A Review of Research on the Interfacial Shear Performance of Ultra-High-Performance Concrete and Normal Concrete Composite Structures

Abstract

:1. Introduction

2. Sources and Mechanisms of Interfacial Bonding Force

3. Research on Test Methods for Shear Performance of UHPC-NC Interface

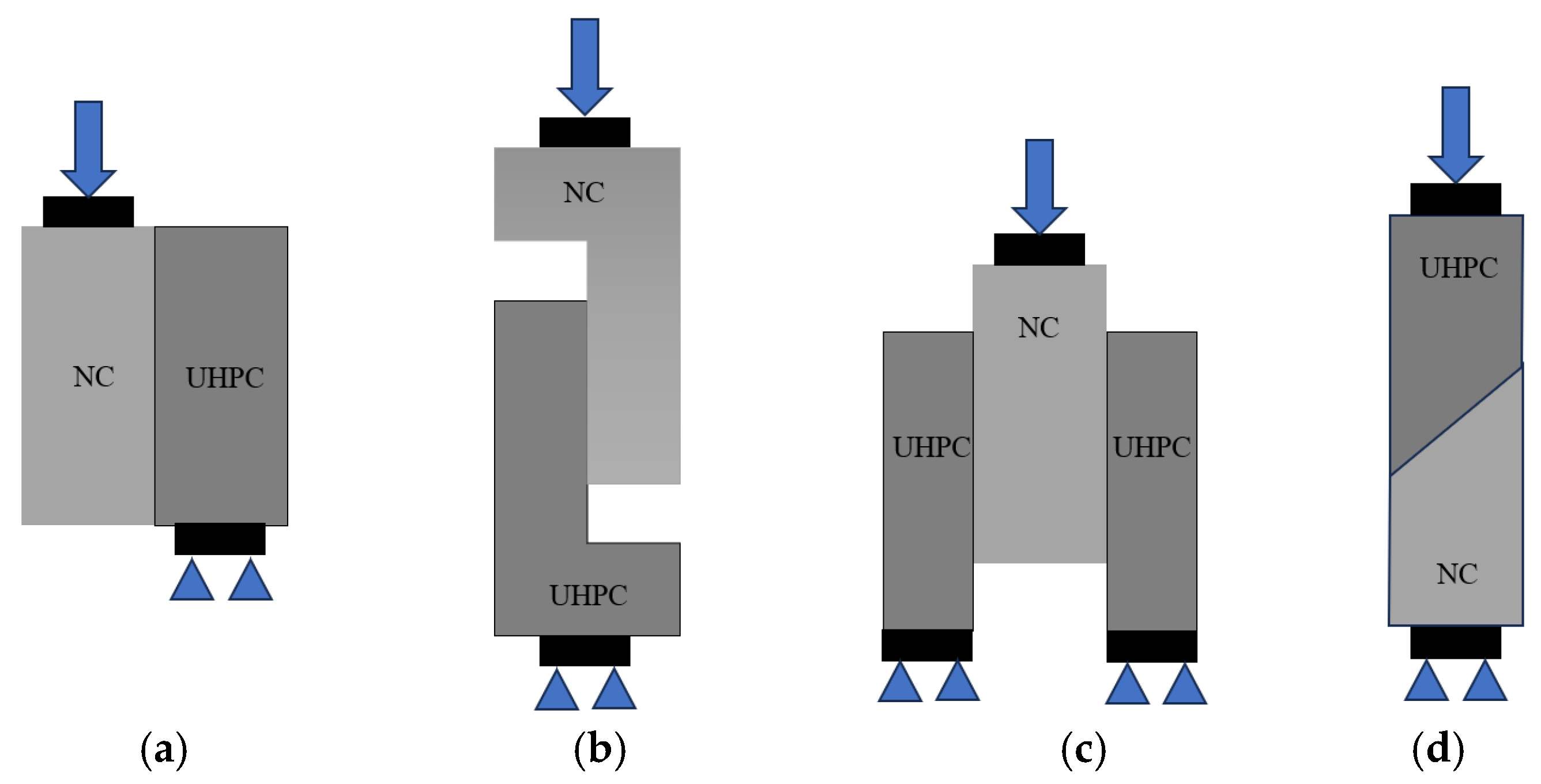

3.1. Single-Shear Test

3.2. Z-Shaped Direct Shear Test

3.3. Double-Shear Test

3.4. Oblique Shear Test

4. The Main Factors Influencing the Interfacial Shear Performance of UHPC Composite Members

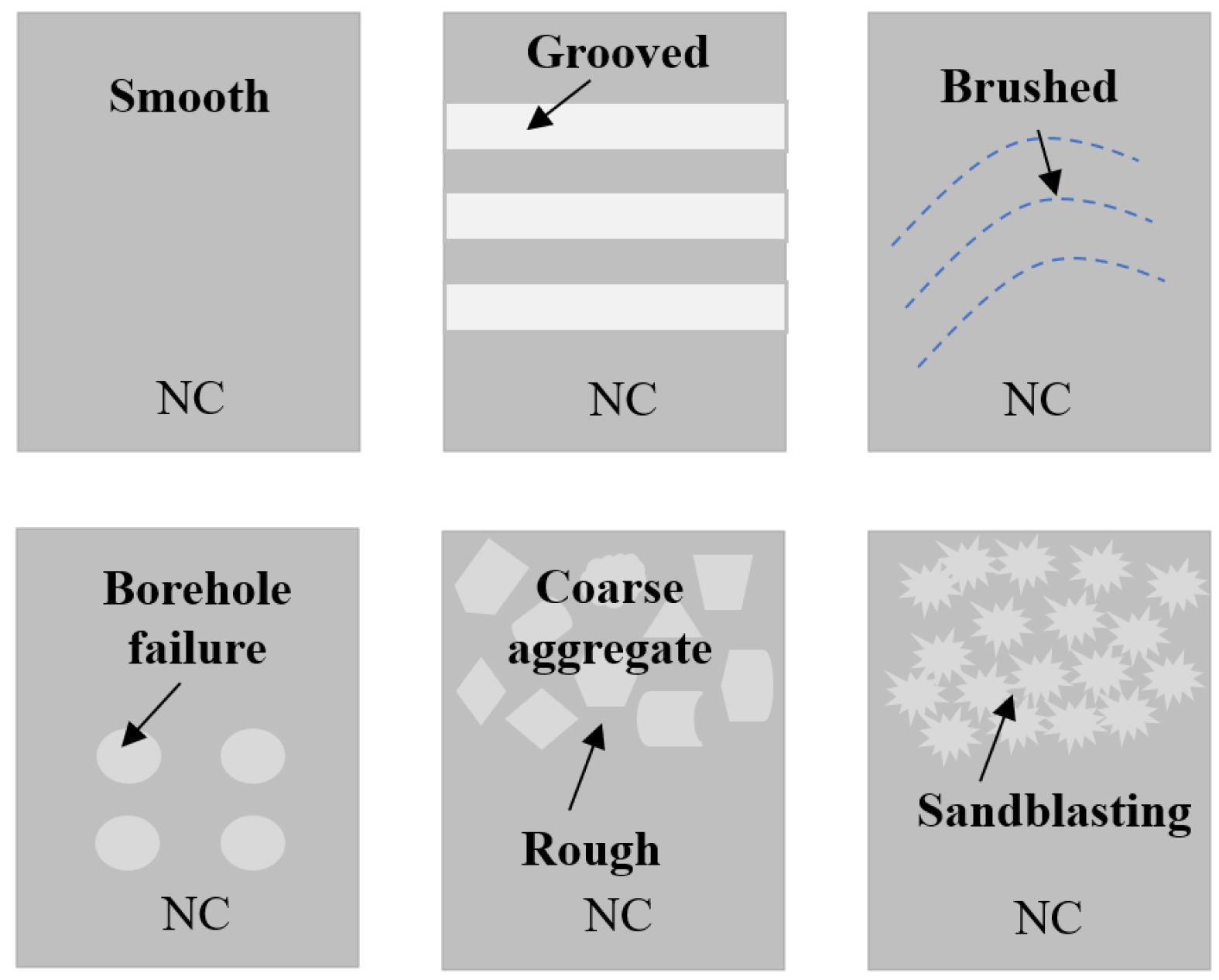

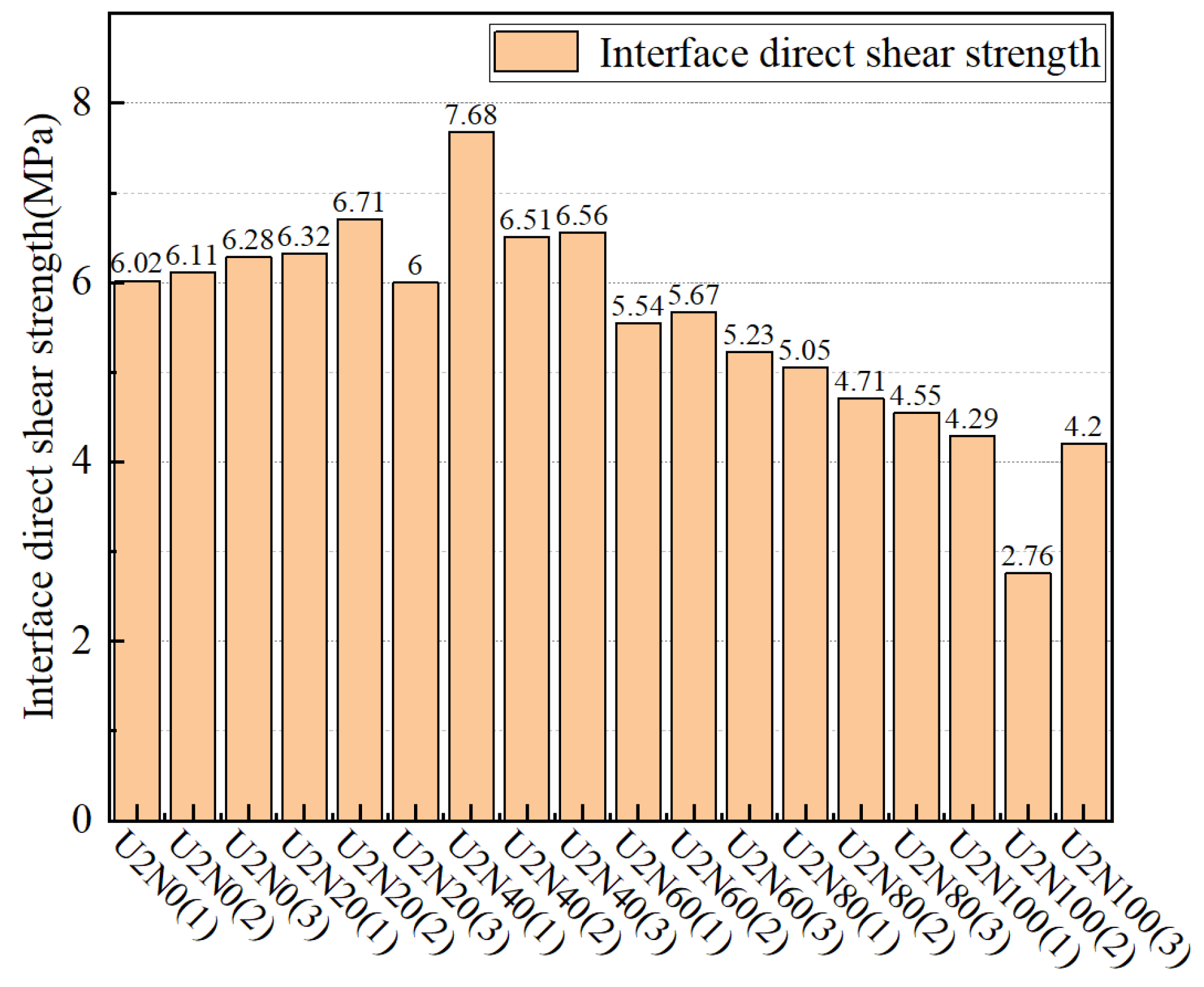

4.1. Interface Treatment Method

4.2. Strength and Wetness of the Substrate Concrete

4.3. Curing Conditions

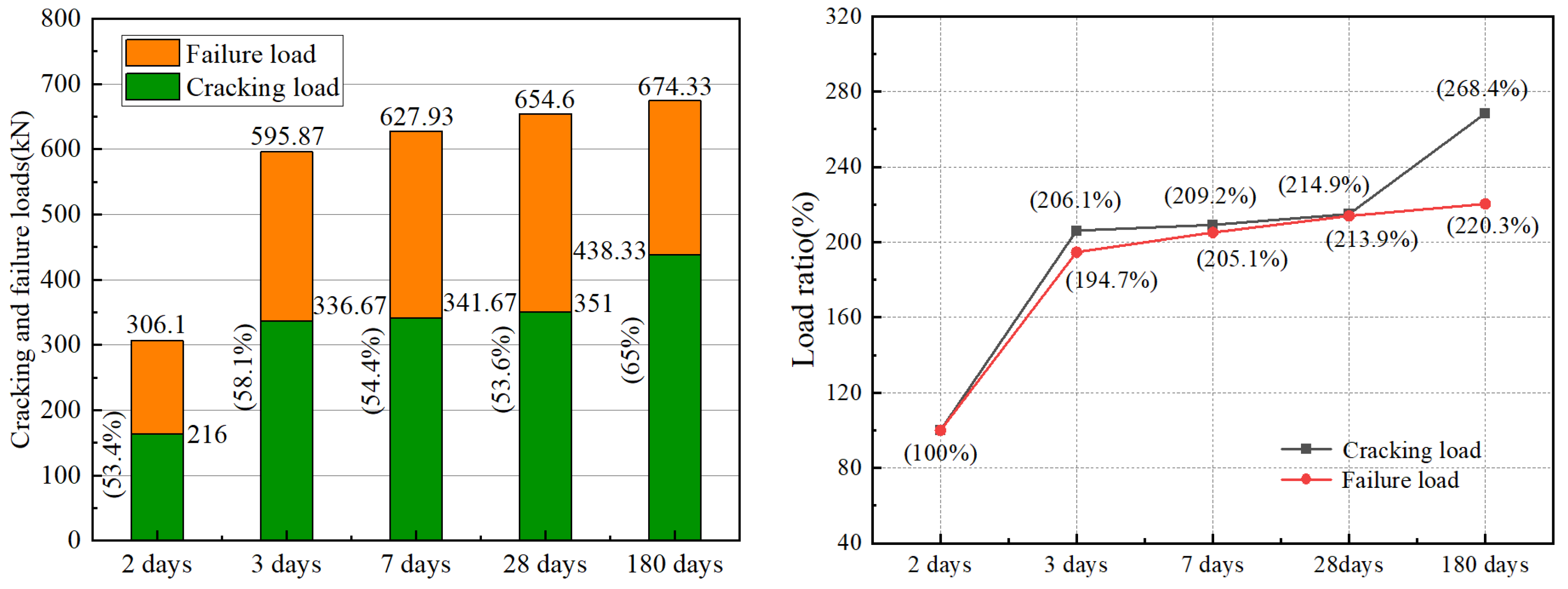

4.4. Age of UHPC

4.5. Load Type and Stress State

4.6. Fiber Content and Distribution

4.7. Environmental Factors

4.8. Pouring Sequence and Process

5. Prediction Model for Shear Strength of UHPC-NC Interface

5.1. Model Based on Mechanical Principles

5.2. Model Based on Finite Element Simulation

5.3. Model Based on Experimental Data

6. Conclusions and Outlook

6.1. Conclusions

6.2. Outlook

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Birchall, J.D.; Howard, A.J.; Kendall, K. Flexural strength and porosity of cements. Nature 1981, 289, 388–390. [Google Scholar] [CrossRef]

- Bache, H.H. Densified cement ultra-fine particle-based materials. Ott. Int. Conf. Superplast. Concr 1981, 33, 10–12. [Google Scholar]

- Xu, H.; Deng, Z. Application of ultra-high performance concrete in bridge engineering. World Bridges 2012, 40, 63–67. [Google Scholar]

