Effect of Trace Er Addition on the Microstructural Evolution and Heat Resistance Properties of an Al-Zn-Mg-Cu Alloy During High Temperature Tensile and Thermal Exposure

Abstract

:1. Introduction

2. Experimental Procedure

3. Results

3.1. The High Temperature Tensile Properties

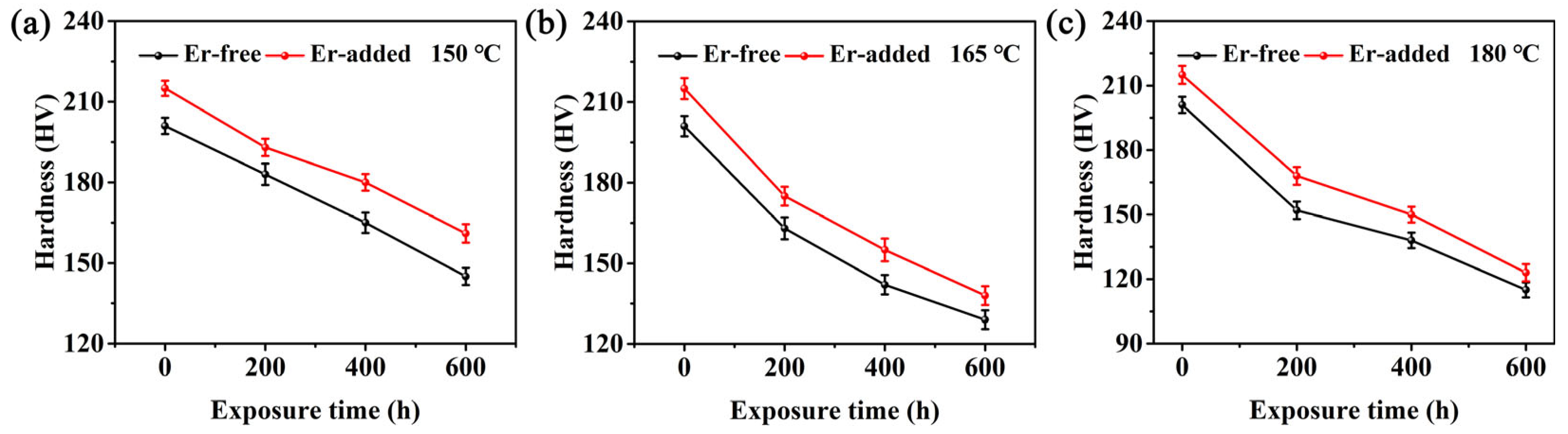

3.2. Thermal Stability Testing After Exposure to 150 °C, 165 °C, and 180 °C for 600 h

