Abstract

The polymer composite frost-resistant rubber–UHMWPE (ultra-high molecular weight polyethylene) has simultaneously damping, anti-wear and anti-friction properties. To use it in seals operating in northern climatic conditions, it is necessary to study the effect of climatic aging on mechanical, strength and tribological properties of the composite. In this study, climatic aging of rubber and UHMWPE separately was made at testing ground in Yakutsk (Russia), as well as accelerated thermal aging of the composite in laboratory conditions. Comparison of the results of climatic and laboratory aging showed that climatic aging has a negative effect on the properties of both rubber and UHMWPE. Accelerated aging, on the contrary, leads to an improvement in the anti-friction properties of the composite with a small (about 10 percent) increase in its stiffness. Thus, with prolonged use in friction units, the composite should be protected from radiation and ozone.

1. Introduction

Rubber-based materials are important in modern industry, finding applications in various sectors, from the automotive industry to aerospace engineering, due to their unique combination of elasticity, strength and damping capacity. However, during operation, these materials are subject to complex environmental influences, including climatic aging, mechanical loads, chemical influences, and radiation, which leads to time-dependent loss of their operational characteristics and reduction in their service life. Particularly important is the study of durability of polymers used in low-temperature conditions, typical of regions with a harsh climate. Under these conditions, frost resistance, or, more generally, the stability of properties at low temperatures, becomes a determining factor in ensuring the reliable operation of polymer products. Low temperatures cause significant changes in the physicochemical properties of the material, such as glass transition (for amorphous polymers), decreased elasticity, and increased hardness.

The climatic aging process of frost-resistant polymers is a complex of physicochemical changes caused by both thermo-oxidative processes occurring under the influence of oxygen and ultraviolet radiation, and structural rearrangements in the polymer matrix at low temperatures, leading to crystallization and phase transitions. These changes directly affect the tribological behavior of the polymer, determining its friction coefficient, wear resistance, resistance to fatigue failure, and the ability to resist the formation of cracks during friction. Understanding the mechanisms is critically important for the development of new materials and technologies that ensure the durability and reliability of polymers operating in extreme conditions.

A large number of studies on the climatic aging of polymeric materials are presented in [1,2,3,4,5]. However, the vast majority of works are focused on studying changes in physical and mechanical properties, such as tensile strength, relative elongation at break, hardness, and elastic modulus, while experimental studies of the tribological properties of frost-resistant polymers after climatic aging remain relatively few. At the same time, it is friction and wear tests that allow us to directly evaluate the performance of the material under conditions as close as possible to real operation, and to identify the mechanisms of destruction that determine durability.

In recent years, there has been growing interest in studying the tribological properties of rubbers after climatic aging using various experimental methods. The authors of [6] investigated various aging modes simulating the effects of elevated temperatures and humidity on the tribological behavior of nitrile–butadiene rubber (NBR). Pin-on-disk tests demonstrated that accelerated aging leads to an increase in the friction coefficient and wear intensity. Chang et al. [7] investigated the aging of silicone rubbers exposed to dry and humid air at different temperatures. With increasing temperature, the aging of silicone rubbers became more intense, as evidenced by changes in mechanical properties and surface morphology. The authors of [8] made controlled tests under conditions of cyclic temperature aging of three typical rubber materials: ethylene–propylene–diene monomer rubber, liquid silicone rubber, and fluororubber. It was found that thermal cycling increases the compression of rubber due to thermal fatigue caused by significant difference in the coefficients of thermal expansion between the rubber sample and the metal fastener. The effect of aging during friction of natural rubber [9] was that, under conditions of intense dry sliding, heat diffusion led to serious mechanical damage and thermal–oxidative degradation of the surface of the samples.

Coatings are one of the ways to improve the tribological characteristics of materials, including elastomers [10]. This method of surface modification is proposed for use in rubber sealing materials that are resistant to the low-temperature conditions of the Far North. Of considerable interest in this case is the use of ultra-high molecular weight polyethylene (UHMWPE) as a coating. UHMWPE, like frost-resistant rubber, is suitable for use at low temperatures [11] and is characterized by wear resistance, a low friction coefficient, high strength, and the ability to withstand high bending deformations. This combination of materials provides both the damping capacity of the composite due to the rubber and durability due to the surface modification [11]. In [12,13], it is shown that UHMWPE is subject to aging, accompanied by some change in mechanical characteristics. External conditions such as temperature and load–velocity parameters play an important role in the study of polymer friction; therefore, the aging effect can influence friction and cause greater or lesser wear depending on the conditions of frictional interaction.

It was obtained that exposure to UV radiation leads to the photooxidation of UHMWPE, causing the formation of carbonyl groups and the rupture of polymer chains. This, in turn, can increase the coefficient of friction and wear rate of the material [14,15]. High temperatures also accelerate the oxidation and degradation processes of UHMWPE, leading to similar negative consequences for the tribological properties [16]. Various efforts are made to improve the resistance of UHMWPE-based materials to climatic aging. This may include the use of antioxidants and UV stabilizers in the material composition, surface modification, the use of protective coatings, or the inclusion of nanofillers (e.g., titanium oxide nanoparticles or carbon nanotubes) [17,18]. These approaches are aimed at slowing down the degradation processes, improving the mechanical properties, and, as a result, increasing the tribological resistance of the material under operating conditions. The effect of radiation exposure on the tribological properties of UHMWPE used in medical implants was investigated in [19]. The authors found that irradiation leads to the crosslinking of the polymer matrix, which increases wear resistance, but can also reduce impact toughness and affect the formation of wear particles. Long-term exposure to ultraviolet light leads to surface oxidation of UHMWPE, an increase in roughness, and changes in tribological properties [20].

In [21], it is shown that when testing UHMWPE in a pair with steel using the pin-on-disk scheme of sliding contact, an increase in sliding velocity leads to an increase in the friction coefficient, and an increase in pressure leads to an insignificant decrease. The friction pair of UHMWPE and a steel ball under conditions of reciprocating motion has a non-monotonic dependence of the friction coefficient on the external temperature in the range of −30–+60 °C [22]. In [23], based on an experiment on the sliding of a steel ball on a UHMWPE disk and the modeling of the process, it is demonstrated that the combination of a thin layer of UHMWPE with rubber makes it possible to obtain a damping material with a low friction coefficient.

The aim of this work is to study the effect of climatic aging on the tribological properties of rubber and UHMWPE, as well as of accelerated thermal aging on the frictional properties of the frost-resistant rubber–UHMWPE composite under conformal contact conditions simulating an end seal at different values of sliding velocity, load, and external temperature. Accelerated thermal aging in the laboratory can be used to study changes in the properties of materials used in units operating outdoors but protected from direct solar radiation.

2. Materials and Methods

The two-layer composite material is a coating of ultra-high-molecular polyethylene (GUR-4022, Celanese, Shanghai, China) with a molecular weight of 5 million g/mol, an average particle size of 145 μm, and a coating thickness of 600 μm on a substrate of nitrile butadiene rubber (SIBUR, Moscow, Russia). The rubber compound formula and the sequence of adding ingredients are given in Table 1.

Table 1.

Rubber compound recipe.