- De Larrard, F.; Sedran, T. Optimization of ultra-high-performance concrete by the use of a packing model. Cem. Concr. Res. 1994, 24, 997–1009. [Google Scholar] [CrossRef]

- Zhang, L.; Jiang, Y.; Guo, Q.; Bai, T.; Jiang, Z.; Chen, R.; Zhen, Z. Production technology and development of ultra-high performance concrete (UHPC). Jiangsu Build. Mater. 2024, 1, 3–5. [Google Scholar]

- Hunan Road & Bridge Construction Group Co., Ltd. Hunan Province’s Hangrui Dongting Bridge. Bull. Chin. Ceram. Soc. 2022, 41, 2222. [Google Scholar] [CrossRef]

- Bajaber, M.A.; Hakeem, I.Y. UHPC evolution, development, and utilization in construction: A review. J. Mater. Res. Technol. 2021, 10, 1058–1074. [Google Scholar]

- Jiang, X.; Tang, D.; Hu, S.; Zhang, Z.; Shi, L. Application of ultra-high performance concrete in bridge engineering at home and abroad. Railw. Eng. 2021, 61, 1–7. [Google Scholar]

- Men, P.; Chen, F.; Qin, F.; Peng, X.; Di, J.; Jiao, H. Behavior of composite beams with UHPC-concrete composite slabs under negative bending moment. J. Constr. Steel Res. 2025, 227, 109415. [Google Scholar]

- Brühwiler, E.; Denarié, E. Rehabilitation and strengthening of concrete structures using ultra-high performance fibre reinforced concrete. Struct. Eng. Int. 2013, 23, 450–457. [Google Scholar]

- Cui, T. A Review of research on reactive powder concrete. Value Eng. 2020, 39, 256–257. [Google Scholar]

- Sun, H.; Zhou, J.; Xu, A.; Zhou, X.; Yang, J. Research progress of UHPC reinforcement technology in bridge engineering. Concrete 2020, 1, 136–143. [Google Scholar]

