Tensile Mechanical Properties and Failure Behavior Analysis of Three-Dimensional Woven Composite with Different Apertures and Braiding Angles

Abstract

:1. Introduction

2. Tensile Test of 3D Braided Composites

2.1. Material Selection

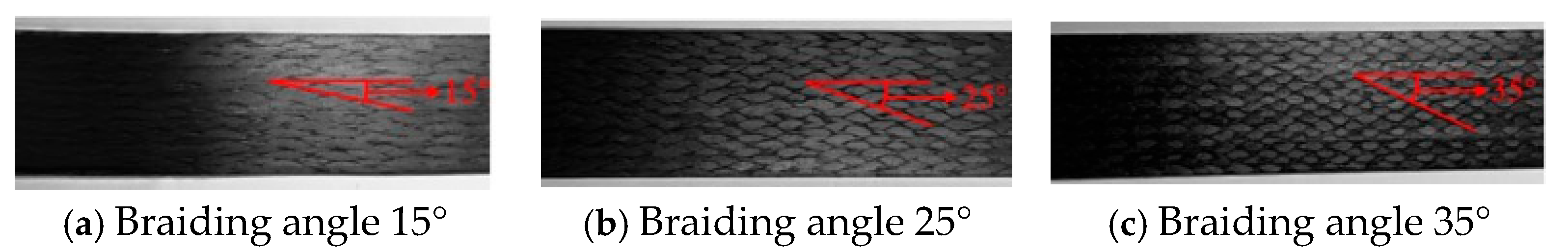

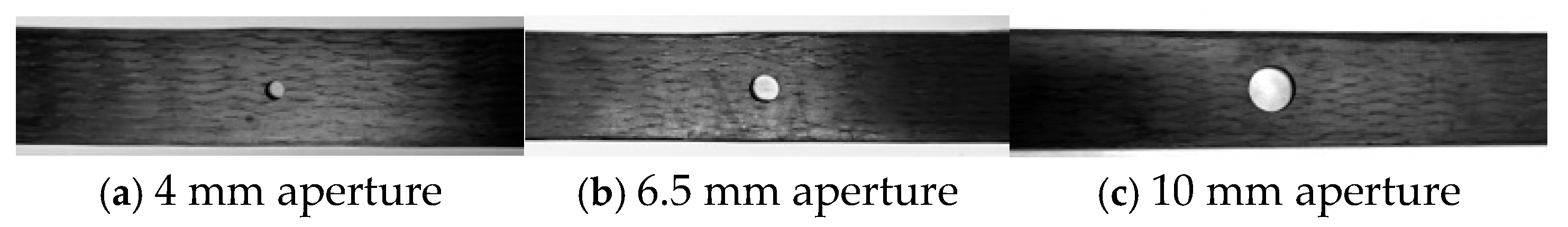

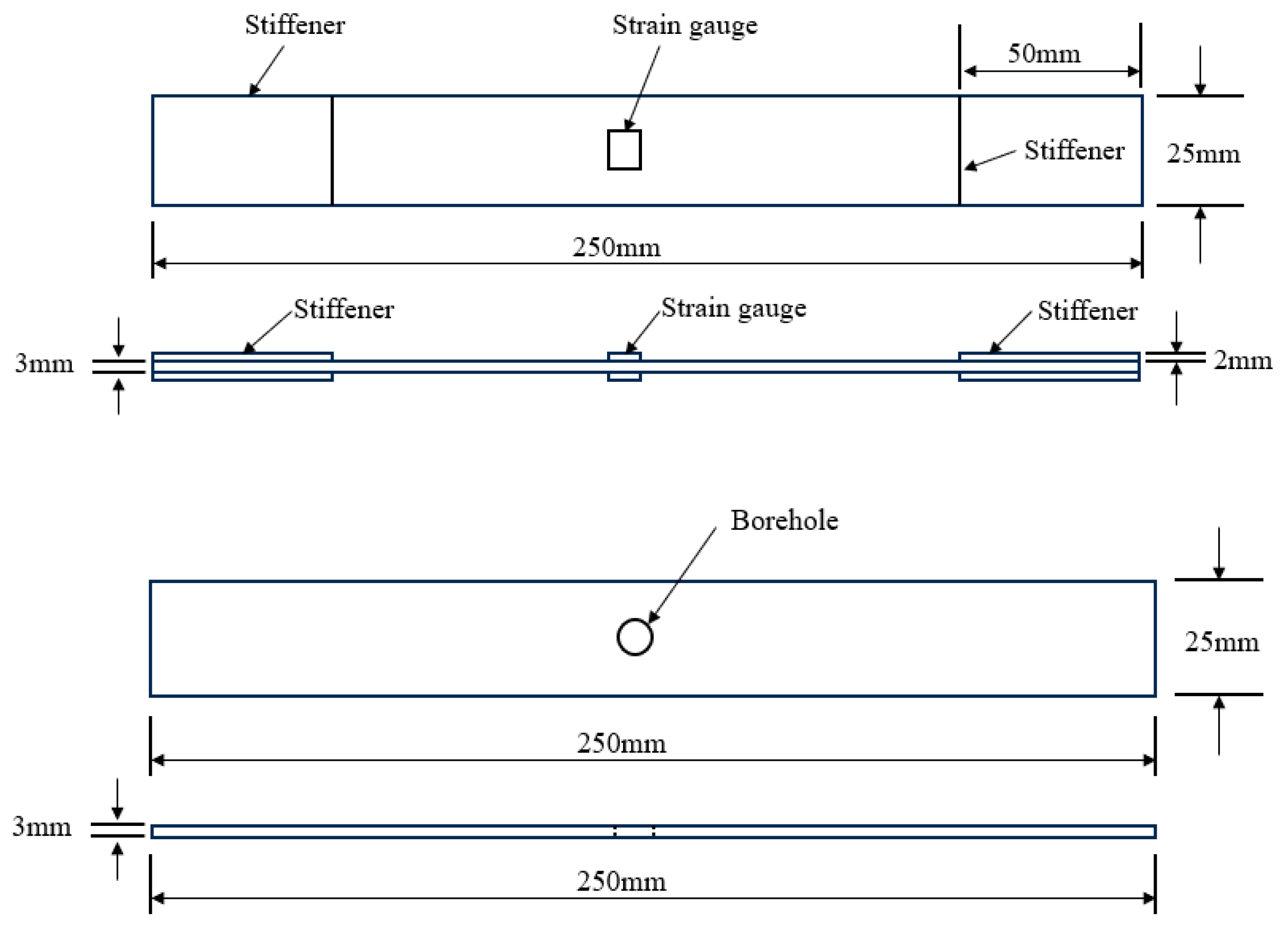

2.2. Prefabricated Part Design

2.3. Prefabricated Fiber Volume Fraction

2.4. Test Setup

3. Experimental Results and Discussion

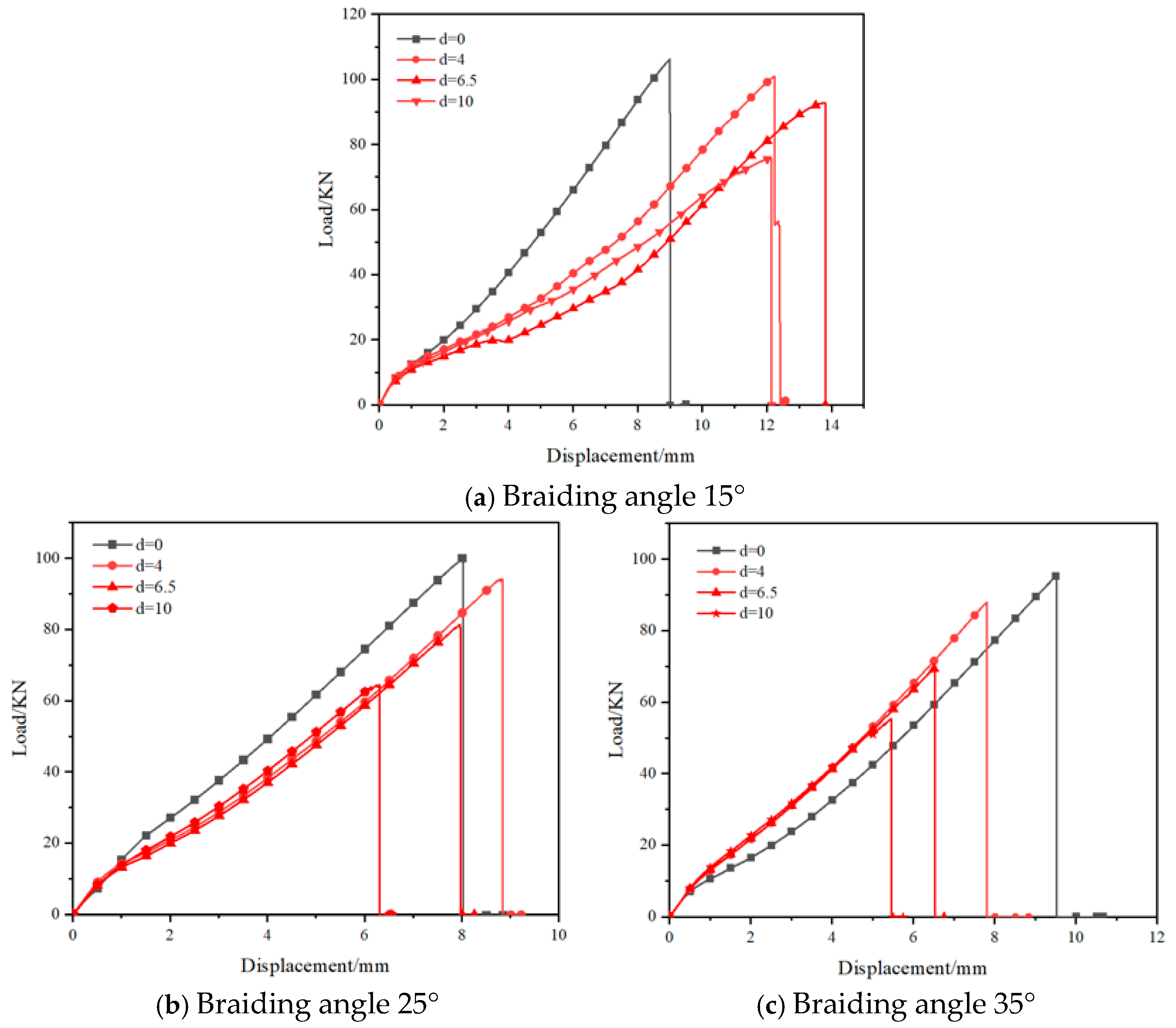

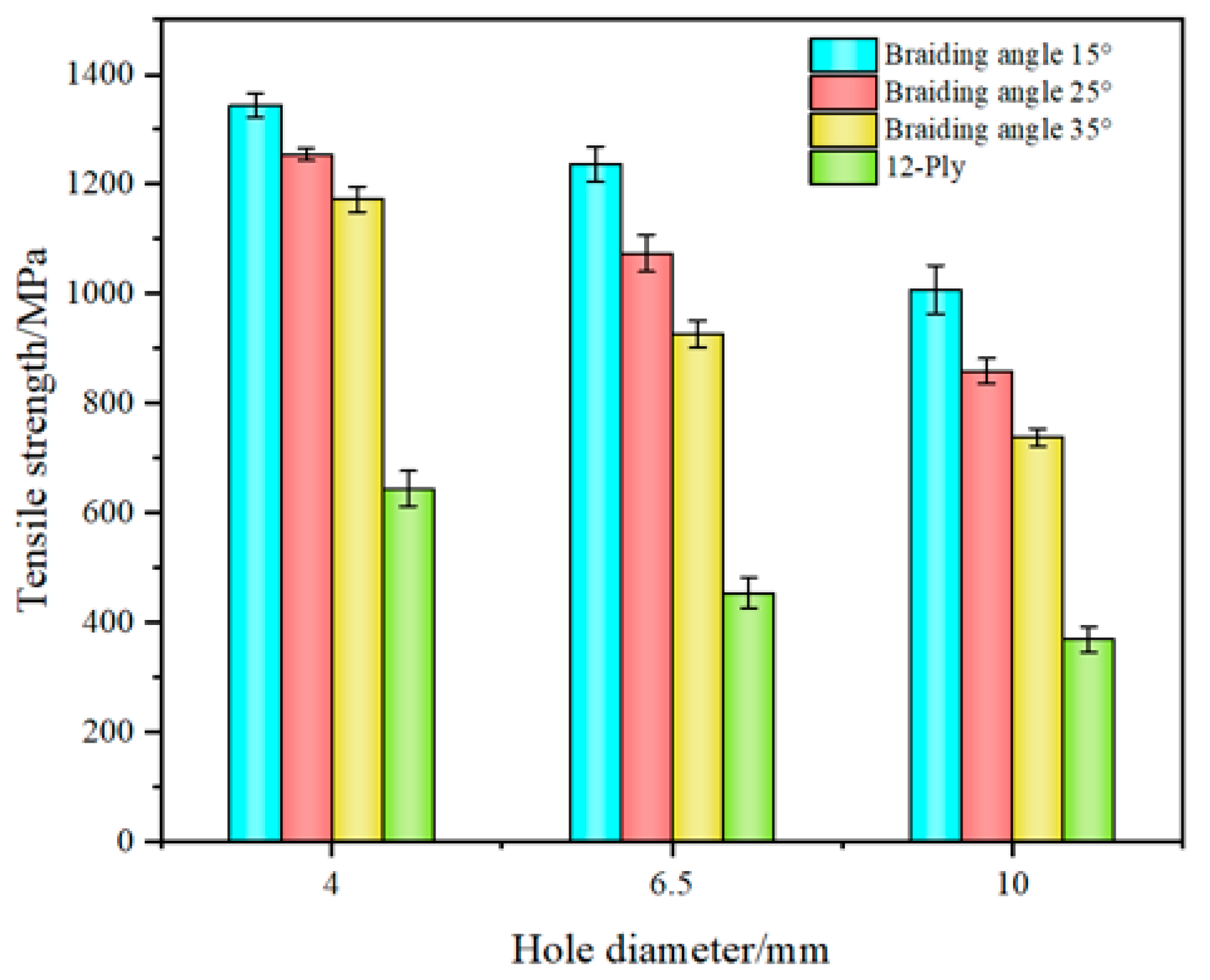