3.3. XRD Patterns

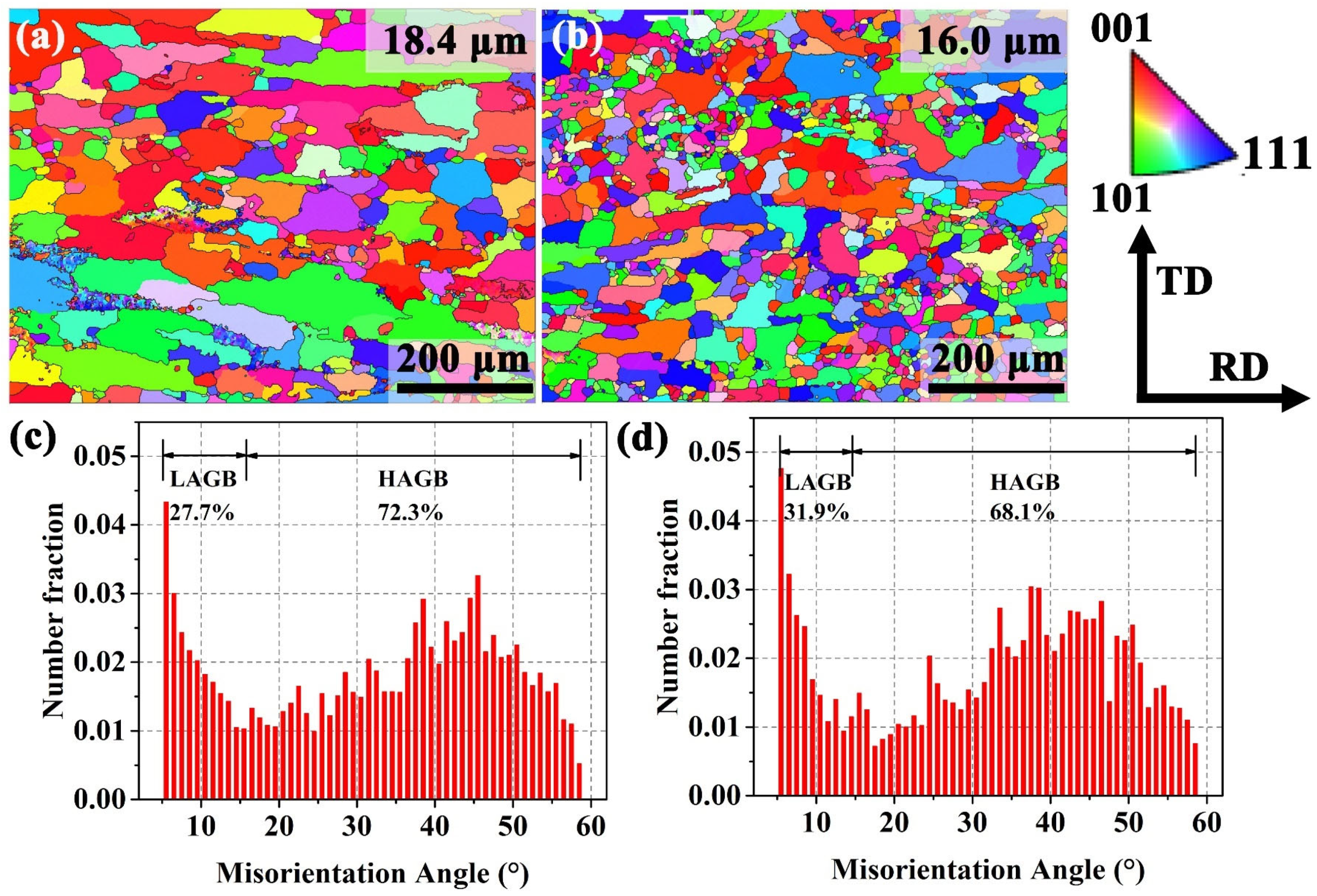

3.4. EBSD Analysis

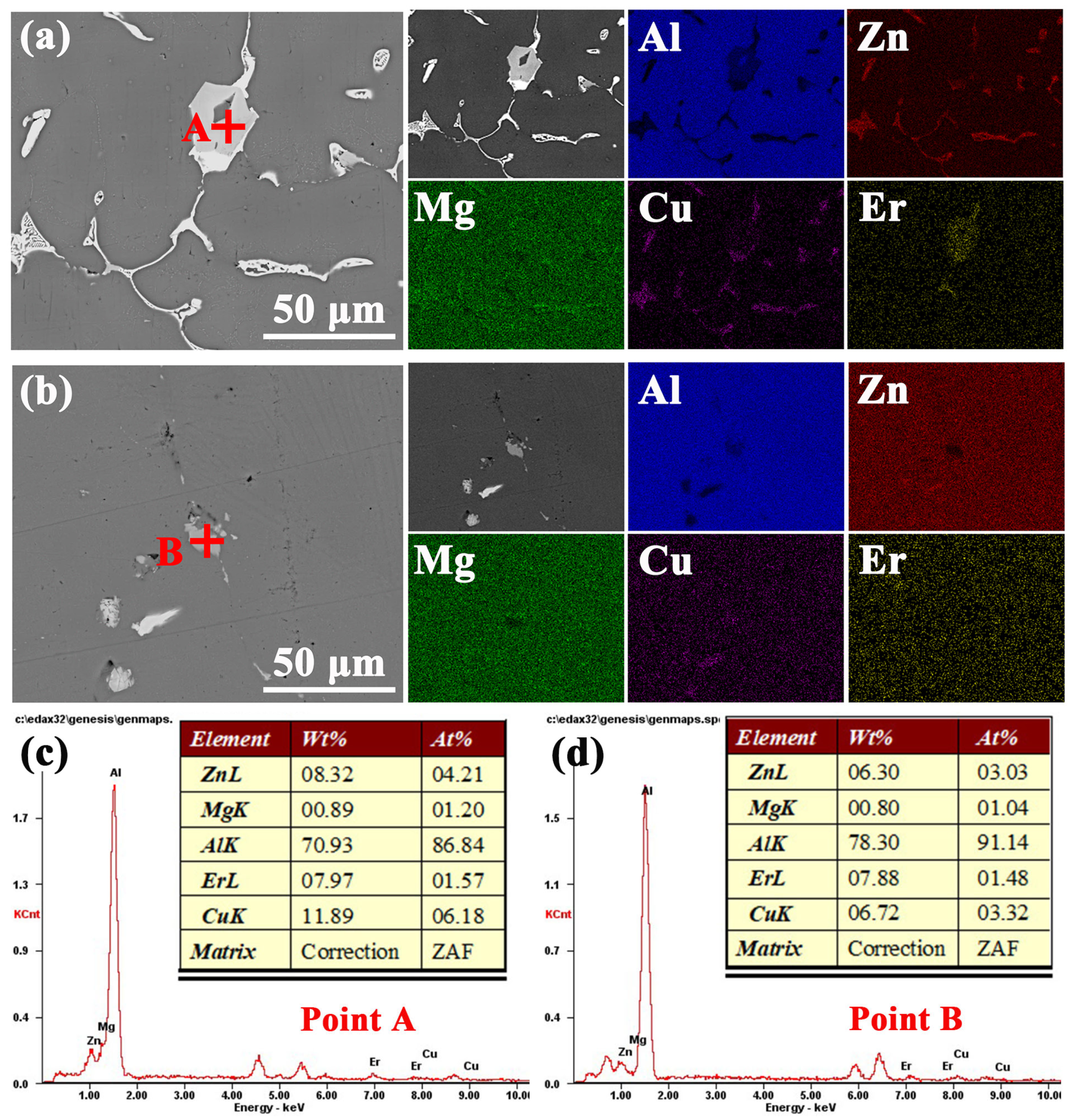

3.5. SEM Observation

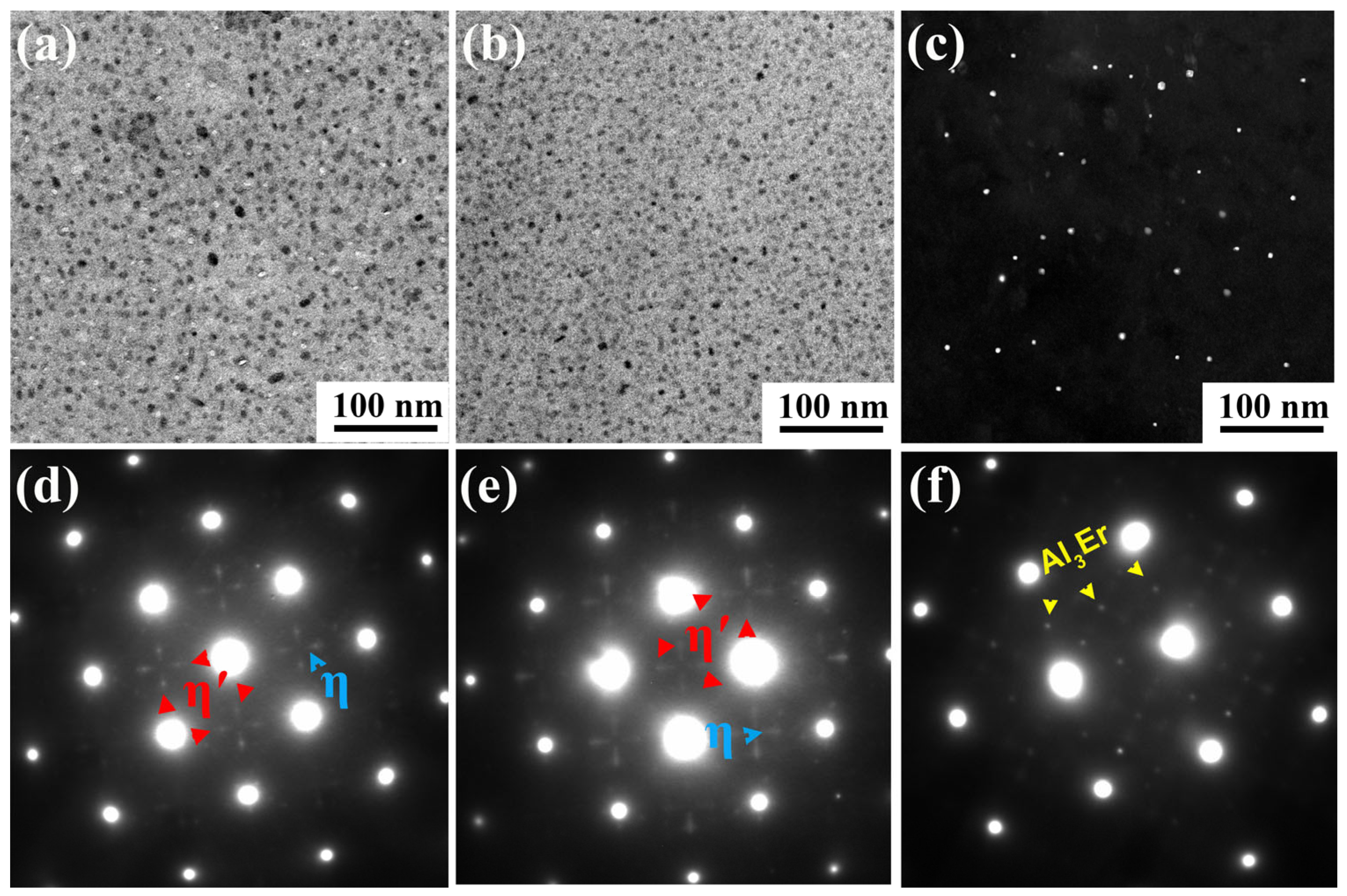

3.6. Conventional TEM Characterization

