Enhancement of Energy Storage Performance in NaNbO3-Modified BNT-ST Ceramics

Abstract

1. Introduction

2. Materials and Methods

2.1. Synthesis of (1 − x){0.97[0.98(BNT-ST)-0.02CN]-0.03AlN}-xNN Ceramics

2.2. Characterization

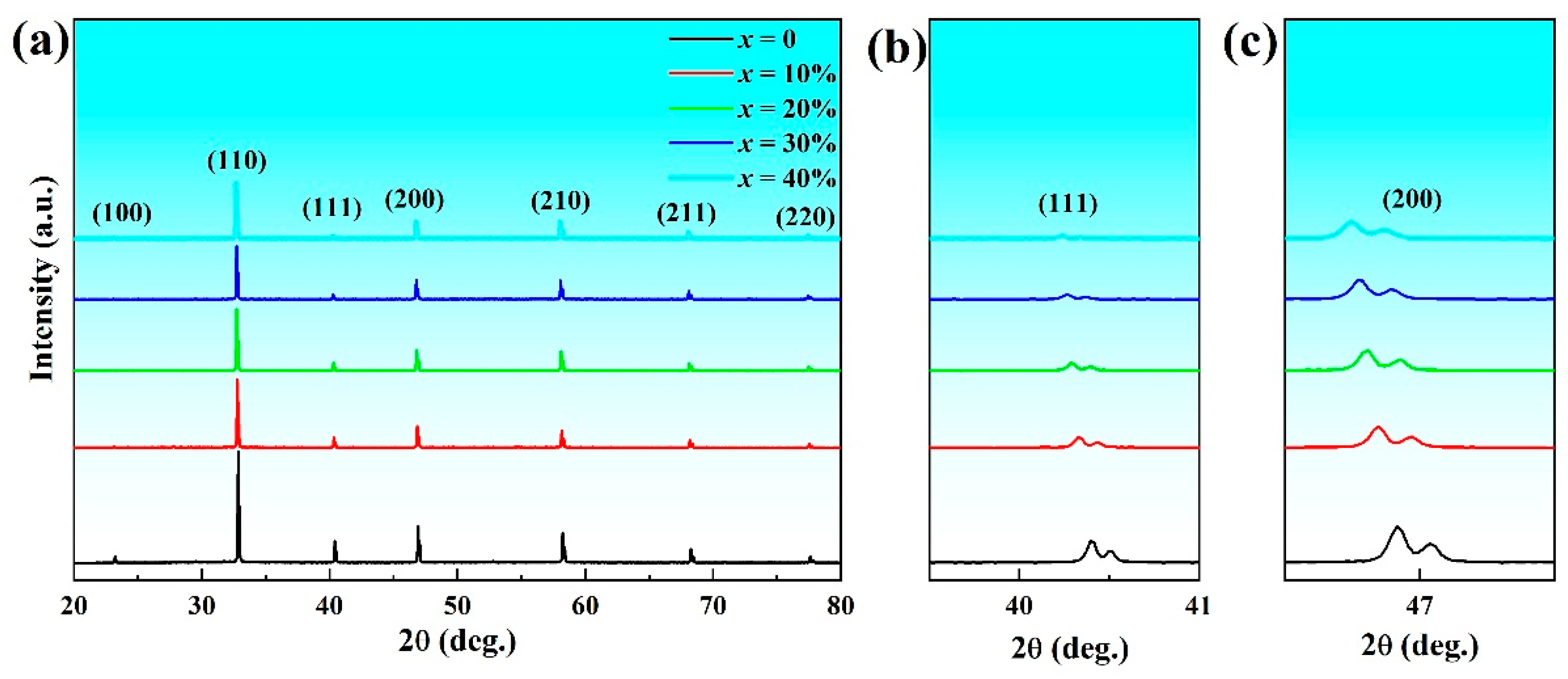

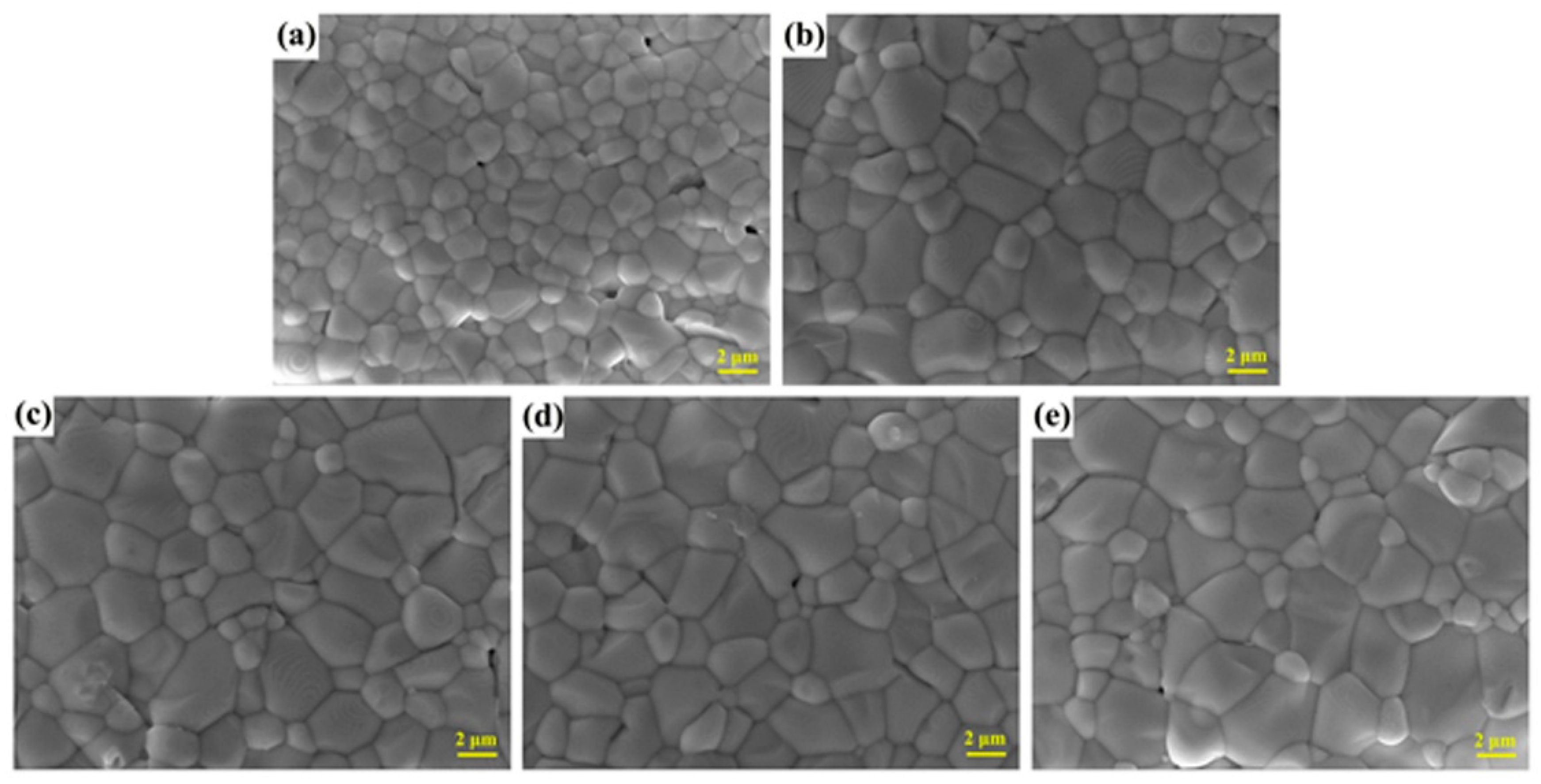

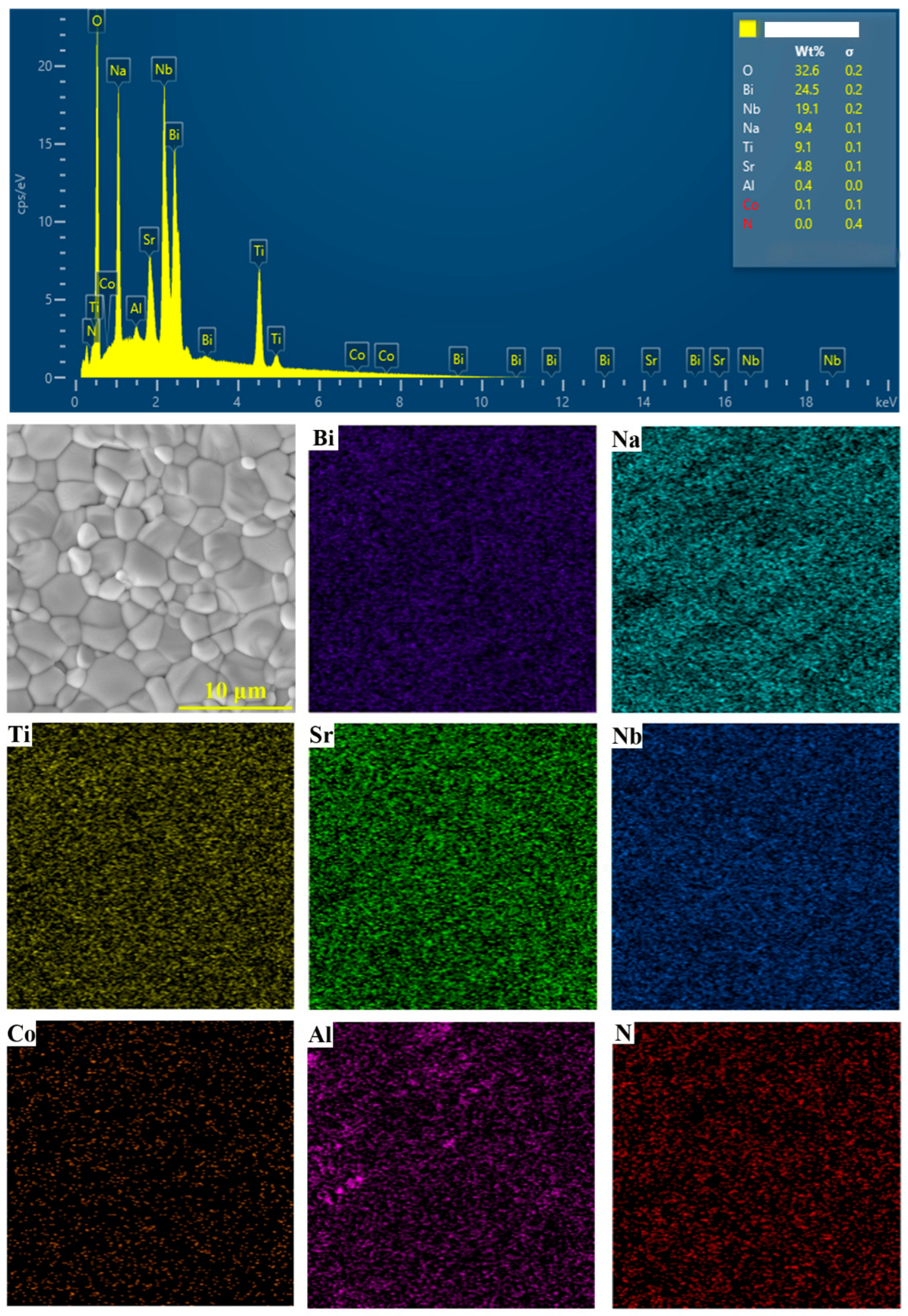

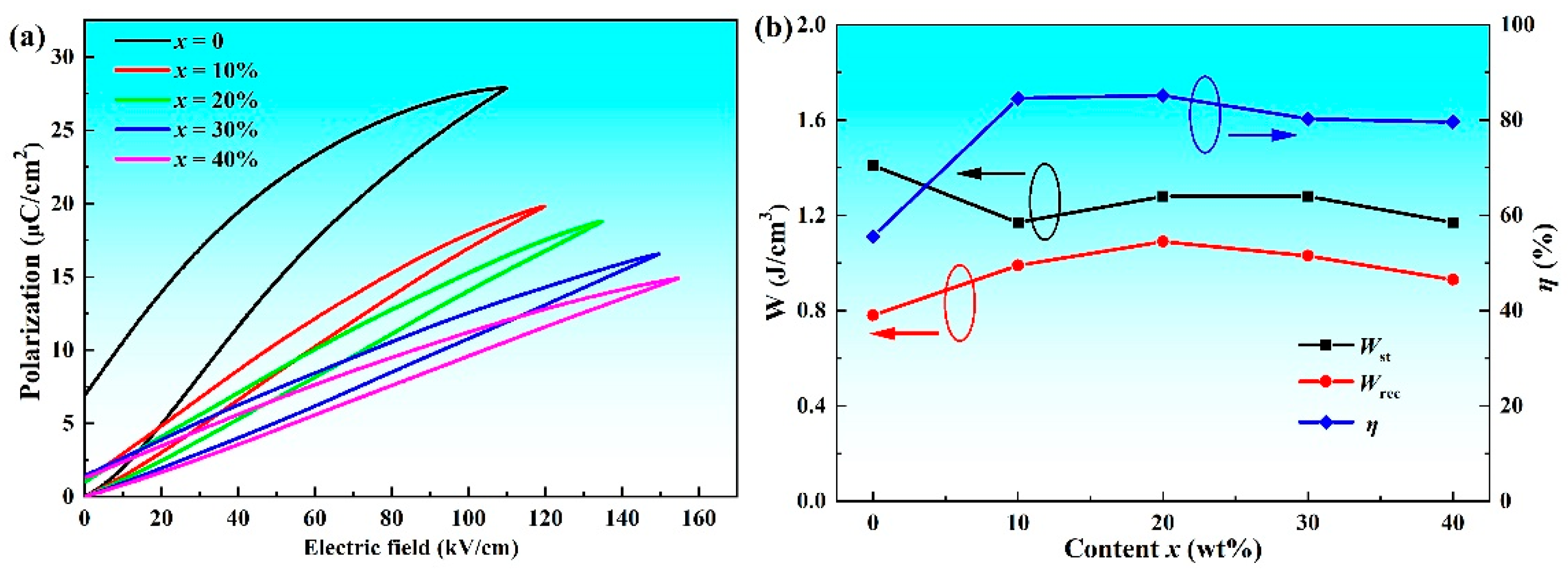

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Bilal, M.K.; Bashir, R.; Asif, S.U.; Xie, J. Enhanced energy storage density and ultrahigh efficiency achieved in BNT-BST-NN