The rubber compound ingredients were mixed in a Plastograph EC Plus closed-type laboratory rubber mixer (Brabender, Duisburg, Germany) for 20 min at a roller speed of 25 rpm and initial temperature of 40 °C. To produce the two-layer material, the UHMWPE powder is pre-pressed to give it shape and to enable further laying of the rubber compound. Molding is performed in a hydraulic press in a mold under pressure of 10 MPa for 5 min. The rubber compound is placed on top of the molded UHMWPE powder, the mold is closed, and further joint hot pressing of the mold is performed in a thermohydraulic press (Impuls, Ivanovo, Russia) at a temperature of 155 °C for 20 min under a pressure of 10 MPa. Upon completion of this stage, the mold cools down to 80 °C under pressure. Cooling is performed to avoid possible deformation of the thermoplastic at temperatures above 100 °C.

For comparative analysis, uncoated rubber samples were also prepared. All samples were made in the form of rings with an internal diameter of 40 mm, an external diameter of 55 mm and a height of 7 mm.

Climatic tests were made in the cold climate of the Republic of Sakha (Yakutia), Russian Federation. Aging in climatic conditions typical for the city of Yakutsk, taking into account the impact of solar radiation, ambient temperature, air humidity, and other factors, was made in accordance with the Russian standard method GOST 9.066-76 (“Unified system of protection against corrosion and aging. Method of testing vulcanized rubbers for resistance to aging in weather conditions”). As the analysis of the cold climate zone shows, Central Yakutia, where Yakutsk is located, is the most severe in terms of climate. In Central Yakutia, the number of days with snow cover is 205–215 (from October to early May), and there are also 10–13 days with thunderstorms and 5–15 days with blizzards. Frosts below −50 °C can accompany fog. The intensity of solar radiation from March to September in clear weather is 0.84–0.92 kJ/(m2∙s). The average humidity is 65%, the number of days with transition through 0 °C is 54. Central Yakutia is characterized by high atmospheric transparency of 0.74–0.88, which provides deep ultraviolet radiation [24]. The exposure took place at the open test site of the North-Eastern Federal University, a specially equipped site located 6 km from Yakutsk, which made it possible to avoid the influence of urban microclimate and dust on the experimental results. The exposure was made on stands located at an angle of inclination to the horizon line of 45°, ensuring the orientation of the samples to the south. The rubber samples were exposed for 2 years, starting from July 2019 and ending in July 2021. The UHMWPE samples were exposed from April to September 2024, when atmospheric transparency and insolation were high. The average ambient temperature for the past exposure period was close to the average long-term temperatures (the minimum temperature was in April 2024 and amounted to −3.6 °C, the maximum temperature was in July, +20.4 °C). The samples were removed from the stand and tested in the laboratory every 2 months. The following indicators were used to evaluate the mechanical properties of the materials: tensile strength, elongation at break, stress at 100% elongation (ISO 37:2024).

Accelerated aging and heat resistance tests are designed to assess the relative resistance of polymers to aging over time. The resistance of composite materials to thermal aging was determined in accordance with ISO 188:2023. Air–heat aging cannot be fully used to simulate natural aging due to the impossibility of providing the polymer with exposure to other climatic factors, but this type of accelerated testing is widely used to study thermal and thermal properties. During accelerated testing, samples were placed in a thermostat at 100 °C and maintained for 72 h. After aging, the samples were removed from the thermostat and left to condition for at least 16 h.

The following physical and mechanical properties were chosen as characteristic aging indicators: tensile strength and elongation at break. These indicators were determined on an Autograph testing machine (Shimadzu, Kyoto, Japan) at room temperature in accordance with ISO 37:2024 (the speed of movement of the grips was 50 mm/min, at least three samples were tested in one series).

To record chemical changes in the surface as a result of polymer aging, the Fourier transform infrared spectroscopy–attenuated total reflectance (FTIR-ATR) method was used. Infrared (IR) spectra of samples were obtained before and after aging on i-Red 7800u-L spectrometer (SILab, Beijing, China).

