Enhancing the Surface Integrity of a Laser Powder Bed Fusion Inconel 718 Alloy by Tailoring the Microstructure and Microrelief Using Various Finishing Methods

Abstract

1. Introduction

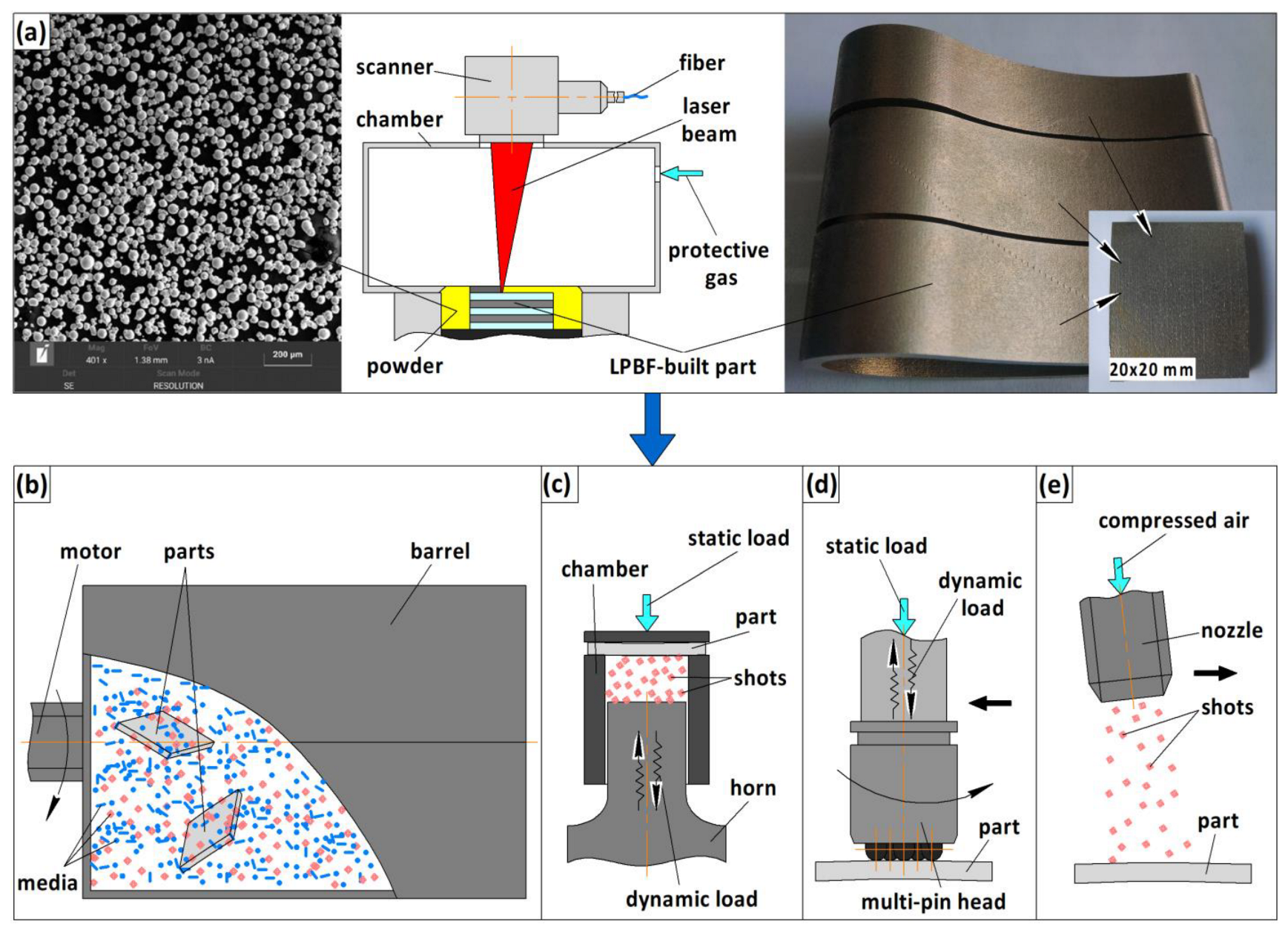

2. Materials and Methods

2.1. Specimen Additive Manufacturing

2.2. Specimen Post-Processing

2.3. Specimen Characterization

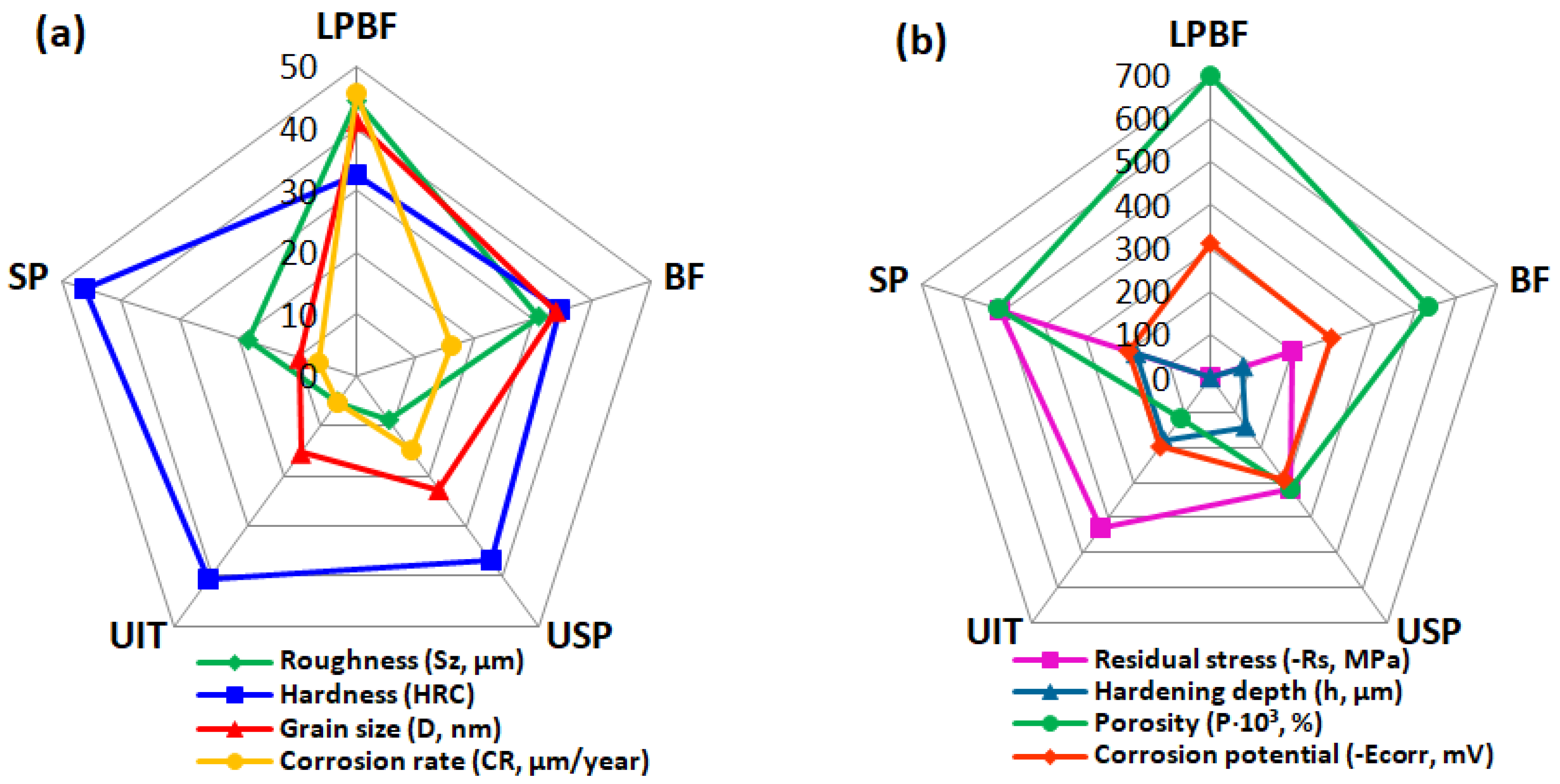

3. Results and Discussions

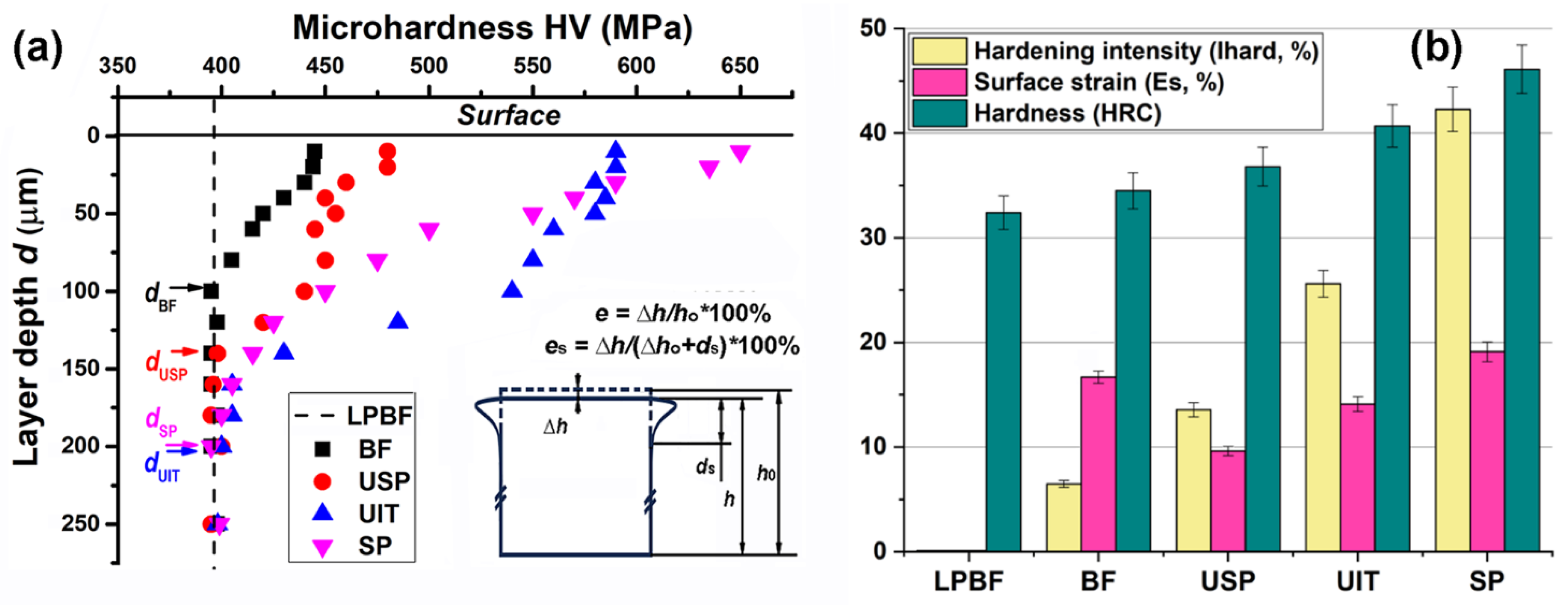

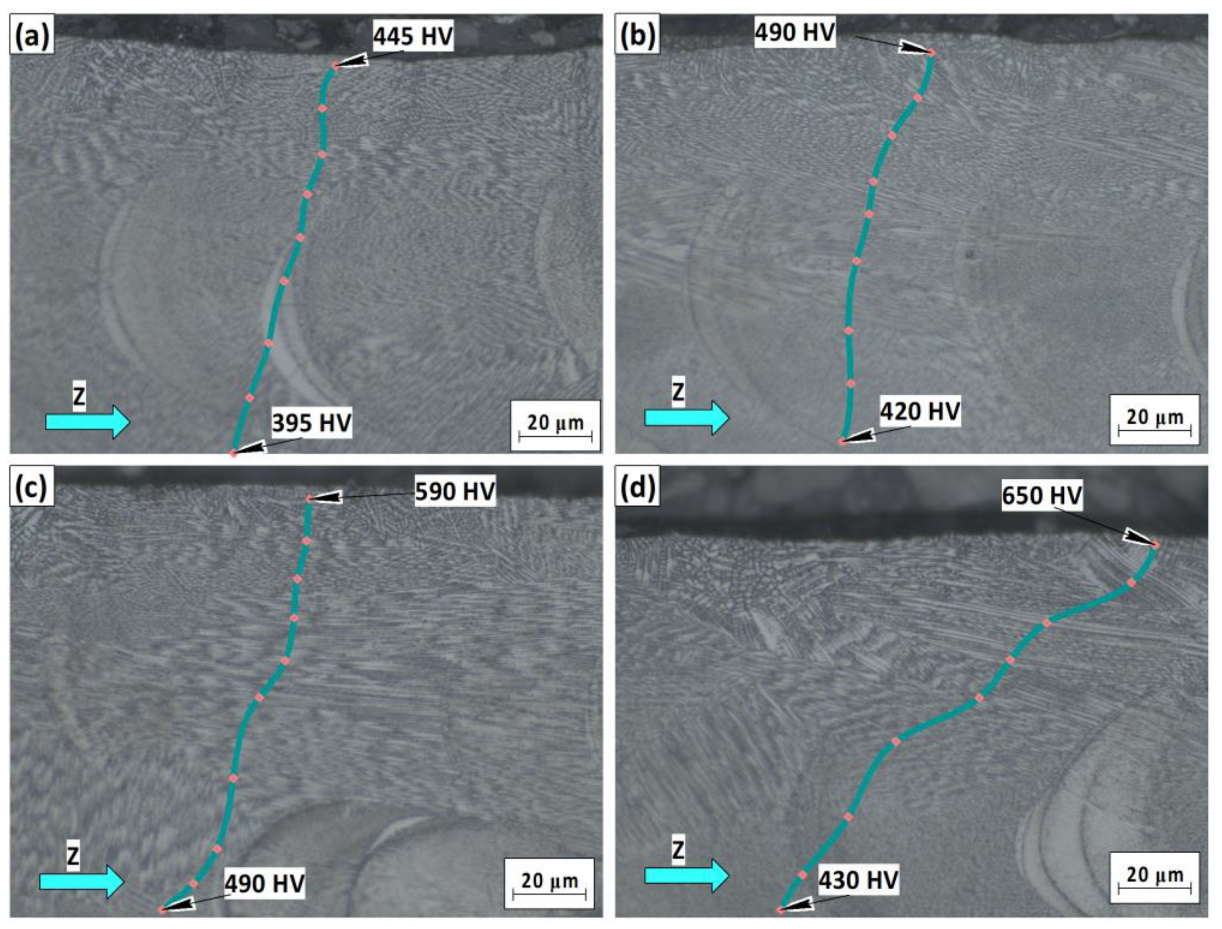

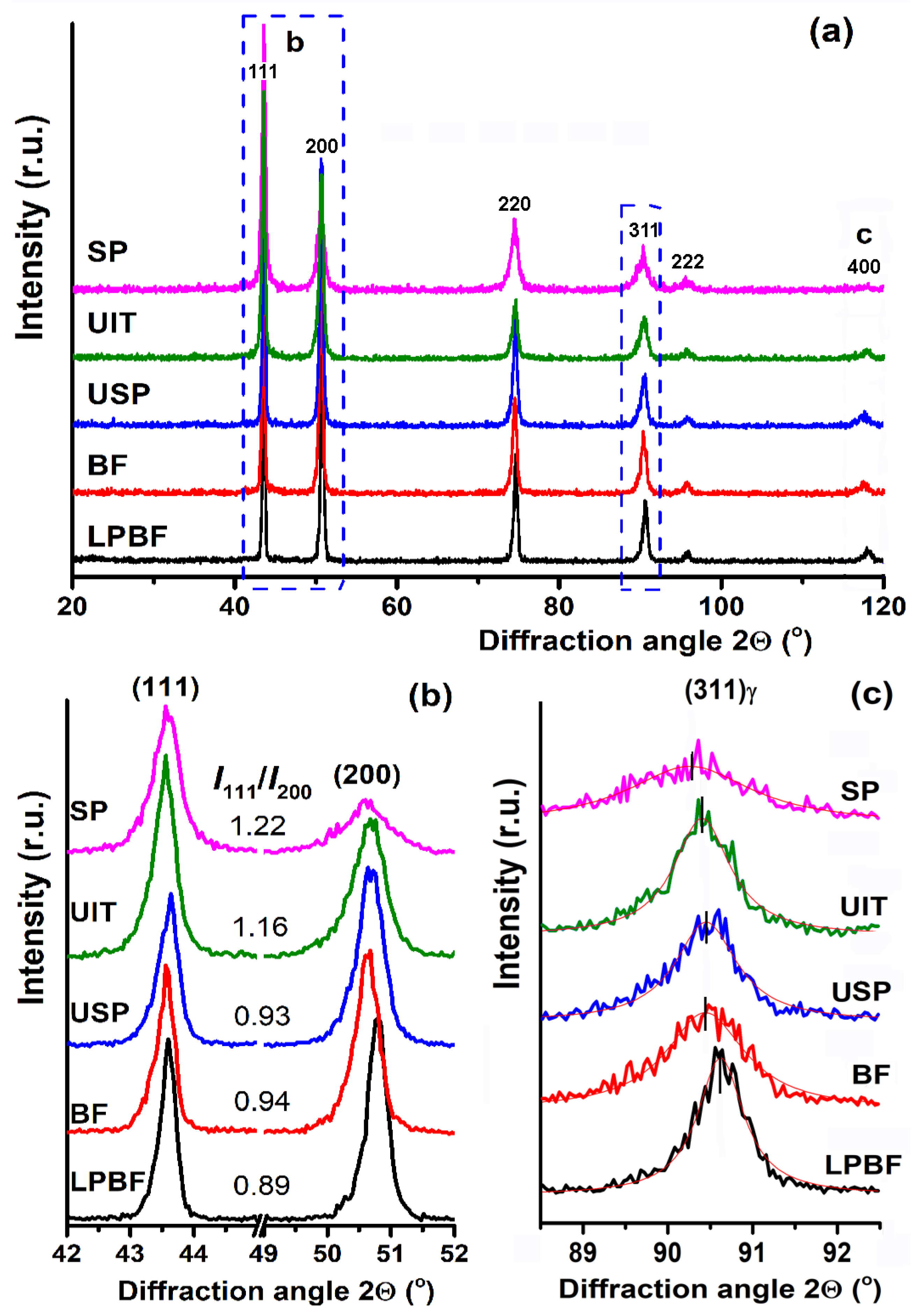

3.1. Surface Strain and Hardening Intensity

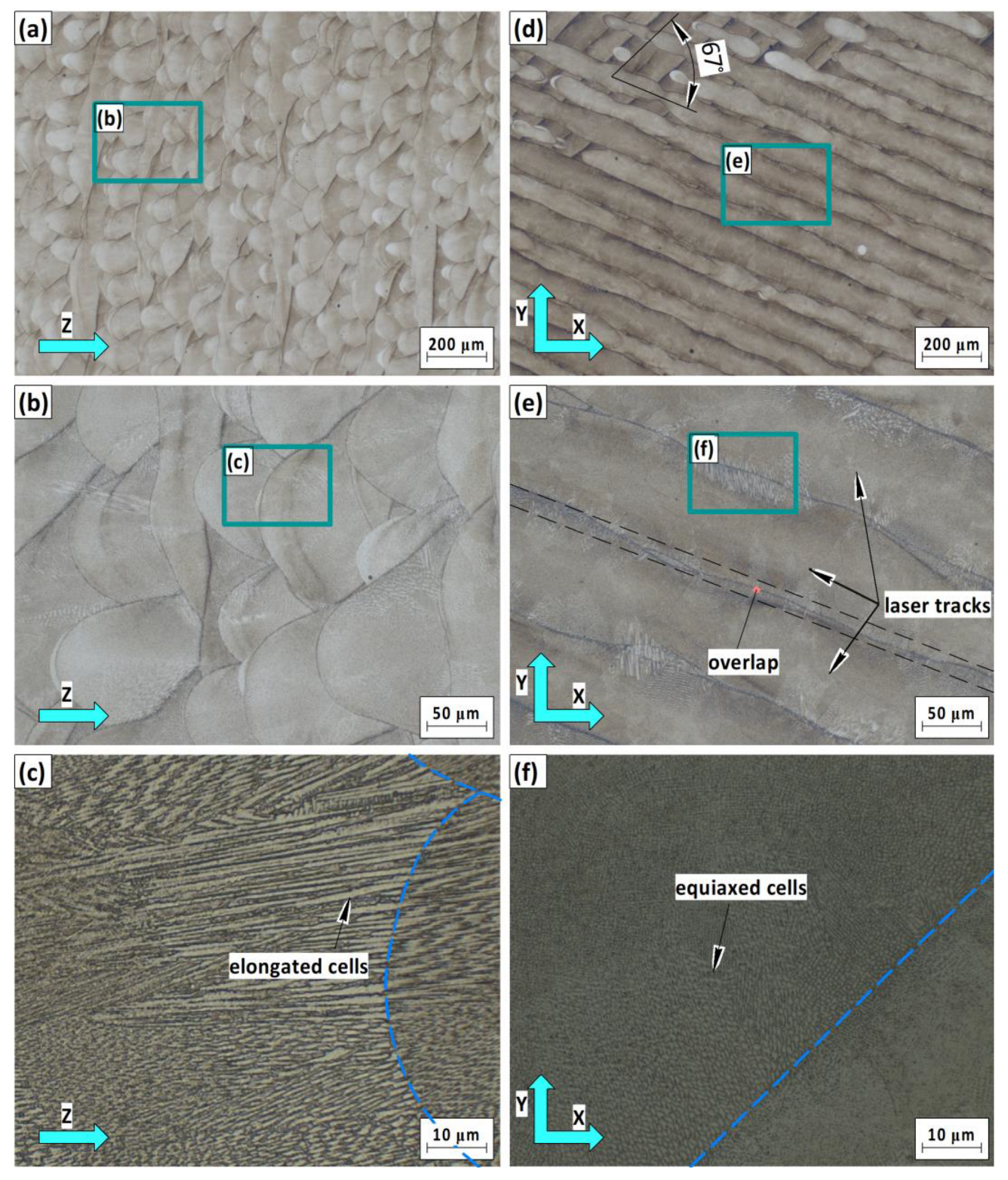

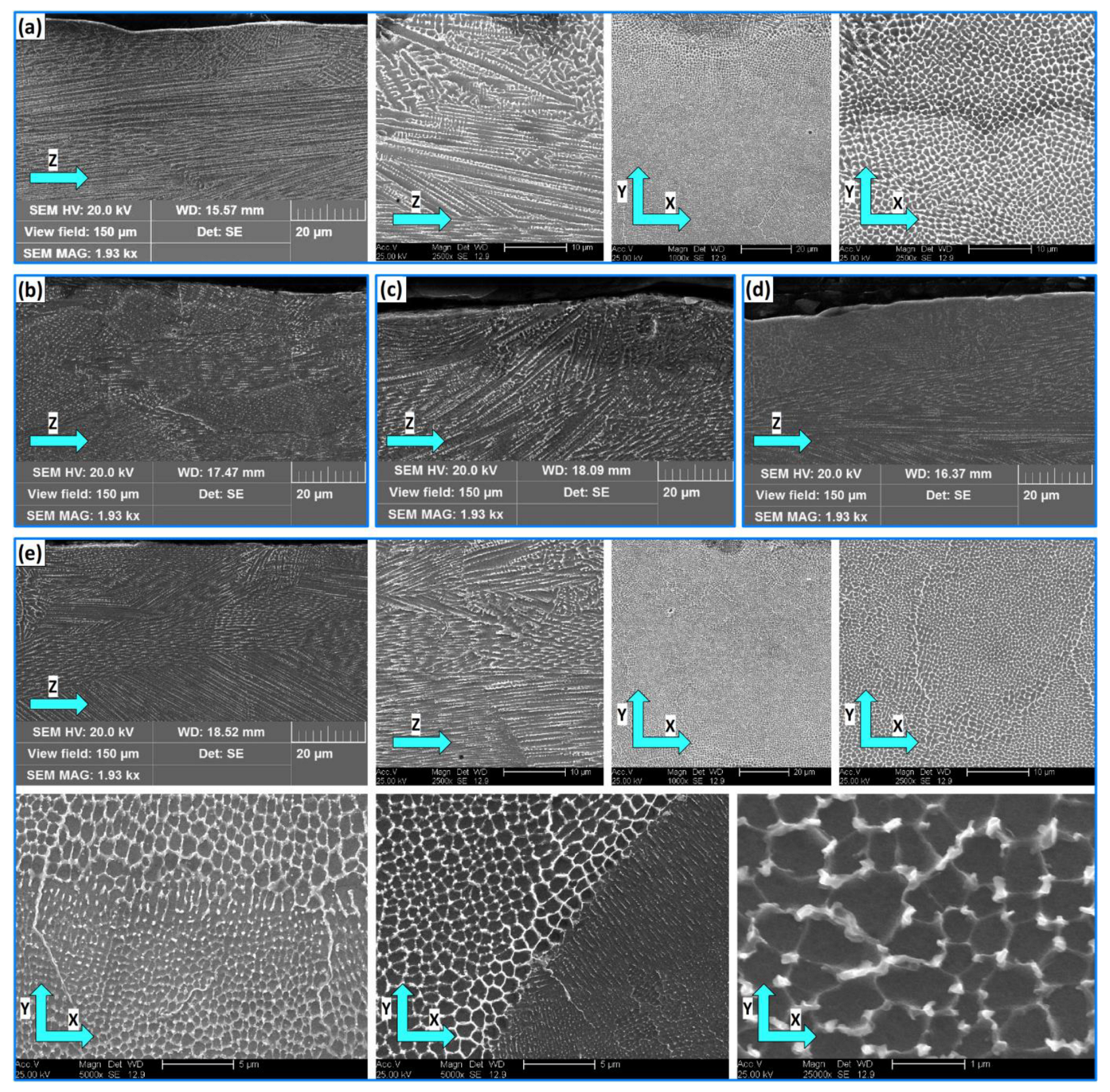

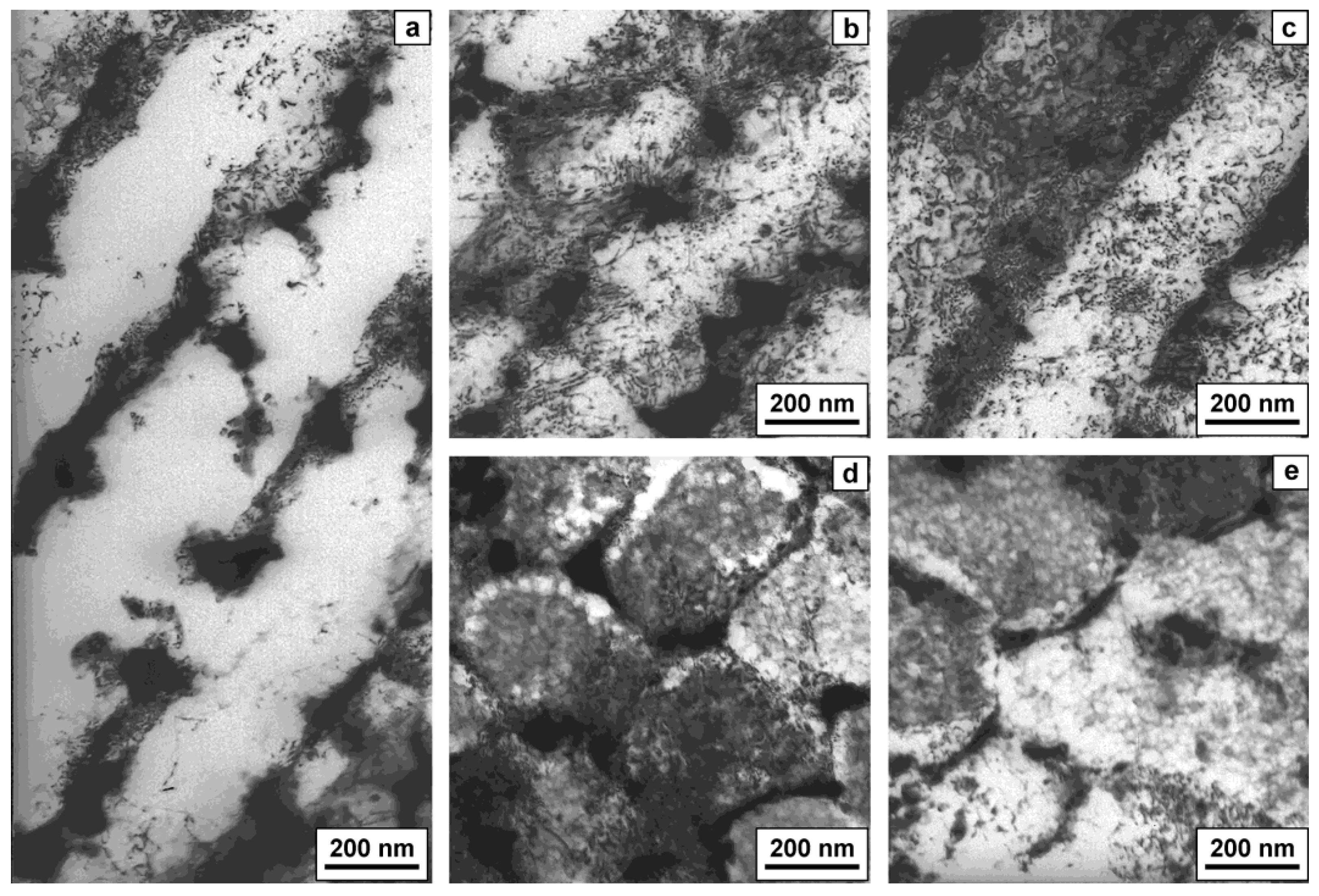

3.2. Microstructure and Microhardness

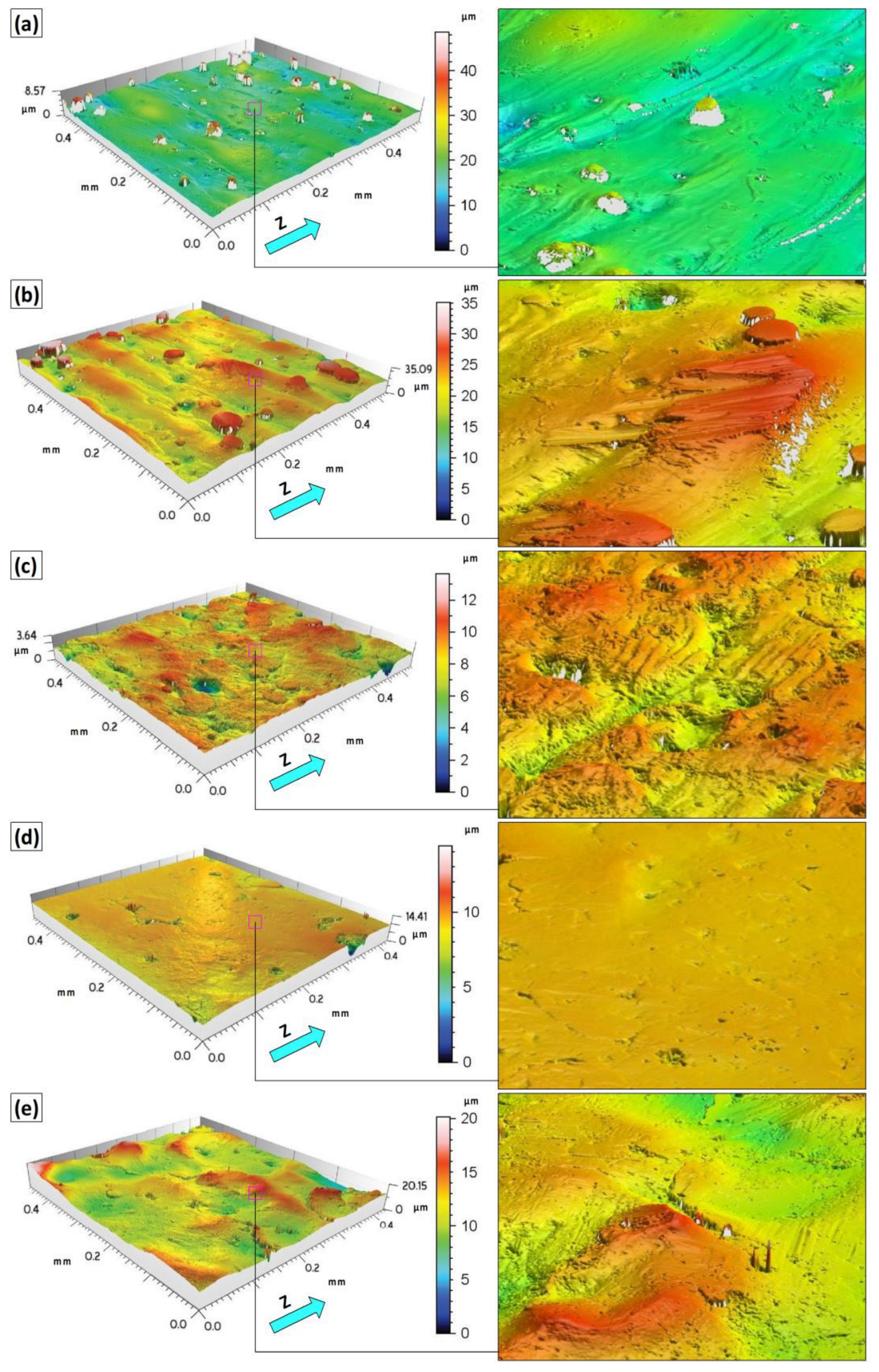

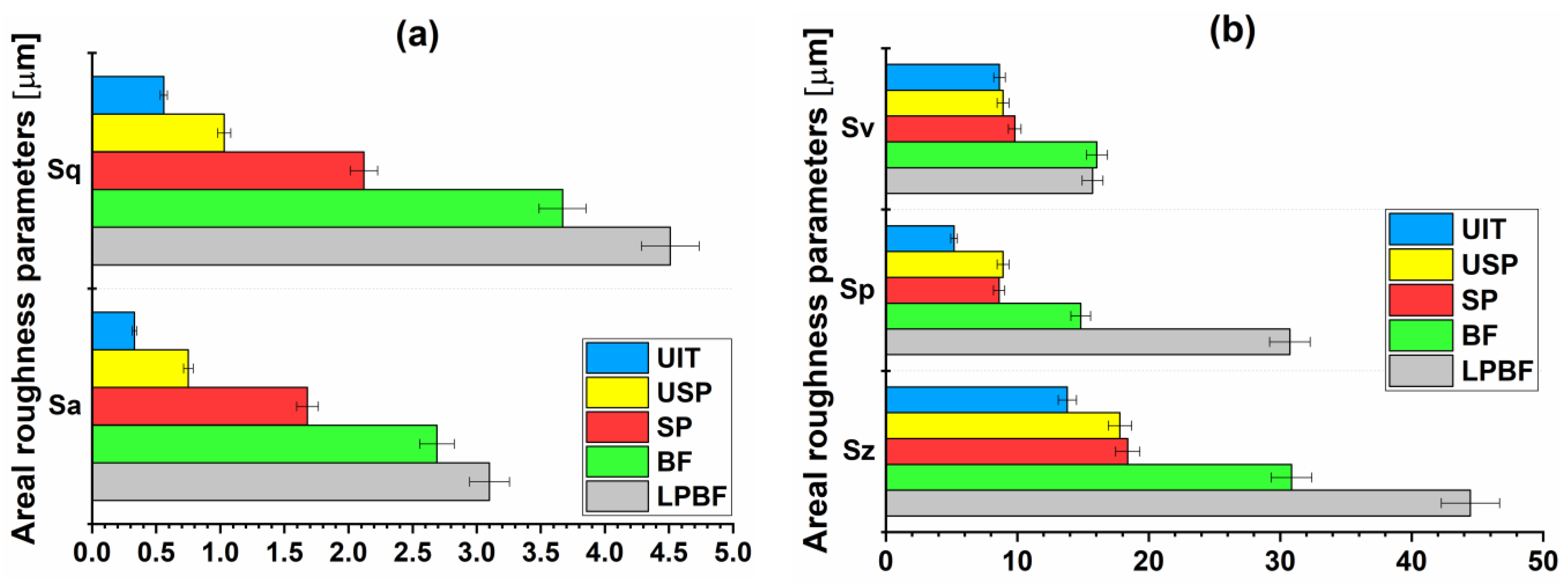

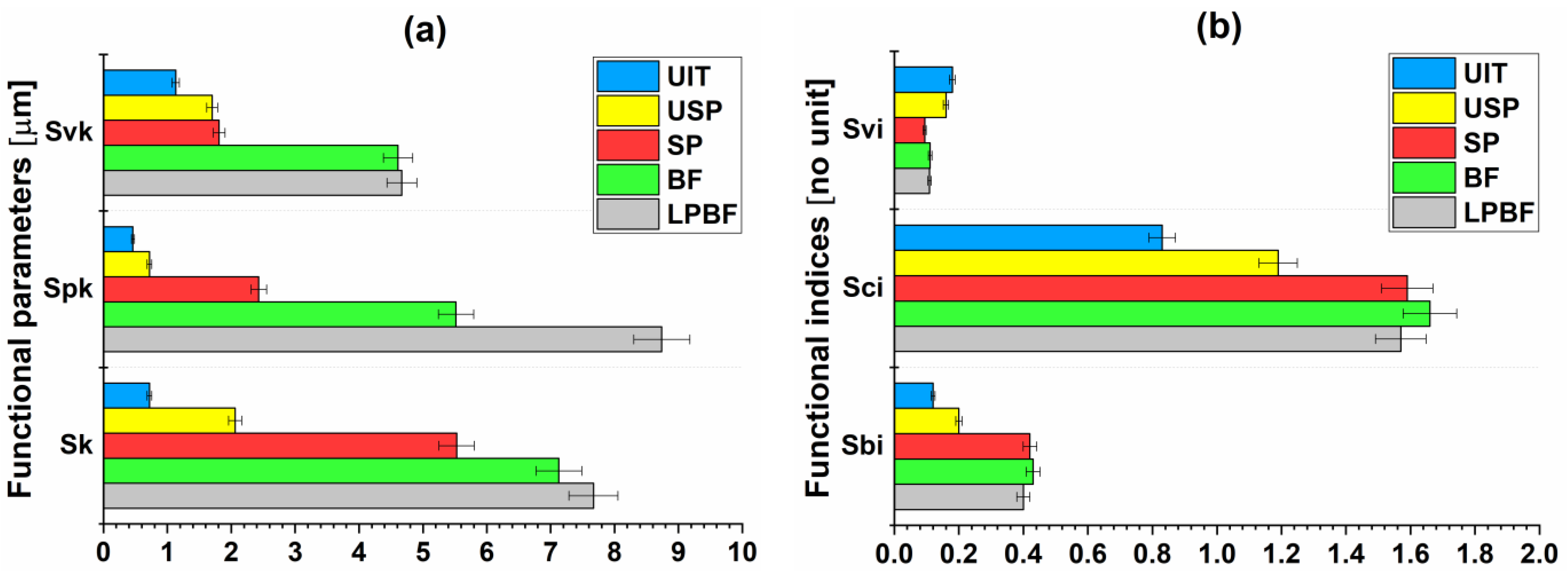

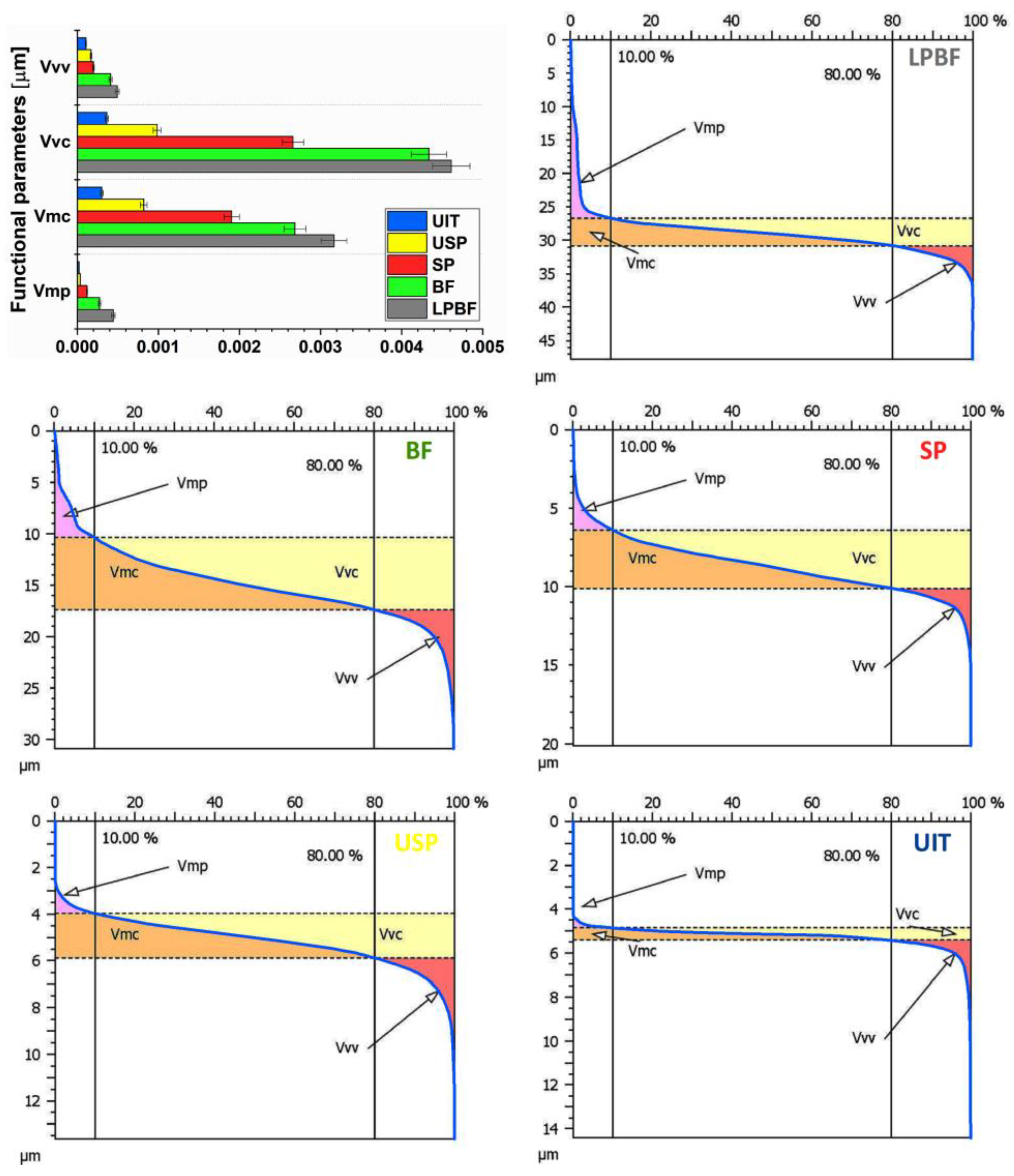

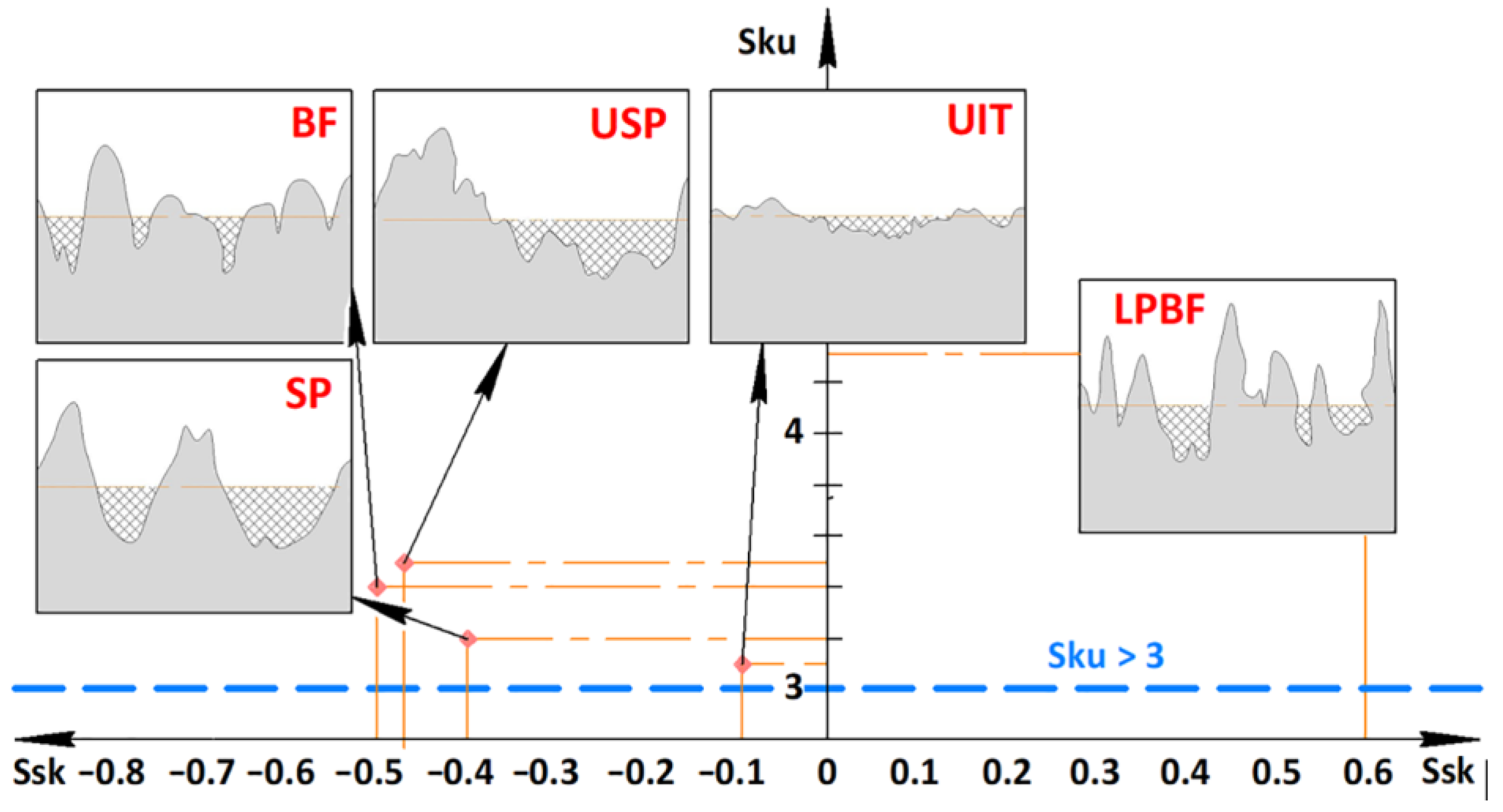

3.3. Surface Microrelief

3.4. Corrosion Resistance Behavior

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| BF | Barrel finishing |

| CSA | Coherent scattering areas |

| CSL | Coincide site lattice |

| DMLS | Direct metal laser sintering |