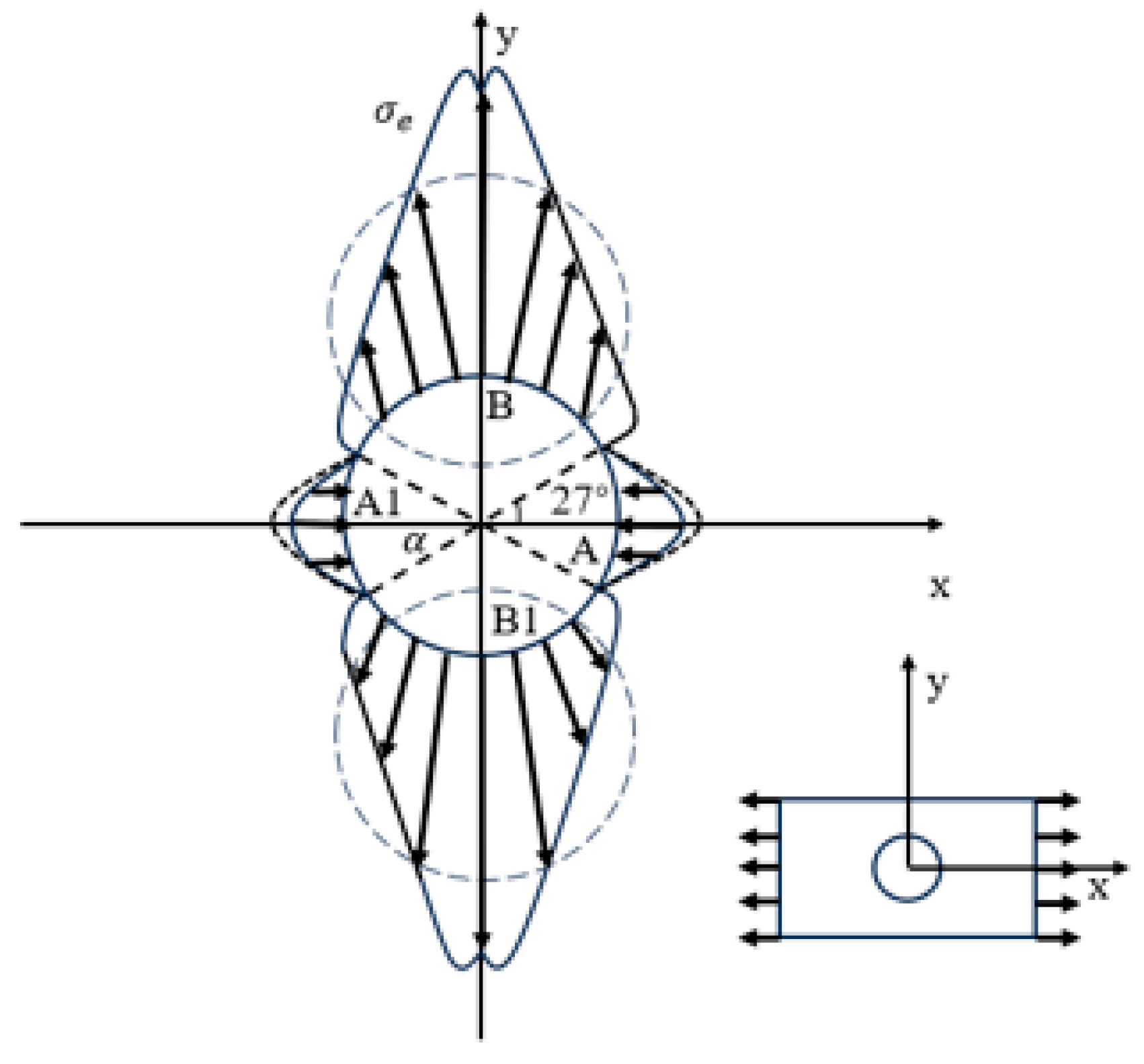

3.1. Effects of Different Braiding Angles and Apertures on the Mechanical Properties

3.2. Comparison of Tensile Test Data of Plain Woven Composites

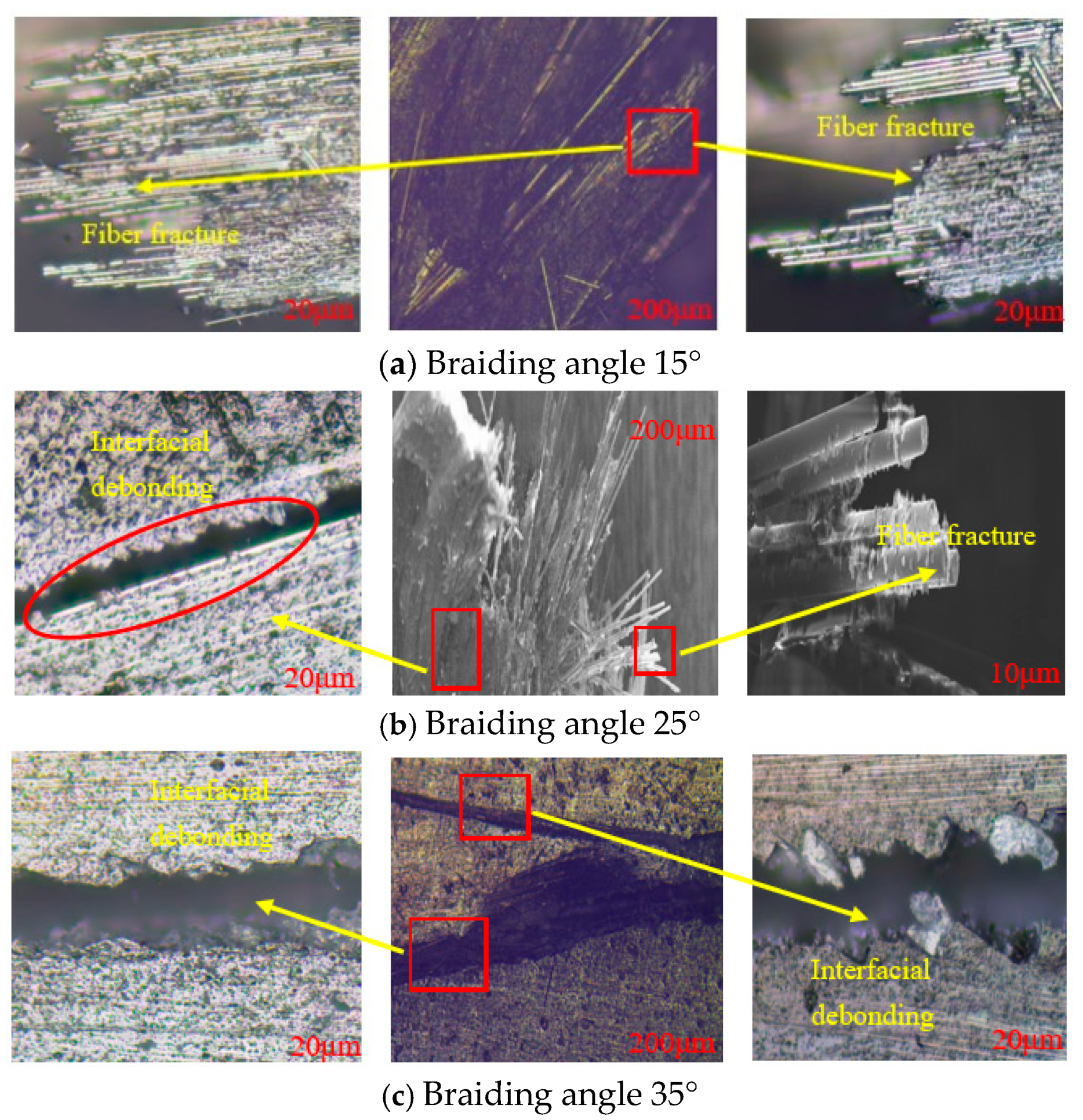

3.3. Tensile Failure Mechanism

3.3.1. Tensile Failure Mechanism of Non-Porous Test Parts

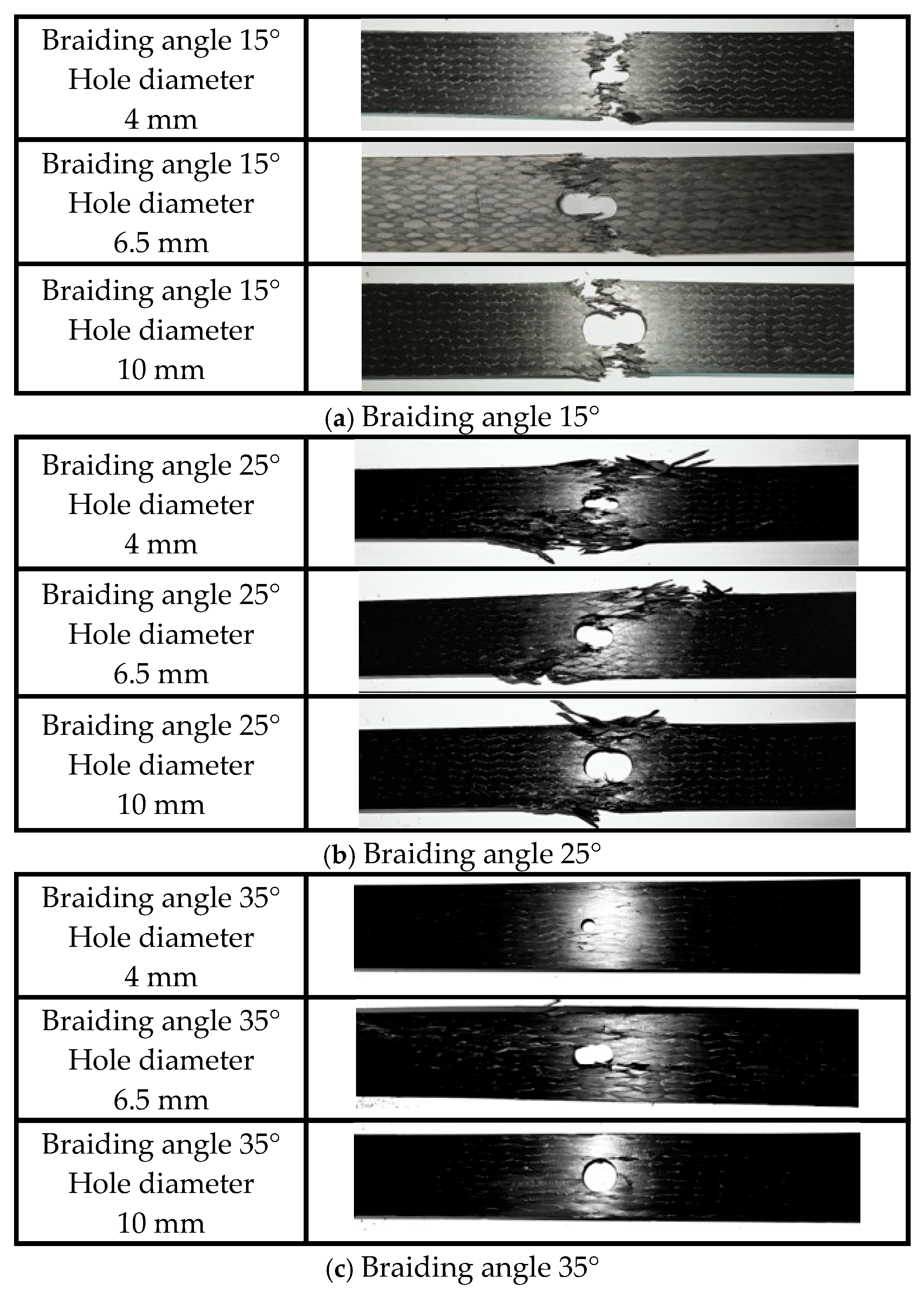

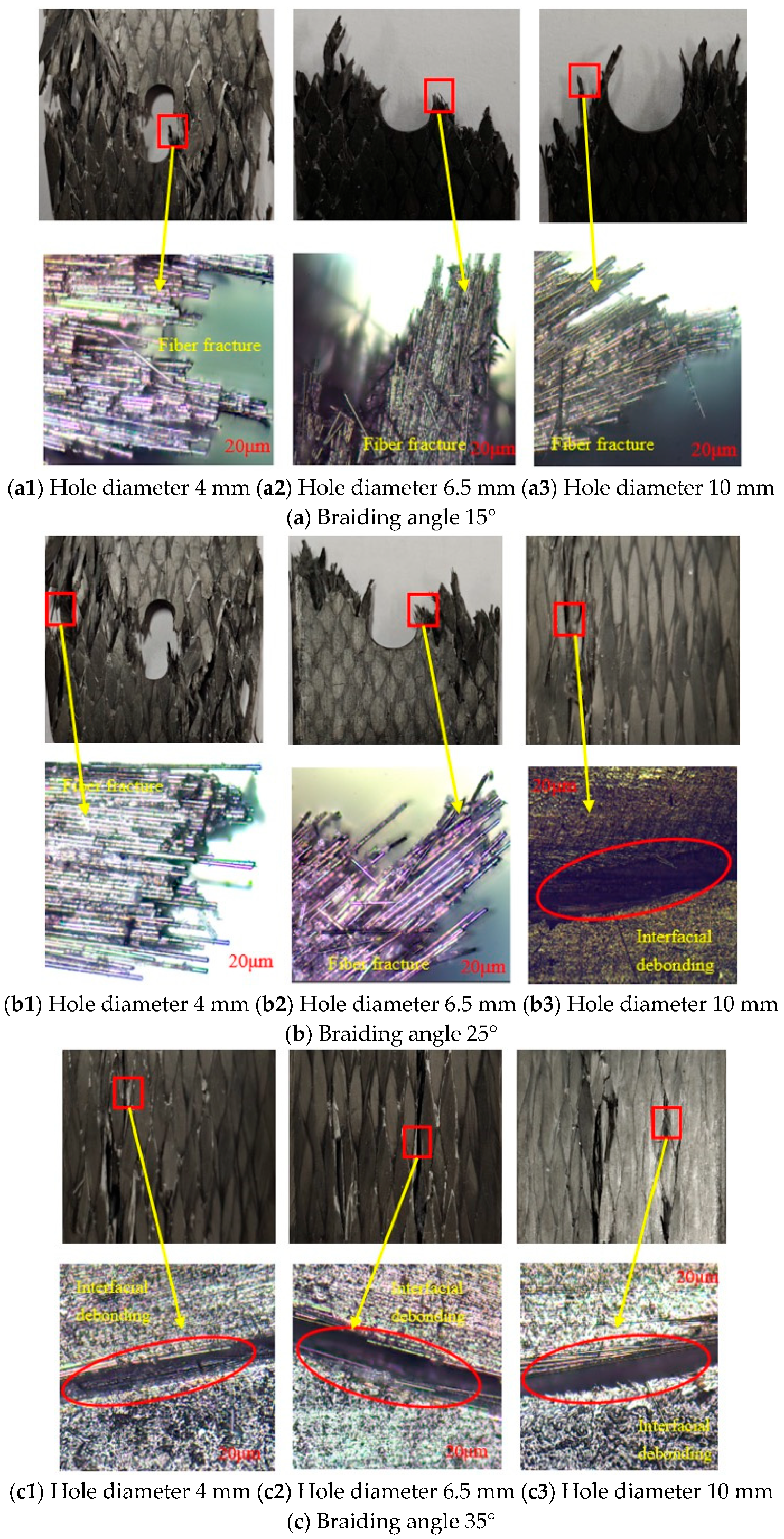

3.3.2. Tensile Failure Mechanism of Open Hole Test Parts

4. Conclusions

- (1)

