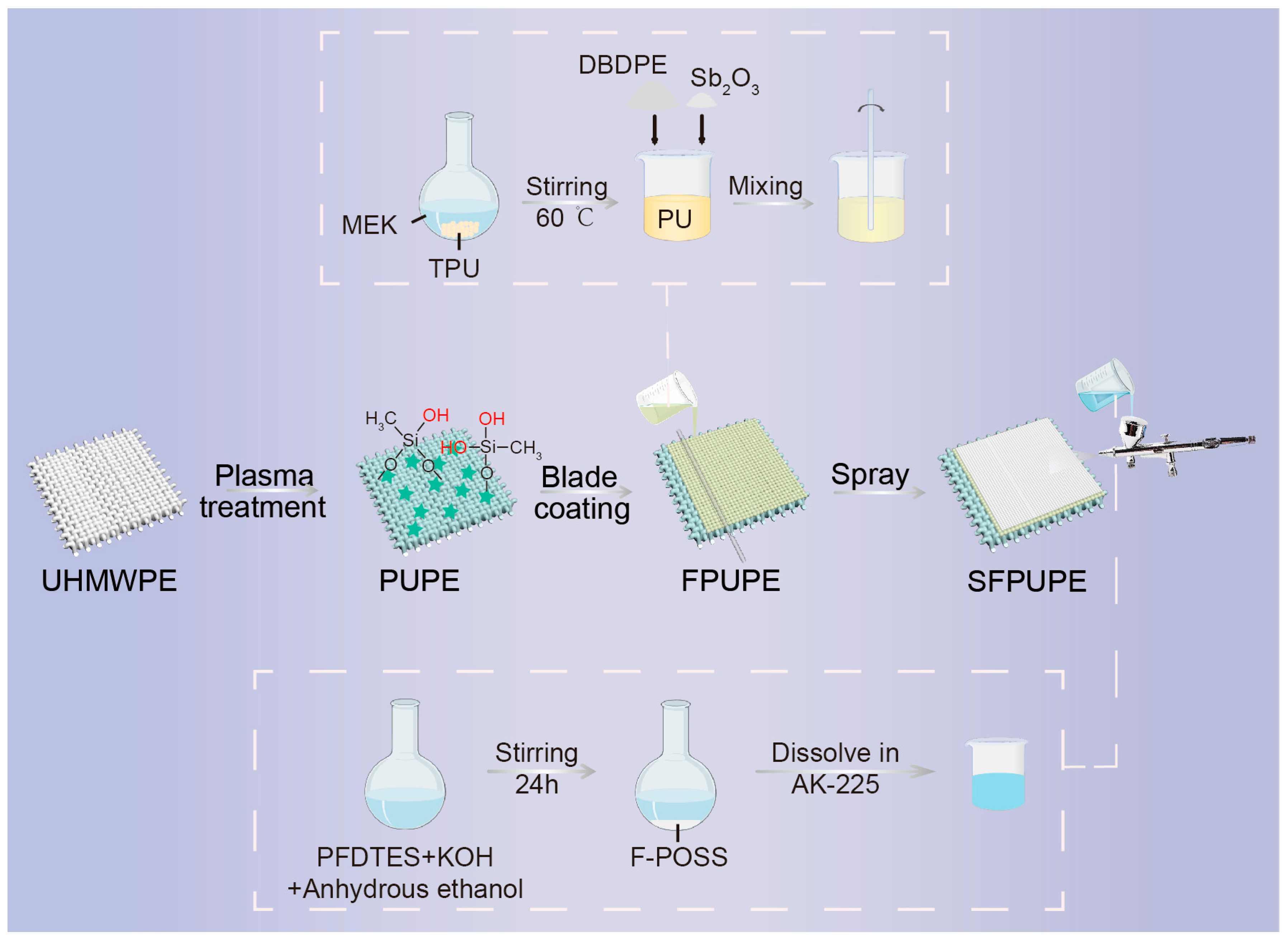

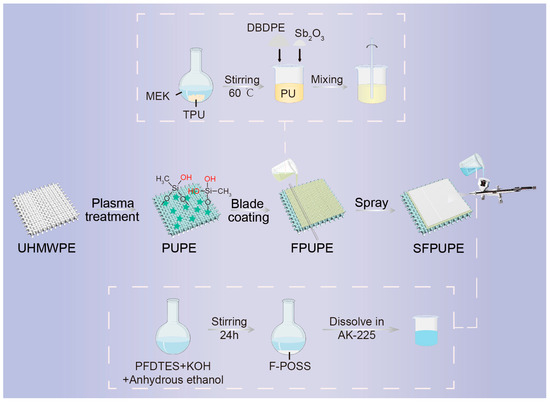

Here, we use the plasma treatment and coating process to prepare a multifunctional UHMWPE fabric with flame retardancy and superhydrophobicity (Figure 1). Firstly, a layer of silane particles with a rough structure was grown on the surface of UHMWPE fabric under plasma-assisted treatment to improve its coating adhesion. Then, decabromodiphenyl ethane and antimony trioxide were mixed in proportion in a butanone solution of polyurethane to prepare a coating on the surface of the fabric. Finally, the coating is waterproofed with a fluorinated hydrophobic agent. The prepared fabric exhibits excellent superhydrophobicity and self-cleaning ability due to its high micro-nano roughness structure and low surface energy. The flame retardancy of decabromodiphenyl ethane and antimony trioxide endows it with flame retardancy.

Figure 1.

Flame retardant and superhydrophobic simulation of coated UHMWPE fabric.

2. Experiment

2.1. Materials

Ultra-high-molecular-weight polyethylene (UHMWPE) fabric was obtained from Jiangsu Putec New Material Technology Co., Ltd., Yangzhou, China. Polyurethane (TPU, Desmodur ® N 3400) was purchased from Covestro Polymer (China) Co., Ltd., Shanghai, China. Butanone (MEK, C4H8O) was purchased from Sichuan Xilong Science Co., Ltd., Chengdu, China. Decabromodiphenyl ethane (DBDPE, C14H4Br10) and antimony trioxide (Sb2O3) were provided by Shandong Yousuo Chemical Technology Co., Ltd., Linyi, China. Perfluorodecyltriethoxysilane (PFDTES) was purchased from Guangzhou Yuanda New Materials Co., Ltd., Guangzhou, China. Potassium hydroxide (KOH) was purchased from Shandong Xuanhai Chemical Co., Ltd., Weifang, China. Anhydrous ethanol was obtained from Tianjin Beilian Fine Chemicals Development Co., Ltd., Tianjin, China.

2.2. Preparation of Flame-Retardant Coating Solution

The PU solution (mass fraction of 15%) was obtained by mixing 15 g of TPU particles with 85 g of MEK solution, heated and stirred in an oil bath at 60 °C until the PU was completely dissolved, and then continued to be heated and stirred for 24 h. DBDPE and Sb2O3 powder were weighed in a beaker (mixing ratio of 3:1), and PU solution was slowly added and stirred evenly until it became a slightly viscous liquid that could flow. At this time, the amount of PU solution used was recorded and the proportion calculated. On this basis, the dosage was gradually increased and simply tested until an optimal PU ratio was obtained, so as to obtain the required coating solution.

2.3. Preparation of Hydrophobic Coating Solution

In total, 5.1 g of PFDTES was added to 0.275 g of KOH solution with a mass fraction of 1.54%, and absolute ethanol was added to the mixed solution until the total solution was 10 g. The solution was magnetically stirred at room temperature for 24 h, and a white solid appeared in the solution. After pouring out the upper layer of liquid, it was placed in the oven to dry, and the hydrophobic powder Fluorinated Polyhedral Oligomeric Silsesquioxane (F-POSS) was successful prepared. A small amount of prepared hydrophobic agent powder was taken and dissolved with AK-225 to form a hydrophobic solution.

2.4. Preparation of UHMWPE Fabric Coating

Surface treatment of UHMWPE fabric using atmospheric plasma treatment equipment. The precursor MTMS was injected into the plasma together with the carrier gas with a uniform flow rate of 20 mL/h. The working gas and carrier gas were both Ar, and the flow rates were constant at 3 SLM. The fabrics (50 cm × 50 cm) were placed below the plasma jet outlet, and the distance between the plasma outlet and the sample was set at 10 mm. Before deposition, the fabrics were cleaned with Ar plasma for 180 s to remove surface impurities [38]. We named the plasma-treated UHMWPE fabric PUPE. We cut the plasma-treated UHMWPE fabric to a size of 50 mm × 50 mm and laid it flat, prepared some flame-retardant coating solution, then used a scraper to evenly scrape the solution on the surface of the fabric, and dried the fabric in the oven at 60 °C for 20 min to obtain the flame-retardant coated fabric, which was named FPUPE. Finally, the prepared hydrophobic coating solution was sprayed on the FPUPE fabric and dried again to obtain a superhydrophobic flame-retardant coated fabric, named SFPUPE. Figure 2 illustrates the complete preparation process.

Figure 2.

Schematic diagram of the preparation process of flame-retardant superhydrophobic coated UHMWPE fabric.

2.5. Characterization

Fourier transform infrared spectroscopy (VERTEX 70 RAMI, BRUKER OPTICS, Beijing, China) was used to analyze the chemical structure of the surface of the fabrics. The scanning range was 4000–400 cm−1, the resolution was 4 cm−1, and the scanning frequency was 32 times. Scanning electron microscopy (SEM, SU8600, Hitachi High-Technologies, Shanghai, China) was used to observe the surface morphology of fabrics after different treatments. Prior to SEM testing, all samples were treated with conductive adhesives and gold spray coatings.