- Soltani, M.; Ross, B.E. Database evaluation of interface shear transfer in reinforced concrete members. ACI Struct. J. 2017, 114, 383. [Google Scholar]

- Ma, W. Study on Shear Characteristics of UHPC-NC Interface. Master’s Thesis, Lanzhou Jiaotong University, Lanzhou, China, 2023. [Google Scholar]

- Lyu, J.; Feng, S.; Zhang, Q.; Xiao, H. Review of factors affecting bond strength between ultra-high-performance concrete and normal strength substrate. Constr. Build. Mater. 2024, 439, 137416. [Google Scholar]

- Deng, Y.; Zhang, Z.; Shi, C.; Wu, Z.; Zhang, C. Steel fiber–matrix interfacial bond in ultra-high performance concrete: A review. Engineering 2023, 22, 215–232. [Google Scholar]

- Ding, J.; Zhu, J.; Kang, J. Bonding properties and mechanism of the interface between precast UHPC and post-cast UHPC. Structures 2022, 43, 822–833. [Google Scholar]

- Bijen, J.; Salet, T. Adherence of young concrete to old concrete development of tools for engineering. In Proceedings of the 2nd Bolomey Workshop on Adherence of Young on Old Concrete, Unterengstringen, Switzerland, 1–2 April 1993. [Google Scholar]

- Fiebrich, M.H. H. Scientific Aspects of adhesion phenomena in the interface mineral substratepolymers. In Proceedings of the Adherence of Young on Old Concrete, Unterengstringen, Switzerland, 1–2 April 1993. [Google Scholar]

- Xie, H.; Li, G.; Xiong, G. Mechanism of Bond force formation at the interface between new and old concrete. Bull. Chin. Ceram. Soc. 2003, 17, 7–10+18. [Google Scholar]