- The tensile modulus of 3D braided composites exhibited a reduction upon the introduction of perforations. As the size of the opening increased, the tensile modulus decreased accordingly. The tensile modulus decreased with increasing knitting angle, and the rate of reduction accelerated once the knitting angle exceeded 25°. At elevated braiding angles, the tensile modulus was significantly influenced.

- (2)

- The three types of 3D braided composite specimens could sustain a strength value of 58.07% or higher, even after the introduction of apertures, demonstrating superior damage tolerance compared with laminate composites. The plain braided composite retained a strength value ranging from 35.07% to 61.05% after aperture introduction, with the test specimen nearing failure at larger apertures. It can be concluded that the 3D braided composite exhibited insensitivity to the presence of apertures.

- (3)

- When the braiding angle increased from 15° to 25°, the failure mode of the 3D woven composite changed from fiber fracture failure to the simultaneous occurrence of fiber fracture and interfacial debonding. When the braiding angle further increased to 35°, its failure mode transformed into interfacial debonding.

- (4)

- Under the current parameters, after introducing the opening, static failure started from the edge of the opening, and the failure mode was that cracks propagated along the edge of the hole, ultimately leading to the failure of the test piece. Unlike the 15° and 25° test specimens, the 35° test specimen remained connected after failure. The increase in aperture had no significant effect on the failure mode.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Warren, K.C.; Lopez-Anido, R.A.; Vel, S.S.; Bayraktar, H.H. Progressive failure analysis of three-dimensional woven carbon composites in single-bolt, double-shear bearing. Compos. Part B 2016, 84, 266–276. [Google Scholar] [CrossRef]

- Isart, N.; El Said, B.; Ivanov, D.S.; Hallett, S.R.; Mayugo, J.A.; Blanco, N. Internal geometric modelling of 3D woven composites: A comparison between different approaches. Compos. Struct. 2015, 132, 1219–1230. [Google Scholar] [CrossRef]

- Anitha Priyadharshani, S.; Meher Prasad, A.; Sundaravadivelu, R. Analysis of GFRP stiffened composite plates with rectangular cutout. Compos. Struct. 2017, 169, 42–51. [Google Scholar] [CrossRef]