The peel strength test and coating mechanical wear test were carried out on the fabric samples to observe the change in coating adhesion on the surface of the samples. The limiting oxygen index was measured by an oxygen index meter (HC-2, Jiangsu Nanjing Analytical Instrument Factory, Nanjing, China). Samples (150 × 58 × 0.4 mm3) were tested according to GB/T 5454-1997. The vertical burning test (VBT) was determined by a vertical burning instrument (UL-94, Dongguan Zhongnuo Quality Inspection Instrument and Equipment Co., Ltd., Dongguan, China), and the samples (300 × 89 × 0.4 mm3) were tested according to GB/T 5455-2014, and the combustion height was 20 mm ± 2 mm. The contact angle (WCA) on the surface of the coated fabric sample was measured by a contact angle measuring instrument (SCI4000, Beijing Global Hengda Technology Co., Ltd., Beijing, China), and the water droplet was 5 μL. Five positions were randomly selected on the fabric surface to be measured, and the WCA was measured and averaged. The air permeability test of the fabric samples was carried out in the environmental material air permeability test system (YG461G, Quanzhou Meibang Instrument Co., Ltd., Nan’an, China). Samples were tested in accordance with GB/T 5453. The fabric samples were tested for air permeability in the fabric air permeability comprehensive performance tester (YG216G, Quanzhou Meibang Instrument Co., Ltd., Nan’an, China), and the test was carried out according to GB/T 40910-2021. The mechanical properties of the samples were tested on an electronic fabric strength tester (YG9026HK, Quanzhou Meibang Instrument Co., Ltd., Nan’an, China). Samples were tested in accordance with GB/T 3923-1997.

3. Results and Discussion

3.1. Surface Morphology and Chemical Structure

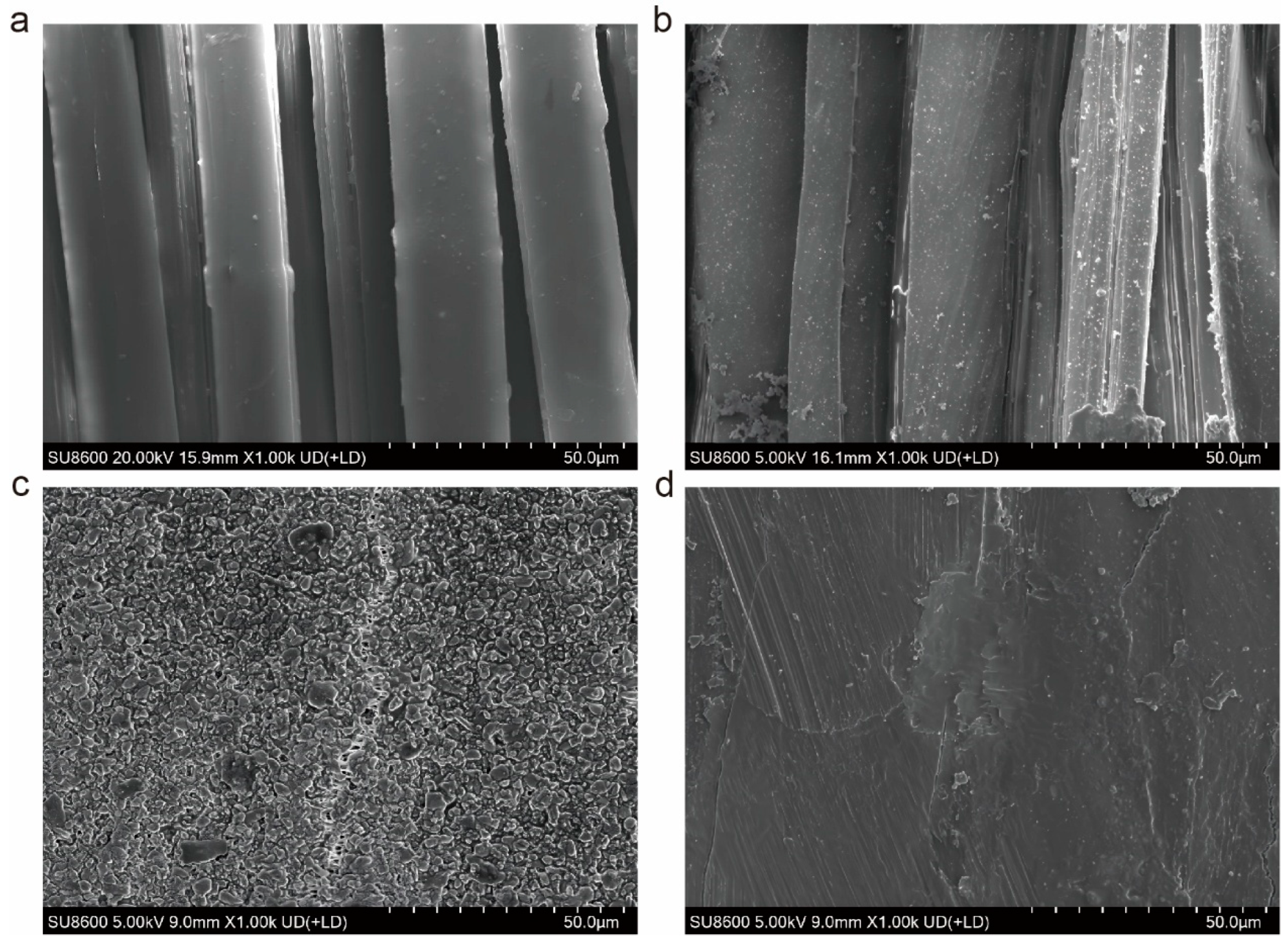

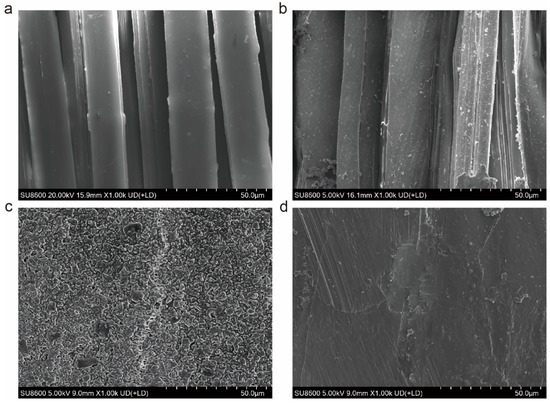

The surface morphology of UHMWPE, PUPE, FPUPE, and SFPUPE fabrics was observed by SEM, as shown in Figure 3a–d. As shown in Figure 3a, the surface of the UHMWPE fabric presents a neat fiber arrangement structure, with a smooth and clear fiber surface and uniform fiber diameter. After plasma treatment, a large amount of particulate matter or small pits can be observed on the PUPE fibers, which are evenly and densely distributed on the fiber surface, showing the rough surface structure of the fibers (Figure 3b). For FPUPE (Figure 3c), the surface morphology of the fabric becomes rough and uneven, with a significant amount of material adhering to the fiber surface to form a continuous coating. The fibers are wrapped by the coated material, and the gaps between the fibers are also filled and covered by the coated material. Figure 3d shows the microstructure of SFPUPE, which is different from the rough state of the FPUPE surface, and the addition of the superhydrophobic coating results in a continuous, dense, and flat surface morphological structure on the surface of the fabric.

Figure 3.

SEM images of (a) UHMWPE fabric, (b) PUPE fabric, (c) FPUPE fabric, and (d) SFPUPE fabric.