- Deng, J.; Li, D.; Zhou, Y.; Tian, Z.; Liu, X. Creep Shear stress analysis at the interface of prestressed UHPC-NC composite beams. J. Appl. Mech. 2024, 41, 1075–1082. [Google Scholar]

- Zhang, Y.; Zhang, Y.; Qiu, J.; Huang, J. Experimental Study on the flexural performance of precast UHPC-NC composite wet joints. J. Hunan Univ. (Nat. Sci.) 2023, 50, 62–71. [Google Scholar]

- Wang, P.; Zhao, M.; Tian, L.; Pan, Z.; Chen, C.; Fu, N. Shear Bond performance of the interface between precast keyway UHPC and post-cast concrete. Acta Mater. Compos. Sin. 2024, 41, 2633–2644. [Google Scholar]

- An, M.; Wang, Y.; Lu, Q.; Liu, R. Research on the durability of reactive powder concrete in marine corrosive environment. Adv. Civ. Eng. Build. Mater. 2012, 22, 109–113. [Google Scholar] [CrossRef]

- Hanjari, K.Z.; Utgenannt, P.; Lundgren, K. Experimental study of the material and bond properties of frost-damaged concrete. Cem. Concr. Res. 2011, 41, 244–254. [Google Scholar]

- Dong, L.; Yang, Y.; Liu, Z.; Zhang, Y.; Wu, C. Interface bonding characteristics of 3D printed ultra-high performance concrete after elevated temperatures. J. Build. Eng. 2024, 93, 109801. [Google Scholar]

- Chen, Y.; Xie, J.; Kang, E.; Tong, C. Shear Performance of interface between normal concrete and ultra-high performance concrete in cryogenic circumstance. In Proceedings of the 17th East Asian-Pacific Conference on Structural Engineering and Construction, 2022: EASEC-17, Singapore, 14 March 2023; Springer Nature: Singapore, 2023; pp. 506–514. [Google Scholar]

- Pan, J. Analysis of interfacial bond-shear performance between UHPC and ordinary concrete. Fujian Commun. Sci. Technol. 2023, 50–54. [Google Scholar]

- Li, B.; Lam, E.S.S. Influence of interfacial characteristics on the shear bond behaviour between concrete and ferrocement. Constr. Build. Mater. 2018, 176, 462–469. [Google Scholar]

- Zhou, Y.; Chen, B.; Luo, Y. Research progress on the bonding performance of UHPC-NC interfaces. Shanghai Build. Mater. 2023, 302, 47–53+69. [Google Scholar]

- American Association of State Highway and Transportation Officials (AASHTO). AASHTO LRFD Bridge Design Specifications, 9th ed.; AASHTO: Washington, DC, USA, 2020. [Google Scholar]

- Xu, T.; Yang, C.; Zhao, R.; Fu, H.; Liu, X.; Deng, K. The integration path of ideological and political education in civil engineering curriculum: Taking the Principles of Concrete Structure Design as an Example. Adv. Archit. Educ. 2021, 30, 182–189. [Google Scholar]

- Guan, P.; Shang, J.; Fan, J.; Zhang, P.; Chen, Q. Experimental study on single-side shear behavior of CFRP sheet-engineered cement-based composites-concrete composite interface. Acta Mater. Compos. Sin. 2022, 39, 2810–2820. [Google Scholar]

- ACI 318-19; ACI Committee 318. Building Code Requirements for Structural Concrete (ACI 318-19) and Commentary (ACI 318R-14). Detroit: American Concrete Institute: Farmington Hills, MI, USA, 2019.

- Hofbeck, J.A.; Ibrahim, I.O.; Mattock, A.H. Shear transfer in reinforced concrete. J. Proc. 1969, 66, 119–128. [Google Scholar]

- Zhao, Y.; Zou, R. Experimental study on shear performance of new-to-old interface in high-strength concrete. J. Tongji Univ. (Nat. Sci.) 2017, 45, 962–969. [Google Scholar]

- Ding, W.; Wei, Q. Introduction to the “technical specification for application of fiber reinforced concrete” JGJ/T 221-2010. Constr. Technol. 2011, 40, 101–103. [Google Scholar]

- Momayez, A.; Ramezanianpour, A.A.; Rajaie, H.; Ehsani, M.R. Bi-surface shear test for evaluating bond between existing and new concrete. Mater. J. 2004, 101, 99–106. [Google Scholar]

- Zhao, Y.; Yang, Y.; Xu, S.; Liu, J.; Chen, Y. Shear connection of reinforcement stiffened cold-formed U-shaped steel and concrete composite beam. Eng. Struct. 2020, 219, 110862. [Google Scholar]

- ASTM C882; Standard Test Method for Bond Strength of Epoxy-Resin Systems Used with Concrete by Slant Shear. American Society of Testing Materials: West Conshohocken, PA, USA, 2005.

- Mizan, M.H.; Ueda, T.; Matsumoto, K. Enhancement of the concrete-PCM interfacial bonding strength using silica fume. Constr. Build. Mater. 2020, 259, 119774. [Google Scholar] [CrossRef]

- Zheng, H.; Gong, Z.; Cui, C.; Chen, Z.; Ma, X.; Li, H.; Li, Y. Experimental study on oblique-shear performance of splicing joint for precast ultrahigh-performance concrete segmental bridges. Case Stud. Constr. Mater. 2023, 19, e02336. [Google Scholar] [CrossRef]

- Feng, S.; Xiao, H.; Liu, R.; Liu, M. Single-side shear bond strength and OTZ microstructure of UHPC repair materials with concrete substrate. J. Mater. Civ. Eng. 2022, 34, 04022216. [Google Scholar]

- Guan, D.; Liu, J.; Jiang, C.; Chen, Z.; Guo, Z. Shear Behaviour of the UHPC-NSC Interface with Castellated Keys: Effects of Castellated Key Dimension and Dowel Rebar. Structures 2021, 31, 172–181. [Google Scholar]

- Kang, S.H.; Hong, S.G. Effect of surface preparation and curing condition on the interfacial bond strength between ultra high performance concrete and normal strength concrete. J. Korea Inst. Struct. Maint. Insp. 2015, 19, 149–160. [Google Scholar]

- Precast/Prestressed Concrete Institute. PCI Design Handbook: Precast and Prestressed Concrete, 7th ed.; Precast/Prestressed Concrete Institute: Chicago, IL, USA, 2010. [Google Scholar]

- Cui, Q.; Yang, J.; Kang, G. Experimental study on seismic performance of reinforced concrete columns with Z-shaped cross-section under bidirectional shear. J. Build. Struct. 2013, 34, 126–134+157. [Google Scholar]