3.6.1. Precipitation Behavior

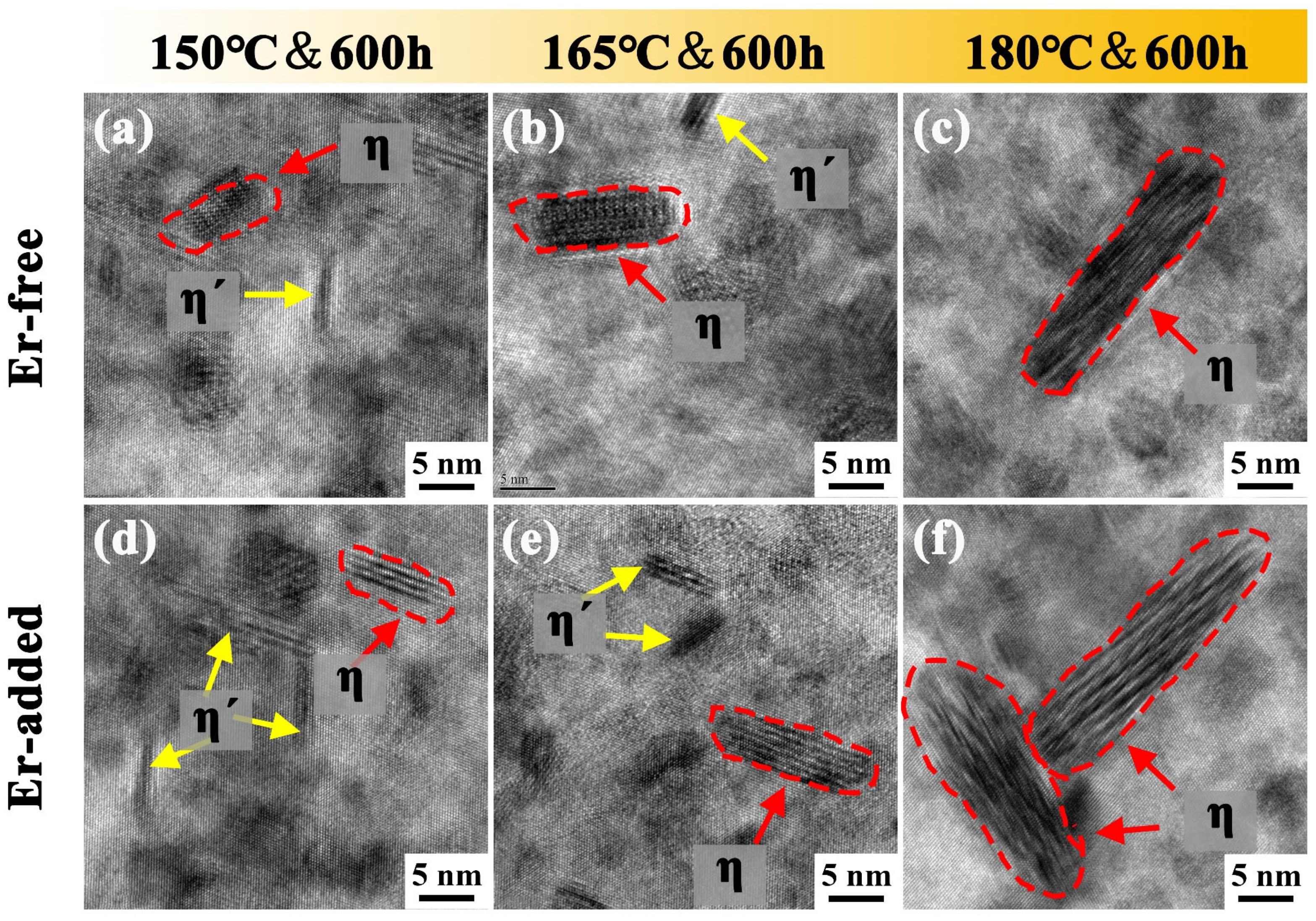

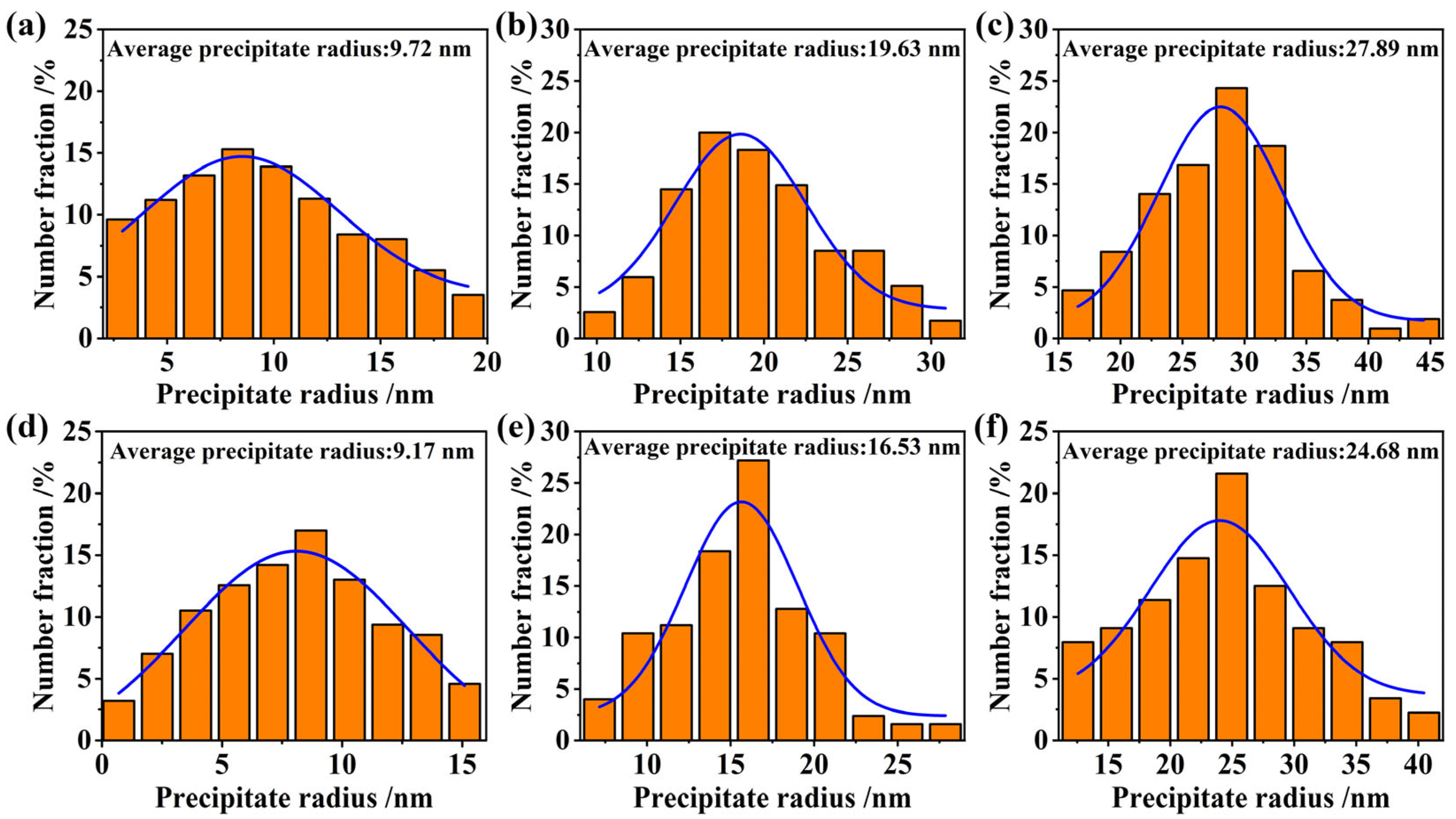

3.6.2. After Further Exposure to 150 °C, 165 °C, and 180 °C for 600 h

