First Identification of a Gypsum-Based Preparatory Layer on Polychrome Wooden Figurines from the Mawangdui Han Tomb No. 1 (2nd Century BCE), Changsha, China

Abstract

:1. Introduction

2. Materials and Methods

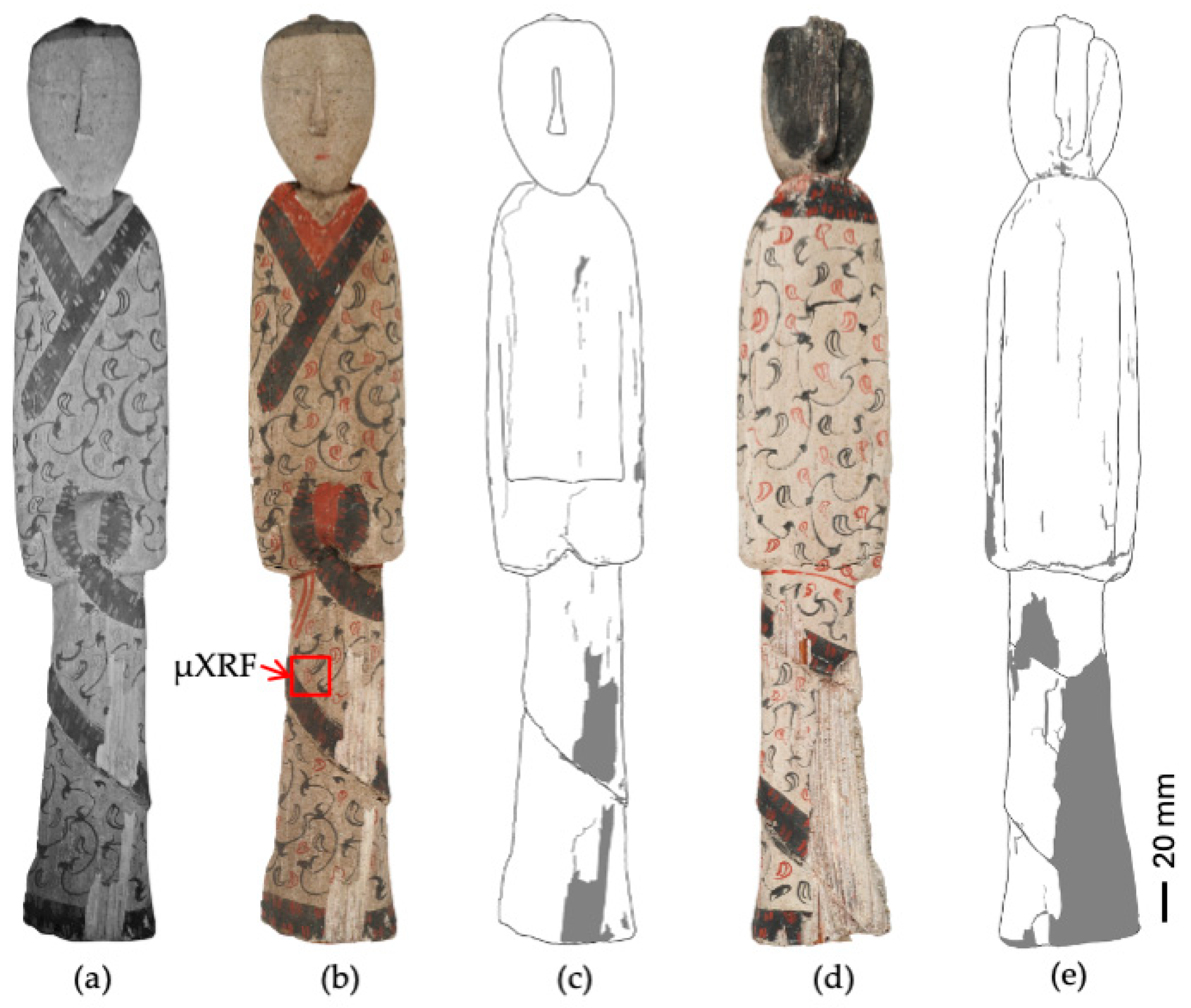

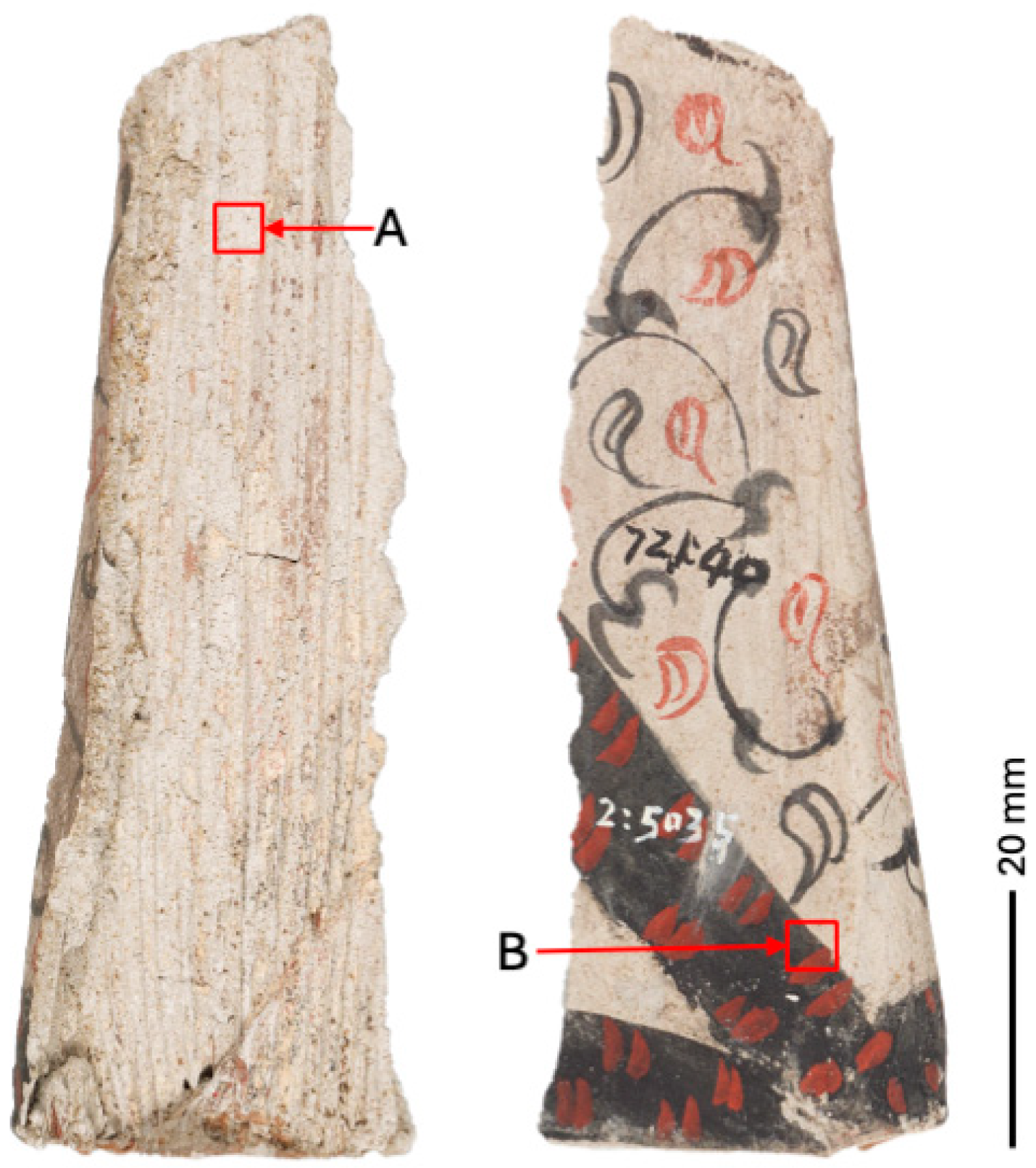

2.1. Description of the Wooden Figurines and Sampling Strategy

2.2. Elemental Mapping by MA-XRF and µXRF

2.3. Scanning Electron Microscopy (SEM) for Microstructural Observation

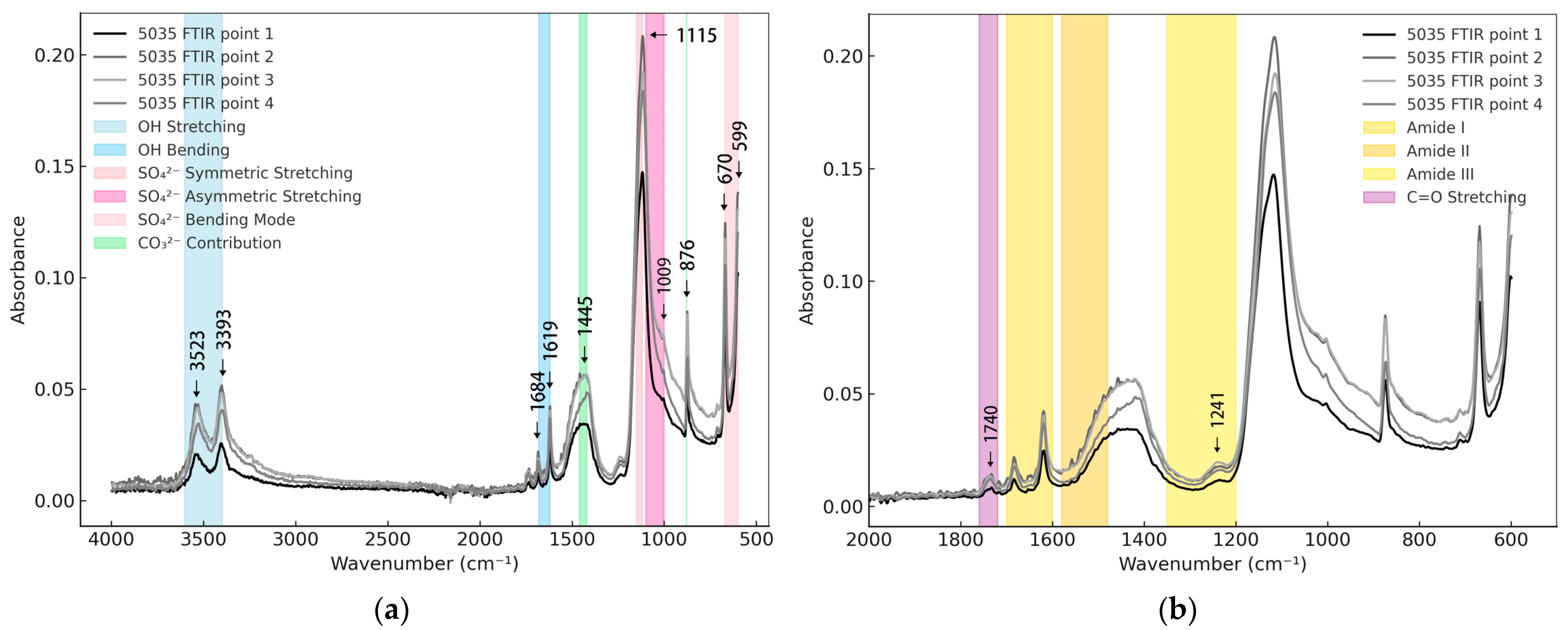

2.4. ATR-FTIR Analysis

2.5. X-Ray Diffraction (XRD)

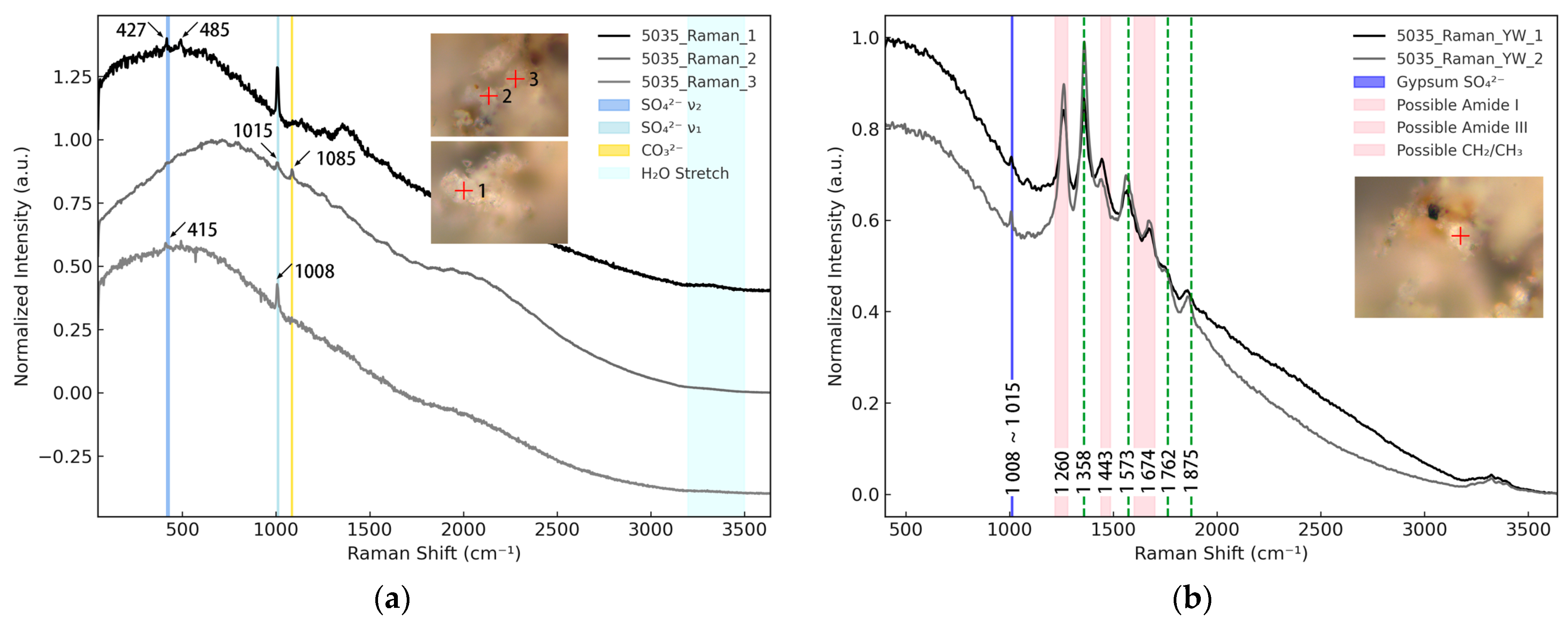

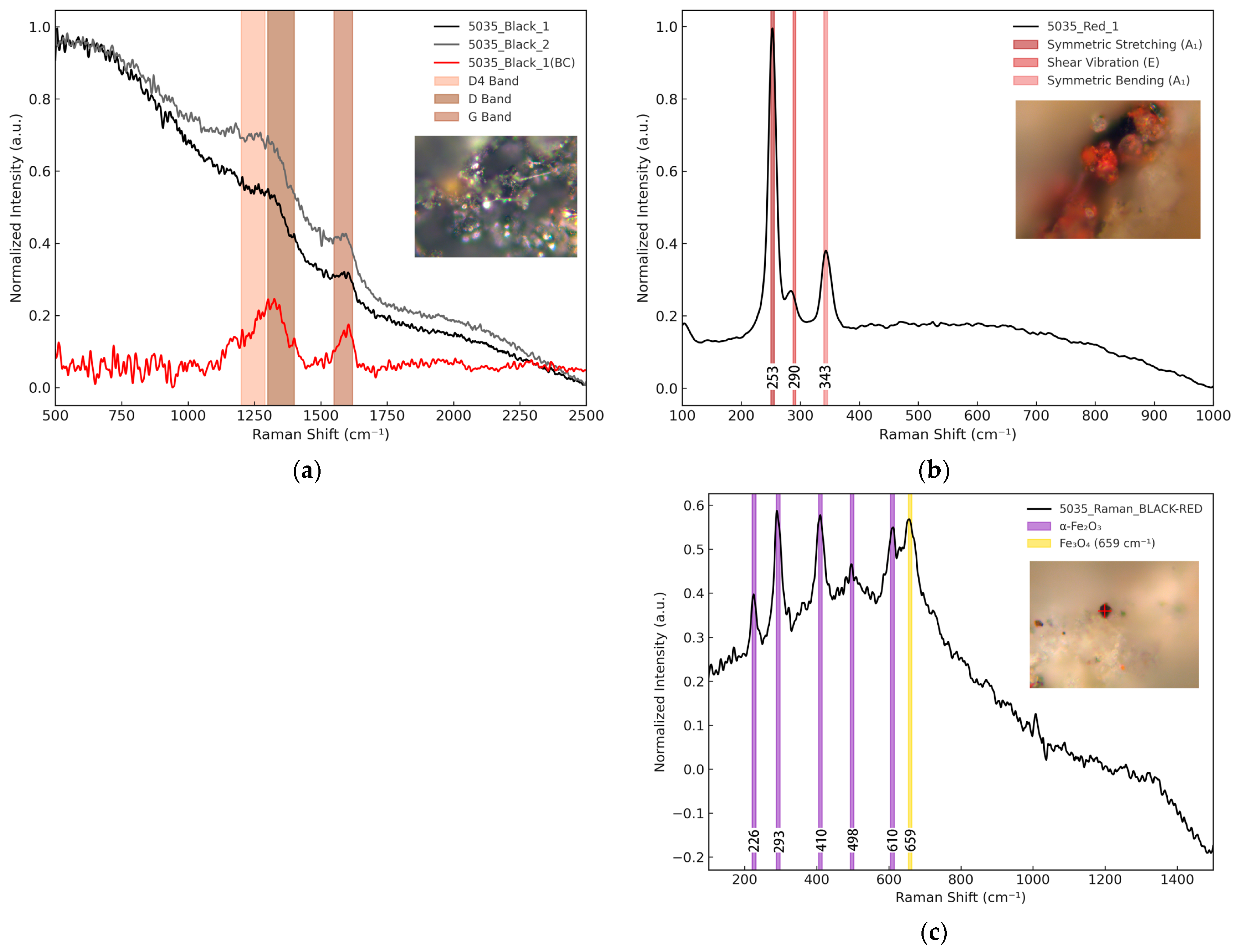

2.6. Raman Spectroscopy

3. Results

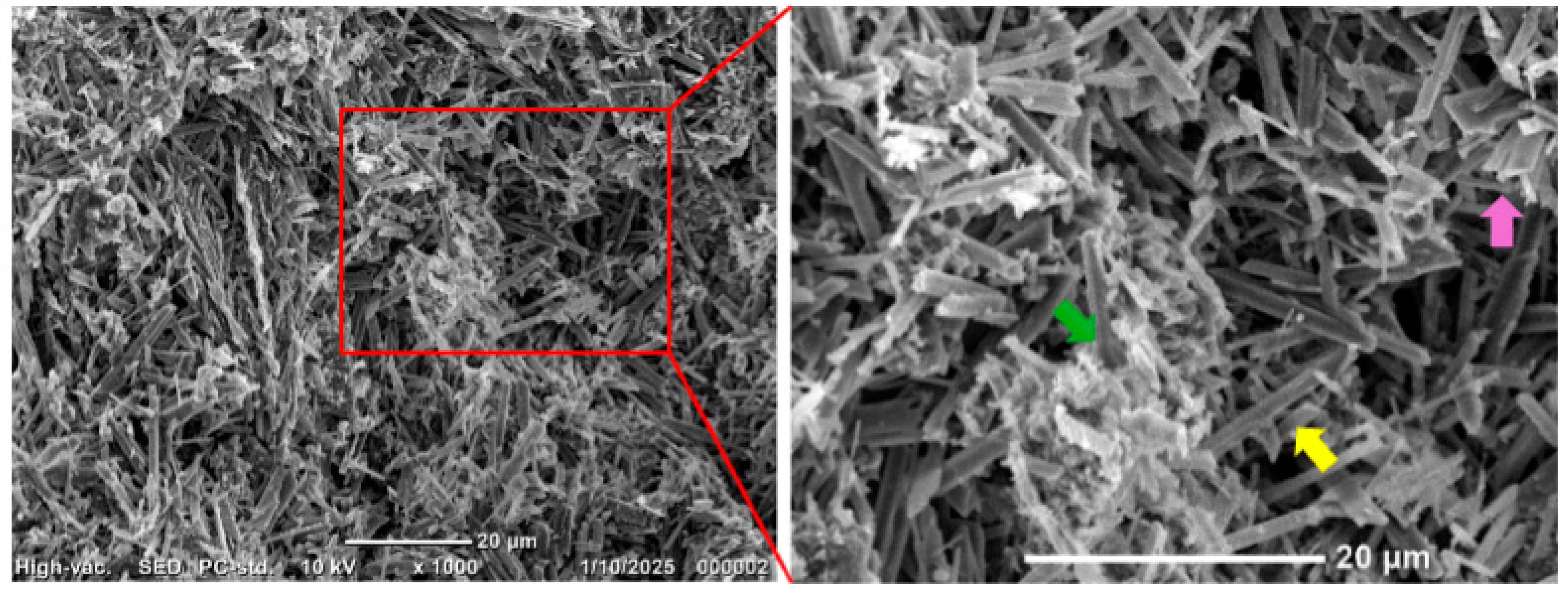

3.1. Microstructural Features

3.2. Elemental Distribution and Material Zoning

- (1)