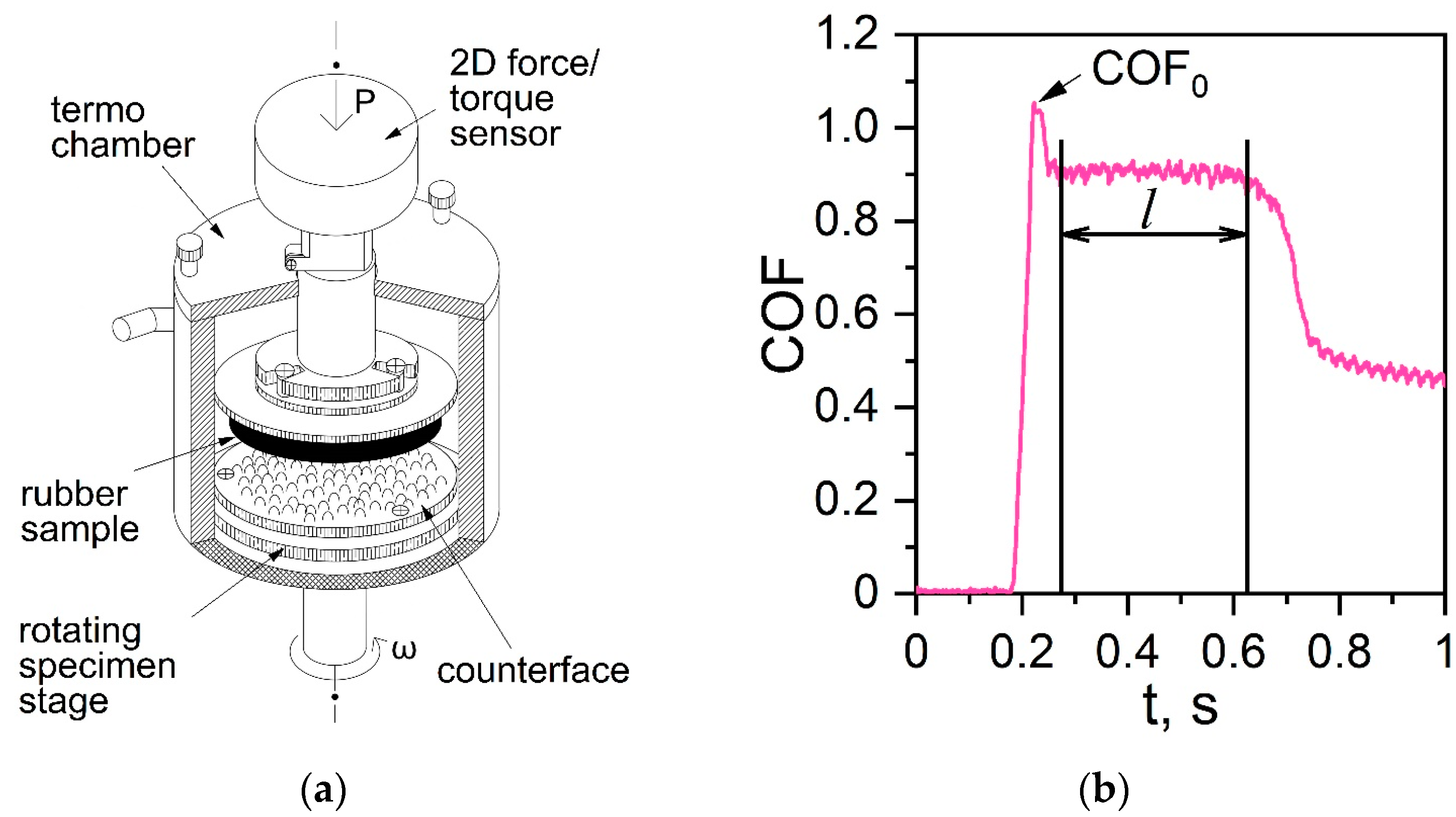

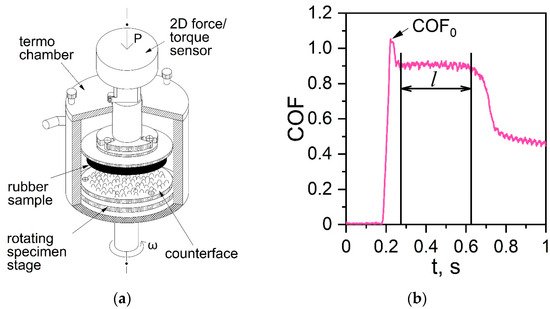

Tribological tests were performed on laboratory tribometer UMT-2 (Cetr, Campbell, CA, USA) according to the kinematic scheme of unidirectional sliding of a ring on a stationary disk with common axis of rotation [25] (Figure 1). Contact interaction occurred between the end surface of the ring and the plane of a disk Ø 65 mm and 2 mm thick. In a friction pair, the ring is polymeric and the counterbody is a polished steel disk (Ra ≤ 0.04 μm, AISI 304 stainless steel).

Figure 1.

(a) Schematic diagram of the tribometer; (b) coefficient of friction COF vs. testing time for a normal load of 422 N and a sliding velocity of 0.1 mm/s, where l is the friction path in established friction mode.

The effect of sliding velocity and normal load on friction of uncoated rubber was under consideration. The sliding velocities varied from 0.001 to 0.1 m/s, and the normal load ranged from 105 to 422 N (normal pressure 0.1 to 0.4 MPa correspondingly). The friction coefficient was studied for two different bulk temperatures: 23 and −25 °C. Both static (in rest) and dynamic coefficients of friction were obtained. To determine the static friction coefficient, we recorded the moment of time at which the system changed from the state of rest to sliding between the interacting surfaces (Figure 1b). The dynamic coefficient of friction was determined at the section of the friction path at which steady-state sliding was characterized by stable friction coefficient.

Due to the fundamentally different properties of the composite, the rubber samples with UHMWPE were tested differently. During a single test with constant load and velocity, the sample made 10 revolutions, which corresponds to friction path of 1.5 m. For a series of tests, the normal load was fixed and the sliding velocity was varied (0.1, 0.2, 0.4, and 0.6 m/s). The following normal loads were used: 50, 100, 200, 400, and 700 N. The pressure range was from 0.05 to 0.7 MPa. The temperatures of −20, 23 (RT), and +60 °C were set in the test chamber. Three tests were performed for each fixed combination of parameters (velocity, load, temperature). As a result, the friction coefficient dependencies on time were obtained for the samples before and after climatic aging at various load-velocity parameters under negative, room, and elevated temperatures.

Surface images with roughness parameters (ISO 25178-2:2021) were obtained on optical profilometer S Neox 3D (Sensofar-Tech, Barcelona, Spain) using 10× objective in confocal mode and automatic stitching of frames into an area of desired size.

The dependences of load on the indentation depth during unloading were obtained using the instrumental indentation method on the scanning nanohardness tester “Nanoscan-4D” (TISNUM, Troitsk, Russia). A 3.1 mm diameter alumina ball was pressed into a local area on the sample with linear velocity of 100 mN/s to a load value of 1 N. To calculate the elastic modulus of the coating, a special program was used to determine the elastic properties of materials with coatings based on theoretical model described in detail in [26,27].

3. Results and Discussion

3.1. Mechanical Properties of UHMWPE After Climatic Aging

Table 2 shows the elastic strength properties of UHMWPE during exposure. The strength and relative elongation of UHMWPE samples after 2 months of exposure increased, then the strength indicators began to deteriorate. In the fourth month of exposure, the samples with satisfactory strength practically did not have elasticity due to the intensive destruction of the thermoplastic. Samples that were aged for six months almost immediately broke down under tension.

Table 2.

Changes in key parameters depending on the duration of exposure for UHMWPE.

Thus, the high rate of degradation processes of thermoplastic UHMWPE was revealed during atmospheric aging. The high degree of destruction of UHMWPE during 6 months of exposure is in good agreement with the results of aging of UHMWPE samples in the climatic conditions of Yakutsk, as described in [13,28]. In these studies, the elasticity of UHMWPE samples of GUR 4150 after 6 months of exposure in open air dropped sharply to 22 times compared to the initial polymer, and during tensile testing, brittle destruction was observed in samples exposed for 6, 9, and 12 months.

During the studies, the main period of sample exposure was in the spring and summer. The temperature of a body heated by the sun can be +60 °C. Under these conditions, due to small amounts of precipitation and high transparency of the atmosphere, higher ozone content in high latitudes, one should expect intensification of thermal aging of polymers against the background of photooxidative destruction. Apparently, the aging of the studied UHMWPE samples passes into the photolysis stage (photolysis is accelerated photooxidative aging initiated by thermal action), when an avalanche-like increase in radical processes leads to rapid destruction of polymer materials. Thus, UHMWPE-based material is not recommended for use in cold, sharply continental climates for periods longer than 6 months without introducing an antiaging agent into the formulation.