| EBM | Electron beam melting |

| EDM | Electrical discharge machining |

| FCC | Face-centered cubic |

| HFMI | High-frequency mechanical impact |

| HRC | Hardness Rockwell C |

| HV | Hardness Vickers |

| LMD | Laser metal deposition |

| LOM | Light optical microscopy |

| LPBF | Laser powder bed fusion |

| SEM | Scanning electron microscopy |

| SLM | Selective laser melting |

| SP | Shot peening |

| TEM | Transmission electron microscopy |

| UIT | Ultrasonic impact treatment |

| USP | Ultrasonic shot peening |

| XRD | X-ray diffraction |

References

- Volpato, G.M.; Tetzlaff, U.; Fredel, M.C. A comprehensive literature review on laser powder bed fusion of Inconel superalloys. Addit. Manuf. 2022, 55, 102871. [Google Scholar] [CrossRef]

- Frazier, W.E. Metal additive manufacturing: A review. J. Mater. Eng. Perform. 2014, 23, 1917–1928. [Google Scholar] [CrossRef]

- Karia, M.C.; Popat, M.A.; Sangani, K.B. Selective laser melting of Inconel super alloy—A review. AIP Conf. Proc. 2017, 1859, 020013–020020. [Google Scholar] [CrossRef]

- Bambach, M.; Sizova, I.; Kies, F.; Haase, C. Directed energy deposition of Inconel 718 powder, cold and hot wire using a six-beam direct diode laser set-up. Addit. Manuf. 2021, 47, 102269. [Google Scholar] [CrossRef]

