Abstract

Emulsified asphalt is widely used for pavement maintenance due to its ease of application. However, its use is limited by poor high-temperature stability and low bonding strength. This study attempted to prepare a self-crosslinking waterborne acrylate (SWA)-type admixture using a diacetone acrylamide (DAAM)-adipic dihydrazide (ADH) crosslinking system and applied it to emulsified asphalt to ultimately obtain self-crosslinking waterborne acrylate-modified emulsified asphalt (AMEA). The research explored the effects of SWA on the fundamental properties, rheological characteristics, microscopic morphology, and bonding performance of AMEA. Results indicated that SWA undergoes self-crosslinking reactions during the demulsification process, forming a continuous and stable network structure that significantly enhances the strength of emulsified asphalt while improving softening point and high-temperature stability. Rheological analysis revealed that within the 10–15 phr dosage range, the influence of frequency on emulsified asphalt was minimized, with notable improvements in high-temperature elastic recovery and deformation resistance. Particularly when the dosage exceeds 10 phr, the material demonstrates adaptability to high-traffic environments. Pull-off tests demonstrated that SWA can increase the interlayer bonding strength of emulsified asphalt by over 50%. However, SWA exhibits some negative impact on the low-temperature ductility of emulsified asphalt, necessitating cautious dosage control during application. This novel self-crosslinking waterborne acrylate-modified emulsified asphalt, with its excellent bonding performance and superior high-temperature stability, emerges as a crucial material choice for pavement preventive maintenance.

1. Introduction

Emulsified asphalt is widely used in the preventive maintenance of asphalt pavements due to its ease of construction, good environmental performance, and excellent economic benefits [1,2]. It is considered a low-carbon maintenance technology [3]. However, emulsified asphalt binders have low strength and poor high-temperature stability, which greatly limits their application in the preventive maintenance of asphalt pavements [4]. Both domestically and internationally, polymer-modified emulsified asphalt is commonly used, with styrene-butadiene rubber (SBR) emulsions being the most widely used [5]. Through experiments, Hu et al. [6] concluded that an SBR content of 4% is relatively optimal. However, numerous studies have shown that the bonding performance and high-temperature stability of emulsified asphalt modified solely with SBR emulsions still require further improvement [7], making it difficult to meet the growing demands of heavy traffic and high volumes of vehicles [8,9]. Therefore, the development of new types of modified emulsified asphalt has become a major focus in the preventive maintenance of pavements.

Waterborne polymers, such as waterborne epoxy resin (WER) and waterborne polyurethane (WPU), are often used in the application of new types of modified emulsified asphalt due to their excellent dispersibility and functionality [10]. Huang et al. [11] modified emulsified asphalt binders using both semi-flexible and rigid types of WER, and their study found that when the WER content is less than 15%, WER exists in a continuous structure, thus enhancing the high-temperature performance and mechanical properties of the binder. Liu et al. [2] studied WER-SBR composite-modified emulsified asphalt (WER-SCMEA) and proposed that the strength mechanism of WER-SCMEA is the combined effect of curing reactions, physical entanglement, and chemical cross-linking reactions, making it suitable as a micro-surfacing binder. Zhou et al., considering environmental benefits, modified epoxy emulsified asphalt (EMEA) with WPU, and utilized the crosslinking interaction between WPU and WER to form an interpenetrating network structure, which brought excellent performance to the composite modified emulsified asphalt [12].

As a waterborne polymer, waterborne acrylate (WA) has received limited attention. Distinguished from traditional modifiers like waterborne epoxy resin (WER) and waterborne polyurethane (WPU), WA is widely used in the coatings industry due to its economic advantages [13], low volatile organic compounds (VOCs) emissions [14], and ease of preparation for modification [15], and it can also be used as an additive in emulsified asphalt [16,17]. In previous studies, WA was typically used in combination with SBR or styrenic block copolymers (SBS) emulsions as a modifier for emulsified asphalt. Although it had a positive effect on the performance of emulsified asphalt, its stability decreased, and the mechanism of WA’s action in emulsified asphalt has not been fully studied [18]. Therefore, in-depth research on the interaction between WA and emulsified asphalt would help guide its application in practical engineering.

Based on this, a self-crosslinking waterborne acrylate system (SWA)-type admixture was prepared using the DAAM-ADH crosslinking system and incorporated into emulsified asphalt to develop a novel self-crosslinking waterborne acrylate-modified emulsified asphalt (AMEA). The modification process of the emulsified asphalt was analyzed at the microscopic level through characterization techniques such as Fourier transform infrared spectroscopy (FT-IR), differential scanning calorimetry (DSC), dynamic shear rheometer (DSR), and polarized light microscopy. Additionally, its macroscopic performance was evaluated using three major performance indicators and interlayer bonding properties. This study provides new insights into the design and preparation of waterborne acrylate-modified emulsified asphalt for pavement preventive maintenance materials.

2. Materials and Methods

2.1. Raw Materials and Their Preparation

2.1.1. Raw Materials

(1) Emulsified asphalt: In this study, a slow-breaking and quick-setting matrix-emulsified asphalt was used as the base material, with the relevant technical indicators presented in Table 1. The testing methods referenced JTG E20 Standard Test Methods of Bitumen and Bituminous Mixtures for Highway Engineering [19].

Table 1.

Basic performance indexes of matrix emulsified asphalt.

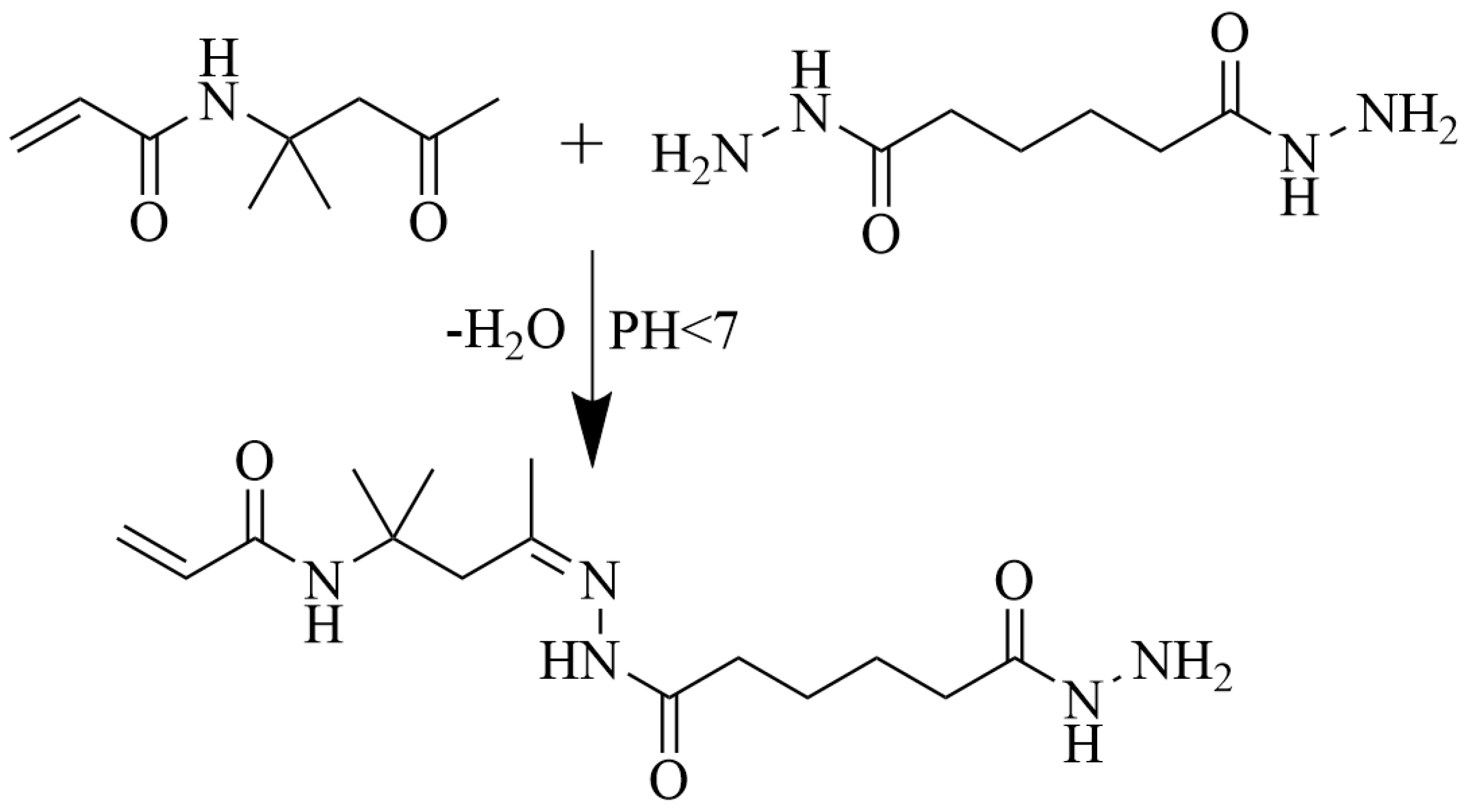

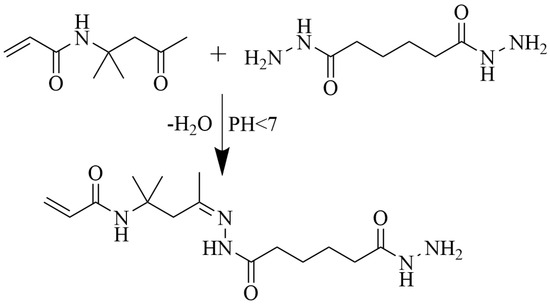

(2) Self-crosslinking waterborne acrylate (SWA): This study used a self-crosslinking waterborne acrylate based on a crosslinking system of diacetone acrylamide (DAAM) and adipic dihydrazide (ADH) [20]. The material was designed with a crosslinking degree of 5% and a solid content of 35%, and the self-crosslinking reaction mechanism is illustrated in Figure 1.