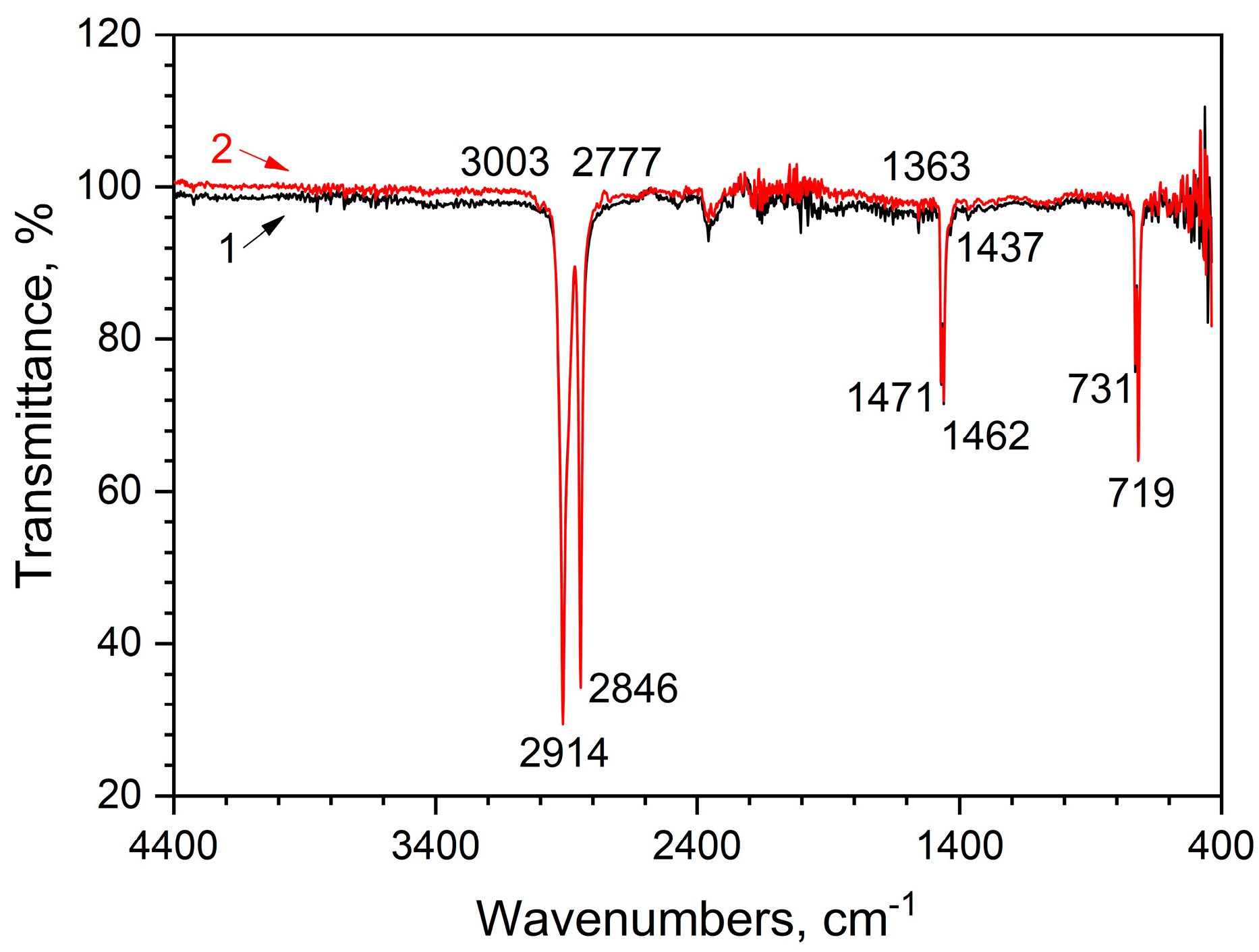

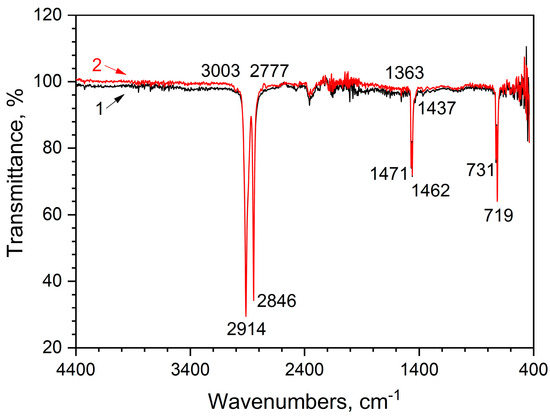

All the obtained FTIR-ATR spectra showed absorption bands characteristic of UHMWPE: a doublet (2914 cm−1 and 2846 cm−1) responsible for symmetric and asymmetric C–H stretching vibrations, a doublet responsible for C–H deformation vibrations (1473 cm−1 and 1462 cm−1), and crystallinity bands (719 cm−1). In the spectra of the samples exposed for 6 months, new bands appeared or their intensity increased, corresponding to aldehydes (1730 cm−1), ketones (1717 and 1437 cm−1), and terminal methyl groups (1387 cm−1), which means the presence of degradation products on the surface of the samples. Analysis of the spectra confirmed significant chemical changes in the polymer structure during natural exposure. Such changes lead to a catastrophic loss of the properties of UHMWPE. A comprehensive study of the thermo-oxidative and photo-oxidative aging of UHMWPE has been carried out, with detailed schemes of chemical reactions [29]. It has been demonstrated that the oxidation of UHMWPE involves two distinct mechanisms: the decomposition of primary peroxides, which are formed as a consequence of mechano-oxidative degradation during material processing, and the oxidation of radicals by the Bolland mechanism (polymer autoxidation). Therefore, an increase in acid and vinyl fragments, as well as aldehyde and ketone groups, is observed in the photooxidation products.

The intensity of the absorption bands at 1717 cm−1 (stretching vibrations of carbonyl groups of the aldehyde and ketone type) was used to calculate the oxidation index (A = T1717/T1473), according to the method specified in [30]. The band at 1473 cm−1 (deformation vibrations of -CH2-groups), which remains stable during the oxidation process, was chosen as the internal standard.

Thus, the value of the oxidation index for samples after 6 months of aging is higher than for the initial sample (0.03) and is 0.11. The presence of some oxidation in the initial sample is quite explainable, since hydroperoxides and their decomposition products begin to accumulate already during the synthesis and processing of the thermoplastic [31]. In [30], the effect of “post-radiation aging” of UHMWPE was studied; a similar technique was used to calculate the oxidation index and the value after 5 months of exposure, with almost the same results.

The strength of UHMWPE samples after 2 months of exposure first increases, then there is a sharp deterioration in strength indicators. Samples that were aged for six months almost immediately collapse under tension. The occurrence of radical processes of combined aging, when thermo-oxidative and photo-oxidative aging are combined with the simultaneous effect of atmospheric ozone, leads to serious changes in the chemical composition of the samples. At the beginning of the process, the processes of material cross-linking (recombination of free radicals, cyclization) prevail, then destructive processes of rupture of the main polymer chains. Externally, the aging process is manifested in the appearance of defects on the surface, which leads to the formation of microcracks, their further deepening, and the destruction of the samples.

3.2. Mechanical Properties of Two-Layer Materials After Thermal Aging

The initial samples had high strength at relatively low values of relative elongation. Apparently, due to high adhesion at the phase boundary of two-layer materials, the development of highly elastic deformation of the rubber layer is restrained by the thermoplastic. The results of thermal aging (Table 3) indicate an insignificant decrease in the relative elongation of the materials while maintaining strength indicators. At these aging times, no significant changes in the physical and mechanical properties of the material occur.

Table 3.

Properties of two-layer materials before and after thermal aging.

No new absorption bands were recorded in the IR spectra of the UHMWPE layer (Figure 2). The spectra before and after aging are almost identical, i.e., aging products (aldehydes, ketones) have not yet accumulated in large quantities on the surface of the material.

Figure 2.

IR spectra of the surface of two-layer samples (from the side of the UHMWPE layer) before (1) and after (2) thermal aging.

At the same time, the results of the study of the rubber substrate by nanoDMA method [23] showed that the long-term elastic modulus after aging is somewhat higher (15.2 MPa compared to the initial value of 13.8 MPa). The relaxation and retardation times for the rubber remain virtually unchanged. Indentation of coated samples to determine the Young’s modulus of the UHMWPE layer was made at room temperature, taking into account the change in the properties of the substrate. It was found that the original sample has the coating 1.09 GPa elastic modulus, which correlates well with the results of indentation of end sections in [23]. Aged UHMWPE is characterized by the modulus that has increased to 1.23 GPa.

