Research on the Correlation of Physical Properties Between NbN Superconducting Thin Films and Substrates

Abstract

:1. Introduction

2. Materials and Methods

- Intra-Substrate Horizontal Comparison. Conducted cross-analysis of NbN film properties on identical substrates to evaluate annealing-induced optimization effects;

- Longitudinal Contrast Studies. As-deposited Films: four-sample longitudinal comparison established substrate influence mechanisms on non-annealed NbN films. Annealed Films: parallel four-sample longitudinal comparison decoupled substrate effects in post-annealing scenarios;

- Correlation and Modeling. Should significant correlations emerge: establish dominant mechanisms through statistical pattern recognition; perform curve fitting analyses using least squares regression; validate models via residual error minimization.

3. Results and Discussion

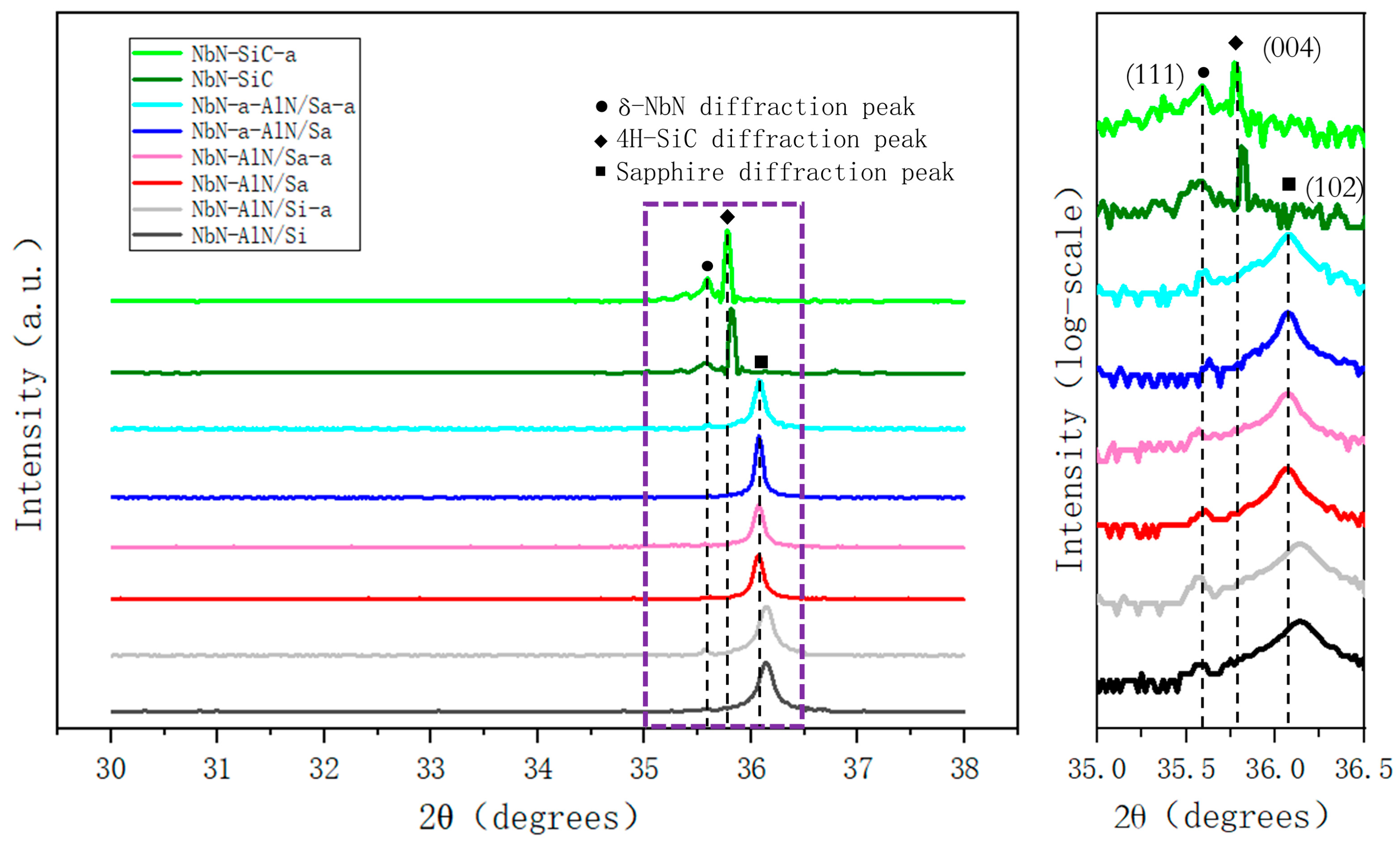

3.1. Characterization Results

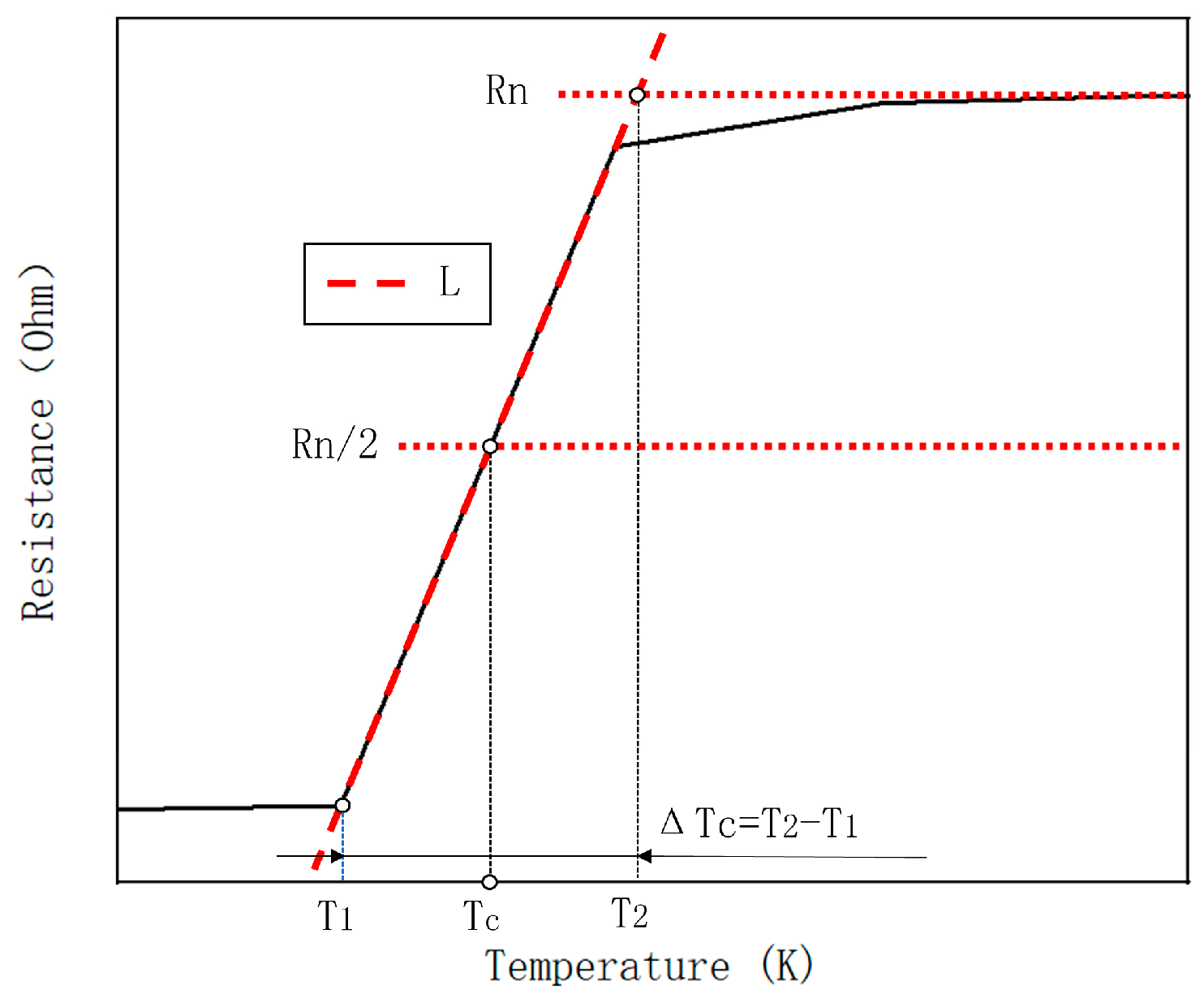

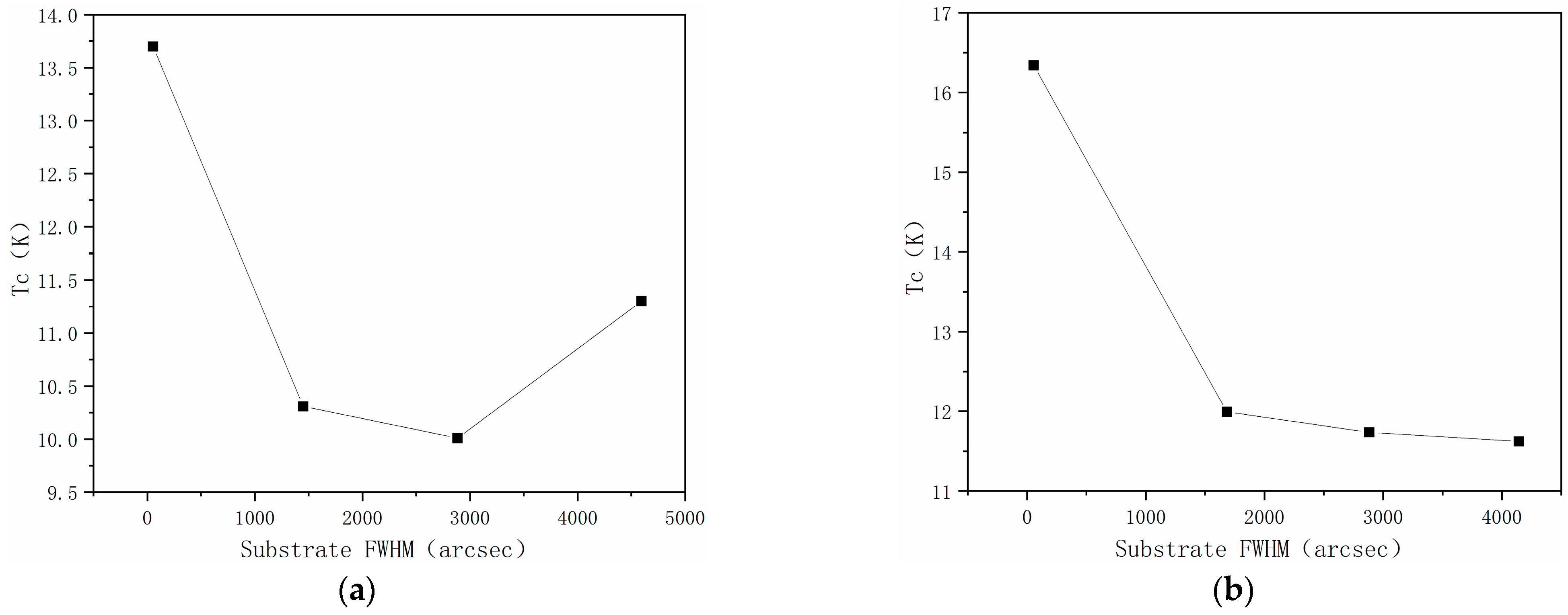

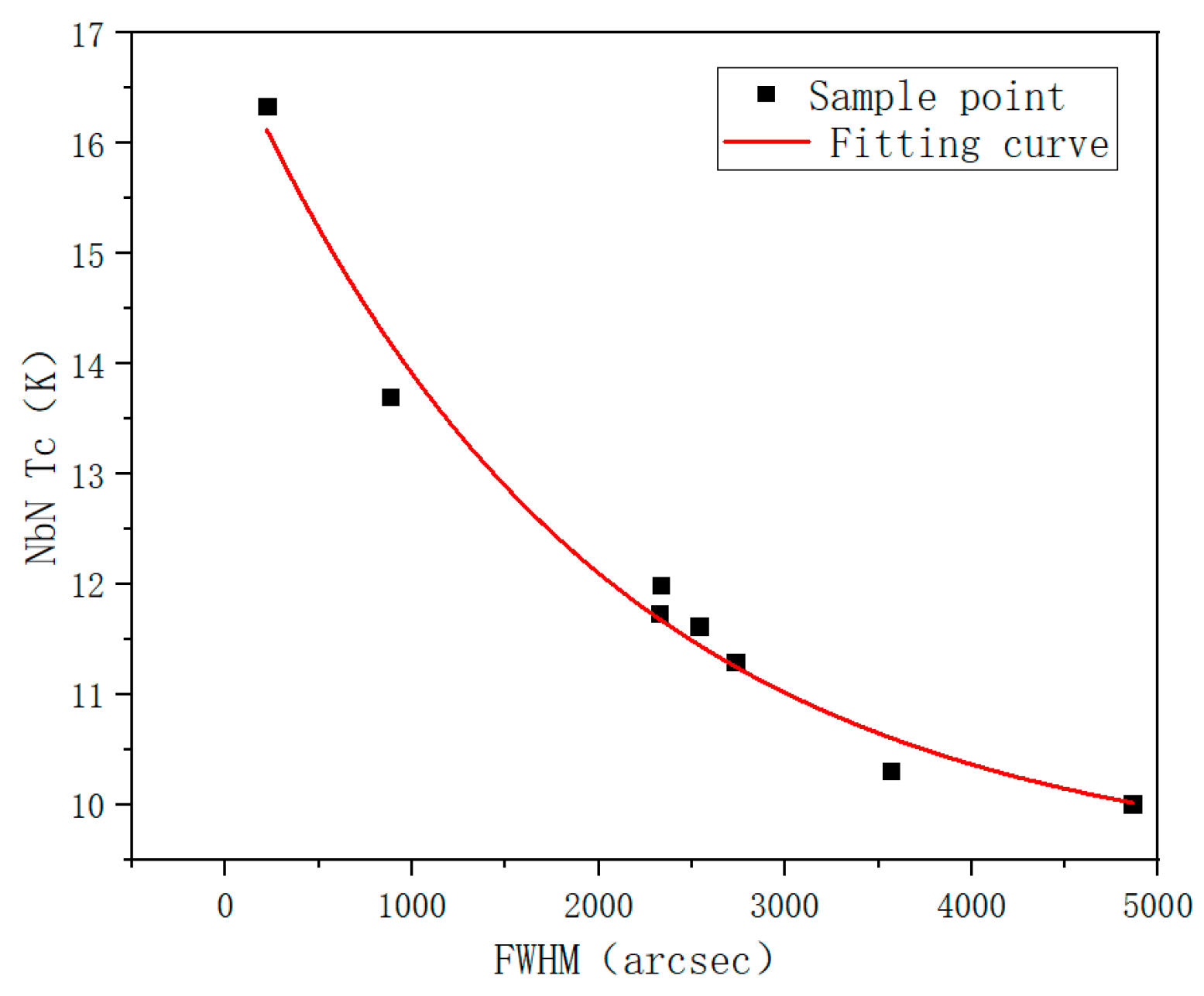