Figure 1.

Reaction mechanism diagram of DAAM-ADH cross-linking system.

2.1.2. Preparation of Modified Emulsified Asphalt

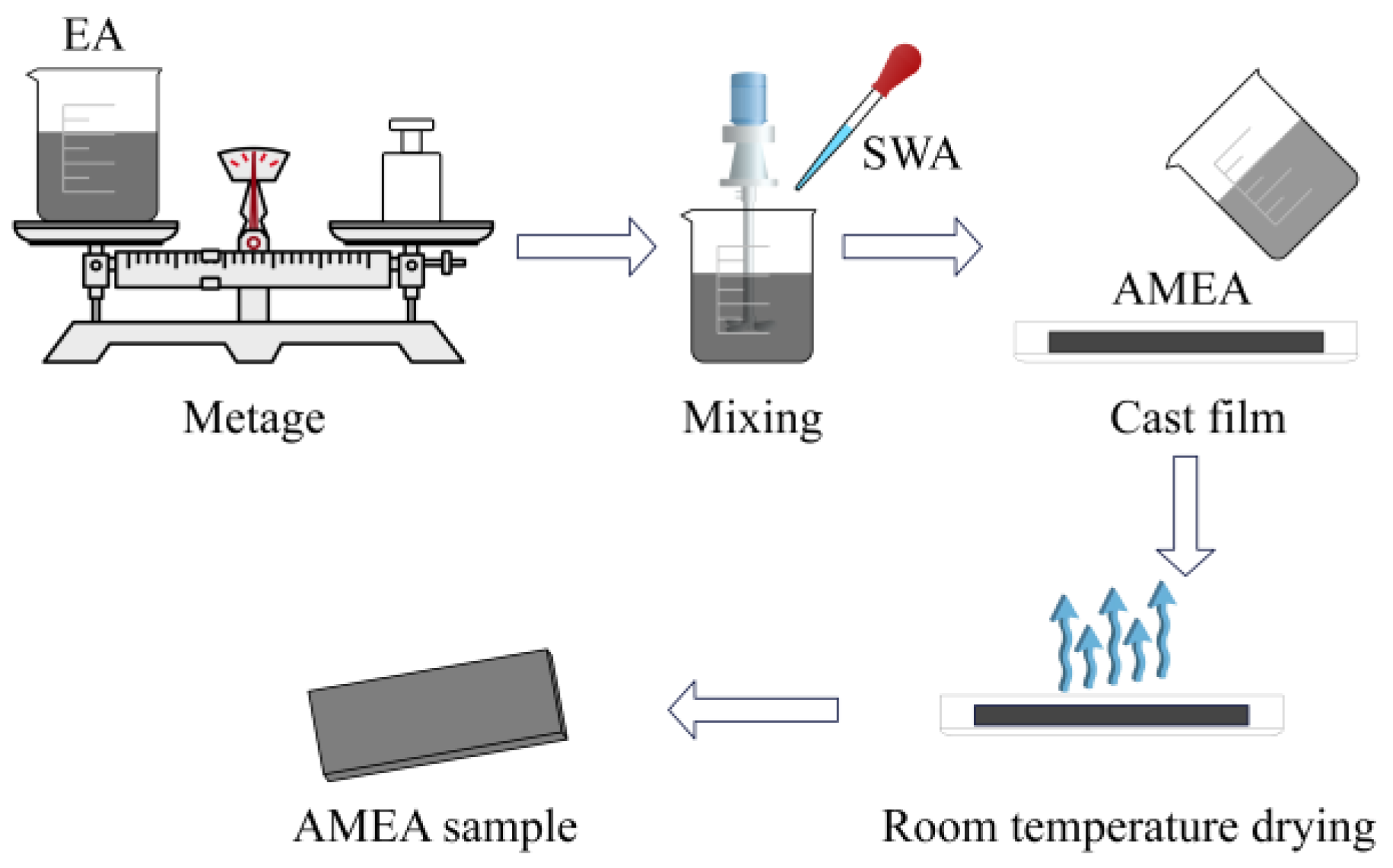

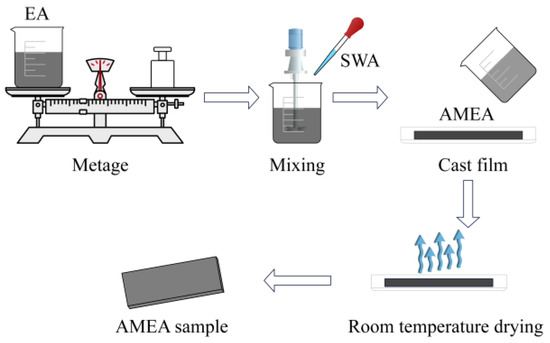

The paper incorporates the self-crosslinking waterborne acrylate (SWA) as an additive into the matrix emulsified asphalt to prepare the modified emulsified asphalt (AMEA). As shown in Figure 2, a controlled amount of matrix emulsified asphalt was mixed with SWA at dosages of 5 phr, 10 phr, 15 phr, 20 phr, and 25 phr under the following conditions: mixing temperature of 25 °C, rotational speed of 500 r/min, and mixing duration of 3 min. Finally, the AMEA was poured into molds and allowed to demulsify and dry at room temperature to obtain samples for testing.

Figure 2.

Flow chart for preparation of modified emulsified asphalt.

2.2. Performance Test Methods

2.2.1. Basic Performance Tests

The three major indicators of asphalt—penetration, ductility, and softening point—are core metrics for evaluating the road performance of asphalt, providing the most direct reflection of its intrinsic characteristics. To investigate the effect of varying dosages of self-crosslinking acrylate emulsion on the fundamental properties of emulsified asphalt, AMEA samples were subjected to the three major indicator tests in accordance with JTG E20 Standard Test Methods of Bitumen and Bituminous Mixtures for Highway Engineering.

2.2.2. FT-IR Tests

Fourier transform infrared spectroscopy (FT-IR) characterization can analyze the mechanism of self-crosslinking acrylate emulsion on emulsified asphalt from the perspective of chemical composition and molecular structure based on changes in functional groups. An appropriate amount of AMEA sample was taken and analyzed using the IS-20 Fourier Transform Infrared Spectrometer from ThermoFisher, located in Waltham, MA, USA. Through KBr pellet transmission mode. The testing range was 500 to 4000 cm−1.

2.2.3. DSR Rheological Tests

The dynamic shear rheology (DSR) technique was employed to investigate the viscoelastic and rheological behavior of AMEA, with temperature and frequency sweep tests conducted using the SYD-0628 instrument from TA Instruments located in Danbury, CT, USA.

For the temperature sweep, AMEA samples were prepared in 25 mm diameter parallel plates (1 mm gap) and subjected to shear testing at 1% constant strain over a temperature range of 45–120 °C, maintaining a loading frequency of 10 rad/s with 1 °C incremental steps.

The frequency sweep was performed on room temperature-dried AMEA samples under similar plate geometry, evaluating the material response across 0.1–100 rad/s at a fixed temperature of 60 °C and 1% shear strain. Both measurements aimed to systematically assess AMEA performance under varying thermal and mechanical conditions through controlled DSR protocols.

2.2.4. MSCR Tests

The Multi-Stress Creep Recovery (MSCR) test is an advanced methodology for investigating the nonlinear viscoelastic behavior of asphalt under complex stress conditions. By simulating polyaxial shear stresses induced by vehicular loads, this technique provides a realistic representation of pavement stress environments, overcoming the limitations of conventional uniaxial testing methods. Following ASTM D7405 [21], multi-stress creep recovery (MSCR) tests were performed on AMEA samples at a temperature of 60 °C, using stresses of 0.1 kPa and 3.2 kPa. Ten cycles were performed at each stress level, with each cycle lasting 10 s, including a 1-s loading creep phase and a 9-s unloading recovery phase. The main parameters of the MSCR test are the average strain recovery rate (R) and the average non-recoverable creep compliance (Jnr), which are calculated using the following formulas:

where is the strain at 1 s per cycle, is the strain at 10 s per cycle, and is the applied shear stress.

2.2.5. DSC Tests

The Differential Scanning Calorimetry (DSC) technique was employed to characterize the thermal properties and phase transition behavior of materials. In this study, DSC tests were conducted using the DSC 25 from TA Instruments located in Danbury, CT, USA. Under a nitrogen atmosphere with a flow rate of 50 mL/min, covering a temperature range from −20 °C to 150 °C. DSC analysis was performed on AMEA samples with varying additive contents to investigate their thermal characteristics and phase transition mechanisms under controlled experimental conditions

2.2.6. Micro Morphology Tests

The Polarized Light Microscopy (PLM) technique allows direct observation of asphalt microstructure, phase composition, and anisotropy characteristics. In this study, a suitable amount of AMEA sample was analyzed using a transmitted polarized light microscopy approach with an OTTO OPTIC BK-POL microscope from Graz Optronik in Germany, featuring a heating stage. Temperature-dependent microstructural analysis was conducted by observing sample behavior across varying temperatures under controlled experimental conditions.