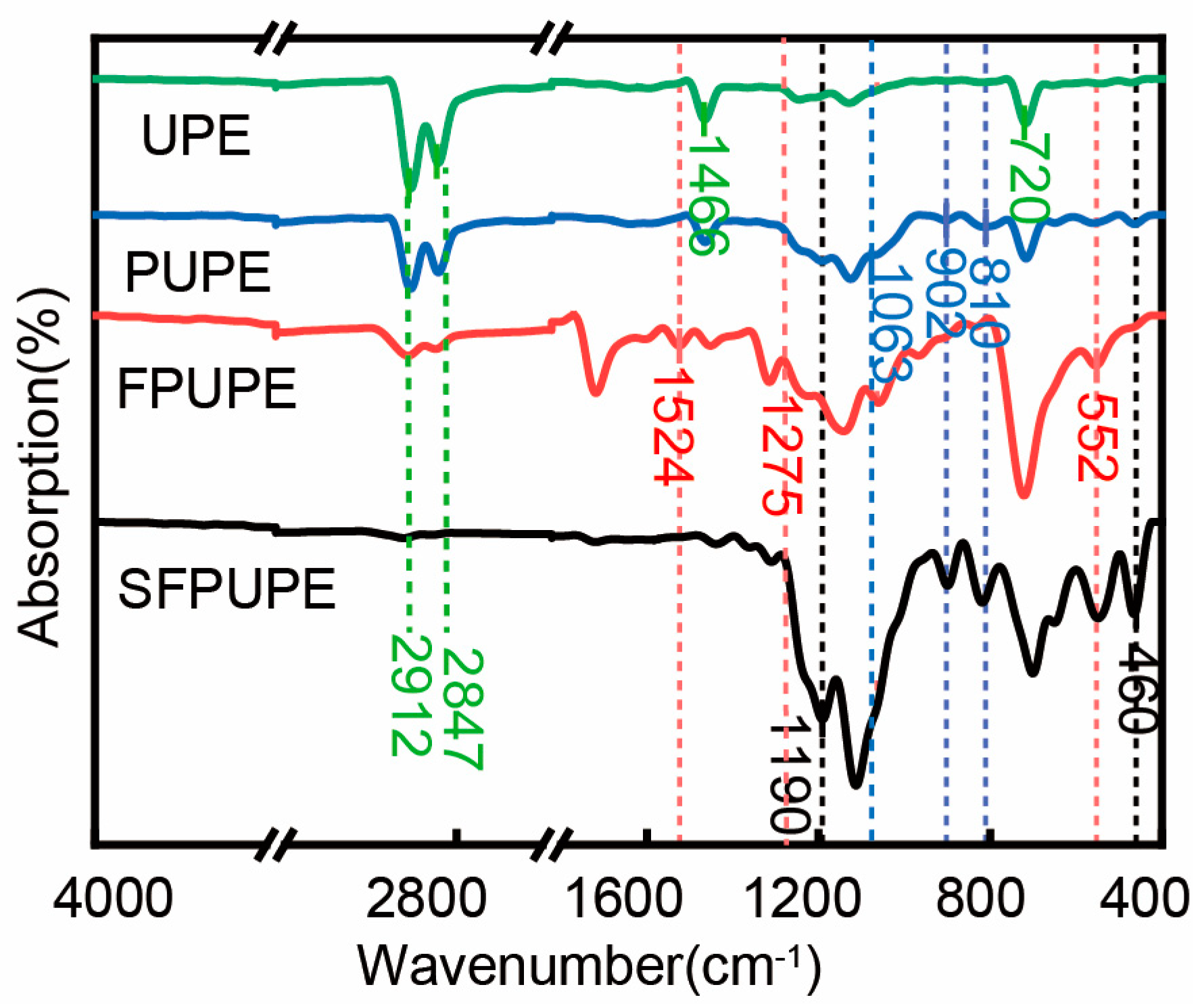

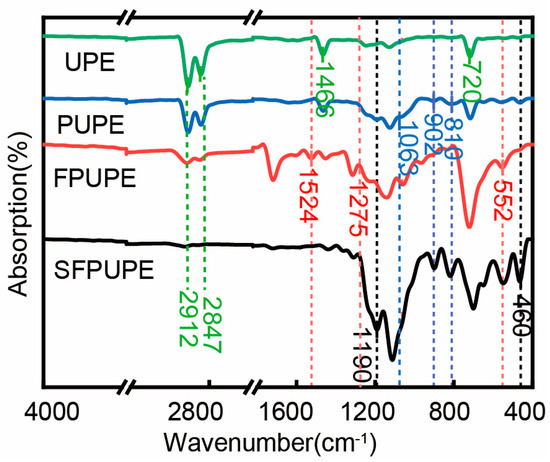

The chemical structures of UHMWPE, PUPE, FPUPE, and SFPUPE fabrics were characterized by FTIR spectroscopy, as shown in Figure 4. Characteristic peaks are detected at 2912 cm−1, 2847 cm−1, 1466 cm−1, and 720 cm−1 for UHMWPE fabric, corresponding to the asymmetric tensile vibration peaks of -methane, the symmetrical tensile vibration peaks of -methane, the asymmetric angular vibration peaks of -CH, and the oscillation peaks of -CH plane vibrations, respectively. Characteristic absorption peaks are detected at 1063 cm−1, 902 cm−1, and 810 cm−1 for PUPE fabric, which may be Si-O-Si tensile vibration absorption peaks, -OH vibration peaks, and -CH vibration peaks. Active functional groups are introduced into the surface of UHMWPE fabric after plasma treatment [39], which can effectively improve the surface chemical properties of the fabric. For FPUPE fabric, the absorption peaks at 1524 cm−1 and 552 cm−1 belong to the benzene ring backbone vibration and the C-Br bond absorption vibration in decabromodiphenylethane, respectively, and 1275 cm−1 belongs to the strong absorption peak of the Sb-O bond in Sb2O3. Further, for SFPUPE fabric, the symmetrical telescopic vibration peak of C-F and the bending vibration peak of Si-O corresponding to F-POSS appear at 1190 cm−1 and 460 cm−1. The FTIR spectroscopy results confirm the surface modification effect of plasma treatment and the successful adhesin of the multifunctional coating.

Figure 4.

FTIR spectra of UPE, PUPE, FPUPE, and SFPUPE.

3.2. Flame Retardancy

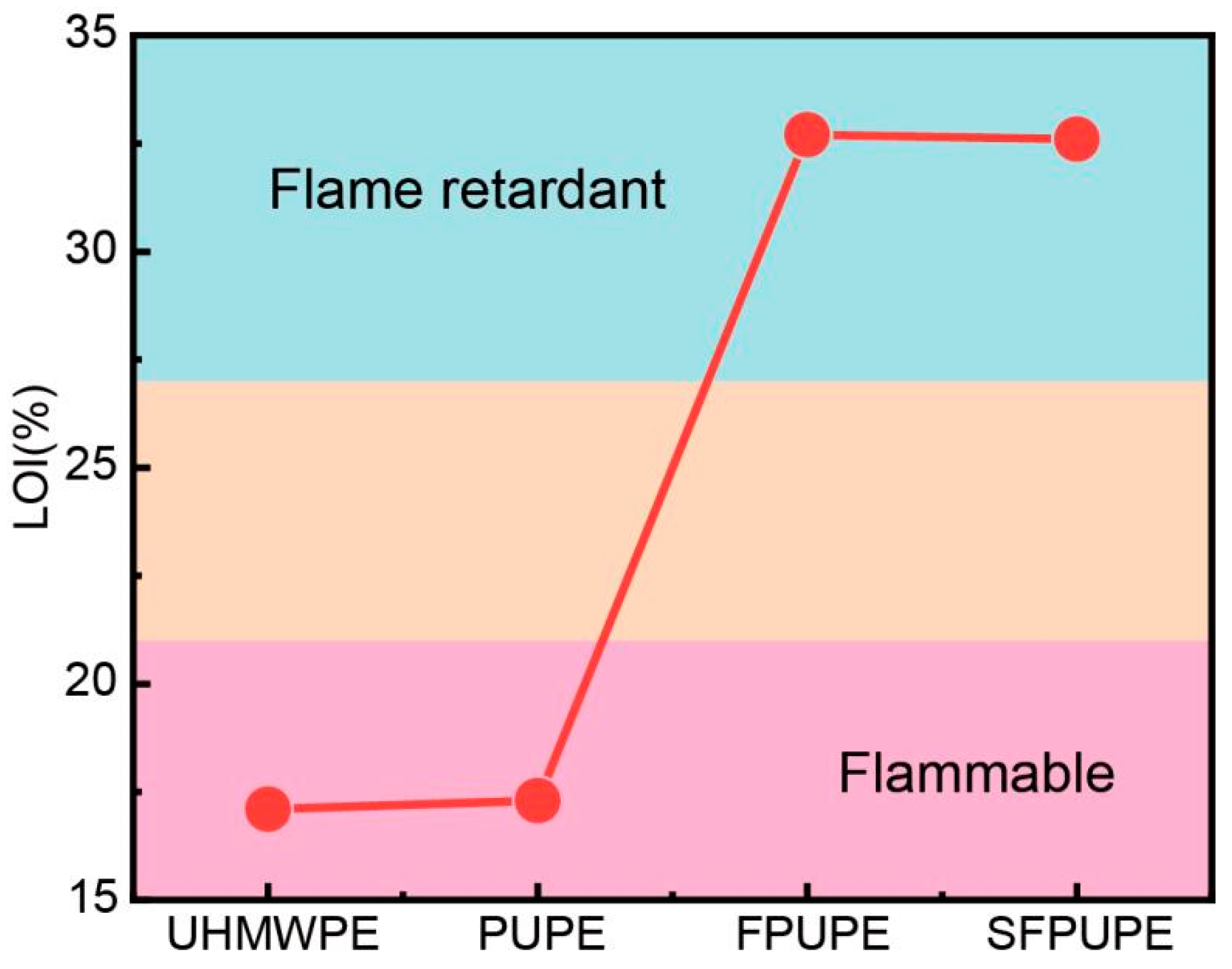

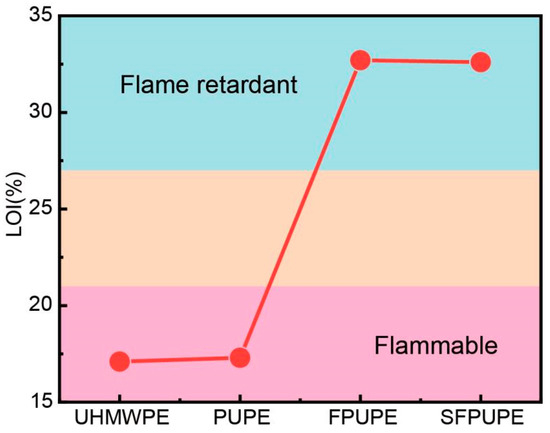

The flame retardancy of the samples was evaluated by LOI and a vertical burning test. As shown in Figure 5, UHMWPE fabric is a flammable fabric with an LOI of only 17.1%. The LOI of PUPE, FPUPE, and SFPUPE fabrics changes to 17.3%, 32.7%, and 32.6%, respectively. The LOI values of FPUPE and SFPUPE fabrics covered with a flame-retardant coating are about 90% higher than that of UHMWPE fabric.

Figure 5.

LOI curves of UHMWPE fabrics after different treatments.