- Jang, H.O.; Lee, H.S.; Cho, K.; Kim, J. Experimental study on shear performance of plain construction joints integrated with ultra-high performance concrete (UHPC). Constr. Build. Mater. 2017, 152, 16–23. [Google Scholar] [CrossRef]

- Cao, C.; Hu, Z.; Chai, Y.; Li, Q.; Li, W.; Pan, H.; Li, Y. Investigations on interface shear-stress transfer behavior of concrete composite slabs with lattice girders. KSCE J. Civ. Eng. 2024, 28, 4457–4472. [Google Scholar] [CrossRef]

- Zhang, Y.; Wu, Y.; Qin, Y.; Zhu, Y.; Qiu, J.; Wang, W. Experimental and analytical study on interfacial shear resistance of prefabricated ultra-high performance concrete-post-cast normal concrete interface. Adv. Struct. Eng. 2024, 27, 1622–1634. [Google Scholar] [CrossRef]

- Yang, J.; Xia, J.; Zhang, Z.; Zhou, J.; Zou, Y.; Wang, Y.; Shen, X. Mesoscopic shear behavior and strength characteristic of UHPC-NC interface considering the combined effect of mechanical interlocking and dowel action. Eng. Fract. Mech. 2024, 307, 110306. [Google Scholar] [CrossRef]

- Yang, J.; Zhou, J.; Zhang, Z.; Wang, Z.; Zou, Y.; Wang, J. Study on shear performance of UHPC-NC interface with keyway. China J. Highw. Transp. 2021, 34, 132–144. [Google Scholar]

- Jiang, H.; Huang, C.; Feng, J.; Gao, X.; Wang, T.; Zhong, Z. Direct shear behavior of castellated dry RPC joints in precast concrete segmental bridges. Structures 2021, 33, 4579–4595. [Google Scholar] [CrossRef]

- Zhang, W.; Yan, B.; Ye, Y.; Yi, W. Direct shear test study on old and new concrete. J. Build. Eng. 2024, 82, 108391. [Google Scholar] [CrossRef]

- Yu, K.; Zhang, Z.; Zou, Y.; Jiang, J.; Zeng, X.; Tang, L. Interfacial shear performance of epoxy adhesive joints of prefabricated elements made of ultra-high-performance concrete. Polymers 2022, 14, 1364. [Google Scholar] [CrossRef]

- Xian, X.; Lin, M.; Chen, T.; Wang, D. Experimental study and finite element simulation on direct shear test of the interface between UHPC and NC with embedded steel bars. Bull. Chin. Ceram. Soc. 2024, 43, 2056–2063+2072. [Google Scholar]

- Li, Q.; Yin, X.; Guo, K.; Xu, S. Experimental study on shear strength of interface between ultra-high toughness cementitious composite and reactive powder concrete. Eng. Mech. 2022, 39, 232–244. [Google Scholar]

- Wang, X.W. Research on the Interfacil Shear Behavior of UHPC and Reinforced Concrete. Master’s Thesis, Hunan University, Changsha, China, 2016. [Google Scholar]

- Yuan, S.; Liu, Z.; Tong, T. Investigation of over-nonlocal damage and interface cohesive models for simulating structural behaviors of composite UHPC-NC members. Structures 2020, 28, 2617–2632. [Google Scholar] [CrossRef]

- Zhang, Y.; Wu, J.; Shao, X.; Hou, C. Experimental study on shear performance of ultra-high performance concrete-ordinary concrete interface. China Civ. Eng. J. 2021, 54, 81–89. [Google Scholar]

- Xie, Z.; Zhao, H.; Zhu, P.; Ma, P.; Zhuo, Y. Experimental and analytical study on anti-slip performance of interface in composite beam bridge with ultra-high performance concrete and ordinary concrete. Highw. Eng. 2019, 44, 198–205. [Google Scholar]

- Zhang, Y.; Zhang, C.; Zhu, Y.; Cao, J.; Shao, X. An experimental study: Various influence factors affecting interfacial shear performance of UHPC-NSC. Constr. Build. Mater. 2020, 236, 117480. [Google Scholar] [CrossRef]

- Chen, L.; Yan, J.; Wu, Z.; Yang, D.; Li, J.; Xiang, N. Experimental and numerical study on shear behavior of shear pockets between ultra-high-performance and normal concrete for precast girder bridges. Structures 2023, 55, 1645–1658. [Google Scholar] [CrossRef]

- Wen, X.; Gong, W.; Zhou, M.; Yin, G.; Deng, Z. Influence of shear stud structural measures on the bond performance of UHPC formwork-cast-in-situ NC interface. Acta Mater. Compos. Sin. 2024, 1–16. [Google Scholar] [CrossRef]

- Wang, D.; Shen, T.; Ju, Y.; Zheng, W.; Zeng, C. Study on shear bond performance between post-cast ordinary concrete and precast UHPC. J. Build. Struct. 2020, 41, 411–419. [Google Scholar]

- Wei, X.Y.; Li, X.; Di, J.; Qin, F.J.; Zhang, Z.G.; Liang, F.H. Flexural performance of U-shaped high-strength ECC permanent formwork-concrete composite beams. Structures 2025, 74, 108641. [Google Scholar] [CrossRef]

- Duan, M.; Xue, J.; Wang, X.; Wu, Y.; Tao, H. Experimental study on shear performance of perfobond steel plate in ultra-high performance concrete (UHPC)-normal concrete (NC) connection. Structures 2024, 66, 106783. [Google Scholar]

- Zhang, Y.; Zhu, P.; Wang, X.; Wu, j. Shear properties of the interface between ultra-high performance concrete and normal strength concrete. Constr. Build. Mater. 2020, 248, 118455. [Google Scholar]

- Zhao, Y.C.; Lei, H.G.; Guo, L.K.; Lu, G.Y. Experimental investigation on interface performance of UHPC-strengthened NC structure through push-out tests. Materials 2023, 16, 1766. [Google Scholar] [CrossRef]

- Wang, B.; Liu, K.; Cao, F.; Shen, P. Research progress on properties of ultra-high performance concrete and its application in prefabricated buildings. Guangdong Build. Mater. 2025, 41, 52–55. [Google Scholar]

- Carbonell Muñoz, M.A.; Harris, D.K.; Ahlborn, T.M.; Froster, D.C. Bond performance between ultrahigh-performance concrete and normal-strength concrete. J. Mater. Civ. Eng. 2014, 26, 04014031. [Google Scholar] [CrossRef]

- Zhang, B.; Yu, J.; Chen, W.; Chen, J.; Li, H.; Niu, J. Interface shear failure behavior between normal concrete (NC) and ultra-high performance concrete (UHPC). Int. J. Concr. Struct. Mater. 2024, 18, 18. [Google Scholar] [CrossRef]