- Zhu, L.; Xue, P.; Lan, Q.; Meng, G.; Ren, Y.; Yang, Z.; Xu, P.; Liu, Z. Recent research and development status of laser cladding: A review. Opt. Laser Technol. 2021, 138, 106915. [Google Scholar] [CrossRef]

- Scendo, M.; Staszewska-Samson, K.; Danielewski, H. Corrosion behavior of Inconel 625 coating produced by laser cladding. Coatings 2021, 11, 759. [Google Scholar] [CrossRef]

- Venturi, F.; Taylor, R. Additive manufacturing in the context of repeatability and reliability. J. Mater. Eng. Perform. 2023, 32, 6589–6609. [Google Scholar] [CrossRef]

- Taghian, M.; Mosallanejad, M.H.; Lannunziata, E.; Del Greco, G.; Iuliano, L.; Saboori, A. Laser powder bed fusion of metallic components: Latest progress in productivity, quality, and cost perspectives. J. Mater. Res. Technol. 2023, 27, 6484–6500. [Google Scholar] [CrossRef]

- Kan, W.H.; Chiu, L.N.S.; Lim, C.V.S.; Zhu, Y.; Tian, Y.; Jiang, D.; Huang, A. A critical review on the effects of process-induced porosity on the mechanical properties of alloys fabricated by laser powder bed fusion. J. Mater. Sci. 2022, 57, 9818–9865. [Google Scholar] [CrossRef]

