1. Introduction

The sol-gel process was developed in the early 1930s and was based on the hydrolysis of silicon alkoxides to prepare silica particles, resembling an inorganic polymerization. The term sol-gel implies the generation of colloidal suspensions, named sols, which are subsequently converted to viscous gels and then to solid materials [

1]. Gel describes the part of a reacted system that has reached the gel point, which implies extensive connectivity on a molecular level. Gel point occurs at a critical extent of reaction, when one large molecule of macroscopic dimensions and infinite molecular weight is produced. At this point, the materials are insoluble and infusible, but further reaction still may occur.

Sol-gel was the first method for producing ceramics in mild conditions [

2,

3]. This fact, together with the good stability of the Si–C bond, aroused the interest of researchers, especially in the field of protective coatings, and opened up the possibility of preparing hybrid organic–inorganic materials using this approach [

4,

5,

6,

7].

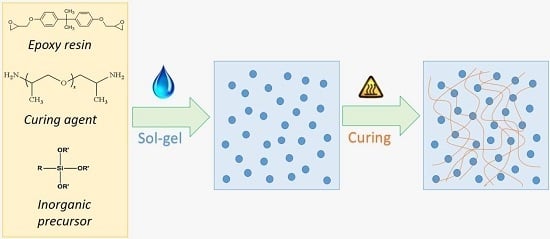

The main idea of using hybrid materials is to take advantage of the best properties of the polymeric material and the inorganic structures while decreasing their drawbacks and obtaining a synergistic effect from their combination. In these new materials, organic and inorganic components can interpenetrate each other in scales ranging from a few micrometers to a few nanometers. In general, organic and inorganic structures are covalently bonded, more or less strongly. In the so-called class I materials, the organic and inorganic structures only interact weakly while they are linked through covalent bonds in class II hybrid materials. The properties of these hybrids are not just the sum of the individual contributions of both phases, and the role of the inner interfaces could even prevail.

There are a huge number of possibilities to prepare new hybrid materials with tailored characteristics based on sol-gel procedures. As inorganic precursors, not only Si derivatives can serve in the sol-gel process, but also Al, Ti, Zr, Sn, V salts and alkoxides and other organometallic substrates in which the metal is linked to organic moieties and can be hydrolyzed and then condensed [

8,

9]. In the condensation step, water is lost. In

Scheme 1, the two-step sol-gel procedure is depicted.

Scheme 1.

Idealized representation of the inorganic network formation by sol-gel procedure.

Scheme 1.

Idealized representation of the inorganic network formation by sol-gel procedure.

As an organic matrix, a great number of monomers or polymers can be used, which allow the preparation of a huge variety of organic–inorganic hybrid materials. Finally, the different proportions of inorganic and organic components in the hybrid materials can also be easily adjusted by changing the composition of the formulation. All these variations can change, appreciably, the behavior and characteristics of the materials and, consequently, their application. The combination of hardness and thermal stability of inorganic glass and toughness of an organic matrix results in improved thermal and mechanical properties of the hybrid materials [

10].

The

in situ sol-gel polymerization of metal precursors in a polymeric (or monomeric) matrix is a better approach in front of the addition of nanoscale inorganic building blocks to the formulation. The fact that small molecules or liquid precursors are used in the preparation of the hybrid materials implies advantages, such as a high control of the purity and composition of the materials and the easy processing of the formulations, which allows to cast coatings in complex shapes and to produce thin films without the need for machining or melting. Moreover, sol-gel is a green technological procedure, due to the fact that it does not introduce impurities into the end product as initial substances, is waste-free and excludes the stage of washing [

11]. However, the sol-gel route also has some limitations, preventing the formation of bulky hybrid materials and, therefore, only thin films can be prepared. The curing shrinkage, produced by of the elimination of by-products in the condensation stage, is responsible for the appearance of internal stresses leading to the formation of defects (microvoids and microcracks) and a reduction of adhesion.

Epoxy nanocomposites (also named hybrid epoxy thermosets) are materials consisting of two phases, a nanometric sized inorganic domain, well-dispersed in a crosslinked epoxy matrix [

12,

13]. These materials constitute one of the most useful hybrid materials, usually containing Si oxide particles. They have been applied in a great number of applications, such as bone and stone restorations, coatings, adhesives, and electronic and optical materials among others [

14,

15,

16,

17,

18,

19].

2. Sol-Gel Reaction

Sol-gel process consists in two different reactions on metal oxide precursors: hydrolysis and condensation, which occur in aqueous solutions, or in the liquid state, or in organic solutions in a highly humid atmosphere, producing polymeric inorganic metal oxide particles (as represented in

Scheme 1). Alkoxides and salts of early transition metals (such as Ti, V and Zr), metals of IIIB group (such as B and Al), or, more frequently, Si, are able to act as sol-gel precursors, Si being the less reactive one [

20]. Among these different precursors, silicon tetrachloride and alkoxides or organosilicon compounds are the most used in the formation of silicon particles within epoxy matrices, in both industrial applications and in academic studies, and, therefore, this review will be mainly focused on them [

21,

22,

23]. In the following scheme (

Scheme 2), the formation of silica structures is represented, taking into account that hydrolysis and condensation reaction takes place leading to a three-dimensional structure according to the number of OR groups per Si atom. Smaller R groups are recommended to reduce shrinkage. Moreover, the smaller the R group, the faster hydrolysis takes place.

