Microstructure and Properties of Al-Cr-N Ternary Wear-Resistant Coatings on Cr12MoV Alloy Tool Steel by Multiarc Ion Plating

Abstract

:1. Introduction

2. Experimental Processes

2.1. Material and Experimental Preparation

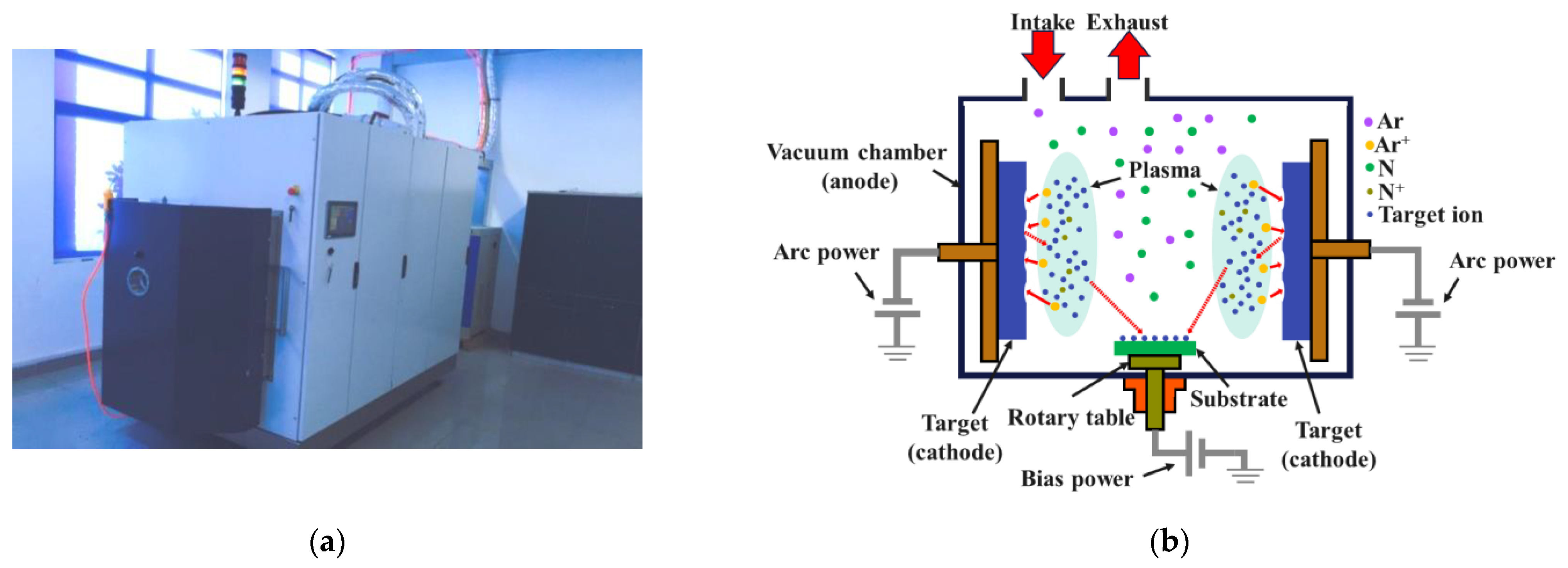

2.2. Coating Preparation Method

2.3. Coating Performance Evaluation

2.3.1. Microstructural Characterization

2.3.2. Tribological Testing