- Hwan, C.-L.; Tsai, K.H.; Chiu, C.H.; Huang, Y. Strength prediction of woven hybrid composite laminates each with a center hole. J. Compos. Mater. 2014, 48, 1637–1644. [Google Scholar] [CrossRef]

- Toubal, L.; Karama, M.; Lorrain, B. Stress concentration in a circular hole in composite plate. Compos. Struct. 2005, 68, 31–36. [Google Scholar] [CrossRef]

- Mohammadi, R.; Najafabadi, M.A.; Saeedifar, M.; Yousefi, J.; Minak, G. Correlation of acoustic emission with finite element predicted damages in open-hole tensile laminated composites. Compos. Part B 2017, 108, 427–435. [Google Scholar] [CrossRef]

- Wang, Z.-Y.; Wang, Q.-Y.; Li, L.; Zhang, N. Fatigue behaviour of CFRP strengthened open-hole steel plates. Thin Walled Struct. 2017, 115, 176–187. [Google Scholar] [CrossRef]

- Saleh, M.N.; Wang, Y.; Yudhanto, A.; Joesbury, A.; Potluri, P.; Lubineau, G.; Soutis, C. Investigating the Potential of Using Off-Axis 3D Woven Composites in Composite Joints’ Applications. Appl. Compos. Mater. 2017, 24, 377–396. [Google Scholar] [CrossRef]

- Xu, F.; Sun, L.; Zhu, L.; Yang, S.; Hui, D.; Qiu, Y. X-ray 3D microscopy analysis of fracture mechanisms for 3D orthogonal woven E-glass/epoxy composites with drilled and moulded-in holes. Compos. Part B 2018, 133, 193–202. [Google Scholar] [CrossRef]

- Song, J.; Wen, W.; Cui, H.; Wang, Y.; Lu, Y.; Long, W.; Li, L. Warp direction fatigue behavior and damage mechanisms of centrally notched 2.5D woven composites at room and elevated temperatures. Compos. Sci. Technol. 2019, 182, 107769. [Google Scholar] [CrossRef]

- Sun, G.; Wang, L.; Chen, D.; Luo, Q. Tensile performance of basalt fiber composites with open circular holes and straight notches. Int. J. Mech. Sci. 2020, 176, 105517. [Google Scholar] [CrossRef]

- Gao, X.; Wen, D.; Siddique, A.; Liu, T.; Fan, W.; Chen, H.; Yu, J.; Cao, M. Flexural performance of three-dimensional braided open-hole composite with different hole diameter and preform size. J. Ind. Text. 2022, 52, 15280837221121939. [Google Scholar] [CrossRef]

- Dong, J.; Gong, Y. Influence of void defects on progressive tensile damage of three-dimensional braided composites. J. Compos. Mater. 2018, 52, 2033–2045. [Google Scholar] [CrossRef]

- Wu, C.; Lai, W.-Y. Mechanical and open hole tensile properties of self-reinforced PET composites with recycled PET fiber reinforcement. J. Appl. Polym. Sci. 2016, 133, 43682. [Google Scholar] [CrossRef]

- Bian, T.; Guan, Z.; Liu, F. Compressive experiment and numerical simulation of 3D carbon/carbon composite open-hole plates. Arch. Appl. Mech. 2018, 88, 913–932. [Google Scholar] [CrossRef]

- Li, X.; Wang, L.; Zhao, W.; Wu, H.; Xu, B. Selection and analysis of optimum stacking sequence and geometry dimensions on bismaleimides composite joints under tensile loading. Polym. Test. 2022, 105, 107421. [Google Scholar] [CrossRef]

- Green, B.G.; Wisnom, M.R.; Hallett, S.R. An experimental investigation into the tensile strength scaling of notched composites. Compos. Part A 2007, 38, 867–878. [Google Scholar] [CrossRef]

- Su, H.; Deng, K.; Yang, D.; Zhan, X.; Xie, Z.; Qin, J.; Ma, L. Performance and failure analysis of perforated CFRP/aluminum alloy bonding and self-piercing riveting hybrid joints. Eng. Fail. Anal. 2024, 156, 107803. [Google Scholar] [CrossRef]

- Gu, Q.; Quan, Z.; Shen, M.; Xie, Y.; Yu, J. Fabrication and braiding angle effect on the improved interlaminar shear performances of 3D braided sandwich hybrid composites. J. Mater. Res. Technol. 2023, 25, 5795–5806. [Google Scholar] [CrossRef]

- Wang, X.; Li, H.; Zhang, Y.; Guan, Y.; Yan, S.; Zhai, J. Compressive Failure Characteristics of 3D Four-Directional Braided Composites with Prefabricated Holes. Materials 2024, 17, 3821. [Google Scholar] [CrossRef]

- Singh, A.; Reynolds, N.; Keating, E.M.; Barnett, A.E.; Barbour, S.K.; Hughes, D.J. The effect of braid angle on the flexural performance of structural braided thermoplastic composite beams. Compos. Struct. 2021, 261, 113314. [Google Scholar] [CrossRef]

- Li, D.-S.; Han, W.-F.; Jiang, L.; Fang, D.-N. Fatigue behavior and failure of three-dimensional six-directional braided composites under tension. Mater. Lett. 2023, 332, 133471. [Google Scholar] [CrossRef]

- Liu, Z.; Wang, Y.-B.; Ou, J. Experiments and progressive damage analyses of three-dimensional full five-directional braided composites under three-point bending. Polym. Compos. 2015, 37, 2478–2493. [Google Scholar] [CrossRef]