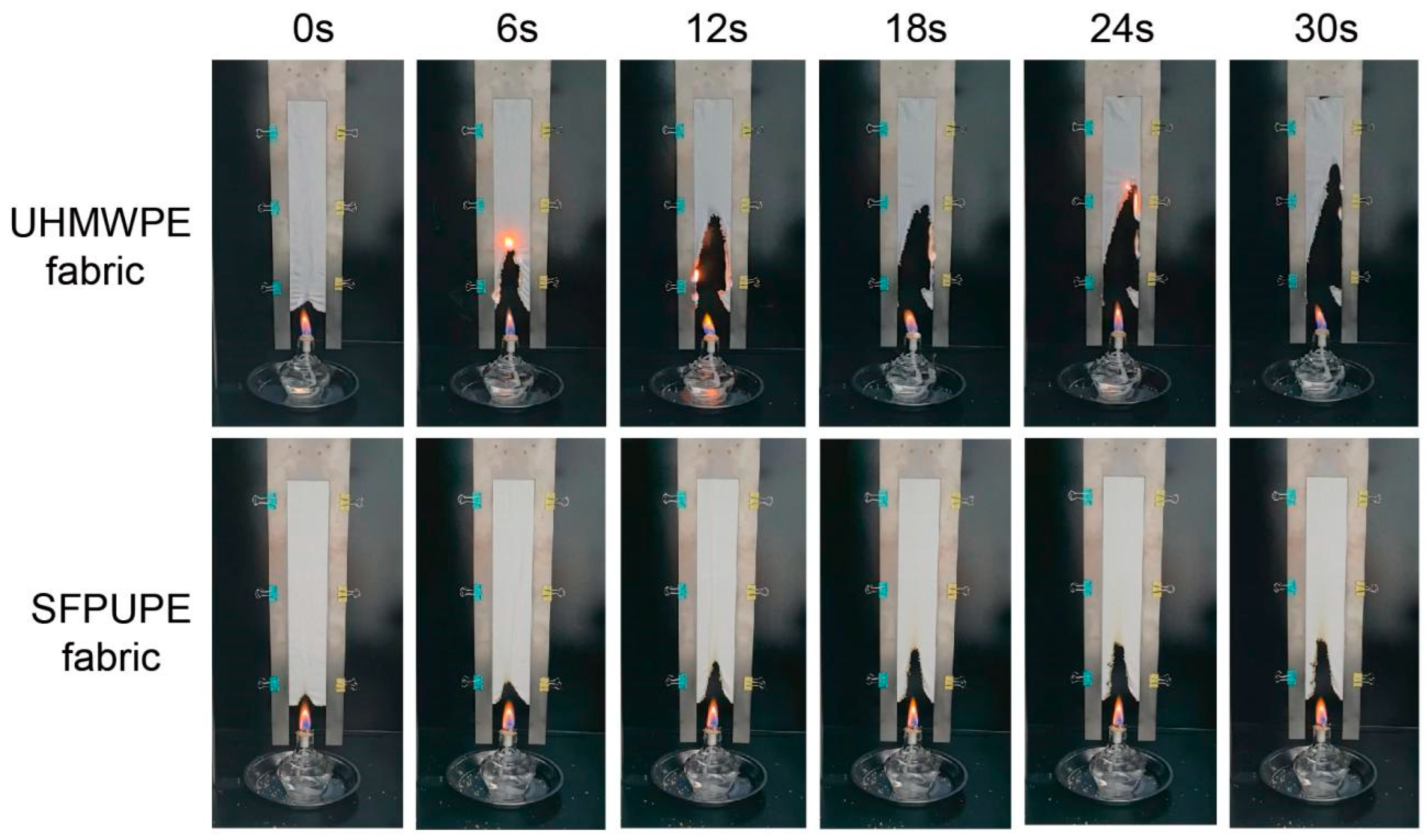

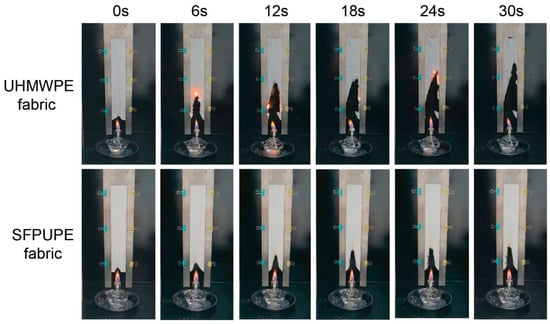

Figure 6 shows the photos of UHMWPE fabric and SFPUPE fabric in the VBT process. UHMWPE fabric burns rapidly after contact with a flame, accompanied by curling and shrinkage, and continues to burn upward after leaving the ignition source until it is completely burned out. During combustion, there is melt dripping, and there are afterflames and afterglow. SFPUPE fabric is not easy to burn when in contact with the flame, and it immediately stops burning after leaving the fire source, without afterflame or afterglow, and exhibits great flame-resistance.

Figure 6.

Vertical combustion of UHMWPE fabric and SFPUPE fabric.

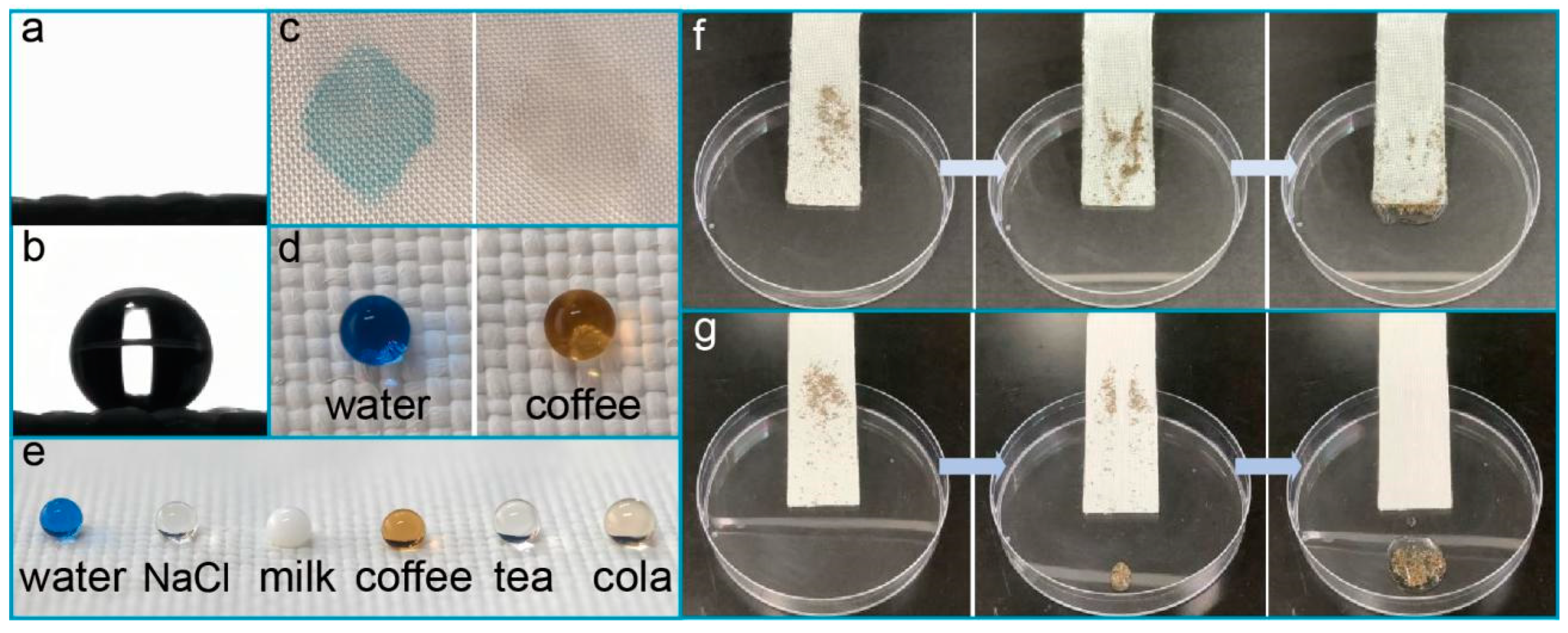

3.3. Superhydrophobicity and Self-Cleaning Performance

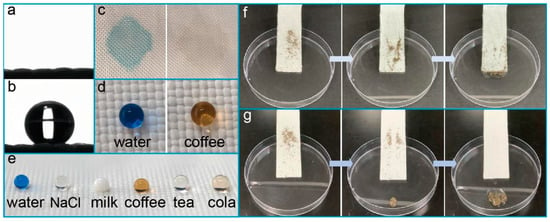

The static water contact angle test (WCA) was conducted on the coated fabric to evaluate its superhydrophobicity, as shown in Figure 7. As can be seen from the figure, the WCA of the original UHMWPE fabric is 0°, and the water droplets seep down immediately after touching the surface of the fabric with no residue, indicating that the original UHMWPE fabric has excellent hydrophilicity (Figure 7a). The WCA on the surface of SFPUPE fabric can reach 156° ± 0.3°, and there is no significant change in the morphology of water droplets within 30 s (Figure 7b). This indicates that SFPUPE fabric has obvious superhydrophobicity.

Figure 7.

The water contact angle between (a) UHMWPE fabric and (b) SFPUPE fabric, the wetting state of some liquids on the surfaces of (c) UHMWPE fabric and (d,e) SFPUPE fabric, and the self-cleaning performance of (f) UHMWPE fabric and (g) SFPUPE fabric.

Liquids of different pH and color (such as sodium chloride, cola, milk, tea, water, etc.) were dropped on the surface of UHMWPE fabric and SFPUPE fabric to observe their surface changes, as shown in Figure 7c–e. It can be seen that the droplets on UHMWPE fabric completely penetrate the surface of the fabric, and the liquid rapidly diffuses to absorb and leave dye traces on the surface of the fabric (Figure 7c). In contrast, the droplets on SFPUPE fabric do not penetrate the fabric and spread across the fabric surface, but instead remain spherical shape on the surface of the coated fabric and roll freely (Figure 7d,e). The droplets roll off without leaving any color or marks on the surface of the fabric, indicating that the coated fabric has a certain degree of dyeing resistance. In response to the self-cleaning properties of fabrics, an equal amount of gravel was sprinkled on the surface of UHMWPE and SFPUPE fabrics, respectively, and then rinsed with an equal amount of water. It can be seen that the surface of UHMWPE fabric has good hydrophilicity, and the water droplets are first quickly absorbed by the fabric after dripping, and the surface grit does not change. After further dripping, a small amount of gravel on the surface of the fabric is carried away or washed away by the water droplets, and a large amount of grit remains on the surface of the fabric. Eventually, all the gravel cannot be completely cleaned and still adheres to the surface of the fabric, making it difficult to clean (Figure 7f). SFPUPE fabric has great superhydrophobicity, taking away a large amount of gravel immediately after the water droplets droplet, and there is no gravel residue in the path through which the water droplets flow. Finally, the gravel on the surface of the fabric is completely cleaned with no residue on the surface (Figure 7g). The color of the fabric is also not contaminated, indicating that SFPUPE fabric self-cleans well.