relaxor ferroelectric through the introduction of nanodomains and grain size engineering. J. Energy Storage 2024, 97, 112841. [Google Scholar] [CrossRef]

- Khan, S.U.; Manan, A.; Ullah, A.; Qazi, I.; Rehman, M.U.; Khan, M.A.; Ahmad, A.S.; Muhammad, R.; Iqbal, Y. Dielectric, impedance, and energy storage properties of Bi (Mg0.5Sn0.5)O3 modified Bi0.5Na0.5TiO3 based ceramics. Int. J. Appl. Ceram. Technol. 2025, 22, e15030. [Google Scholar] [CrossRef]

- Fan, X.H.; Wang, J.; Yuan, H.; Zheng, Z.H.; Zhang, J.; Zhu, K.J. Multi-scale synergic optimization strategy for dielectric energy storage ceramics. J. Adv. Ceram. 2023, 12, 649–680. [Google Scholar] [CrossRef]

- Zhang, X.; Huang, Y.; Yang, S.; Liu, Y.; Chen, X.; Li, X.; Huang, F.; Zhou, H. Realizing high energy storage performance under low electric fields in Bi0.5Na0.5TiO3-based ceramics by introducing rare earth elements. J. Power Sources 2024, 624, 235548. [Google Scholar] [CrossRef]

- Dinh, T.H.; Tran, V.D.N.; Le Manh, T.; Lee, J.S. Effects of BaZrO3 on the phase evolution and energy storage capacities of BNT-based lead-free dielectric ceramics. J. Phys. Chem. Solids 2025, 198, 112462. [Google Scholar] [CrossRef]

- Aly, K.A.; Ismail, Y.A.; Alsubaie, A.S.; Mahmoud, A.E.R. High entropy induced superior weakly coupled relaxor phase and suppression interfacial polarization in (Bi0.3Na0.3Sr0.3Ba0.1)(Ti1-xNbx)O3 ceramics. Mater. Chem. Phys. 2025, 334, 130446. [Google Scholar] [CrossRef]

- Yan, Y.; Hui, J.; Wang, X.; Zhang, D.; Zhang, M.; Zhao, M.; Wan, M.; Jin, L.; Li, Z. Improvement of energy storage properties of BNT-based ceramics via compositional modification. Ceram. Int. 2024, 50, 48918–48930. [Google Scholar] [CrossRef]