2.2.7. Bond Strength Tests

The asphalt bond strength is a critical factor in ensuring the structural integrity and long-term durability of pavement systems. In this study, a pull-off test was employed to evaluate the vertical bond strength of AMEA. Cement concrete specimens were used as the substrate, coated with emulsified asphalt samples. After drying and attaching the pull-off head, the specimens were conditioned at 25 ± 2 °C for 4 h before testing. The interlayer bond strength τ was calculated using the following formula:

where is peak tensile force (N); S is effective contact area (mm2)

3. Results and Discussion

3.1. Basic Performance Tests

According to the data in Table 2, with the increase in the amount of waterborne acrylic ester added, the solid content of AMEA decreases. At the same time, the softening point of the room-temperature dried product increases, while the penetration decreases. This is because the self-crosslinking acrylic emulsion at room temperature undergoes a self-crosslinking reaction during the drying process, forming a network structure of polymers that are dispersed in the saturated and aromatic components of the asphalt. As the amount of waterborne acrylic ester increases, the resulting network structure becomes denser, leading to a higher softening point of the dried AMEA. However, the addition of waterborne acrylic ester causes a decrease in the low-temperature ductility of the emulsified asphalt. This is mainly due to the glass transition temperature of the crosslinked polymer from the self-crosslinking waterborne acrylic ester being around 52 °C [20], at which it exhibits brittleness at low temperatures, thus affecting the low-temperature ductility of the emulsified asphalt.

Table 2.

Basic performance of AMEA.

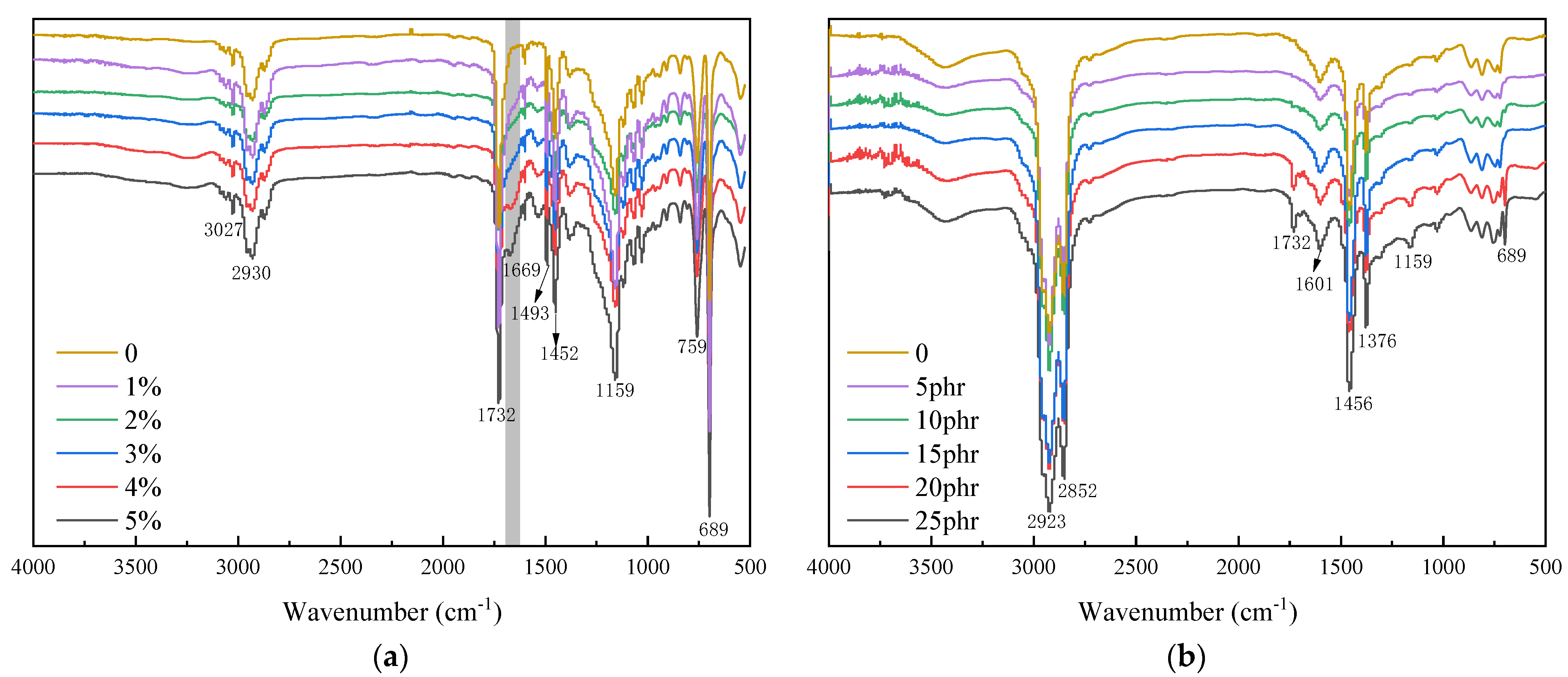

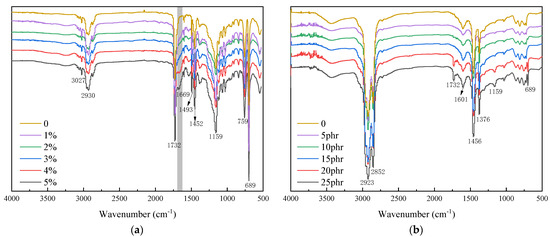

3.2. FT-IR Tests

By analyzing the changes in absorption peaks from FT-IR testing, it is possible to determine whether the waterborne acrylic ester is uniformly mixed in the emulsified asphalt matrix and whether crosslinking reactions have occurred. Figure 3 presents the test results.

Figure 3.

FT-IR Analysis Chart: (a) waterborne acrylic esters with different degrees of crosslinking; (b) AMEA with different incorporation.

Figure 3a shows the FT-IR spectrum of waterborne acrylic esters with different degrees of crosslinking prepared by the research group. It can be observed that a stretching vibration peak corresponding to the keto hydrazone group appears around 1669 cm−1, indicating that a self-crosslinking reaction occurred after the emulsion cured. Additionally, noticeable absorption peaks for carbonyl groups at 1732 cm−1, C-O bending vibrations at 1159 cm−1, and aromatic C-H bending vibrations at 689 cm−1 are present.

Figure 3b presents the infrared spectrum of AMEA dried at room temperature after incorporating the self-crosslinking emulsion. By comparing this spectrum with that of the self-crosslinking emulsion and the matrix emulsified asphalt, it is evident that AMEA exhibits distinct vibration peaks at 1732 cm−1, 1159 cm−1, and 689 cm−1, which suggests a homogeneous mixing between the two. The modification of emulsified asphalt by SWA mainly relies on physical modification. It is important to note that at approximately 1669 cm−1, the large area of the bending vibration peak for phenyl rings in asphalt prevents the observation of the stretching vibration peak for the keto hydrazone group resulting from the crosslinking of SWA in the emulsified asphalt. Further tests are required to confirm whether self-crosslinking of SWA occurs in the emulsified asphalt.

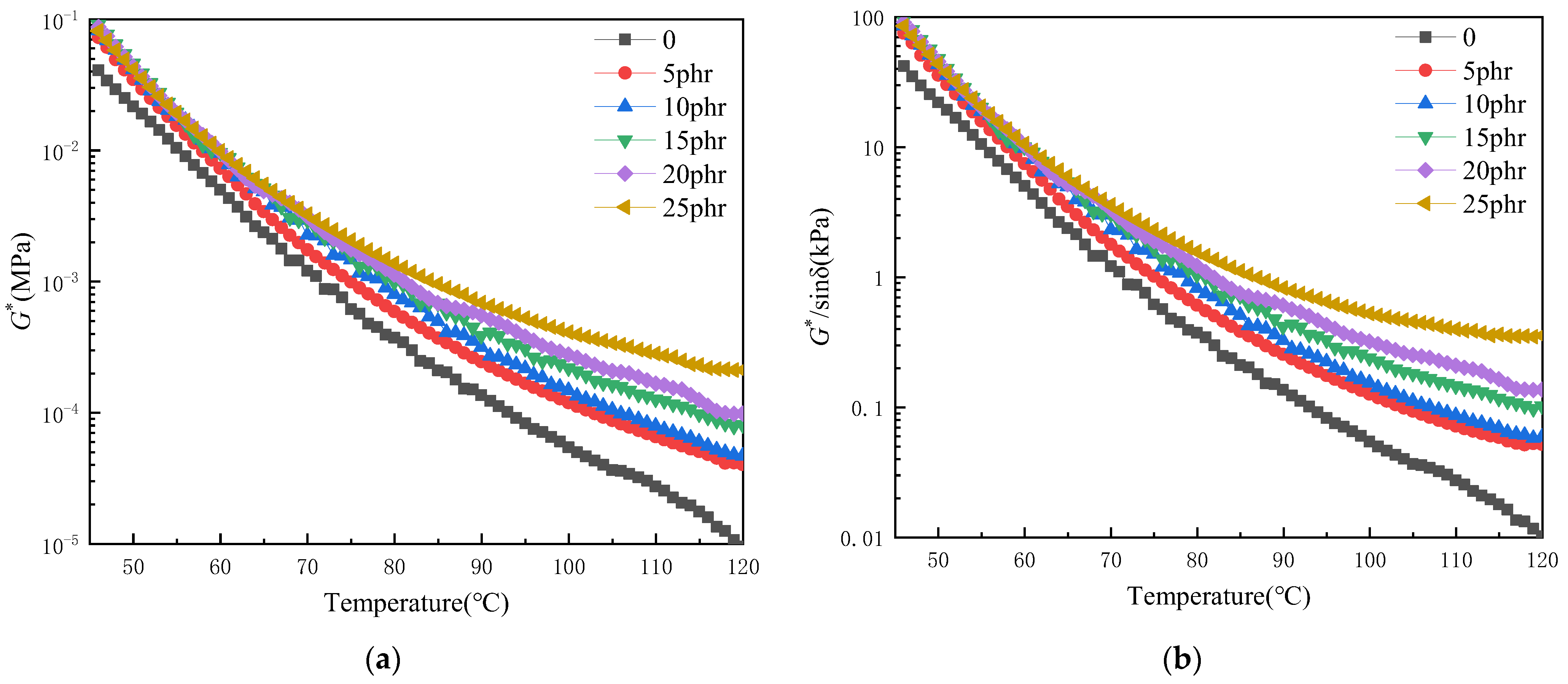

3.3. DSR Rheological Tests

3.3.1. DSR Temperature Sweep

The mechanical properties of asphalt vary with changes in temperature and external loads, which is closely related to the high-temperature stability of the asphalt itself [22]. The high-temperature stability of AMEA samples can be evaluated through DSR temperature scanning tests.