3.2. Correlation Between TC of NbN Thin Films and Substrate Crystalline Quality

3.3. Correlation Analysis Between ΔTC and Thin Film FWHM

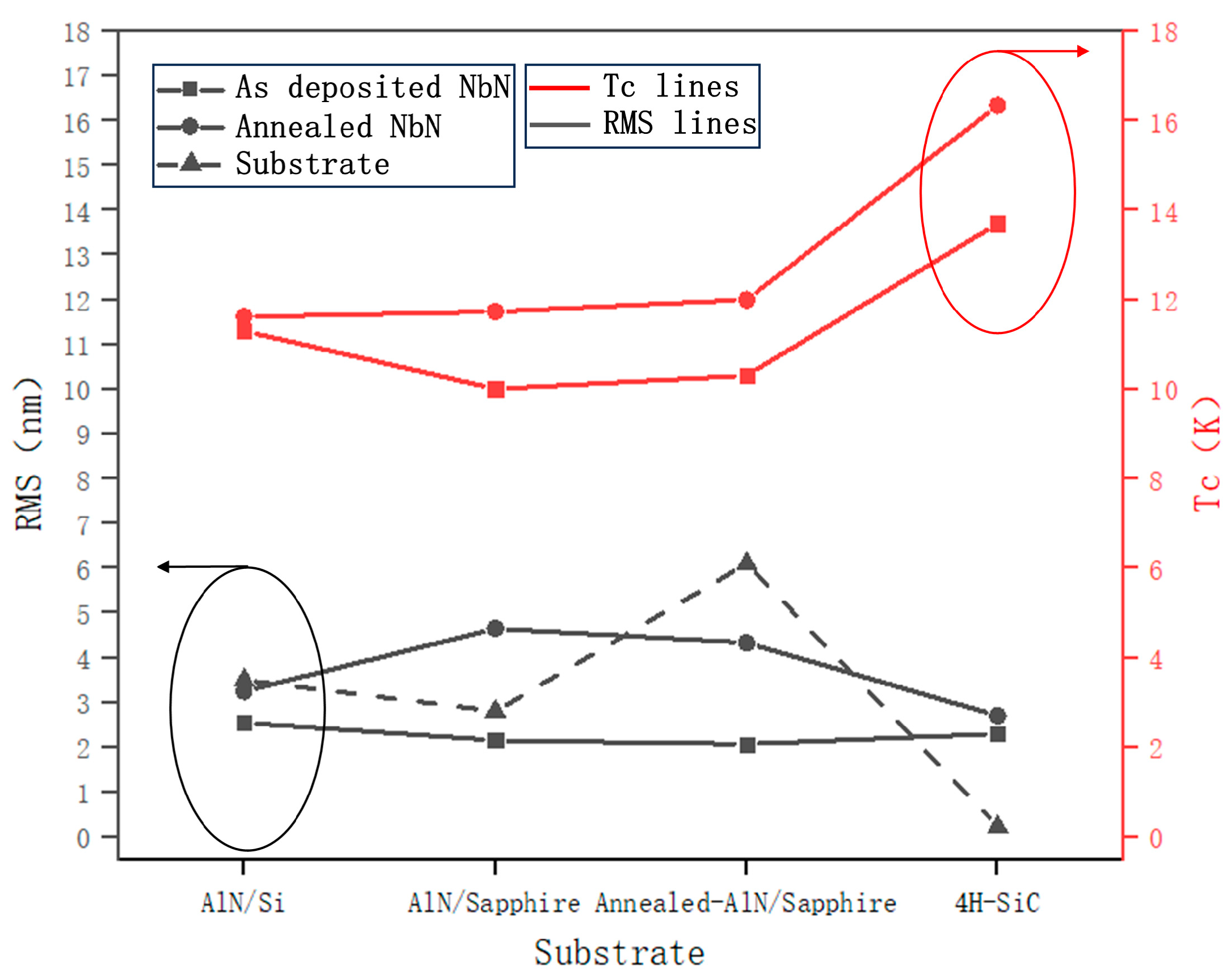

3.4. Correlation Between NbN Thin Films and Substrate Surface Morphology

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Cucciniello, N.; Lee, D.; Feng, H.Y.; Yang, Z.; Zeng, H.; Patibandla, N.; Zhu, M.; Jia, Q. Superconducting Niobium Nitride: A Perspective from Processing, Microstructure, and Superconducting Property for Single Photon Detectors. J. Phys. Condens. Matter 2022, 34, 374003. [Google Scholar] [CrossRef] [PubMed]