- Li, C.; Wang, F.; Wang, H.; Wang, B.; Sun, X.; Peng, X.; Li, W.; Diao, C.; Zheng, H. Optimized energy storage properties of Bi0.5Na0.5TiO3-based lead-free ceramics by composition regulation. Ceram. Int. 2024, 50, 18454–18461. [Google Scholar] [CrossRef]

- Buhrer, C.F. Some properties of bismuth perovskites. J. Chem. Phys. 1962, 36, 798–803. [Google Scholar] [CrossRef]

- Guo, B.; Jin, F.; Li, L.; Pan, Z.Z.; Xu, X.W.; Wang, H. Design strategies of high-performance lead-free electroceramics for energy storage applications. Rare Met. 2024, 43, 853–878. [Google Scholar] [CrossRef]

- Ezzeldien, M.; Mohamed, W.S.; Al-Qaisi, S.; Ameen, I.G.; Mahmoud, A.E.R. Enhancement of energy storage and pyroelectric properties of (Na0.5Bi0.5)TiO3-SrTiO3-BaTiO3 ceramics by addition of (Ba0.9B0.1)TiO3 glass-phase. Phys. Scr. 2024, 99, 105935. [Google Scholar] [CrossRef]

- Che, Z.Y.; Ma, L.; Luo, G.G.; Xu, C.; Cen, Z.Y.; Feng, Q.; Chen, X.Y.; Ren, K.L.; Luo, N.N. Phase structure and defect engineering in (Bi0.5Na0.5)TiO3-based relaxor antiferroelectrics toward excellent energy storage performance. Nano Energy 2022, 100, 107484. [Google Scholar] [CrossRef]

- Zhao, X.; Li, C.; Liu, J.; Ding, Y.; Bai, W.; Zheng, P.; Li, P.; Zhang, J.; Zhai, J. (Bi0.5Na0.5)TiO3-based relaxor ferroelectrics with simultaneous high energy storage properties and remarkable charge-discharge performances under low working electric fields for dielectric capacitor applications. Ceram. Int. 2021, 47, 25800–25809. [Google Scholar] [CrossRef]

- Qi, H.; Xie, A.; Fu, J.; Zuo, R. Emerging antiferroelectric phases with fascinating dielectric, polarization and strain response in NaNbO3-(Bi0.5Na0.5)TiO3 lead-free binary system. Acta Mater. 2021, 208, 116710. [Google Scholar] [CrossRef]

- Li, D.; Li, Z.; Luo, W.; Song, F.; Wang, X.; Wang, Z.; Li, Y. Optimization of polarization behavior in (1−x)BSBN–xNN ceramics for pulsed power capacitors. J. Mater. Chem. C 2020, 8, 7650–7657. [Google Scholar] [CrossRef]

- Li, B.Y.; Yan, Z.N.; Zhou, X.F.; Qi, H.; Koval, V.; Luo, X.G.; Luo, H.; Yan, H.X.; Zhang, D. Achieving Ultrahigh Energy Storage Density of La and Ta Codoped AgNbO3 Ceramics by Optimizing the Field-Induced Phase Transitions. ACS Appl. Mater. Interfaces 2023, 15, 4246–4256. [Google Scholar] [CrossRef] [PubMed]

- Sun, H.; Wang, X.; Zhang, X.; Ma, Z.; Guo, M.; Sun, B.; Zhu, X.; Liu, Q.; Lou, X. Large energy storage density in BiFeO3-BaTiO3-AgNbO3 lead-free relaxor ceramics. J. Eur. Ceram. Soc. 2020, 40, 2929–2935. [Google Scholar] [CrossRef]

- Chen, X.; Zhang, D.; Liu, H.; Zhou, C.; Shen, M.; Liu, P.; Liu, X. Enhanced energy storage performance of BNT-ST based ceramics under low electric field via domain engineering. Ceram. Int. 2022, 48, 31381–31388. [Google Scholar] [CrossRef]

- Kornphom, C.; Saenkam, K.; Bongkarn, T. Enhanced Energy Storage Properties of BNT-ST-AN Relaxor Ferroelectric Ceramics Fabrication by the Solid-State Combustion Technique. Phys. Status Solidi 2023, 220, 2200240. [Google Scholar] [CrossRef]