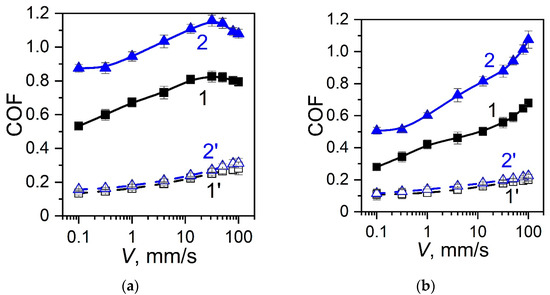

3.3. Tribological Properties of Rubber Before and After Climatic Aging

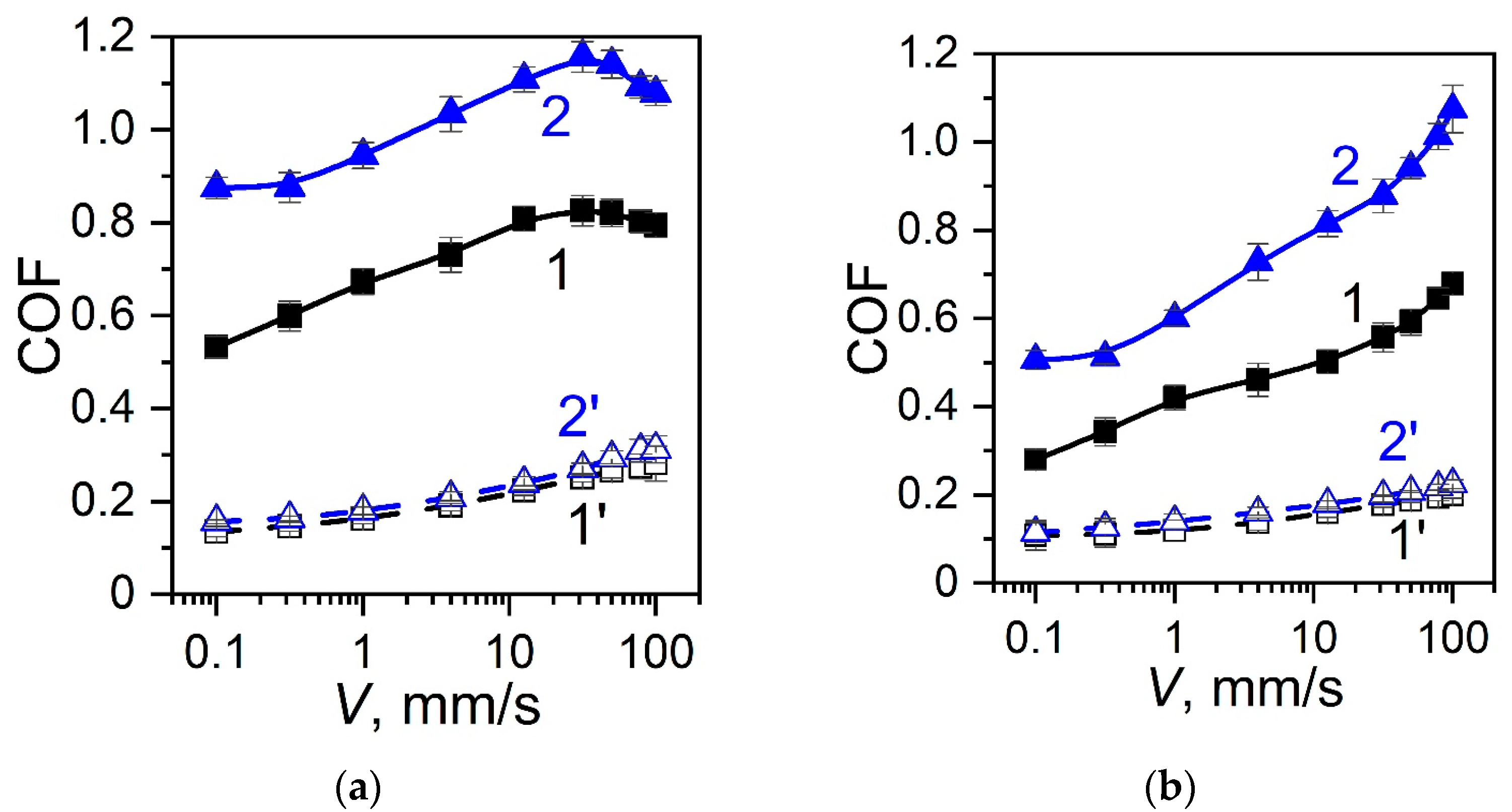

Table 4 shows the values of static friction coefficient for two different bulk temperatures at constant load of P = 422 N and wear rate of the tested rubber samples. Figure 3 shows the dependences of dynamic friction coefficient on the sliding velocity at two load values. The experimental data on wear were calculated on the basis of three measurements of the weight loss over a sliding distance of 4 m at a normal pressure of 0.4 MPa and room temperature (23 °C). Linear wear rate was obtained using rubber density and the fact that contact square is constant. Sandpaper with a grain size of 120 μm was used as the working surface in the experiments.

Table 4.

Static coefficient of friction and wear rate of frost-resistant rubbers before and after aging.

Figure 3.

Dependence of coefficient of friction (COF) on sliding velocity (V) at negative (a) and room (b) temperatures for NBR samples before aging (1, 2) and after aging (1′, 2′) under normal loads of 105 N (1, 1′) and 422 N (2, 2′).

It can be noted here that the difference (before and after aging) in the static and dynamic friction coefficients is very large, especially for negative temperatures. Polymer friction is usually explained by adhesive forces and hysteresis losses caused by rheological properties of rubber. Judging by the weak dependence of the friction coefficient of aged samples on velocity, the rheological properties and, consequently, the damping capacity of rubber are significantly reduced in the process of climatic aging. And the fact that the friction coefficient of aged samples is practically independent of load allows us to assume that the adhesive component is also significantly reduced. At the same time, the wear rate increases, which may be associated both with an increase in the discreteness of contact due to an increase in stiffness during aging, and with a drop in the strength properties of the surface layers of rubber.