- Wei, X.; Roy, P.; Yang, Z.; Zhang, D.; He, Z.; Lu, P.; Licata, O.; Wang, H.; Mazumder, B.; Patibandla, N.; et al. Ultrathin Epitaxial NbN Superconducting Films with High Upper Critical Field Grown at Low Temperature. Mater. Res. Lett. 2021, 9, 336–342. [Google Scholar] [CrossRef]

- Pogrebnjak, A.D.; Bondar, O.V.; Abadias, G.; Ivashchenko, V.; Sobol, O.V.; Jurgal, S.; Coy, E. Structural and Mechanical Properties of NbN and Nb-Si-N Films: Experiment and Molecular Dynamics Simulations. Ceram. Int. 2016, 42, 11743–11756. [Google Scholar] [CrossRef]

- Jia, X.Q.; Kang, L.; Gu, M.; Yang, X.Z.; Chen, C.; Tu, X.C.; Jin, B.B.; Xu, W.W.; Chen, J.; Wu, P.H. Fabrication of a Strain-Induced High Performance NbN Ultrathin Film by a Nb5N6 Buffer Layer on Si Substrate. Supercond. Sci. Technol. 2014, 27, 035010. [Google Scholar] [CrossRef]

- Shi, S.C.; Li, J.; Zhang, W. Ultra-High Sensitivity Terahertz Superconducting Detectors; East China University of Science and Technology Press: Shanghai, China, 2021; p. 56. ISBN 978-7-5628-6272-7. [Google Scholar]