- Calcium is widely distributed in the basal areas of the sample, showing a strong correlation with the gray–white regions observed in the optical image. This suggests that these areas are composed of Ca-rich materials. Silicon exhibits a similarly broad distribution, further supporting its role as a major component of the substrate. The µXRF system offers enhanced clarity, revealing minor variations in Ca and Si concentrations that are not readily apparent in the MA-XRF data.

- (2)

- Sulfur shows a distribution pattern closely aligned with that of calcium, although some regions exhibit strong Ca signals with weaker S signals. This suggests the presence of multiple Ca-bearing phases, with sulfur associated only with specific ones. The µXRF data provide finer detail, clearly illustrating small-scale heterogeneity in sulfur distribution and depletion.

- (3)

- The distribution relationship between Si and K is also noteworthy. Both elements show localized co-enrichment in certain areas, which may indicate the presence of a mixed Si-K-bearing phase. However, potassium is more sporadically distributed, suggesting that it exists in relatively minor amounts or is associated with surface deposits. In contrast, the broader and more consistent presence of silicon across the mapped area implies that Si may also exist in the form of a separate Si-rich phase independent of potassium. This interpretation is supported by the µXRF results, which revealed significantly lower concentrations of K than Si in most areas.

- (4)

- Iron is mainly concentrated in the dark-colored decorative motifs seen in the optical image but is also scattered across the entire sample surface. This implies that iron may be associated with black pigments as well as being a minor component of the underlying substrate.

- (5)

- Mercury appears as highly concentrated patches that precisely align with red motifs in the optical image. The sharply defined signal boundaries suggest that mercury was deliberately applied through painting rather than being naturally present in the substrate. In areas rich in Hg, the signals of Ca, S, and Si are significantly attenuated. This attenuation is likely due to the high atomic number of Hg, which can block or absorb X-ray fluorescence from underlying layers [21]. The µXRF system, due to its higher resolution, provides a more detailed view of this shielding effect, including areas where Ca and S signals are only partially reduced rather than completely suppressed.