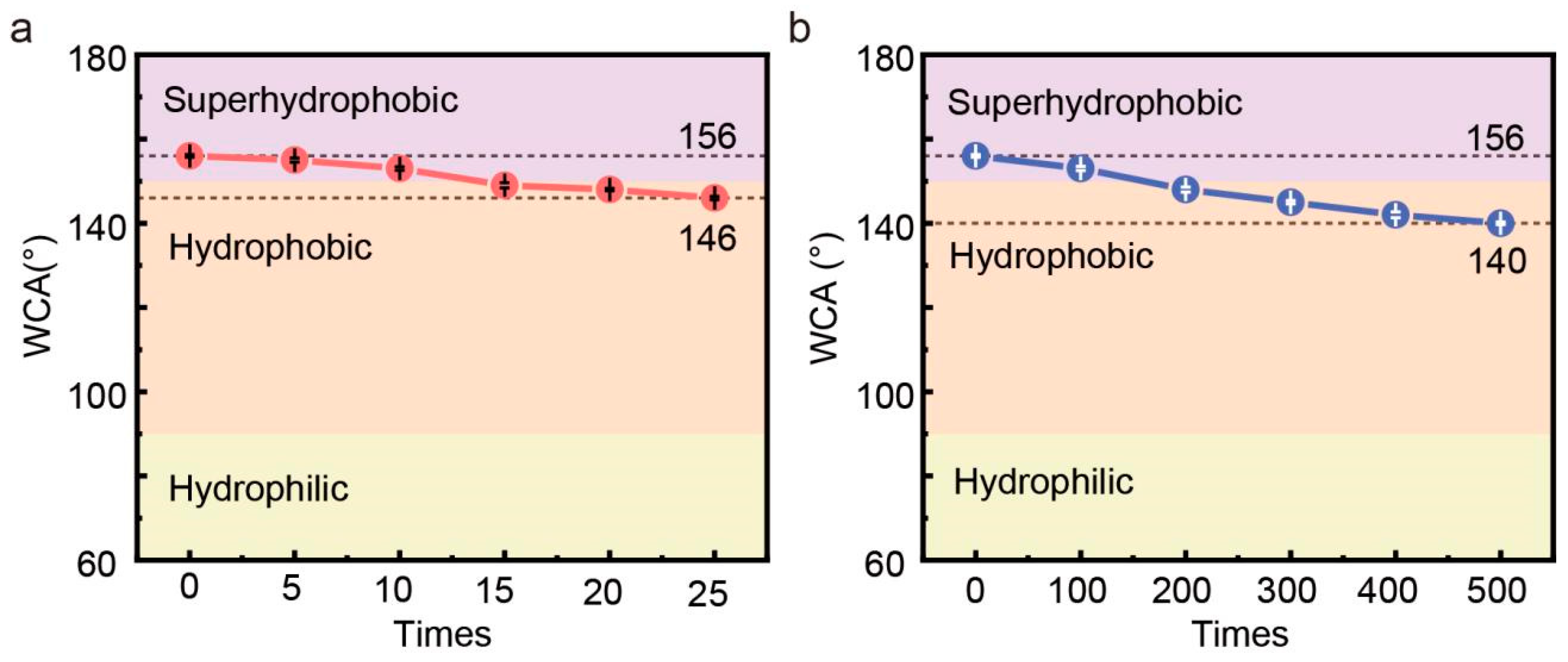

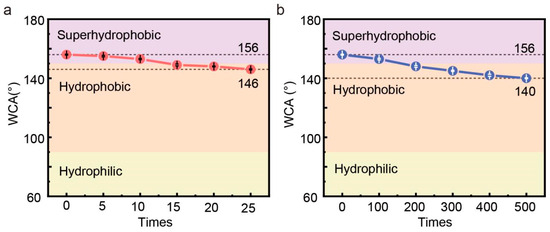

The washability of SFPUPE fabric was evaluated by calculating the mass loss after 20 min of washing in a simple mechanical washing unit and evaluating its vertical burning behavior and static contact angle after washing. The mass loss rate of SFPUPE fabric is 0.19%, and the vertical burning results show that the washed SFPUPE fabric still self-extinguished immediately when exposed to fire. This is because the superhydrophobic coating on the surface protects the integrity of the flame-retardant coating and reduces the loss of the flame-retardant coating. The variation curve of the number of washes on the WCA of SFPUPE fabric is shown in Figure 8a. After washes for 5 and 10 cycles, the WCA of SFPUPE fabric are still higher than 150° and the WCA is 153° ± 0.4°, which demonstrates the good superhydrophobic stability performance of SFPUPE. It is worth noting that even after 25 washes, the surface of SFPUPE fabric can maintain a significant hydrophobic effect, with a WCA of more than 146° yet.

Figure 8.

The changes in WCA caused by the (a) washing and (b) friction times of SFPUPE fabric.

The abrasion resistance of SFPUPE fabric was evaluated by friction experiments. There was no significant change in the mass of SFPUPE fabric after friction, and a vertical burning test was carried out. The results show that SFPUPE fabric still has good flame retardancy after friction, and the fabric is extinguished immediately after removing the ignition source. As shown in Figure 8b, SFPUPE fabric surface still maintains superhydrophobicity with WCA of 153° ± 0.5° after 100 friction cycles. The WCA after 300 frictions is 145° ± 0.4°. However, it has to be mentioned that after 500 friction cycles, the WCA changes from 156° ± 0.3° to 140° ± 0.3°. This is because the superhydrophobic coating on the surface has been slightly lost by repeated friction, but still maintains its hydrophobicity. SFPUPE fabric has good abrasion resistance. The above results reveal that the constructed superhydrophobic coating on SFPUPE fabric possesses great stability.

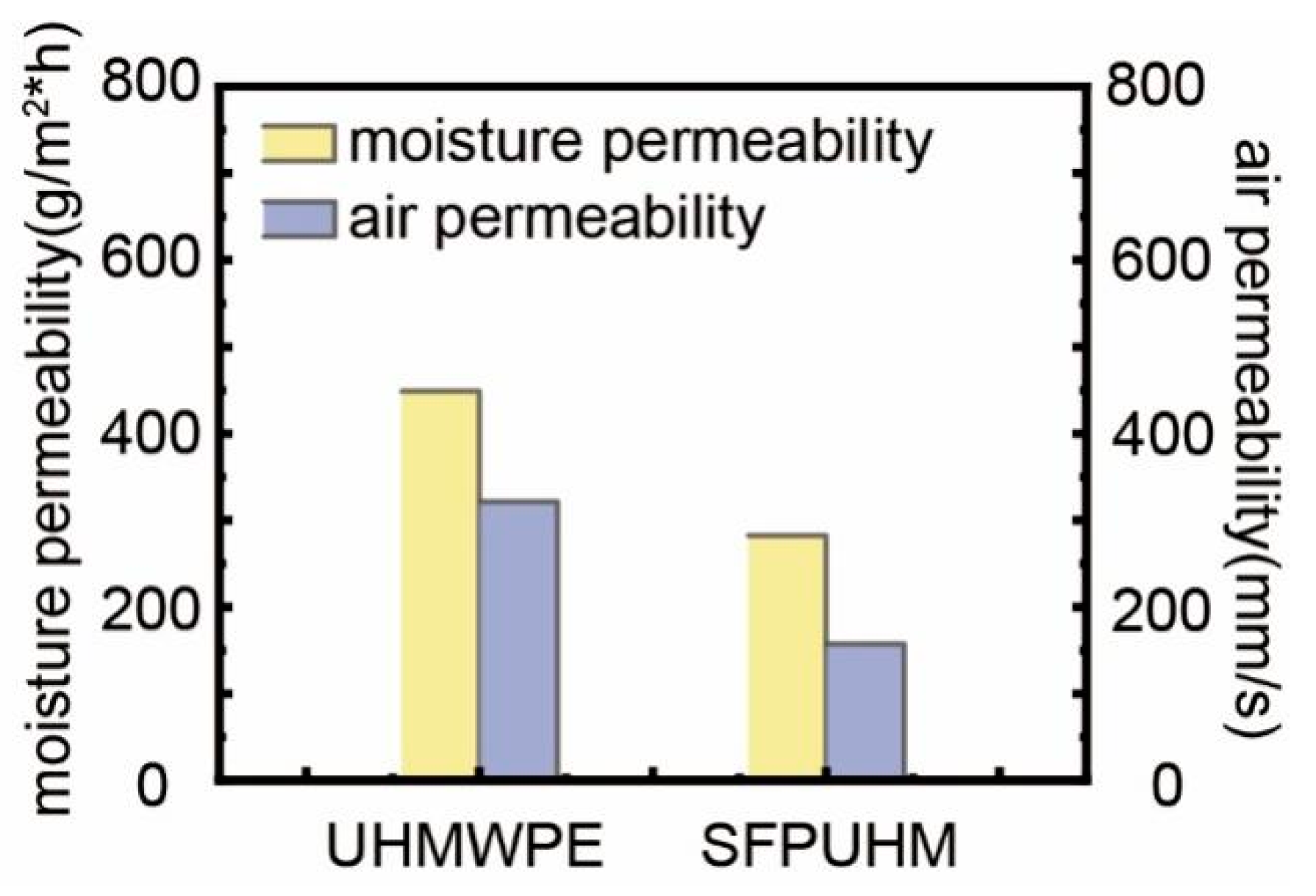

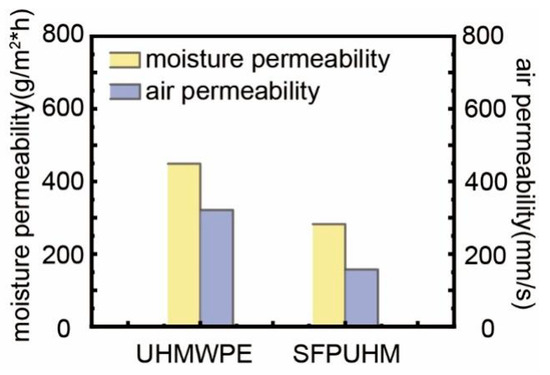

3.4. Breathability Performance

The air permeability and moisture permeability of UHMWPE fabric and SFPUPE fabric were compared. As shown in Figure 9, the average air permeability of UHMWPE fabric after 10 tests is 321.4 mm/s, and the moisture permeability is 448.69 g/m2·h. The air permeability and moisture permeability of SFPUPE fabric both decreased, and the average air permeability is 157.37 mm/s, a decrease of 51%. The moisture permeability is 282.38 g/m2·h, a decrease of 37%. The reason for this situation is that the surface of the fabric is adhered to by an adhesive coating. While increasing the thickness of the fabric, the coating material fills the voids between the fibers, reducing the possibility of gas and liquid passing through the fabric, thereby reducing air and moisture permeability. Therefore, the use of an adhesive will affect the air permeability and moisture permeability of the coated fabric to a certain extent.

Figure 9.

Breathability and moisture permeability of UHMWPE fabric and SFPUPE fabric.