- Shi, W.J.; Yang, Y.L.; Zhang, L.Y.; Jing, R.Y.; Hu, Q.Y.; Alikin, D.O.; Shur, V.Y.; Gao, J.H.; Wei, X.Y.; Jin, L. Enhanced energy storage performance of eco-friendly BNT-based relaxor ferroelectric ceramics via polarization mismatch-reestablishment and viscous polymer process. Ceram. Int. 2022, 48, 6512–6519. [Google Scholar] [CrossRef]

- Ning, Y.; Pu, Y.; Wu, C.; Zhou, S.; Zhang, L.; Zhang, J.; Zhang, X.; Shang, Y. Enhanced capacitive energy storage and dielectric temperature stability of A-site disordered high-entropy perovskite oxides. J. Mater. Sci. Technol. 2023, 145, 66–73. [Google Scholar] [CrossRef]

- Jia, W.X.; Hou, Y.D.; Zheng, M.P.; Xu, Y.R.; Yu, X.L.; Zhu, M.K.; Yang, K.Y.; Cheng, H.R.; Sun, S.h.Y.; Xing, J. Superior temperature-stable dielectrics for MLCC s based on Bi0.5Na0.5TiO3-NaNbO3 system modified by CaZrO3. J. Am. Ceram. Soc. 2018, 101, 3468–3479. [Google Scholar] [CrossRef]

- Qiao, X.S.; Zhang, X.S.; Wu, D.; Chao, X.L.; Yang, Z.P. Influence of Bi nonstoichiometry on the energy storage properties of 0.93KNN–0.07BixMN relaxor ferroelectrics. J. Adv. Dielectr. 2019, 08, 1830006. [Google Scholar] [CrossRef]

- Zhao, N.S.; Fan, H.Q.; Ma, J.W.; Ren, X.H.; Shi, Y.G.; Zhou, Y.Y. Large strain of temperature insensitive in (1-x)(0.94Bi0.5Na0.5TiO3-0.06BaTiO3)-xSr0.7La0.2TiO3 lead-free ceramics. Ceram. Int. 2018, 44, 11331–11339. [Google Scholar] [CrossRef]

- Panpho, P.; Charoonsuk, T.; Vittayakorn, N.; Bongkarn, T.; Sumang, R. Flexible hybrid piezo/triboelectric energy harvester based on a lead-free BNT-BT-KNN ceramic-polymer composite film. Ceram. Int. 2024, 50, 52041–52050. [Google Scholar] [CrossRef]

- Boonlakhorn, J.; Thongbai, P.; Putasaeng, B.; Yamwong, T.; Maensiri, S. Very high-performance dielectric properties of Ca1-3x/2YbxCu3Ti4O12 ceramics. J. Alloys Compd. 2014, 612, 103–109. [Google Scholar] [CrossRef]

- Sahu, R.K.; Asthana, S. Enhanced energy storage performance, breakdown strength, and thermal stability in compositionally designed relaxor Eu3+ substituted Na0.2K0.3Bi0.5TiO3. J. Energy Storage 2024, 91, 112020. [Google Scholar] [CrossRef]

- Ma, W.G.; Zhu, Y.W.; Marwat, M.A.; Fan, P.Y.; Xie, B.; Salamon, D.; Ye, Z.G.; Zhang, H.B. Enhanced energy-storage performance with excellent stability under low electric fields in BNT–ST relaxor ferroelectric ceramics. J. Mater. Chem. C 2019, 7, 281–288. [Google Scholar] [CrossRef]

- Wei, J.; Yang, T.Q.; Wang, H.S. Excellent energy storage and charge-discharge performances in PbHfO3 antiferroelectric ceramics. J. Eur. Ceram. Soc. 2019, 39, 624–630. [Google Scholar] [CrossRef]

- Zhao, L.; Liu, Q.; Zhang, S.; Li, J.F. Lead-free AgNbO3 anti-ferroelectric ceramics with an enhanced energy storage performance using MnO2 modification. J. Mater. Chem. C 2016, 4, 8380–8384. [Google Scholar] [CrossRef]

- Yang, Y.; Wang, H.; Bi, L.N.; Zheng, Q.J.; Fan, G.F.; Jie, W.J.; Lin, D.M. High energy storage density and discharging efficiency in La3+/Nb5+-co-substituted (Bi0.5Na0.5)0.94Ba0.06TiO3 ceramics. J. Eur. Ceram. Soc. 2019, 39, 3051–3056. [Google Scholar] [CrossRef]