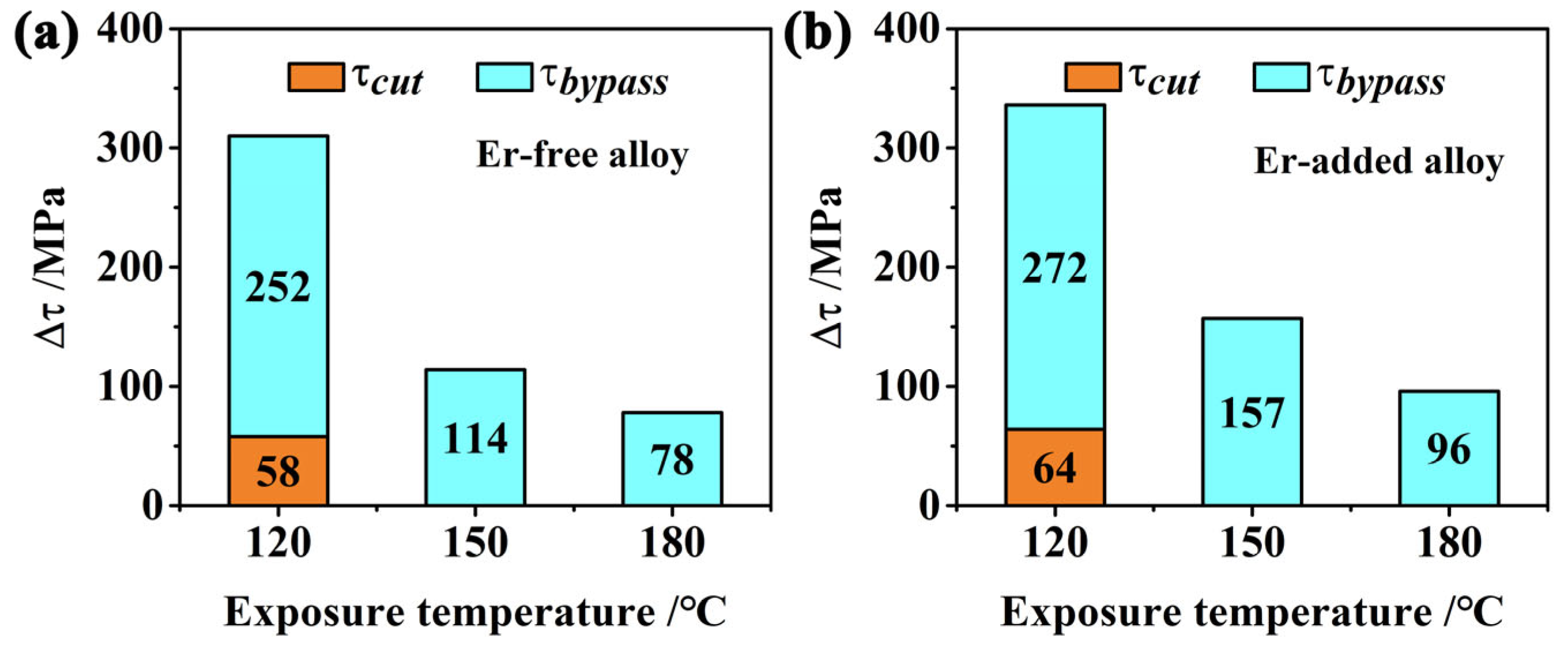

4. Discussion

4.1. Effect of Er Addition on High Temperature Tensile Properties

4.2. Microstructure Evolution and Thermal Stability During Extended Exposure

5. Conclusions

- 1.