3.3. Mineralogical Composition and Spectroscopy Studies

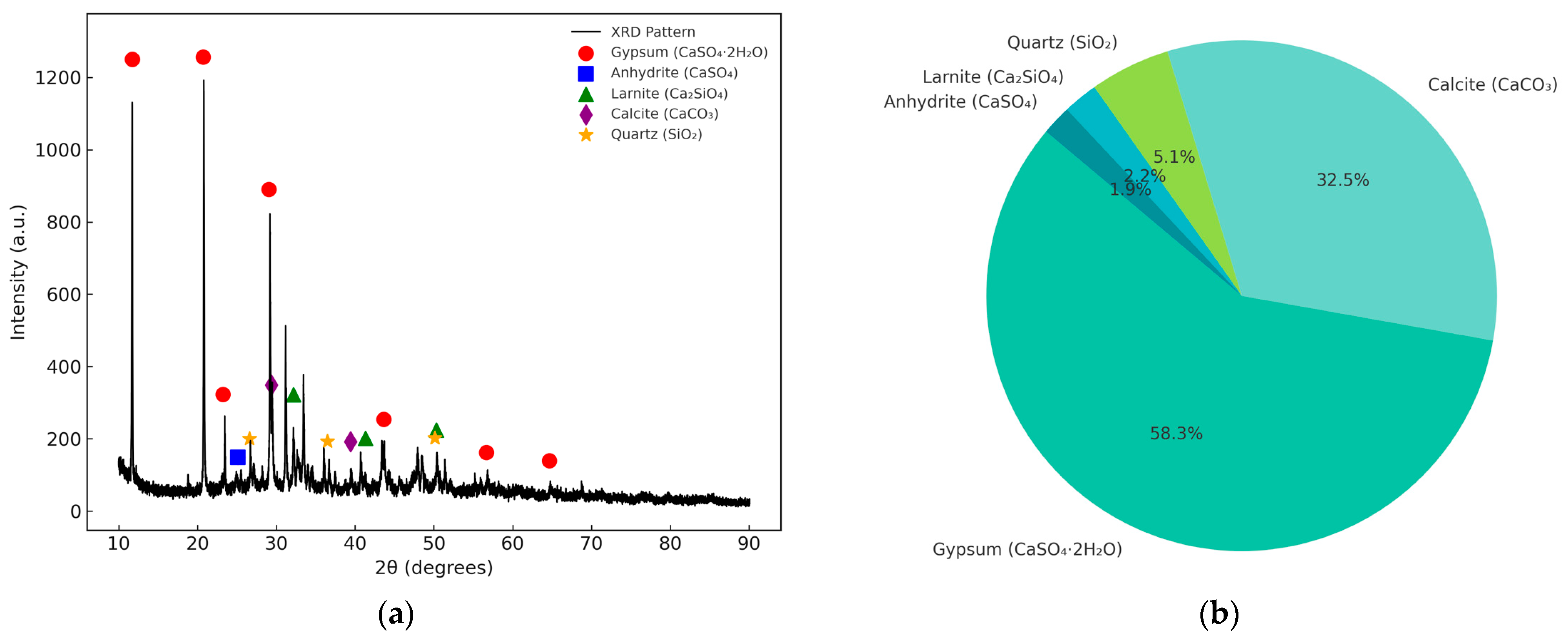

3.3.1. XRD Phase Analysis

3.3.2. ATR-FTIR and Raman Characteristics

4. Discussion

4.1. Technological Interpretation of the Preparatory Material

4.2. Historical Context and Regional Utilization of Gypsum-Based Materials

4.3. Deterioration Mechanisms and Conservation Implications

5. Conclusions

- This study presents the first scientific characterization of a white preparatory layer on polychrome wooden figurines excavated from the Mawangdui Tomb No. 1, dated to the Han dynasty. Multi-analytical techniques, including XRF mapping, SEM, ATR-FTIR, XRD, and Raman spectroscopy, revealed that the preparatory layer consists primarily of gypsum (CaSO4·2H2O) and calcite (CaCO3), with minor high-temperature phases such as anhydrite and larnite. The preparatory layer exhibits a porous microstructure composed of interlocking needle-like gypsum crystals, consistent with the characteristics of low-strength plaster. In certain areas, it also functioned as a putty, filling surface irregularities and providing structural support for polychrome decoration. Spectroscopic analyses further indicate the possible presence of organic binders, although their composition remains inconclusive. The use of such a preparatory layer reflects a localized technological innovation specific to Hunan and represents the first confirmed application of gypsum-based materials in ancient Chinese woodcarving. While comparable surface preparation techniques involving gypsum and calcite have been observed in New Kingdom Egyptian artifacts, the considerable spatial and temporal distance between the two traditions suggests independent development. These similarities are better understood as examples of convergent technological responses, in which artisans in different cultural settings arrived at comparable solutions through practical engagement with similar materials.

- In addition to material identification, this study highlights several conservation challenges and methodological limitations. The gypsum-based preparatory layer showed deterioration after excavation, including cracking, delamination, and powdering, reflecting its sensitivity to environmental fluctuations such as humidity, temperature, and air exposure. These issues emphasize the need for environmental control during excavation, transport, and storage. However, due to equipment constraints and the immovability of the artifacts, advanced imaging techniques such as high-resolution X-ray radiography and computed tomography (CT) were not applied. As a result, the internal structure of the wooden cores and the extent to which the external morphology was shaped by wood versus gypsum remains unclear. Likewise, the absence of molecular analyses such as pyrolysis–gas chromatography–mass spectrometry (py-GC-MS) limited the identification of potential organic binders. Future research should address these gaps through the application of non-invasive or minimally invasive imaging and molecular techniques, which will be essential for clarifying the construction logic of these figurines and refining conservation strategies tailored to their complex material composition.

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| SEM | Scanning Electron Microscopy |

| ATR-FTIR | Attenuated Total Reflectance Fourier Transform Infrared Spectroscopy |

| Raman | Raman Spectroscopy |

| MA-XRF | Macro X-ray Fluorescence Mapping |

| µXRF | Micro X-ray Fluorescence Mapping |

| XRD | X-ray Diffraction |

| GC-MS | Gas Chromatography–Mass Spectrometry |

| Py-GC-MS | Pyrolysis–Gas Chromatography–Mass Spectrometry |

| MWD | Mawangdui |

References

- Wei, S.; Ma, Q.; Schreiner, M. Scientific investigation of the paint and adhesive materials used in the Western Han Dynasty polychromy terracotta army, Qingzhou, China. J. Archaeol. Sci. 2012, 39, 1628–1633. [Google Scholar] [CrossRef]

- Miller, A.R. Painting bronze in early China: Uncovering polychromy in China’s classical sculptural tradition. Arch. Asian Art 2022, 72, 1–53. [Google Scholar] [CrossRef]

- Blänsdorf, C.; Yin, X. A colourful world for the emperor’s soul: The polychromy of the terracotta sculptures at Qin Shihuang’s burial complex. Stud. Conserv. 2006, 51 (Suppl. S2), 177–183. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhang, Z.; Rong, B.; Dang, H. Structural survey and pigment analysis of the paint layer on the cultural relics from the Han Yangling. Sci. Conserv. Archaeol. 2013, 25, 88–92. [Google Scholar]

- Feng, J.; Zhao, F.; Li, S. On-site conservation of the tomb mural of the Western Han Dynasty at Xi’an University of Technology, Xi’an, China. Stud. Conserv. 2014, 59 (Suppl. S1), S40–S43. [Google Scholar] [CrossRef]