- Wu, Y.; Wang, G.; Jiao, Z.; Fan, Y.; Peng, P.; Dong, X. High electrostrictive properties and energy storage performances with excellent thermal stability in Nb-doped Bi0.5Na0.5TiO3-based ceramics. RSC Adv. 2019, 37, 21355–21362. [Google Scholar] [CrossRef]

- Liu, X.; Tan, X. Giant strains in non-textured (Bi1/2Na1/2)TiO3-based lead-free Ceramics. Adv. Mater. 2016, 3, 574–578. [Google Scholar] [CrossRef]

- Qiao, X.S.; Wu, D.; Zhang, F.D.; Chen, B.; Zhao, X.M.; Liang, P.F.; Wei, L.L.; Chao, X.L.; Yang, Z.P. Enhanced energy density and thermal stability in relaxor ferroelectric Bi0.5Na0.5TiO3-Sr0.7Bi0.2TiO3 ceramics. J. Eur. Ceram. Soc. 2019, 39, 4778–4784. [Google Scholar] [CrossRef]

- Wu, L.; Tang, L.; Zhai, Y.; Zhang, Y.; Sun, J.; Hu, D.; Liu, J. Enhanced energy-storage performance in BNT-based lead-free dielectric ceramics via introducing SrTi0.875Nb0.1O3. J. Mater. 2022, 8, 537–544. [Google Scholar] [CrossRef]

- Zheng, Q.; Xie, B.; Tian, Y.; Wang, Q.; Luo, H.; Liu, Z.; Zhang, H. High recoverable energy density of Na0.5Bi0.5TiO3-based ceramics by multi-scale insulation regulation and relaxor optimization strategy. J. Mater. 2024, 10, 845–856. [Google Scholar] [CrossRef]

- Yang, J.; Zhu, X.; Wang, H.; Zhang, Y.; Guan, P.; Yan, S.; Zheng, M. Achieving outstanding energy storage behaviors via combinatorial optimization design in BNT-based relaxor ferroelectric ceramics under medium–low electric fields. J. Mater. Chem. C 2024, 12, 6479–6486. [Google Scholar] [CrossRef]

- Yang, J.; Ge, G.; Chen, C.; Shen, B.; Zhai, J.; Chou, X. Field-induced strain engineering to optimize antiferroelectric ceramics in breakdown strength and energy storage performance. Acta Mater. 2023, 257, 119186. [Google Scholar] [CrossRef]

- Luo, N.; Han, K.; Liu, L.; Peng, B.; Wang, X.; Hu, C.; Zhou, H.; Feng, Q.; Chen, X.; Wei, Y. Lead-free Ag1-3xLaxNbO3 antiferroelectric ceramics with high- energy storage density and efficiency. J. Am. Ceram. Soc. 2019, 102, 4640–4647. [Google Scholar] [CrossRef]

- Luo, N.; Han, K.; Zhuo, F.; Xu, C.; Zhang, G.; Liu, L.; Chen, X.; Hu, C.; Zhou, H.; Wei, Y. Aliovalent A-site engineered AgNbO3 lead-free antiferroelectric ceramics toward superior energy storage density. J. Mater. Chem. A 2019, 7, 14118–14128. [Google Scholar] [CrossRef]

- Li, S.; Nie, H.; Wang, G.; Xu, C.; Liu, N.; Zhou, M.; Cao, F.; Dong, X. Significantly enhanced energy storage performance of rare-earth-modified silver niobate lead-free antiferroelectric ceramics via local chemical pressure tailoring. J. Mater. Chem. C 2019, 7, 1551–1560. [Google Scholar] [CrossRef]

- Gao, J.; Zhang, Y.; Zhao, L.; Lee, K.; Liu, Q.; Studer, A.; Hinterstein, M.; Zhang, S.; Li, J. Enhanced antiferroelectric phase stability in La-doped AgNbO3: Perspectives from the microstructure to energy storage properties. J. Mater. Chem. A 2019, 7, 2225–2232. [Google Scholar] [CrossRef]

- Shao, T.; Du, H.; Ma, H.; Qu, S.; Wang, J.; Wang, J.; Wei, X.; Xu, Z. Potassium-sodium niobate based lead-free ceramics: Novel electrical energy storage materials. J. Mater. Chem. A 2017, 5, 554–563. [Google Scholar] [CrossRef]