- The high temperature tensile properties and thermal stability of the alloy were effectively improved by adding trace Er.

- 2.

- The Al3Er particles will precipitate after homogenization treatment. It was observed that the Al8Cu4Er phase is uniformly distributed along the grain boundary in the Er-added alloy, which can effectively pin the grain boundary when the alloy is stretched at high temperatures.

- 3.

- The precipitates in both alloys coarsen with the increase in thermal exposure time or temperature, which subsequently reduces the tensile properties of the alloys. Compared with the thermal exposure time, the thermal exposure temperature has a greater influence on the thermal stability. During long-period thermal exposure, the metastable η′ phase transforms to coherent η phase in both alloys.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Liu, H.; Zhang, Z.; Zhang, D.; Zhang, J. The effect of Ag on the tensile strength and fracture toughness of novel Al-Mg-Zn alloys. J. Alloys Compd. 2022, 908, 164640. [Google Scholar] [CrossRef]

- Yang, M.; Lu, F.; Zhou, S.; Liu, S.; Ye, L. Evolution of strengthening precipitates in Al-4.0Zn-1.8Mg-1.2Cu (at%) alloy with high Zn/Mg ratio during artificial aging. J. Alloys Compd. 2024, 1009, 176895. [Google Scholar] [CrossRef]

- Zhang, M.; Jiang, J.; Ma, Z.; Liu, S. Effect of Cu content on tensile behavior of Al-Zn-Mg-(Cu) alloys after alternate immersion. J. Alloys Compd. 2024, 1008, 176875. [Google Scholar] [CrossRef]

- Ma, N.; Zhu, J.; Chang, K.; Wu, Y. Study on the effect of aging heat treatment temperature on the microstructure and properties of soluble Al-Zn-Mg-Ga-In-Sn aluminum alloys in solid solution state. J. Alloys Compd. 2024, 1005, 176048. [Google Scholar] [CrossRef]

- Deng, S.; Wang, L.; Zhao, H.; Shao, J.; Li, J.; Ojo, O.A.; Zhang, L.; Li, R.; Xu, L. Microstructure and mechanical properties of selective laser melted Al-Zn-Mg-Si-Sc-Zr alloy with high hot-cracking resistance. J. Alloys Compd. 2024, 973, 172930. [Google Scholar] [CrossRef]

- Xu, Y.; Zhang, Z.; Gao, Z.; Bai, Y.; Zhao, P.; Mao, W. Effect of main elements (Zn, Mg and Cu) on the microstructure, castability and mechanical properties of 7xxx series aluminum alloys with Zr and Sc. Mater. Charact. 2021, 182, 111559. [Google Scholar] [CrossRef]

- Zou, Y.; Cao, L.; Wu, X.; Tang, S.; Guo, M. Synergetic effect of natural ageing and pre-stretching on the ageing behavior in Tʹ/ηʹ phase-strengthened Al-Zn-Mg-Cu alloys. J. Mater. Sci. Technol. 2023, 146, 240–251. [Google Scholar] [CrossRef]

- Mondol, S.; Alam, T.; Banerjee, R.; Kumar, S. Chattopadhyay, Development of a high temperature high strength Al alloy by addition of small amounts of Sc and Mg to 2219 alloy. Mater. Sci. Eng. A 2017, 687, 221–231. [Google Scholar] [CrossRef]

- Yu, Z.; Jin, S.; Feng, M.; Murashkin, M.Y.; Valiev, R.Z.; Ringer, S.P.; Sha, G. Temperature-dependent-composition of η phase in an Al-Zn-Mg-Cu alloy under high pressure torsion: Kinetics and thermodynamics. Acta Mater. 2022, 237, 118181. [Google Scholar] [CrossRef]

- Ye, J.; Pan, Q.; Liu, B.; Hu, Q.; Qu, L.; Wang, W.; Wang, X. Effects of co-addition of minor Sc and Zr on aging precipitates and mechanical properties of Al–Zn–Mg–Cu alloys. J. Mater. Res. Technol. 2023, 22, 2944–2954. [Google Scholar] [CrossRef]

- Lee, E.W.; Oppenheim, T.; Robison, K.; Aridkahari, B.; Neylan, N.; Gebreyesus, D.; Richardson, M.; Arzate, M.; Bove, C.; Iskandar, M.; et al. The effect of thermal exposure on the electrical conductivity and static mechanical behavior of several age hardenable aluminum alloys. Eng. Fail. Anal. 2017, 14, 1538–1549. [Google Scholar] [CrossRef]

- Sauvage, X.; Bobruk, E.V.; Murashkin, M.Y.; Nasedkina, Y.; Enikeev, N.A.; Valiev, R.Z. Optimization of electrical conductivity and strength combination by structure design at the nanoscale in Al-Mg-Si alloys. Acta Mater. 2015, 98, 355–366. [Google Scholar]