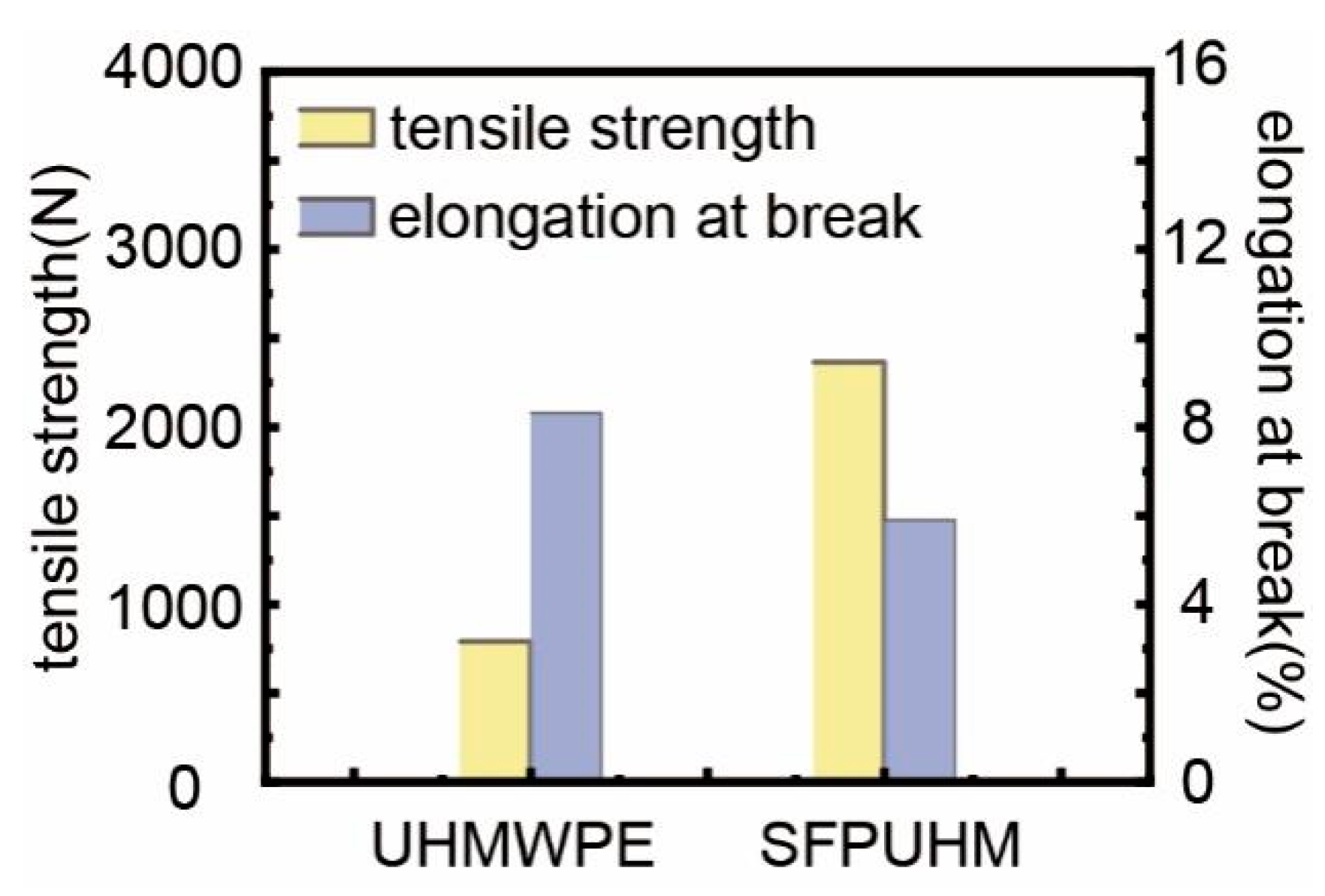

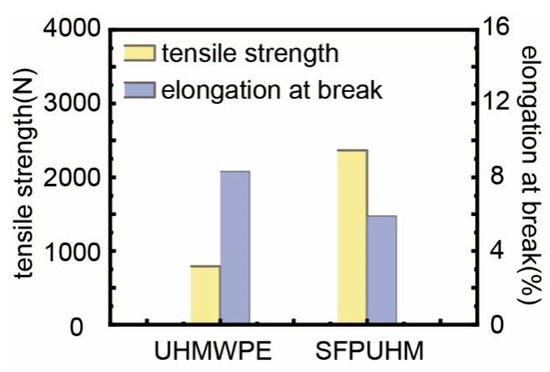

3.5. Mechanical Performance

The tensile fracture properties of UHMWPE and SFPUPE fabric were characterized by an electronic fabric strength machine, as shown in Figure 10. As can be seen from the figure, the breaking strength of UHMWPE fabric is relatively low at 790.67 N, and the elongation at break is 8.31%. The fibers slip between each other in a very short period of time and the fabric breaks. The breaking strength of SFPUPE fabric reaches 2365.08 N, which was 199% higher than that of UHMWPE fabric, the elongation at break was 5.9%, and the fabric is less prone to fiber slippage and breakage. This is because, on the one hand, the presence of coating increases the thickness of the fabric, and the tight bond between the coating and the substrate also enhances the integrity of the fabric, reduces the wear of the fabric when subjected to force, and improves the breaking strength. On the other hand, the coating material fills the gaps in the arrangement of the fibers, increasing the friction and adhesion between the fibers, making it less prone to sliding, thereby increasing the breaking strength of the fabric under stretching. Therefore, the above results show that the presence of the coating can effectively improve the tensile fracture performance and the ability to withstand external forces of the fabric.

Figure 10.

Mechanical properties of UHMWPE fabric and SFPUPE fabric.

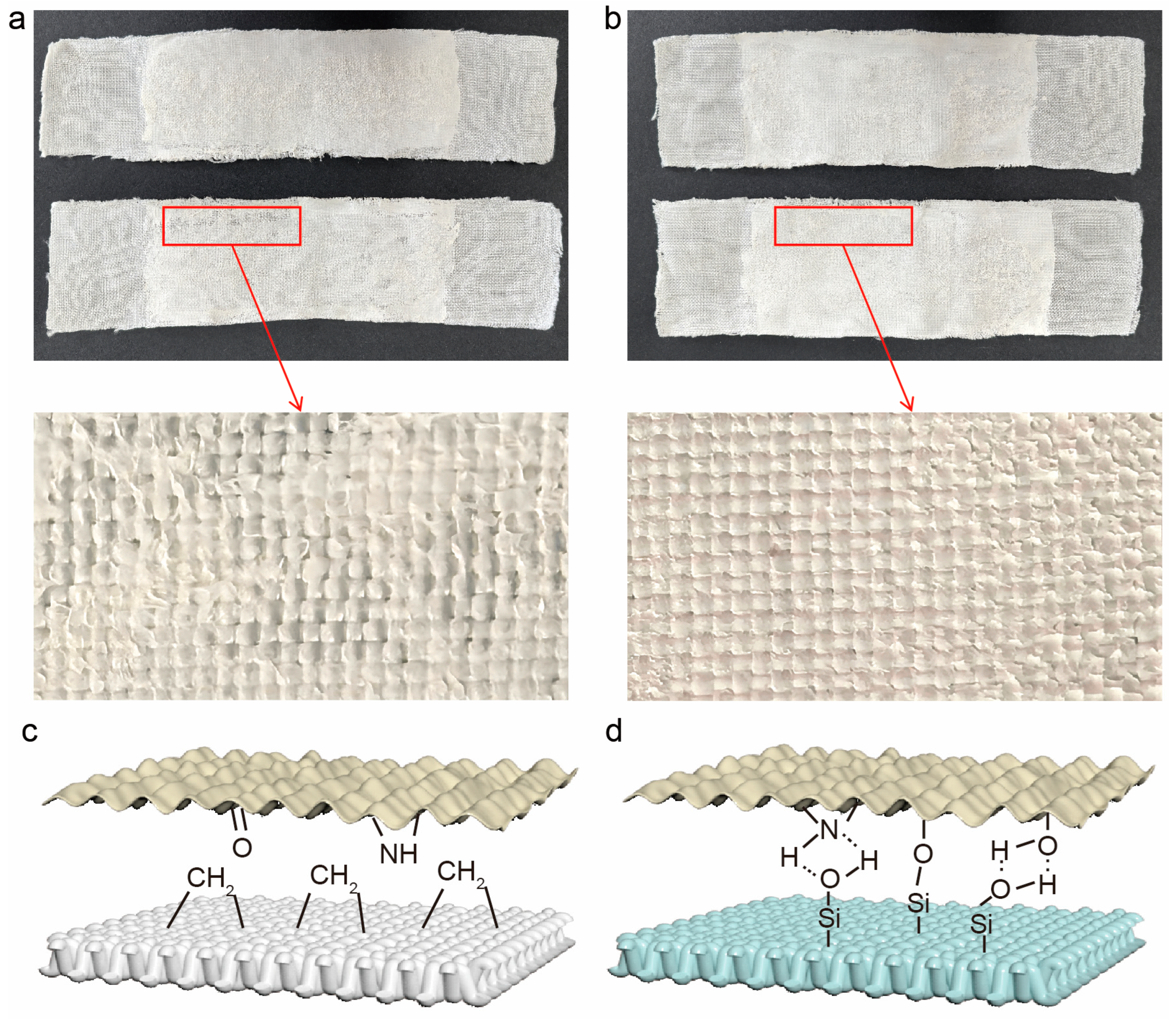

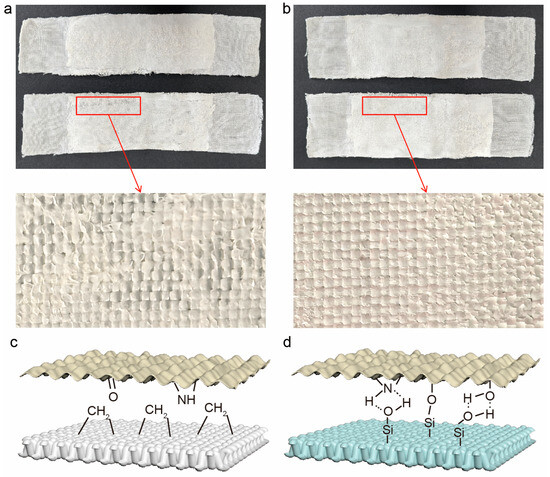

3.6. Adhesion Enhancement Mechanism

Two pieces of UHMWPE fabric and two pieces of PUPE fabric were bonded together by coating, and then the two layers of fabric were vigorously peeled off. The peeling of the surface coatings of the fabrics was observed, and the effect of plasma treatment on the adhesion between the coating and the fabric was discussed, as shown in Figure 11. After the UHMWPE fabric was coated and then peeled off (Figure 11a), it can be seen that the coating on the surface of the fabric surface has peeled off and the fibers are exposed. The surface of the coated fabric becomes mottled, and the exposed area of the fabric after peeling off is 12%, indicating that the adhesion effect between the coating and UHMWPE fabric is poor. After the PUPE double-layer fabric is coated and then vigorously peeled off (Figure 11b), the two pieces of fabric are separated, but there is no separation between the fabric and the coating. The fabric on both sides is still completely covered by the coating, and there is no peeling off of the coating and bare fabric fibers, indicating that the peeling strength of the coating is high, and the adhesion effect between the coating and PUPE fabric is excellent. Figure 11c,d illustrate the effect of plasma treatment on the surface of the fabric. The methylene groups on the surface of UHMWPE fabric without plasma treatment have no polarity and cannot be polarly connected with the carbonyl and amino groups in the coating, resulting in poor adhesion between the fabric and the coating. The surface of the fabric after plasma treatment is activated with silanol groups, which can be dehydrated with the amino groups in the coating to form covalent bonds. The fabric and the coating are connected by hydrogen bonds, resulting in good adhesion performance. Therefore, plasma treatment can provide more and more uniform binding sites for subsequent coating and fabric surface, improving surface adhesion.