3.4. Tribological Properties of Rubber-UHMWPE Composite Before and After Thermal Aging

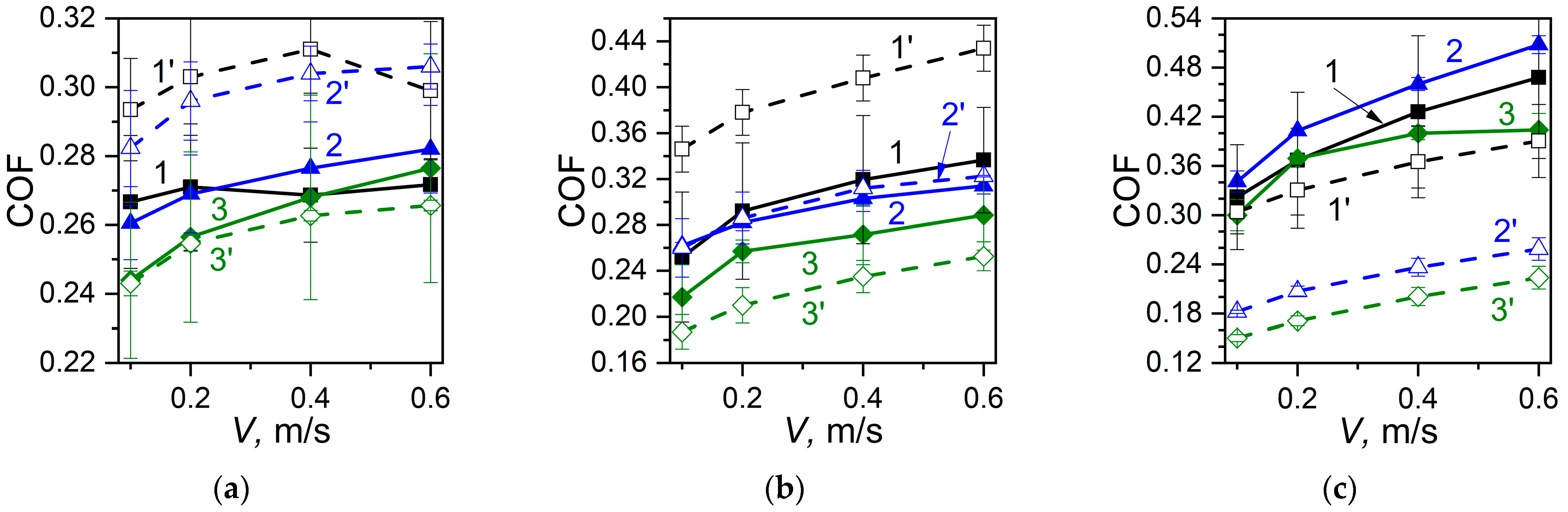

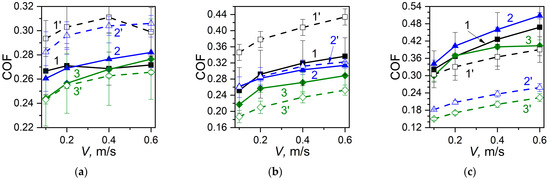

The dependences of the friction coefficient on load and velocity for two-layer samples are shown in Figure 4 for three different temperatures.

Figure 4.

Dependence of the coefficient of friction (COF) on the sliding speed (V) at negative (a), room (b), and elevated (c) temperatures for two-layer samples before aging (1, 2, 3) and after aging (1′, 2′, 3′) under normal load of 50 N (1, 1′), 200 N (2, 2′), and 700 N (3, 3′).

The first thing to note is the increase in the range of variation in the friction coefficient with increasing temperature. At a temperature of −20 °C, it varies within 0.1 taking into account the standard deviation (Figure 4a), and at elevated temperatures (+60 °C), it varies within 0.4 (Figure 4c). An increase in temperature leads to a complex change in the properties of the material. Stiffness of the polymers decreases, the surface energy increases. The surface is not perfectly smooth (Figure 5), so the contact discontinuity factor also affects the frictional interaction. Under conditions of nominally conformal contact, the discreteness is greater when the load and temperature is lower. Thus, the most saturated contact is realized for curves 2 and 3 in Figure 4c. In this case, the friction force is determined mainly by the adhesive component. It can be noted that the friction coefficient of the aged samples is significantly lower, from which we can conclude that the surface energy of UHMWPE decreases during thermal aging. Under normal conditions of elastic contact, roughness reduces the adhesion forces between the surfaces due to the discreteness of the contact, since the adhesion forces depend on the area of the actual contact [32]. This is true if the contact is far from saturated, i.e., the contact spots under the asperities do not merge. Experiments for polymeric materials [33,34] have shown that with a gradual increase in roughness, the adhesion and adhesive friction forces first increase compared to the case of a smooth surface, and only then decrease. The solution to the contact problem for an indenter and a half-space with a small waviness, when the contact area remains simply connected, was obtained analytically [35]. It was found that under conditions of continuous contact, the application of relief increases the effective adhesive properties of the surface, as well as the magnitude of the adhesive hysteresis [36], which correlates with the magnitude of the adhesive friction force. These considerations can explain the fact that curves 2 and 2′ (at a load of 200 N) in Figure 4c lie above curves 3 and 3′ (700 N).

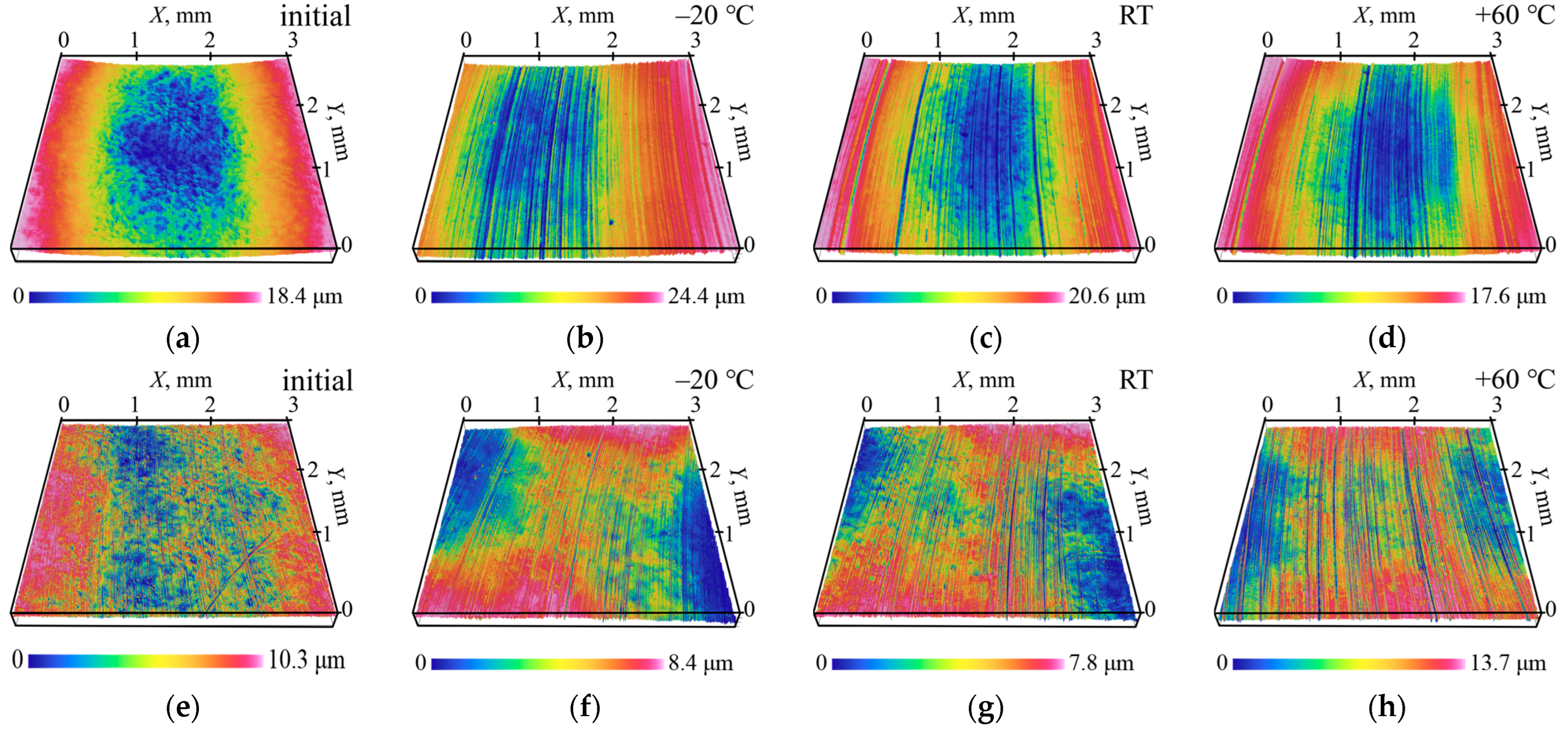

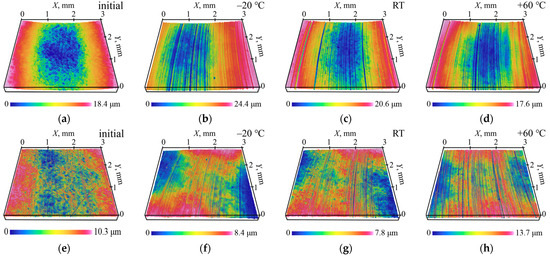

Figure 5.