- Song, L.; Zeng, G.; Xiao, H.; Xiao, X.; Li, S. Repair of 304 stainless steel by laser cladding with 316L stainless steel powders followed by laser surface alloying with WC powders. J. Manuf. Process. 2016, 24, 116–124. [Google Scholar] [CrossRef]

- Sanchez, S.; Smith, P.; Xu, Z.; Gaspard, G.; Hyde, C.J.; Wits, W.W.; Ashcroft, I.A.; Chen, H.; Clare, A.T. Powder bed fusion of nickel-based superalloys: A review. Int. J. Mach. Tools Manuf. 2021, 165, 103729. [Google Scholar] [CrossRef]

- Lesyk, D.A.; Martinez, S.; Mordyuk, B.N.; Dzhemelinskyi, V.V.; Lamikiz, A.; Prokopenko, G.I. Post-processing of the Inconel 718 alloy parts fabricated by selective laser melting: Effects of mechanical surface treatments on surface topography, porosity, hardness and residual stress. Surf. Coat. Technol. 2020, 381, 125136. [Google Scholar] [CrossRef]

- Lesyk, D.A.; Martinez, S.; Dzhemelinskyi, V.V.; Stamann, O.; Mordyuk, B.N.; Lamikiz, A. Surface polishing of laser powder bed fused superalloy components by magnetic post-treatment. In Proceedings of the NAP 2020, Sumy, Ukraine, 9–13 November 2020; pp. 02SAMA17-1–02SAMA17-4. [Google Scholar] [CrossRef]