Compared to transition metals, silicon is less electropositive, which leads to a lower reactivity of silylalkoxides towards the nucleophilic attack of water in the hydrolysis step. The hydrolysis takes place even at pH 7 forming silicic acid [

3]. However, silicate gels are mostly obtained from tetrafunctional silicon alkoxides catalyzed by an acid or a base.

Hydrolysis can be complete or only partial, therefore opening the possibility of condensation by two different ways. The first one represented in

Scheme 2 consists in the loss of a water molecule to form an oxygen bridge, and the second one is the loss of an alcohol molecule to lead to the same siloxane structure. The formation of water in the condensation step allows the hydrolysis process to be performed in under-stoichiometric proportions of water. However, even in excess of water the hydrolysis reaction does not reach complete conversion.

Scheme 2.

Chemical processes in a sol-gel procedure on silicon precursors.

Scheme 2.

Chemical processes in a sol-gel procedure on silicon precursors.

Depending on the number of alkoxides (functionality,

f) of the silicon precursor, which usually is three or four, and the reaction conditions, the silicon structure produced can be linear or branched oligomeric, cubic or networked. It should be noted that the functionality of a molecule (monomer) is the number of bonds that can be formed on reacting [

3]. At a higher functionality of the precursors, the higher the branching degree of the structure formed. Tetraethyl orthosilicate (TEOS), with a functionality of four, is the precursor used to generate silica particles or to increase the crosslinking of silicon structures after sol-gel reaction [

24,

25]. Upon hydrolysis and condensation of different proportions of TEOS with an organosilicon compound with

f = 3, silicon particles of different size can be obtained. On increasing the proportion of TEOS in the reactive mixture, the size of the particles will increase if the reaction conditions remain unaltered, with the formation of densely crosslinked structures. Although it falls out of the scope of this review, it should be noted that the type of catalysis, basic or acid, affects the inorganic structure formed. Thus, acid catalysis favors a faster hydrolysis of the precursor, finally leading to an open weakly branched polymer-like structure. On the contrary, in a basic medium, the hydrolysis occurs slower but the polycondensation is faster, producing compact colloidal particles [

3,

22]. In

Scheme 3 the effect of the catalyst in the morphology of the network is depicted.

Scheme 3.

Catalyst influence in the formation of the inorganic network by sol-gel.

Scheme 3.

Catalyst influence in the formation of the inorganic network by sol-gel.

Hydrolysis is a reversible process in which there is the possibility that alcohol attacks the silanol leading to the formation of an alkoxide. This process is known as re-esterification and is favored at high content of alcohol as the solvent or in the presence of other hydroxylic species [

26,

27].

Another reaction that can occur during a sol-gel process is transesterification, which is the reaction of an alcohol with a silylalkoxide with the corresponding formation of a different silylalkoxide (see

Scheme 4).

Scheme 4.

Transesterification reaction.

Scheme 4.

Transesterification reaction.

This reaction occurs when the alcohol used as the solvent is different from that formed in the hydrolysis reaction, but can also be used to link poly(hydroxylic) compounds to silica structures or to functionalize hydroxylated surfaces.

In interesting work [

23], Matějka

et al. proposed an alternative procedure for the preparation of epoxy-silica hybrids by a non-aqueous sol-gel process, based on the use of borontrifluoride monoethylamine complex (BF

3MEA). This procedure helps to overcome solvent or water evaporation, which usually leads to the apparition of defects produced by the elevated curing shrinkage. Moreover, this non-aqueous sol-gel technique provides a better control at molecular level that allows to obtain more uniform morphologies, due to the slower rate of formation of silica structures in the epoxy matrix. The sol-gel mechanism was studied by NMR spectroscopy of

11B,

13C and

29Si. It could be proved that the boron complex was split and the amine released, which can act as initiator. Moreover, BF

3MEA activates the C–OH group of the epoxy resin, promoting the protolysis of TEOS, and it was confirmed that the reaction did not proceed in the absence of the boron complex.

More recently, the use of ionic liquids in sol-gel processes have also been reported by Matějka

et al. [

28,

29]. The ionic liquids used in the process act as a dynamic template that leads to silica with decreased random interparticle aggregation and control on the structure with a tremendous decrease in the gelation time. The interaction of ionic liquids with the growing silica particles enables the formation of new organic-inorganic materials in one-pot procedures under mild reaction conditions. Differences in size and geometry, compactness and morphology of silica structure depend on the Coulomb coupling forces between anions and cations. By comparing the mechanical properties obtained by both procedures it was confirmed that epoxy–silica interphase bonding was crucial for both nanocomposite morphologies to reach the mechanical properties enhancement [

30]. Improved dispersion of silica nanodomains in the epoxy matrix were achieved for both the hydrolytic and non-hydrolytic sol-gel approaches.

4. Structural and Morphological Characterization of the Inorganic Silicon Structure

Because of the complexity of the sol-gel process, the structural characterization of the new bonds and structures formed is of key importance, since factors such as the proportion of water, temperature, and the pH of the reaction medium affect to a great extent the structure of the formed inorganic domains. Therefore, a number of publications focusing on the structural characterization of silicon sol-gel products can be found in the literature [

25,

36,

37]. Vibrational spectroscopic techniques, such as Raman or Infrared, or Nuclear Magnetic Resonance of

29Si in the solid state, are generally used in the characterization of inorganic structures of hybrid materials.