- Esmaeil Zadeh, I.; Chang, J.; Los, J.W.N.; Gyger, S.; Steinhauer, S.; Elshaari, A.W.; Dorenbos, S.N.; Zwiller, V. Superconducting Nanowire Single-Photon Detectors: A Perspective on Evolution, State-of-the-Art, Future Developments, and Applications. Appl. Phys. Lett. 2021, 118, 190502. [Google Scholar] [CrossRef]

- Mazzocchi, F.; Ilin, K.; Kempf, S.; Kuzmin, A.; Strauß, D.; Scherer, T. Design and Comparison of Diamond- and Sapphire-Based NbN KIDs for Fusion Plasma Polarimetric Diagnostics. Phys. Status Solidi A 2023, 220, 2200271. [Google Scholar] [CrossRef]

- Zhang, X. Research on Growth of NbN/AlN Thin Films Based on Terahertz Superconducting SIS Tunnel Junction. Master’s Thesis, Shanghai Normal University, Shanghai, China, 3 April 2021. [Google Scholar] [CrossRef]

- Jiang, S.; Li, X.; Su, R.; Jia, X.; Tu, X.; Kang, L.; Jin, B.; Xu, W.; Chen, J.; Wu, P. Terahertz Direct Detectors Based on Superconducting Hot Electron Bolometers with Microwave Biasing. Chin. Phys. Lett. 2017, 34, 090701. [Google Scholar] [CrossRef]

- Pei, Y.; Fan, Q.; Ni, X.; Gu, X. Controlling the Superconducting Critical Temperature and Resistance of NbN Films through Thin Film Deposition and Annealing. Coatings 2024, 14, 496. [Google Scholar] [CrossRef]

- Rhazi, R.; Machhadani, H.; Bougerol, C.; Lequien, S.; Robin, E.; Rodriguez, G.; Souil, R.; Thomassin, J.-L.; Mollard, N.; Désières, Y.; et al. Improvement of Critical Temperature of Niobium Nitride Deposited on 8-Inch Silicon Wafers Thanks to an AlN Buffer Layer. Supercond. Sci. Technol. 2021, 34, 045002. [Google Scholar] [CrossRef]

- Babu, K.R. Electron-phonon coupling, superconductivity, and nontrivial band topology in NbN polytypes. Phys. Rev. B 2019, 99, 104508. [Google Scholar] [CrossRef]

- Hazra, D.; Tsavdaris, N.; Jebari, S.; Grimm, A.; Blanchet, F.; Mercier, F.; Blanquet, E.; Chapelier, C.; Hofheinz, M. Superconducting Properties of Very High Quality NbN Thin Films Grown by High Temperature Chemical Vapor Deposition. Supercond. Sci. Technol. 2016, 29, 105011. [Google Scholar] [CrossRef]

- Shoji, A.; Kiryu, S.; Kohjiro, S. Superconducting Properties and Normal-State Resistivity of Single-Crystal NbN Films Prepared by a Reactive Rf-Magnetron Sputtering Method. Appl. Phys. Lett. 1992, 60, 1624–1626. [Google Scholar] [CrossRef]

- Kang, L.; Jin, B.B.; Liu, X.Y.; Jia, X.Q.; Chen, J.; Ji, Z.M.; Xu, W.W.; Wu, P.H.; Mi, S.B.; Pimenov, A.; et al. Suppression of Superconductivity in Epitaxial NbN Ultrathin Films. J. Appl. Phys. 2011, 109, 033908. [Google Scholar] [CrossRef]

- Zhang, Q.; Wang, H.; Tang, X.; Peng, W.; Wang, Z. Superconductivity Dependence on Epitaxial NbN Film Thickness. IEEE Trans. Appl. Supercond. 2019, 29, 7500305. [Google Scholar] [CrossRef]

- Ilin, K.; Schneider, R.; Gerthsen, D.; Engel, A.; Bartolf, H.; Schilling, A.; Semenov, A.; Huebers, H.W.; Freitag, B.; Siegel, M.; et al. Ultra-thin NbN films on Si: Crystalline and superconducting properties. J. Phys. Conf. Ser. 2008, 97, 012045. [Google Scholar] [CrossRef]