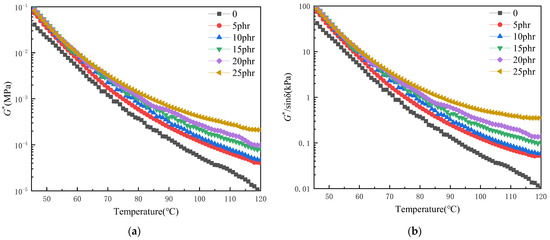

From Figure 4, it can be observed that as the testing temperature increases, the G* significantly decreases, and the G*/sinδ also declines. This is due to the gradual transition of the elastic components within the asphalt to viscous components, resulting in a reduced proportion of elastic components and a macroscopic change from a solid state to a viscous state. At a reference temperature of 60 °C, the complex modulus G* of AMEA under modifier dosages of 0–25 phr was measured as 0.0050 MPa, 0.0073 MPa, 0.0095 MPa, 0.0096 MPa, 0.0098 MPa, and 0.0099 MPa, respectively. The progressive increase in G* demonstrates that the waterborne acrylate undergoes crosslinking reactions within the asphalt matrix, forming a stable crosslinked network structure (polymer network), thereby enhancing its elastic properties. According to the Strategic Highway Research Program(SHRP) asphalt binder specification system, the rutting factor (G*/sinδ) threshold of 2 kPa is defined as the failure temperature of asphalt [23]. Therefore, the high-temperature performance grade (PG) of asphalt can be determined by analyzing the rutting factor. As shown in Figure 4b, the failure temperatures corresponding to the 2 kPa rutting factor for AMEA at dosages of 0–25 phr are 66.3 °C, 68.9 °C, 72.3 °C, 73.8 °C, 74.6 °C, and 76.0 °C, respectively. The failure temperature of AMEA is higher than that of matrix-emulsified asphalt, and as the dosage of self-crosslinking waterborne acrylate (SWA) increases, the failure temperature of AMEA gradually rises. This indicates that the self-crosslinking emulsion has a significant impact on the PG grade of the modified asphalt and is beneficial for improving the high-temperature resistance to permanent deformation of the modified asphalt.

Figure 4.

The variation curves of rheological properties with temperature: (a) Complex modulus (G*); (b) Rutting factor (G*/sinδ).

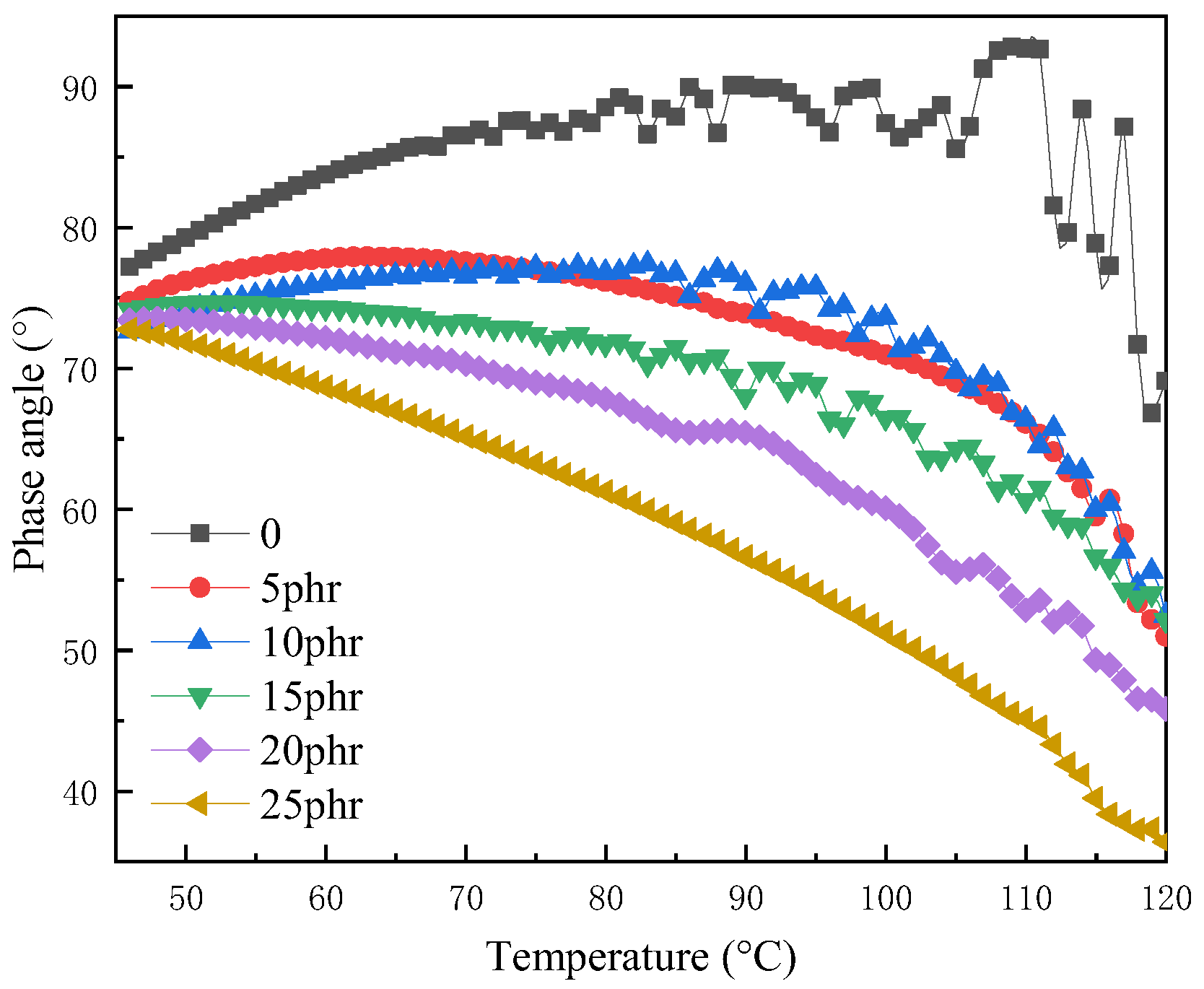

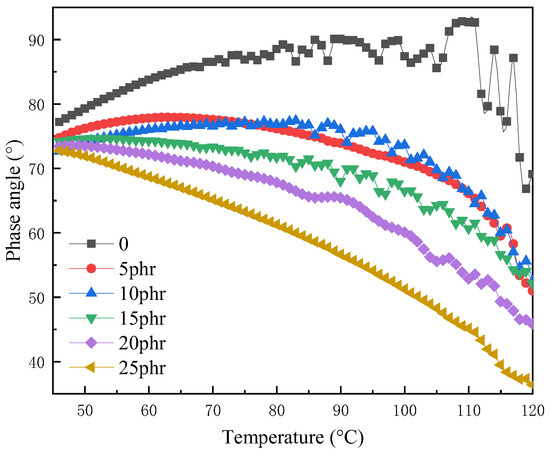

Through phase angle analysis, it can be observed from Figure 5 that as the testing temperature increases, the phase angle of AMEA shows an overall decreasing trend, while the phase angle of the matrix emulsified asphalt exhibits a mild increasing trend. Additionally, at high temperatures, the phase angle of asphalt oscillates, which may be attributed to the melting of the asphalt causing the test sample to flow out between the clamps, leading to unstable performance. At the same temperature, as the content of waterborne acrylic esters increases, the phase angle of AMEA decreases, indicating better elastic performance of the samples. This observation corresponds with the results of the G* and the G*/sinδ tests.

Figure 5.

The variation curves of rheological properties with temperature: phase angle.

3.3.2. DSR Frequency Sweep

The loading rate is also an important factor affecting the rheological properties of asphalt materials [24]. In this study, the rheological characteristics of AMEA were evaluated using a frequency sweep method.