The formation of the inorganic silicon network depends on the condensation reaction of the previously-formed silanol structures that leads to new Si–O–Si bonds. The presence of silanols can be detected by Fourier-Transform Infrared Spectroscopy (FTIR) by the absorption of Si–OH stretching at ~3470 cm

−1, which disappears on condensing. The new Si–O–Si bonds formed produces absorptions in the FTIR spectrum at about 1078 cm

−1 with a shoulder at 1163 cm

−1 and another peak at approximately 460 cm

−1 [

25].

29Si-NMR renders more information than FTIR, since it allows the determination of the environment of the silicon atoms and therefore it can provide details on the degree of hydrolysis and polycondensation. As the precursors generally have three or four hydrolyzable groups, some peaks at chemical shifts attributable to T

n or Q

n structures can be observed by this technique. T and Q stand for trialkoxysilane and tetraalkoxysilane derivatives, respectively, and the subscript

n indicates the number silanol groups condensed to siloxane bonds.

Scheme 6 depicts the chemical structures of silanols (T

0 and Q

0) and the possible structures produced in the condensation. T

n signals, derived from organoalkoxysilanes, appear in the range −40 to −80 ppm and Q

n signals, coming from the use of TEOS in the sol-gel process, appear between −80 and −120 ppm in reference to tetramethylsilane (TMS) [

22,

38,

39]. As a general trend, on increasing the condensation degree (from T

0 to T

3 or from Q

0 to Q

4) the signals shift downfield. The evolution of the intensity of these signals during sol-gel process is used to analyze the kinetics of the process and to find out the adequate conditions to reach the desired inorganic structure [

40,

41]. Complete hydrolysis and further condensation is achieved when only signals T

3 and Q

4 appear in the

29Si NMR spectrum.

Scheme 6.

Structure of the possible units formed in the sol-gel process for the structural characterization by 29Si-NMR derived from an organo trialkoxysilane (T structures) and TEOS (Q structures).

Scheme 6.

Structure of the possible units formed in the sol-gel process for the structural characterization by 29Si-NMR derived from an organo trialkoxysilane (T structures) and TEOS (Q structures).

In principle, the sol-gel reaction can be followed by 29Si NMR in the liquid state, but, when gelation is reached, the silicon network structure separates from the solvent and the experiment is no longer valid. For this reason, the use of NMR magic angle spinning (29Si-CPMAS) in the characterization of these materials is recommended for solid samples, taking into account that the probe should be Si free.

In

Figure 1 a typical

29Si NMR spectrum for the condensation of a trialkoxysilane with TEOS is shown.

Figure 1.

29Si-NMR spectrum of the material obtained by condensation of a trialkylalkoxysilane with TEOS.

Figure 1.

29Si-NMR spectrum of the material obtained by condensation of a trialkylalkoxysilane with TEOS.

As we can see, there are T3 and T2 signals corresponding to the complete condensed and partially condensed trialkoxysilanol, respectively. In addition, between −95 and −120 ppm the signals corresponding to the units formed by condensation of silanol derived from TEOS appear (Q signals). The apparition of T2, Q3 and Q2 signals are due to the incomplete condensation of the silanol groups, which produces a more open inorganic network.

Cyclization of alkoxysilanes is a well-known process that is used to synthesize polyhedral polysilsesquioxanes (POSS), such as branched and ladder polymers or octamer cages [

41]. POSS with organic functionalities at their vertex are of great interest as building blocks of hybrid materials. Silsesquioxane structures, octamer T

8 cages bearing functional groups (see

Scheme 7), have been observed in sol-gel processes starting from trialkoxysilanes under some particular synthetic conditions, both basic and acidic [

42]. Incomplete condensed cages containing eight silicon atoms with some unreacted silanol groups can also be formed.

Scheme 7.

Preparation and structure of octameric cages bearing organic groups in the vertices produced by sol-gel reaction from trialkoxysilanes.

Scheme 7.

Preparation and structure of octameric cages bearing organic groups in the vertices produced by sol-gel reaction from trialkoxysilanes.

The NMR signals of Si atoms in cyclic cage-like structures, in contrast to linear or branched structures, show a higher chemical shift value because cyclization reduces the valence angles and the density of positive charge on the silicon atoms decreases [

41]. The

29Si NMR spectrum of perfect octamer T

8 cages shows an only T

3 signal at

ca. −66 ppm [

42]. This indicates that the product has a symmetric structure with only one type of Si atoms, which are substituted with three siloxane bonds (

i.e., absence of silanol group).

Morphological characterization of the silica particles can be performed using small angle X-ray scattering technique (SAXS) and TEM. As previously discussed, optical transparency of the hybrid materials evidences that the characteristic domain sizes remain below 400 nm. Small angle X-ray scattering technique (SAXS) is an important tool for the characterization of the nanoscopic structure of hybrid materials containing nanoparticles and their aggregates or agglomerates and provides information regarding hierarchical structures and particle size distribution [

43]. The fact that SAXS provides information without the constraint of requiring a repeated structure is one of the advantages of this technique to be applied in such complex materials. SAXS allows for analysis of larger aggregates and can measure particles on the order of 5–25 nm with weakly repeating structures of up to 150 nm. However, there is a loss of information in comparison with microscopic techniques such as TEM. This is due to the fact that SAXS provides a more holistic view of the structure. TEM provides information about individual grains by actually looking at them, while SAXS gives more information about the average of the particles [

44,

45].