- Miki, S.; Fujiwara, M.; Sasaki, M.; Wang, Z. NbN Superconducting Single-Photon Detectors Prepared on Single-Crystal MgO Substrates. IEEE Trans. Appl. Supercond. 2007, 17, 285–288. [Google Scholar] [CrossRef]

- Kobayashi, A.; Ueno, K.; Fujioka, H. Autonomous Growth of NbN Nanostructures on Atomically Flat AlN Surfaces. Appl. Phys. Lett. 2020, 117, 231601. [Google Scholar] [CrossRef]

- Ezaki, S.; Makise, K.; Shinozaki, B.; Odo, T.; Alsano, T.; Terai, H.; Yamashita, T.; Miki, S.; Wang, Z. Localization and Interaction Effects in Ultrathin Epitaxial NbN Superconducting Films. J. Phys. 2012, 24, 475702. [Google Scholar] [CrossRef]

- Zhang, J.J.; Su, X.; Zhang, L.; Zheng, L.; Wang, X.F.; You, L. Improvement of the Superconducting Properties of NbN Thin Film on Single-Crystal Silicon Substrate by Using a TiN Buffer Layer. Supercond. Sci. Technol. 2013, 26, 045010. [Google Scholar] [CrossRef]

- Krause, S.; Meledin, D.; Desmaris, V.; Pavolotsky, A.; Belitsky, V.; Rudziński, M.; Pippel, E. Epitaxial Growth of Ultra-Thin NbN Films on AlxGa1− xN Buffer-Layers. Supercond. Sci. Technol. 2014, 27, 065009. [Google Scholar] [CrossRef]

- Tian, L.; Bottala-Gambetta, I.; Marchetto, V.; Jacquemin, M.; Crisci, A.; Reboud, R.; Mantoux, A.; Berthomé, G.; Mercier, F.; Sulpice, A.; et al. Improved Critical Temperature of Superconducting Plasma-Enhanced Atomic Layer Deposition of Niobium Nitride Thin Films by Thermal Annealing. Thin Solid Film. 2020, 709, 138232. [Google Scholar] [CrossRef]

- Tan, B. Study of MOCVD Growth of AlN and AlGaN Films Based on PVD-AlN Buffer. Master’s Thesis, Huazhong University of Science & Technology, Wuhan, China, 18 May 2019. [Google Scholar] [CrossRef]

- Luo, W.; Wang, Y.; Li, L.; Li, C.; Zhang, D.; Peng, D.; Li, Z. Influence of High Temperature Annealing on the Crystalline quality of AlN Epitaxial Layers. Res. Prog. Solid State Electron. 2024, 44, 167–172. Available online: http://gtdzx.cetc55.com:81/CN/10.12450/j.gtdzx.202402012 (accessed on 23 March 2025).

- Zhang, Y. Superconductor Physics; University of Science and Technology of China Press: Hefei, China, 1997; p. 24. ISBN 7-312-00941-7. [Google Scholar]

- Sui, J.; Zhou, D.; Tong, Y.; Wang, X.; Zhao, W.; Zhao, Y. Thermal residual stress-dependent coercive field and polarization switching dynamics of Al0.75Sc0.25N ferroelectric films. Mater. Today Commun. 2025, 44, 112078. [Google Scholar] [CrossRef]

- Moriwaki, N.; Minh, L.; Kuwano, H. Highly Oriented and Stress Modified Thick AlN Films Deposited on Low Thermal Expansion Alloy Substrates for Flexible Electronics in Harsh Environment. J. Phys. Conf. Ser. 2019, 1407, 012109. [Google Scholar] [CrossRef]

- Li, Y.; Li, T.; Wang, J.; Sun, Y.; Zheng, J.; Yang, C. The effects of in-situ AlN particles on thermal expansion behavior of AZ91 alloy. J. Mater. Res. Technol. 2025, 1, 158. [Google Scholar] [CrossRef]

- Krishnan, R.S.; Srinivasan, R.; Devanarayanan, S. Thermal Expansion of Crystals; Pergamon press: Oxford, UK, 1979; pp. 147–148. ISBN 978-0-08-021405-4. [Google Scholar] [CrossRef]