Topography of two-layer materials before (a–d) and after (e–h) aging.

The combination of adhesion and discreteness of contact, which provides the deformation component of the friction force due to the rheological properties of rubber substrate, can be analyzed based on the results shown in Figure 4b. The difference between curves 1 and 1′, obtained for a load of 50 N, can be explained by the fact that the discreteness of contact and, therefore, the deformation component of the friction force, is higher for more rigid polymer composite. Curves 2 and 2′ practically coincide, probably due to the fact that the decrease in the surface energy of the coating material (and the adhesive component of the friction force) compensates for the increase in the deformation component. The difference between curves 3 and 3′, obtained for the maximum load, demonstrates the predominance of the adhesive component.

No full-scale experiments have been performed to assess the effect of thermal aging on wear resistance. However, an indirect assessment can be made by analyzing the change in roughness parameters of the initial and aged samples during friction at different temperatures (Table 5). The main cause of UHMWPE wear is plastic deformation when in contact with the unevenness of the counter-body. This deformation and removal of material are accompanied by a change in the shape of the surface. Therefore, an analysis of the change in roughness can indirectly show whether there is wear in each specific case or not. The surface of the original sample before and after friction tests differs significantly in the main roughness parameters for all temperature conditions. The aged sample is characterized by stable indicators at subzero and room temperatures. The roughness parameters significantly increase, only as a result of frictional interaction at elevated temperatures.

Table 5.

Roughness parameters of two-layer materials before and after thermal aging.

4. Conclusions

Destruction processes in UHMWPE during atmospheric aging are accompanied by the formation of carbonyl, aldehyde, and ether groups on the surface, which was recorded using IR spectroscopy. The oxidation index calculated from these data after 6 months of exposure is 0.11. During natural exposure, as a result of the simultaneous action of different types of aging (thermo-and photooxidative, ozone), UHMWPE after 6 months of exposure undergoes brittle destruction due to the transition of aging processes to the photolysis stage.

Taking into account that the damping and strength properties of the surface layers of rubber also significantly decrease during climatic aging, it can be concluded that neither rubber nor the rubber–UHMWPE composite are suitable for long-term use in units subject to both temperature fluctuations and exposure to solar radiation.

Accelerated aging and heat resistance tests conducted for the polymer composite rubber–UHMWPE showed that, in the absence of solar radiation and ozone, the composite retains its basic properties and structure. There is some increase in stiffness in both rubber and UHMWPE (while maintaining the rheological properties of rubber), and an insignificant decrease in the relative elongation of the materials. The maximum friction coefficient recorded for aged samples is 15% lower than for the initial ones. Thus, in friction units protected from radiation, this composite can be used under conditions of significant temperature differences.

Author Contributions

Conceptualization, E.T. and J.-H.H.; formal analysis, E.T. and N.P.; investigation, I.S., V.M., P.B. and A.D.; methodology, I.S., A.M. and P.B.; software, F.S.; supervision, E.T.; visualization, F.S.; writing—original draft, E.T., F.S. and A.M.; writing—review and editing, I.S. and P.B. All authors have read and agreed to the published version of the manuscript.

Funding

This research received financial support from the Russian Science Foundation (project no. 23-19-00484).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The data are contained within the article.

Conflicts of Interest

The authors declare no conflicts of interest. The funders had no role in the design of the study; in the collection, analyses, or interpretation of data; in the writing of the manuscript; or in the decision to publish the results.

References

- Balasooriya, W.; Schrittesser, B.; Pinter, G.; Schwarz, T. Induced Material Degradation of Elastomers in Harsh Environments. Polym. Test. 2018, 69, 107–115. [Google Scholar] [CrossRef]

- Alexander, J.; Khaladkar, P.; Moniz, B.; Stahl, B.; Taylor, T. Environmental Performance of Elastomers. In Corrosion: Materials; Cramer, S.D., Covino, B.S., Eds.; ASM International: Almere, The Netherlands, 2005; pp. 608–617. ISBN 978-1-62708-183-2. [Google Scholar]

- Sokolova, M.D.; Fedorova, A.F.; Pavlova, V.V. Research of Influence of Plasticizers on the Low-Temperature and Mechanical Properties of Rubbers. Mater. Sci. Forum 2019, 945, 459–464. [Google Scholar] [CrossRef]

- Frigione, M.; Rodríguez-Prieto, A. Can Accelerated Aging Procedures Predict the Long Term Behavior of Polymers Exposed to Different Environments? Polymers 2021, 13, 2688. [Google Scholar] [CrossRef]

- Allen, N.S. Light and UV Stabilization of Polymers. In Plastics Additives; Polymer Science and Technology Series; Pritchard, G., Ed.; Springer: Dordrecht, The Netherlands, 1998; Volume 1, pp. 427–441. ISBN 978-94-010-6477-4. [Google Scholar]

- Dong, C.L.; Yuan, C.Q.; Bai, X.Q.; Yan, X.P.; Peng, Z. Tribological Properties of Aged Nitrile Butadiene Rubber under Dry Sliding Conditions. Wear 2015, 322–323, 226–237. [Google Scholar] [CrossRef]

- Chang, H.; Wan, Z.; Chen, X.; Wan, J.; Luo, L.; Zhang, H.; Shu, S.; Tu, Z. Temperature and Humidity Effect on Aging of Silicone Rubbers as Sealing Materials for Proton Exchange Membrane Fuel Cell Applications. Appl. Therm. Eng. 2016, 104, 472–478. [Google Scholar] [CrossRef]

- Li, S.; Ke, Y.; Xie, L.; Zhao, Z.; Huang, X.; Wang, Y.; Wang, Z. Study on the Aging of Three Typical Rubber Materials under High- and Low-Temperature Cyclic Environment. e-Polymers 2023, 23, 20228089. [Google Scholar] [CrossRef]

- Chen, X.; Kong, Y.; Wang, M.; Huang, X.; Huang, Y.; Lv, Y.; Li, G. Wear and Aging Behavior of Vulcanized Natural Rubber Nanocomposites under High-Speed and High-Load Sliding Wear Conditions. Wear 2022, 498–499, 204341. [Google Scholar] [CrossRef]

- Bai, C.; Qiang, L.; Zhang, B.; Gao, K.; Zhang, J. Optimizing the Tribological Performance of DLC-Coated NBR Rubber: The Role of Hydrogen in Films. Friction 2022, 10, 866–877. [Google Scholar] [CrossRef]