5. Epoxy Hybrids

Epoxy thermosets have several limitations mainly related to their low mechanical properties and high thermal expansion coefficient (CTE) compared with inorganic materials. Thus, when applied as protective coatings on metal substrates, they are quite fragile, and the variation in the temperature leads to a mismatch between the substrate and the coating leading to the loss of adhesion and to the apparition of cracks. In addition to that, epoxy resins cannot be used alone as the molding compounds usually applied in electrical and structural applications [

46]. These limitations can be overcome by using inorganic/epoxy materials [

13,

17]. Inorganic fillers are the most common additives used in epoxy formulations to improve mechanical properties, such as modulus and strength. The inclusion of inorganic fillers into thermosets aims at cost reduction and improvement of resistance to scratching, abrasion, heat stability and barrier properties, corrosion resistance and fire retardancy abilities [

11,

47,

48], but epoxy coatings lose their transparency, increase weight and become more fragile [

49].

Hybrid materials containing both inorganic and organic components are expected to have increased performance capabilities relative to their non-hybrid materials because of the compatibility between both components, caused by the existence of covalent bonding or strong interactions at the interphase. A relevant difference between hybrid epoxy thermosets and epoxy nanocomposites is the fact that in the former ones the inorganic phase is formed

in situ, for instance by a sol-gel process, while nanocomposites are usually produced by dispersing inorganic particles with at least one dimension less than 100 nm in the liquid epoxy mixture. Both hybrid materials and nanocomposites are reinforced materials with improved mechanical properties that maintain their transparency, which is a desired characteristic in protective coatings [

13,

50].

Epoxy resins are monomers or oligomers containing two or more epoxy groups in their structure. Epoxy resins are capable of reacting with different active compounds known as curing agents (with or without catalyst) or with themselves (via an initiator) to form solid, crosslinked thermosets. This transformation is generally referred to as curing [

46,

51]. Depending on the particular details of the epoxy formulation, curing may be accomplished with the application of external heat (in some cases it works also at room temperature), or with the application of an external source of energy other than heat, such as ultraviolet (UV) or electron beam (EB) energy [

52]. However, the most extended way of promoting the curing reaction is the use of heat. Depending on the curing agent, the temperature required to start the curing can vary from room temperature to more than 200 °C. In general, one can distinguish two different types of the so-called thermal curing systems: (a) stoichiometric systems, which are those that require a certain amount of a second molecule with active functional groups to react with the epoxides of the resin; and (b) catalytic systems, where homopolymerization takes place initiated either by an anionic or cationic specie in very low amount.

As stoichiometric crosslinking agents one can mention aliphatic and aromatic amines, carboxylic acids, isocyanates, hydrazides, thiols, polyphenols,

etc. In this case, the reaction consists of a polycondensation reaction between the reactive groups coming from the crosslinking agent and the epoxide groups. Therefore, the kinetics of the process is that of a step-growth reaction. In order to obtain a polymer network, the global functionality of the formulation, that is, the one of the base epoxy resin plus that of the curing agent, should be five at least [

51].

Scheme 8 represents the curing of the most typical diglycidylic resin (DGEBA) with primary diamines as curing agent. It should be noted that the curing process occurs through the formation of intermediate linear oligomers, which by reaction of the formed secondary amines leads to the formation of the epoxy network.

Scheme 8.

Structures formed in the curing of DGEBA with primary diamines.

Scheme 8.

Structures formed in the curing of DGEBA with primary diamines.

Alternatively, crosslinking of epoxy resins can take place without using curing agents but using initiators instead. Initiators used in catalytic amounts promote the homopolymerization of epoxides via ring-opening polymerization (ROP). This mechanism is similar in terms of kinetics to polyaddition since it presents an initiation step, a propagation and finally a termination. In general, there are mainly two types of ROPs for epoxy curing depending on the propagation mechanism: anionic, and cationic [

53]. In this curing system, a monomer or an oligomer with two epoxide groups in their structure are required to form a crosslinked material. Anionic mechanism is shown in

Scheme 9.

Scheme 9.

Initiation and propagation steps in the curing of epoxides promoted by an anionic initiator.

Scheme 9.

Initiation and propagation steps in the curing of epoxides promoted by an anionic initiator.

As we can see, the network structure is quite different in primary amine curing than in anionic initiated curing systems, being the former a more open structure which can be easily modified by varying the amine structure. In initiated systems, the type of initiator and its proportion also modulate the network structure but, in general, higher crosslinking density can be achieved. Moreover, in amine cured systems there are a great number of hydroxyl groups, which can interact or even react with the silicon structure whereas in initiated curing processes the network structure is mainly constituted by ether groups coming from the epoxy homopolymerization. Thus, the mechanisms and the curing agents selected to prepare sol-gel hybrid materials affect to a great extent the structure of the organic phase and, consequently, the characteristics of the hybrid material.