- Rong, B.; Zhao, Q.; Wu, Z.; Zheng, H.; Zhao, J. Research on the polychrome potteries excavated from the Chengyangcheng site in Xinyang. Sci. Conserv. Archaeol. 2018, 30, 9–14. [Google Scholar]

- Zhang, Y. The types and characteristics of the Han Dynasty wooden figurines unearthed in Jiangsu. J. Natl. Mus. China 2018, 8, 48–58. [Google Scholar]

- Liu, L.; Zhou, C.; Chen, N. Brief analysis on wooden human figurines of the Western Han Dynasty unearthed in the Jingzhou area. Jianghan Archaeol. 2023, 5, 103–111. [Google Scholar]

- Luo, T. An analysis of wooden figurines unearthed from Chu tombs in the Jingzhou area. Identif. Appreciat. Cult. Relics 2024, 17, 8–11. [Google Scholar] [CrossRef]

- Gao, Z. A study on Chu figurines. In Bronzes of the Shang and Zhou Dynasties and Chu Culture; Yuelu Shushe: Changsha, China, 1999; pp. 180–207. [Google Scholar]

- Fu, J. Wooden figurine unearthed in Hunan Province. Collectors 2009, 10, 41–49. [Google Scholar]

- Zhou, W.; Xu, D. A study on Chu-style wooden figurines. Jianghan Archaeol. 2019, 83–93. [Google Scholar]

- Yang, H. A summary of the research on the wooden figurines from the Han tombs at Mawangdui. J. Hunan Prov. Mus. 2013, 84–87. [Google Scholar]

- Ren, T. A brief analysis of wooden disks from Han Tomb 1 at Mawangdui and other Chu and Han tombs. J. Hunan Mus. 2022, 79–93. [Google Scholar]

- Chen, G.; Han, J. Analysis and restoration of pigments from Han Dynasty painted wooden horses at Mozuizi, Wuwei, Gansu Province. Sci. Conserv. Archaeol. 2011, 23, 40–46. [Google Scholar]

- Mazzinghi, A.; Ruberto, C.; Castelli, L.; Czelusniak, C.; Giuntini, L.; Mandò, P.A.; Taccetti, F. MA-XRF for the characterisation of the painting materials and technique of The Entombment of Christ by Rogier van der Weyden. Appl. Sci. 2021, 11, 6151. [Google Scholar] [CrossRef]

- Saverwyns, S.; Currie, C.; Lamas-Delgado, E. Macro X-ray fluorescence scanning (MA-XRF) as tool in the authentication of paintings. Microchem. J. 2018, 137, 139–147. [Google Scholar] [CrossRef]

- Vanden Berghe, I.; Van Bos, M.; Vandorpe, M.; Coudray, A. Non-invasive analysis of heritage textiles with MA-XRF mapping—Exploring the possibilities. The study of Bishop Jacques de Vitry’s mitres and fragile medieval reliquary purses from Namur (Belgium). Herit. Sci. 2023, 11, 183. [Google Scholar] [CrossRef]

- Shen, G.; Wang, S.; Peng, S.; Ren, T.; Liu, Q. Discussion on the unearthed Yu Lü tubes and their silk packaging bags from the Mawangdui Han Tomb No. 1. Cult. Relics World 2024, 4, 56–60. [Google Scholar]

- Capobianco, G.; Sferragatta, A.; Lanteri, L.; Agresti, G.; Bonifazi, G.; Serranti, S.; Pelosi, C. µXRF mapping as a powerful technique for investigating metal objects from the archaeological site of Ferento (Central Italy). J. Imaging 2020, 6, 59. [Google Scholar] [CrossRef]

- Ruberto, C.; Mazzinghi, A.; Massi, M.; Castelli, L.; Czelusniak, C.; Palla, L.; Gelli, N.; Betuzzi, M.; Impallaria, A.; Brancaccio, R.; et al. Imaging study of Raffaello’s La Muta by a portable XRF spectrometer. Microchem. J. 2016, 126, 63–69. [Google Scholar] [CrossRef]

- Liu, L.; He, J.; Ye, M.; Zhu, Z.; Zhong, Q.; Yang, J. Spectral characterization of pigment from the No. 1 Cave, Kizil Cave-Temple Complex. J. Spectrosc. 2019, 2019, 8502524. [Google Scholar] [CrossRef]

- Nakamoto, K. Infrared and Raman Spectra of Inorganic and Coordination Compounds, Part B: Theory and Applications in Inorganic Chemistry, 6th ed.; Wiley: Hoboken, NJ, USA, 2009. [Google Scholar]

- Cvetković, J.; Petruševski, V.; Šoptrajanov, B. Reinvestigation of the water bending region in the spectra of gypsum-like compounds—An FTIR study. J. Mol. Struct. 1997, 408–409, 463–466. [Google Scholar] [CrossRef]

- Böke, H.; Akkurt, S.; Ozdemir, S.; Göktürk, E.; Saltik, E. Quantification of CaCO3–CaSO3·0.5H2O–CaSO4·2H2O mixtures by FTIR analysis and its ANN model. Mater. Lett. 2004, 58, 723–726. [Google Scholar] [CrossRef]

- Reig, F.B.; Adelantado, J.; Moya Moreno, M.C.M. FTIR quantitative analysis of calcium carbonate (calcite) and silica (quartz) mixtures using the constant ratio method. Application to geological samples. Talanta 2002, 58, 811–821. [Google Scholar] [CrossRef] [PubMed]

- Derrick, M.R.; Stulik, D.; Landry, J.M. Infrared Spectroscopy in Conservation Science; Getty Conservation Institute: Los Angeles, CA, USA, 1999. [Google Scholar]

- González-Cabrera, M.; Domínguez-Vidal, A.; Ayora-Cañada, M.J. Monitoring UV-Accelerated Alteration Processes of Paintings by Means of Hyperspectral Micro-FTIR Imaging and Chemometrics. Spectrochim. Acta A Mol. Biomol. Spectrosc. 2021, 253, 119568. [Google Scholar] [CrossRef]