- Yang, Z.; Du, H.; Qu, S.; Hou, Y.; Ma, H.; Wang, J.; Wang, J.; Wei, X.; Xu, Z. Significantly enhanced recoverable energy storage density in potassium-sodium niobate-based lead free ceramics. J. Mater. Chem. A 2016, 4, 13778–13785. [Google Scholar] [CrossRef]

- Zhang, L.; Pu, Y.; Chen, M.; Wei, T.; Peng, X. Novel Na0.5Bi0.5TiO3 based lead-free energy storage ceramics with high power and energy density and excellent hightemperature stability. Chem. Eng. J. 2020, 383, 123154. [Google Scholar] [CrossRef]

- Liu, X.; Zhao, Y.; Shi, J.; Du, H.; Xu, X.; Lu, H.; Che, J.; Li, X. Improvement of dielectric and ferroelectric properties in bismuth sodium titanate based relaxors through Bi non-stoichiometry. J. Alloys. Compd. 2019, 799, 231–238. [Google Scholar] [CrossRef]

- Xie, H.; Zhao, Y.; Yang, L.; Pang, S.; Yuan, C.; Wang, H.; Zhou, C.; Xu, J. Comparative studies on structure, dielectric, strain and energy storage properties of (Bi0.5Na0.5)0.94Ba0.06Ti0.965(Mg1/3Nb2/3)0.035O3 lead-free ceramics prepared by traditional and two-step sintering method. J. Mater. SCI.—Mater. El 2018, 29, 5349–5355. [Google Scholar] [CrossRef]

- Zheng, D.; Zuo, R. Enhanced energy storage properties in La(Mg1/2Ti1/2)O3-modified BiFeO3-BaTiO3 lead-free relaxor ferroelectric ceramics within a wide temperature range. J. Eur. Ceram. Soc. 2017, 37, 413–418. [Google Scholar] [CrossRef]

- Li, F.; Zhai, J.; Shen, B.; Zeng, H.; Jian, X.; Lu, S. Multifunctionality of lead-free BiFeO3 -based ergodic relaxor ferroelectric ceramics: High energy storage performance and electrocaloric effect. J. Alloys Compd. 2019, 803, 185–192. [Google Scholar] [CrossRef]

- Liu, N.; Liang, R.; Zhao, X.; Xu, C.; Zhou, Z.; Dong, X. Novel bismuth ferrite-based leadfree ceramics with high energy and power density. J. Am. Ceram. Soc. 2018, 101, 3259–3265. [Google Scholar] [CrossRef]

- Zhu, L.; Lei, X.; Zhao, L.; Hussain, M.; Zhao, G.; Zhang, B. Phase structure and energy storage performance for BiFeO3-BaTiO3 based lead-free ferroelectric ceramics. Ceram. Int. 2019, 45, 20266–20275. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, E.; Yang, H.; Guo, H.; Li, H.; Zhang, H.; Li, J.; Gu, M.; Yang, T.; Zhang, Y. Enhancement of Energy Storage Performance in NaNbO3-Modified BNT-ST Ceramics. Coatings 2025, 15, 504. https://doi.org/10.3390/coatings15050504

Wang E, Yang H, Guo H, Li H, Zhang H, Li J, Gu M, Yang T, Zhang Y. Enhancement of Energy Storage Performance in NaNbO3-Modified BNT-ST Ceramics. Coatings. 2025; 15(5):504. https://doi.org/10.3390/coatings15050504

Chicago/Turabian StyleWang, Erping, Hongjun Yang, Haizhou Guo, Hongxia Li, Haosong Zhang, Jinyu Li, Mingsai Gu, Tao Yang, and Yangyang Zhang. 2025. "Enhancement of Energy Storage Performance in NaNbO3-Modified BNT-ST Ceramics" Coatings 15, no. 5: 504. https://doi.org/10.3390/coatings15050504

APA StyleWang, E., Yang, H., Guo, H., Li, H., Zhang, H., Li, J., Gu, M., Yang, T., & Zhang, Y. (2025). Enhancement of Energy Storage Performance in NaNbO3-Modified BNT-ST Ceramics. Coatings, 15(5), 504. https://doi.org/10.3390/coatings15050504