The formation of the inorganic silicon structure in epoxy hybrids can take place before or after the curing process. Proper selection of the curing methodology should always consider the kinetics and reaction conditions of both processes. Sol-gel hybrids can be performed by either a simultaneous one-step or a sequential two-step procedure. In one-step procedures there is only one formulation containing all the monomers, curing agents and silica precursor, while in two-step procedures sol-gel is carried out separately to produce inorganic precursors, and the epoxy formulation is added afterwards. Transmission electronic microscopy (TEM) and small angle X-ray scattering analysis (SAXS) on the hybrids usually revealed a strong phase separation when the materials are prepared by sequential polymerization and extensive mixing of phases for simultaneous reaction routes [

15].

However, in the non-aqueous system proposed by Matějka

et al. [

23], the experimental procedure was a two-step, consisting in the generation of the silica particles in the DGEBA with a 2% of BF

3MEA in reference to TEOS and subsequent addition of the stoichiometric amount of diamine to the prereacted mixture. The curing schedule varied, depending on the amine selected as crosslinking agent. In this case, because of the small extent of TEOS protolysis, the inorganic structure growth during polycondensation proceeded by the monomer-cluster aggregation mechanism leading to a fine morphology consisting of branched structures interconnected, well dispersed in the epoxy matrix.

As noted above, in order to reach good mechanical properties, the compatibilization of organic and inorganic structures by the formation of covalent bonding is an essential condition. For this reason, the use of reactive organoalkoxysilane precursors as components of the initial formulation is always needed and therefore they can be considered as coupling agents [

54]. Some commercially available trialkoxysilyl compounds usually applied in epoxy hybrids are collected in

Scheme 5. It should be noted that, in order to reach the covalent coupling, the structure of organoalkoxysilane compound should be selected according to the curing chemistry of epoxy formulation. This includes the type of resin, curing agent or initiator selected and the modifiers added to the formulation. In the case of epoxy formulations cured with stoichiometric curing agents, the amount of reactive groups coming from the silicon precursor should also be considered in the stoichiometry of the formulation. Hydroxyl groups present in the resin, or in the curing agent, can also react with siloxanes, according to the transesterification reaction (see

Scheme 4), which opens a new way of compatibilizing organic and inorganic domains. The addition of TEOS to a formulation containing organoalkoxysilane precursors usually aims to increase the SiO

2 content and the size of the particles formed.

In photopolymerized hybrids it has been reported that if the UV-initiated homopolymerization is carried out in the first place the low viscosity of the initial mixture favors the processability, but the high shrinkage occurring during the sol-gel process due to the evaporation of by-products produces a high internal stress resulting in cracking of the final material [

55]. If epoxide photopolymerization is done after completion of the sol-gel process, evaporation and shrinkage occurs when the material is still liquid and, as a consequence, no internal stresses appear and the defects in the final hybrid thermosets are reduced. However, the sol-gel process compromises the processability of the formulation, since the viscosity increases by the formation of silica structures. Thus, the preparation of hybrids should consider all of these effects in order to select the appropriate processing sequence.

Matějka

et al. [

22] studied the evolution of the silica structure in the hybrid from DGEBA-Jeffamine 2000-TEOS formulations and determined that the sol-gel process was much faster under the selected experimental conditions than the formation of the epoxide-amine network. While the silicon system gelled quickly at room temperature, gelation of the organic polymer occurred in 10 h at 80 °C. Therefore, the silica network is formed first and the sol-gel process proceeds in a low viscosity organic medium.

Piscitelli

et al. [

39] reported the preparation of hybrids from DGEBA/m-xylylenediamine/ GPTMS/TEOS formulations by a two-step procedure, consisting of a first hydrolysis/condensation of siloxane precursors followed by the addition of epoxy/amine mixture. They observed a reduction in the glass transition temperature (

Tg) and reinforcement by the inorganic siloxane domains within the rubbery plateau region. Moreover, nanoindentation studies showed that hardness did not change significantly with the increase of siloxane content. These facts were explained on the basis of a plasticization produced by the rapid epoxy-amine reaction that linked the pre-hydrolized coupling agent to the siloxane network, as T

0 species, and prevented it from segregating. It should be noted that the higher reactivity of m-xylylenediamine in comparison with Jeffamine 2000 would make it necessary to adopt a two-step procedure to prepare the hybrid thermosets.

Davis

et al. [

56] reported that the hydrolysis of GPTMS in acidic conditions could be performed without affecting the epoxide rings. Upon addition of diethylenetriamine (DETA) as curing agent, the formation of interconnected organic and inorganic networks was observed. However, the formation of the organic network also produced geometrical constraints that inhibited condensation reactions leading to the inorganic network, especially when the crosslinking density increased. Constraints in the formation of the hybrid structure can be explained by considering that the process consists in the first gel formation of the growing silica structure up to the gel point, organic-inorganic phase separation and final vitrification of inorganic-rich phase/organic-rich phase in the case that the process is carried below the

Tg of the organic network. All this provokes that, at the end of the whole process, the reactions become diffusion-controlled [

3].