- Zhen, L.; Peng, P.; Qiu, C.; Zheng, B.; Antonios, A.; Zhong, R. Effect of Pre-deposited Al Layer on Growth of AlN Buffer Layer and GaN Film on Si Substrate by Metal-organic Chemical Vapor Deposition. Chin. J. Mater. Res. 2020, 34, 744–752. [Google Scholar]

| Substrate Material | RMS (nm) | (102)XRC-FWHM (arcsec) |

|---|---|---|

| AlN/Si | 3.7, 3.5 | 4595, 4143 |

| AlN/Sapphire | 3.1, 2.8 | 2883, 2883 |

| Annealed-AlN/Sapphire | 6.5, 6.1 (2.9 *, 2.9 *) | 1450, 1684 (2964 *, 3050 *) |

| 4H-SiC | 0.19, 0.23 | 53, 56 |

| Substrate Material | Sample Name | Annealed Sample Name |

|---|---|---|

| AlN/Si | NbN-AlN/Si | NbN-AlN/Si-a |

| AlN/Sapphire | NbN-AlN/Sa | NbN-AlN/Sa-a |

| Annealed-AlN/Sapphire | NbN-a-AlN/Sa | NbN-a-AlN/Sa-a |

| 4H-SiC | NbN-SiC | NbN-SiC-a |

| Equipment | Manufacturer, City, Country | Specifications |

|---|---|---|

| Sputtering platform | Kurt J. Lesker Company, Clairton, United States | PRO Line PVD 75 |

| AFM | Danish Micro Engineering A/S, Horsholm, Denmark | DME C-26 |

| X-ray diffractometer | Malvern Panalytical, Almelo, Netherlands | PANalytical X’Pert MRD |

| PPMS | Southeast University, Nanjing, China | PPMS-8 |

| Sample | TC (K) | ΔTC (K) | FWHM of NbN (arcsec) | Film Thickness (nm) | FWHM (102) of Substrate (arcsec) |

|---|---|---|---|---|---|

| NbN-AlN/Si | 11.3 | 3.0 | 2732.6 | 34.4 | 4595 |

| NbN-AlN/Sa | 10.0 | 3.5 | 4860 | 34.6 | 2883 |

| NbN-a-AlN/Sa | 10.3 | 2.7 | 3564 | 34.7 | 1450 |

| NbN-SiC | 13.7 | 1.0 | 880.9 | 34.5 | 53 |

| NbN-AlN/Si-a | 11.6 | 1.2 | 2538.3 | 34.3 | 4143 |

| NbN-AlN/Sa-a | 11.7 | 1.8 | 2323 | 34.1 | 2883 |

| NbN-a-AlN/Sa-a | 12.0 | 1.6 | 2334.3 | 34.4 | 1684 |

| NbN-SiC-a | 16.3 | 1.1 | 220.7 | 34.5 | 56 |

| Material | AlN (a-Axis) | Si | Sapphire (A-axis) |

|---|---|---|---|

| CTE (10−6/°C) | 4.4–4.7 | 3.1–3.9 | 4.9–5.8 |

| Substrate | As-Deposited NbN RMS (mm) | Annealed NbN RMS (mm) | Substrate RMS (mm) |

|---|---|---|---|

| AlN/Si | 2.6 | 3.3 | 3.5 |

| AlN/Sapphire | 2.2 | 4.7 | 2.8 |

| Annealed-AlN/Sapphire | 2.1 | 4.3 | 6.1 |

| 4H-SiC | 2.3 | 2.7 | 0.23 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hu, Z.; Pei, Y.; Fan, Q.; Ni, X.; Gu, X. Research on the Correlation of Physical Properties Between NbN Superconducting Thin Films and Substrates. Coatings 2025, 15, 513. https://doi.org/10.3390/coatings15050513

Hu Z, Pei Y, Fan Q, Ni X, Gu X. Research on the Correlation of Physical Properties Between NbN Superconducting Thin Films and Substrates. Coatings. 2025; 15(5):513. https://doi.org/10.3390/coatings15050513

Chicago/Turabian StyleHu, Zeming, Yang Pei, Qian Fan, Xianfeng Ni, and Xing Gu. 2025. "Research on the Correlation of Physical Properties Between NbN Superconducting Thin Films and Substrates" Coatings 15, no. 5: 513. https://doi.org/10.3390/coatings15050513

APA StyleHu, Z., Pei, Y., Fan, Q., Ni, X., & Gu, X. (2025). Research on the Correlation of Physical Properties Between NbN Superconducting Thin Films and Substrates. Coatings, 15(5), 513. https://doi.org/10.3390/coatings15050513