- Osoba, L.O.; Oladoye, A.M.; Ogbonna, V.E. Corrosion evaluation of superalloys Haynes and Inconel 718 in hydrochloric acid. J. Alloys Compd. 2019, 804, 376–384. [Google Scholar] [CrossRef]

- Lesyk, D.A.; Martinez, S.; Mordyuk, B.N.; Grochala, D.; Lamikiz, A. Functionality-related performance of surface microrelief evaluation in ultrasonically and shot peened Inconel 718 alloy manufactured by laser powder bed fusion process. In New Technologies, Development and Application VII. NT 2024; Lecture Notes in Networks and Systems; Karabegović, I., Ed.; Springer: Cham, Switzerland, 2025; Volume 1069, pp. 201–211. [Google Scholar] [CrossRef]

- Thiede, T.; Cabeza, S.; Mishurova, T.; Kromm, A.; Bode, J.; Haberland, C.; Bruno, G. Residual stress in selective laser melted Inconel 718: Influence of the removal from base plate and deposition hatch length. Mater. Perform. Character. 2017, 7, 0119–0138. [Google Scholar] [CrossRef]

- Fardan, A.; Klement, U.; Brodin, H.; Hryna, E. Effect of part thickness and build angle on the microstructure, surface roughness, and mechanical properties of additively manufactured IN-939. Metall. Mater. Trans. A 2023, 54, 1792–1807. [Google Scholar] [CrossRef]