2.3.3. Mechanical Property Assessment

3. Results and Discussion

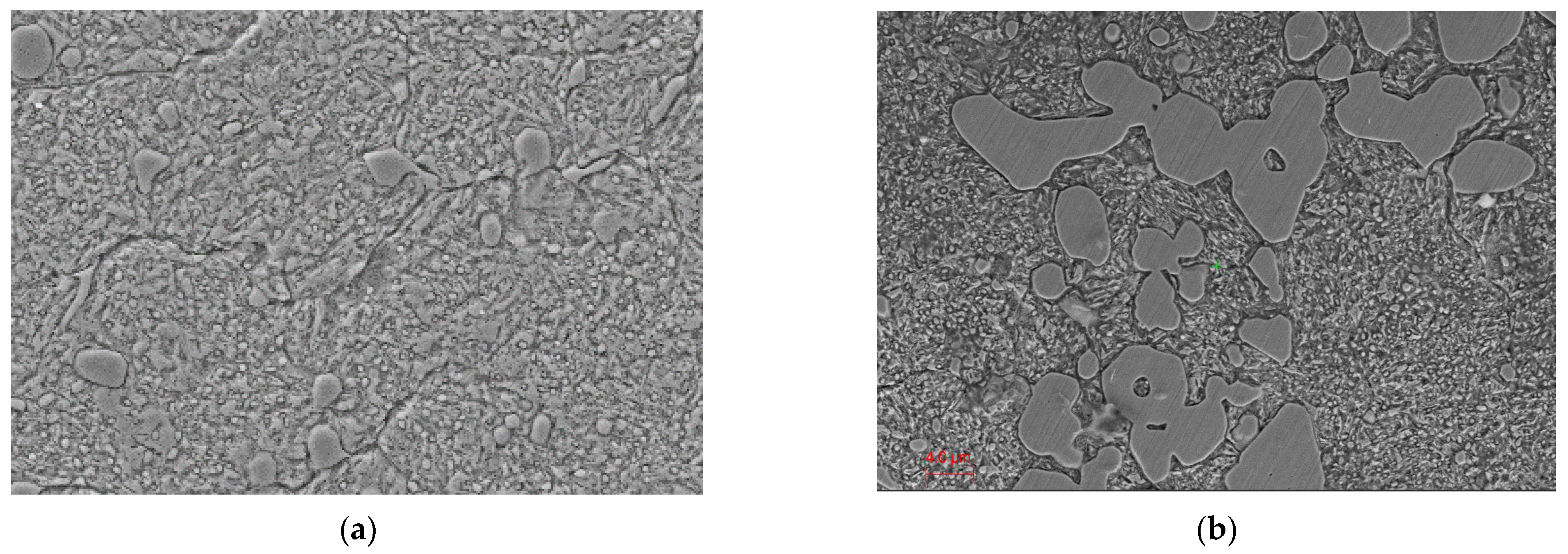

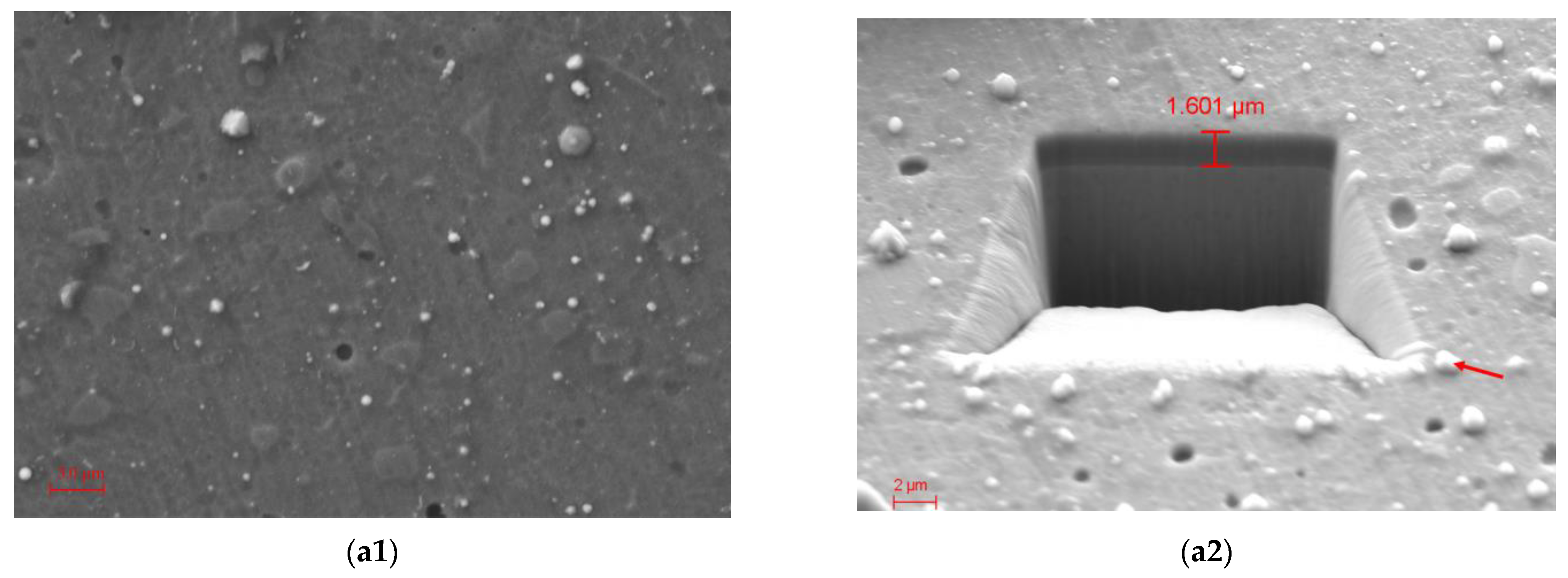

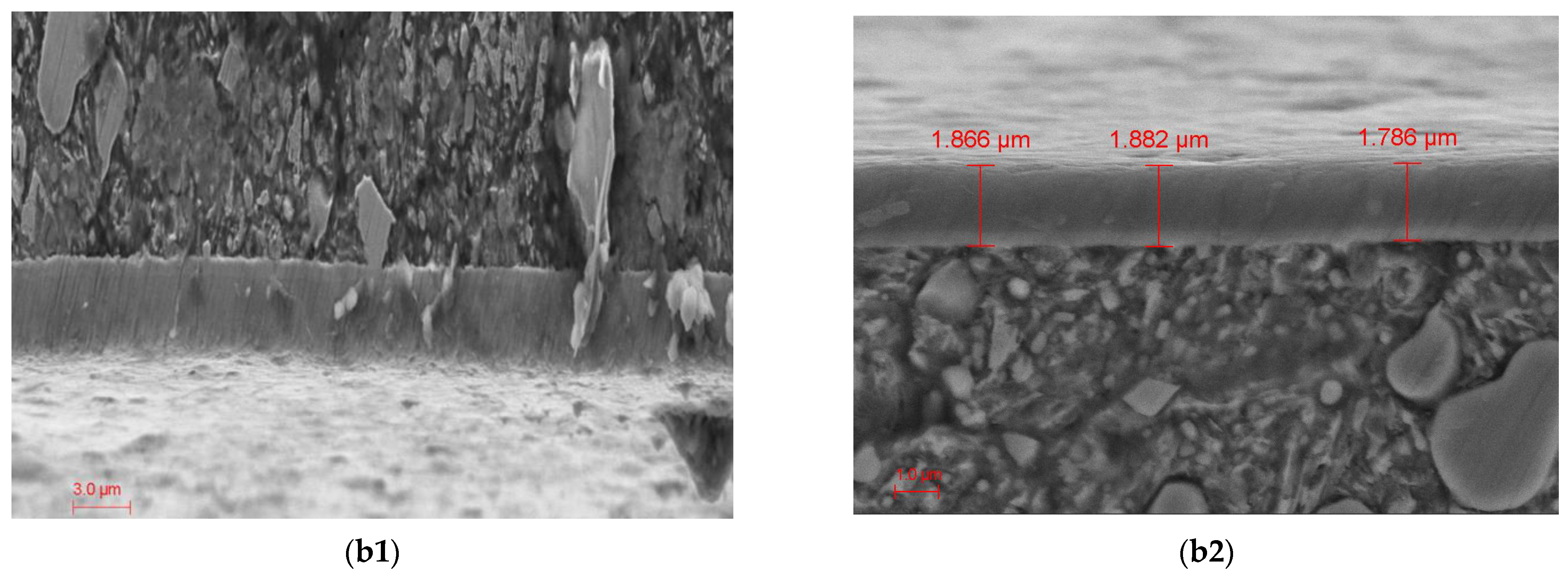