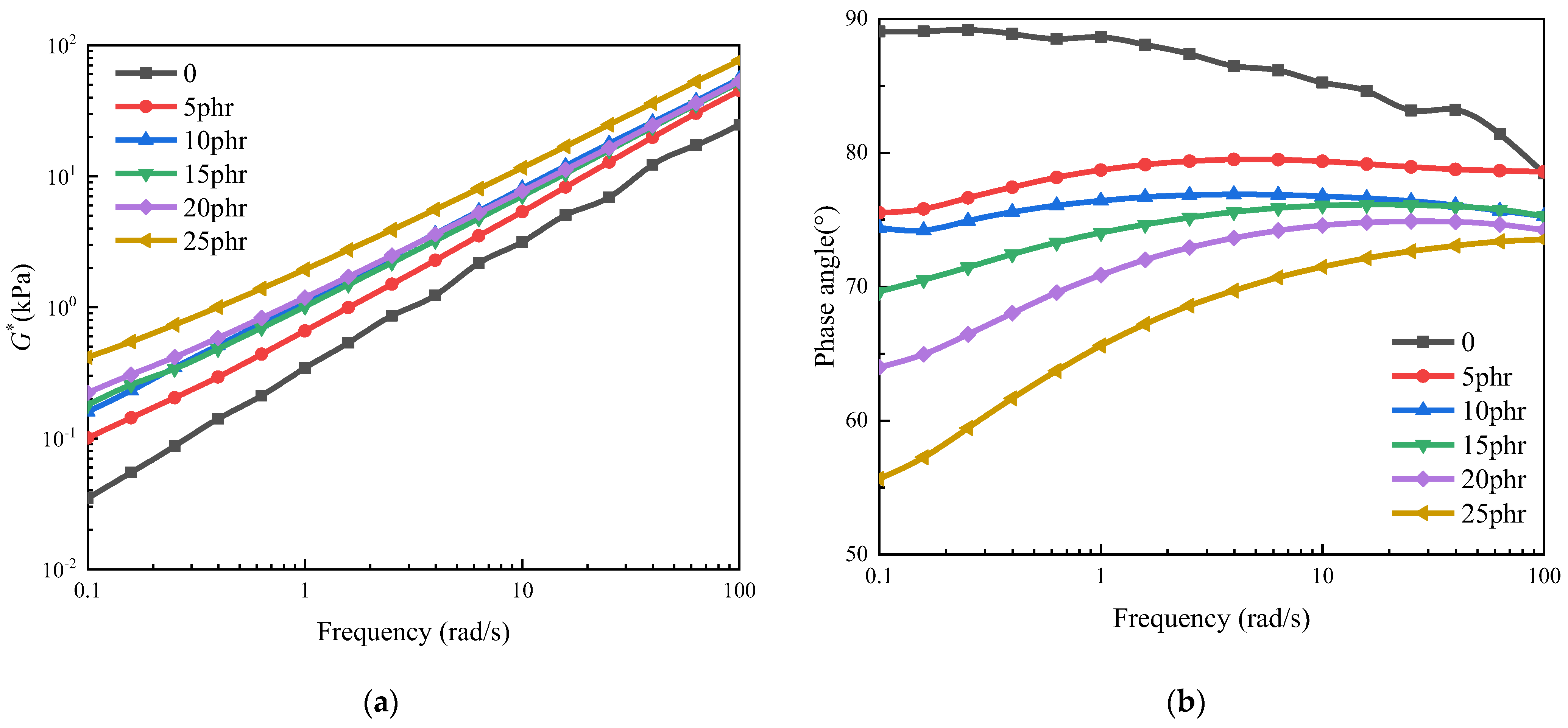

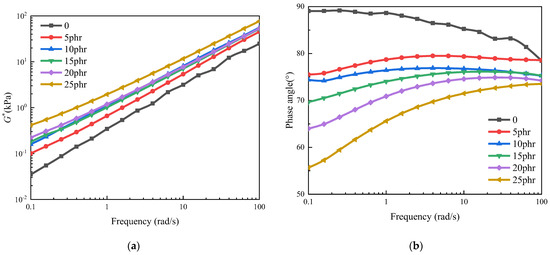

From Figure 6a, it can be seen that with the increase in shear frequency, AMEA exhibits a shear hardening phenomenon, leading to a gradual increase in the complex modulus. At the same time, as the content of SWA increases, the complex modulus also increases, and the trend of change with frequency becomes less pronounced, indicating that SWA enhances the elastic performance of the emulsified asphalt. The phase angle analysis in Figure 6b shows that with an increase in SWA content, the phase angle of the emulsified asphalt decreases, further indicating that SWA is beneficial for improving the elasticity of the emulsified asphalt. Within the frequency range of 0.1 rad/s to 100 rad/s, the absolute changes in phase angle for AMEA at modifier dosages of 0–25 phr are 10.5, 3.0, 0.9, 5.7, 10.2, and 17.9, respectively. Notably, however, as the SWA dosage continues to rise, the phase angle’s sensitivity to frequency shifts first decreases and then increases. This implies that while higher SWA dosages impart superior elasticity to modified emulsified asphalt, excessive dosages may destabilize the frequency-dependent phase angle response due to overly dense self-crosslinked networks. A comprehensive analysis indicates that controlling the SWA content within the range of 10 to 15 phr minimizes the impact of frequency effects on emulsified asphalt at high temperatures.

Figure 6.

The variation curves of rheological properties with frequency: (a) Complex modulus (G*); (b) Phase angle.

3.4. MSCR Text

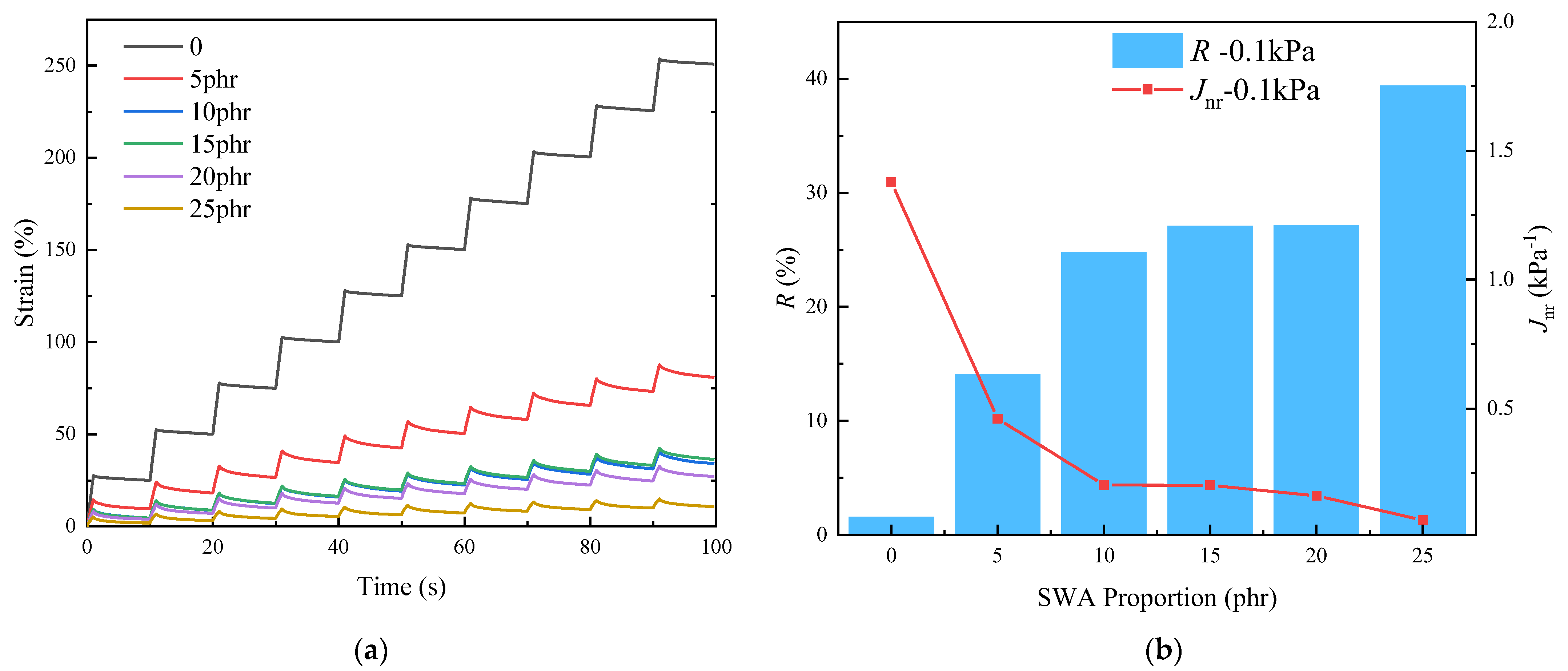

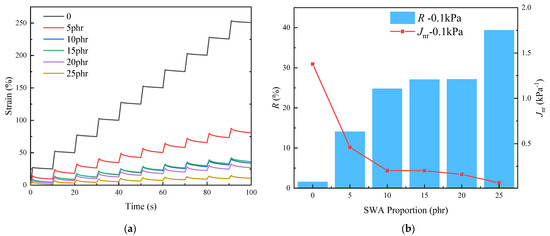

The results of the MSCR test reflect the viscoelastic-plastic behavior of asphalt binders. During the unloading phase, elastic strain recovers quickly, while viscous strain recovers more slowly [25,26]. The strain recovery rate (R) is used to evaluate the elastic performance of asphalt binders under load; a higher R value indicates stronger deformation resistance of the asphalt binder. The non-recoverable creep compliance (Jnr) can be used to assess the rutting resistance of asphalt binders; a lower Jnr value indicates better rutting performance.

Figure 7a shows the MSCR strain curve of AMEA at a stress level of 0.1 kPa. It can be observed from the figure that the incorporation of SWA reduces the strain of the emulsified asphalt, and this reduction is significant as the SWA content increases, indicating that the SWA modifier can significantly enhance the elastic modulus of the binder. In Figure 7b, the R value of the binder without SWA is nearly 0, while the elastic recovery rate significantly increases with the addition of SWA. Furthermore, as the SWA content increases, the Jnr value of the binder decreases and stabilizes when the dosage reaches over 10 phr, demonstrating excellent deformation resistance.

Figure 7.

The variation curves of rheological properties with repeated creep (0.1 kPa): (a) Strain curve; (b) Strain characteristic value.

