A Low-Temperature Alumina/Copper Diffusion Bonding Process using La-Doped Titanium Interlayers

Abstract

:1. Introduction

2. Materials and Methods

2.1. Material and Diffusion Bonding Processes

2.2. Microstructure Characterizations

2.3. Mechanical Properties

2.3.1. Hardness Tests

2.3.2. Adhesion Tensile Tests

3. Results and Discussion

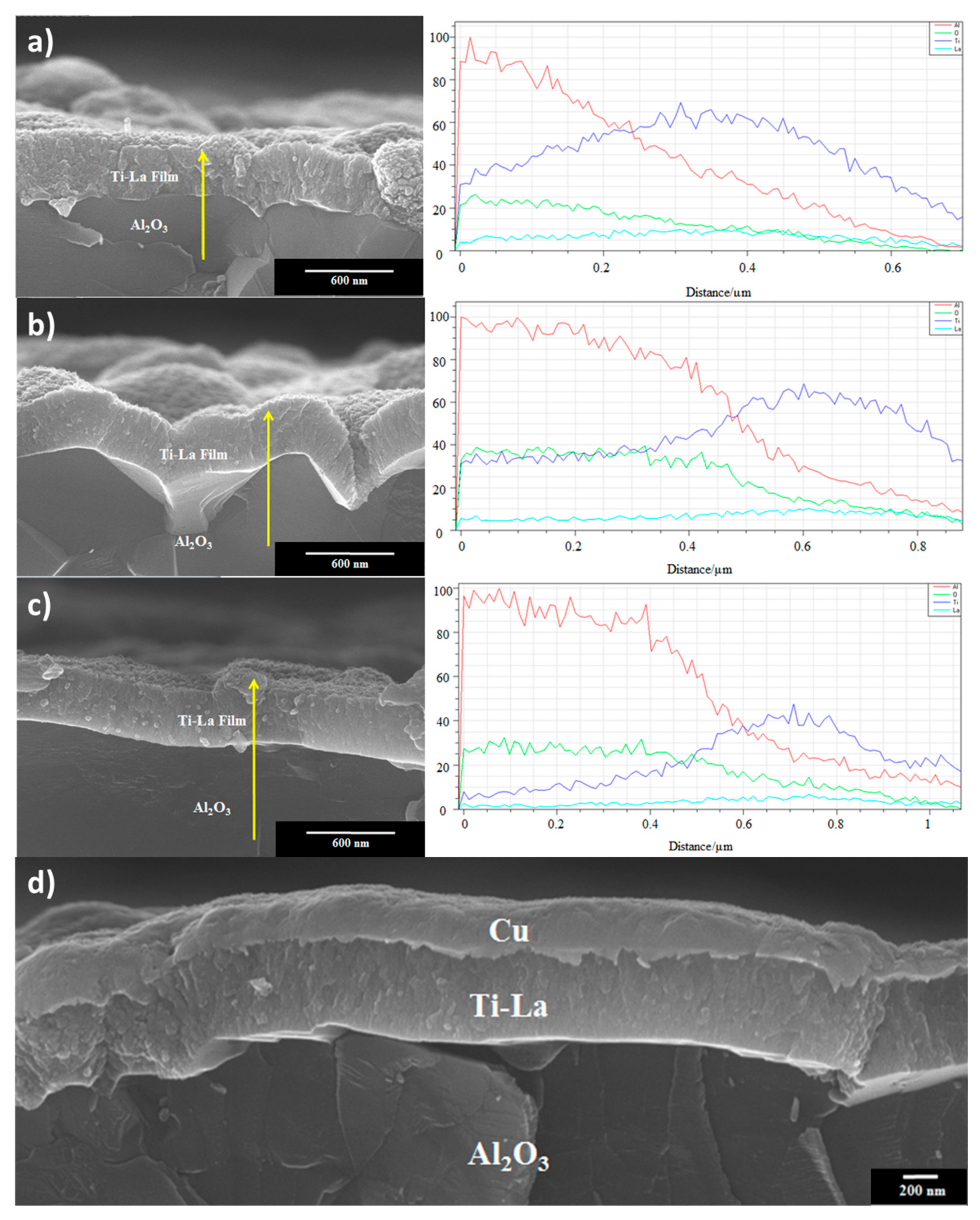