By curing different mixtures of DGEBA, TEOS and GPTMS with a Jeffamine, Pisticelli

et al. demonstrated the possibility of producing epoxy-silica hybrids with a morphology consisting of well-organized cage-like structures interdispersed within the epoxy network [

57]. At low silica contents, the hybrid exhibits a finely dispersed morphology, consisting of homogeneous nanostructures embedded in the epoxy matrix. However, the cage-like structures formed a co-continuous phase upon reaching a threshold siloxane concentration, in the range of 12–18 wt % wt of silica content. In the rubbery plateau region of the DMTA spectra of the hybrids with a high siloxane content a very large increase in the modulus, relative to the pristine epoxy system, was evidenced, which was associated with the efficient reinforcement provided by the siloxane network within the co-continuous organic-inorganic domains. Moreover, it was noted that value of

Tg exhibited a sharp rise at equivalent silica contents greater than 12 wt %, which was associated with the threshold conditions for the formation of co-continuous phases.

There are a number of characteristics of epoxy materials that can be enhanced by the participation of the sol-gel process. Some examples of improvements reached on some of the most interesting properties are collected in the next paragraphs.

Cold-cured epoxy-silica hybrids, prepared by sol-gel process and cured with 4,4′-methylene

bis-cyclohexaneamine can be enhanced, by adding

bis-(γ-propyltrimethoxysilane)amine, TEOS and GPTMS to the formulation. This opens the possibility of overcoming some of the deficiencies of conventional epoxy adhesives in concrete/masonry repairing and structure strengthening applications, since environmental factors have a significant detrimental effect on the performance of the adhesives in service [

58]. These epoxy-silica hybrids showed much higher values of humidity uptake than the control system at the same exposure conditions. This was related to the higher polymer-water affinity and free volume of the hybrids, caused by the slow condensation proportion of silanols at room temperature. With increasing moisture uptake, the

Tg decreases due to the plasticization of the network. However, after reaching a minimum, the

Tg began to increase with exposure time, due to a further crosslinking reaction during environmental aging, leading to the reactivation of the incomplete curing for the not-fully-cured samples.

Self-cleaning coatings with excellent water-repellence and good mechanical properties were prepared by adding TEOS, GPTES and perfluorodecyltriethoxysilane to the formulation [

59]. Fluorinated moieties yield hydrophobicity while the alkoxysilane groups stick to the substrate and promote adhesion. The coatings with 15 wt % loading of 10–20 nm silica had good mechanical properties and resistance to weathering. In addition, they were able to maintain the required hydrophobicity even after the removal of the top surface by accelerated abrasion. These coatings showed approximately 96% of self-cleaning efficiency.

Sol-gel hybrid materials have been applied to protect metals from the corrosion, which is one of their worse environmental problems, resulting in decay and loss of material due to chemical attack [

60]. These hybrids can constitute a good environmental alternative to chromate coatings, with chromium (VI) compounds that are slowly leached on exposure to aqueous media from scratches and other defects [

61,

62]. It has been found that hybrid coatings provide good corrosion resistance for metal substrates based on their ability to form dense barriers to the penetration of corrosion initiators [

63]. Failure of hybrid protective coatings in an aggressive environment occurs through localized pit formation that is likely to form at defect sites, possibly in regions where there are hydrophilic groups, such as remaining uncondensed silanols or with lack of organic phase. In order to reduce pit formation, it is necessary to produce a dense, continuous film, impermeable to electrolytes and corrosion initiators. Therefore, a tight and uniform crosslinked network in the organic phase is essential.

Corrosion evaluation by electrochemical impedance spectroscopy (EIS) suggests that the protection of epoxy-silica coatings against corrosion is attributable to the formation of an intermediate silica layer at the coating-substrate interface, which prevents the penetration of electrolyte and decreases the corrosion rate [

60]. In this sense, an advantage of the hybrid systems prepared from organically modified coupling agents is the possibility of preparing thick, crack-free films, without much possibility of water and oxygen penetration [

64]. Thus, the hydrophilicity of the surface was dependent on the GPTMS amount (or other organoalkoxysilanes) in the formulation, and it was reduced by increasing the inorganic content. Salt spray investigations showed that the corrosion protection properties of sol-gel derived coatings were strongly dependent on the type of silane precursors (

i.e., TMOS and TEOS), silane content, and type of nanostructures formed. The inspection using SEM of the protective coatings proved that TEOS induced higher porous structure to hybrid coating than TMOS, possibly due to the smaller size of MeOH molecules produced in the condensation step. Moreover, the adhesion of hybrid films on aluminum substrates improved by adding the organosilane content but the corrosion protection was reduced, according to the reduction of the protective silica layer. However, the durability of the material, surface roughness and EIS behavior depend, not only in the inorganic network, but also on the amine crosslinking agent used. The creation of a densely crosslinked coating is responsible for improved substrate corrosion protection and can be related to the structure of the amine crosslinking agent [

65].