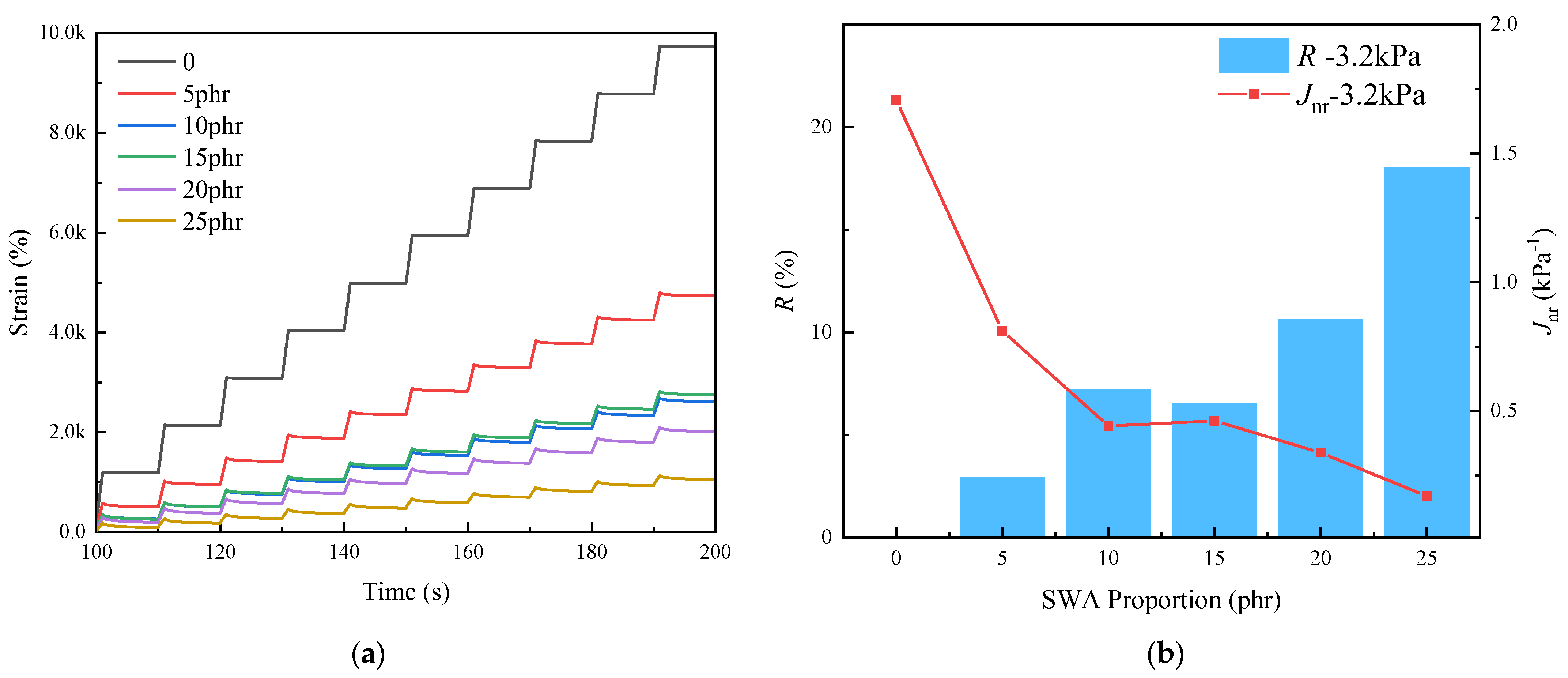

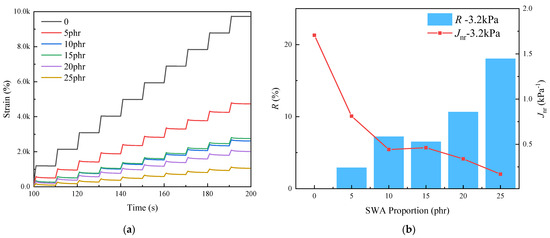

Figure 8 shows the MSCR curve of AMEA at a stress level of 3.2 kPa. At high stress, the asphalt binder exhibits higher strain, but its variation trend remains consistent with that observed at the 0.1 kPa stress level. According to ASTM D7405 and recommendations by Dubois et al. [27], the Jnr value of asphalt binders should not exceed 0.5 kPa−1 under heavy traffic loads. By comparing the Jnr values of AMEA at both 0.1 kPa and 3.2 kPa stress levels, it was found that when the SWA content exceeds 10 phr, the binder meets the demands of heavy traffic on roads. Therefore, the AMEA binder developed in this study demonstrates good elastic recovery and deformation resistance.

Figure 8.

The variation curves of rheological properties with repeated creep (3.2 kPa): (a) Strain curve; (b) Strain characteristic value.

3.5. DSC Tests

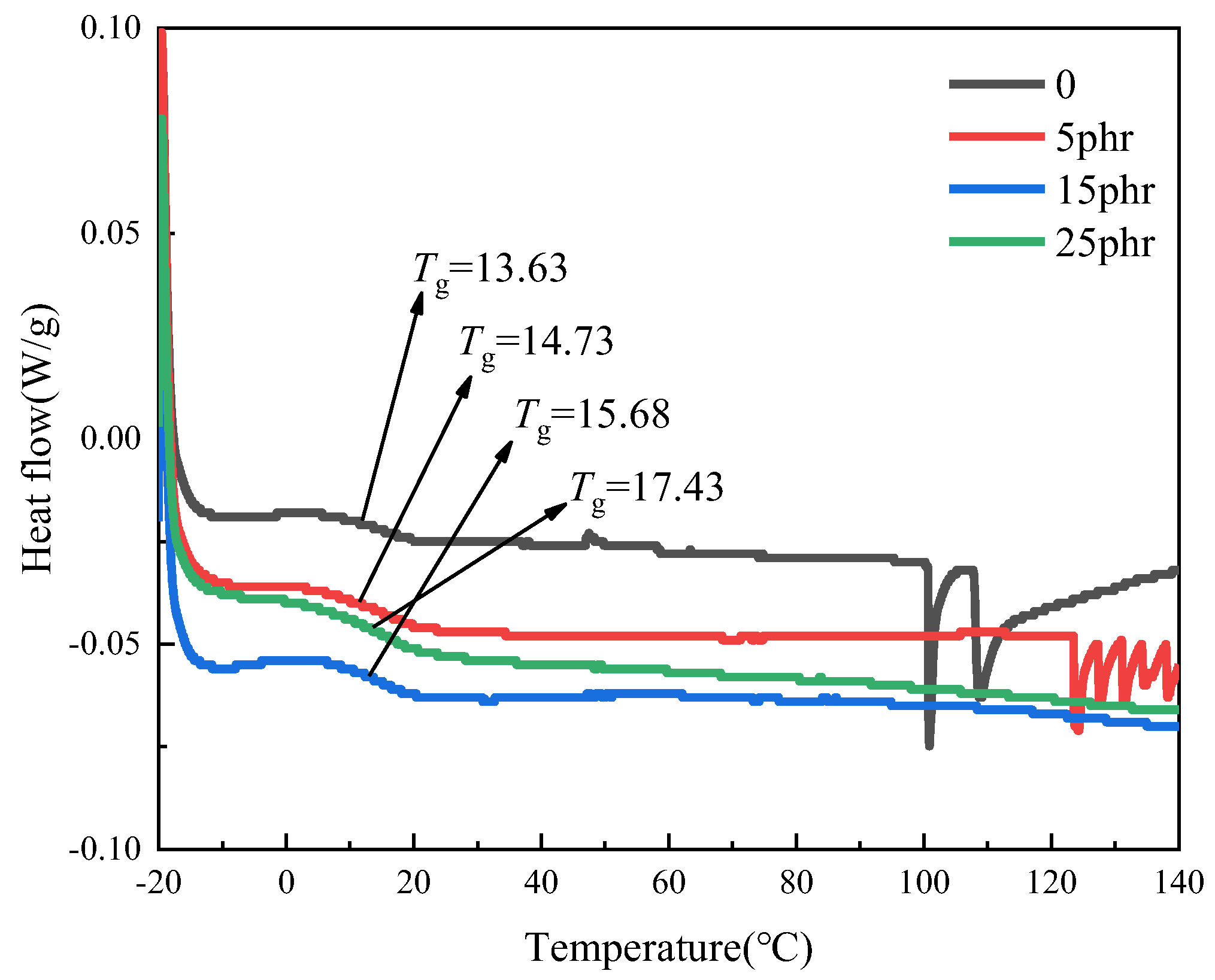

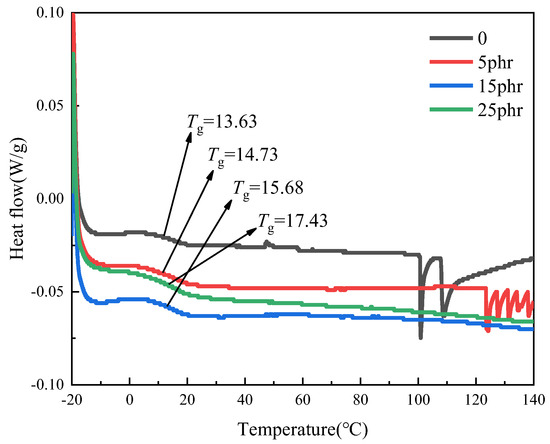

Through DSC analysis, it can be observed that the addition of SWA affects the glass transition temperature (Tg) of emulsified asphalt, which can be used to assess its impact on the thermal properties of the emulsified asphalt.

From Figure 9, it can be concluded that after the addition of the SWA modifier, the Tg of AMEA shows a significant increase. With the increase in SWA content, the Tg of AMEA rises from 13.63 °C to 17.43 °C. This indicates that SWA is beneficial in improving the glass transition temperature of emulsified asphalt, having a positive impact on its thermal properties. The above results also indicate that SWA will negatively impact the low-temperature performance of emulsified asphalt binder.

Figure 9.

DSC Analysis Chart of AMEA.