Figure 11.

The peeling situation of coatings: (a) fabrics without plasma treatment; (b) fabrics treated with plasma; The red box shows the peeling of two coatings of different treated fabrics, and the arrows are magnifying the coating peeling state by 30×. (c) fabrics without plasma treatment; (d) adhesion mechanism between the surface of fabrics treated with plasma and coatings.

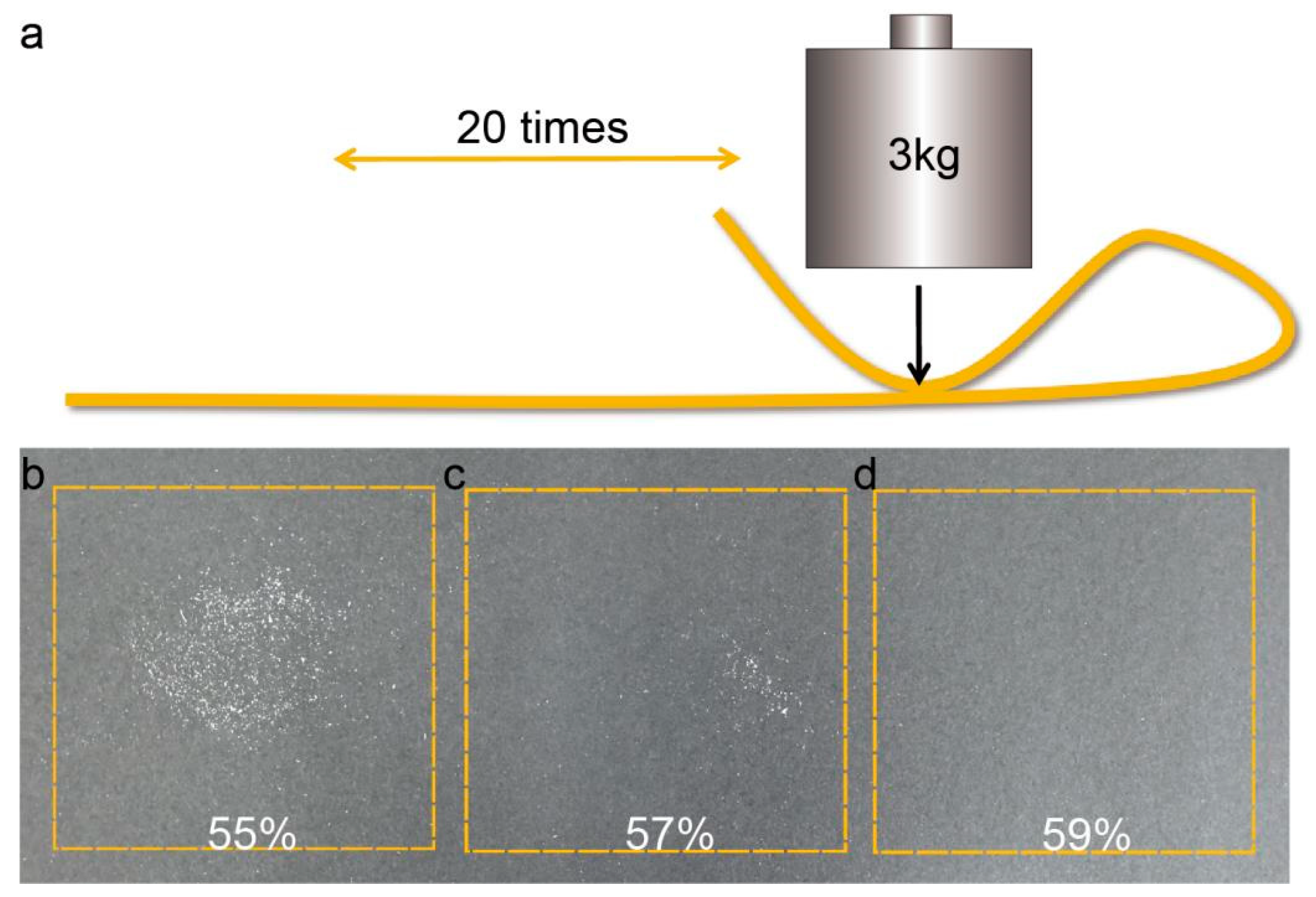

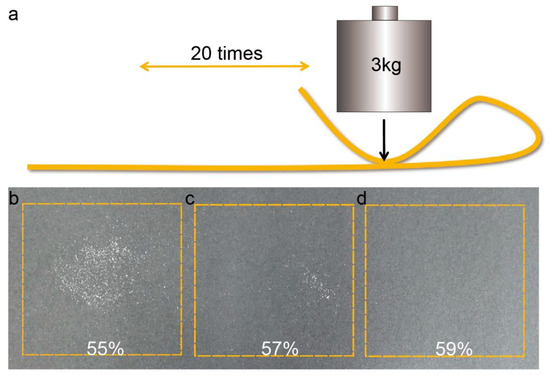

The dropping of the coating powder was observed after repeated mechanical action on UHMWPE-coated fabrics with different PU additions (Figure 12a), and the optimal amount of adhesive was explored. Here, we use an additional external force to perform a test method of repeated friction, the force value is set at 3 kg, the number of repetitions is 20, and the specimen size is 10 cm × 20 cm. As shown in Figure 12b–d, when the proportion of PU is 55%, a large amount of white powder falls off after the external force, indicating that the amount of PU added at this time has a bad bonding effect on the flame retardant, and the coating falls off easily under the action of external force. When the proportion of PU is increased to 57%, a small amount of white powder falls off the fabric after the action of external force, indicating that the ideal adhesive effect has not been achieved at this time. When the proportion is increased to 59%, the coated fabric under the action of external force does not see the white powder falling, the bonding effect is good, and the coating is not easy to fall off when subjected to external mechanical action.

Figure 12.

(a) Mechanical simulation of coated UHMWPE fabric; powder drop of UHMWPE fabrics coated with different PU concentrations under mechanical action: (b) 55%, (c) 57%, and (d) 59%.

4. Conclusions

In this study, a composite coating UHMWPE fabric with flame retardancy and superhydrophobicity (SFPUPE) is successfully prepared by simple coating and spraying methods. SFPUPE fabrics are non-flammable when exposed to fire, and it extinguishes immediately after leaving the fire. The LOI is increased by 90%, demonstrating excellent flame retardancy. In the WCA test, the WCA on the surface of SFPUPE fabric reaches 156°, which exhibits great superhydrophobicity and anti-dyeing properties against other liquids of acidic, alkaline, and different color, proving its excellent superhydrophobicity. Despite some changes in the breaking strength, air permeability, and moisture permeability of SFPUPE fabric, the coating still endows the fabric with excellent functionality and durability. In summary, this study provides a convenient and efficient method for the study of flame retardancy and superhydrophobicity of functional textiles and has potential application prospects in the design of functional textiles. Meanwhile, through further research and optimization of the method, it is expected to promote the research and development of flame retardancy and superhydrophobicity in the textile industry and contribute to the innovative development and progress of the textile industry.

Author Contributions

Conceptualization, X.S., X.L. and Z.L.; Methodology, X.S., J.W. and Y.W.; Software, Q.G. and J.C.; Validation, Q.G., J.S. and Y.W.; Formal analysis, X.L. and J.W.; Investigation, X.S., J.W. and Y.L.; Resources, X.L. and J.C.; Data curation, X.S., Z.L., J.W. and J.S.; Writing—original draft, X.S. and J.W.; Writing—review & editing, Y.L., J.S., J.C., Y.W., Z.L. and X.L.; Visualization, Q.G., Y.L. and J.C.; Supervision, Y.L., Z.L. and X.L.; Project administration, J.W. and Y.L.; Funding acquisition, X.S. and X.L. All authors have read and agreed to the published version of the manuscript.

Funding

This work was supported by the PhD Research Startup Foundation of Xinjiang University (620323013), the Scientific Research Program of the Higher Education Institution of Xinjiang, China (XJEDU2023P030), the Program of Tianchi Talent of Xinjiang Uygur Autonomous Region (5105240151n), and the Key R&D Task Special Program of Xinjiang Uyghur Autonomous Region (2024B04004-3).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Data is contained within the article.

Conflicts of Interest

Author Ying Li was employed by Shaanxi Textile Science Research Institute Co., Ltd. The remaining authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

References

- Lin, J.; Li, Y.; Fan, H. Anti-ballistic properties of hybrid UHMWPE fiber-reinforced composite armour. Compos. Sci. Technol. 2025, 259, 110941. [Google Scholar]

- Xu, R.; Lu, S.; Miao, J.; Tang, C.; Yu, J. Fiber-reinforced gypsum composites with ultra-high ductility: Investigation of physical and mechanical properties. Constr. Build. Mater. 2024, 457, 139285. [Google Scholar]

- Yu, J.; Chen, H.; Huang, H.; Zeng, M.; Qin, J.; Liu, H.; Ji, M.; Bao, F.; Zhu, C.; Xu, J. Protein-induced decoration of applying MXene directly to UHMWPE fibers and fabrics for improved adhesion properties and electronic textiles. Compos. Sci. Technol. 2022, 218, 109158. [Google Scholar]

- Cha, J.H.; Kumar, S.K.S.; Noh, J.E.; Choi, J.S.; Kim, Y.; Kim, C.G. Ultra-high-molecular-weight polyethylene/hydrogen-rich benzoxazine composite with improved interlaminar shear strength for cosmic radiation shielding and space environment applications. Compos. Struct. 2022, 300, 116157. [Google Scholar]

- Liu, H.; Zhang, H.; Yu, X.; Xu, Z.; Cui, J.; Lai, M.; Yu, J.; Bao, F.; Tang, Z.; Zhu, C.; et al. Flexible, lightweight, high strength and high efficiently hierarchical Gd2O3/PE composites based on the UHMWPE fibers with self-reinforcing strategy for thermal neutron shielding. Compos. Sci. Technol. 2024, 251, 110549. [Google Scholar]