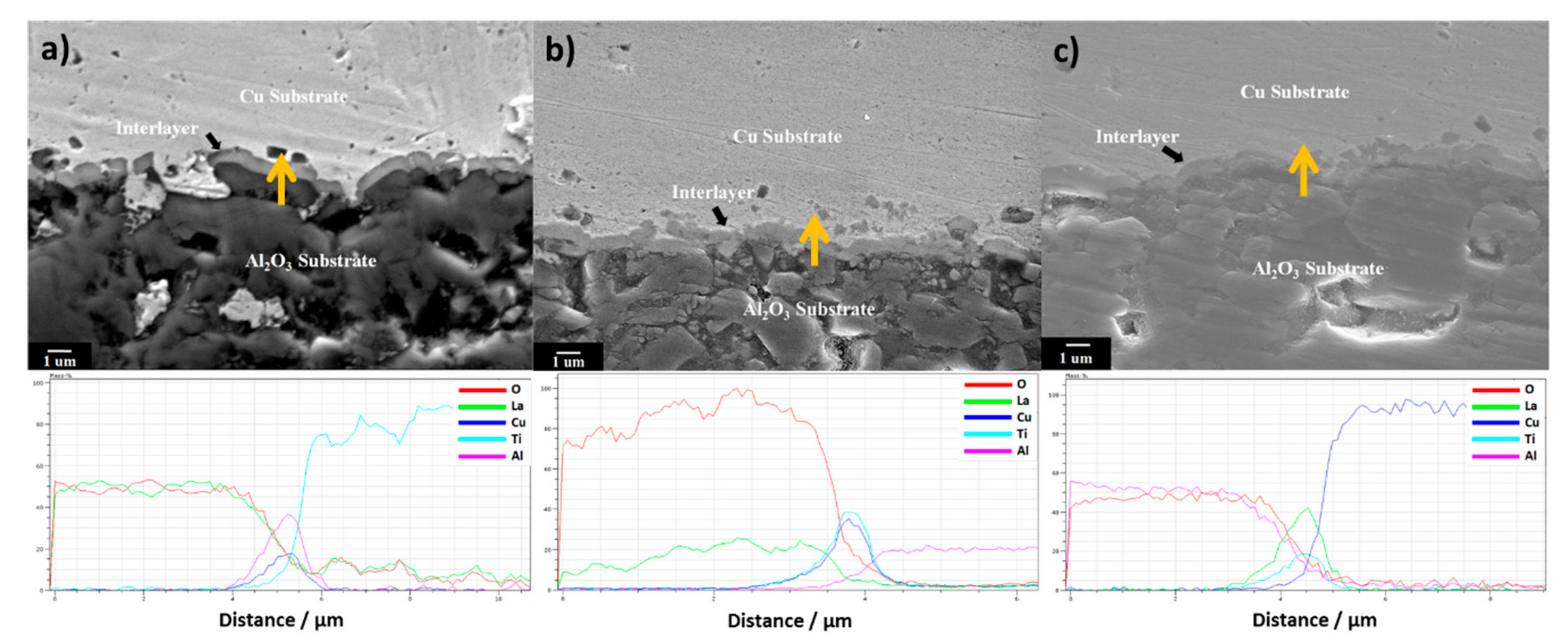

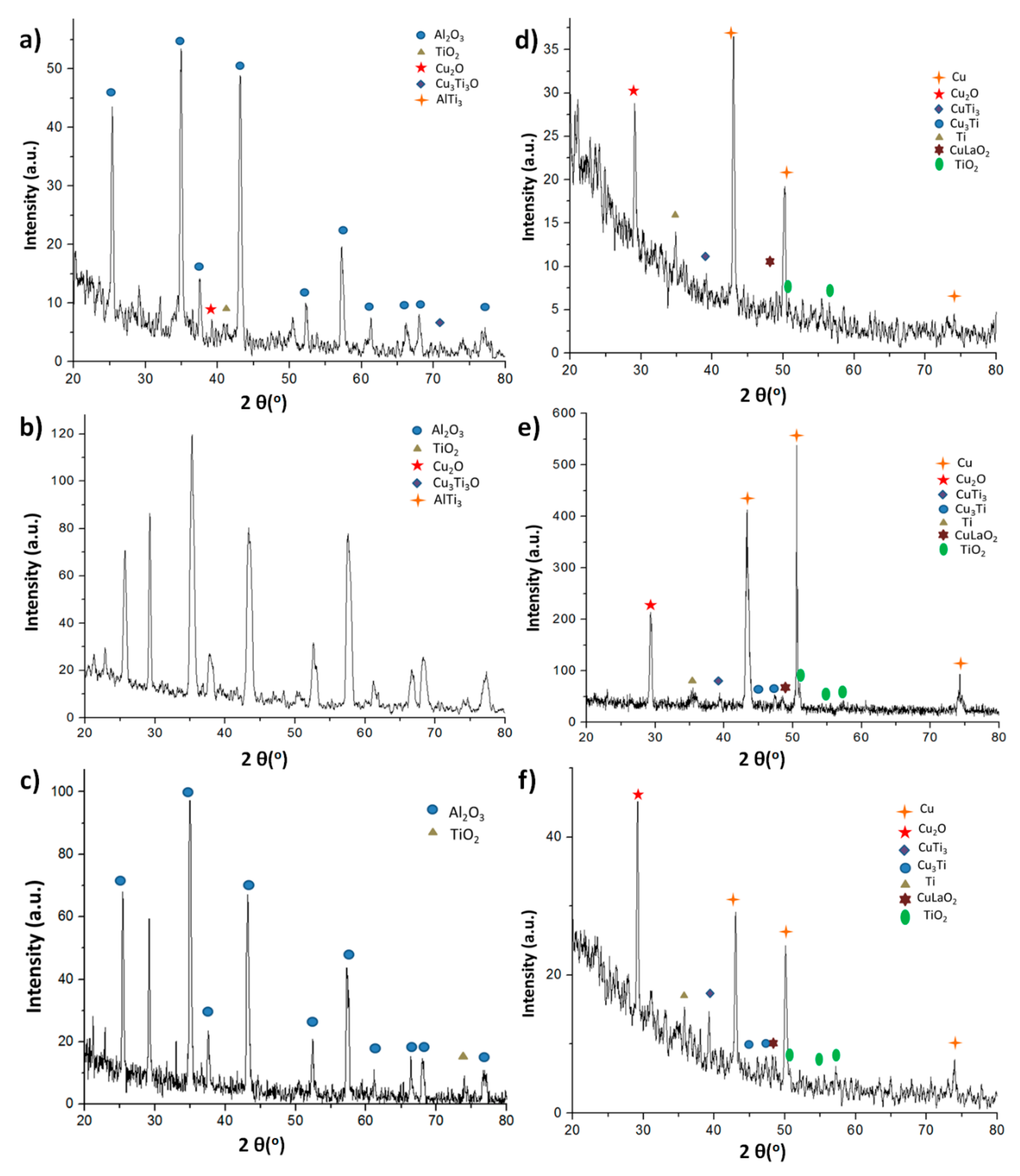

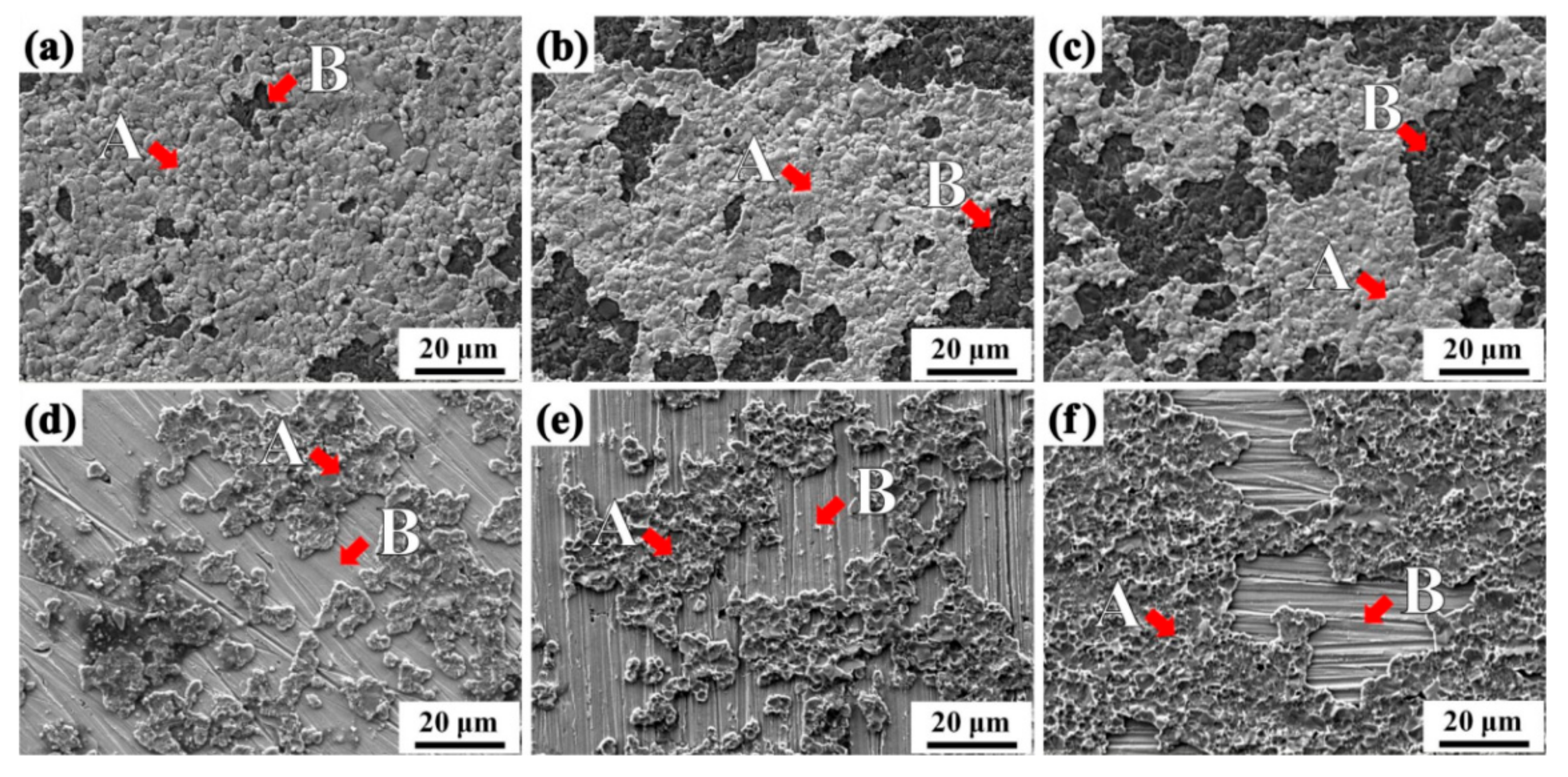

3.1. Microstructure Characterizations

3.2. Mechanical Properties

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Zhang, Y.; Di, F.; He, Z.-Y.; Chen, X.-C. Progress in joining ceramics to metals. J. Iron Steel Res. Int. 2006, 13, 1–5. [Google Scholar] [CrossRef]

- Simões, S.; Ramos, A.; Viana, F.; Vieira, M.; Vieira, M. Joining of tial to steel by diffusion bonding with Ni/Ti reactive multilayers. Metals 2016, 6, 96. [Google Scholar] [CrossRef]

- Smith, R.W. Active solder joining of metals, ceramics and composites: Brazing and soldering. Weld. J. 2001, 80, 30–35. [Google Scholar]

- Chuang, C.-H.; Lin, Y.-C.; Lin, C.-W. Intermetallic reactions during the solid-liquid interdiffusion bonding of Bi2Te2.55Se0.45 thermoelectric material with Cu electrodes using a Sn interlayer. Metals 2016, 6, 92. [Google Scholar] [CrossRef]

- Zheng, C.; Lou, H.; Fei, Z.; Li, Z. Partial transient liquid-phase bonding of Si3N4 with Ti/Cu/Ni multi-interlayers. J. Mater. Sci. Lett. 1997, 16, 2026–2028. [Google Scholar] [CrossRef]