- Colombini, M.P.; Modugno, F.; Galanakis, E.; Ribechini, A. Analytical strategies for characterizing organic materials in wall paintings. Anal. Chim. Acta 2001, 440, 43–54. [Google Scholar] [CrossRef]

- Prieto-Taboada, N.; Martinez-Arkarazo, I.; Castro, K.; Madariaga, J.M. Raman spectra of the different phases in the CaSO4–H2O system. Anal. Chem. 2014, 86, 10131–10137. [Google Scholar] [CrossRef]

- Schmid, T.; Kempe, U.; Panne, U.; Beckhoff, B. Insights into the CaSO4–H2O system: A Raman-spectroscopic study. Minerals 2020, 10, 115. [Google Scholar] [CrossRef]

- Wang, X.; Hua, F.; Xie, X.; Wu, Y.; Sun, W.; Jiang, Z.; Zhang, J.; Luo, X. Infrared Raman spectroscopy enables noninvasive biochemical assessment of skin tissue and the thermal stability. Heliyon 2023, 9, e21974. [Google Scholar] [CrossRef]

- Cluff, K.; Naganathan, G.K.; Jonnalagada, D.; Mortensen, I.; Wehling, R.; Subbiah, J. Determination of yolk contamination in liquid egg white using Raman spectroscopy. Poult. Sci. 2016, 95, 1702–1708. [Google Scholar] [CrossRef]

- Jurašeková, Z.; Fabriciová, G.; Silveira, L.F.; Lee, Y.-N.; Gutak, J.M.; Ataabadi, M.M.; Kundrát, M. Raman spectra and ancient life: Vibrational ID profiles of fossilized (bone) tissues. Int. J. Mol. Sci. 2022, 23, 10689. [Google Scholar] [CrossRef] [PubMed]

- Raii, M. Formulation, Caracterization and Implementation of Permeable Reactive Barrier (PRB) Made of Calcium Phosphate. Ph.D. Thesis, Institut National Polytechnique de Toulouse, Toulouse, France, 2012. Available online: https://tel.archives-ouvertes.fr/tel-00842771 (accessed on 2 March 2025).

- Coccato, A.; Jehlička, J.; Moens, L.; Vandenabeele, P. Raman spectroscopy for the investigation of carbon-based black pigments. J. Raman Spectrosc. 2015, 46, 1003–1015. [Google Scholar] [CrossRef]

- De Faria, D.L.A.; Venâncio Silva, S.; Oliveira, M.T. Raman microspectroscopy of some iron oxides and oxyhydroxides. J. Raman Spectrosc. 1997, 28, 873–878. [Google Scholar] [CrossRef]

- Vind, J.; Malfliet, A.; Bonomi, C.; Paiste, P.; Sajó, I.E.; Blanpain, B.; Tkaczyk, A.H.; Vassiliadou, V.; Panias, D. Modes of occurrences of scandium in Greek bauxite and bauxite residue. Miner. Eng. 2018, 123, 35–48. [Google Scholar] [CrossRef]

- Mishmastnehi, M.; Van Driessche, A.E.S.; Smales, G.J.; Moya, A.; Stawski, T.M. Advanced materials engineering in historical gypsum plaster formulations. Proc. Natl. Acad. Sci. USA 2023, 120, e2208836120. [Google Scholar] [CrossRef] [PubMed]

- Mason, B. Larnite, Scawtite, and Hydrogrossular from Tokatoka, New Zealand. Am. Mineral. 1957, 42, 379–392. [Google Scholar]

- Yan, R.; Zheng, C.; Wang, Y.; Zeng, Y. Evaluation of combustion characteristics of Chinese high-ash coals. Energy Fuels 2003, 17, 1522–1527. [Google Scholar] [CrossRef]

- Folgueras, M.B.; Díaz, R.M.; Xiberta, J. Sulphur retention during co-combustion of coal and sewage sludge. Fuel 2004, 83, 1315–1322. [Google Scholar] [CrossRef]

- Sanz-Rubio, E.; Sánchez-Moral, S.; Cañaveras, J.C.; Calvo, J.P.; Rouchy, J.M. Calcitization of Mg–Ca carbonate and Ca sulphate deposits in a continental Tertiary Basin (Calatayud Basin, NE Spain). Sediment. Geol. 2001, 140, 123–142. [Google Scholar] [CrossRef]

- Mansour, A.S. Sedimentology and environmental interpretation of carbonate deposits associating the evaporites-bearing Miocene succession, Northern Western Desert, Egypt. Carbonates Evaporites 2015, 30, 167–179. [Google Scholar] [CrossRef]

- Elert, K.; Benavides-Reyes, C.; Cardell, C. Effect of animal glue on mineralogy, strength and weathering resistance of calcium sulfate-based composite materials. Cem. Concr. Compos. 2019, 96, 274–283. [Google Scholar] [CrossRef]

- Gettens, R.J.; Mrose, M.E. Calcium sulphate minerals in the grounds of Italian paintings. Stud. Conserv. 1954, 1, 174–189. [Google Scholar] [CrossRef]

- Romero-Pastor, J.; Duran, A.; Rodríguez-Navarro, A.B.; Van Grieken, R.; Cardell, C. Compositional and quantitative microtextural characterization of historic paintings by micro-X-ray diffraction and Raman microscopy. Anal. Chem. 2011, 83, 8420–8428. [Google Scholar] [CrossRef] [PubMed]

- Antunes, V.; Candeias, A.; Oliveira, M.J.; Longelin, S.; Serrão, V.; Seruya, A.L.; Coroado, J.; Dias, L.; Mirão, J.; Carvalho, M.L. Characterization of gypsum and anhydrite ground layers in 15th and 16th century Portuguese paintings by Raman spectroscopy and other techniques. J. Raman Spectrosc. 2014, 45, 1026–1033. [Google Scholar] [CrossRef]

- Moropoulou, A.; Bakolas, A.; Anagnostopoulou, S. Composite materials in ancient structures. Cem. Concr. Compos. 2005, 27, 295–300. [Google Scholar] [CrossRef]

- Kingery, W.D.; Vandiver, P.B.; Prickett, M. The beginnings of pyrotechnology, part II: Production and use of lime and gypsum plaster in the Pre-Pottery Neolithic Near East. J. Field Archaeol. 1988, 15, 219–244. [Google Scholar] [CrossRef]