- Dyakonov, A.A.; Vasilev, A.P.; Danilova, S.N.; Okhlopkova, A.A.; Tarasova, P.N.; Lazareva, N.N.; Ushkanov, A.A.; Tuisov, A.G.; Kychkin, A.K.; Vinokurov, P.V. Two-Layer Rubber-Based Composite Material and UHMWPE with High Wear Resistance. Materials 2022, 15, 4678. [Google Scholar] [CrossRef]

- Chang, T.; Yuan, C.; Guo, Z. Tribological Behavior of Aged UHMWPE under Water-Lubricated Condition. Tribol. Int. 2019, 133, 1–11. [Google Scholar] [CrossRef]

- Kolesova, E.S.; Gogoleva, O.V.; Petrova, P.N. Development of Polymer Composite Materials Based on Ultra-High Molecular Weight Polyethylene with the High Stability of Characteristics under the Conditions of Sharply Continental Climate. Arct. Subarct. Nat. Resour. 2021, 26, 122–131. [Google Scholar] [CrossRef]

- Cai, T.; Zhan, S.; Yang, T.; Li, Y.; Jia, D.; Tu, J.; Li, J.; Duan, H. Study on the Tribological Properties of UHMWPE Modified by UV-Induced Grafting under Seawater Lubrication. Tribol. Int. 2022, 168, 107419. [Google Scholar] [CrossRef]

- Naresh Kumar, N.; Yap, S.; Bt Samsudin, F.; Khan, M.; Pattela Srinivasa, R. Effect of Argon Plasma Treatment on Tribological Properties of UHMWPE/MWCNT Nanocomposites. Polymers 2016, 8, 295. [Google Scholar] [CrossRef]

- Baena, J.-C.; Peng, Z. Mechanical and Tribological Performance of UHMWPE Influenced by Temperature Change. Polym. Test. 2017, 62, 102–109. [Google Scholar] [CrossRef]

- Padhan, M.; Paul, G.; Bijwe, J. Roles of Size, Shape, Amount, and Functionalization of Nanoparticles of Titania in Controlling the Tribo-Performance of UHMWPE Composites. Front. Mater. 2020, 7, 205. [Google Scholar] [CrossRef]

- Manoj Kumar, R.; Sharma, S.K.; Manoj Kumar, B.V.; Lahiri, D. Effects of Carbon Nanotube Aspect Ratio on Strengthening and Tribological Behavior of Ultra High Molecular Weight Polyethylene Composite. Compos. Part A Appl. Sci. Manuf. 2015, 76, 62–72. [Google Scholar] [CrossRef]

- Nayak, C.; Balani, K. Effects of Reinforcements and GAMMA‐IRRADIATION on Wear Performance of ULTRA‐HIGH Molecular Weight Polyethylene as Acetabular Cup Liner in HIP‐JOINT Arthroplasty: A Review. J. Appl. Polym. Sci. 2021, 138, 51275. [Google Scholar] [CrossRef]

- Verma, N.; Keshri, A.K.; Zafar, S.; Prasad, A.; Pathak, H. Comparative Analysis on Tribological and Biological Responses of UHMWPE-Based Composite and UV Irradiated UHMWPE. Biotribology 2022, 32, 100225. [Google Scholar] [CrossRef]

- Wang, Y.; Yin, Z.; Li, H.; Gao, G.; Zhang, X. Friction and Wear Characteristics of Ultrahigh Molecular Weight Polyethylene (UHMWPE) Composites Containing Glass Fibers and Carbon Fibers under Dry and Water-Lubricated Conditions. Wear 2017, 380–381, 42–51. [Google Scholar] [CrossRef]

- Wang, Q.; Wang, Y.; Wang, H.; Fan, N.; Yan, F. Fretting Wear Behavior of UHMWPE Under Different Temperature Conditions. J. Macromol. Sci. Part B 2017, 56, 493–504. [Google Scholar] [CrossRef]

- Torskaya, E.; Shkalei, I.; Stepanov, F.; Makhovskaya, Y.; Dyakonov, A.; Petrova, N. Using Thin Ultra-High-Molecular-Weight Polyethylene Coatings to Reduce Friction in Frost-Resistant Rubbers. Polymers 2024, 16, 2870. [Google Scholar] [CrossRef]

- Gavrilova, M.K. Klimat Centralnoy Yakutii; Yakutskoe Knizhnoe Izdatelstvo: Yakutsk, Russia, 1973. [Google Scholar]

- Morozov, A.V.; Petrova, N.N. Method of Evaluating the Coefficient of Friction of Frost-Resistant Sealing Rubbers. J. Frict. Wear 2016, 37, 124–128. [Google Scholar] [CrossRef]

- Stepanov, F.I.; Torskaya, E.V. Modeling of Indentation of Hard Coatings by an Arbitrarily Shaped Indenter. J. Frict. Wear 2019, 40, 326–331. [Google Scholar] [CrossRef]

- Wani, M.F.; Stepanov, F.I.; Torskaya, E.V.; Shkalei, I.V. The Elastic and Frictional Properties of Nanoscale Coatings Based on Molybdenum Disulfide at Micro and Nano Levels. J. Frict. Wear 2023, 44, 291–297. [Google Scholar] [CrossRef]

- Gogoleva, O.V.; Petrova, P.N.; Kolesova, E.S. Study of the Properties and Structure of Composites Based on UHMWPE Exposed to the Conditions of Yakutia. In Proceedings of the EURASTRENCOLD-2022, Yakutsk, Russia, 12–16 September 2022; MCITO: Kirov, Russia, 2022; pp. 96–100. [Google Scholar]

- Costa, L.; Luda, M.P.; Trossarelli, L. Ultra High Molecular Weight Polyethylene—II. Thermal- and Photo-Oxidation. Polym. Degrad. Stab. 1997, 58, 41–54. [Google Scholar] [CrossRef]

- Premnath, V.; Bellare, A.; Merrill, E.W.; Jasty, M.; Harris, W.H. Molecular Rearrangements in Ultra High Molecular Weight Polyethylene after Irradiation and Long-Term Storage in Air. Polymer 1999, 40, 2215–2229. [Google Scholar] [CrossRef]

- Shlyapintoh, V.Y. Photochemical Transformations and Stabilization of Polymers; Himiya, M., Ed.; Hanser Verlag: Munich, Germany, 1979. [Google Scholar]

- Fuller, K.N.G.; Tabor, D. The Effect of Surface Roughness on the Adhesion of Elastic Solids. Proc. R. Soc. Lond. A 1975, 345, 327–342. [Google Scholar] [CrossRef]

- Briggs, G.A.D.; Briscoe, B.J. The Effect of Surface Topography on the Adhesion of Elastic Solids. J. Phys. D Appl. Phys. 1977, 10, 2453–2466. [Google Scholar] [CrossRef]

- Purtov, J.; Gorb, E.V.; Steinhart, M.; Gorb, S.N. Measuring of the Hardly Measurable: Adhesion Properties of Anti-Adhesive Surfaces. Appl. Phys. A 2013, 111, 183–189. [Google Scholar] [CrossRef]

- Guduru, P.R. Detachment of a Rigid Solid from an Elastic Wavy Surface: Theory. J. Mech. Phys. Solids 2007, 55, 445–472. [Google Scholar] [CrossRef]

- Kesari, H.; Lew, A.J. Effective Macroscopic Adhesive Contact Behavior Induced by Small Surface Roughness. J. Mech. Phys. Solids 2011, 59, 2488–2510. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).