- Hongqi, H.; Yonglan, W.; Zhihao, J.; Xiaotian, W. Interfacial reaction of alumina with Ag-Cu-Ti alloy. J. Mater. Sci. 1995, 30, 1233–1239. [Google Scholar] [CrossRef]

- Jadoon, A.K.; Ralph, B.; Hornsby, P.R. Metal to ceramic joining via a metallic interlayer bonding technique. J. Mater. Process. Technol. 2004, 152, 257–265. [Google Scholar] [CrossRef]

- Yoshino, Y. Role of oxygen in bonding copper to alumina. J. Am. Ceram. Soc. 1989, 72, 1322–1327. [Google Scholar] [CrossRef]

- Fu, W.; Song, X.G.; Hu, S.P.; Chai, J.H.; Feng, J.C.; Wang, G.D. Brazing copper and alumina metallized with Ti-containing Sn0.3Ag0.7Cu metal powder. Mater. Des. 2015, 87, 579–585. [Google Scholar] [CrossRef]

- Yilbaş, B.S.; Şahin, A.Z.; Kahraman, N.; Al-Garni, A.Z. Friction welding of St Al and Al Cu materials. J. Mater. Process. Technol. 1995, 49, 431–443. [Google Scholar] [CrossRef]

- Abbasi, M.; Taheri, A.K.; Salehi, M. Growth rate of intermetallic compounds in Al/Cu bimetal produced by cold roll welding process. J. Alloy Compd. 2001, 319, 233–241. [Google Scholar] [CrossRef]

- Lanin, A. Effect of residual stresses on the strength of ceramic materials (Review). Rus. Metall. Met. 2012, 2012, 307–322. [Google Scholar] [CrossRef]

- Bartlett, A.; Evans, A.; Rühle, M. Residual stress cracking of metal/ceramic bonds. Acta Metall. Mater. 1991, 39, 1579–1585. [Google Scholar] [CrossRef]

- Hynes, N.R.J.; Velu, P.S.; Kumar, R.; Raja, M.K. Investigate the influence of bonding temperature in transient liquid phase bonding of SiC and copper. Ceram. Int. 2017, 43, 7762–7767. [Google Scholar] [CrossRef]

- Wang, J.-X.; Xue, S.-B.; Han, Z.-J.; Yu, S.-L.; Chen, Y.; Shi, Y.-P.; Wang, H. Effects of rare earth Ce on microstructures, solderability of Sn–Ag–Cu and Sn–Cu–Ni solders as well as mechanical properties of soldered joints. J. Alloy Compd. 2009, 467, 219–226. [Google Scholar] [CrossRef]

- Wang, S.; Zhou, H.; Kang, Y. The influence of rare earth elements on microstructures and properties of 6061 aluminum alloy vacuum-brazed joints. J. Alloy Compd. 2003, 352, 79–83. [Google Scholar] [CrossRef]

- Lim, J.D.; Lee, P.M.; Chen, Z. Understanding the bonding mechanisms of directly sputtered copper thin film on an alumina substrate. Thin Solid Films 2017, 634, 6–14. [Google Scholar] [CrossRef]

- Xia, Z.; Chen, Z.; Shi, Y. Effect of rare earth element additions on the microstructure and mechanical properties of tin-silver-bismuth solder. J. Electron. Mater. 2002, 31, 564–567. [Google Scholar] [CrossRef]

- Kim, J.-H.; Kim, D.S.; Lim, S.T.; Kim, D.K. Interfacial microstructure of diffusion-bonded SiC and Re with Ti interlayer. J. Alloy. Compd. 2017, 701, 316–320. [Google Scholar] [CrossRef]

- Wu, C.M.L.; Yu, D.Q.; Law, C.M.T.; Wang, L. Properties of lead-free solder alloys with rare earth element additions. Mater. Sci. Eng. R Rep. 2004, 44, 1–44. [Google Scholar] [CrossRef]

- ASTM D4541 Standard Test Method for Pull-Off Strength of Coatings Using Portable Adhesion Testers; ASTM International: West Conshohocken, PA, USA, 2010.