- Cui, C.; Dong, J.; Mao, X. Effect of braiding angle on progressive failure and fracture mechanism of 3-D five-directional carbon/epoxy braided composites under impact compression. Compos. Struct. 2019, 229, 111412. [Google Scholar] [CrossRef]

- Dai, S.; Cunningham, P.R.; Marshall, S.; Silva, C. Influence of fibre architecture on the tensile, compressive and flexural behaviour of 3D woven composites. Compos. Part A 2015, 69, 195–207. [Google Scholar] [CrossRef]

- Yuan, H.; Wen, W.; Wang, Y.; Zheng, Z.; Wu, X. A model for longitudinal tensile strength prediction of low braiding angle three-dimensional and four-directional composites. Sci. Eng. Compos. Mater. 2017, 24, 447–453. [Google Scholar] [CrossRef]

- Li, Y.; Pan, Z.; Gu, B.-H.; Sun, B. Numerical analysis of punch shear failure and stress characteristics of three-dimensional braided composite with different braiding angles. Int. J. Damage Mech. 2019, 28, 1418–1437. [Google Scholar] [CrossRef]

- Zhang, D.; Zheng, X.; Zhou, J.; Song, X.; Jia, P.; Liu, H.; Liu, X. Effect of Braiding Architectures on the Mechanical and Failure Behavior of 3D Braided Composites: Experimental Investigation. Polymers 2022, 14, 1916. [Google Scholar] [CrossRef]

- Gao, X.; Siddique, A.; Sun, B.; Gu, B. Influence of Braiding Angle on Multiple Impact Damages of 3-D Braided Composite along Longitudinal Direction. Appl. Compos. Mater. 2019, 26, 1261–1280. [Google Scholar] [CrossRef]

- Jang, Y.; Kim, J.-H.; Lee, D.; Chon, J.S.; Lee, S.; Kwon, D.-J. Comprehensive analysis of the effect of braiding angle on the wettability and mechanical properties of 3D braided carbon fiber fabric-reinforced composites. Mater. Today Commun. 2024, 41, 110798. [Google Scholar] [CrossRef]

- Zhu, H.; Li, D.-S.; Han, W.-F.; Jiang, L. Experimental and numerical study of in-plane compressive properties and failure of 3D six-directional braided composites with large braiding angle. Mater. Des. 2020, 195, 108917. [Google Scholar] [CrossRef]

| Properties | Values | |

|---|---|---|

| Elastic modulus/GPa | E11 | 230 |

| E22 | 14 | |

| E33 | 14 | |

| Shear modulus/GPa | G12 | 9 |

| G13 | 9 | |

| G23 | 5 | |

| Poisson’s ratio/[1] | μ12 | 0.25 |

| μ13 | 0.25 | |

| μ23 | 0.3 | |

| Name | Chemical Component | Viscosity (mpa·s°C) | Epoxy Equivalent (g/eq) | Mixing Ratio |

|---|---|---|---|---|

| JL-235 | Epoxy resin | 2000–4000 | 180–188 | 100:34 |

| JH-238 | Curing agent | 5–15 | - |

| Braiding Angle | Fiber Volume Fraction |

|---|---|

| 15° | 55% |

| 25° | 55% |

| 35° | 55% |

| Material | No Defect Strength (MPa) | Hole Diameter 4 mm (MPa) | Hole Diameter 6.5 mm (MPa) | Hole Diameter 10 mm (MPa) |

|---|---|---|---|---|

| Braiding Angle 15° | 1415.3 ± 15.2 | 1344.4 ± 22.1 | 1236.4 ± 33.5 | 1007.9 ± 44.8 |

| Braiding Angle 25° | 1333.1 ± 21.7 | 1254.5 ± 12.4 | 1074.1 ± 34.3 | 859.1 ± 23.6 |

| Braiding Angle 35° | 1271.0 ± 20.4 | 1172.4 ± 23.7 | 926.4 ± 25.5 | 738.1 ± 16.5 |

| Plain Woven Composite | 1055.5 ± 17.1 | 644.43 ± 32.2 | 454.23 ± 28.1 | 370.13 ± 10.4 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Su, H.; Han, Z.; Wei, T.; An, D.; Qin, Q.; Wei, Z. Tensile Mechanical Properties and Failure Behavior Analysis of Three-Dimensional Woven Composite with Different Apertures and Braiding Angles. Coatings 2025, 15, 440. https://doi.org/10.3390/coatings15040440

Su H, Han Z, Wei T, An D, Qin Q, Wei Z. Tensile Mechanical Properties and Failure Behavior Analysis of Three-Dimensional Woven Composite with Different Apertures and Braiding Angles. Coatings. 2025; 15(4):440. https://doi.org/10.3390/coatings15040440

Chicago/Turabian StyleSu, Hailiang, Zhe Han, Tengteng Wei, Deng An, Qiulin Qin, and Zhenxiao Wei. 2025. "Tensile Mechanical Properties and Failure Behavior Analysis of Three-Dimensional Woven Composite with Different Apertures and Braiding Angles" Coatings 15, no. 4: 440. https://doi.org/10.3390/coatings15040440

APA StyleSu, H., Han, Z., Wei, T., An, D., Qin, Q., & Wei, Z. (2025). Tensile Mechanical Properties and Failure Behavior Analysis of Three-Dimensional Woven Composite with Different Apertures and Braiding Angles. Coatings, 15(4), 440. https://doi.org/10.3390/coatings15040440