- Feng, S.; Xiao, H.; Li, Y. Influence of interfacial parameters and testing methods on UHPC–NSC bond strength: Slant shear vs. direct tensile testing. Cem. Concr. Compos. 2022, 131, 104568. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhu, P.; Liao, Z.; Wang, L. Interfacial bond properties between normal strength concrete substrate and ultra-high performance concrete as a repair material. Constr. Build. Mater. 2020, 235, 117431. [Google Scholar] [CrossRef]

- Austin, S.; Robins, P.; Pan, Y. Shear bond testing of concrete repairs. Cem. Concr. Res. 1999, 29, 1067–1076. [Google Scholar] [CrossRef]

- Al-Madani, M.K.; Al-Osta, M.A.; Ahmad, S.; Khalid, H.R.; AI-Huri, M. Interfacial bond behavior between ultra high performance concrete and normal concrete substrates. Constr. Build. Mater. 2022, 320, 126229. [Google Scholar] [CrossRef]

- Zhang, D.; Ma, X.; Shen, H.; Guo, S.; Liu, C. Analysis of structural parameters of steel–NC–UHPC composite beams. Materials 2023, 16, 5586. [Google Scholar] [CrossRef]

- Jiang, X.; Song, H.; Li, K.; Qiang, J.; Tian, J. Experimental investigation on shear strength between ultra-high-performance concrete and normal concrete substrates. Adv. Mater. Sci. Eng. 2023, 15, 3169912. [Google Scholar]

- Aaleti, S.; Sritharan, S. Quantifying bonding characteristics between UHPC and normal-strength concrete for bridge deck application. J. Bridge Eng. 2019, 24, 04019041. [Google Scholar]

- Sun, W.; Zhang, J.; Yang, S.; Chen, X.; Wu, J.; Wu, Q.; Yang, Y. Study on the influence of roughness and coarse aggregate area on UHPC-NC interface bonding performance. Mater. Struct. 2024, 57, 222. [Google Scholar] [CrossRef]

- Wu, C.; Chu, F.; Gong, M.; Zeng, Z. Experimental study on bond performance of steam-free ultra-high performance concrete and existing concrete interface. Mater. Rep. 2023, 37, 23010119-8. [Google Scholar]

- Tian, J.; Jiang, X.; Yang, X.; Ma, M.; Li, L. Shear performance and calculation method of shear strength for UHPC-NC interface with grooves. J. Build. Mater. 2024, 1–14. Available online: https://link.cnki.net/urlid/31.1764.TU.20240810.1105.010 (accessed on 20 February 2025).

- Wang, Y.; Jiang, X.; Li, K.; Qiang, J. Experimental study of interfacial adhesion performance of prefabricated UHPC-NC diagonal shear groove. Case Stud. Constr. Mater. 2023, 19, e02343. [Google Scholar]

- Yang, J.; Xia, J.; Cheng, C.; Wang, J.; Zhang, J.; Wang, G. Research on the bonding performance of UHPC–NC interfaces with different sizes of grooves. Front. Mater. 2022, 9, 859717. [Google Scholar] [CrossRef]

- He, Y.; Zhang, X.; Hooton, R.D.; Zhang, X. Effects of interface roughness and interface adhesion on new-to-old concrete bonding. Constr. Build. Mater. 2017, 151, 582–590. [Google Scholar]

- Wu, Y.; Yi, A.; He, J.; Kuang, Y.; Yuan, Y. Study on the mechanism of mechanical property enhancement of steam-cured ultra-high performance concrete (UHPC) with Nano C-S-H/PCE. Bull. Chin. Ceram. Soc. 2024, 43, 2797–2805. [Google Scholar]

- Feng, S.; Xiao, H.; Li, H. Comparative studies of the effect of ultrahigh-performance concrete and normal concrete as repair materials on interfacial bond properties and microstructure. Eng. Struct. 2020, 222, 111122. [Google Scholar]

- An, N. Study on the Influence of UHPC-NC Interface Characteristics on Bond Performance. Ph.D. Thesis, Beijing Jiaotong University, Beijing, China, 2018. [Google Scholar]

- Ganesh, P.; Murthy, A.R. Simulation of surface preparations to predict the bond behaviour between normal strength concrete and ultra-high performance concrete. Constr. Build. Mater. 2020, 250, 118871. [Google Scholar]

- He, S.; Huang, X.; Zhong, H.; Wan, Z.; Liu, G.; Xin, H. Experimental study on bond performance of UHPC-to-NC interfaces: Constitutive model and size effect. Eng. Struct. 2024, 317, 118681. [Google Scholar] [CrossRef]

- Zeng, X.; Wang, P.; You, X. Shear performance of interface between ultra-high performance concrete and normal concrete treated with ribs. Structures 2024, 60, 105867. [Google Scholar]

- Kos, Z.; Kroviakov, S.; Kryzhanovskyi, V.; Crnoja, A. Influence of fibres and hardening accelerator on concrete for rigid pavements. Mag. Concr. Res. 2023, 75, 865–873. [Google Scholar]

- Chen, K.; Lin, Y.; Wang, Z.; Zheng, Y.; Wang, W. Shear and tensile bonding performance of prefabricated UHPC and cast-in-place NC interface in composite girder bridges. Constr. Build. Mater. 2025, 462, 139952. [Google Scholar]

- Bentz, D.P.; Varga, I.; Muñoz, J.F.; Spragg, R.P.; Graybeal, B.A.; Hussey, D.S.; Jacobson, D.L.; Jones, S.Z.; LaManna, J.M. Influence of substrate moisture state and roughness on interface microstructure and bond strength: Slant shear vs. pull-off testing. Cem. Concr. Compos. 2018, 87, 63–72. [Google Scholar]

- Luković, M.; Šavija, B.; Schlangen, E.; Ye, G.; Breugel, K.V. A 3D lattice modelling study of drying shrinkage damage in concrete repair systems. Materials 2016, 9, 575. [Google Scholar] [CrossRef]

- Vasumithran, M.; Anand, K.B.; Sathyan, D. Effects of fillers on the properties of cement grouts. Constr. Build. Mater. 2020, 246, 118346. [Google Scholar]

- Zhu, Y.; Zhang, Y.; Hussein, H.H.; Liu, J.; Chen, G. Experimental study and theoretical prediction on shrinkage-induced restrained stresses in UHPC-RC composites under normal curing and steam curing. Cem. Concr. Compos. 2020, 110, 103602. [Google Scholar]

- De La Varga, I.; Muñoz, J.F.; Bentz, D.P.; Spragg, R.P.; Stutzman, P.E.; Graybeal, B.A. Grout-concrete interface bond performance: Effect of interface moisture on the tensile bond strength and grout microstructure. Constr. Build. Mater. 2018, 170, 747–756. [Google Scholar]

- Wang, T.; Xu, J.; Du, D.; Su, C.; Shi, X. Interfacial cohesion model of ultra-high performance concrete wet joints under the influence of multiple factors. Struct. Concr. 2024, 25, 3430–3449. [Google Scholar]

- Wu, Y.; Zhang, Y.; Liu, Y.; Wang, W.; Qiu, J. Experimental study and numerical analysis on shear performance of interface between precast UHPC and cast-in-situ NC. Railw. Eng. 2023, 1–6. Available online: https://link.cnki.net/urlid/11.2027.U.20230908.1550.002 (accessed on 20 February 2025).