Sol-gel technique is also a novel strategy for fabrication of environmentally friendly flame retardant coatings. Hybrid coatings, prepared from TEOS and octyltriethoxysilane, served to encapsulate ammonium phosphate (APP), which was added to epoxy formulations to increase flame retardancy. The LOI (limiting oxygen index), UL-94 (plastics flammability standard), and cone calorimetry results indicated that the flame retardancy and the water resistance of the epoxy matrix could be improved with a synergistic effect between polysiloxane and APP [

66]. It was reported that on heating the gel film of the capsule could release water vapor that would reduce the concentration of oxygen in the surrounding atmosphere. Meanwhile, the shell of SiO

2, generated from the decomposition of the gel film, could make the materials swell to form a more stable intumescent char by the synergistic effect with APP. LOI value increased from 29 in the neat epoxy to 32.5 in the hybrid material and by the UL-94 it was classified as V-0. Using cone calorimetry, it could be proved that, while the neat epoxy material quickly burned after ignition, with a heat release rate of 1192 kW/m

2 and a total heat release of 175 MJ/m

2 within 360 s, the heat release rate of the modified material was reduced remarkably to 184 kW/m

2 and a total heat release of 98 MJ/m

2 within 900 s.

Thermomechanical properties are also modified in epoxy hybrids. In an original approach, it has been reported the use of 4-aminophenyl trialkoxysilane (APTMOS) as a crosslinker [

67,

68]. In these studies, APTMOS was first used to prepare epoxy-terminated oligomers by reacting DGEBA with amino groups of the silicon precursor and then performing the sol-gel process by adding water. To achieve the complete curing of the pre-polymers formed a required amount of Jeffamine D-400 was added and a co-continuous hybrid morphology was obtained. The silica particles greatly hindered the rotational movements of the organic chains and an increase in the

Tg (from 60 °C from the neat, to 78 and 84 °C, for a 7.6% and 25% of SiO

2 content, respectively) and a broadening of the network relaxation curve were observed. In the glassy region storage modulus values increased with the silica content (from 1.97 to 2.81 GPa) and in the rubbery state the moduli of the hybrids did not decrease sharply but the higher value was maintained, which is related with the binding of the rigid silica network with the matrix. Subsequently, the thermal expansion coefficient of the hybrids was also reduced and thermal stability was increased.

The mechanical properties of hybrid materials mostly composed of polymer depend essentially on those of the polymeric phase whereas the properties of materials with a high inorganic content present tunable characteristics between plastic and brittle behaviors [

69]. The addition of TEOS to the initial formulation and the type of coupling agent also affect mechanical and thermomechanical properties [

70]. Changes in mechanical characteristics will be expected when raising the inorganic content in the hybrid material. In coatings applications, the easy tailoring of the organic-inorganic network is a great advantage to improve the adhesion of the film to the substrate [

71].

In DGEBA/Jeffamine D-400 materials, mechanical characteristics were improved by adding different proportions of TEOS as a source of SiO

2 and APTES as coupling agent [

72]. Simultaneous improvements in stiffness and toughness could be obtained when relatively higher temperatures of hydrolysis were applied. The smaller, well-dispersed and well-matched filler particles efficiently dissipate the fracture energy, and result in matrix stiffness and toughening. A monotonic increase in tensile strength and stiffness of the composite systems was observed with increasing silica loadings.

The importance of the size of the silica particles was investigated by Palraj

et al. [

73]. They compared the effect of the addition of SiO

2 nanoparticles prepared in a first step by sol-gel with the addition of microsized particles to DGEBA/polyamide formulations without any type of coupling agent. They proved that the abrasion resistance of the hybrid containing nanosilica was 50% higher than that of microsilica. Mechanical properties as adhesion strength and impact resistance were superior for hybrids with nanosilica. The smaller size of the nanoparticles leads to a larger contact area and hence better wear resistance is offered by the nanosilica particles. Corrosion resistance measurements showed that whereas the nanosilica coating withstood 720 h in salt spray test, the microsilica coatings withstood up to 650 h. EIS results of the nanosilica coatings showed a resistance of 2.36 × 10

6 Ω·cm

2 after 30 days of immersion in 3% NaCl solution, whereas microsilica coatings showed a resistance of 5.41 × 10

4 Ω·cm

2 under similar conditions. Thus, this study allowed to confirm that the replacement of conventional micro SiO

2 particles with its nano counterpart improved the performance of coating in all aspects.

Optical properties are one of the most interesting characteristics of hybrids. UV-curable hybrid coatings were prepared by a combination of cationic and radical mechanisms from bisphenol A epoxy acrylate and GPTMS as inorganic precursor using a diaryl iodonium salt as cationic photo initiator [

74]. The coatings exhibit higher transparency in the visible region (400–800 nm) and lower transparency at around 346 nm, which tends to increase with the GPTMS proportion, indicating that the silica network contributed to enhance the transparency of coatings. It was attributed to the formation of Si–O–Si bonds, which reduced the chain orientation degree of cured coatings and then decrease the absorption in the UV region.

6. Epoxy Hybrids by Using Hyperbranched Polymers

Hyperbranched polymers (HBP)s are advantageous polymeric modifiers to enhance toughness in epoxy thermosets [

75,

76]. In addition, they help to keep the processability of the initial formulation without compromising other thermomechanical properties, due to their densely branched and globular structure and their multifunctionality. The high number of ending groups and the possibility of their functionalization makes it possible to tailor the compatibility of the HBPs in the resin by the total or partial modification of reactive groups at the chain ends. Taking all of this into account, some authors combined the strategy of the generation of silica particles by sol-gel procedure with the use of hyperbranched structures to improve some characteristics of epoxy thermosets [

48,

55,

77].