- Chang, S.; Chuang, T.; Tsao, L.; Yang, C.; Yang, Z. Active soldering of ZnS–SiO2 sputtering targets to copper backing plates using an Sn3.5Ag4Ti (Ce, Ga) filler metal. J. Mater. Process. Technol. 2008, 202, 22–26. [Google Scholar] [CrossRef]

- Howard, S.M. Ellingham Diagrams; SD School of Mines and Technology: Rapid City, SD, USA, 2006. [Google Scholar]

- Tsao, L. Interfacial structure and fracture behavior of 6061 Al and MAO-6061 Al direct active soldered with Sn–Ag–Ti active solder. Mater. Des. 2014, 56, 318–324. [Google Scholar] [CrossRef]

- Kassner, M.; Tolle, M.; Rosen, R.; Henshall, G.; Elmer, J. Discussion of void nucleation. Metall. Trans. A 1993, 24, 1877–1878. [Google Scholar] [CrossRef]

- Zalar, A.; Baretzky, B.; Hofmann, S.; Rühle, M.; Panjan, P. Interfacial reactions in Al2O3/Ti, Al2O3/Ti3Al and Al2O3/TiAl bilayers. Thin Solid Films 1999, 352, 151–155. [Google Scholar] [CrossRef]

- Jacob, K.T.; Jayadevan, K.P. Phase relations in the system Cu-La-O and thermodynamic properties of CuLaO2 and CuLa2O4. J. Mater. Sci. 2002, 37, 1611–1620. [Google Scholar] [CrossRef]

| Target | Ti–0.5 La (wt %) |

| Power (W) | 150 |

| Sputtering time (min) | 24 |

| Ambient pressure (torr) | 2 × 10−6 |

| Working pressure (torr) | 5.5 × 10−3 |

| Working distance (cm) | 9 |

| Sputtering rate (nm min−1) | 20.83 |

| Samples | Area | O (at %) | Al (at %) | Ti (at %) | Cu (at %) |

|---|---|---|---|---|---|

| 250 °C alumina | A | 9.47 | 0.12 | 5.53 | 84.89 |

| B | 67.32 | 31.21 | 1.16 | 0.31 | |

| 250 °C Cu | A | 48.78 | 0.01 | 47.58 | 3.64 |

| B | 4.05 | 0.13 | 0.07 | 95.75 | |

| 300 °C alumina | A | 4.38 | 0.26 | 6.77 | 88.58 |

| B | 67.82 | 31.01 | 0.98 | 0.18 | |

| 300 °C Cu | A | 32.09 | 0.34 | 65.53 | 2.03 |

| B | 2.33 | − | − | 97.67 | |

| 350 °C alumina | A | 3.99 | 0.37 | 3.52 | 92.11 |

| B | 15.55 | 3.55 | 26.75 | 54.16 | |

| 350 °C Cu | A | 40.87 | 0.18 | 56.47 | 2.48 |

| B | − | 0.01 | 0.60 | 99.39 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Su, C.-Y.; Huang, J.-L.; Chen, P.-C.; Yu, H.-J.; Ma, D.-L.; Yu, B.-Y. A Low-Temperature Alumina/Copper Diffusion Bonding Process using La-Doped Titanium Interlayers. Coatings 2018, 8, 401. https://doi.org/10.3390/coatings8110401

Su C-Y, Huang J-L, Chen P-C, Yu H-J, Ma D-L, Yu B-Y. A Low-Temperature Alumina/Copper Diffusion Bonding Process using La-Doped Titanium Interlayers. Coatings. 2018; 8(11):401. https://doi.org/10.3390/coatings8110401

Chicago/Turabian StyleSu, Cherng-Yuh, Jia-Liang Huang, Po-Chun Chen, Hsin-Jung Yu, Dai-Liang Ma, and Bang-Ying Yu. 2018. "A Low-Temperature Alumina/Copper Diffusion Bonding Process using La-Doped Titanium Interlayers" Coatings 8, no. 11: 401. https://doi.org/10.3390/coatings8110401

APA StyleSu, C.-Y., Huang, J.-L., Chen, P.-C., Yu, H.-J., Ma, D.-L., & Yu, B.-Y. (2018). A Low-Temperature Alumina/Copper Diffusion Bonding Process using La-Doped Titanium Interlayers. Coatings, 8(11), 401. https://doi.org/10.3390/coatings8110401