- Esin, V.A.; Briez, L.; Sennour, M.; Köster, A.; Gratiot, E.; Crépin, J. Precipitation-hardness map for Al-Cu-Mg alloy (AA2024-T3). J. Alloys Compd. 2021, 854, 157164. [Google Scholar]

- Wang, Y.; Cao, L.; Wu, X.; Lin, X.; Yao, T.; Peng, L. Multi-alloying effect of Ti, Mn, Cr, Zr, Er on the cast Al-Zn-Mg-Cu alloys. Mater. Charact. 2023, 201, 112984. [Google Scholar]

- Chen, J.; Rong, L.; Huang, H.; Ma, C.; Wei, W.; Wen, S.; Wang, Z.; Nie, Z. The effects of η phases and Al3(Er, Zr) particles pre-precipitation on the hot workability and recrystallization of Al-Zn-Mg-Er-Zr alloy. J. Mater. Res. Technol. 2024, 29, 2414–2424. [Google Scholar]

- Fang, H.C.; Chao, H.; Chen, K.H. Effect of Zr, Er and Cr additions on microstructures and properties of Al–Zn–Mg–Cu alloys. Mater. Sci. Eng. A 2014, 610, 10–16. [Google Scholar] [CrossRef]

- Zou, Y.; Cao, L.; Wu, X.; Mou, C.; Tang, S. Revealing the coarsening behavior of precipitates and its effect on the thermal stability in Tʹ and ηʹ dual-phase strengthened Al-Zn-Mg-Cu alloys. J. Mater. Sci. Technol. 2025, 220, 54–66. [Google Scholar]

- Zhang, X.; Wu, G.; Zhang, L.; Shi, C. Effects of Mg and Sc additions on the microstructure, mechanical properties, and thermal stability of a cast Al-2Li-2Cu-0.2Zr alloy after thermal exposure. J. Alloys Compd. 2019, 788, 367–382. [Google Scholar]

- Xu, W.; Wang, H.; Lu, H.; Liu, Y.; Dong, J. Effect of thermal exposure on microstructure and mechanical properties of friction stir welding 7B50-T7451 aluminium alloy thick plate joint. J. Mater. Res. Technol. 2021, 15, 6415–6433. [Google Scholar]

- Wu, M.; Liu, W.; Xiao, D.; Huang, L. Influence of thermal exposure on the microstructure evolution and mechanical behaviors of an Al-Cu-Li alloy. Mater. Des. 2023, 227, 111767. [Google Scholar] [CrossRef]

- Zhang, Z.; Li, S.; Li, D.; Tang, H.; Dong, T.; Lin, Y. Effect of Er addition on the microstructure, mechanical properties and corrosion behaviour of Al-Zn-Mg-Cu alloy manufactured by laser powder bed fusion. Mater. Today Commun. 2024, 40, 109547. [Google Scholar]

- Wang, Y.; Wu, X.; Cao, L.; Tong, X.; Couper, M.J.; Liu, Q. Effect of trace Er on the microstructure and properties of Al-Zn-Mg-Cu-Zr alloys during heat treatments. Mater. Sci. Eng. A 2020, 792, 139807. [Google Scholar]

- Li, C.; Zhou, Q.; Han, M.; Sha, S.; Luo, Y.; Xu, X. Effect of rare earth element Er on the microstructure and properties of highly alloyed Al-Zn-Mg-Cu-Zr-Ti alloy. J. Alloys Compd. 2023, 956, 170248. [Google Scholar]

- Wang, Y.; Wu, X.; Cao, L.; Tong, X.; Zou, Y.; Zhu, Q.; Tang, S.; Song, H.; Guo, M. Effect of Ag on aging precipitation behavior and mechanical properties of aluminum alloy 7075. Mater. Sci. Eng. A 2021, 804, 140515. [Google Scholar]

- Kim, Y.Y.; Euh, K.; Kim, S.-H.; Son, H.-W. Effects of Ag/Sc microadditions on the precipitation of over-aged Al–Zn–Mg–Cu alloys. J. Mater. Sci. Technol. 2025, 209, 219–229. [Google Scholar]

- Dai, P.; Luo, X.; Yang, Y.; Kou, Z.; Huang, B.; Zang, J.; Ru, J. High temperature tensile properties, fracture behaviors and nanoscale precipitate variation of an Al–Zn–Mg–Cu alloy. Prog. Nat. Sci. Mater. Int. 2020, 30, 63–73. [Google Scholar]

- Dai, P.; Luo, X.; Yang, Y.; Kou, Z.; Huang, B.; Zang, J.; Ru, J. Thermal stability analysis of a lightweight Al-Zn-Mg-Cu alloy by TEM and tensile tests. Mater. Charact. 2019, 153, 271–283. [Google Scholar]

- Cheon, H.S.; Kim, B.J.; Kim, J.; Jung, J.; Kim, S.H.; Lee, J.I. Effect of prerolling before artificial aging on the mechanical properties of high-Zn-content Al–Zn–Mg–Cu–Sc–Zr–Mn alloy. J. Mater. Res. Technol. 2024, 33, 1249–1259. [Google Scholar]