- Koutiri, I.; EPessard, E.; Peyre, P.; Amlou, O.; De Terris, T. Influence of SLM process parameters on the surface finish, porosity rate and fatigue behavior of as-built Inconel 625 parts. J. Mater. Process. Technol. 2018, 255, 536–546. [Google Scholar] [CrossRef]

- Calignano, F.; Minetola, P. Influence of process parameters on the porosity, accuracy, roughness, and support structures of hastelloy X produced by laser powder bed fusion. Materials 2019, 12, 3178. [Google Scholar] [CrossRef]

- Sun, W.; Ma, Y.; Li, P.; Zhang, W. Residual stress distribution and Its effect on fatigue crack path of laser powder bed fusion Ti6Al4V alloy. Aerospace 2025, 12, 103. [Google Scholar] [CrossRef]

- Witkin, D.B.; Patel, D.N.; Helvajian, H.; Steffeney, L.; Diaz, A. Surface treatment of powder-bed fusion additive manufactured metals for improved fatigue life. J. Mater. Eng. Perform. 2019, 28, 681–692. [Google Scholar] [CrossRef]

- Lesyk, D.A.; Dzhemelinskyi, V.V.; Martinez, S.; Grzesiak, D.; Mordyuk, B.N. Functional evaluation of surface texture in laser selective melted Inconel 718 alloy parts processed by shot peening. In Advanced Manufacturing Processes IV; Tonkonogyi, V., Ed.; InterPartner 2022; Lecture Notes in Mechanical Engineering; Springer: Cham, Switzerland, 2023; pp. 294–305. [Google Scholar] [CrossRef]