- Xia, J.; Zhou, J.; Yang, J.; Zhang, Z.; Zou, Y. Damage evolution and residual shear resistance of toughness-improved UHPC-NSC interface under high-stress level of fatigue shear loading. Constr. Build. Mater. 2024, 430, 136403. [Google Scholar]

- Zhang, X.; Cheng, L.; Xu, F.; Yang, C.; Wang, L. A novel model for shear strength prediction of a steel–UHPC composite structure considering interface friction. J. Struct. Eng. 2024, 150, 04024100. [Google Scholar]

- Mei, M.; Ge, S.; Chen, J.; Zhuo, J. Research on shrinkage stress in concrete Structures. J. Hohai Univ. (Nat. Sci. Ed.) 2002, 30, 73–78. [Google Scholar]

- Wu, Y.; Zheng, X.; Huang, W.; Zheng, X.; Chen, B. Review on bond performance of ultra-high performance concrete-existing ordinary concrete interface. Mater. Rep. 2023, 37, 144–154. [Google Scholar]

- Mo, S.; Huang, Y.; Zheng, Y.; Chai, L. Flexural Strength of UHPC-NC composite beam with narrow steel box filled in flange plate in negative moment zone. Concrete 2025, 01, 33–39+46. [Google Scholar] [CrossRef]

- Yang, D.; Bai, Q. Causes of cracking in Ultra-High performance concrete panels (UHPC panels) for curtain walls and corresponding measures. China Build. Decor. 2025, 02, 123–125. [Google Scholar] [CrossRef]

- Liu, J.; Zhang, B.; Zhao, B.; Li, G.; Deng, Y. Study on the Influence of fiber type and orientation on the pullout performance of fiber-UHPC matrix. Mater. Sci. Technol. 2022, 30, 36–43. [Google Scholar]

- Cheng, J.; Liu, J.; Zhang, L. Test and mechanism analysis of fiber-matrix bond performance of ultra-high performance concrete. China Concr. Cem. Prod. 2016, 05, 62–66. [Google Scholar] [CrossRef]

- Guo, X.; Li, H.; Wang, S. Effects of pre-corroded steel fibers on mechanical properties and interface bond behavior of ultra-high performance concrete-normal concrete. Constr. Build. Mater. 2022, 356, 129234. [Google Scholar]

- Chen, Z.; Wang, X.; Ding, L.; Jiang, K.; Huang, H.; Liu, J.; Wu, Z. Synergistic effects of hybrid macro basalt fibers and micro fibers on the mechanical properties of UHPC. Arch. Civ. Mech. Eng. 2023, 23, 264. [Google Scholar]

- Ma, G.; Bai, G.; Wang, L.; Wang, F. Explosion resistance of 3D printing ultra-high performance concrete based on contact explosion tests. Int. J. Impact Eng. 2022, 169, 104316. [Google Scholar]

- Qiu, H.; Lai, H.; Liao, F.; Chen, Y. Experimental study on dynamic fracture of UHPC-NC specimens after high temperature burning treatment. Theor. Appl. Fract. Mech. 2024, 131, 104384. [Google Scholar]

- Xie, J.; Yang, Y.; Chen, Y.; Yang, R. Experimental study on bond performance of UHPC-NC interface in chloride environment. J. Tianjin Univ. (Sci. Technol.) 2024, 57, 11–20. [Google Scholar]

- Xu, J.; Wang, T.; Su, C.; She, W.; Fu, C. Study of chloride transport pattern in the interface zone of UHPC wet joints under different influencing factors. J. Build. Eng. 2024, 95, 110236. [Google Scholar]

- Yu, X.; Yang, J.; Zhang, Z.; Leng, J.; Chen, R.; Zhou, J.; Zou, Y. Shear performance and degradation mechanism of UHPC-NC interface under composite salts freeze-thaw cycles. Case Stud. Constr. Mater. 2025, 22, e04408. [Google Scholar]

- Wang, Y.; Chen, J.; He, S.; Huang, X.; Sun, X. Experimental Study on Shear Performance of UHPC-NC Interface Under Salt Freezing and Thawing Cycles. Ph.D. Thesis, Chongqing Jiaotong University, Chongqing, China, 2024. [Google Scholar]

- Yuan, S.; Liu, Z.; Tong, T.; Fu, C. Bond behaviors between UHPC and normal-strength concrete: Experimental investigation and database construction. J. Mater. Civ. Eng. 2022, 34, 04021398. [Google Scholar]

- Du, C.; Liu, X.; Liu, Y.; Tong, T. Prediction of the interface shear strength between ultra-high-performance concrete and normal concrete using artificial neural networks. Materials 2021, 14, 5707. [Google Scholar] [CrossRef]

- Liu, S.; He, Z.; Hu, L. Interface adhesion of fresh-on-fresh cast ultra-high performance concrete-normal concrete: Effect and mechanism of pour delay and ambient humidity. J. Build. Eng. 2023, 78, 107679. [Google Scholar]

- Lee, H.S.; Jang, H.O.; Cho, K.H. Evaluation of bonding shear performance of ultra-high-performance concrete with increase in delay in formation of cold joints. Materials 2016, 9, 362. [Google Scholar] [CrossRef]

- Ji, H. Mesoscopic Numerical Simulation and Computational Theory of Shear Performance of UHPC-NC Composite Beams. Ph.D. Thesis, Tongji University, Shanghai, China, 2022. [Google Scholar]

- Farzad, M.; Shafieifar, M.; Azizinamini, A. Experimental and numerical study on bond strength between conventional concrete and ultra high-performance concrete (UHPC). Eng. Struct. 2019, 186, 297–305. [Google Scholar]

- Farouk AI, B.; Zhu, J.; Yuhui, G. Finite element analysis of the shear performance of box-groove interface of ultra-high-performance concrete (UHPC)-normal strength concrete (NSC) composite girder. Innov. Infrastruct. Solut. 2022, 7, 212. [Google Scholar]