- Zhou, H.; Wang, F.; Tang, S.; Ma, Y.; Liu, W.; Liang, C. Unraveling the leverage effect in phases stability and mechanical properties of Al-Zn-Mg-Cu alloy. J. Alloys Compd. 2024, 982, 173763. [Google Scholar]

- Dai, P.; Luo, X.; Yang, Y.; Kou, Z.; Huang, B.; Wang, C.; Zang, J.; Ru, J. Nano-scale precipitate evolution and mechanical properties of 7085 aluminum alloy during thermal exposure. Mater. Sci. Eng. A 2018, 729, 411–422. [Google Scholar]

- Zheng, J.K.; Xu, X.; Luo, R.; Zeng, X.; Chen, B. Degradation of precipitation hardening in 7075 alloy subject to thermal exposure: A Cs-corrected STEM study. J. Alloys Compd. 2018, 741, 656–660. [Google Scholar] [CrossRef]

- Huang, Y.C.; Zhang, C.C.; Ma, Y.L.; Liu, Y. Effects of homogenization on the dissolution and precipitation behaviors of intermetallic phase for a Zr and Er containing Al-Zn-Mg-Cu alloy. Prog. Nat. Sci. Mater. Int. 2020, 30, 47–53. [Google Scholar]

- Li, H.; Zhu, C.; Gu, X.; Li, M.; Wang, Y.; Jiang, B.; Wang, Z.; Huang, L.; Zhang, H. Understanding the strength increment of Al–Zn–Mg–Cu aluminum alloys by enhanced solution-treatment (EST). Mater. Sci. Eng. A 2024, 903, 146667. [Google Scholar]

- Lu, Y.; Wen, S.; Wei, W.; Wu, X.; Gao, K.; Huang, H.; Nie, Z. High thermal stability of Si-containing Al-Zn-Mg-Cu crossover alloy caused by metastable GPB-II phase. Mater. Charact. 2025, 223, 114870. [Google Scholar] [CrossRef]

| Alloy | Zn | Mg | Cu | Mn | Zr | Ti | Er | Fe | Si | Al |

|---|---|---|---|---|---|---|---|---|---|---|

| Er-free | 6.51 | 1.83 | 1.28 | 0.29 | 0.98 | 0.07 | - | 0.04 | 0.04 | Bal. |

| Er-added | 6.48 | 1.81 | 1.28 | 0.30 | 0.10 | 0.06 | 0.10 | 0.03 | 0.05 | Bal. |

| Alloy | Expose Temperature/°C | Precipitate | f/% | r/nm | Dislocation Mechanism |

|---|---|---|---|---|---|

| Er-free | 150 | η′ + η | 10.7 | 9.72 | 9.8/% Shear + 90.2% Bypass |

| 165 | η′ + η | 7.2 | 19.63 | Bypass | |

| 180 | η | 6.8 | 27.89 | Bypass | |

| Er-added | 150 | η′ + η + Al3(Er, Zr) | 11.6 | 9.17 | 10.2/% Shear + 89.8% Bypass |

| 165 | η′ + η + Al3(Er, Zr) | 9.7 | 16.53 | Bypass | |

| 180 | η + Al3(Er, Zr) | 8.1 | 24.68 | Bypass |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhao, J.; Zhang, R.; Li, R.; Liu, Y.; Bai, S.; Zhao, X.; Sang, J.; Huang, J.; Liu, C.; Liu, X.; et al. Effect of Trace Er Addition on the Microstructural Evolution and Heat Resistance Properties of an Al-Zn-Mg-Cu Alloy During High Temperature Tensile and Thermal Exposure. Coatings 2025, 15, 368. https://doi.org/10.3390/coatings15040368

Zhao J, Zhang R, Li R, Liu Y, Bai S, Zhao X, Sang J, Huang J, Liu C, Liu X, et al. Effect of Trace Er Addition on the Microstructural Evolution and Heat Resistance Properties of an Al-Zn-Mg-Cu Alloy During High Temperature Tensile and Thermal Exposure. Coatings. 2025; 15(4):368. https://doi.org/10.3390/coatings15040368

Chicago/Turabian StyleZhao, Juangang, Ruizhi Zhang, Ruiting Li, Yu Liu, Song Bai, Xuetong Zhao, Jianquan Sang, Jianping Huang, Chunquan Liu, Xinbin Liu, and et al. 2025. "Effect of Trace Er Addition on the Microstructural Evolution and Heat Resistance Properties of an Al-Zn-Mg-Cu Alloy During High Temperature Tensile and Thermal Exposure" Coatings 15, no. 4: 368. https://doi.org/10.3390/coatings15040368

APA StyleZhao, J., Zhang, R., Li, R., Liu, Y., Bai, S., Zhao, X., Sang, J., Huang, J., Liu, C., Liu, X., & Du, F. (2025). Effect of Trace Er Addition on the Microstructural Evolution and Heat Resistance Properties of an Al-Zn-Mg-Cu Alloy During High Temperature Tensile and Thermal Exposure. Coatings, 15(4), 368. https://doi.org/10.3390/coatings15040368