- Lesyk, D.A.; Martinez, S.; Pedash, O.O.; Mordyuk, B.N.; Dzhemelinskyi, V.V.; Lamikiz, A. Nickel superalloy turbine blade parts printed by laser powder bed fusion: Thermo-mechanical post-processing for enhanced surface integrity and precipitation strengthening. J. Mater. Eng. Perform. 2022, 31, 6283–6299. [Google Scholar] [CrossRef]

- Maleki, E.; Unal, O.; Guagliano, M.; Bagherifard, S. The effects of shot peening, laser shock peening and ultrasonic nanocrystal surface modification on the fatigue strength of Inconel 718. Mater. Sci. Eng. A 2021, 810, 141029. [Google Scholar] [CrossRef]

- Kumar, H.; Singh, G. Parametric studies on finishing of inconel 718 flat surfaces with chemically assisted magnetic abrasive finishing process. Mater. Today Proc. 2021, 37, 3262–3269. [Google Scholar] [CrossRef]

- Mohammadian, N.; Turenne, S.; Brailovsk, V. Surface finish control of additively-manufactured Inconel 625 components using combined chemical-abrasive flow polishing. J. Mater. Process Technol. 2018, 252, 728–738. [Google Scholar] [CrossRef]

- Trdan, U.; Hocevar, M.; Gregorcic, P. Transition from superhydrophilic to superhydrophobic state of laser textured stainless steel surface and its effect on corrosion resistance. Corros. Sci. 2017, 123, 21–26. [Google Scholar] [CrossRef]

- Obeidi, M.A.; Conway, A.; Mussatto, A.; Dogu, M.N.; Sreenilayam, S.P.; Ayu, H.; Ahad, I.U.; Brabazon, D. Effects of powder compression and laser re-melting on the microstructure and mechanical properties of additively manufactured parts in laser-powder bed fusion. Results Mater. 2022, 13, 100264. [Google Scholar] [CrossRef]

- Metelkova, J.; Vanmunster, L.; Haitjema, H.; Ordnung, D.; Kruth, J.-P.; Van Hooreweder, B. Hybrid dual laser processing for improved quality of inclined up-facing surfaces in laser powder bed fusion of metals. J. Mater. Process. Technol. 2021, 298, 117263. [Google Scholar] [CrossRef]

- Balantič, D.A.S.; Donik, Č.; Podgornik, B.; Kocijan, A.; Godec, M. Improving the surface properties of additive-manufactured Inconel 625 by plasma nitriding. Surf. Coat. Technol. 2023, 452, 129130. [Google Scholar] [CrossRef]

- Karimbaev, R.M.; Cho, I.S.; Pyun, Y.S.; Amanov, A. Effect of ultrasonic nanocrystal surface modification treatment at room and high temperatures on the high-frequency fatigue behavior of Inconel 718 fabricated by laser metal deposition. Metals 2022, 12, 515. [Google Scholar] [CrossRef]

- Lee, S.J.; Shao, S.; Wells, D.N.; Zetek, M.; Kepka, M.; Shamsaei, N. Fatigue behavior and modeling of additively manufactured IN718: The effect of surface treatments and surface measurement techniques. J. Mater. Process. Technol. 2022, 302, 117475. [Google Scholar] [CrossRef]

- Karabulut, Y.; Kaynak, Y.; Sharif, S.; Suhaimi, M.A. Effect of machining and drag finishing on the surface integrity and mechanical properties of Inconel 718 alloys fabricated by laser powder bed fusion additive manufacturing. Mater. Sci. Eng. Technol. 2022, 53, 109–118. [Google Scholar] [CrossRef]

- Boschetto, A.; Bottini, L.; Macera, L.; Veniali, F. Post-processing of complex SLM parts by barrel finishing. Appl. Sci. 2020, 10, 1382. [Google Scholar] [CrossRef]

- Khorasani, M.; Gibson, I.; Ghasemi, A.H.; Brandt, M.; Leary, M. On the role of wet abrasive centrifugal barrel finishing on surface enhancement and material removal rate of LPBF stainless steel 316L. J. Manuf. Process. 2020, 59, 523–534. [Google Scholar] [CrossRef]

- Nalli, F.; Bottini, L.; Bottini, L.; Cortese, L.; Veniali, F. Effect of industrial heat treatment and barrel finishing on the mechanical performance of Ti6Al4V processed by selective laser melting. Appl. Sci. 2020, 10, 2280. [Google Scholar] [CrossRef]

- Mahmood, M.A.; Chioibasu, D.; Rehman, A.U.; Mihai, S.; Popescu, A.C. Post-processing techniques to enhance the quality of metallic parts produced by additive manufacturing. Metals 2022, 12, 77. [Google Scholar] [CrossRef]

- Chen, L.; Xie, J.; Li, Y.; Yu, G.; Zhang, X.; Ren, X. Effect of laser/ultrasonic shock peening on the microstructure and mechanical properties of nickel-based superalloys prepared by Powder Bed Fusion Laser Beam (PBF-LB). J. Mater. Res. Technol. 2024, 33, 7668–7680. [Google Scholar] [CrossRef]

- Lesyk, D.A.; Martinez, S.; Lamikiz, A. Effects of Ni-based powder reuse on porosity, surface quality and reproducibility of thin-walled structures in Laser Powder Bed Fusion process. Procedia CIRP 2024, 124, 89–92. [Google Scholar] [CrossRef]

- Sarafan, S.; Wanjara, P.; Pelletier, R.; Atabay, S.E.; Gholipour, J.; Soost, J.; Amos, R.; Patnaik, P. Elevated-temperature tensile behavior and properties of Inconel 718 fabricated by in-envelope additive–subtractive hybrid manufacturing and post-process precipitation hardening. J. Manuf. Mater. Process. 2024, 8, 297. [Google Scholar] [CrossRef]

- Lesyk, D.A.; Martinez, S.; Pedash, O.O.; Dzhemelinskyi, V.V.; Lamikiz, A. Porosity and surface defects characterization of hot isostatically pressed Inconel 718 alloy turbine blades printed by 3D laser metal fusion technology. MRS Adv. 2022, 7, 197–201. [Google Scholar] [CrossRef]

- Lesyk, D.A.; Martinez, S.; Mordyuk, B.N.; Pedash, O.O.; Dzhemelinskyi, V.V.; Lamikiz, A. Ultrasonic surface post-processing of hot isostatic pressed and heat treated superalloy parts manufactured by laser powder bed fusion. Addit. Manuf. Lett. 2022, 3, 100063. [Google Scholar] [CrossRef]

- Lesyk, D.A.; Martinez, S.; Pedash, O.O.; Dzhemelinskyi, V.V.; Mordyuk, B.N. Combined thermo-mechanical techniques for post-processing of the SLM-printed Ni-Cr-Fe alloy parts. In Advances in Design, Simulation and Manufacturing III; DSMIE 2018; Lecture Notes in Mechanical Engineering; Ivanov, V., Ed.; Springer: Cham, Switzerland, 2019; pp. 97–107. [Google Scholar] [CrossRef]

- Lesyk, D.A.; Dzhemelinskyi, V.V.; Martinez, S.; Mordyuk, B.N.; Lamikiz, A. Surface shot peening post-processing of Inconel 718 alloy parts printed by laser powder bed fusion additive manufacturing. J. Mater. Eng. Perform. 2021, 30, 6982–6995. [Google Scholar] [CrossRef]

- Chan, H.L.; Ruan, H.H.; Chen, A.Y.; Lu, J. Optimization of the strain rate to achieve exceptional mechanical properties of 304 stainless steel using high speed ultrasonic surface mechanical attrition treatment. Acta Mater. 2010, 58, 5086–5096. [Google Scholar] [CrossRef]

- Dai, K.; Villegas, J.; Stone, Z.; Shaw, L. Finite element modeling of the surface roughness of 5052 Al alloy subjected to a surface severe plastic deformation process. Acta Materialia 2004, 52, 5771–5782. [Google Scholar] [CrossRef]

- Magini, M.; Iasonna, A.; Padella, F. Ball milling: An experimental support to the energy transfer evaluated by the collision model. Scr. Mater. 1996, 34, 13–19. [Google Scholar] [CrossRef]

- Suryanarayana, C.; Norton, M.G. X-Ray Diffraction: A Practical Approach; Plenum: New York, NY, USA, 1998. [Google Scholar] [CrossRef]

- Pawlus, P.; Reizer, R.; Wieczorowski, M. Functional importance of surface texture parameters. Materials 2021, 14, 5326. [Google Scholar] [CrossRef]

- Choi, J.-P.; Shin, G.-H.; Yang, S.; Yang, D.-Y.; Lee, J.-S.; Brochu, M.; Yu, J.-H. Densification and microstructural investigation of Inconel 718 parts fabricated by selective laser melting. Powder Technol. 2017, 310, 60–66. [Google Scholar] [CrossRef]

- Osório, W.R.; Freire, C.M.; Garcia, A. The effect of the dendritic microstructure on the corrosion resistance of Zn–Al alloys. J. Alloys Compd. 2005, 397, 179–191. [Google Scholar] [CrossRef]