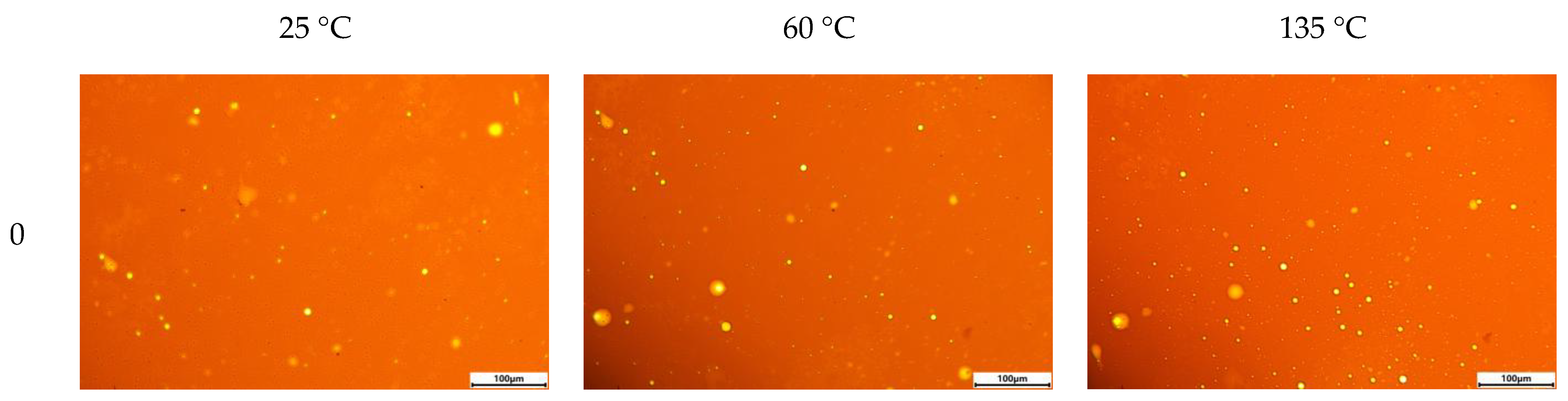

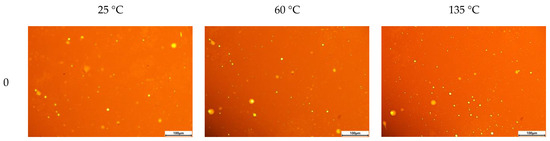

3.6. Micro Morphology Tests

By observing the micromorphology of the AMEA room-temperature dried products, we can visually analyze the distribution of the waterborne acrylate after drying within the asphalt matrix, and further determine whether a crosslinking reaction has occurred.

From Figure 10, it can be seen that the morphology of the emulsified asphalt without the addition of waterborne acrylate is uniform, presenting an overall appearance of relatively homogeneous asphalt material. After the incorporation of waterborne acrylate, a distinct network structure appears in the microscopic morphology of AMEA, indicating that a crosslinking reaction occurs during the demulsification process. Additionally, as the amount of waterborne acrylate increases, the network structure in AMEA becomes denser, which further suggests an increase in the internal crosslinking density. By comparing the morphologies of AMEA at different temperatures, it can be observed that the internal network structure is less affected by temperature, indicating that the network structure formed by the waterborne acrylate in the emulsified asphalt matrix possesses strong stability, effectively locking in the asphalt components and enhancing high-temperature stability. Through the analysis of the microscopic morphology of AMEA, it can be confirmed that waterborne acrylate can undergo self-crosslinking reactions within the emulsified asphalt matrix to form a stable network structure, which also corresponds with the results of DSR rheological performance tests.

Figure 10.

Micro morphology Chart of AMEA.

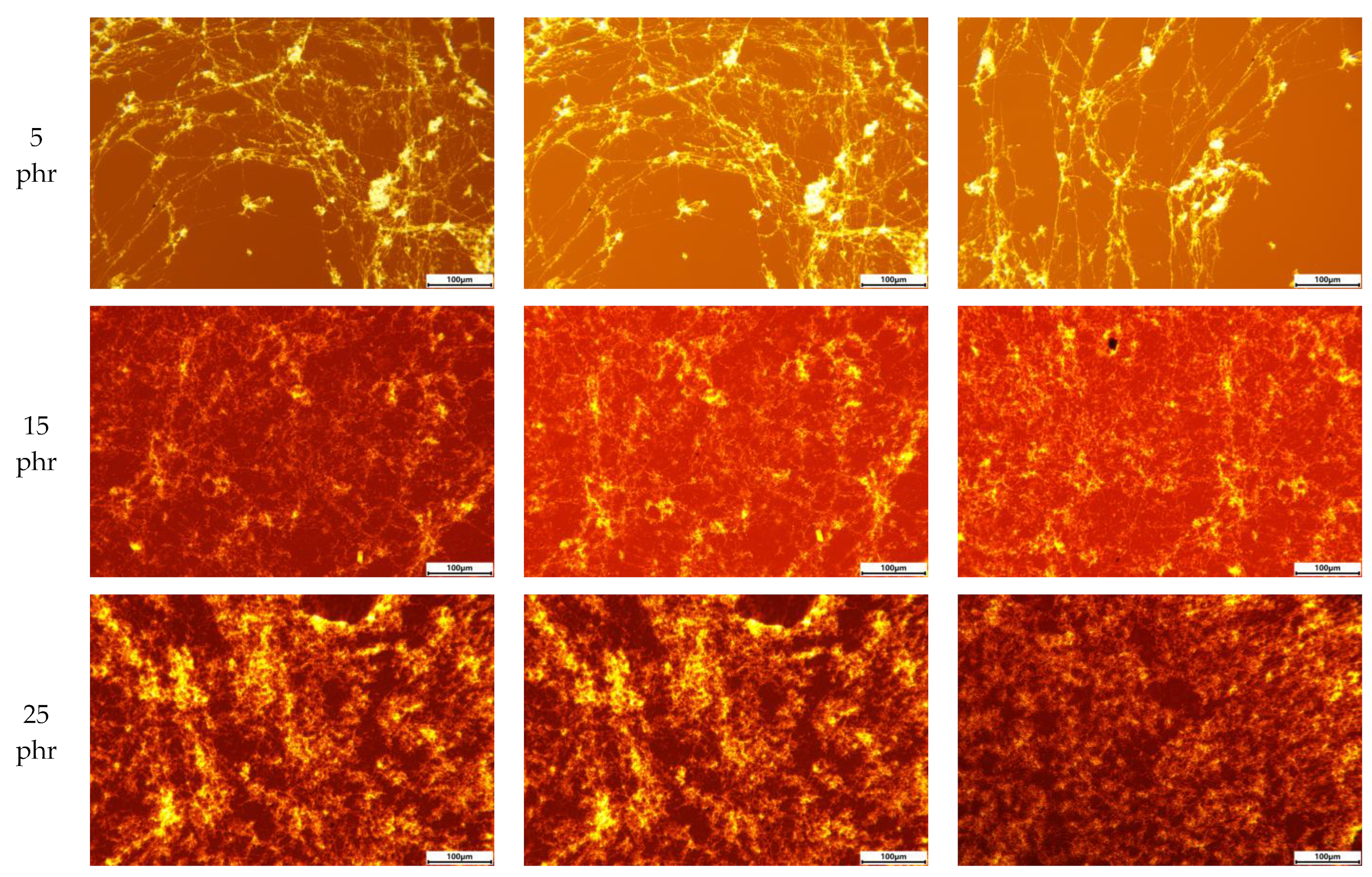

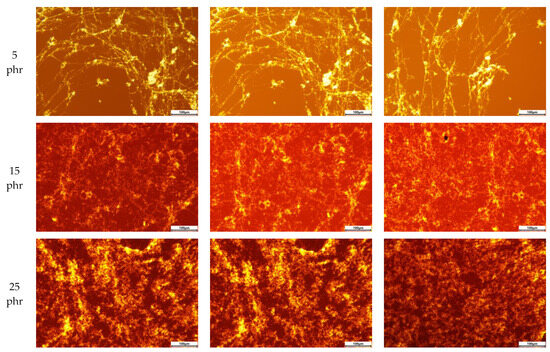

3.7. Bond Strength Tests

Pull-off tests were conducted on matrix emulsified asphalt (EA), commercially available SBR emulsion-modified emulsified asphalt (SMEA), and the AMEA prepared in this study (dosage: 10 phr). The substrate is roughened via shot blasting to achieve an Sa2 cleanliness grade and a texture depth of 0.6–0.8 mm. At least three samples per group were tested to calculate their pull-off strength, with the average value taken as the reference for evaluating bonding performance. The Figure 11 illustrates the interlayer delamination conditions of each substrate after the pull-off tests.

Figure 11.

Surface morphology of pull-off samples.

In Figure 11, from left to right, the fracture surface morphologies of EA, SMEA, and AMEA after pull-off testing are shown. Calculated interfacial pull-off strengths for these three materials are 0.64 MPa, 0.73 MPa, and 0.99 MPa, respectively. Based on the calculations, the incorporation of the SWA-type admixture enhances the bonding strength of emulsified asphalt by approximately 54.7%, surpassing the commercially available SBR emulsion-modified emulsified asphalt by 35.6%. This significant improvement indicates that the crosslinked network structure formed by the self-crosslinking reaction of SWA substantially enhances the bonding performance of emulsified asphalt, which holds critical practical implications for ensuring pavement durability and structural integrity.

4. Conclusions

In this study, a novel self-crosslinking waterborne acrylate-modified emulsified asphalt was prepared using a self-developed self-crosslinking waterborne acrylate as an external additive. Various characterization techniques, such as FT-IR, DSR, DSC, and polarized light microscopy, were employed to analyze the modification process of the emulsified asphalt from a microscopic perspective. The rheological and thermal properties of AMEA at different SWA contents were investigated. Microscopic morphological analysis was conducted to explain the changes in the macro properties of the binder. The main conclusions are as follows:

- (1)

- Through basic physical performance tests, it was found that SWA is beneficial in increasing the softening point of emulsified asphalt and reducing its penetration, but it has a certain negative impact on its low-temperature ductility.

- (2)

- From the DSR temperature sweep and DSC analysis, it was observed that the incorporation of SWA is beneficial for enhancing the elasticity and high-temperature stability of emulsified asphalt, with the effect becoming more pronounced as the dosage increases. Phase angle analysis further indicates that SWA significantly influences the PG grade of emulsified asphalt, which helps to improve its resistance to permanent deformation at high temperatures.