- Gourdin, W.H.; Kingery, W.D. The beginnings of pyrotechnology: Neolithic and Egyptian lime plaster. J. Field Archaeol. 1975, 2, 133–150. [Google Scholar] [CrossRef]

- Regourd, M.; Kerisel, J.; Deletie, P.; Haguenauer, B. Microstructure of mortars from Egyptian pyramids. Cem. Concr. Res. 1988, 18, 81–90. [Google Scholar] [CrossRef]

- Verhoeven, K. Abü Qubür 1990. III. Operation F. A gypsum wall plaster from the ‘Parthian Building’. Micromorphological description and mineralogical analyses. North. Akkad Proj. Rep. 1991, 7, 35–40. [Google Scholar]

- Stoops, G.; Tsatskin, A.; Canti, M.G. Gypsic mortars and plasters. In Archaeological Soil and Sediment Micromorphology; Nicosia, C., Stoops, G., Eds.; John Wiley & Sons: Hoboken, NJ, USA, 2017; pp. 201–204. [Google Scholar]

- Rollefson, G.O. The uses of plaster at Neolithic’Ain Ghazal, Jordan. Archaeomaterials 1990, 4, 33–54. [Google Scholar]

- Heldal, T.; Bloxam, E.G.; Degryse, P.; Storemyr, P.; Kelany, A. Gypsum quarries in the northern Faiyum quarry landscape, Egypt: A geo-archaeological case study. In QuarryScapes: Ancient Stone Quarry Landscapes in the Eastern Mediterranean; Abu Jaber, N., Bloxam, E.G., Degryse, P., Heldal, T., Eds.; Special Publication 12; Norwegian Geological Survey of Norway: Bergen, Norway, 2009; pp. 51–66. [Google Scholar]

- Harrell, J.A. Amarna gypsite: A new source of gypsum for ancient Egypt. J. Archaeol. Sci. Rep. 2017, 11, 536–545. [Google Scholar] [CrossRef]

- Li, X.; Wang, C.; Huang, K.; Shen, L.; You, C.; Jiang, H.; Zhao, Y. Analysis of Gypsum Distribution, Types, Industrial Applications, and Prospecting Potential in China. Geol. China 2025, 1–32. Available online: http://kns.cnki.net/kcms/detail/11.1167.P.20240819.1414.009.html (accessed on 10 January 2025).

- Yi, M. Geological characteristics of the Liangshitang gypsum mine in Shaodong, Hunan. Build. Mater. Geol. 1987, 4, 17–23+66. [Google Scholar]

- Chen, X.; Ma, Q.; Song, D.; Hu, Z.; Li, Z. X-ray diffraction analysis of black and white pigments on Majiayao-type painted pottery. J. Lanzhou Univ. 2000, 2, 54–58. [Google Scholar] [CrossRef]

- Zhu, X. Analysis of painted pottery pigments from the Majiayao Culture unearthed at the Niumendong site in Huining. Mus. Emperor Qin 2018, 207–212. [Google Scholar]

- Lu, H.; Meng, F. Discussion on the processing methods of gypsum in different historical periods. Chin. Med. Mater. 2000, 23, 142–143. [Google Scholar]

- Dodd, L.S.; Scott, D.A.; Nikias, G.A.; Au, J.; Ramos, A. The ritual significance of colour: Specialised pigments in a wooden Egyptian funerary statuette from the New Kingdom. J. Egypt. Archaeol. 2009, 95, 83–104. [Google Scholar] [CrossRef]

- Frederiksen, R. Plaster casts in antiquity. In Plaster Casts: Making, Collecting and Displaying from Classical Antiquity to the Present, Transformationen der Antike; Frederiksen, R., Marchand, E., Eds.; De Gruyter: Berlin, Germany; Volume 18. [CrossRef]

- Qu, J.; Zhang, M.; Zhang, W.; Wang, Y.; Dai, F.; Zhang, H.; Zeng, Z. A preliminary study on weathering process of salt in rock body at Mogao Grottoes, Dunhuang. Sci. Geogr. Sin. 1995, 15, 182–187+200. [Google Scholar]

- Downs, R.T. The RRUFF Project: An Integrated Study of the Chemistry, Crystallography, Raman and Infrared Spectroscopy of Minerals. RRUFF Database: R050009 (Calcite). Available online: http://rruff.info/R050009 (accessed on 12 April 2025).

- Downs, R.T. The RRUFF Project: An Integrated Study of the Chemistry, Crystallography, Raman and Infrared Spectroscopy of Minerals. RRUFF Database: R040029 (Gypsum). Available online: http://rruff.info/R040029 (accessed on 12 April 2025).

- Downs, R.T. The RRUFF Project: An Integrated Study of the Chemistry, Crystallography, Raman and Infrared Spectroscopy of Minerals. RRUFF Database: R150020 (Calcite). Available online: http://rruff.info/R150020 (accessed on 12 April 2025).

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xu, N.; Ren, T.; Xiao, P.; Liu, Q. First Identification of a Gypsum-Based Preparatory Layer on Polychrome Wooden Figurines from the Mawangdui Han Tomb No. 1 (2nd Century BCE), Changsha, China. Coatings 2025, 15, 492. https://doi.org/10.3390/coatings15040492

Xu N, Ren T, Xiao P, Liu Q. First Identification of a Gypsum-Based Preparatory Layer on Polychrome Wooden Figurines from the Mawangdui Han Tomb No. 1 (2nd Century BCE), Changsha, China. Coatings. 2025; 15(4):492. https://doi.org/10.3390/coatings15040492

Chicago/Turabian StyleXu, Ningning, Tingyan Ren, Pan Xiao, and Qi Liu. 2025. "First Identification of a Gypsum-Based Preparatory Layer on Polychrome Wooden Figurines from the Mawangdui Han Tomb No. 1 (2nd Century BCE), Changsha, China" Coatings 15, no. 4: 492. https://doi.org/10.3390/coatings15040492

APA StyleXu, N., Ren, T., Xiao, P., & Liu, Q. (2025). First Identification of a Gypsum-Based Preparatory Layer on Polychrome Wooden Figurines from the Mawangdui Han Tomb No. 1 (2nd Century BCE), Changsha, China. Coatings, 15(4), 492. https://doi.org/10.3390/coatings15040492