Since the use of coupling agents is highly advisable, the preparation of multifunctional coupling agents by silylation of the final groups of hyperbranched polymers can be greatly advantageous to improve epoxy resins by generation of silica particles by sol-gel process from the alkoxysilanes at the end groups of the hyperbranched structures. This approach was used in the UV curing of cycloaliphatic epoxy resins with hyperbranched polyesters [

77]. The HBP was partially functionalized at the chain ends by reacting IPTMS with the OH groups in the HBP structure. TEOS was also added to the curing formulation in different proportions. It could be demonstrated the higher transparency of the hybrid thermosets in samples containing trialkoxysilylated HBP, because of the smaller size of the particles formed, observed by TEM, which was attributed to the beneficial effect of the HBP. In this case, the photopolymerization reaction was performed in the first place, followed by the sol-gel process.

In our research team, we developed novel hybrid materials by using triethoxysilylated poly(ethyleneimine) (Si-PEI), easily prepared by reacting amino groups with triethoxysilyl isocyanate (IPTES), as shown in the following scheme (

Scheme 10) [

78].

Scheme 10.

Preparation of PEI-Si by reacting poly(ethyleneimine) and IPTES.

Scheme 10.

Preparation of PEI-Si by reacting poly(ethyleneimine) and IPTES.

Different formulations of DGEBA and 20%, 30%, 50% and 80% of Si-PEI were tested by performing an initial sol-gel process followed by an anionic homopolymerization of DGEBA initiated by 1-methylimidazole (1-MI).

29Si-NMR spectroscopy confirmed the formation of cage-like and branched silicon structures. The hybrid thermosets obtained were transparent because of the nanometric silicon particles embedded within the epoxy matrix without aggregates. Scratch tests of the hybrid films showed the highest resistance to the penetration for the materials with intermediate PEI-Si content. The elastic recovery after scratching increased with the proportion of PEI-Si in the material and the hybrid thermoset with 80% of PEI-Si showed the capacity of self-repairing. Depth Sensing Indentation measurements were performed on these materials and compared to the scratching studies [

79]. The resistances to either permanent or recoverable deformation increased if the PEI-Si content was raised, by the reinforcement effect of POSS nanostructures finely dispersed in the epoxy matrix. Additionally, the kinetics of the recovery could be studied. Thus, the anelastic self-repairing behavior could be explained as the consequence of the increment of the volumetric fraction of the soft and flexible hyperbranched PEI coupling agent.

Formulations containing a 50% of PEI-Si and different amounts of TEOS or GPTMS were similarly cured to increase the particle sizes or the compatibility of inorganic and organic phases [

80]. When 40% of TEOS was in the material, TEM microscopy revealed well separated silica particles, whereas lower proportions produced bicontinuous nanophase separated morphologies, similarly to what usually happens in hybrids containing GPTMS. The addition of GPTMS or TEOS to the formulation did not further improve the scratch resistance, but the incorporation of GPTMS to the formulation allowed to prepare non-detachable coatings.

Figure 2 shows the TEM microphotographs of some of the hybrids materials prepared.

Figure 2.

TEM micrographs of hybrid materials at 120 K magnifications of (a) DGEBA/PEI-Si 50/50; (b) DGEBA/PEI-Si/GPTMS 50/50/40; and (c) DGEBA/PEI/TEOS 50/40/40.

Figure 2.

TEM micrographs of hybrid materials at 120 K magnifications of (a) DGEBA/PEI-Si 50/50; (b) DGEBA/PEI-Si/GPTMS 50/50/40; and (c) DGEBA/PEI/TEOS 50/40/40.

An alternative use of HBPs in hybrid epoxy thermosets was proposed, using an epoxy-terminated hyperbranched polyester as the epoxy component [

81]. Hybrid epoxy thermosets were prepared by reaction of the epoxy-HBP with APTMS and curing with anhydrides. The addition of APTMS and anhydride led to a significant and steadily increase of both

Tg and relaxed modulus, due to the increase in the O–Si–O bonding and the crosslinking density of the organic matrix. Thermal stability was also improved. SEM inspection of the hybrid composites showed aggregation at high concentration of silica but in low concentration the silica particles were well dispersed in the polymer matrix.

Scratch resistant coatings were prepared by sol-gel/UV curing of biscycloaliphatic epoxy based formulations containing a hyperbranched polyester with phenolic groups as chain ends and an alkoxysilane compound with cycloaliphatic groups (ECHETMS) [

48]. The addition of the HBP to the UV curable epoxy resin produced an important flexibilization, since it loosened the tight organic networked structure produced in the cationic homopolymerization, leading to an increase in toughness of the epoxy coatings. By further adding ECHETMS into the UV curable formulations, an improvement in surface hardness was obtained without strongly affecting the flexibilization and the toughness achieved in the pure organic material. Inorganic domains in the 20–80 nm range could be observed and the materials obtained presented a good transparency. The increase in surface hardness was accompanied by an increase in scratch resistance and Young modulus.

To conclude, it should be said that sol-gel hybrid epoxy thermosets are highly interesting materials especially for coatings applications, because of their great versatility. This is due to the possibility of tailoring the inorganic structure, the organic matrix and the interphase interactions. However, a deep understanding of all chemical reactions and phenomenological events occurring in the sol-gel process and epoxy curing is needed in order to produce materials with the desired characteristics.