3.1. Coating Microstructure

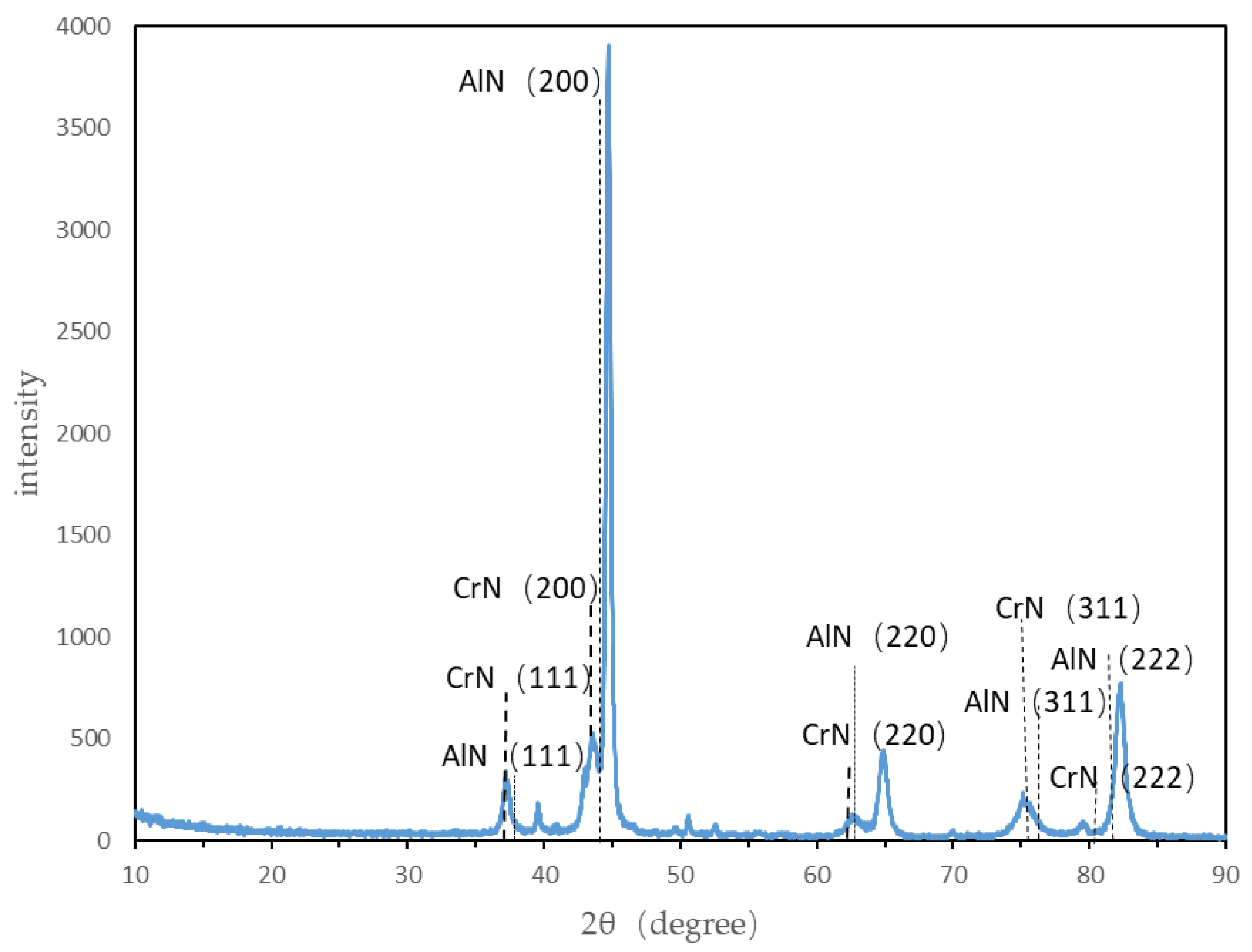

3.2. Physical Phase Composition

3.3. Coating Hardness

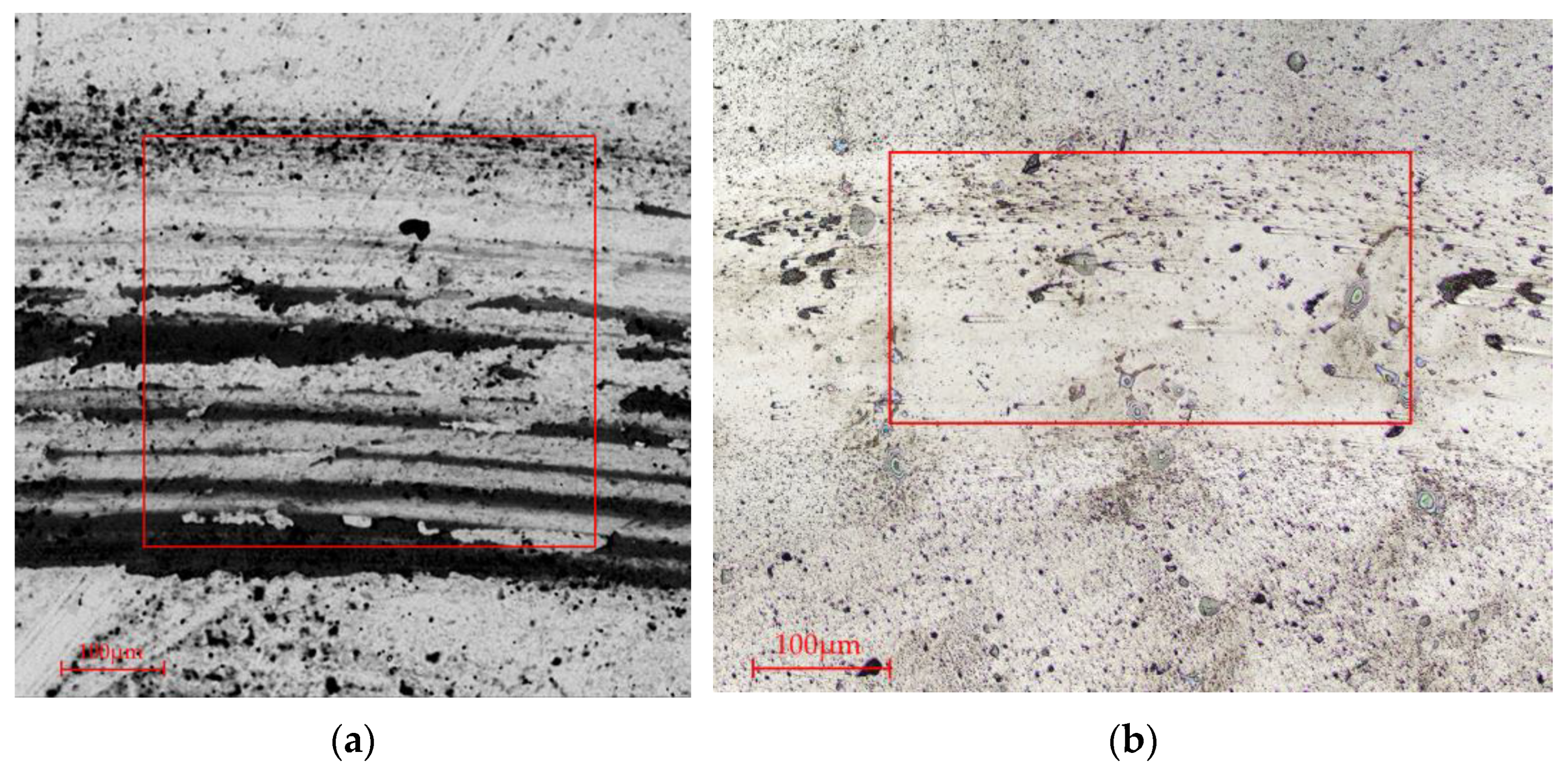

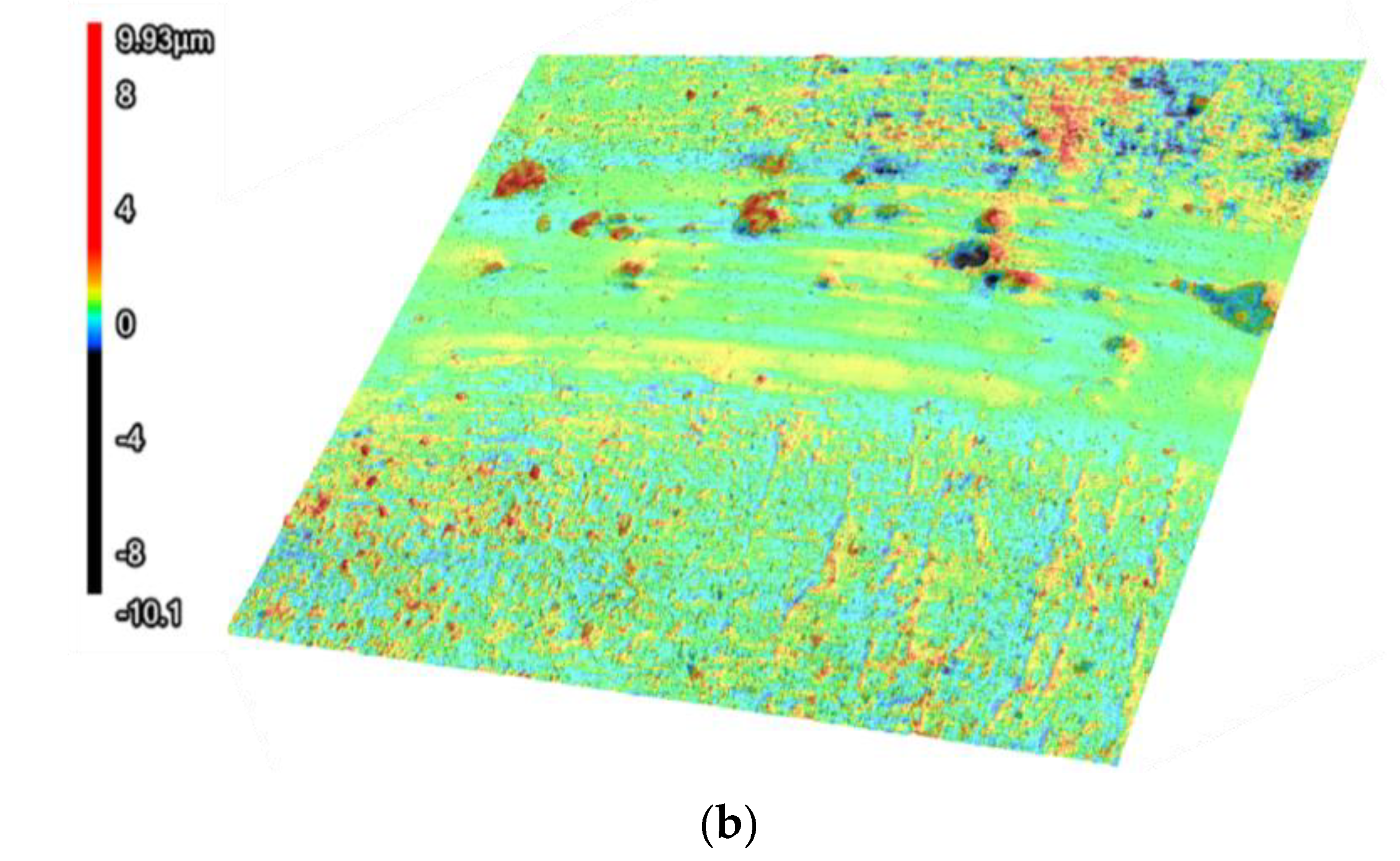