- Marquis, C.; Song, R.; Waddell, S.; Luong, A.; Arola, D. Additive manufacturing with continuous ultra-high molecular weight polyethylene yarn. Mater. Des. 2023, 235, 112411. [Google Scholar]

- Chhetri, S.; Bougherara, H. A comprehensive review on surface modification of UHMWPE fiber and interfacial properties. Compos. Part A Appl. Sci. Manuf. 2021, 140, 106146. [Google Scholar]

- Wang, S.; Ma, J.; Feng, X.; Cheng, J.; Ma, X.; Zhao, Y.; Chen, L. An effective surface modification of UHMWPE fiber for improving the interfacial adhesion of epoxy resin composites. Polym. Compos. 2020, 41, 1614–1623. [Google Scholar]

- Fang, Z.; Tu, Q.; Shen, X.; Yang, X.; Liang, K.; Pan, M.; Chen, Z. Biomimetic surface modification of UHMWPE fibers to enhance interfacial adhesion with rubber matrix via constructing polydopamine functionalization platform and then depositing zinc oxide nanoparticles. Surf. Interfaces 2022, 29, 101728. [Google Scholar]

- Shelly, D.; Nanda, T.; Mehta, R. Addition of compatibilized nanoclay and UHMWPE fibers to epoxy based GFRPs for improved mechanical properties. Compos. Part A Appl. Sci. Manuf. 2021, 145, 106371. [Google Scholar]

- Hu, S.; Yuan, X.; Ma, Y.; Zhang, G.; Wang, C.; Pang, X.; Xiong, F. Temperature-influenced cutting mechanism of UHMWPE fibres. J. Manuf. Process. 2024, 113, 183–196. [Google Scholar]

- Cheng, B.; Duan, H.; Chen, S.; Shang, H.; Li, J.; Shao, T. Effects of thermal aging on the blend phase morphology and tribological performance of PI/UHMWPE blend composites. Wear 2021, 477, 203840. [Google Scholar] [CrossRef]

- Lau, S.; Gonchikzhapov, M.; Paletsky, A.; Shmakov, A.; Korobeinichev, O.; Kasper, T.; Atakan, B. Aluminum diethylphosphinate as a flame retardant for polyethylene: Investigation of the pyrolysis and combustion behavior of PE/AlPi-Mixtures. Combust. Flame 2022, 240, 112006. [Google Scholar]

- Liu, X.; Shao, Q.; Cao, J.; Du, Z.; Yu, W. Superamphiphobic and flame-resistant cotton fabrics for protective clothing. Cellulose 2022, 29, 619–632. [Google Scholar]

- Cheng, X.W.; Liu, Y.W.; Jin, J.H.; Guan, J.P.; Chen, R. Metallic phytates modified polyurethane coating for constructing long-lasting flame-retardant outdoor polyester fabric. Prog. Org. Coat. 2024, 188, 108205. [Google Scholar]

- Miao, Z.; Yan, D.; Zhang, T.; Yang, F.; Zhang, S.; Liu, W.; Wu, Z. High-efficiency flame retardants of a P–N-Rich polyphosphazene elastomer nanocoating on cotton fabric. ACS Appl. Mater. Interfaces 2021, 13, 32094–32105. [Google Scholar]

- Li, N.; Kang, G.; Liu, H.; Qiu, W.; Wang, Q.; Liu, L.; Wang, X.; Yu, J.; Li, F.; Wu, D. Fabrication of eco-friendly and efficient flame retardant modified cellulose with antibacterial property. J. Colloid Interface Sci. 2022, 618, 462–474. [Google Scholar]

- Zhang, A.-N.; Zhao, H.-B.; Cheng, J.-B.; Li, M.-E.; Li, S.-L.; Cao, M.; Wang, Y.-Z. Construction of durable eco-friendly biomass-based flame-retardant coating for cotton fabrics. Chem. Eng. J. 2021, 410, 128361. [Google Scholar]

- Cheng, X.W.; Dong, S.; Yang, H.J.; Zhao, L.P.; Guan, J.P. The development of phosphorus-doped hybrid silica sol coating for silk with durable flame retardancy. Polym. Degrad. Stab. 2022, 201, 109974. [Google Scholar]

- Liu, L.; Ma, Z.; Zhu, M.; Liu, L.; Dai, J.; Shi, Y.; Gao, J.; Dinh, T.; Nguyen, T.; Tang, L.-C.; et al. Superhydrophobic self-extinguishing cotton fabrics for electromagnetic interference shielding and human motion detection. J. Mater. Sci. Technol. 2023, 132, 59–68. [Google Scholar]

- Li, N.; Han, H.; Li, M.; Qiu, W.; Wang, Q.; Qi, X.; He, Y.; Wang, X.; Liu, L.; Yu, J.; et al. Eco-friendly and intrinsic nanogels for durable flame retardant and antibacterial properties. Chem. Eng. J. 2021, 415, 129008. [Google Scholar] [CrossRef]

- Lau, S.; Atakan, B. Isothermal pyrolysis investigation of aluminum diethylphosphinate mixed as a flame retardant additive into ultra-high molecular weight polyethylene. Combust. Flame 2020, 222, 272–284. [Google Scholar] [CrossRef]

- Korobeinichev, O.; Gonchikzhapov, M.; Paletsky, A.; Tereshchenko, A.; Shundrina, I.; Kuibida, L.; Shmakov, A.; Hu, Y. Counterflow flames of ultrahigh-molecular-weight polyethylene with and without triphenylphosphate. Combust. Flame 2016, 169, 261–271. [Google Scholar] [CrossRef]

- Wang, H.; Cao, J.; Luo, F.; Cao, C.; Qian, Q.; Huang, B.; Xiao, L.; Chen, Q. Simultaneously enhanced mechanical properties and flame retardancy of UHMWPE with polydopamine-coated expandable graphite. RSC Adv. 2019, 9, 21371–21380. [Google Scholar] [CrossRef] [PubMed]

- Shen, L.; Li, J.; Lin, H.; Feng, S.; Zhang, Y. The enhanced compatibility and flame retarding ability of UHMWPE-MH composites by adding phenoxycyclophosphazene (HPCTP). Polym. Bull. 2017, 74, 3639–3655. [Google Scholar] [CrossRef]

- Sun, R.Y.; Wang, F.; Li, C.B.; Deng, Z.P.; Song, F.; Wang, Y.Z. Formulation of environmentally robust flame-retardant and superhydrophobic coatings for wood materials. Constr. Build. Mater. 2023, 392, 131873. [Google Scholar] [CrossRef]

- Chen, S.; Li, X.; Zhang, C.; Long, L.; Zhao, X.; Zhu, C.; Li, B.; Yi, X. Superhydrophobic nanocellulose aerogel for thermal insulation and thermal resistance up to 1300 °C. Chem. Eng. J. 2024, 499, 156043. [Google Scholar] [CrossRef]

- Wu, S.; Chen, D.; Zhao, G.; Cheng, Y.; Sun, B.; Yan, X.; Han, W.; Chen, G.; Zhang, X. Controllable synthesis of a robust sucrose-derived bio-carbon foam with 3D hierarchical porous structure for thermal insulation, flame retardancy and oil absorption. Chem. Eng. J. 2022, 434, 134514. [Google Scholar] [CrossRef]

- Zang, X.; Bian, J.; Ni, Y.; Zheng, W.; Zhu, T.; Chen, Z.; Cao, X.; Huang, J.; Lai, Y.; Lin, Z. A robust biomimetic superhydrophobic coating with superior mechanical durability and chemical stability for inner pipeline protection. Adv. Sci. 2024, 11, 2305839. [Google Scholar] [CrossRef]

- Zhao, Z.; Sun, S.; Li, C.; Hu, S. In situ growth of micro-nano structured black oxide coating on steel with excellent superhydrophobicity and corrosion resistance. Compos. Struct. 2024, 344, 118338. [Google Scholar] [CrossRef]

- Deng, H.; Guo, L.; Chen, K.; You, P.; Zhang, P.; Xu, Y.; Song, N.; Tian, C.; Wang, J.; Liang, S. End group capturing in polyurea elastomer by using aromatic dianhydrides for flame retardance. Compos. Part B Eng. 2024, 274, 111276. [Google Scholar]

- Xavier, J.R.; Vinodhini, S.P. Improved anticorrosion, flame retardant and mechanical behaviors of multifunctional polyurethane nanocomposite coatings for industrial applications. Polym. Degrad. Stab. 2023, 213, 110370. [Google Scholar]

- Yang, S.; Chen, L.; Wang, S.; Liu, S.; Xu, Q.; Zhu, J.; Zhang, Q.; Zhao, P. Honeycomb-like cobalt hydroxide nanosheets induced basalt fiber fabrics with robust and durable superhydrophobicity for anti-icing and oil-water separation. J. Hazard. Mater. 2022, 429, 128284. [Google Scholar]

- Shao, J.; Sheng, W.; Wang, C.; Ye, Y. Solvent-free fabrication of tough self-crosslinkable short-fluorinated copolymer nanocoatings for ultradurable superhydrophobic fabrics. Chem. Eng. J. 2021, 416, 128043. [Google Scholar]

- He, Q.; Wang, J.; Wang, G.; Hao, X.; Li, A. Construction of a durable superhydrophobic flame-retardant coating on the PET fabrics. Mater. Des. 2023, 233, 112258. [Google Scholar]

- Huang, J.; Li, M.; Ren, C.; Huang, W.; Wu, Q.; Li, Q.; Zhang, W.; Wang, S. Preparation of high-efficiency flame-retardant and superhydrophobic cotton fabric by a multi-step dipping. Coatings 2021, 11, 1147. [Google Scholar] [CrossRef]

- Li, C.; Song, J.; Xing, W.; Wang, L.; Cui, Y.; Pei, X. Mechanical properties of interlayer hybrid textile composite materials based on modified aramid and UHMWPE fabrics. Polym. Adv. Technol. 2023, 34, 205–216. [Google Scholar]

- Gao, M.; Wang, Y.; Zhang, Y.; Li, Y.; Tang, Y.; Huang, Y. Deposition of thin films on glass fiber fabrics by atmospheric pressure plasma jet. Surf. Coat. Technol. 2020, 404, 126498. [Google Scholar]

- Palaskar, S.S. Adhesion studies of atmospheric pressure plasma-modified polyester fabrics with polyurethane coating. J. Adhes. Sci. Technol. 2023, 37, 3468–3484. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).