- Huang, S.; Xi, Y.; Li, X.; Men, P.; Wu, G. Flexural behaviour of damaged concrete T-beams reinforced with ultra-high performance concrete filling. Front. Mater. 2024, 11, 1410016. [Google Scholar] [CrossRef]

- Ouyang, N.; Deng, S.W. Study on the interfacial properties of UHPC-NC composite component. J. Chongqing Univ. 2021, 44, 63–74. [Google Scholar]

- Liu, K.; Wu, T.; Shi, Z.; Yu, X.; Lin, Y.; Chen, Q.; Jiang, H. Interpretable machine learning models for predicting the bond strength between UHPC and normal-strength concrete. Mater. Today Commun. 2024, 40, 110006. [Google Scholar] [CrossRef]

| Testing Methods | Testing Standards (Not Limited to the Following) | Applicable Fields | Brief Description | Application Examples |

|---|---|---|---|---|

| (a) Single-shear test | AASHTO LRFD [31] | Evaluation of shear performance at interfaces between new and repaired materials (NC interfaces); Shear resistance of the contact surface between concrete slabs and bedding materials | In the early 20th century, Morsch et al. [32] proposed the rectangular short-beam direct shear test method, which is one of the earliest experimental methods for determining the shear strength of concrete. | Evaluation of CFRP-Concrete Interfacial Debonding [33] |

| (b) Z-shaped direct shear test | ACI 318-14 [34] | Analysis of shear behavior at composite interfaces (such as fiber-reinforced concrete, UHPC-NC composite structures) | Proposed by Hofbeck et al. [35] in 1969 and widely used ever since, it can effectively reduce the influence of bending stress. The provisions on shear design in the specifications and the requirements for material testing provide a theoretical basis for the experiment. | The shear strength of the interface between new and old concrete can be verified, and the results are in good agreement with the calculated values provided by specifications such as ACI 318-14 [36]. |

| (c) Double-shear test | JGJ/T 221-2010 [37] | Measurement of the shear strength of structural connectors (bolts, anchors) or prefabricated components between concrete | It was improved and proposed by Momayez et al. [38] based on the single-side shear test. In the relevant specifications issued in China in 2010, the application of the double-side shear test for measuring the shear strength of fiber-reinforced concrete was clearly stated, promoting the popularization of this method in engineering practices in China. | Evaluation of Shear Connection Behavior in Composite Beams with Stiffened Cold-Formed U-Shaped Steel and Concrete [39]. |

| (d) Oblique shear test | ASTM C882 [40] | Research on Multi-Angle Shear Behavior of Inclined Joints, Sloped Structures, or Adhesive Interfaces | This standard describes a method for oblique shear testing, which combines compression and shear actions to avoid issues such as local compression failure and crack bending [41]. | Investigation of the Shear Resistance Performance of Joints in Prefabricated UHPC Segmental Bridges [42]. |

| Interface Treatment Methods | Comparison Parameters | Impact Effects | |

|---|---|---|---|

| UHPC-NC (A: Single-sided Shear; B: Double-sided Shear; C: oblique shear) | roughening (exposing coarse aggregate) | Smooth interface | C: Compared to the smoother interface (6.88 MPa), there is a 69% increase [77]. |

| quantity of grooves | Single groove interface | C: The shear strength of interfaces with two grooves and three grooves increased by 94% and 178%, respectively [78]. | |

| Grooved angle | Right-angle groove | A: There is a 0.2-fold increase; approximately a 117% improvement for additional 5 mm of grooved depth [52]. | |

| Combination of grooving and rebar embedding. | Smooth interface (2.1 MPa) | A: The strength reaches 8.7 MPa, representing a 315% increase. When the grooving spacing is reduced to 50 mm, the shear strength further increases to 9.5 MPa [50]. | |

| 45° and 60° trapezoidal grooves | Rectangular groove | C: The average interfacial bond strength of 60° trapezoidal grooves is 80% higher than that of rectangular grooves, and 45° trapezoidal grooves are also 28% higher than rectangular grooves [83]. | |

| rough surface | Smooth, drilled holes and grooves. | B: It is a 54% improvement compared to the smooth interface, a 35% improvement compared to the drilled hole interface, and a 10.4% improvement compared to the grooved interface [62]. | |

| Same grooving density | The strength of post-cast NC is upgraded from C30 to C50. | B: The interfacial strength can be increased by 16.05% to 58.59% [65]. | |

| rib | When comparing specimens with rib widths of 15 mm and 20 mm, and with rib spacings increased from 40 to 100. | A: The interfacial strength of specimens with a rib width of 15 mm decreased by 29%, while those with a rib width of 20 mm increased by 40%. Increasing the rib width helps to improve the strength [91]. |

| Model Type | Advantages | Limitations | Applicable Scenarios |

|---|---|---|---|

| mechanical model | The physical meaning is clear, and the computational efficiency is high. | Poor adaptability to complex boundary conditions. | Simple Force Member Preliminary Design |

| finite element model | It can simulate complex loads and interface characteristics. | High computational cost and reliance on experimental calibration for parameters. | Refined Structural Analysis and Optimization |

| experimental data model | Has a strong ability to capture multi-parameter nonlinear relationships. | Relies on large amounts of high-quality data and has limited extrapolation capabilities. | Rapid evaluation of engineering cases with multi-factor coupling |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xu, Z.; Qin, F.; Yang, Q.; Peng, X.; Xu, B. A Review of Research on the Interfacial Shear Performance of Ultra-High-Performance Concrete and Normal Concrete Composite Structures. Coatings 2025, 15, 414. https://doi.org/10.3390/coatings15040414

Xu Z, Qin F, Yang Q, Peng X, Xu B. A Review of Research on the Interfacial Shear Performance of Ultra-High-Performance Concrete and Normal Concrete Composite Structures. Coatings. 2025; 15(4):414. https://doi.org/10.3390/coatings15040414

Chicago/Turabian StyleXu, Zhenjie, Fengjiang Qin, Qiuwei Yang, Xi Peng, and Bin Xu. 2025. "A Review of Research on the Interfacial Shear Performance of Ultra-High-Performance Concrete and Normal Concrete Composite Structures" Coatings 15, no. 4: 414. https://doi.org/10.3390/coatings15040414

APA StyleXu, Z., Qin, F., Yang, Q., Peng, X., & Xu, B. (2025). A Review of Research on the Interfacial Shear Performance of Ultra-High-Performance Concrete and Normal Concrete Composite Structures. Coatings, 15(4), 414. https://doi.org/10.3390/coatings15040414