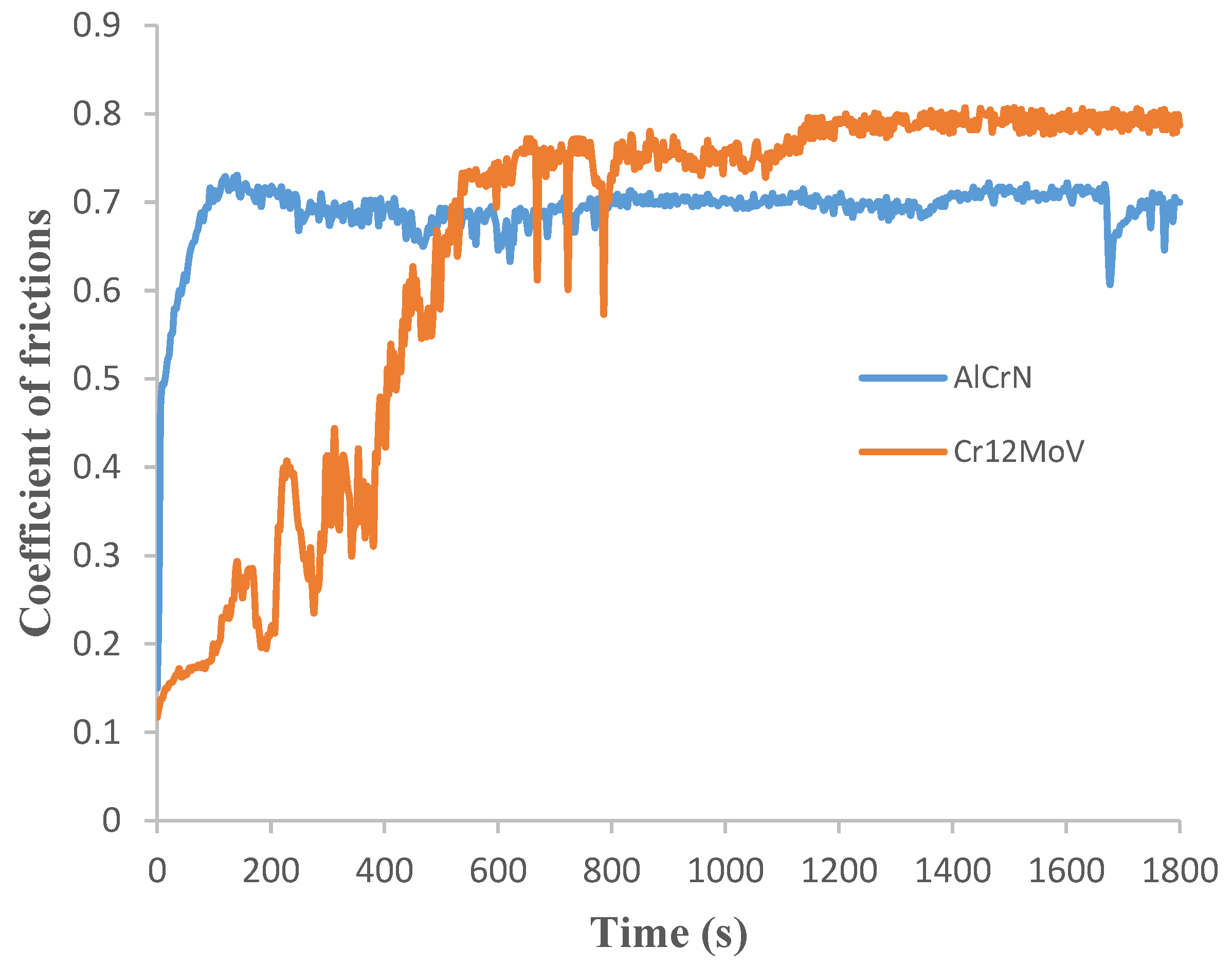

3.4. Wear Performance

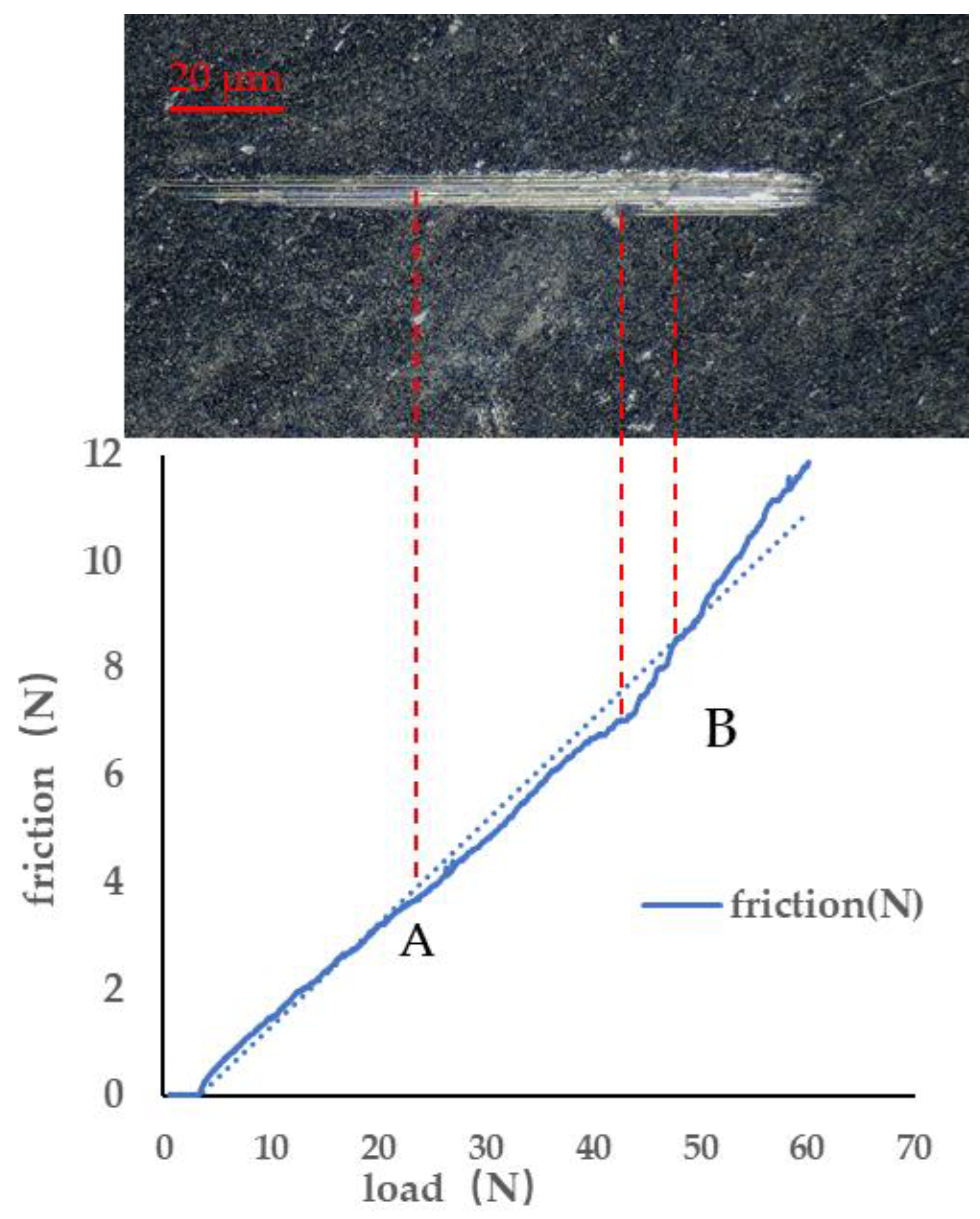

3.5. Coating Bonding Strength

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Bao, C.; Yang, Y.; Xu, C. The wear analysis and life prediction of Cr12MoV alloy steel hammer dies during the radial forging process. CIRP J. Manuf. Sci. Technol. 2025, 57, 63–77. [Google Scholar] [CrossRef]