- Lesyk, D.A.; Mordyuk, B.M.; Martinez, S.; Dzhemelinskyi, V.V.; Grzesiak, D.; Grochala, D.; Lamikiz, A. Laser-based additive manufacturing and mechanical surface post-processing: Comparison of barrel finishing, shot and ultrasonic peening for corrosion resistance improvement of superalloy. Lasers Manuf. Mater. Process. 2023, 10, 702–734. [Google Scholar] [CrossRef]

- Tang, Y.; Shen, Y.; Qiao, Y.; Yang, L.; Chen, J.; Lu, D.; Zhang, Z. Corrosion behavior of a selective laser melted Inconel 718 alloy in a 3.5 wt.% NaCl solution. J. Mater. Eng. Perform. 2021, 30, 5506–5514. [Google Scholar] [CrossRef]

- Thuneman, T.; Raja, K.S.; Charit, I. Room temperature corrosion behavior of selective laser melting (SLM)-processed Ni-Fe superalloy (Inconel 718) in 3.5% NaCl solution at different pH conditions: Role of microstructures. Crystals 2024, 14, 89. [Google Scholar] [CrossRef]

- Mesta, B.L.V.; Taylor, H.C.; Mireles, J.; Borup, D.; Wicker, R.B. User-enabled installation qualification method for laser-based powder bed fusion of metals (PBF-LB/M) machine scanner subsystem. J. Mater. Eng. Perform. 2025, 100, 104694. [Google Scholar] [CrossRef]

- Adegoke, O.; Andersson, J.; Brodin, H.; Pederson, R.; Harlin, P. Influence of laser powder bed fusion process parameters on the microstructure and cracking susceptibility of nickel-based superalloy alloy 247LC. Scripta Mater. 2022, 13, 100256. [Google Scholar] [CrossRef]

- Zhang, S.Y.; Lin, X.; Wang, L.L.; Yu, X.B.; Hu, Y.L.; Yang, H.; Lei, L.M.; Huang, W.D. Strengthening mechanisms in selective laser-melted Inconel718 superalloy. Mater. Sci. Eng. A 2021, 812, 141145. [Google Scholar] [CrossRef]

- Munther, M.; Tajyar, A.; Holtham, N.; Hackel, L.; Beheshti, A.; Davami, K. An investigation into the mechanistic origin of thermal stability in thermal-microstructural-engineered additively manufactured Inconel 718. Vacuum 2022, 199, 110971. [Google Scholar] [CrossRef]

- Zeng, Q.; Qin, Y.; Chang, W.; Luo, X. Correlating and evaluating the functionality-related properties with surface texture parameters and specific characteristics of machined components. Int. J. Mech. Sci. 2018, 149, 62–72. [Google Scholar] [CrossRef]

- Marteau, J.; Bigerelle, M.; Mazeran, P.-E.; Bouvier, S. Relation between roughness and processing conditions of AISI316L stainless steel treated by ultrasonic shot peening. Tribol. Int. 2015, 82, 319–329. [Google Scholar] [CrossRef]

- To, D.; Umezawa, O.; Shinohara, T. Detection of surface roughness evolution of carbon steel subjected to outdoor exposure and constant humidity corrosion tests. Mater. Trans. 2018, 59, 1239–1243. [Google Scholar] [CrossRef]

- Carmona-Hernández, A.; Orozco-Cruz, R.; Carpio-Santamaria, F.A.; Campechano-Lira, C.; López-Huerta, F.; Mejía-Sánchez, E.; Contreras, A.; Galván-Martínez, A. Electrochemical noise analysis of the X70 pipeline steel under stress conditions using symmetrical and asymmetrical electrode systems. Metals 2022, 12, 1545. [Google Scholar] [CrossRef]

- Maamoun, A.H.; Elbestawi, M.A.; Veldhuis, S.C. Influence of shot peening on AlSi10Mg parts fabricated by additive manufacturing. J. Manuf. Mater. Process. 2018, 2, 40. [Google Scholar] [CrossRef]

- Xing, X.; Duan, X.; Jiang, T.; Wang, J.; Jiang, F. Ultrasonic peening treatment used to improve stress corrosion resistance of AlSi10Mg components fabricated using selective laser melting. Metals 2019, 9, 103. [Google Scholar] [CrossRef]

- Ralston, K.D.; Birbilis, N. Effect of grain size on corrosion: A review. Corrosion 2010, 66, 075005-1–075005-13. [Google Scholar] [CrossRef]

- Zhang, W.; Huo, W.T.; Lu, J.W.; Hu, J.J.; Zhang, L.C.; Zhang, Y.S. Significantly improved corrosion properties of ultrafine-grained pure Mg processed by sliding friction treatment. JOM 2018, 70, 2596–2602. [Google Scholar] [CrossRef]

- Guo, C.; Wang, J.C.; Lu, H.X.; Wang, Y.M.; Bai, J.; Li, G.; Yin, Y.; Yao, L.; Zhu, Q.; Lu, J. Enhanced oxidation resistance of additively manufactured Inconel 718 superalloy by surface mechanical attrition treatment. Corrosion Sci. 2025, 246, 112719. [Google Scholar] [CrossRef]

- Wu, X.; Qi, Z.; Zhou, Z.; Zhang, H.; Wu, W.; Wang, Y. Surface grain refinement of 304L stainless steel by combined severe shot peening and reversion annealing treatment. Coatings 2020, 10, 470. [Google Scholar] [CrossRef]

- Wang, G.; Song, D.; Zhou, Z.; Klu, E.E.; Liu, Y.; Liang, N.; Jiang, J.; Sun, J.; Ma, A. Effect of ultrafine grains on the coating reaction and anticorrosion performance of anodized pure aluminum. Coating 2020, 10, 216. [Google Scholar] [CrossRef]

- Wasekar, N.P. The influence of grain size and triple junctions on corrosion behavior of nanocrystalline Ni and Ni-W alloy. Scripta Mater. 2022, 213, 114604. [Google Scholar] [CrossRef]

- Palumbo, G.; Aust, K.T.; Lehockey, E.M.; Erb, U.; Lin, P. On a More Restrictive Geometric Criterion for “Special” CSL Grain Boundaries. Scripta Mater. 1998, 38, 1685–1690. [Google Scholar] [CrossRef]

- Lin, Y.; Han, L.; Wang, G. Relationship between Σ3 boundaries, dislocation slip, and plasticity in pure nickel. Materials 2023, 16, 2853. [Google Scholar] [CrossRef]

- Palumbo, G.; Lehockey, E.M.; Lin, P. Application of microdiffraction in SEM for assessing intrinsic materials susceptibility to intergranular corrosion and stress corrosion cracking. Microsc. Microanal. 1997, 3, 573–574. [Google Scholar] [CrossRef]

- Palumbo, G.; Lehockey, E.M.; Lin, P. Applications for Grain Boundary Engineered Materials. JOM 1998, 50, 40–43. [Google Scholar] [CrossRef]

- Bettayeb, M.; Maurice, V.; Klein, L.H.; Lapeire, L.; Verbeken, K.; Marcus, P. Nanoscale intergranular corrosion and relation with grain boundary character as studied in situ on copper. J. Electrochem. Soc. 2018, 165, 835–841. [Google Scholar] [CrossRef]

| Finishing Method | Number of Balls/Pins | Impact Frequency, fi (Hz) | Treatment Duration, t (min) | Energy, E (mJ) | Accumulated Energy, ΣE (J/mm2) |

|---|---|---|---|---|---|

| BF | ~20 | ~1 | 240 | 1.6 | 1.15 |

| USP | 22 | ~22 | 5 | 5.6 | 2.03 |

| UIT | 7 | ~1000 | 2 | 2 | 4.2 |

| SP | ~100 | ~70 | 2 | 1.5 | 3.15 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lesyk, D.; Mordyuk, B.; Martinez, S.; Dzhemelinskyi, V.; Grochala, D.; Kotko, A.; Lamikiz, A. Enhancing the Surface Integrity of a Laser Powder Bed Fusion Inconel 718 Alloy by Tailoring the Microstructure and Microrelief Using Various Finishing Methods. Coatings 2025, 15, 425. https://doi.org/10.3390/coatings15040425

Lesyk D, Mordyuk B, Martinez S, Dzhemelinskyi V, Grochala D, Kotko A, Lamikiz A. Enhancing the Surface Integrity of a Laser Powder Bed Fusion Inconel 718 Alloy by Tailoring the Microstructure and Microrelief Using Various Finishing Methods. Coatings. 2025; 15(4):425. https://doi.org/10.3390/coatings15040425

Chicago/Turabian StyleLesyk, Dmytro, Bohdan Mordyuk, Silvia Martinez, Vitaliy Dzhemelinskyi, Daniel Grochala, Andriy Kotko, and Aitzol Lamikiz. 2025. "Enhancing the Surface Integrity of a Laser Powder Bed Fusion Inconel 718 Alloy by Tailoring the Microstructure and Microrelief Using Various Finishing Methods" Coatings 15, no. 4: 425. https://doi.org/10.3390/coatings15040425

APA StyleLesyk, D., Mordyuk, B., Martinez, S., Dzhemelinskyi, V., Grochala, D., Kotko, A., & Lamikiz, A. (2025). Enhancing the Surface Integrity of a Laser Powder Bed Fusion Inconel 718 Alloy by Tailoring the Microstructure and Microrelief Using Various Finishing Methods. Coatings, 15(4), 425. https://doi.org/10.3390/coatings15040425