- (3)

- The DSR frequency sweep further indicates that SWA is beneficial in improving the elasticity of emulsified asphalt; however, excessive dosages can lead to an increased frequency effect. It is believed that the SWA dosage of 10 to 15 phr has the least impact on the frequency effect of emulsified asphalt. The MSCR tests demonstrate that SWA significantly enhances the high-temperature elastic recovery and rutting resistance of emulsified asphalt, and a dosage exceeding 10 phr is suitable for high traffic volume environments.

- (4)

- The changes in FT-IR functional groups confirmed that the modifier is uniformly mixed with the emulsified asphalt, primarily achieving physical modification. Further analysis using polarized light microscopy validated that SWA can undergo self-crosslinking reactions within the emulsified asphalt matrix, forming a stable network structure.

- (5)

- The bond performance test indicates that SWA can increase the pull-off strengths of emulsion asphalt by more than 50%, which is higher than that of the commonly used SBR-modified emulsion asphalt systems in the market. This new self-crosslinking waterborne acrylic acid-modified emulsion asphalt has the potential for application in practical engineering projects.

Author Contributions

Conceptualization, J.X. and S.T.; methodology, H.L. and Z.H.; validation, S.T., J.D. and Y.L.; formal analysis, J.W.; investigation, S.T. and J.W.; resources, J.X.; data curation, S.T. and J.D.; writing—original draft preparation, S.T. and J.D.; writing—review and editing, J.X., Z.H. and H.L.; visualization, S.T.; supervision, J.X.; project administration, Z.H.; funding acquisition, J.X. All authors have read and agreed to the published version of the manuscript.

Funding

This work was supported by a grant from the National Key Technologies Research and Development Program of China (No. 2022YFB2602605) and National Natural Science Foundation of China 52178440.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The original contributions presented in the study are included in the article, further inquiries can be directed to the corresponding author.

Conflicts of Interest

Jianhui Xu was employed by the Chongqing Expressway Group Co., Ltd. and China Merchants Chongqing Communications Technology Research & Design Institute Co., Ltd. Haiying Li was employed by the Chongqing Expressway Group Co., Ltd. Shutong Tang and Jie Wang were employed by China Merchants Chongqing Communications Technology Research & Design Institute Co., Ltd. and China Merchants Zhixiang Road Technology (Chongqing) Co., Ltd. Jing Dang and Yuanyuan Li were employed by China Merchants Zhixiang Road Technology (Chongqing) Co., Ltd. Zhaoyi He declares that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

References

- Ji, J.; Shi, Q.; Zhang, R.; Suo, Z.; Wang, J. Viscosity, mechanical properties and phase-separated morphology of waterborne epoxy asphalt. Constr. Build. Mater. 2022, 334, 127074. [Google Scholar] [CrossRef]

- Liu, F.; Zheng, M.; Fan, X.; Li, H.; Lin, X. Properties and mechanism of waterborne epoxy resin-SBR composite modified emulsified asphalt. Constr. Build. Mater. 2021, 274, 122059. [Google Scholar] [CrossRef]

- Xu, P.; Wang, Y.; Cheng, P.; Cong, P.; Li, D.; Zhang, Z.; Hui, J.; Ye, M. Toughness modification of waterborne epoxy emulsified asphalt by waterborne polyurethane elastomer. Constr. Build. Mater. 2023, 386, 131547. [Google Scholar] [CrossRef]

- Yang, F.; Zhou, Q.; Yang, L.; He, L.; Chen, Q.; Tang, S. Preparation and performance evaluation of waterborne epoxy resin modified emulsified asphalt binder. Case Stud. Constr. Mater. 2024, 21, e03548. [Google Scholar] [CrossRef]

- Takamura, K.; Heckmann, W. Polymer network formation in the pavement using SBR latex modified asphalt emulsions. Stud. Surf. Sci. Catal. 2001, 132, 271–274. [Google Scholar] [CrossRef]

- Fu, H.; Xiao, T.; Hong, H.; Guang, L.; Chang, G. Effect of SBR Latex Content on Performance of Modified Emulsified Asphalt. J. Build. Mater. 2021, 24, 895–900. [Google Scholar]

- Sun, Z.; Chen, J.; Liu, S.; Qian, J.; Huang, R. Evaluation of the performance of SBS/CR composite-modified deicing asphalt mixture prepared for ultra-thin wearing course. Constr. Build. Mater. 2024, 416, 135085. [Google Scholar] [CrossRef]

- Meng, Y.; Chen, J.; Kong, W.; Hu, Y. Review of emulsified asphalt modification mechanisms and performance influencing factors. J. Road Eng. 2023, 3, 141–155. [Google Scholar] [CrossRef]

- Shi, S.; Zang, D.; Chen, X.; Ma, T.; Gu, L.; Xu, D.; Liu, J. Preparation and properties of a novel waterborne epoxy resin modified emulsified asphalt. Constr. Build. Mater. 2023, 371, 130767. [Google Scholar] [CrossRef]

- Han, S.; Yao, T.; Yang, X. Preparation and anti-icing properties of a hydrophobic emulsified asphalt coating. Constr. Build. Mater. 2019, 220, 214–227. [Google Scholar] [CrossRef]

- Huang, S.; Jin, F.; Chen, D.; Xiao, Q.; Ding, Q. Study on Modification Mechanism and Performance of Waterborne Epoxy Resin Micro-Surfacing. Coatings 2023, 13, 504. [Google Scholar] [CrossRef]

- Zhou, X.; Wang, Z.; Guo, H.; Wang, X.; Chen, W.; Liu, J.; Zhang, H.; Wan, C. Property improvement of epoxy emulsified asphalt modified by waterborne polyurethane in consideration of environmental benefits. Case Stud. Constr. Mater. 2024, 21, e03559. [Google Scholar] [CrossRef]

- Parvate, S.; Mahanwar, P. Advances in self-crosslinking of acrylic emulsion: What we know and what we would like to know. J. Dispers. Sci. Technol. 2018, 40, 519–536. [Google Scholar] [CrossRef]

- Steinerová, D.; Kalendová, A.; Machotová, J.; Knotek, P.; Humpolíček, P.; Vajdák, J.; Slang, S.; Krejčová, A.; Beneš, L.; Wolff-Fabris, F. Influence of Metal Oxide Nanoparticles as Antimicrobial Additives Embedded in Waterborne Coating Binders Based on Self-Crosslinking Acrylic Latex. Coatings 2022, 12, 1445. [Google Scholar] [CrossRef]

- Liu, J.; Zhang, Y. Effect of ethylene-acrylic acid copolymer on flame retardancy and properties of LLDPE/EAA/MH composites. Polym. Degrad. Stab. 2011, 96, 2215–2220. [Google Scholar] [CrossRef]

- Scaffaro, R.; Mantia, F.P.L.; Canfora, L.; Polacco, G.; Magagnini, P. Reactive compatibilization of PA6/LDPE blends with an ethylene–acrylic acid copolymer and a low molar mass bis-oxazoline. Polymer 2003, 44, 6951–6957. [Google Scholar] [CrossRef]

- Chen, D.; Wu, H.; Chen, X.; Zhan, Y.; Wada, S.A. Fabrication of High-Performance Asphalt Mixture Using Waterborne Epoxy-Acrylate Resin Modified Emulsified Asphalt (WEREA). Polymers 2024, 16, 2743. [Google Scholar] [CrossRef]

- Xu, L.; Han, Y.; Yan, B.; Zhao, Z.; Li, X.; Xiao, F. Investigation on the stability and interaction of asphalt emulsion with waterborne acrylate as pavement maintenance coating. Prog. Org. Coat. 2023, 174, 107234. [Google Scholar] [CrossRef]

- JTGE20-2011; Standard Test Methods of Bitumen and Bituminous Mixtures for Highway Engineering. Ministry of Transport of the People’s Republic of China: Beijing, China, 2011.

- Xu, J.; Li, H.; Tang, S.; Chen, S.; Huang, H.; Dang, J.; Li, Y. Preparation and Properties of Ambient Self-Crosslinking Acrylic Emulsion; IOP Publishing Ltd.: Bristol, UK, 2024. [Google Scholar] [CrossRef]

- ASTM D7405; Standard Test Method for Multiple Stress Creep and Recovery (MSCR) of Asphalt Binder Using a Dynamic Shear Rheometera. ASTM: West Conshohocken, PA, USA, 2024.

- Zhang, S.; Zhang, H.; Zhou, M. Investigation on the high-temperature stability and fatigue behavior of cold mixed epoxy asphalt mixture with different gradations. Case Stud. Constr. Mater. 2024, 20, e02694. [Google Scholar] [CrossRef]

- Li, Q.; Chen, X.; Sun, X. The experimental analysis of technical indicators for high modulus asphalt binder. Highw. Transp. Technol. (Appl. Technol. Ed.) 2015, 11, 74–77. [Google Scholar]

- Hu, M.; Ling, S.; Sun, D.; Lu, T.; Ma, J.; Sun, Y. A sustainable high-viscosity modified asphalt modified with multiple anti-aging agents: Micro-chemical analysis and macro-rheological characterization. Constr. Build. Mater. 2022, 339, 127701. [Google Scholar] [CrossRef]

- Yang, X.; You, Z. High temperature performance evaluation of bio-oil modified asphalt binders using the DSR and MSCR tests. Constr. Build. Mater. 2015, 76, 380–387. [Google Scholar] [CrossRef]

- Zhao, P.; Liang, H.; Wu, W.; Yang, Y.; Liu, Y.; Li, C.; Meng, W.; Zhang, R.; Song, X.; Wang, C. Rheological properties of high-asphalt-content emulsified asphalt. Constr. Build. Mater. 2024, 419, 135511. [Google Scholar] [CrossRef]

- Dubois, E.; Mehta, Y.; Nolan, A. Correlation between multiple stress creep recovery (MSCR) results and polymer modification of binder. Constr. Build. Mater. 2014, 65, 184–190. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).