- Wang, R.; Song, Z.F.; Wei, D.Q.; Li, X.K.; Song, J.J.; Mo, Z.Z.; Weng, Y.T.; Yang, F.T. Unveiling the effect of electron beam shock on the microstructure and wear resistance of Cr12MoV steel. VACUUM 2024, 226, 113347. [Google Scholar] [CrossRef]

- Liu, Z.; Wang, C.; Mi, G.; Zhang, W.; Wang, J. Surface morphological evolution and microhardness change of Cr12MoV steel by pulsed laser polishing. Opt. Laser Technol. 2024, 171, 110419. [Google Scholar] [CrossRef]

- Wang, X.; Zhang, Z.; Men, Y.; Li, X.; Liang, Y.; Ren, L. Fabrication of nano-TiC functional gradient wear-resistant composite coating on 40Cr gear steel using laser cladding under starved lubrication conditions. Opt. Laser Technol. 2020, 126, 106136. [Google Scholar] [CrossRef]

- Shi, Y.; Li, Y.; Liu, J.; Yuan, Z. Investigation on the parameter optimization and performance of laser cladding a gradient composite coating by a mixed powder of Co50 and Ni/WC on 20CrMnTi low carbon alloy steel. Opt. Laser Technol. 2018, 99, 256–270. [Google Scholar] [CrossRef]

- Dobrzanski, L.A.; Polok, M.; Adamiak, M. Structure and properties of wear resistance PVD coatings deposited onto X37CrMoV5-1 type hot work steel. Mater. Process. Technol. 2005, 164–165, 843–849. [Google Scholar] [CrossRef]

- Vengesa, Y.; Fattah-alhosseini, A.; Elmkhah, H.; Imantalab, O.; Keshavarz, M.K. Investigation of corrosion and tribological characteristics of annealed CrN/CrAlN coatings deposited by CAE-PVD. Ceram. Int. 2023, 49, 3016–3029. [Google Scholar] [CrossRef]

- Fereshteh-Saniee, N.; Elmkhah, H.; Nouri, M.; Meghdari, M. An investigating of how mechanical properties impact the erosion resistance of CrN, CrTiN, and CrTiSiN PVD coatings. Results Surf. Interfaces 2025, 18, 100422. [Google Scholar] [CrossRef]

- Ezugwu, E.O.; Okeke, C.I. Tool life and wear mechanisms of TiN coated tools in an intermittent cutting operation. J. Mater. Process. Technol. 2001, 116, 10–15. [Google Scholar] [CrossRef]

- Chiadikobi, C.I.; Thornton, R.; Statharas, D.; Weston, D.P. The effects of deep cryogenic treatment on PVD-TiN coated AISI M2 high speed steel. Surf. Coat. Technol. 2024, 493, 131248. [Google Scholar] [CrossRef]

- Xi, Y.; Bai, Y.; Gao, K.; Pang, X.; Yang, H.; Yan, L.; Alex, A. Volinsky. Residual stress and microstructure effects on mechanical, tribological and electrical properties of TiN coatings on 304 stainless steel. Ceram. Int. 2018, 44, 15851–15858. [Google Scholar] [CrossRef]

- Liu, L.; Shao, L.; Li, W.; Shang, L.; Zhang, C.; Song, Q. Improving the tribological behavior of CrN film by PVD/HVOF design. Surf. Coat. Technol. 2023, 475, 130171. [Google Scholar] [CrossRef]

- Edis, R.; Sinmazcelik, T.; Erturk, A.T. Measuring applied force and energy consumption in deep drawing die Sets: An experimental and numerical analysis of CrN and CrTiN PVD coating effects. Measurement 2024, 224, 113841. [Google Scholar] [CrossRef]

- Xu, X.; Sun, J.; Xu, Z.; Li, Z.; Su, F. Microstructure, electrochemical and tribocorrosion behaviors of CrCN nanocomposite coating with various carbon content. Surf. Coat. Technol. 2021, 411, 126997. [Google Scholar] [CrossRef]

- Pei, F.; Liu, H.J.; Chen, L.; Xu, Y.X.; Du, Y. Improved properties of TiAlN coating by combined Si-addition and multilayer architecture. J. Alloys. Compd. 2019, 790, 909–916. [Google Scholar] [CrossRef]

- Alhafian, M.R.; Valle, N.; Chemin, J.B.; Bourgeois, L.; Penoy, M.; Useldinger, R.; Ghanbaja, J.; Mücklich, F.; Choquet, P. Choquet. Influence of Si addition on the phase structure and oxidation behavior of PVD AlTiN and AlTiCrN coatings using high-resolution characterization techniques. J. Alloys Compd. 2023, 968, 171800. [Google Scholar] [CrossRef]

- Shan, L.; Zhang, Y.-r.; Wang, Y.-x.; Li, J.-l.; Jiang, X.; Chen, J.-m. Corrosion and wear behaviors of PVD CrN and CrSiN coatings in seawater. Trans. Nonferrous Met. Soc. China 2016, 26, 175–184. [Google Scholar] [CrossRef]

- Chen, J.; Guo, Q.; Li, J.; Yang, Z.; Guo, Y.; Yang, W.; Xu, D.; Yang, B. Microstructure and tribological properties of CrAlTiN coating deposited via multi-arc ion plating. Mater. Today Commun. 2022, 30, 103136. [Google Scholar] [CrossRef]

- Danek, M.; Fernandes, F.; Cavaleiro, A.; Polcar, T. Influence of Cr additions on the structure and oxidation resistance of multilayered TiAlCrN films. Surf. Coat. Technol. 2017, 313, 158–167. [Google Scholar] [CrossRef]

- Ramírez-Reyna, F.O.; Rodríguez-Castro, G.A.; Figueroa-López, U.; Morón, R.C.; Arzate-Vázquez, I.; Meneses-Amador, A. Effect of nitriding pretreatment on adhesion and tribological properties of AlCrN coating. Mater. Lett. 2021, 284, 128931. [Google Scholar] [CrossRef]

- Li, X.; Meng, C.; Xu, X.; He, X.; Wang, C. Effect of Al content on high-temperature oxidation behavior and failure mechanism of CrAl-coated Zircaloy. Corros. Sci. 2021, 192, 109856. [Google Scholar] [CrossRef]

- He, Q.; DePaiva, J.M.; Martins, M.M.; Amorim, F.L.; Torres, R.D.; Arif, A.F.; Veldhuis, S.C. PVD coating strategies: Developing a combination of AlCrN and AlTiSiN for enhanced surface performance during threading of super duplex stainless steel. Int. J. Refract. Met. Hard Mater. 2024, 121, 106670. [Google Scholar] [CrossRef]

- Fan, Q.; Zhang, S.; Ma, D.; Wu, Z.; Cao, F.; Liu, Y.; Wang, T. Bias voltage optimization and cutting performance of AlCrN coatings deposited by a hybrid technology. Vacuum 2022, 204, 111348. [Google Scholar] [CrossRef]

- Neto, N.D.C.; Kloenne, Z.T.; Korenyi-Both, A.L.; Midson, S.P.; Kaufman, M.J. Influence of Al/(Al+Cr) ratio and doping effects on wear and molten aluminum attack resistance in AlCrN-based PVD coatings for lube-free aluminum die casting. J. Mater. Res. Technol. 2022, 20, 1057–1078. [Google Scholar] [CrossRef]

- Oliver, W.C.; Pharr, G.M. Measurement of hardness and elastic modulus by instrumented indentation: Advances in understanding and refinements to methodology. J. Mater. Res. 2004, 19, 3–20. [Google Scholar] [CrossRef]

- Beake, B.D.; Roberts, J.; Zhu, Y.; Liskiewicz, T.W. Simulating erosion tests with statistically distributed micro-scale impact: A study on PVD TiAlN and AlCrN coatings. Wear 2025, 205911. [Google Scholar] [CrossRef]

- Geng, D.; Li, H.; Chen, Z.; Xu, Y.X.; Wang, Q. Microstructure, oxidation behavior and tribological properties of AlCrN/Cu coatings deposited by a hybrid PVD technique. J. Mater. Sci. Technol. 2022, 100, 150–160. [Google Scholar] [CrossRef]

| Element | C | Si | Mn | Cr | Mo | V |

|---|---|---|---|---|---|---|

| Percentage of mass | 1.45~1.70 | ≤0.40 | ≤0.40 | 11.0~12.5.0 | 0.40~0.60 | 0.15~0.30 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhou, Y.; Huang, Q.; Luo, S.; Lin, R. Microstructure and Properties of Al-Cr-N Ternary Wear-Resistant Coatings on Cr12MoV Alloy Tool Steel by Multiarc Ion Plating. Coatings 2025, 15, 487. https://doi.org/10.3390/coatings15040487

Zhou Y, Huang Q, Luo S, Lin R. Microstructure and Properties of Al-Cr-N Ternary Wear-Resistant Coatings on Cr12MoV Alloy Tool Steel by Multiarc Ion Plating. Coatings. 2025; 15(4):487. https://doi.org/10.3390/coatings15040487

Chicago/Turabian StyleZhou, Yuhui, Qingmin Huang, Shanming Luo, and Rongchuan Lin. 2025. "Microstructure and Properties of Al-Cr-N Ternary Wear-Resistant Coatings on Cr12MoV Alloy Tool Steel by Multiarc Ion Plating" Coatings 15, no. 4: 487. https://doi.org/10.3390/coatings15040487

APA StyleZhou, Y., Huang, Q., Luo, S., & Lin, R. (2025). Microstructure and Properties of Al-Cr-N Ternary Wear-Resistant Coatings on Cr12MoV Alloy Tool Steel by Multiarc Ion Plating. Coatings, 15(4), 487. https://doi.org/10.3390/coatings15040487